Page 1

Instructions

332101A

EN

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

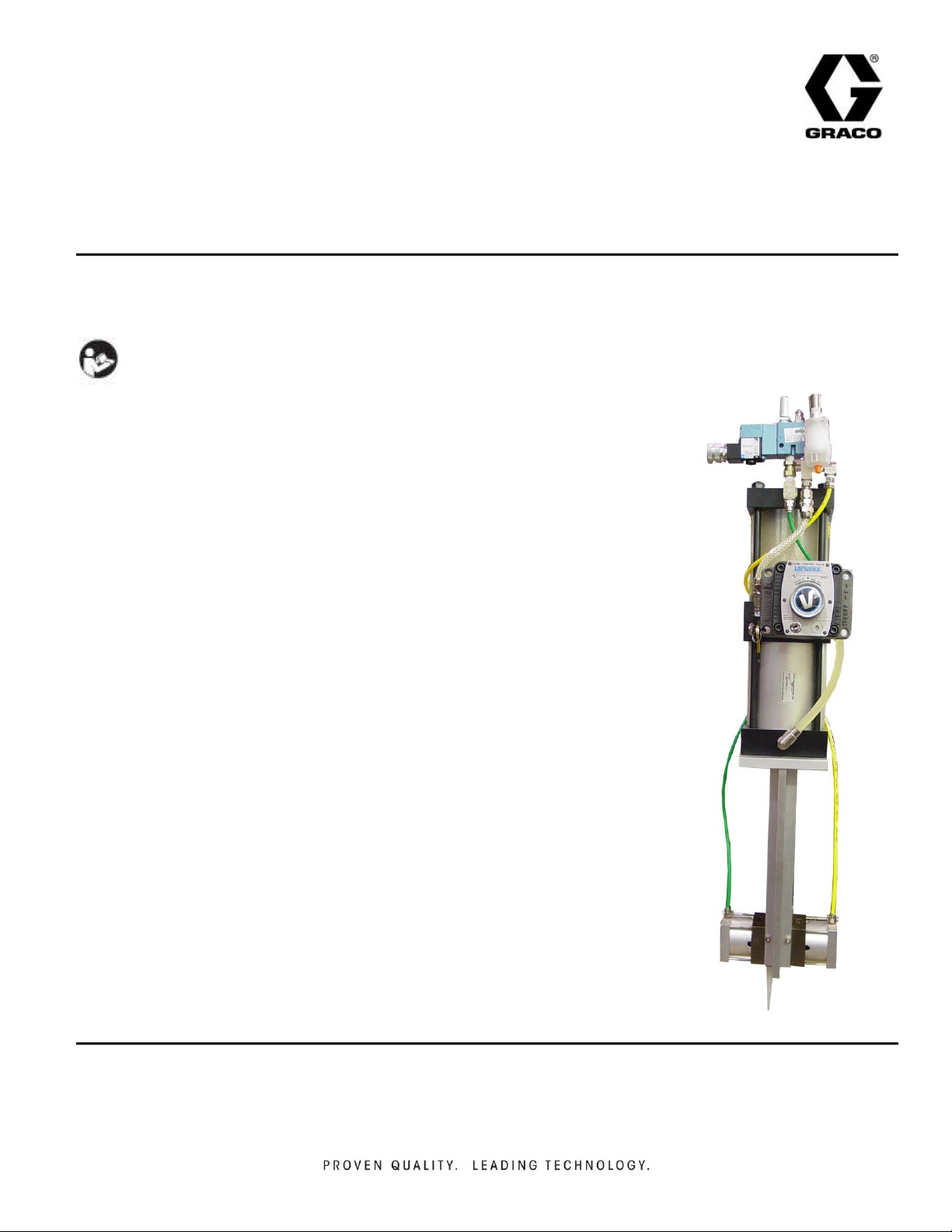

Dispensit

Dispense Valve

1095 Air/Oil Drive

Page 2

Quick Start Up

Initial Start up

Install the Air Oil unit in the normal upright position.

It is not required to install material to the dispense valve in the initial startup.

Metering rod up

Air/Oil reservoir filed to line

70 psi dry non lubricated air supply

Set the flow control knob set to “A” scale

Adjust pneumatic flow control to almost closed (want slow travel during purge)

Never over fill oil

Never tip air oil cylinder when oil is in reservoir otherwise every time the solenoid cycles, oil will be atomized

by the exhaust mufflers.

Wet The System

Connect the material feed and dispense valve

Activate pneumatic solenoid on top of Air Oil unit either by using override control or using control circuit

Lower metering rod to almost dead head position (no more than 4 inches of travel)

Release solenoid control to allow metering rod to raise

Check oil lever in reservoir

Repeat lower / raise cycle until air is purged from Air Oil cylinder

Once most air is purged from system adjust oil flow control to approximate speed of dispense

Adjust pneumatic flow control to achieve fill rate - adjust for slowest refill possible so as to prevent metering rod

cavitation (reintroducing air)

Adjust the control system timer to control the Air Oil solenoid valve

The higher the timer resolution the more accurate the dispense volume

For minor bead adjustments, use the hydraulic flow control to achieve precise bead control

Usually the control system is used to start and stop the bead.

The on/off dispensing flow valve is tied into the starting and stopping of the Air Oil

Occasionally it will be necessary to change the sequencing of the on/off valve to compensate for the uniqueness of

the material handling characteristics.

Page 3

Quick Start Up con’t

Cycle to purge air from system

Activate pneumatic solenoid on top of Air Oil unit either by using override control or using control circuit

Lower metering rod to almost dead head position (no more than 4 inches of travel)

Release solenoid control to allow metering rod to raise

Check oil lever in reservoir

Repeat lower / raise cycle until air is purged from Air Oil cylinder

Once most air is purged from system adjust oil flow control to approximate speed of dispense

Adjust pneumatic flow control to achieve fill rate - adjust for slowest refill possible so as to prevent metering rod

cavitation (reintroducing air)

Sequence of Operation

Metering rod in the home position (up)

The oil reservoir is at its low level (lower black mark on the side of the upper chamber)

To dispense ---- the solenoid is activated air is directed into the cap end of the cylinder forcing the oil residing in the

cylinder’s rod end across the adjustable orifice in the flow control and back into the upper reservoir chamber.

To refill ---- the solenoid shifts and pressurized air is forced into the upper reservoir chamber and oil is directed into

the flow control and free flows around the orifice into the cylinder rod raising the metering rod. The exhausting cap

end air is passed thru a pneumatic flow control to control the refill speed.

To adjust the rate of dispense the knurl knob of the hydraulic flow control is rotated to achieve the desired speed.

To adjust the refill rate the pneumatic flow control is similarly adjusted.

Page 4

DISPENSIT® MODEL 1095

DISPENSE VALVE

OPERATING AND MAINTENANCE MANUAL

General Information ........................................................................ 3

Safety Information ........................................................................... 3

Illustration References .................................................................... 3

General Accessories ....................................................................... 4

Sequence of Operation ................................................................... 4

Operation Illustration ..................................................................... 5

Setup Procedure ............................................................................. 6

Priming the Air/Oil Drive ............................................................... 6

Mounting Dispense Valve ............................................................. 6

On/Off Dispense Valve ................................................................. 6

Air Controller ................................................................................ 6

Air Lines ........................................................................................ 6

Optional Cycle Detection Spool Sensors ...................................... 6

Model 1095 General Illustration ..................................................... 7

Operating Procedures .................................................................... 8

Dry Run ....................................................................................... 8

Loading & Priming ....................................................................... 8

Output Verification ....................................................................... 9

Daily Operation and Maintenance ............................................... 9

Operation Adjustments .................................................................. 10

Periodic Maintenance ..................................................................... 10

Refilling the Hydraulic Oil Reservoir ................................................ 10

Changing the Reclassifier Filter Element ......................................... 10

Disassemby – Metering Unit ............................................................ 11

Model 1095 Metering Unit Illustration .............................................. 12

Assembly – Metering Unit ................................................................ 13

Troubleshooting ............................................................................. 15

Model 1095 Recommended Spare Parts ....................................... 16

General Guidelines for O-rings and U-cup Seals .......................... 17

Warranty ........................................................................................... 18

Page 2

Page 5

GENERAL INFORMATION

The Model 1095 Series Metering Rod Positive Displacement Dispense Valve is designed for applications that

require precise metering and volumetric consistency at a wide range of material inlet pressures.

The 1095 operates with material supply pressures up to 1,200 psi (82.7 bar) or 400 psi (27.6 bar) for plastic spool

models. Material viscosity dispensing capabilities range from very thin material to high viscosity pastes with

viscosities in excess of 1,000,000 cps (1000 Pas).

The Model 1095 series ships complete with the following:

Model 1095 Dispense Valve

Solenoid Valve (110 VAC)

Air/Oil Drive Cylinder

Oil Flow Control

Metering Unit

Mounting Bracket

Seal Kit

Optional Cycle Detection Sensors (comes with cycle detection option)

Operating and Maintenance Manual

SAFETY INFORMATION

Only properly trained employees with a knowledge of the operations and safety warnings as set forth in this

manual should use this product. Read all applicable manuals completely before operating.

Note: The 1095 is shipped less the hydraulic oil in the Air/Oil cylinder. Add the oil before putting the 1095 into

service. See “Priming the Air/Oil Drive” in the Setup Procedure section for details.

WARNING: Do not exceed 100 psi (6.9 bar) pressure on the operating system. For 1095 valves with steel spools

do not exceed 1200 psi (82.7 bar) material inlet pressure. For 1095 valves with plastic spools do not exceed 400

psi (27.6 bar) material inlet pressure. Higher pressures may cause a hazard or serious injury.

Note: The minimum recommended pneumatic operating system pressure is 70 psi (4.8 bar) clean/dry air.

Toxicity and flammability hazards depend upon the product being dispensed by this unit, and the user should take

appropriate safety precautions as indicated on the MSDS of the product.

Always wear safety glasses.

ILLUSTRATION REFERENCES

Throughout this manual you will find references by illustration item number to the illustrations in the manual. The

references are indicated by parentheses around a number such as: (7). Illustrations represent typical valve

configurations. The drawings for your exact model are inserted at the back of the manual and include the part

numbers for ordering replacement parts.

Page 3

Page 6

GENERAL ACCESSORIES

Liquid Control offers a full line of standard and custom accessories for your dispensing needs including:

Valve Controllers

Cartridge Retainers and Pressure Reservoirs

Titan 200 High Pressure Cartridge Feed Systems

Transfer Pump Feed Systems for 1, 5 and 55 gallon containers

Consult your Dispensit dealer or the factory for details.

SEQUENCE OF OPERATION

The 1095 series Dispense Valve is a positive displacement valve. The sequence of operation of the system is as

follows:

1. Material enters the valve through the material inlet port located on the adapter block and fills the spool and

dispense cavities. This is the normal “ready” state.

2. The controller activates the dispense cycle.

3. The spool shifts to the dispense position, internally blocking the material inlet port and opening the dispense

outlet.

4. The metering rod cycles, pushing material from the dispense cavity.

5. After the time delay set by the air controller the spool shifts again blocking the material outlet port and

opening the material inlet port to refill the dispense cavity. At the same time the metering rod rises and the

cavity fills. The system is again in the normal “ready” state.

Page 4

Page 7

OPERATION ILLUSTRATION

Page 5

Page 8

SETUP PROCEDURE

PRIMING THE AIR/OIL DRIVE

OIL

The reservoir on the Air/Oil cylinder is not shipped wetted. When filling, be sure the unit is mounted firmly to the

machine frame or other suitable surface. Remove the plug on the top of the unit and be sure that the metering rod

is in the full down position (rod coupler is full down). Use new hydraulic oil with a viscosity of 100 SSU or lower.

Pour the oil slowly into the port. WARNING: Do not use synthetic oils or oils with synthetic additives.

WARNING: Do not overfill. Fill to the line MAX on the side of the unit.

Reinstall the plug and set the air pressure to approximately 20 psi. Open the oil flow control fully and cycle the

unit through the full range of travel until the air is entirely out of the lines (20 or 30 times). Check the oil level. If

needed, release the air pressure, remove the plug and add oil. Reinstall the plug and increase air pressure to 70

psi.

Caution: While cycling the unit use low pressure air as high pressure air may cause emulsion that results in

frothing, which could carry over into the air lines and exhaust ports.

Note: After adding oil, expect some oil escaping from the air valve exhaust for several cycles until the oil is blown

off the internal screen inside the unit.

MOUNTING DISPENSE VALVE

Mount the 1095 in a vertical position only using the Mounting Bracket (25).

ON/OFF DISPENSE VALVE

Most applications require connection of the 1095 metering unit outlet to a high pressure On/Off dispense valve

such as the Dispensit® Model 710 using a flexible hose that has a very low volumetric expansion ratio within the

specified pressure ranges. We recommend stainless steel overbraided PTFE line.

AIR CONTROLLER

Operation of the 1095 requires a controller that provides the following:

A minimum of 0.5 SCFM (2/3 cm3/s) of dry, unlubricated air at a minimum pressure of 70 psi (4.8 bar).

Time delay capability to allow the valve to cycle.

Independent air pressure regulators for material reservoir and valve operation.

Logic and controls necessary to cycle the 110 volt Solenoid Valve.

AIR LINES

Install pneumatic supply lines to the Solenoid Valve.

Minimum air pressure required is 70 psi (4.8 bar).

Maximum air pressure is 100 psi (6.9 bar).

OPTIONAL CYCLE DETECTION SPOOL SENSORS

The spool sensors are magnetic reed switches and must be connected to an electrical control. An LED on the

switch illuminates to indicate the shifting of the spool.

Page 6

Page 9

MODEL 1095 GENERAL ILLUSTRATION

1

MUFFLER,AIR,1/4NPT11

2

SOLENOID VALVE

3

TEE, STREET

4

ELBOW, STREET

5

PUSH-IN CONNECTOR

6

OIL FLOW CONTROL VALVE SUBPLATE

7

OIL FLOW CONTROL VALVE

8

BOLT KIT

9

AIR/OIL CYLINDER

10

TUBING, 1/4 OD, GREEN

10

TUBING, 1/4 OD, YELLOW

11

T-BLOCK

12

METERING UNIT

13

AIR/OIL CYLINDER FILL PORT PLUG

14

ADAPTER,HEX

15

ADAPTER,SWIVEL

16

TUBING, .47 OD BRAIDED

17

ADAPTER,HOSE

18

ADAPTER,HEX

19

NIPPLE,ADAPTER

20

AIR FLOW CONTROL VALVE

21

RETRACT OIL LINE

22

RETRACT OIL PORT ELBOW

23

NIPPLE

24

ELBOW,STREET

25

MOUNTING BRACKET

26

ADAPTER,SWIVEL,

27

BUSHING

28

ELBOW,

29

SCREW,SHS,#8-32 X 3/16

30

SCREW,SHC,1/4-20 X 3-3/4

31

SCREW,HHC

32

ADAPTER

33

NIPPLE, HEX

34

OIL RECLASSIFIER/MUFFLER

35

SCREW,SHC

36

BACKING PLATE

37

SLUG,PTFE

38

WASHER

Page 7

Page 10

OPERATING PROCEDURES

A Dry Run demonstrates the valve’s controls and dispensing steps. It also

verifies that the valve is working correctly before you load materials.

Recommended Material Supply Pressure

Minimum - 20 psi (1.4 bar)

For Plastic Spools Maximum - 400 psi (27.6 bar)

For Steel Spools Maximum - 1200 psi (82.7 bar)

The above settings depend on the cycle rate and viscosity of the material.

DRY RUN

1. Attach the pneumatic supply lines from the air line fittings on the valve to the air supply outlets on the air

controller. Factory supplied air lines and fittings are color-coded yellow for the air supply to initiate the

dispense cycle and green for the refill shuttle and match the color-coding on Dispensit® 4100 series air

controllers.

2. Turn on the electric and air supply.

3. Set the air pressure to 70 psi (4.8 bar) on the system pressure gauge.

4. Momentarily activate the controller’s Dispense Valve cycling control switch. The 1095 valve should go through

a complete cycle and cause a slight fluctuation in the system pressure gauge. If the valve is equipped with

optional cycle detection the illumination of the LED’s on the spool reed sensors verifies spool shifting.

5. When this happens, the system installation is correct.

LOADING & PRIMING

1. Fill the oil cups with a compatible lubricant (suitable for use with material). Use them when dispensing a

material that air cures easily. They are designed to act as reservoirs for compatible material to help prevent

having material cure on movable shafts. Cured material can cause premature wear of the seals.

2. If not removed, remove the material line from the inlet port of the valve.

3. Prime the material line.

4. Extend the valve to the Dispense Cycle(refer to Sequence of Operation).

5. Install the material line to the inlet port of the valve.

6. Increase the material inlet pressure for loading.

7. Perform the loading sequence of the valve until air free material is visible.

Page 11

OPERATING PROCEDURES

Output verification is a simple procedure where individual samples of material are

collected, weighed, and compared for desired output. We recommend that you

perform output verification at least once a day, and if the machine is used in

production for more than one shift, then once a shift.

If there are any problems in getting started, refer to the Troubleshooting

section or call Technical Service at (330) 494-1313.

OUTPUT VERIFICATION

1. Position a clean container under the valve outlet.

2. Set the stroke of the metering rod to desired shot size.

3. Weigh three small empty cups and label.

4. Take a purge shot into an unweighed empty cup.

5. Dispense ten shots into the first labeled cup.

6. Proceed in the same manner with the other labeled cups.

7. Reweigh all three cups and record results (results will be ten times desired shot size).

If shot weights are inconsistent an adjustment of the material pressure and/or Operation Adjustments

may be necessary.

DAILY OPERATION & MAINTENANCE

Before operating, perform all Daily maintenance listed below. Also, complete all loading, priming, and output

verification procedures.

MATERIAL RESERVOIR

Check material levels and refill as necessary.

OIL CUPS

Fill with lubrication suitable for use with material.

EXTERIOR

Check and clean the exterior of the valve.

Page 9

Page 12

OPERATION ADJUSTMENTS

Adjust the 1095 Valve for proper operation as follows (refer to the 1095 General Illustration on page 7):

1. Make sure that all the connections are in place.

2. Dry cycle the 1095 Valve through its complete cycle and make these adjustments as needed.

3. The Air Flow Control Valve (20) controls how fast the refill stroke moves. Adjust it so that the stroke is smooth

and slow enough to refill completely without cavitating.

4. The Oil Flow Control Valve (7), the Vickers knob with key lock on the front, controls how fast the dispense

stroke moves. Adjust it so that this stroke is smooth and does not cause the material to dispense in an

uncontrolled manner. The dispense flow should be adjusted to match the speed of the dispensing tip.

Note: The key is used to lock and unlock the Vickers knob to prevent unauthorized adjustment.

5. Connect the material for dispensing. Position a container to catch the dispensed material. Cycle the unit until

you are getting consistent dispensing (no inconsistencies or air in the dispensed material, symmetrical deposit

shape).

6. Weigh or measure a sample of the dispensed material to see if the volume is correct.

7. Continue to observe the cycling of the unit to see if the material has caused any change in the dispense and

reload strokes. If necessary, make minor adjustments to the flow controllers to restore smooth operation.

8. To adjust the volume, use the logic controller to regulate how long air pressure is supplied to the dispensing

unit, and adjust the rate of flow using the Oil Flow Control Valve (7).

9. Repeat the above steps until you obtain the correct stroke and volume.

10. Adjust the operation timing so that the 1095 Valve is able to finish its dispense before the Dispense Head

needle moves away from the part.

PERIODIC MAINTENANCE

REFILLING THE HYDRAULIC OIL RESERVOIR

Refer to the 1095 General Illustration on page 7.

Oil Selection: Use new hydraulic oil with a viscosity of 100 SSU (ISO 22) such as Mobil Velocite #10 or any SAE

10 weight rust (R) and oxidation (O) inhibited motor oil. WARNING: Do not use synthetic oils or oils with synthetic

additives.

1. When the hydraulic oil falls below the minimum level indicated on the Air/Oil Cylinder with the cylinder rod

fully extended it requires refilling.

2. When refilling the hydraulic reservoir, place the Air/Oil cylinder in the retracted position (cylinder rod inside the

the Air/Oil Cylinder), disconnect the air supply, remove the Air/Oil fill port plug (13), and slowly fill the Air/Oil

cylinder to the maximum fluid level. Install and tighten Air/Oil fill port plug (13) securely.

CHANGING THE RECLASSIFIER FILTER ELEMENT

Refer to the 1095 General Illustration on page 7.

1. The 1095 is equipped with an Oil Reclassifier (34) to collect hydraulic oil mist that may exhaust from the

solenoid valve during operation. If oil mist begins to emerge the filter is full. Remove it and change the filter

element.

2. The Oil Reclassifier (34) has a drain outlet on the bottom. If your application generates an undue amount of

oil mist you may run a drain line from this outlet.

Page 10

Page 13

PERIODIC MAINTENANCE

DISASSEMBLY – METERING UNIT

Refer to the 1095 General Illustration on page 7 to remove the metering unit from the 1095.

1. Note: This step is only for models with cycle detection sensors. Disconnect the electrical power from the

cycle detection sensors. Note the position of the sensors, then remove them by loosening the set screws and

sliding them out carefully.

2. Turn off the material inlet pressure to the 1095.

3. Cycle the valve a few times to remove residual material pressure.

4. Turn off the air pressure to the 1095.

5. Disconnect the air line Tubing (10) from the lower Push-In Connectors (5).

6. Remove the material inlet and outlet lines.

7. Remove any fluid from the oil cups.

8. Remove the two Screws (30) that extend through the Backing Plates (36) and Metering Unit (12). Carefully

slide the metering rod head out of the T-Block (11) to remove the Metering Unit (12).

Refer to the 1095 Metering Unit Illustration on the next page for the remaining steps.

9. At the top of the valve, remove the two Screws (1) and remove the Top Cap (2). Remove the Metering Rod

(8) if it was not previously removed.

10. Remove the Posipak Seal (7) from the Top Cap (2). Remove the O-ring (21).

11. Remove the four Screws (14) and the End Cap (5) on each side of the valve.

12. Remove the two Spool Shift Pistons (16) from the End Caps (5). They should come out easily but if not use

low pressure (less than 2 psi or .1 bar) air at the Push-In Connector (13) to move them. Remove the U-cup

seals (17) from the Spool Shift Pistons (16).

13. Remove the Dispense Sleeve (3) from the Main Body (4). If the sleeve is plastic and does not slide out readily

then you can thread an appropriately sized tap into it a turn or two and pull it out. A few turns of threads in the

plastic will do no harm but wear or cracking will mean that you must replace it. Keep track of which end of the

sleeve you tapped into as you will want it at the top again upon reassembly.

14. Remove the Screws (19) that hold the Oil Cup Seal Plates (9) to each side of the Main Body (4). The Seal

Retainer Washers (11), and the Posipak Seals (10 and 7) will come off with the Oil Cup Seal Plates. Remove

those seals and the O-rings (20).

15. Push the Spool/Sleeve Assembly (6) out with a finger. If it does not slide out, tap it gently using a wood or

plastic dowel. A worn spool and sleeve assembly must be replaced with a new (matched) assembly. If you

are rebuilding multiple valves be sure to keep the spools and sleeves matched.

16. Remove the O-rings (18) from the Spool/Sleeve Assembly (6).

17. Check the contents of the seal kit versus what you removed then discard the old items.

Page 11

Page 14

MODEL 1095 METERING UNIT ILLUSTRATION

11

SEAL RETAINER WASHER

12

POSIPAK SEAL

13

PUSH-IN CONNECTOR

14

SCREW,RHM,#10-32 X 2-1/2

15

PLUG,SOCKET,1/8 NPT

16

SPOOL SHIFT PISTON

17

U-CUP SEAL

18

O-RING

19

SCREW,SHC,#10-32 X 1-1/4

20

O-RING

21

O-RING

1

SCREW,SHC,#10-32 X 7/8

2

TOP CAP

3

DISPENSE SLEEVE

4

MAIN BODY

5

END CAP

6

SPOOL/SLEEVE ASSEMBLY

7

POSIPAK SEAL

8

METERING ROD

9

OIL CUP SEAL PLATE

10

POSIPAK SEAL

Page 12

Page 15

PERIODIC MAINTENANCE

ASSEMBLY – METERING UNIT

Refer to the Metering Unit Illustration on page 12 and the drawings in the back of this manual for your exact

model.

Note: Clean all valve parts with an appropriate solvent prior to reassembly. Always install new, lubricated

O-rings and seals when assembling the valve. Use Krytox 203GPL (part number 84/0200-K3/11) for lubricating

valve parts including seals and o-rings. Check the Metering Rod (8), Dispense Sleeve (3), and Spool/Sleeve

Assembly (6) for wear and if they are worn secure replacements before proceeding.

Note: Use caution as you install new U-cup and Posipak seals so that they are not pinched or torn. Do this by

making sure they are lubricated, and by tucking the lips of the seal inward before uniformly pushing them into

position.

1. Install four lubricated O-rings (18) onto the Spool/Sleeve Assembly (6). Lubricate the Spool O.D. and Sleeve

O.D. too.

2. Insert the Spool/Sleeve Assembly (6) carefully into the Main Body (4) rocking it to ease it into place. Align the

bottom holes of the Sleeve piece of the Spool/Sleeve (6) with the inlet/outlet holes of the Main Body (4).

Page 13

Page 16

PERIODIC MAINTENANCE

ASSEMBLY – METERING UNIT

Install the Seal Plate Cups on the Main Body

3. Install a lubricated O-ring (20) on the left side of the Main Body (4) next to the sleeve part of the Spool/Sleeve

Assembly (6).

4. Install lubricated Posipak Seals (7 and 10) in the left Seal Plate Cup (9) so that the O-ring side of both

Posipaks will be facing the Main Body (4). Be sure to tuck the lip of the Posipak into its cavity to avoid tearing

it.

5. Position the left Seal Cup Plate (9) with the oil cup upwards and slide it over the Spool part of the

Spool/Sleeve Assembly (6) with the counterbore for the Seal Retainer Washer (11) facing out. Slide the Seal

Retainer Washer (11) over the Spool and install two Screws (19).

6. Repeat steps 3, 4 and 5 for the right side Seal Plate Cups.

Mount the Valve End Caps to the Seal Plate Cups

7. Install a lubricated U-cup Seal (17) onto the left Spool Shift Piston (16) with lip side out as shown. Lubricate

the bore in the End Cap (5). Slide the piston into the left End Cap (5) tucking the lip of the seal into the End

Cap carefully.

8. Install the Piston/End Cap onto the left Oil Cup Seal Plate (9) using four Screws (14). Tighten the screws in a

cross pattern gradually to prevent binding due to misalignment (like you would tighten lug nuts on a car tire).

9. Push the Spool into the left side until it contacts the piston.

10. Repeat steps 7 and 8 for the right side.

Install the Dispense Sleeve, Top Cap and Metering Rod

11. Lubricate the dispense sleeve bore in the Main Body (4). Insert the Dispense Sleeve (3) into the Main Body

(4). Check for threads that may be in the inside of the sleeve due to tapping during removal and make sure

these are at the top.

12. Install the lubricated O-ring (21) around the Dispense Sleeve (3).

13. Install the lubricated Posipak Seal (12) into the Top Cap (2). Be sure to tuck the lip of the Posipak into its

cavity to avoid tearing it.

14. Insert the Metering Rod (8) through the Top Cap (2) and Posipak Seal (12) carefully.

15. Using the projecting Metering Rod (8) as a guide into the Dispense Sleeve (3), position the Top Cap (2) on

the Main Body (4).

16. Install the two Screws (1) through the Top Cap (2) and into the Main Body (4). Tighten the screws in a cross

pattern gradually to prevent binding due to misalignment (like you would tighten lug nuts on a car tire).

Install the Metering Unit on the 1095 Valve

Refer to the 1095 General Illustration on Page 7 for these steps.

17. Insert the head of the metering rod fully into the T-Block (11) and slide the Metering Unit (12) into position.

18. Position the Backing Plates (36) and install the two screws (30) to secure the Metering Unit (12) to the 1095

Mounting Bracket (25).

19. Connect the air line Tubing (10) to the Push-In Connectors (5).

20. If your valve has cycle detection, slide the cycle detection sensors into the slots on the end caps and secure

with the set screws. Do not overtighten the set screws as the sensors may be damaged.

21. Connect the material inlet and outlet lines.

22. Perform the Dry Run, Loading & Priming and Output Verification procedures. Perform Operation Adjustment

procedures if required.

Page 14

Page 17

TROUBLESHOOTING

Review the symptoms below for operating difficulties. With each problem there are one or more possible causes

to investigate.

NOTHING HAPPENS - If absolutely nothing happens when trying to cycle the 1095, check the electric and

pneumatic power.

VALVE CYCLES, NOTHING DISPENSED - First, if there is an On/Off valve downstrean of the 1095, make sure

the On/Off Dispense Valve is sequencing properly with the metering unit. Try to purge the metering unit; this

should fix most situations. Then, if nothing dispenses, check to see that there is enough air pressure to the

reservoir. Perhaps material has “set up” in the reservoir or supply hoses; examine and clear or replace as

necessary. Refer to the Operation and Periodic Maintenance Procedures in the appropriate manuals.

IRREGULAR VOLUME DISPENSED - Faulty material will cause irregular dispensing. The material must be a

smooth (homogeneous) mixture, without any air trapped in it. A second cause could possibly be that the material

is not filling the metering rod chamber fully and in time. Check the reservoir pressure as it may be too low for the

type of material being dispensed and/or the cycle time may be too fast. Cycle time is a function of

1. adequate air supply pressure,

2. the duration of supply signal, and

3. the stroke speed.

To adjust, follow the directions found in the Operation Adjustments section of this manual.

SLOW OR SLUGGISH CYCLE - This may be due to inadequate lubrication of the piston walls. Apply a very thin

film of a compatible lubricant to the outside diameter surfaces of the pistons and the U-seals and reassemble.

This should restore smooth and consistent operation. Another cause may be misalignment between the Metering

Rod and the Metering Body. Loosen the two Screws (30) that hold the Metering Unit (12) to the Mounting Bracket

(25). Power the metering rod to its full down position and tighten the Retaining Nuts. The unit is now realigned.

ON/OFF DISPENSE VALVE DROOLS OR OOZES - This can result from air trapped in the material being

dispensed, wear on the valve seat of the On/Off valve, or a worn seal in the 1095 as well as the On/Off valve, or

the On/Off Valve is out of sequence. Check the sequence and refer to the On/Off Dispense Valve Manual.

Page 15

Page 18

MODEL 1095 RECOMMENDED SPARE PARTS

Note: These parts are routine supply items or wear parts not covered by warranty for normal wear.

Quantity

Description

Part Number

1

SEAL KIT,1095

see assembly drawing for part number

1

DISPENSE SLEEVE

see assembly drawing for part number

1

METERING ROD

see assembly drawing for part number

1

SPOOL/SLEEVE ASSEMBLY

see assembly drawing for part number

1

RECLASSIFIER FILTER ELEMENT

82/0021-E/11

A/R

KRYTOX 203GPL ASSEMBLY LUBRICANT

84/0200-K3/11

Page 16

Page 19

GENERAL GUIDELINES FOR O-RINGS AND U-CUP SEALS

Sizes and materials of construction for O-rings and U-cup seals are selected by Liquid Control based on

compatibility with the chemicals to which they will be exposed. Solvents that may remove residual chemicals often

have negative effects on the mechanical properties of O-rings and seals.

O-Ring Guidelines

Always replace an O-ring with the identical one in size, durometer hardness, type and material of

construction. Always be alert to the location and size of each O-ring as many look alike and be careful not to

mix them. Often similar sizes may be used in various locations on the equipment and if replaced incorrectly,

the equipment may not function properly. Refer to the Machine Operation and Service Manual for the correct

part number of all O-rings used throughout the equipment and replace them with factory approved parts only.

Re-use of O-rings is not recommended. Only re-use O-rings as a last resort. If you must re-use them, be

sure that they are clean, have no cuts or flat spots and contain NO foreign material. Also, be sure not to soak

them in solvent for extended periods as this can cause deterioration of the O-ring. Always replace O-rings

that are cut, nicked, or distorted in shape or cross-section.

Always apply a very thin film of Krytox 203GPL lubricant, item 84/0200-K3/11, to the entire surface of the o-

ring before installation. Avoid excessive lubrication. If installing O-rings over threads on a shaft or across

sharp edges, roll or push the O-ring carefully into place being careful to avoid cutting or nicking it.

Avoid stretching the O-ring too much as it may not return to the proper size.

Do not use any sharp tools or objects to install O-rings

U-cup Seal Guidelines

Always replace a U-cup seal with the identical one in size, durometer hardness, type and material of

construction. Always be alert to the location and size of each U-cup seal as many look alike and be careful

not to mix them. Often similar sizes may be used in various locations on the equipment and if replaced

incorrectly, the equipment may not function properly. Refer to the Machine Operation and Service Manual for

the correct part number of all U-cups used throughout the equipment and replace them with factory approved

parts only.

Always apply a very thin film of Krytox 203GPL lubricant, item 84/0200-K3/11, to the inner and outer lips of

the seal before installation.

Re-use of U-cup seals is not recommended. Only re-use U-cups as a last resort. If you must re-use them, be

sure that they are clean, have no cuts or flat spots and contain NO foreign material. Also, be sure not to soak

them in solvent for extended periods as this can cause deterioration of the seal. Always replace U-cups that

are cut, have flat spots, are distorted in shape or are damaged in any manner.

Always be alert to the proper orientation of the sealing lips and re-install them in the same direction as shown

on the specific equipment assembly drawing. The U-cup seals are intended to seal in only one direction and

if installed incorrectly, chemical leakage through the U-cup can occur.

Whenever possible, push the back side of the seal over the shaft to protect the inner and outer lips. If this is

not possible, carefully tuck the lip in to avoid rolling it back or cutting it.

If installing over sharp edges, slide the seal carefully into place to avoid cutting it.

Do not use any sharp tools or objects to install U-cups.

Page 17

Page 20

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of nonGraco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification

of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be

returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship,

repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental

or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder,

or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered

into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu

que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés,

à la suite de ou en rapport, directement ou indirectement, avec les procédures concernées.

For the latest information about Graco products, visit www.graco.com.

contact your Graco distributor or call to identify the nearest distributor.

612-623-6921 1-800-746-1334 330-966-3006

Minneapolis

Belgium, China, Japan, Korea

• • •

www.graco.com

Loading...

Loading...