Page 1

Installation - Operation - Parts

ti24476a

ti20576b

Complete Pressurized Bead System for

LineLazer IV 200

Models:

16R955 1-Gun LL200HS

16R962 1-Gun LL250

16R960 2-Gun LL200

16R961 2-Gun LL250

80 psi (.55 MPa, 5.5 bar) Maximum Working Pressure

9

Important Safety Instructions

Read all warnings and instructions in the striper manual.

Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

HS and LineLazer IV 250SPS

- For professional use only -

HS

332230F

EN

Related Manual

Bead Gun Kit 332226

Page 2

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and

explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and can

ignite or explode if spilled on hot surface.

• Keep work area free of debris, including solvent, rags and gasoline.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are antistatic

or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until you iden-

tify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your

material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

• Do not carry passengers.

• Check work area for reduced overhead clearance (e.g. doorways, tree branches, parking ramp ceilings) and

avoid contacting them.

2 332230F

Page 3

Warnings

WARNING

INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a cut, but it

is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye injury,

hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause

cancer, birth defects or other reproductive harm.

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

NOTICE

Never store glass beads in tank between jobs. Begin the day with moisture-free beads. Moisture will cause glass beads to resist flow or

solidify over time.

If moisture or condensation is present on tank interior, leave lid open until dry. When operating without the bead system, always leave

the moisture drain valve open.

332230F 3

Page 4

Tools Needed:

CE Safety Checklist

(To be completed during non-factory installation)

Covers and shrouds for moving parts are in place (see guard installation section).

Fasteners, belts, covers, grills, and compressor are tight-mounted securely.

Read and understand all warnings and instructions in this manual and the striper manual.

Tools Needed:

• 1/8 in. Allen Wrench (supplied with kit)

• Alignment tool 17C504 (supplied with kit)

• 5/32 in. Allen Wrench

• 1/4 in. Allen Wrench

• 3/16 in. Allen Wrench

• 7/16 in. Wrench

• 3/8 in. Wrench

• 1/2 in. Wrench

• 5/8 in. Wrench

• 9/16 in. Wrench

• 11/16 in. Wrench

• T-20 Torx Bit

• Cutting Blade

• Rubber Mallet

• Phillips Screwdriver

• Straight Edge

4 332230F

Page 5

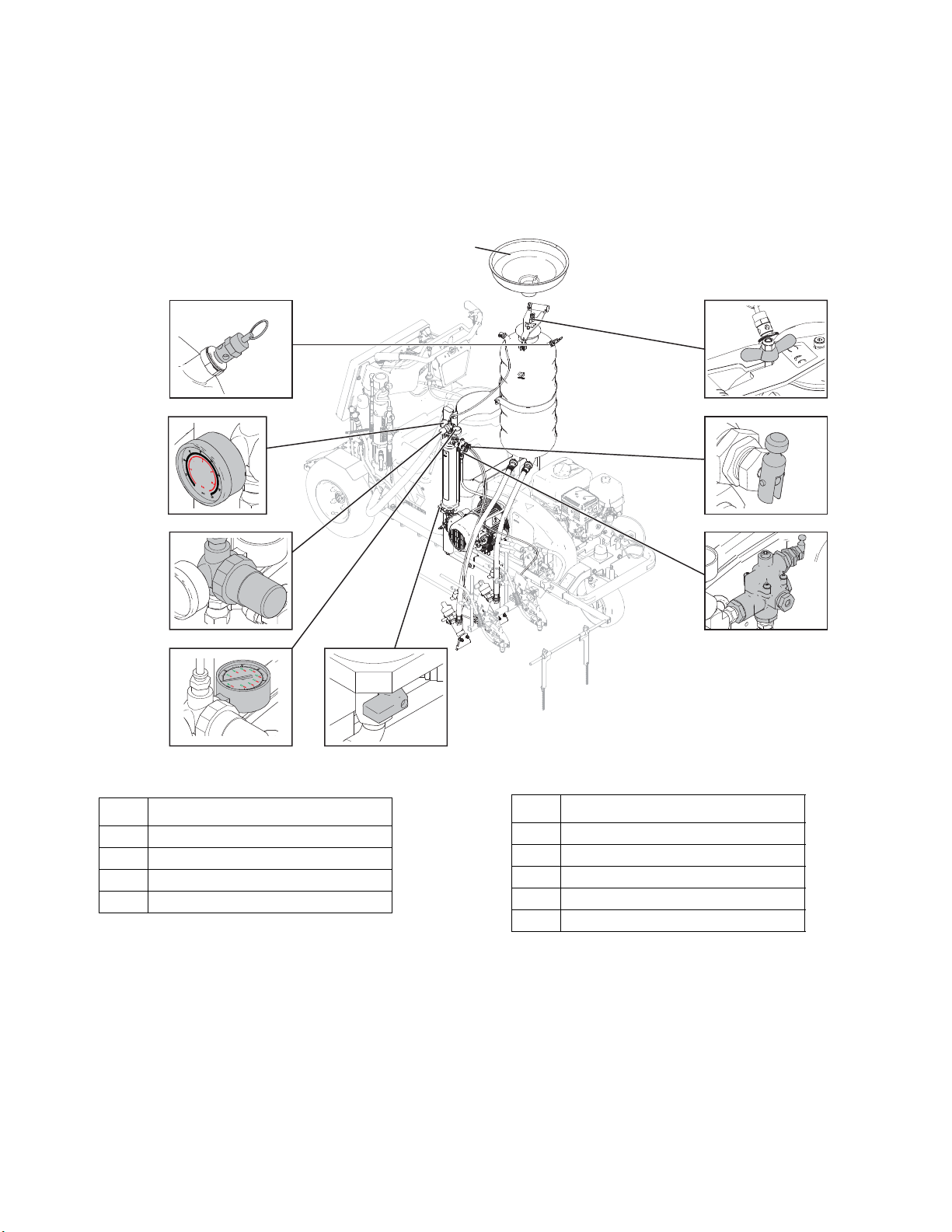

Operation for LL200 and LL250

ti24477a

9

8

7

65

2

1

3

4

Component Identification

Operation for LL200 and LL250

Ref. Description

1 Funnel

2Wing Nut

3 Compressor Bypass Switch

4 Regulator Unloader

Ref. Description

5 Pressure Relief Valve

6 Bead Tank Gauge

7 Pressure Regulator Valve

8 Air Tank Gauge

9 Safety Relief Valve

332230F 5

Page 6

200HS Pressurized Bead System Kit 16R955

ti20715a

AA

BB

ti20525a

DD

CC

EE

ti20713a

FF

ti20519a

Shroud

Shroud

FF

FF

ti20714a

ti21196a

BB

200HS Pressurized Bead System Kit 16R955

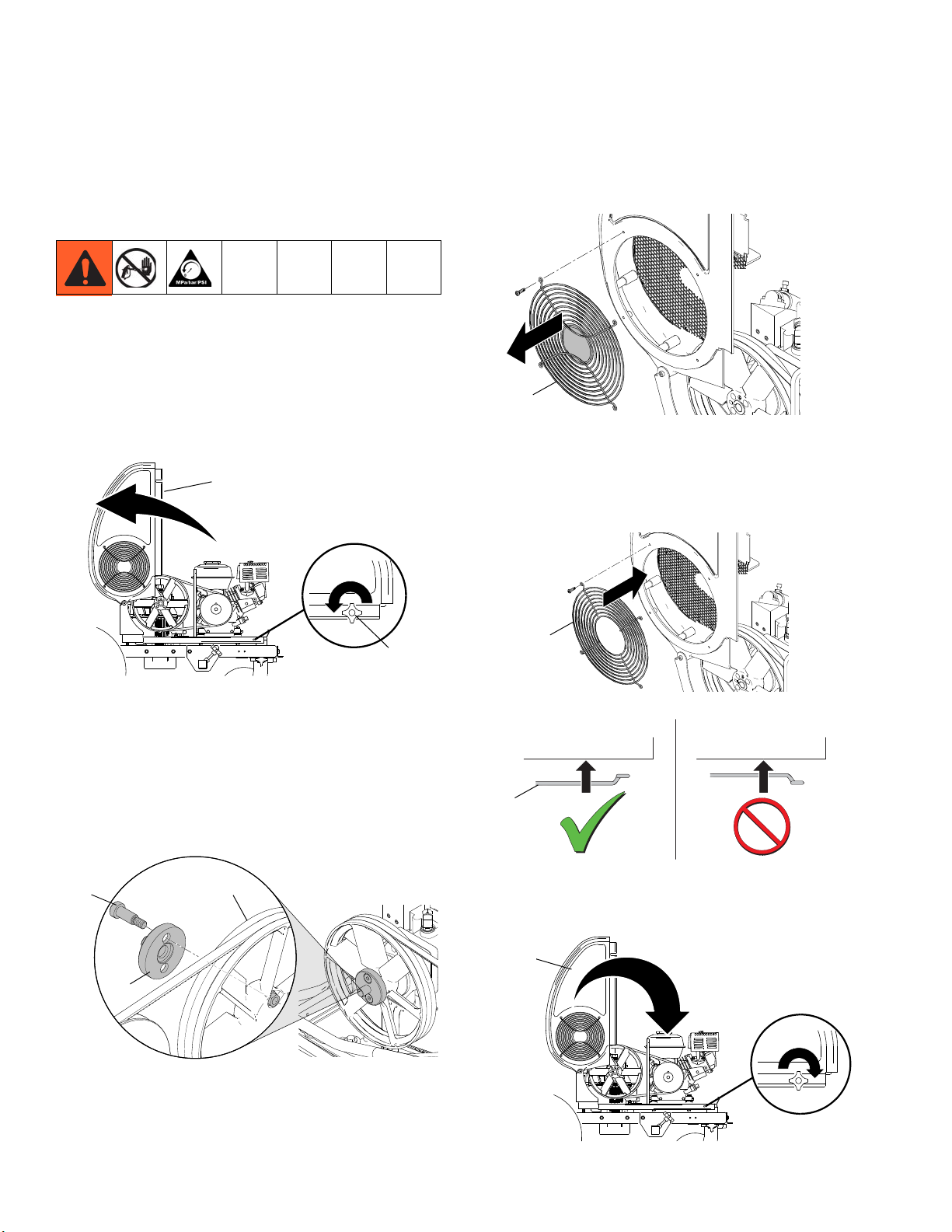

Assemble Compressor Mounting

and Drive Components

NOTE: Glass bead system and paint guns can be

mounted on either side of sprayer.

1. Turn off unit. Relieve pressure in paint striper and

remove hopper.

2. Locate belt shroud. Loosen knob (AA) and rotate

shroud (BB).

4. Use star bit (supplied) to remove four screws from

shroud. Remove original fan grill.

5. Use existing hardware to install new open-centered

fan grill (FF). Do not over-tighten. Make sure fan

protrudes out, not into the unit. Discard or store old

close-centered fan grill.

3. With belt guard off, install mounting plate coupler

(CC) onto pulley (DD) with two shoulder screws

(EE) and serrated nuts. Position slot on back of

pulley up and move serrated nut with finger to

accept shoulder bolt threads. Tighten shoulder bolt

by hand until the teeth on the serrated nut catch the

aluminum on the fan. Torque to 16 to 18 ft-lb

(21 to 24 N•m).

6. Close belt shroud (BB) with new fan grill onto unit.

NOTE: You may need to flex shroud around

extended shaft on the fan pulley.

6 332230F

Page 7

200HS Pressurized Bead System Kit 16R955

ti20516a

GG

ti24336a

ti21198c

KK

ti21201a

NN

MM

ti21194a

XX

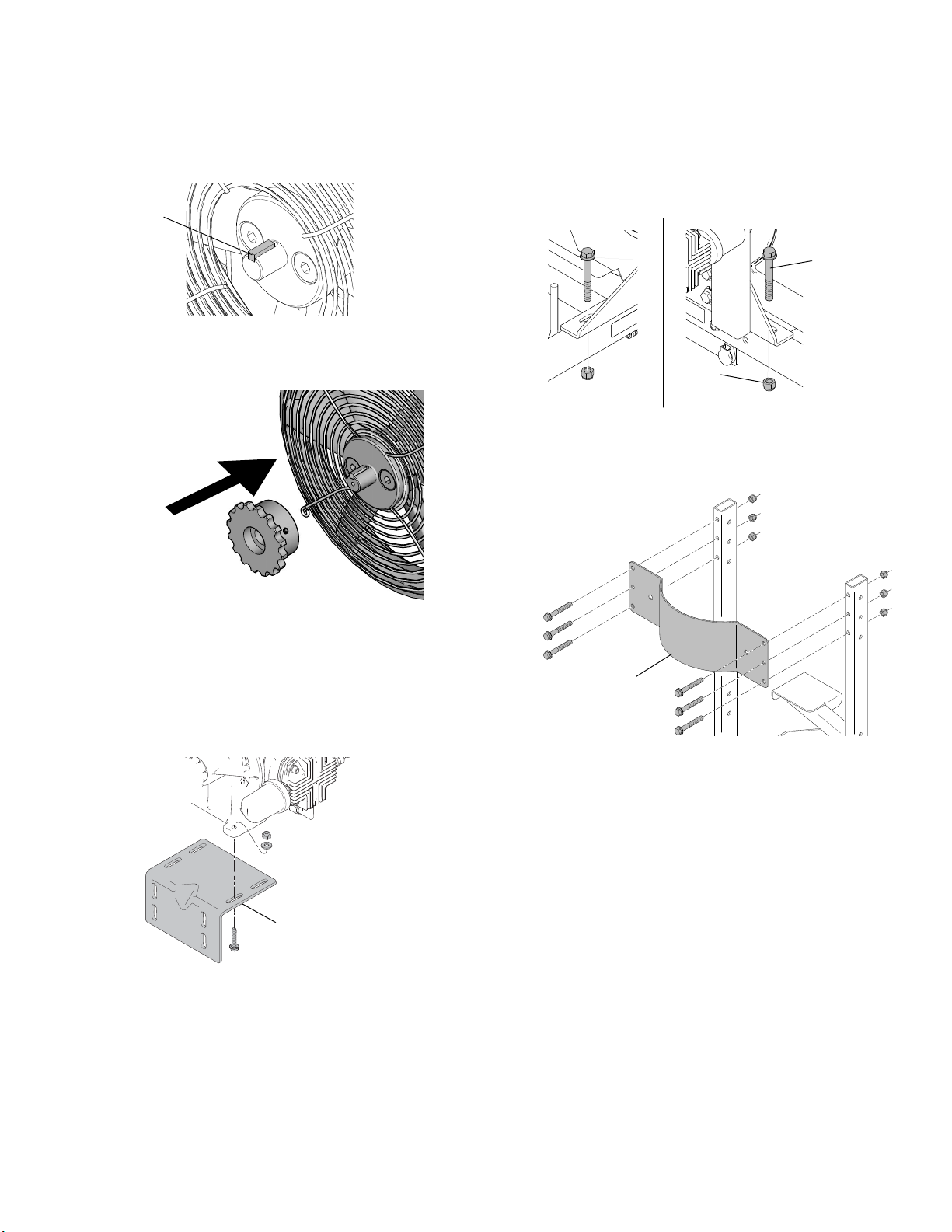

7. Place key (GG) in keyway opening. Tap into place

so that face of key sits recessed slightly from face of

hub.

8. Push chain coupler against the shoulder on the

mounting plate coupler.

12. Loosely install two screws (MM) and two locknuts

(NN) through bottom of frame mount but do not

tighten. Remove existing gun arm bracket to gain

access to nut (NN). NOTE: See “Compressor Alignment (200HS)” on page 8.

13. Assemble hopper basket (XX) and base with hardware as shown below. Use 9/16 in. wrench to snug

screws. Loosen all six screws 1/4 turn.

9. Use 1/8 in. Allen wrench to secure coupler set

screw. Torque to 58-62 in-lb (6.6-7.0 N•m).

10. Use hardware (shown below) to mount compressor

to compressor bracket (KK). Make certain that the

square of the carriage bolt heads are seated in the

compressor bracket slots.

11. Snug all four nuts down then back the nuts off 1/4

turn. Bracket KK should slide in the slots with some

effort.

332230F 7

Page 8

200HS Pressurized Bead System Kit 16R955

ti24337a

0.80 +/- 0.050

Maintain gap set at factory

ti24339a

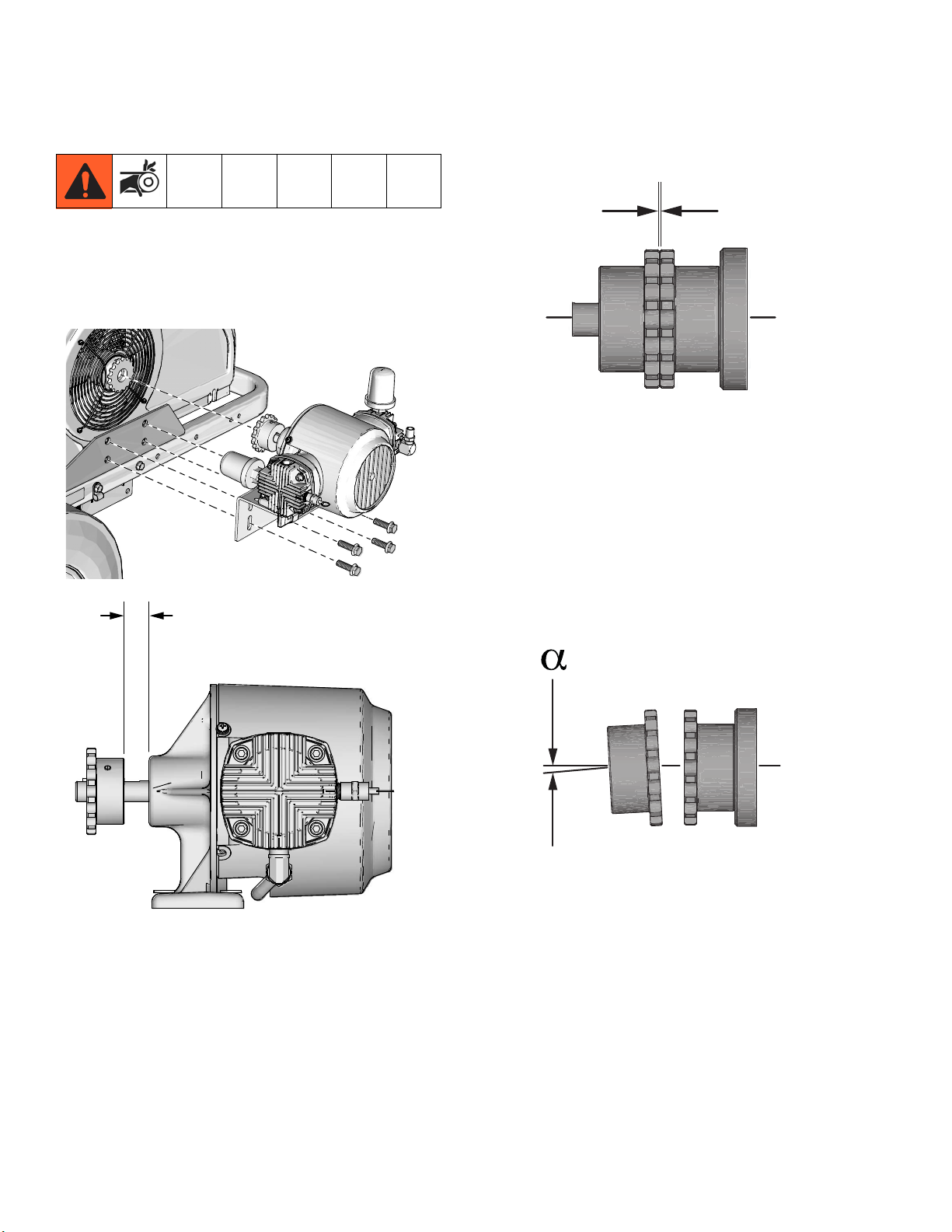

Compressor Alignment (200HS)

Install Compressor Assembly

1. Position compressor (RR) and bracket assembly

(SS) on frame. Install four screws (VV), snug all four

screws down then back the screws off 1/4 turn.

2. Move compressor and mounting bracket up to the

chain coupler on the mounting plate so that the two

sprockets contact each other.

ti24386a

3. Move compressor assembly up or down (vertical)

and left or right (horizontal) until the compressor is

aligned with the hydraulic pump.

Angular Adjustment

If the two sprocket faces are in full contact, the angular

adjustment is good. Go to “Vertical Adjustment” on page

9.

1. The allowable angular misalignment is 1°.

ti24387a

8 332230F

Page 9

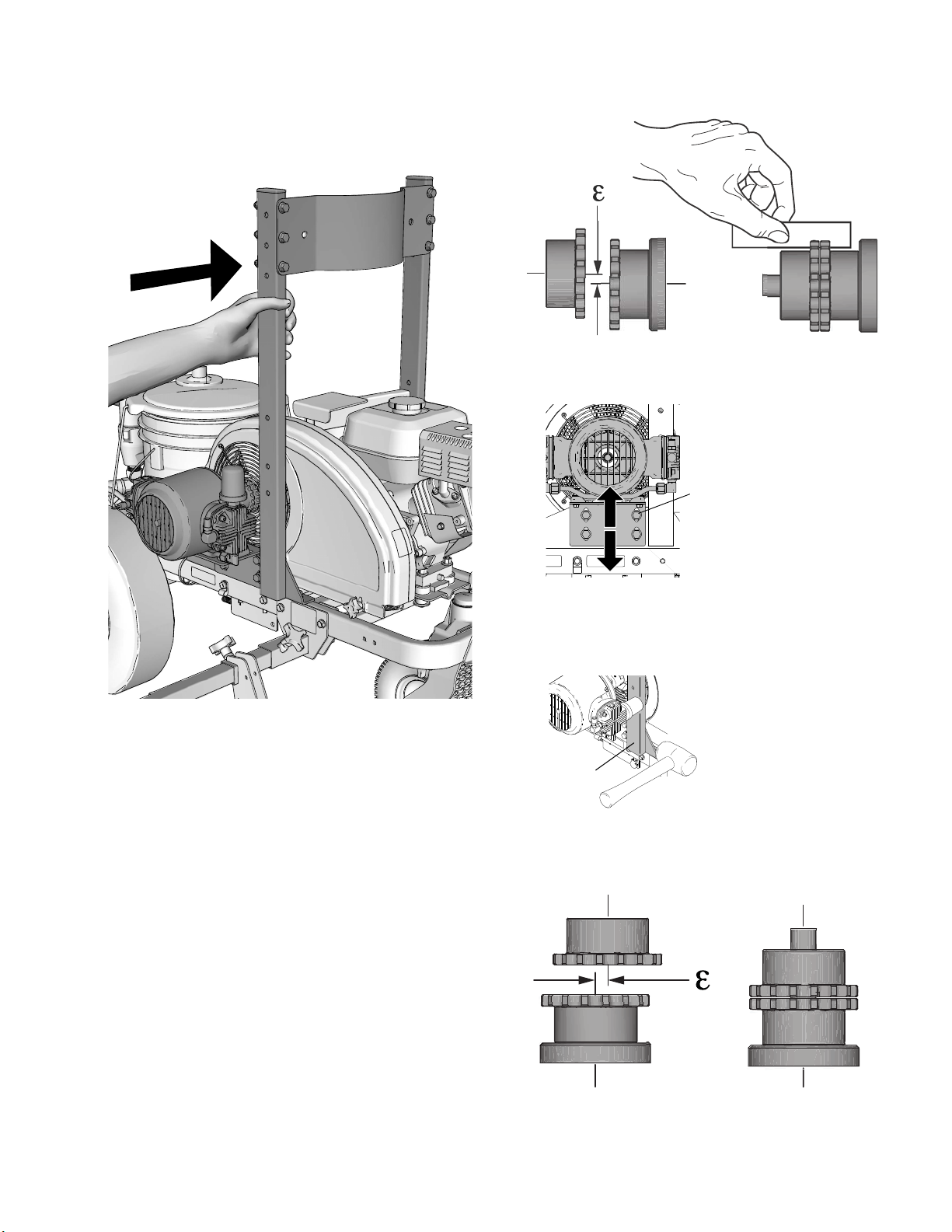

2. Adjustment can be made by pushing on the hopper

ti24491a

ti21417a

VV

ti21203a

LL

ti24388a

basket vertical supports.

200HS Pressurized Bead System Kit 16R955

ti24341a

2. Use 9/16 in. wrench to tighten compressor bracket

screws (VV).

3. After the sprocket faces make full contact, use 9/16

in. wrenches to tighten all six screws.

Vertical Adjustment

1. Place a straight edge at the bottom of corresponding teeth of the two sprockets and raise or lower the

compressor to adjust until the offset misalignment is

minimized (use a straightedge for accurate alignment). Repeat this at both the top and bottom of the

sprockets. The allowable offset misalignment is

0.005 to 0.010.

Horizontal Adjustment

1. Tap vertical frame mount with rubber mallet to the

left or right.

2. Adjust the horizontal misalignment until the sides of

the two hubs are even with each other and the

sprocket teeth are in alignment.

332230F 9

Page 10

200HS Pressurized Bead System Kit 16R955

ti21201a

NN

ti24342a

c

ti24389a

3. Use 9/16 in. wrench to tighten two nuts (NN) to hold

vertical frame mount to 200HS frame.

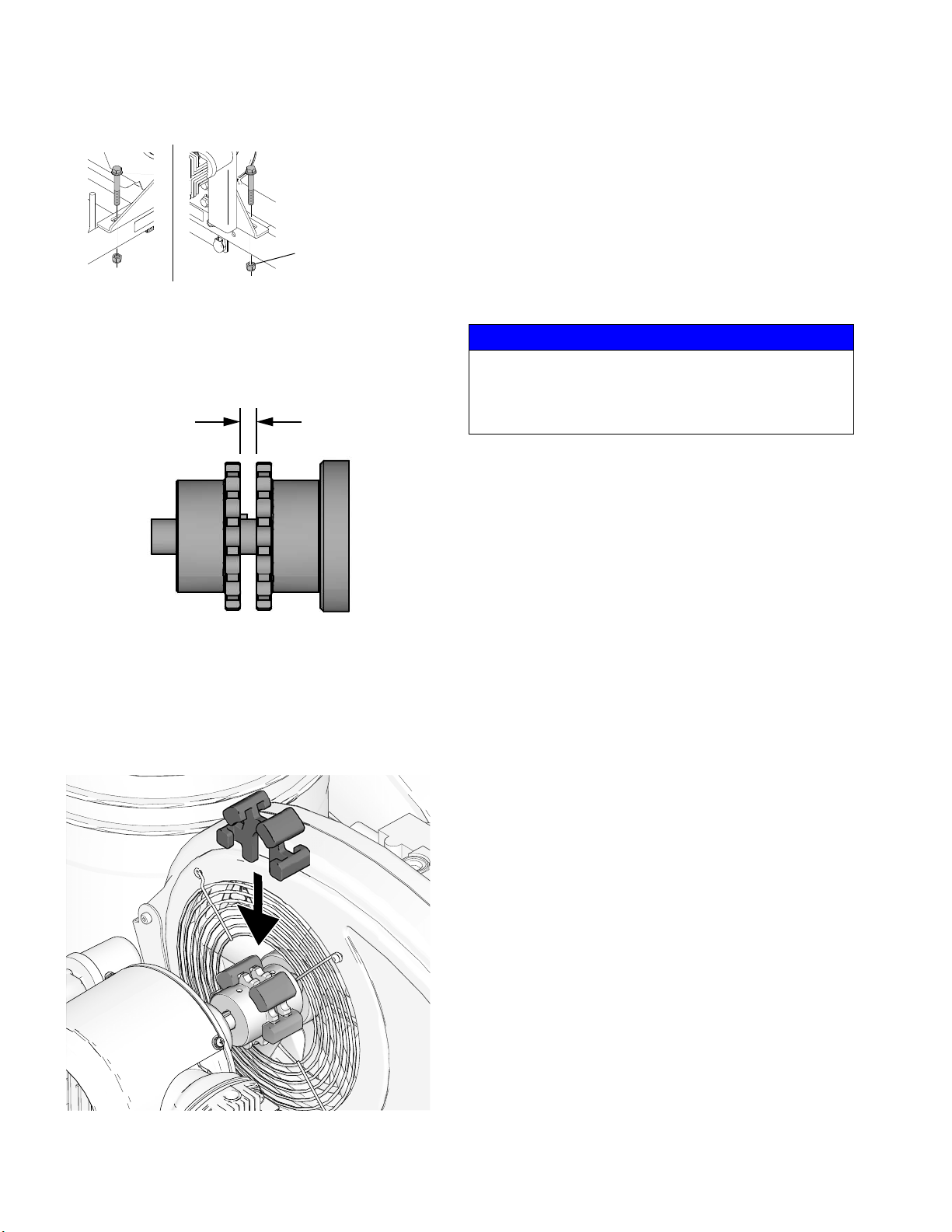

Coupler Spacing

1. Slide compressor assembly away from the mounting plate coupler leaving a (C) 9/32” (6.35mm)

space between the sprockets.

4. After tightening compressor to mounting bracket

nuts verify that the 9/32” space between the two

sprockets has not changed. Alignment tool

(17C504) should slide in and out of the gap between

the sprockets with little resistance.

5. If the spacing has changed repeat Compressor

Alignment (200HS) procedure.

6. Properly tighten all screws and nuts.

7. Wrap chain around both sprockets. Install connecting pin and spring clip.

NOTICE

Broken hydraulic pump or compressor shafts may

result, if not aligned properly. Always verify compressor alignment whenever a compressor is installed or

the belt is tightened or replaced.

8. Install coupler guard using three pan head screws

with flatwashers and lockwashers.

Chain Coupler Maintenance

Periodic chain coupler lubrication is necessary to ensure

proper operation of your striper regularly once a month.

2. Use spacer alignment tool (17C504) to set the

sprocket spacing. Slide tool between the sprockets.

The sprocket teeth of both sprockets should sit flush

in the inner pockets of the tool.

3. With alignment tool holding sprockets in alignment,

tighten four compressor to mounting bracket nuts.

1. Remove three pan head screws with flatwashers

and lockwashers from chain coupler guard.

2. Remove chain coupler guard.

3. Lubricate coupler chain with Justice Brothers heavy

duty chain lube or equivalent (NLGI grade 1 or 2

grease).

4. Install coupler guard using three pan head screws

with flatwashers and lockwashers.

10 332230F

Page 11

Complete Frame Assembly

ti21500a

ti21200a

MM

ti21194a

XX

ti20884a

ZZ

200HS Pressurized Bead System Kit 16R955

NOTE: If desired, rotate recoil 90° counter-clockwise.

1. Use 9/16 wrench to tighten bottom screws (MM) to

hardware shown.

2. Use 9/16 in. wrench to tighten hopper basket (XX)

and base bolts.

3. Install plastic end caps (ZZ) into frame. Use rubber

mallet to pound end caps into place.

332230F 11

Page 12

200HS Pressurized Bead System Kit 16R955

ti20704a

aa

ti21193a

ti21197a

bb

ti21191a

cc

ti21195a

dd

Bead Tank Mounting

1. Place bead tank on supporting base with outlet

fittings facing compressor.

NOTE: Position handle to best suit filling needs.

Loosen bolt (aa) to help swivel, then retighten.

2. Place clamping band around tank and secure with

mounting hardware shown below. Tighten until

there is no movement between clamp and bead

tank.

Air Tank Mounting

1. Install air tank to frame mount as shown below and

use 9/16 in. wrench to tighten two screws (bb).

2. Use 11/16 in. wrench to attach braided hose (cc)

from air tank to compressor.

3. Install 36 in. nylon air line (dd) from top of regulator

to swivel fitting on top of bead hopper. Cut air line to

desired length. Push air line into fitting until end

NOTE: The flats on the clamp are not intended to

touches bottom of fitting.

touch the hopper bracket when tightened.

12 332230F

Page 13

LL250 Pressurized Bead System Kit 16R962

ti20518a

B

A

ti20525a

D

C

E

ti20519a

Shroud

Shroud

F

ti20518a

B

ti20516a

G

ti24336a

LL250 Pressurized Bead System Kit 16R962

Assemble Compressor Mounting

and Drive Components

NOTE: Glass bead system and paint guns can be

mounted on either side of sprayer.

1. Turn off unit. Relieve pressure in paint striper and

remove hopper.

2. Locate belt shroud. Loosen four screws (A) and

remove shroud (B).

3. With belt guard off, install mounting plate coupler

(C) onto pulley (D) with two shoulder screws (E) and

serrated nuts. Position slot on back of pulley up and

move serrated nut with finger to accept shoulder

bolt threads. Tighten shoulder bolt by hand until the

teeth on the serrated nut catch the aluminum on the

fan. Torque shoulder bolt to 16 to 18 ft-lb (21 to 24

N•m) to secure mounting plate coupler.

5. Install belt shroud with new fan grill onto unit.

NOTE: You may need to flex shroud around

extended shaft on the fan pulley.

6. Place key (G) in keyway opening. Tap into place so

that face of key sits recessed slightly from face of

hub.

7. Push chain coupler against the shoulder on the

mounting plate coupler.

4. Use existing hardware to install new open-centered

fan grill (F). Make sure fan protrudes out, not into

the unit. Discard or store old close-centered fan grill.

8. Use 1/8 in. Allen wrench to secure coupler set

screw. Torque to 58-62 in-lb (6.6-7.0 N•m).

332230F 13

Page 14

LL250 Pressurized Bead System Kit 16R962

ti24480a

L

Inches

Centimeter

ti20511a

L

ti20512a

ti20509a

N

M

ti20507a

9. Use hardware (shown below) to mount compressor

to compressor bracket. Make certain that the square

of the carriage bolt heads are seated in the compressor bracket slots.

cross member of LL250 frame). NOTE: To ensure

flush sitting, scrape frame free of any raised debris

on frame surface.

13. Cut any existing tie wraps that interfere (they will be

replaced later with new tie straps).

10. Snug all four nuts down then back the nuts off 1/4

turn. Bracket KK should slide in the slots with some

effort.

11. Use rubber mallet or wood block to position frame

mount (L) flush to LL250 frame (this location will be

adjusted to help center the compressor with the

drive pulley).

12. Place right frame mount (L) onto LL250 frame in

location shown below (approximately 1 in. from

14. Loosely install two screws (M) and two locknuts (N)

through bottom of frame mount. NOTE: See alignment section then use 9/16 in. wrench to fully

tighten.

15. Secure hydraulic lines with zip ties.

14 332230F

Page 15

16. Assemble hopper bracket (X) and base (Y) with

ti24390a

hardware provided. Install carriage bolts with the

heads facing the paint tanks. Use 9/16 in. wrench to

tighten bolts. Loosen all eight nuts 1/4 turn.

2.674"

Compressor Alignment (LL250)

LL250 Pressurized Bead System Kit 16R962

1. Position compressor and bracket assembly on

frame. Align compressor coupler sprocket with

chain coupler installed on mounting plate coupler.

Install three screws, snug all three screws down

then back the screws off 1/4 turn.

ti24481a

0.80 +/- 0.050

Maintain gap set at factory

ti24339a

332230F 15

Page 16

LL250 Pressurized Bead System Kit 16R962

ti24478a

2. Move compressor and mounting bracket up to the

chain coupler on the mounting plate so that the two

sprockets contact each other.

ti24386a

3. Move compressor assembly up or down (vertical)

and left or right (horizontal) until the compressor is

aligned with the hydraulic pump.

Angular Adjustment

If the two sprocket faces are in full contact, the angular

adjustment is good. Go to “Vertical Adjustment” on page

17.

2. Adjustment can be made by pushing on the hopper

basket vertical supports.

1. The allowable angular misalignment is 1°.

ti24340a2

3. After the sprocket faces make full contact, use 9/16

in. wrenches to tighten all eight nuts.

16 332230F

Page 17

Vertical Adjustment

ti24341a

ti24482a

VV

ti20510a

ti24388a

ti20509a

N

ti24342a

c

1. Place a straight edge at the bottom of corresponding teeth of the two sprockets and raise or lower the

compressor to adjust until the offset misalignment is

minimized (use a straightedge for accurate alignment). Repeat this at both the top and bottom of the

sprockets. The allowable offset misalignment is

0.005 to 0.010.

LL250 Pressurized Bead System Kit 16R962

2. Adjust the horizontal misalignment until the sides of

the two hubs are even with each other and the

sprocket teeth are in alignment.

2. Use 9/16 in. wrench to tighten compressor bracket

screws (VV).

3. Use 9/16 in. wrench to tighten two nuts (N) to fully

clamp vertical frame mount to LL250 frame.

Coupler Spacing

1. Slide compressor assembly away from the mounting plate coupler leaving a (C) 9/32” (6.35mm)

space between the sprockets.

Horizontal Adjustment

1. Tap vertical frame mount with rubber mallet to the

left or right.

332230F 17

Page 18

LL250 Pressurized Bead System Kit 16R962

ti24389a

2. Use spacer alignment tool (17C504) to set the

sprocket spacing. Slide tool between the sprockets.

The sprocket teeth of both sprockets should sit flush

in the inner pockets of the tool.

3. With alignment tool holding sprockets in alignment,

tighten four compressor to mounting bracket nuts.

4. After tightening compressor to mounting bracket

nuts verify that the 9/32” space between the two

sprockets has not changed. Alignment tool

(17C504) should slide in and out of the gap between

the sprockets with little resistance.

5. If the spacing has changed repeat Compressor

Alignment (LL250) procedure.

6. Properly tighten all screws and nuts.

7. Wrap chain around both sprockets. Install connecting pin and spring clip.

NOTICE

Broken hydraulic pump or compressor shafts may

result, if not aligned properly. Always verify compressor alignment whenever a compressor is installed or

the belt is tightened or replaced.

8. Install coupler guard using three pan head screws

with flatwashers and lockwashers.

Chain Coupler Maintenance

Periodic chain coupler lubrication is necessary to ensure

proper operation of your striper regularly once a month.

1. Remove three pan head screws with flatwashers

and lockwashers from chain coupler guard.

2. Remove chain coupler guard.

3. Lubricate coupler chain with Justice Brothers heavy

duty chain lube or equivalent (NLGI grade 1 or 2

grease).

4. Install coupler guard using three pan head screws

with flatwashers and lockwashers.

18 332230F

Page 19

Complete Frame Assembly

ti20501a

W

Inches

Centimeter

ti20502a

ti20500a

M

ti24390a

Y

X

ti20884a

Z

LL250 Pressurized Bead System Kit 16R962

1. Position left frame mount (W) on LL250 frame.

Remove any zip ties in the way. Use a rubber mallet

to tap into place if needed.

2. Make sure left and right frame mounts are aligned.

The left leg should mirror the right leg location from

LL250 frame cross member.

4. Use 9/16 in. wrench to tighten hopper bracket (X)

and base (Y) nuts.

5. Install plastic end caps (Z) into frame. Use rubber

mallet to pound end caps into place.

3. Use 9/16 wrench to tighten bottom screws (M) to

hardware shown.

332230F 19

Page 20

LL250 Pressurized Bead System Kit 16R962

ti24483a

ti24485a

ti20704a

AA

Bead Tank Mounting

1. When only one bead tank is being installed, it

should be placed on the side of the frame furthest

from the compressor to best distribute weight.

there is no movement between clamp and bead

tank. NOTE: The flats on the clamp are not intended

to touch when hopper bracket is tightened.

NOTE: Position handle to best suit filling needs.

Loosen bolt (AA) to help swivel, then retighten.

2. Place bead tank on supporting base with outlet

fittings facing compressor.

3. Place clamping band around tank and secure with

mounting hardware shown below. Tighten until

20 332230F

Page 21

LL250 Pressurized Bead System Kit 16R962

BB

BB

CC

ti24487a

ti20493a

DD

Air Tank Mounting

1. Install air tank to frame mount as shown below and

use 9/16 in. wrench to tighten two screws (BB).

2. Use 11/16 in. wrench to attach braided hose (CC)

from air tank to compressor.

ti24486a

3. Install 36 in. nylon air line (DD) from top of regulator

to swivel fitting on top of bead hopper. Cut air hose

to desired length. Push air line into fitting until end

touches bottom of fitting.

332230F 21

Page 22

Operation

ti21074a

9

ti21081a

8

ti21073a

ti21082a

8

9

ti21079a

4

5

4

ti21083a

Operation

Charging Air Tank

1. Start engine and engage clutch. Compressor is now

engaged.

2. If compressor is not needed for a job, move compressor bypass switch (9) to horizontal ON position.

Compressor is now exhausting air into atmosphere.

3. Move compressor bypass switch (9) to vertical OFF

position to charge air pressure tank. Air tank will

continue to charge to 80 psi (5.5 bar, 55 MPa) then

cycle between 60-80 psi (4.1-5.5 bar, 41-55 MPa).

Setting Bead Hopper Pressure

The pressure regulator valve (5) controls pressure sent

from the air tank to the bead tank. The regulator is set

to 0 pressure from the factory.

1. Before charging bead tank, confirm that bead tank

lid is fully secured and beads have been loaded into

tank.

2. To increase pressure, pull knob on pressure regulator valve (5) out and turn counter-clockwise. Watch

bead tank gauge (4) pressure and continue turning

valve until desired pressure is met.

4. See bead tank gauge (4) to read air tank pressure.

Pressure from air tank is used to open bead valves

at bead gun.

3. See bead flow chart to find proper settings for your

application.

4. Various orifices can be used in gun to obtain

different flow rates in conjunction with bead tank

pressure. See Determining Bead Application

Pressure Table, page 24.

22 332230F

Page 23

Bead Timing With Gun

To air tank

Exhaust

To

bead gun

Y

X

ti21326a

Operation

1. Use air flow restrictor valves to help time the opening and closing of the bead guns to best match the

start and stop of paint lines.

2. Valve (X) is exhausting air and will control the timing

end of the bead application. Valve (Y) is sending air

to the gun and will control the timing of the start of

the bead application.

3. Turning the valve clockwise will delay gun opening/closing time. Turning the valve counter-clockwise will speed up gun opening/closing time.

NOTICE

Never store glass beads in tank between jobs. Begin the

day with moisture-free beads. Moisture will cause glass

beads to resist flow or solidify over time.

If moisture or condensation is present on tank interior,

leave lid open until dry. When operating without the bead

system, always leave the moisture drain valve open.

332230F 23

Page 24

Operation

Determining Bead Application Pressure

The table below lists bead delivery rates for 4 inch

(10 cm) lines with standard size highway beads.

• Wider lines use multiples of 4 in. to determine bead

delivery.

• Larger beads reduce flow rates, so a larger nozzle

and higher pressure may be required.

• Always verify flow rates with a stopwatch and a

scale for weight.

To determine application pressure, follow steps 1 - 4

below:

1. Determine speed the machine will travel when

applying line.

2. Identify what the required bead delivery rate is in job

specifications.

3. Under bead gun nozzle size, find nearest value

compared to Step 2.

4. Match pressure needed to Step 3. Set air regulator

to this pressure.

† EXAMPLE:

a. At 4 mph and 6 lb/gal with 0.234 nozzle set tank

pressure to 15 psi.

b. At 4 mph and 6 lb/gal with 0.281 nozzle set tank

pressure to psi.

c. For 8 in. width, multiply weight/min value

(7.1) x 2 and for 12 in. width x 3.

Step 1 Step 2 Step 3 Step 4

Speed

mph lb/min lb/min lb/min lb/min psi

23.6 4.7 4 5 5

35.3 7.1 6 † 7 10

4 † 7.1 9.5 † 7 915

58.9 11.9 9 11 20

6 10.7 14.2 11 14 25

7 12.4 16.6 13 16 30

814.2 19 16 19 35

Bead Delivery Requirement (4 in.) Nozzle Size

6 lb/gal 8 lb/gal 0.234 0.281

Pressure Needed

Step 1 Step 2 Step 3 Step 4

Speed

mph lb/min lb/min lb/min lb/min psi

23.6 4.7 4 5 5

35.3 7.1 6 † 7 10

4 † 7.1 9.5 † 7 915

58.9 11.9 9 11 20

6 10.7 14.2 11 14 25

7 12.4 16.6 13 16 30

814.2 19 16 19 35

24 332230F

Bead Delivery Requirement (10 cm) Nozzle Size

720 gram/liter 960 gram/liter 0.234 0.281

Pressure Needed

Page 25

Filling Bead Hopper

ti21074a

9

ti21075a

ti21081a

3

8

ti21077a

2

ti21076a

1

ti21080a

Operation

1. Move compressor bypass switch (9) to horizontal

position to disengage compressor or turn engine off.

2. Release pressure on bead tank to 0 psi (0 bar, 0

MPa). Turn pressure relief valve (8) to vertical position and watch bead tank pressure gauge (3) until

pressure reads 0 psi (0 bar, 0 MPa). Do not use

safety valve (3) to release pressure from bead tank.

4. Place funnel (1) into opening. Pour beads into hopper. Beads should not be filled to a height higher

than shown in figure below. Bead level can be

viewed through tank wall if light is present.

5. Secure lid over opening and tighten wing nut until lid

is level with hopper.

3. Loosen wing nut (2) until it reaches end of threads.

If any remaining pressure is in bead tank, it will be

released through seal while wing nut secures lid to

hopper. Confirm pressure is at 0 psi

(0 bar, 0 MPa) and open lid.

332230F 25

Page 26

Operation

ti20977a

ti20978b

ti21258a

ti21085c

0 to 8 in. Line Setup

For wider lines it may be necessary to mount bead gun

as shown below.

2 Tank 1 Gun Setup

Connect “Y” fitting as shown below to allow two tanks to

flow into one gun.

8 - 12 in. Line Setup

26 332230F

Page 27

Double Drop Setup

ti20564a

Use a “Y” fitting to create a dual bead gun setup for

double drop beads. Splice exit hose on bottom of air

switch and branch into both guns.

Operation

332230F 27

Page 28

Parts - Model 16R955

214a

209

208

232

215

213

224

218

207

205

203

204

211

210

235

234

206

229

219219

230

214

217

212

222

220

223

223

225227206 220

221

222

223

228

237

248

240

251

250

249

243

245

226

238

201

242

ti20720d

247

ti20720c

Parts - Model 16R955

28 332230F

Page 29

Parts List - 16R955

Parts - Model 16R955

Ref. Part Description Qty.

201 156971 FITTING, nipple, short 3

202 15K299 FITTING, tee, street, modification 1

203 126804 REGULATOR, unloader 1

204 16U375 REGULATOR 1

205 16U174 TANK, pressure 1

206 187357 ELBOW, street 2

207 113321 FITTING, elbow, tube 1

208 118486 FITTING, elbow, push 1

209 101970 PLUG, pipe, hdls 1

210 104655 GAUGE, press air 1

211 15B565 VALVE, ball 1

212 16T580 BAND, clamping, bead hopper 1

213 16T763 FRAME, bead hopper, left 1

214 126789 COMPRESSOR, piston air, 1.7 hp

(6 cfm)

214a 24V932 FAN, compressor 1

215 16T762 FRAME, bead hopper, right 1

216 101690 TOOL, Allen wrench 1

217 16T579 BRACKET, compressor, 130 and

200

218 24V582 TANK, bead 1

219 111194 SCREW, cap flang hd 2

220 111193 SCREW, cap flang hd 6

221 115087 PLUG, tubing 2

222 121488 SCREW, hex hd, flanged 9

Ref. Part Description Qty.

223 101566 NUT, lock 11

224 16T593 BRACKET, hopper 1

225 120757 SCREW, carriage 4

226 16T939 HOSE, coupled 1

227 110755 WASHER, plain 4

228 126833 SCREW, shoulder, socket head 2

229 116720 COUPLER, quick disconnect 1

230 16T736 COUPLER, mounting plate 1

232 16U273 HOSE, pneumatic 1

234 162453 FITTING, (1/4 npsm x 1/4 npt) 1

235 124762 GAUGE, pressure, air, bsp 1

237 112958 NUT, hex, flanged 2

238 102040 NUT, lock, hex 4

239 16T437 FUNNEL, bead tank 1

1

240 120376 KEY, square 0.188 1

241 16R963 KIT, accessory, bead gun 1

242 120087 SCREW, set, 1/4 x 1/2 4

243 16X197 GUARD, coupler, assembly 1

245 16U327 GRILL, fan guard, cap trimmed 1

1

247 16X252 COUPLING, keyway hub, flex,

L type

248 117632 KEY, square, 0.188 x 1.25 1

249 867489 SCREW, pan head 3

250 116876 WASHER, flat 3

251 100020 WASHER, lock 3

1

332230F 29

Page 30

Parts - Model 16R962

25

21

43

51

20

45

44

18

13

22

14

23

47

17

15

62

62

50

12

24

26

25

25

25

25

25

19

27

24

30

28

33

52

6

1

26

56

57

26

6

63

54

55

53

41

35

4

10

3

34

49

5

29

ti24488a

14a

40

42

Parts - Model 16R962

30 332230F

Page 31

Parts List - Model 16R962

Parts - Model 16R962

Ref. Part Description Qty.

1 156971 FITTING, nipple, short 3

2 15K299 FITTING, tee, street, modification 1

3 126804 REGULATOR, unloader 1

4 16U375 REGULATOR 1

5 16U174 TANK, pressure 1

6 187357 ELBOW, street 2

7 113321 FITTING, elbow, tube 1

8 118486 FITTING, elbow, push 1

9 101970 PLUG, pipe, hdls 1

10 104655 GAUGE, press air 1

11 15B565 VALVE, ball 1

12 16T580 BAND, clamping, bead hopper 1

13 16T698 FRAME, bead hopper, left, LL250 1

14 126789 COMPRESSOR, piston air, 1.7

hp(6 cfm)

14a 24V932 FAN, compressor 1

15 125626 SCREW, hex hd, flanged 10

16 16T437 FUNNEL, bead tank 1

17 16T596 BASE, hopper frame, LL250 1

18 16T697 FRAME, bead hopper, right, LL250 1

19 16X197 GUARD, coupler, assembly 1

20 16U327 GRILL, fan guard, cap trimmed 1

21 16T736 COUPLER, mounting plate 1

22 16T594 BRACKET, bead hopper, LL250 1

23 16T591 BRACKET, compressor, LL250 1

24 111193 SCREW, cap flang hd 4

25 101566 NUT, lock 15

26 111194 SCREW, cap flang hd 6

27 120757 SCREW, hex hd, flanged 4

28 102040 NUT, lock, hex 4

29 116720 COUPLER, quick disconnect 1

Ref. Part Description Qty.

30 110755 WASHER, plain 4

32 16U273 HOSE, pneumatic 1

33 115087 PLUG, tubing 2

34 162453 FITTING, (1/4 npsm x 1/4 npt) 1

35 124762 GAUGE, pressure, air, bsp 1

37 101690 TOOL, Allen wrench 1

39 16R963 KIT, accessory, bead gun 1

40 120376 KEY, square 0.188 2

41 260387 SCREW, pan hd, x recess 4

42 120087 SCREW, set, 1/4 x 1/2 4

43 126833 SCREW, shoulder, socket head 2

44 116969 NUT, lock 4

45 116876 WASHER, flat 4

47 16X252 COUPLING, keyway hub, flex, L

1

type

49 16T939 HOSE, coupled, 061120, 1.5 ft 1

50 24V582 TANK, bead 1

51 112958 NUT, hex, flanged 2

52 117632 KEY, square, 3/16 x 1.25 1

53 867489 SCREW, pan head 3

54 116876 WASHER, flat 3

55 100020 WASHER, lock 3

56 17A647 BRACKET, air tank, LL250 1

57 111192 SCREW, cap flange head 2

62 124258 BOLT, carriage 4

63 16C394 LABEL, pinch hazard ISO 1

Replacement warning labels may be ordered free of

charge.

1

332230F 31

Page 32

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2013, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 332230

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision F September 2014

Loading...

Loading...