Page 1

Instructions

332092B

EN

Dispense Valve

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Dispensit 1230

Page 2

2

WELCOME

Thank you for purchasing a Dispensit 1230 Series Positive Displacement Dispense Valve. This manual

explains the steps for proper setup, operation, and maintenance of the dispense valve.

This manual is an overview of the valve and how it works. You have also received (where applicable),

other manufacturer’s guides and technical references that detail the specifics of their particular products

which have been integrated into the dispense valve. The information in this manual is designed to help you

get the most use out of your dispense valve.

This manual is written with the ease of understanding for not only you, but maintenance personnel, and

management. Support tasks and procedures in this manual require that you have some mechanical

knowledge and a “working “ knowledge of basic pneumatics. If you do not have this basic knowledge,

obtain the proper training before attempting any of the tasks and/or procedures detailed in this manual.

Only properly trained, authorized personnel should operate or maintain this dispense valve.

It is important that you keep this manual in an easily accessible place for future reference.

Page 3

3

Table of Contents

Introduction .................................................................................................................................................... 4

Safety Precautions .......................................................................................................................................... 5

Main Components .......................................................................................................................................... 7

Valve Operation ............................................................................................................................................. 8

Optional Equipment........................................................................................................................................ 9

Valve Disassembly ........................................................................................................................................10

Subassemblies ...............................................................................................................................................14

Valve Assembly ............................................................................................................................................16

Operation Adjustments ..................................................................................................................................17

Troubleshooting .............................................................................................................................................17

Glossary of Terms .........................................................................................................................................19

Graco Standard Warranty ..............................................................................................................................20

Graco Information .........................................................................................................................................20

Page 4

4

CAUTION

To avoid damage to property, equipment, and/or personal

injury, please adhere to common safety practices. Failure

to do so may result in such damage or injury.

Introduction

This manual is for the 1230 Series Positive Displacement Dispense Valves, designed and manufactured by

Dispensit. This manual addresses the setup, operation, maintenance and adjustment of all aspects of the

valve, which will be useful for management, support technicians as well as the operator.

Its design also permits quick change out of the wetted module (wet head), allowing the drive module

(power head) to remain permanently fixed to its mounting, assuring a minimal downtime for material

change or replacement. The valve has a linear shot adjustment scale which provides volumetric

consistency in shot applications.

The 1230, made of corrosion resistant plastic and has either plastic or stainless steel metering rods and is

offered in three different Metering Rod sizes and volume output ranges. The .125 valve has a dispense

range of 0.010cc’s-0.126cc’s, the .188 valve has a dispense range of 0.022cc’s-0.283cc’s, and the .250

valve has a dispense range of 0.040cc’s-0.503cc’s.

The 1230 will allow the operator to place a precise amount of material on a specific part with excellent

repeatability, with cycle times as fast as 1.5 shots per second (depending on the application). This valve is

capable of handling pressures, up to 60psi (.41MPa), and non-metallic material viscosities ranging from

water type materials to medium viscosity fluxes. Material can be supplied by means of different types of

material transfer systems, ranging from low-pressure syringes or cartridges to 55-Gallon transfer pump

systems.

The 1230’s modular design and lightweight allow it to easily integrate into a variety of applications. The

valve is most commonly mounted vertically (with two 8-32 machine screws) however; it may be necessary

to mount it at other angles, depending on the application. This valve has a variety of uses ranging from a

simple bench top dispense system to robotic cells or conveyorized systems. This valve can dispense

through a single luer lock needle, or a custom designed needle block configuration.

NOTE: Mounting the valve vertically will enable the use of the wet cups, while mounting the valve on an

angle will disable the use of the wet cups.

Safety considerations are an extremely important element in the proper operation of this dispense valve.

Actively thinking about the safety of yourself and others, as well as the condition of the equipment, is of

most importance. Regard all warnings, cautions, and notices that are listed (on the left margins) throughout

this manual and in any accompanying literature.

Page 5

5

Snuff-back can be monitored with DV

MODE in AUTO, but must be

adjusted with DV MODE in OPEN

Caution

Make sure EMERGENCY STOP is

locked in before manually aligning

the ratio block to the ratio beam.

WARNING

DO NOT OPERATE THIS

MACHINE WITH

GUARD(S) DETACHED

DANGER

UNPLUG MACHINE

BEFORE OPENING

ENCLOSURE

WARNING

OVERCURRENT

PROTECTION

PROVIDED AT MACHINE

SUPPLY TERMINALS

NOTICE

WEAR EAR

PROTECTION

CAUTION

WEAR EYE

PROTECTION

CAUTION

Safety Precautions

This manual provides installation, operation, and maintenance instructions for Graco Ohio Inc. meter, mix, and

dispense machines. Read this manual before you install and operate your machine. Use your machine only as directed.

Safety Terms within our manuals

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment, and/or process. Warnings are given where failure to observe the instruction could result in injury or death to

people.

Some examples follow.

Safety Labeling on our machinery

All our machines carry the following safety labels wherever necessary:

• Danger Labels indicate an imminently hazardous situation, which, if not avoided, could result in death or serious

injury.

• Warning Labels indicate potentially hazardous situations which, if not avoided, could result in death or serious

injury.

• Caution Labels indicate an unsafe practice that may result in moderate or minor injury.

• Notice Labels state a company policy. Some examples are:

Page 6

6

Safety Precautions (Cont’d)

Dispensit recommends, as many companies require, that the primary air source to the dispense valve be

disconnected before being serviced. It is the users responsibility to ensure that the primary air pressure is

OFF. If the valve is controlled by an electrical system, (e.g., solenoid valve or PLC), the electrical system

should be placed in a position where the air supply to the dispense valve is OFF.

All personnel working with this system should observe the following precautionary guidelines:

• Abide by all OSHA and NEC safety guidelines

• All operators, at minimum, must have proper instruction and practice in the use of pneumatics

• All maintenance personnel must have proper instruction and practice in the proper operation of

this dispense valve.

• Observe all company safety guidelines pertaining to dispensing equipment

• Remove watches, rings, and all other jewelry

• If the unit is to be moved or serviced, wear protective eyewear and, depending on the material

used, any necessary protective clothing (e.g., gloves, long sleeved shirt or smock).

CAUTION: It is the users responsibility to ensure that the primary air pressure is OFF before servicing the

dispense valve.

CAUTION: Always be alert of other potential hazards within your work area.

Page 7

7

AND ACCESS TO THE

WET CUP FOR FILLING

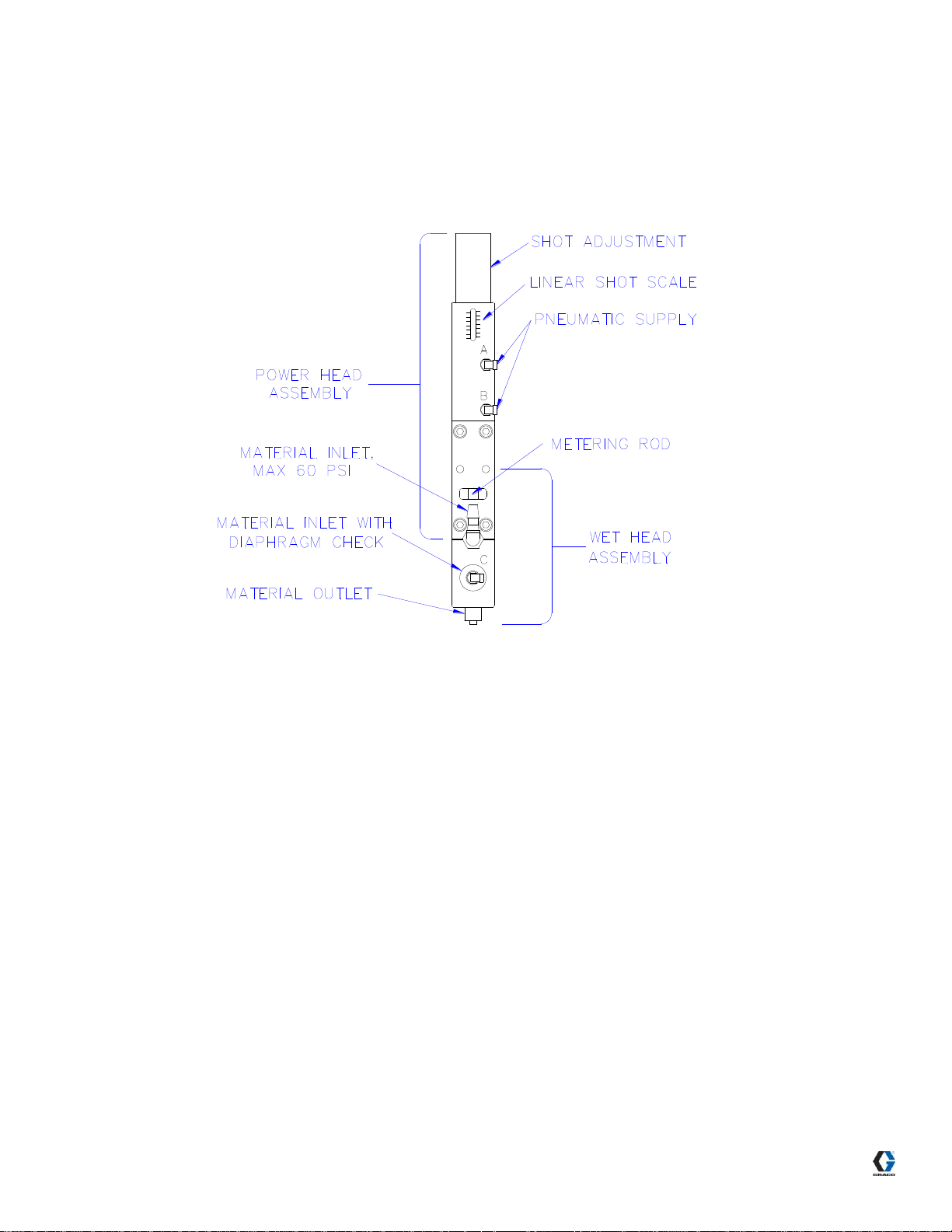

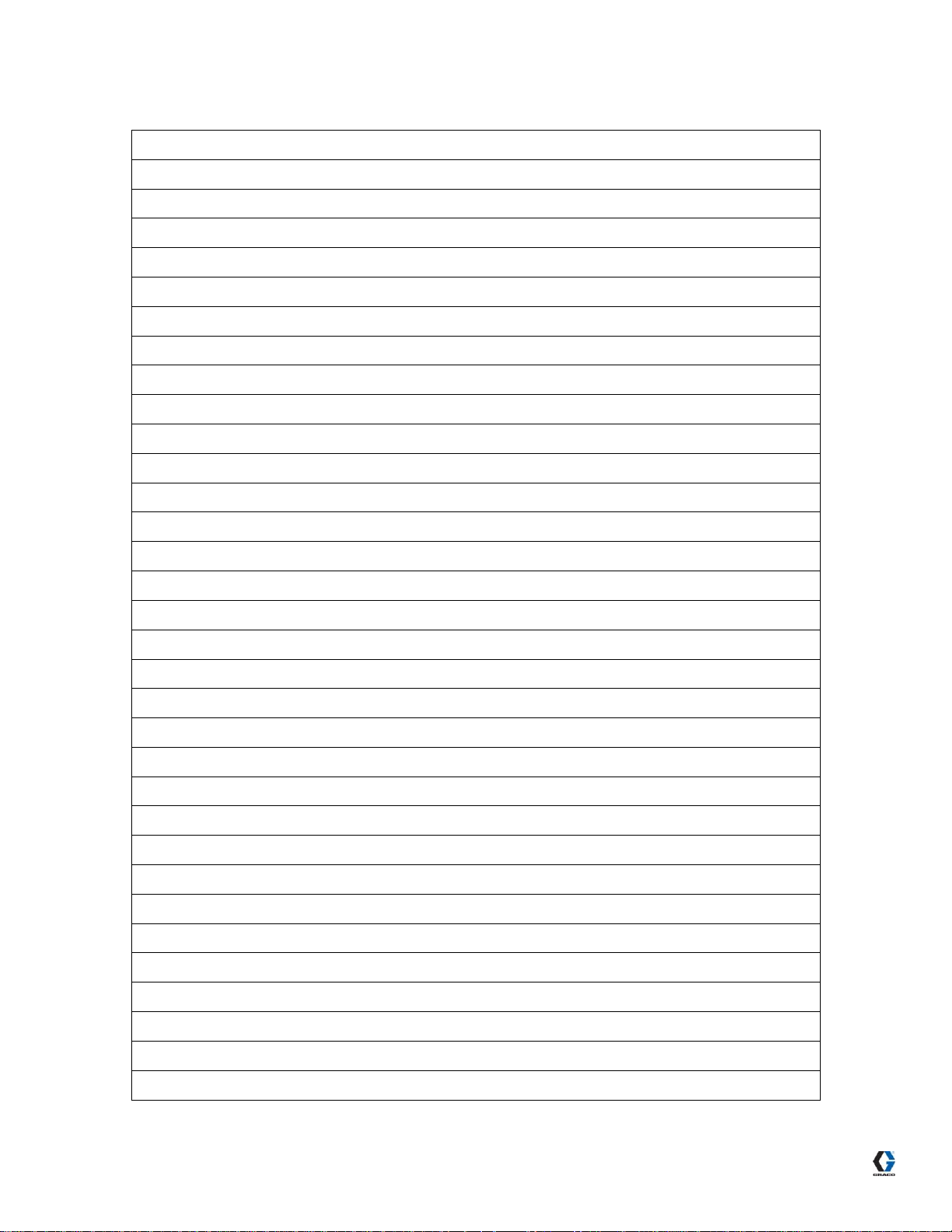

Main Components

As figure 2 shows, the main components of the 1230 dispense valve are easily recognized. For more valve

specifics, refer to p11-1, .

Figure 2. Main Components: The main components of the 1230 dispense valve are easily recognizable and

accessible. Detailed drawings can be found in the back of this manual.

The 1230 standard valve components are manufactured of high quality and wear resistant plastic, and the

metering rod is manufactured of high quality stainless steel. Other materials are available for different

material compatibilities. Refer to the, “Optional Equipment” section, for a complete list of available

component materials.

Page 8

8

Material fills the valve through

the material inlet port located on

the inlet block and fills the spool

and dispense chamber.

Air is supplied to the dispense

port which moves the metering

rod down.

The metering rod moves down,

pushing material through the

diaphragm check valve, and out the

dispense needle.

Air is shifted back to the fill

position. The metering rod moves

back up, drawing material through

the inlet port.

Valve Operation

Figure 3 is an illustrated description of the sequential steps in the cycling of the 1230 dispense valves.

Figure 3. Valve Operation Sequence.

The 1230 Dispense Valve has a simple fourstep operation, Normal (Home), Shift, Dispense, and Reload.

Page 9

9

Optional Equipment

5.1 Controller

Operation of the 1230 dispense valve, requires the use of a pneumatic, cycle sequencing, controller.

Dispensit offers the optional 4134 Pneumatic Controller, as seen in figure 4, which when triggered by

either a foot switch or toggle switch, can control the dispense valve and the optional Dispensit 1105 Z-Lift

station. The 4134 Controller can operate the following:

• Time/cycle speeds

• Cycle sequencing

• Independent air pressure regulators for material reservoir, valve cycling and Z-Lift operations

• Automatic or semi-automatic applications

Figure 4. Pneumatic Controller

The yellow port will extend the metering rod allowing the valve to dispense material, and the green port

will retract the metering rod allowing the valve to reload with material. The auxiliary port will apply a

constant flow of air pressure for the diaphragm check valve. The auxiliary port air pressure (for the

diaphragm check valve) is typically set to 5 to 10 psi above material inlet port pressure.

NOTE: The auxiliary port (for the diaphragm check valve) air pressure is not to exceed 70 psi.

Lowering the diaphragm check valve air pressure until material flows will purge the 1230 valve.

5.2 Plastic Metering Rod

Use of a high quality, wear resistant, plastic metering rod provides a wetted section (Wet Head) free of

metallic components. Such a configuration can be beneficial for applications handling especially strong

acids (certain fluxes), and for anaerobic materials (thread lockers).

5.3 Needle Blocks

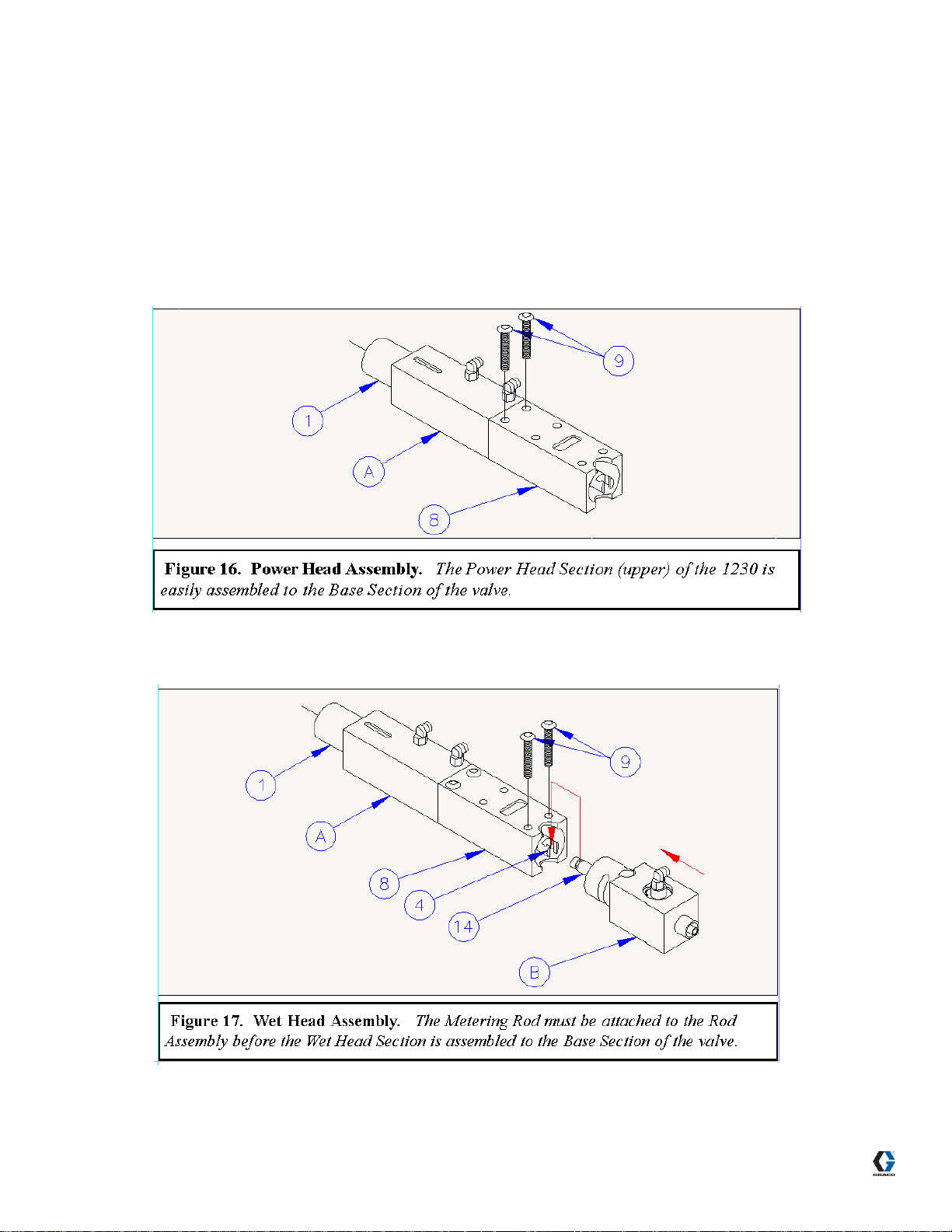

The 1230 dispense valve has the option of dispensing material through a single luer lock needle of various

gauges, or a custom designed multi-needle block as illustrated in figure 5. An adapter block is used to

accommodate custom designed single or multiple needle dispense blocks for applications requiring precise

needle lengths or, more than one dispense location or height.

Figure 5. Adapter with Multi-Needle Block Assembly

Page 10

10

Valve Disassembly

6.1 Removing the Valve

To remove the valve from its work position requires a few steps to assure that the valve can be replaced in

the same manner. Use care when servicing! This valve contains plastic components. Complete these few

steps to remove the dispense valve:

• Purge residual pressure from material line, and then remove the material line from the dispense valve.

• Carefully remove the incoming air line from the diaphragm. Do not break the plastic barbs.

• Move the metering rod to its lower position by setting the maximum stroke on the adjustment knob.

• Remove the dispense valve by removing the two 8-32 machine screws from the front of the valve.

• Carefully slide the metering head from the slot in the drive piston.

• Take the valve to a clean work area for disassembly.

6.2 Required Tooling

The following tools will be required to rebuild either dispense valve:

• 1/8” Straight Screwdriver

• Hooked Dental Pick

• 1/4” Open-End Box Wrench

• Internal Snap Ring Pliers

• 3/32” Allen Wrench

• 5/64” Allen Wrench

• Small Bar Clamp.

WARNING: Remove residual material pressure before removing the material line from the valve.

CAUTION: Use caution when handling the valve so the needle(s) don’t get damaged or broke.

Page 11

11

1

Valve Disassembly (Cont’d)

6.3 Main Sections

The 1230 Valve can first be broken down into two main sections, the “Power Head”, and the “Wet Head.”

For simplicity sake, this manual will describe the procedures for a valve containing a luer-lock needle and

adapter.

To disassemble the 1230 into its main sections, refer to figure 6 and follow these steps.

1. Remove the Luer-Lock Adapter (24) and with the Luer-Lock Needle (25) from the bottom of the Valve.

2. Unscrew the Adjustment Knob (1) until it reaches the top of the scale, then press the Adjustment Knob

down until it bottoms out.

3. Remove the two lower 8-32 BHCS (9) from the front of the Valve and pull the Wet Head (B) section

from the Base (8), separate the Metering Rod from the Piston Rod, and remove the Wet Head.

4. Remove the two upper 8-32 BHCS from the front of the Valve and pull the Power Head (A) from the

Base.

Figure 6. Main Sections. The 1230 is built with three main components, the Power Head, Wet Head, and the Base

Section. The three sections can easily be seperated and each can be easily disassembled.

Page 12

12

Valve Disassembly (Cont’d)

6.4 Power Head Section

Typically the power head section will only require servicing if material leaks into the air chamber or the

air chamber is leaking pressurized air.

To disassemble the Power Head Section follow these steps. It is not necessary to remove the air lines if

still attached. Refer to figure 7 for part orientation.

1. Loosen the Set Screw (13) on the Adjustment Knob (1), and remove the Adjustment Knob by turning it

counter clockwise until it comes off the Rod Assembly (4).

2. Remove the Internal Snap Ring (2) from the top of the Power Head.

3. Remove the Rod Assembly by pulling it out the top of the Power Head. The Insert (12) will come out

with the Rod Assembly.

4. Remove and discard the Pressure Seal (11) and “O” Ring (3) from the Insert.

5. Remove and discard the Pressure Seal (6) from the Rod Assembly.

6. Remove and discard the “U” Cup Seal (7) from the bottom of the Power Head Body (5).

Figure 7. Power Head Components. The Power Head section of the 1230 dispense valve has a small number of

components which makes maintenance easy.

Page 13

13

Valve Disassembly (Cont’d)

6.5 Wet Head Section

To disassemble the Wet Head Section follow these steps. It is necessary to remove the air line from the

diaphragm barb fitting. Refer to figure 8 for part orientation.

1. Pull the Metering Rod (14) from the top of the Wet Head Section (14).

2. Remove the Internal Snap Ring (15) from the top of the Wet Head.

3. With a small dull dental pick, remove and keep the Washer (16) and remove and discard the High

Pressure Seal (17) from the top of the Wet Head Section.

4. Remove the Internal Snap Ring (15) which holds the Diaphragm in the Wet Head Section. This snap

ring is under pressure. Use Caution when removing.

5. Remove the Diaphragm Insert (20) by pulling it out and then remove and discard the “O” Ring (21) and

the Diaphragm (22).

Figure 8. Wet Head Components. The Wet Head section of the 1230 dispense valve has a small number of

components which makes maintenance easy.

Page 14

14

Subassemblies

7.1 Component Cleaning

WARNING: Clean the valve components with a solvent or cleaner that is compatible with the material that

was dispensed through the valve. Personal injury or damage to the valve may occur if the wrong cleaner or

solvent is used.

With the valve completely disassembled, the individual components can be cleaned. Using a solvent or

cleaning solution that is compatible with the material dispensed with this valve, thoroughly clean all the

components. The “O” Rings , “U” Cup Seals, and High Pressure Seals should be discarded and replaced.

Do not discard the plastic Washer (16), or the Diaphragm Insert (20), unless they are being replaced.

While cleaning the components, be sure that all material is removed. Cured or old material left in the valve

may cause the valve to operate improperly. Dry all components and make sure there is no cleaning solution

or material film/residue, left on the components.

Inspect the metering rod (#14 Fig.8), replace if there are any surface imperfections on the metering rod.

NOTE: Any surface imperfections on the metering rod will cause material leakage prematurely.

7.2 Seal Replacement

Replacement seals are available in complete kits. Each seal kit has all the necessary seals needed to rebuild

one valve. After the components have been cleaned, new seals can be installed, cylinders can be lubricated

with KRYTOX® lubricant (included in the Seal Kit), and subassemblies can be reassembled as described

below.

7.2.1 Pressure Head Seals

Install one High Pressure “Quad” Seal (6) onto the Rod Assembly (4) as shown in figure 9. Install the other

“U” Cup (7) into the groove on the inside of the Power Head Body, with the open side of the “U” Cup Seal

facing in, as shown in figure10. Likewise, using a seal installation tool or small screwdriver with no sharp

edges, install the smaller “U” Cup Seal (11) into the groove on the inside of the Insert (12) with the open

side of the “U” Cup Seal facing out, and then install the “O” Ring (3) on the outside of the Insert, as shown

in figure 11. After installation, lubricate the outside of the “U” Cup Seals with a liberal amount of

KRYTOX® lubricant (included in the Seal Kit). Assemble item in the reverse order per figure 8.

NOTICE: Do not cut, tear or damage the Seals when installing them. The slightest nick or cut will cause

the valve to leak.

Page 15

15

Subassemblies (Cont’d)

7.2 Seal Replacement

NOTICE: Do not cut, tear or damage the Seals when installing them. The slightest nick or cut will cause

the valve to leak.

7.2.2 Wet Head

Install a High Pressure Seal (17) with the “O” Ring side facing in, into the smaller pocket in the top of the

Wet Head (18). Place the plastic Washer (16) over the High Pressure Seal and gently press the two

components into place. Refer to figure 12 for the proper component orientation. Install the internal Snap

Ring (15) into the groove above the plastic Washer. Lubricate inside if seals and

Insert the Metering Rod (14) into the top of the Wet Head. Gently press the

Metering Rod in until it just passes the High Pressure Seal. The opposite

end of the Metering Rod needs to extend as far as possible for the final assembly.

Lay the Wet Head on its side with the diaphragm cavity facing up, as seen in figure 13. Making sure that

the surface is clean; insert the Diaphragm (22) into the pocket. Place the “O” Ring (21), then the

Diaphragm Insert (20), followed by the internal Snap Ring (15), on top of the Diaphragm.

To install the Snap Ring, place a 10-32 x 1.0 SHCS into the insert (20), then use

a small Bar Clamp (with a soft protective material between the clamp and Wet

Head), to compress the components as figure 14 shows. When the components

are compressed and the snap ring groove is accessible, install the Snap Ring. Be

sure the Snap Ring is securely installed before removing the bar clamp. When

the clamp is removed, install the Barb Fitting (10).

Roll the “O” Ring (23) over the threads of the Luer Lock Adapter (24) as shown

in figure 15. Screw the Adapter into the bottom of the Wet Head until it is snug.

Do not use PTFE tape on the threads and do not over tighten.

NOTICE: Do not use PTFE tape on the Adapter threads and do not over tighten

the Adapter when installing.

Page 16

16

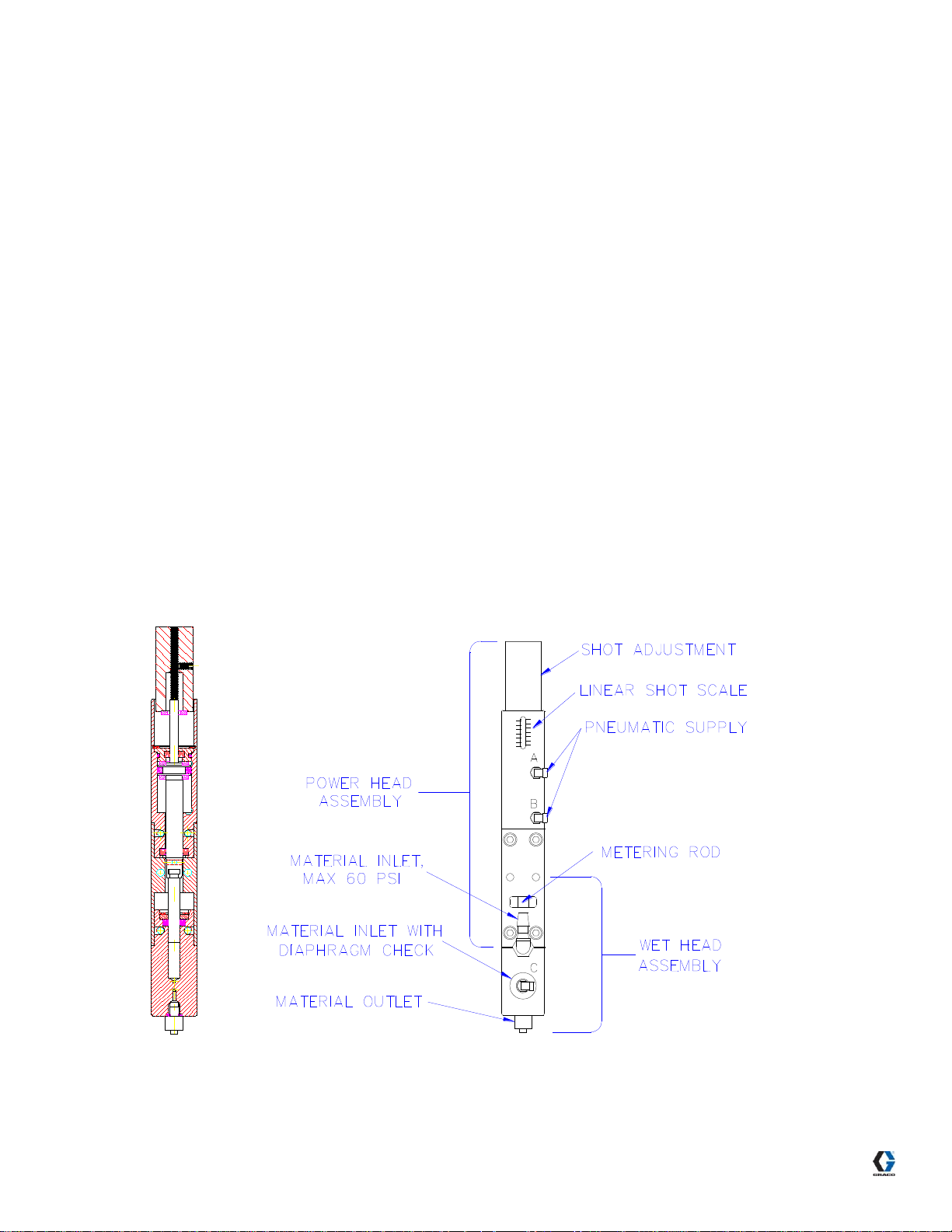

Valve Assembly

8.1 Final Assembly

Complete the following steps to assemble the Power Head and Wet Head to the Base Section. Refer to

figures 16 and 17 for the proper orientation of these parts.

1. Attach the Power Head Assembly (A) to the top of the Base Section (8) by sliding it into the Base

section. Align the two sections with the cut outs on the same side, and secure them together with two

BHCS (9). Attach the Adjustment Knob (1) to the threaded end of the Rod Assembly (4) which is

protruding from the top of the Power Head. After a few turns of the Adjustment Knob (1), press the Rod

Assembly down as far as it will go. This will aid in the assembly with the Wet Head Assembly.

2. Attach the Wet Head Assembly to the bottom of the Base Section by connecting the Metering Rod (14)

to the Rod Assembly (which is extending through the bottom of the Base Section) and sliding the Wet

Head into the Base Section. Square up the two sections with the diaphragm assembly facing the front, and

secure them together with two BHCS (9).

3. Connect air lines, reset adjustment knob, cycle valve for leaks and connect material and purge valve.

The valve is ready to resume production.

Page 17

17

AND ACCESS TO THE

WET CUP FOR FILLING

Operation Adjustments

Adjust the Dispense Head for proper operation as follows. See step 6 for volume adjustment.

1. Make sure that all the Dispense Head pneumatic connections are in place.

2. Fill wet cup (if equipped) with compatible material.

3. Connect the material for dispensing. Position a container to catch the dispensed material. Cycle the

Dispense Head until you are getting consistent dispensing (no inconsistencies in the dispensed material,

symmetrical deposit shape).

4. Weigh at measure a sample of the dispensed material to see if the volume is correct.

5. Continue to observe the cycling of the Dispense Head to see if the material has caused any change in the

dispense and reload strokes.

6. To adjust the volume; loosen the set screw on the shot adjustment and change the volume by turning shot

adjustment (raise the collar to increase volume). Snug the set screw and reconnect the air line after

adjusting the stroke adjustment collar

7. Repeat the above steps until you obtain the correct stroke and volume.

8. Adjust the operation timing so that the Dispense Head is able to dispense completely before moving the

part.

Page 18

18

Problem

Possible Cause

Solution

Nothing Happens

1. Pneumatic or electrical problems with the

controller or controlling device.

2. Foot switch or cycle start switch are not

working properly.

3. Valve is locked up.

1. Have the controller or controlling devices

checked and serviced as needed.

2. Have the foot switch or cycle start switch

checked and serviced as needed.

3. See problem “Valve Locked Up” below.

Valve Cycles but

Material is Not

Dispensed

1. Material line is closed off at the valve.

2. Low air pressure on the material transfer

system.

3. Low material pressure setting on material

transfer system.

4. Material is cured in the needle or needle

block.

5. Not enough M.R. stroke

1. Open any “in-line” restrictions so material

flows smoothly to the dispense valve.

2. Adjust air pressure to proper determined

setting, which is needed to dispense the

material involved.

3. Adjust material output pressure to proper

determined setting, which is needed to

dispense the material involved.

4. Replace the dispense needle with a new

one.

5. Increase the stroke of the Metering Rod to

get more material.

Irregular Dispense

1. Inconsistent material (cured, dried, or

separated)

2. Air in the material.

3. Valve is cycling too fast, not allowing the

metering rod chamber to fill.

4. Cycle timing on the controller or

controlling device is improperly set.

1. Replace the material supply.

2. Replace the material supply.

3. Controller timing needs to be adjusted.

4. Adjust as needed, as per manufacturers

recommendations.

Sluggish Cycle Time

1.Pistons and/or cylinder walls are poorly

lubricated.

1.Disassemble the Drive Cylinder Assembly

and the End Cap Assemblies, lubricate, align,

and reassemble.

Valve Drools

1. Air in the material.

2. Worn Metering Rod.

3. Worn seals.

4. Worn diaphragm.

1. Replace the material supply.

2. Replace Metering Rod.

3. Rebuild valve with a new seal kit.

4. Replace the diaphragm.

Dispense Valve is

Locked Up

1. Wrong material for this particular valve

design.

2. Oil buildup on cylinder walls from air

supply.

3. Too low air pressure on valve.

1. Make sure the wetted components and

spool/sleeve assembly are compatible with

material. Refer to p5-2, “Optional Equipment”.

2.Disassemble, clean and/or rebuild valve.

Use only NON-lubricated air with this valve.

3. Increase air pressure.

Material build upon

metering rod.

1. Material getting past the upper seal due to

a lack of fluid in the wet cup.

1. Rebuild the valve and pay special attention

to the metering rod.

Troubleshooting

Although good housekeeping, preventive maintenance and proper operating procedures will lengthen the

life of the valve, all mechanical devices will develop problems from normal wear. Following are some of

the possible difficulties and likely causes that may arise with the valve. If these do not correct the situation,

call the technical service department at Dispensit®.

Page 19

19

Glossary of Terms

Not all terms listed below are part of your system.

ANSI (American National Standards Institute): an association of industry representatives which

develops technical standards including safety. These standards comprise a consensus from a variety of

industries on good practice and design. ANSI standard relevant to Dispensit is ANSI/RIA R15.06

(industrial robots and robot systems).

AUTHORIZED PERSONNEL: properly trained individual who has been given permission from a

supervisor or management personnel, to operate or service a particular piece of equipment.

BASE SECTION: the center section of the dispense valve which seals the material from coming out the

top of the dispense valve body.

BHCS: button head cap screw

CC’S: a volumetric unit of measure.

DISPENSE VALVE: a mechanical devise used to apply a precise amount of a specified material.

Depending on the specifics, the material can be placed in a predetermined location or on a predetermined

path on a specified part.

DRY CYCLE: the process of operating the valve under normal working conditions, except material is not

dispensed. This process is done to verify that the valve is cycling correctly before applying material.

FLOW CONTROL: a mechanical devise that controls (or restricts) the air flow which travels through it.

Controlling the air flow at both sides of the dispense piston, regulates how fast the piston moves up and

down.

HIGH PRESSURE SEAL: a type of seal which combines an O-ring with a U-cup seal. This combination

provides a superior seal in high and low pressure circumstances.

INLET BLOCK: a component between the body of the valve and the needle block, where the material

enters the dispense valve.

MAINTENANCE PERSONNEL: an specific individual or group who’s properly trained to fix and/or

adjust a particular piece(s) of equipment when problems occur.

METERING ROD: a component which draws material into the metering chamber and presses material

out of the metering chamber.

METERING CHAMBER: an area where a certain amount of material is stored within the dispense valve

before dispensing.

MPa: a unit of measure which is equal to 1000 Pascals. 1Pa =1Newton of weight per square meter.

NEC (National Electrical Code): a publication put out by the National Fire Protection Association which

contains guidelines for proper installations of electrical products, in order to safeguard personnel and

property.

NEEDLE BLOCK: a component on the bottom of the dispense valve where the material is dispensed

from. The needle block may consist of a simple single needle or a complex configuration of multiple

different needle sizes and lengths.

Page 20

20

Glossary of Terms (Cont’d)

OSHA (Occupational Safety and Health Administration): a division of the U.S. Department of Labor,

responsible for the regulation of workplace safety. OSHA regulations often follow ANSI standards which

become law when adopted by OSHA and must be followed.

PLC (PROGRAMMABLE LOGIC CONTROLLER): an electronic device used to decipher electrical

signals from input devices and energizes output devices. A PLC also gives you the ability to manipulate

how and when the output devices are energized by the information being sent by the input devices.

PNEUMATIC: a devise which is being controlled by the use of compressed air.

POSITIVE DISPLACEMENT: a process of where a known precise volume of material is displaced

(dispensed) during a given motion of the dispense valve.

POWER HEAD ASSEMBLY: the top section of the dispense valve which controls the length of stroke

and the volume of material being dispensed.

PRIMARY AIR SOURCE: the main supply of air pressure which is being used to operate the dispense

valve.

PSI: pounds of pressure per square inch.

QUALIFIED PERSONNEL: a person who by possession of a recognized degree or certificate of

professional training, or who, by extensive knowledge, training, and experience, has successfully

demonstrated the ability to solve problems related to the subject matter and work (ANSI B30.2-1983).

RESIDUAL PRESSURE: pressure that is still in the material or airlines that has not been reduced even

though the primary source of the pressure has been turned off.

RHMS: round head machine screw

ROBOTIC MOTION SYSTEM: a complex device which uses robotic arms to precisely move the

dispense valve or other components about the dispense valve.

SEAL PLATE CUP: a block on each side of the body, used to lubricate the sides of the spool.

SHCS: socket head cap screw.

SOLENOID VALVE: an electrical devise used for turning the flow of air on and off.

SHCS: socket head cap screw.

U-CUP: a pneumatic seal used in low pressure-low speed situations.

VISCOSITY: a numerical measure of the degree to which a fluid resists flow under an applied force.

Wet Cup: Place to put compatible lubricant fluid to keep air from being drawn into the material chamber,

and to lubricate seals.

WET HEAD ASSEMBLY: the lower section of the dispense valve which is where the material flow

takers place.

Z-AXIS: a pneumatic slide which moves the dispense valve down onto a part for dispensing, and back up

into a neutral position.

Page 21

21

Page 22

22

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of nonGraco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered

into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu

que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à

la suite de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

contact your Graco distributor or call to identify the nearest distributor.

612-623-6921 1-800-746-1334 330-966-3006

Original Instructions. This manual contains English. MM 332092

Minneapolis

Belgium, China, Japan, Korea

• • •

www.graco.com

Revised September 2014

Loading...

Loading...