Page 1

Instructions - Schematics

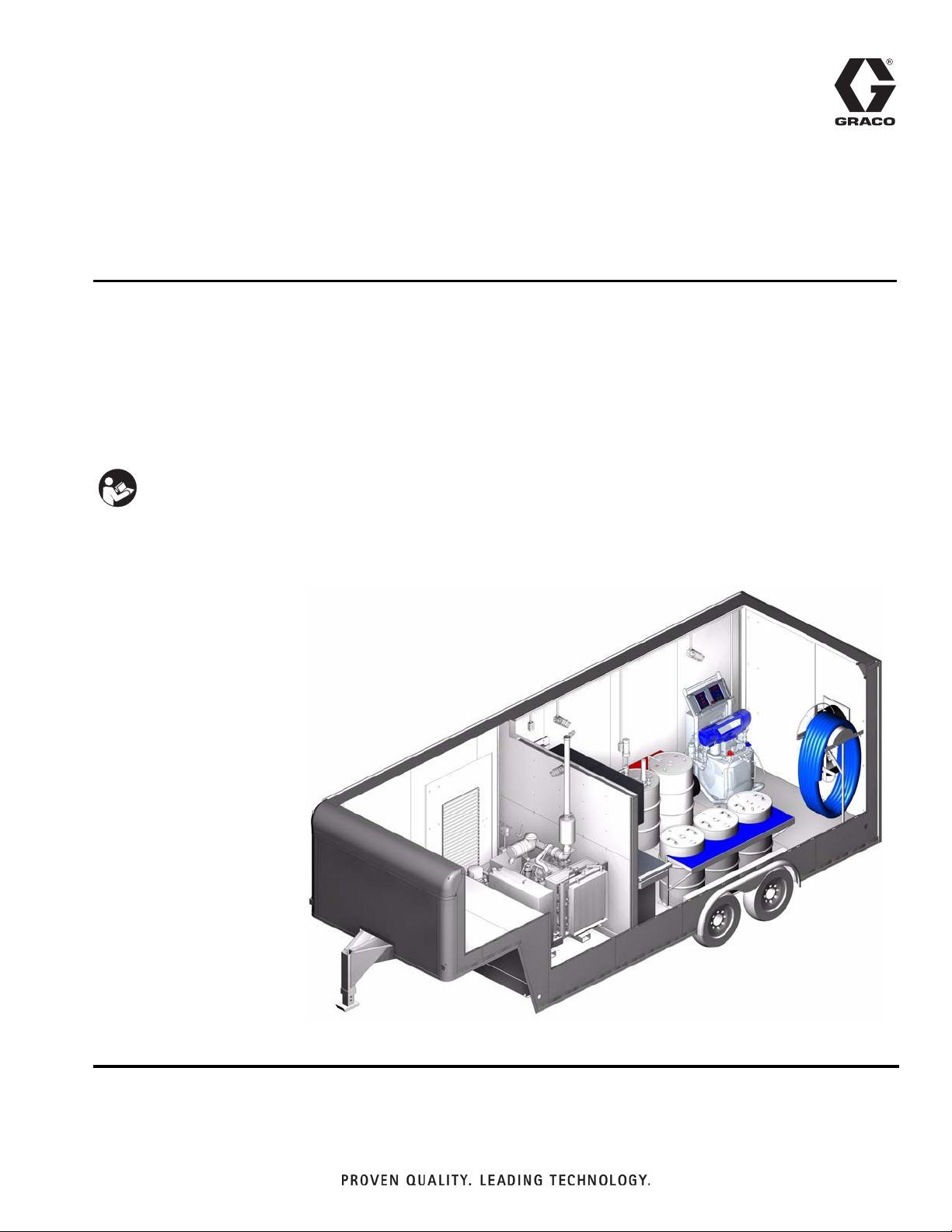

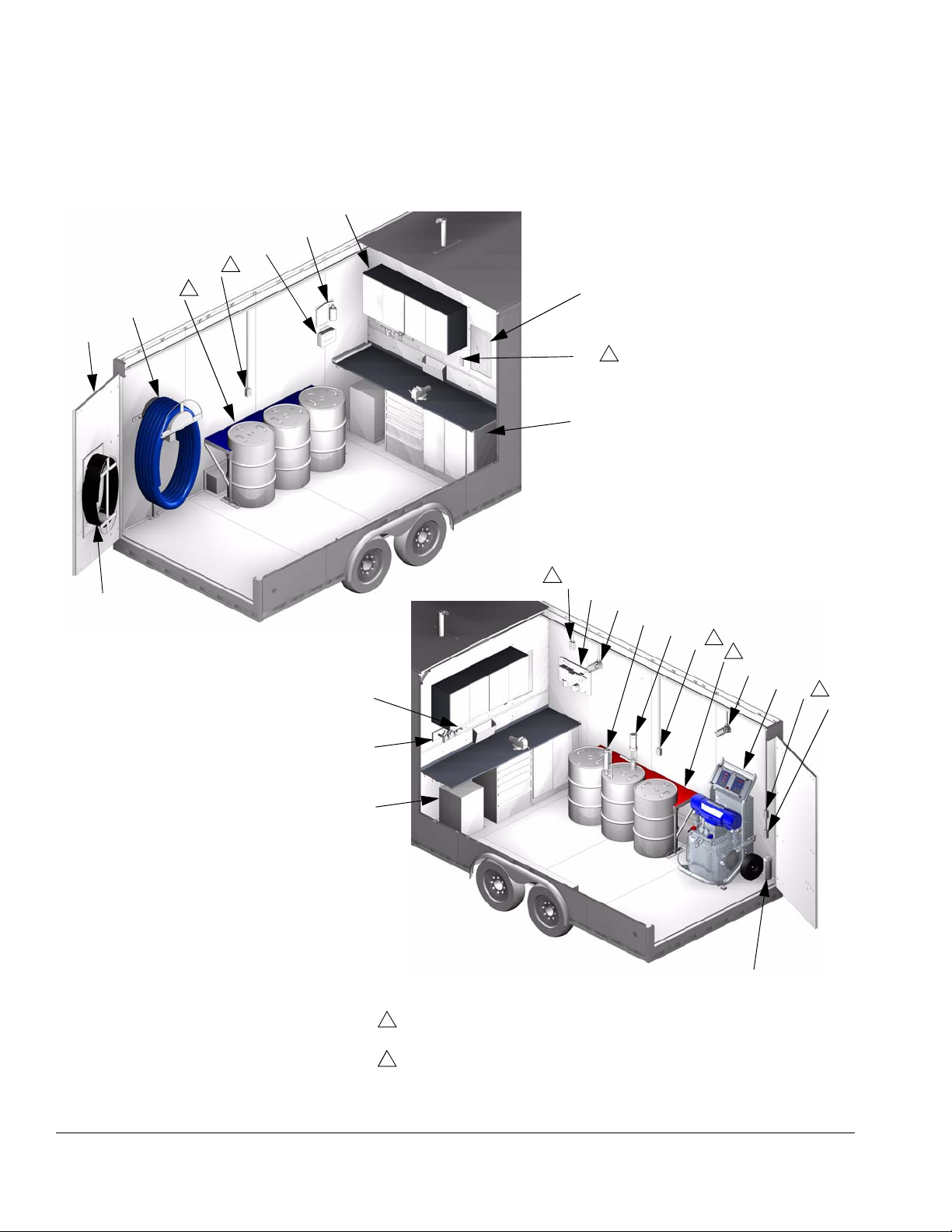

Mobile Spray Rig

For mobile spraying or dispensing of epoxies, polyurethane foam, and polyurea coatings.

Not for use in explosive atmospheres.

120 psi (0.8 MPa, 8.2 bar) Maximum Working Air Pressure

See Technical Data on page 45 and Related Manuals on page 3 for Maximum Working Fluid Pressures

Important Safety Instructions

Read all warnings and instructions in this manual and all

supplied manuals. Save these instructions. See Related

Manuals on page 3.

See page 4 for product configurator information.

312765B

28 ft Trailer Shown

TI12880b

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Configurator . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Component Identification . . . . . . . . . . . . . . . . . . . 12

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Transporting Trailer . . . . . . . . . . . . . . . . . . . . . . . . 18

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 26

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Simplified Electrical Schematics . . . . . . . . . . . . . 30

Simplified Pneumatic Schematic . . . . . . . . . . . . . 38

Simplified Fluid Schematics . . . . . . . . . . . . . . . . . 40

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Graco Ohio Standard Warranty . . . . . . . . . . . . . . 46

Graco Ohio Information . . . . . . . . . . . . . . . . . . . . 46

2 312765B

Page 3

Related Manuals

Related Manuals

Graco Manuals

These manuals can be found at www.graco.com. See

Product Configurator on page 4 to determine which

components are installed in your assembly. All manuals

for installed components are supplied with each Spray

Rig.

Proportioners

Part Description

311511 Air Reactor Operation Manual

311512 Air Reactor Repair Manual

312062 Hydraulic Reactor Operation Manual

312063 Hydraulic Reactor Repair Manual

312064

312065 Electric Reactor Operation Manual

312066 Electric Reactor Repair Manual

Gun Packages

Part Description

309550 Fusion Air Purge Gun Manual

309856 Fusion Mechanical Purge Gun Manual

311320 D-Gun Manual

311321 GX-7A, GX-7 DI, and GX-7 400 Spray

311322 GAP Pro Spray Gun Manual

311338 Gusmer GX-8 Gun Manual

312666 Fusion ClearShot Gun Manual

313213 Probler P2 Manual

Pumps

Hydraulic Reactor Electrical Diagrams

Manual

Guns Manual

Hoses

Part Description

309572 Power-Lock Heated Hose Manual

Kits

Part Description

309815 Feed Pump Kits Manual

309852 Circulation and Return Tube Kits

Non-Graco Manuals

The following manuals are for non-Graco Spray Rig

components. See Product Configurator on page 4 to

determine which components are installed in your

assembly. All manuals for installed components are supplied with each Spray Rig.

Description

Breathable Air System Manual

Air Dryer Manual

Trailer Manual

Generator Manual

Compressor Manual

Air Conditioning Unit Manual

Band Heaters Manual

NOTE: The manual for each rotary compressor is

included in the generator manual.

Part Description

308479 Husky 1040 Air-Operated Diaphragm

Pumps Manual

311882 T2 2:1 Ratio Transfer Pump Manual

312766 T1 2:1 Ratio Transfer Pump Manual

Agitators

Part Description

308175 Twistork Helix Mixer

312765B 3

Page 4

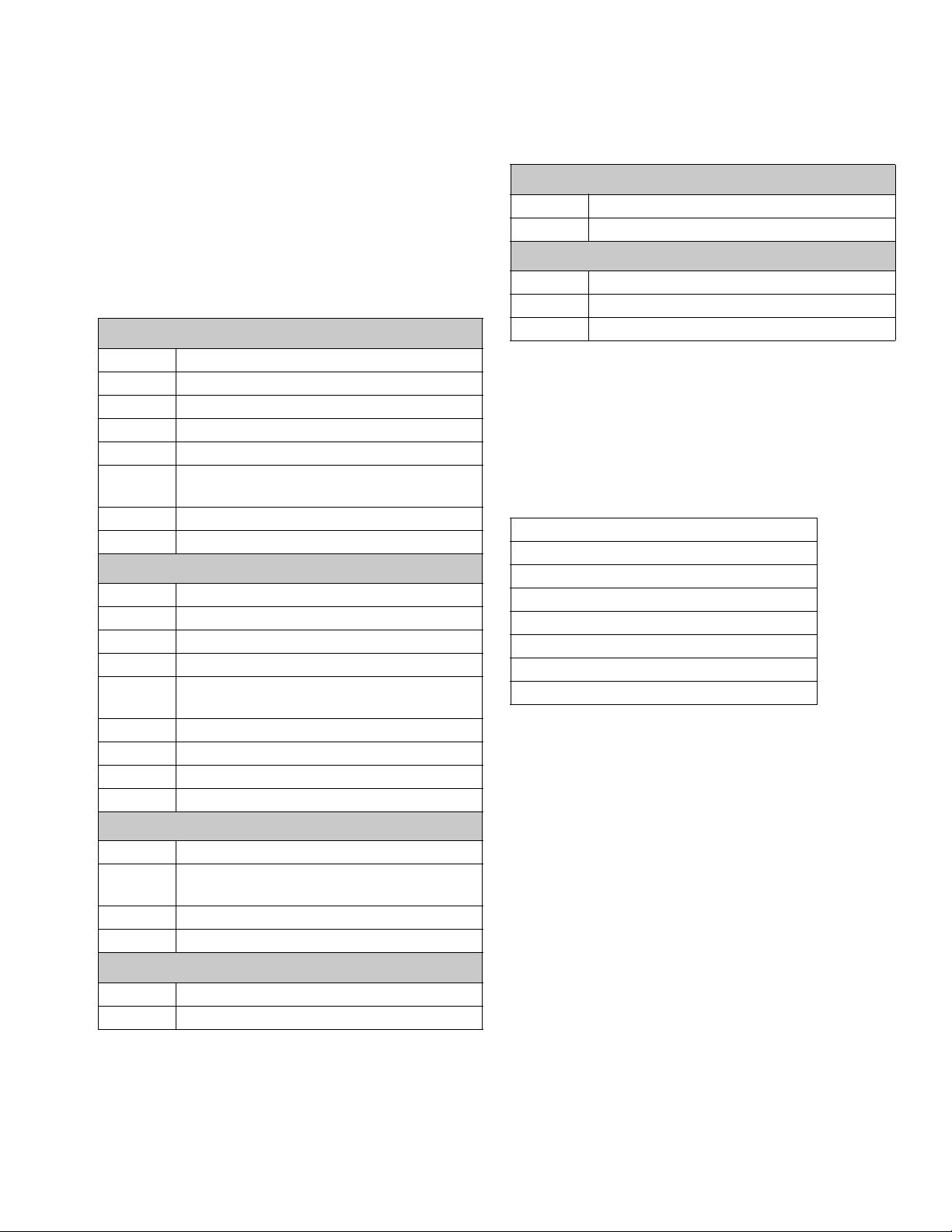

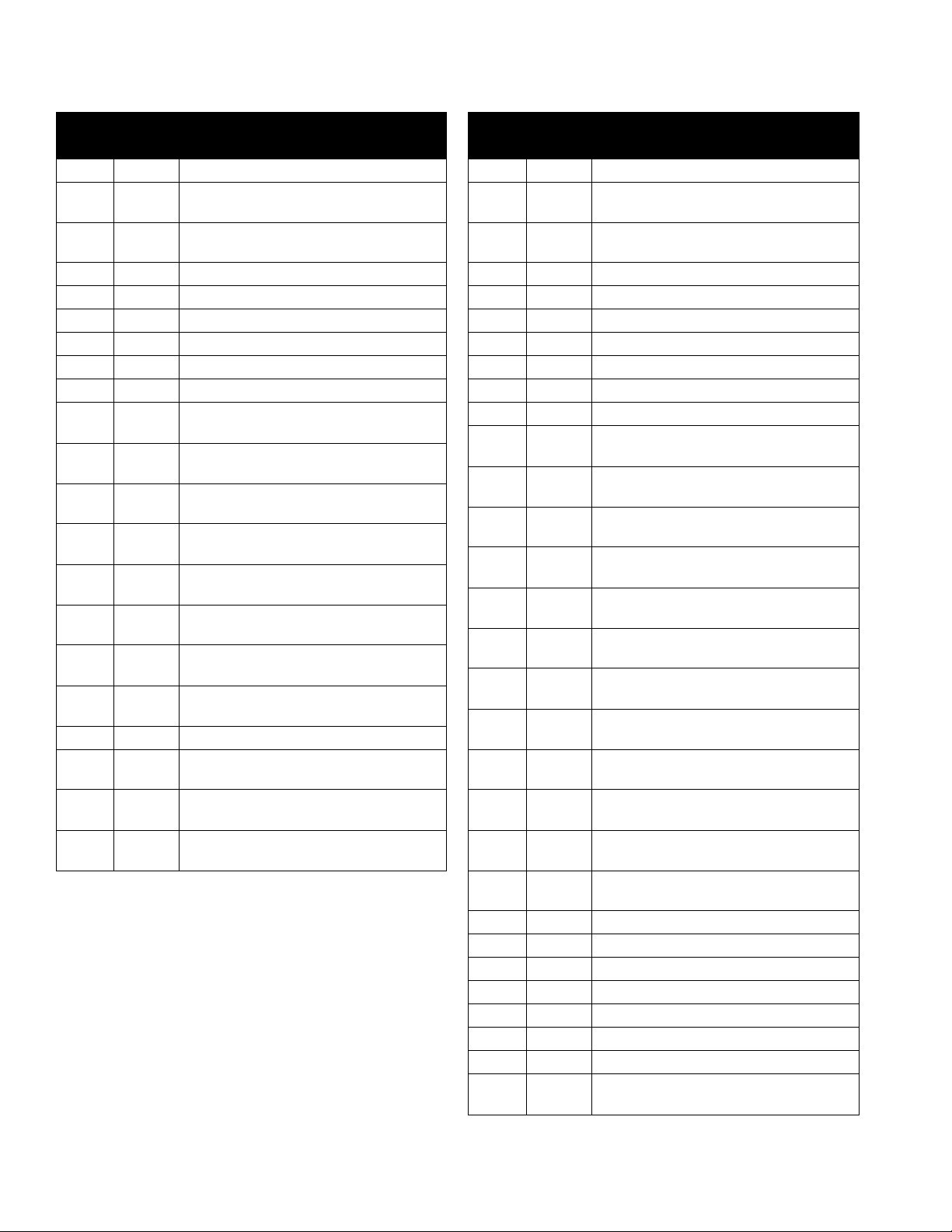

Product Configurator

Product Configurator

US-G----------------

Code: A B C D E F-G H-I J K L M N O P Q-R S

Configurator Series Level

Tr a i l e r Ty p e

Air Compressor

Proportioner(s)

Air Dryer

Generator

Pump System

Gun

Work Bench

Band Heaters

Air Conditioning

Agitator(s)

Gun Recirculation Kit

Machine Recirculation Kit

An example of the product configurator would be the following configurator code.

US -G-T-M-D-4-N-04-06-1-2-A-1-3-N-2-26-B

Code: A B C D E F-G H-I J K L M N O P Q-R S

Configurator Series Level

Tra i le r Typ e

Air Compressor

Proportioner(s)

Air Dryer

Generator

Pump System

Gun

Work Bench

Band Heaters

Air Conditioning

Agitator(s)

Gun Recirculation Kit

Machine Recirculation Kit

Drum Lids

Drum Lids

Heated Hoses

Breathable Air System

Heated Hoses

Breathable Air System

The following part number fields apply for the Spray Rig part numbering configurator fields.

Code A Part Trailer Type

A U90840 28 ft Trailer, 3-Phase, OEM Insulation,

Dual Proportioner

B U90678 18 ft Modified Truck Box, 3-Phase, Insu-

lated by Graco

C U91000 18 ft Modified Truck Box, 3-Phase, OEM

Insulation

D U91001 18 ft Modified Truck Box, 1-Phase, OEM

Insulation

F U90677 18 ft Modified Truck Box, 1-Phase, Insu-

lated by Graco

G U90380 28 ft Trailer, 3-Phase, OEM Insulation,

Single Proportioner

H U90638 28 ft Trailer, 1-Phase, OEM Insulation, Sin-

gle Proportioner

J U91002 18 ft Modified Truck Box, 3-Phase, OEM

Insulation,

K U91003 18 ft Modified Truck Box, 1-Phase, OEM

Insulation

M U90668 20-28 ft Modified Truck Box, 3-Phase,

OEM Insulation, Single Proportioner

P U90669 20-28 ft Modified Truck Box, 1-Phase,

OEM Insulation, Single Proportioner

Q U91004 20-28 ft Modified Truck Box, 1-Phase,

Insulated by Graco, Single Proportioner

R U91005 20-28 ft Modified Truck Box, 3-Phase,

Insulated by Graco, Single Proportioner

S U90884 20-28 ft Modified Truck Box, 3-Phase,

Insulated by Graco, Dual Proportioner

T U90381 20 ft Trailer, 3-Phase, OEM Insulation

U U90661 20 ft Trailer, 1-Phase, OEM Insulation

V U91006 20-28 ft Modified Truck Box, 1-Phase,

OEM Insulation, Single Proportioner

W U91007 20-28 ft Modified Truck Box, 3-Phase,

OEM Insulation, Single Proportioner

X U90883 20-28 ft Modified Truck Box, 3-Phase,

OEM Insulation, Dual Proportioner

Z U90850 20-28 ft Modified Truck Box, 3-Phase,

OEM Insulation, Dual Proportioner

4 312765B

Page 5

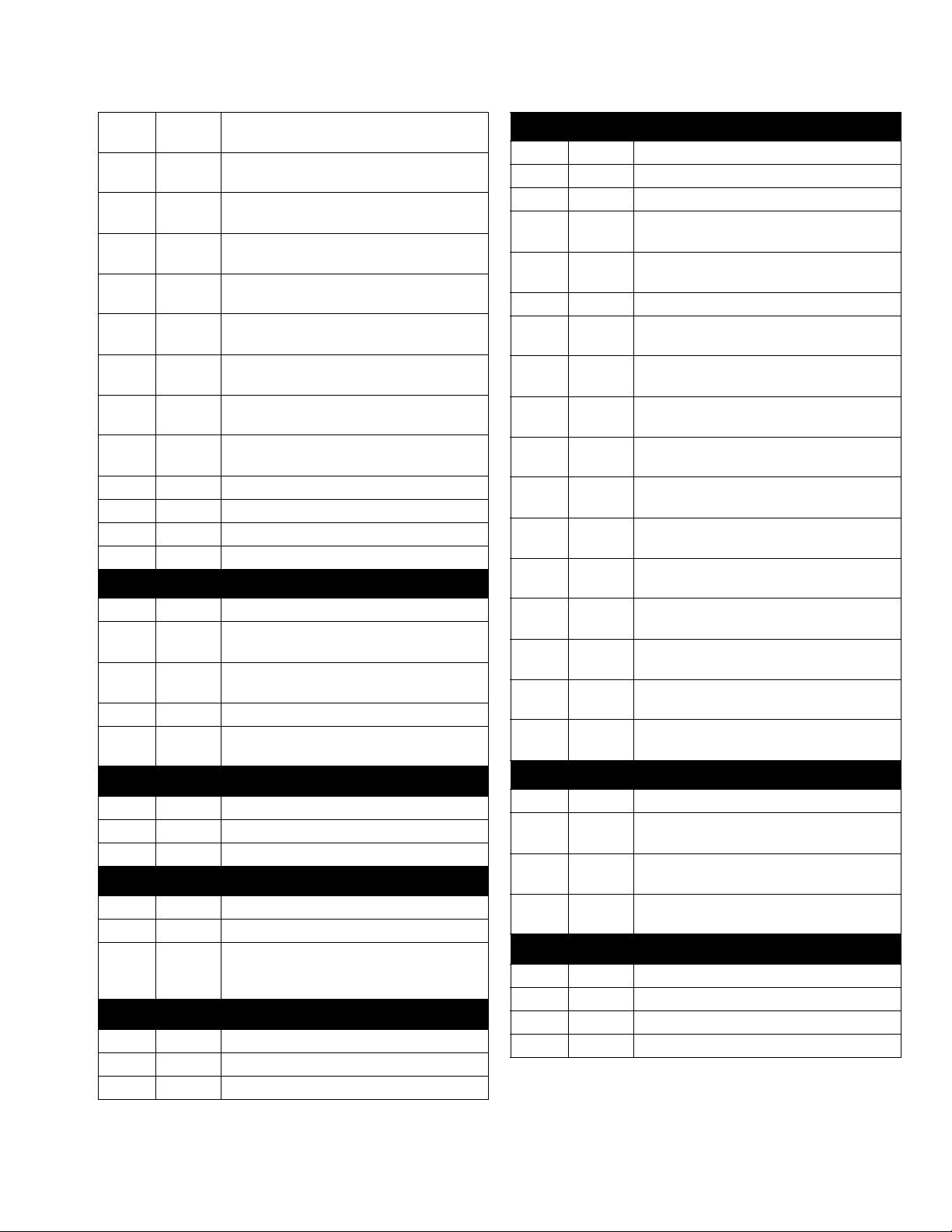

Product Configurator

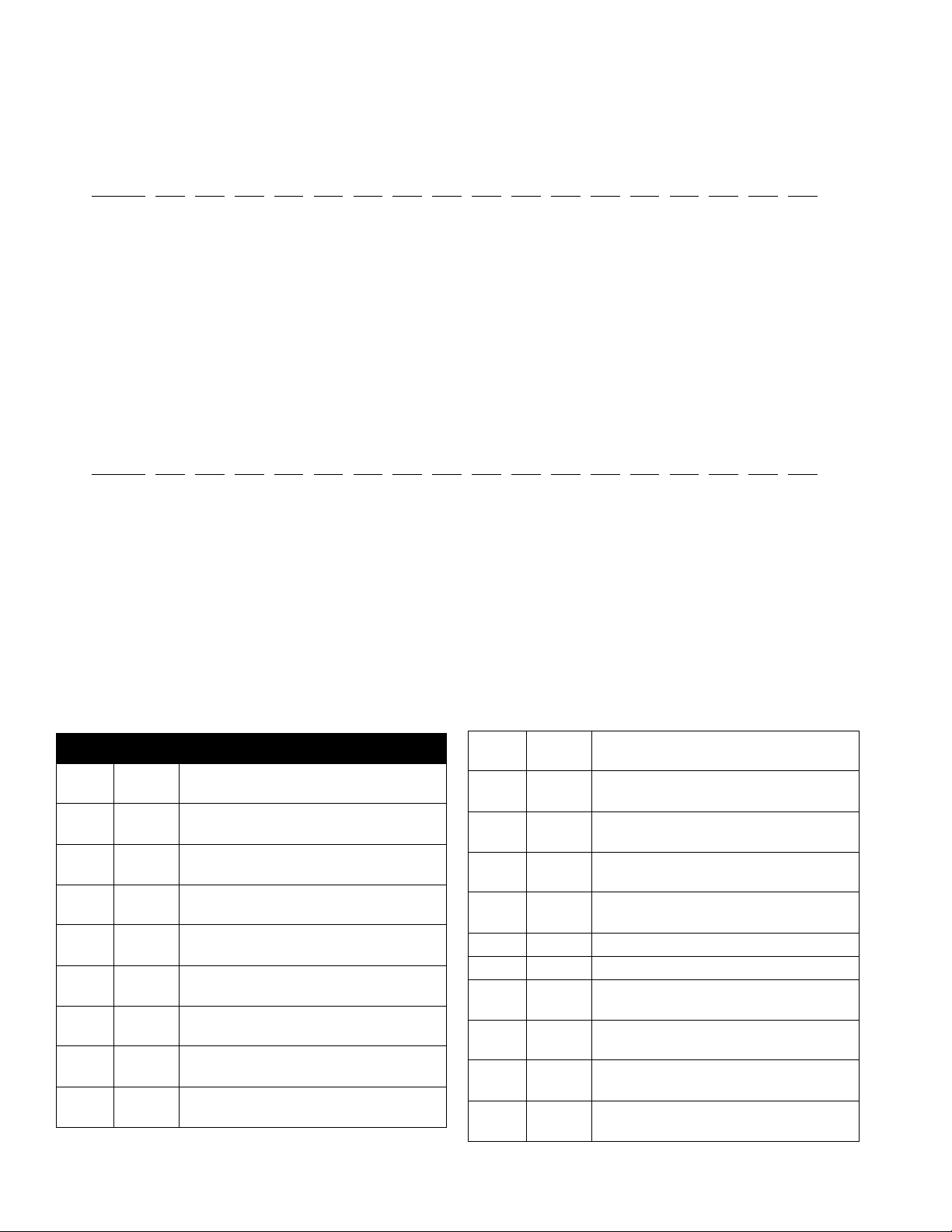

Code B Part Air Compressor

X U91010 None - Female Quick Connect Fitting Only

A U90757 Rotary (Includes 40 kW, 3-Phase Genera-

tor) No Air Conditioning, 28 ft, 3-Phase

B U90756 Rotary (Includes 40 kW, 3-Phase Genera-

tor), No Air Conditioning, 20 ft, 3-Phase

C U90383 5 hp Horizontal, 3-Phase

D U90384 5 hp Vertical, 3-Phase

E U90385 10 hp Base Mount, 3-Phase

F U90753 Rotary (Includes 40 kW, 1-Phase Genera-

tor) No Air Conditioning, 28 ft, 1-Phase

G U90752 Rotary (Includes 40 kW, 1-Phase Genera-

tor) No Air Conditioning, 20 ft, 1-Phase

H U90672 5 hp Horizontal, 1-Phase

J U90673 5 hp Vertical, 1-Phase

K U90674 10 hp Vertical, 3-Phase, 80 Gallon

M U90754 Rotary (Includes 40 kW, 3-Phase Genera-

tor), With Air Conditioning, 20 ft, 3-Phase

P U90750 Rotary (Includes 40 kW, 1-Phase Genera-

tor), With Air Conditioning, 20 ft, 1-Phase

Q U90755 Rotary (Includes 40 kW, 3-Phase Genera-

tor), With Air Conditioning, 28 ft 3-Phase

R U90751 Rotary (Includes 40 kW, 1-Phase Genera-

tor), With Air Conditioning, 28 ft, 1-Phase

S U90841 Rotary (Includes 40 kW, 3-Phase Genera-

tor), Without Air Conditioning, Dual Proportioner

T U90842 Rotary (Includes 40 kW, 3-Phase Genera-

tor), With Air Conditioning, Dual Proportioner

Code C Part Proportioner(s)

X U91008 None - Wires Only For 100 Amp,

3-Phase

A U90389 H-40, 20.4 kW Heater, 3-phase

B U90390 H-40, 12.0 kW Heater, 1-phase

C U90391 H-40, 15.3 kW Heater, 3-phase

D U90392 H-XP3, 20.4 kW Heater, 3-phase

E U90393 H-25, 8.0 kW Heater, 1-phase

F U90394 H-25, 8.0 kW Heater, 3-phase

G U90395 H-25, 15.3 kW Heater, 1-phase

H U90396 H-25, 15.3 kW Heater, 3-phase

J U90397 H-XP2, 15.3 kW Heater, 1-phase

K U90398 H-XP2, 15.3 kW Heater, 3-phase

L U90399 E-30, 15.3 kW Heater, 1-phase

M U90400 E-30, 15.3 kW Heater, 3-phase

P U90401 E-30, 10.2 kW Heater, 1-phase

Q U90402 E-30, 10.2 kW Heater, 3-phase

R U90403 E-20, 6.0 kW Heater, 1-phase

S U90404 E-20, 6.0 kW Heater, 3-phase

T U90405 E-XP2, 15.3 kW Heater, 1-phase

U U90406 E-XP2, 15.3 kW Heater, 3-phase

V U90844 (Dual) H-25, 8.0 kW Heater, 3-phase

W U90845 (Dual) E-30, 10.2 kW Heater, 3-phase

Y U91074 H-50, 15.3 kW Heater, 3-phase

Z U91075 H-40, 20.4 kW Heater, 3-phase

Code D Part Air Dryer

1 - None - Fittings Only

2 U90366 20 cfm

4 U90365 40 cfm

8 U90843 40 cfm for Dual Proportioners

Code E Part Generator

N-None

A U90760 40 kW, 1-Phase (No Air Conditioning),

20 ft

C U90761 40 kW, 1-Phase (No Air Conditioning),

28 ft

F U90764 40 kW, 3-Phase (No Air Conditioning),

20 ft

H U90765 40 kW, 3-Phase (No Air Conditioning),

28 ft

K U90758 40 kW, 1-Phase (Air Conditioning), 20 ft

M U90759 40 kW, 1-Phase (Air Conditioning), 28 ft

P U90762 40 kW, 3-Phase (Air Conditioning), 20 ft

R U90763 40 kW, 3-Phase (Air Conditioning), 28 ft

312765B 5

Page 6

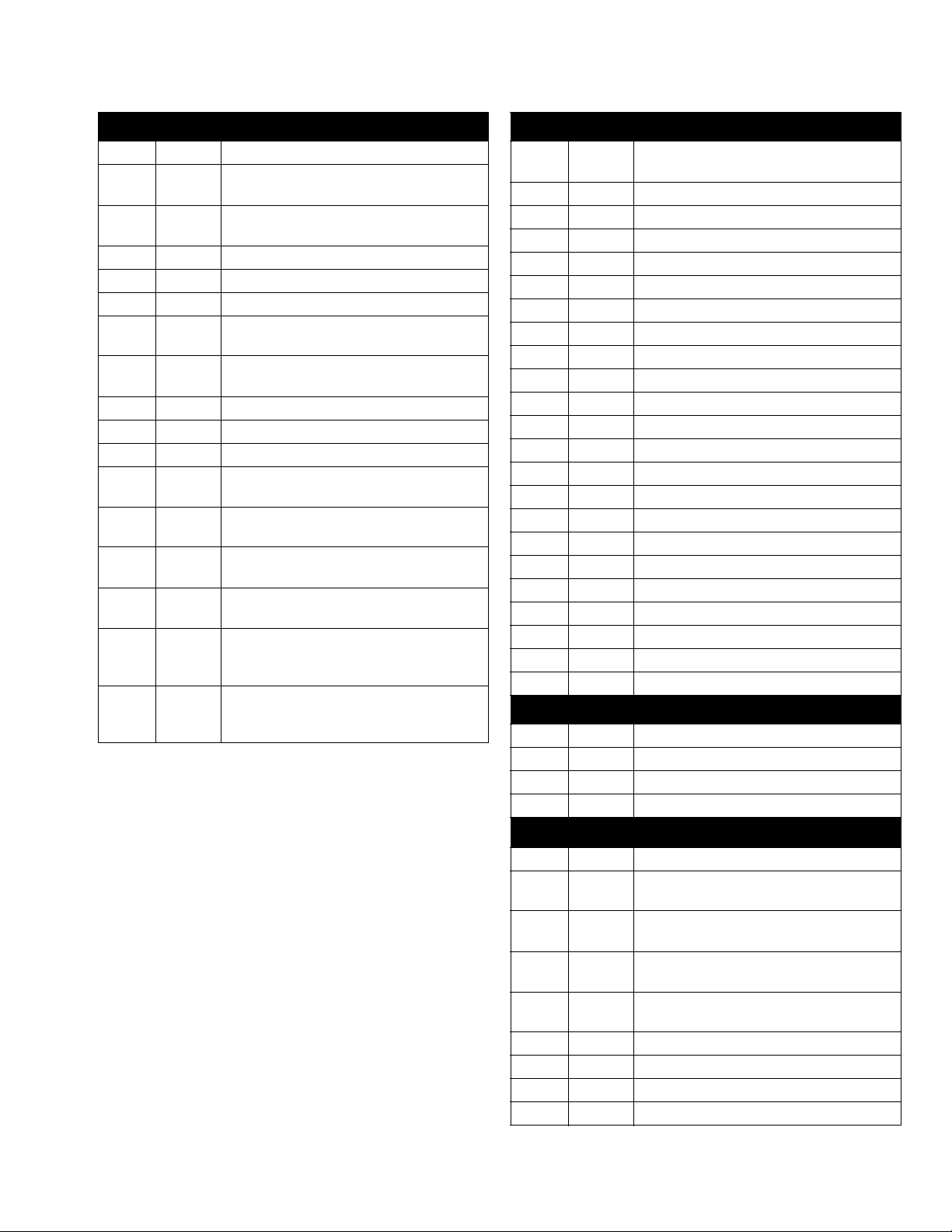

Product Configurator

Code

F-G

NP - None

01 U90353 Husky 1040 (2 Pumps with Supply

02 U90578 Husky 1040 (2 Pumps with Supply

04 U90414 T2 (2 Pumps with Supply Hoses), 20 ft

05 U90567 T2 (2 Pumps with Supply Hoses), 28 ft

07 U90727 T1 (2 Pumps with Supply Hoses), 20 ft

08 U90728 T1 (2 Pumps with Supply Hoses), 28 ft

11 U90814 System, Supply Lines, 20 ft

12 U90815 System, Supply Lines, 28 ft

13 U90665 Husky 1040 (2 Pumps with Supply

14 U90664 Husky 1040 (2 Pumps with Supply

16 U90739 T2 (2 Pumps with Supply Hoses), 20 ft,

17 U90740 T2 (2 Pumps with Supply Hoses), 28 ft,

19 U90742 T1 (2 Pumps with Supply Hoses), 20 ft,

20 U90743 T1 (2 Pumps with Supply Hoses), 28 ft,

23 U90817 System, Supply Lines, 20 ft, with Electric

24 U90818 System, Supply Lines, 28 ft, with Electric

25 U90885 System, Supply Lines, Dual Proportioners

26 U90886 System, Supply Lines, Dual Proportioners,

27 U90846 T2 (2 Pumps with Supply Hoses), Dual

28 U90847 T2 (2 Pumps with Supply Hoses), Dual

Part Pump System

Hoses), 20 ft

Hoses), 28 ft

Hoses), 20 ft, with Electric Proportioner

Hoses), 28 ft, with Electric Proportioner

with Electric Proportioner

with Electric Proportioner

with Electric Proportioner

with Electric Proportioner

Proportioner

Proportioner

with Electric Proportioner

Proportioners

Proportioners, with Electric Proportioner

Code

H-I

NG - None

01 246101 Fusion Air Purge, Includes AR4242 And

02 246102 Fusion Air Purge, Includes AR4242 And

03 247102 Fusion Flat Air Purge 0438, Qty 1

04 295560 GAP Pro Round 02, Qty 1

05 295552 GAP Pro Flat 02, Qty 1

06 247212 Fusion Mechanical Purge 040, Qty 1

07 295542 GX-7 1/90, Qty 1

08 295541 GX-7 DI 4/213, Qty 1

09 295533 D Gun 70, Qty 1

10 CS20RD Fusion ClearShot, Includes RD2020,

11 CS00RD Fusion ClearShot, Includes RD0000,

12 CS01RD Fusion ClearShot, Includes RD0101,

13 CS02RD Fusion ClearShot, Includes RD0202,

14 CS03RD Fusion ClearShot, Includes RD0303,

15 CS00WD Fusion ClearShot, Includes WD0000,

16 CS20F2 Fusion ClearShot, Includes FL2020 and

17 CS00F2 Fusion ClearShot, Includes FL0000 and

18 CS01F2 Fusion ClearShot, Includes FL0101 and

19 CS02F2 Fusion ClearShot, Includes FL0202 and

20 U90795 Fusion Air Purge, Includes AR4242 and

21 U90796 Fusion Air Purge, Includes AR4242 and

22 U90797 Fusion Flat Air Purge 0438, Qty 2

23 U90798 GAP Pro Round 02, Qty 2

24 U90799 GAP Pro Flat 02, Qty 2

25 U90800 Fusion Mechanical Purge 040, Qty 2

26 U90801 GX-7 1/90, Qty 2

27 U90802 GX-7 DI 4/213, Qty 2

28 U90803 D-Gun 70, Qty 2

29 U90819 Fusion ClearShot, Includes RD2020,

Part Gun

AR5252, Qty 1

AR2020, Qty 1

Qty 1 Gun

Qty 1 Gun

Qty 1 Gun

Qty 1 Gun

Qty 1 Gun

Qty 1 Gun

FT0438, Qty 1 Gun

FT0438, Qty 1 Gun

FT0438, Qty 1 Gun

FT0438, Qty 1 Gun

AR5252, Qty 2

AR2020, Qty 2

Qty 2 Guns

6 312765B

Page 7

Product Configurator

30 U90820 Fusion ClearShot, Includes RD0000,

Qty 2 Guns

31 U90821 Fusion ClearShot, Includes RD0101,

Qty 2 Guns

32 U90822 Fusion ClearShot, Includes RD0202,

Qty 2 Guns

33 U90823 Fusion ClearShot, Includes RD0303,

Qty 2 Guns

34 U90824 Fusion ClearShot, Includes WD0000,

Qty 2 Guns

35 U90825 Fusion ClearShot, Includes FL2020 and

FT0438, Qty 2 Guns

36 U90826 Fusion ClearShot, Includes FL0000 and

FT0438, Qty 2 Guns

37 U90827 Fusion ClearShot, Includes FL0101 and

FT0438, Qty 2 Guns

38 U90828 Fusion ClearShot, Includes FL0202 and

FT0438, Qty 2 Guns

39 U91076 Probler P2 (GCP2R1), Qty 1 Gun

40 U91077 Probler P2 (GCP2R2), Qty 1 Gun

41 U91083 Probler P2 (GCP2R1), Qty 2 Gun

42 U91084 Probler P2 (GCP2R2), Qty 2 Gun

Code J Part Work Benches

N - None

1 U90411 Workbench, Toolbox, Cabinets, Vise,

Small

2 U90412 Workbench, Toolbox, Cabinets, Vise,

Large

4 189233 None - (Gauges)

5 U90848 Toolbox and Upper Cabinets, No Vise or

Lower Cabinets

Code K Part Band Heater(s)

N - None

1 U90045 One Band Heater with Thermostat

2 U90804 Two Band Heaters with Thermostat

Code L Part Air Conditioning

N - None

A U90356 Rooftop Air Conditioning

B U90733 Rooftop Air Conditioning, Low Profile,

Truck Must Be Lower Than 12 ft 6 in.

Overall Height

Code M Part Agitator(s)

N - None

1 U90521 One Twistork Agitator

2 U90805 Two Twistork Agitators

Code N Part Gun Recirculation Kit

N-None

A U90656 Fusion Gun Circulation System

B U90657 GAP Pro Circulation System

C U90793 Fusion Gun Circulation System with

Machine Recirculation

F U90794 GAP Pro Circulation System with Machine

Recirculation

G U90829 ClearShot Gun Circulation System

H U90830 ClearShot Gun Circulation System with

Machine Recirculation

J U90851 Fusion Gun Circulation System, Dual Pro-

portioners

K U90852 GAP Pro Circulation System, Dual Propor-

tioners

M U90854 Fusion Gun Circulation System with

Machine Recirculation, Dual Proportioners

P U90855 GAP Pro Circulation System with Machine

Recirculation, Dual Proportioners

Q U90853 ClearShot Gun Circulation System, Dual

Proportioners

R U90856 ClearShot Gun Circulation System with

Machine Recirculation, Dual Proportioners

S U91078 P2 Gun Circulation System, Single Pro-

portioner

T U91081 P2 Gun Circulation System with Machine

Recirculation, Single Proportioner

U U91080 P2 Gun Circulation System, Dual Propor-

tioner

V U91082 P2 Gun Circulation System with Machine

Recirculation, Dual Proportioner

Code O Part Machine Recirculation Kit

N-None

A U90561 Machine Recirculation, 28 ft Trailer or

20-28 ft Truck

B U90355 Machine Recirculation, 20 ft Trailer or 18 ft

Tr uc k

D U90849 Machine Recirculation, 28 ft Trailer or

20-28 ft Truck, Dual Proportioner

Code P Part Drum Lids

N-None

1 U90053 One Blue Drum Lid

2 U90052 One Red Drum Lid

3 U90413 One Red and One Blue Drum Lid

312765B 7

Page 8

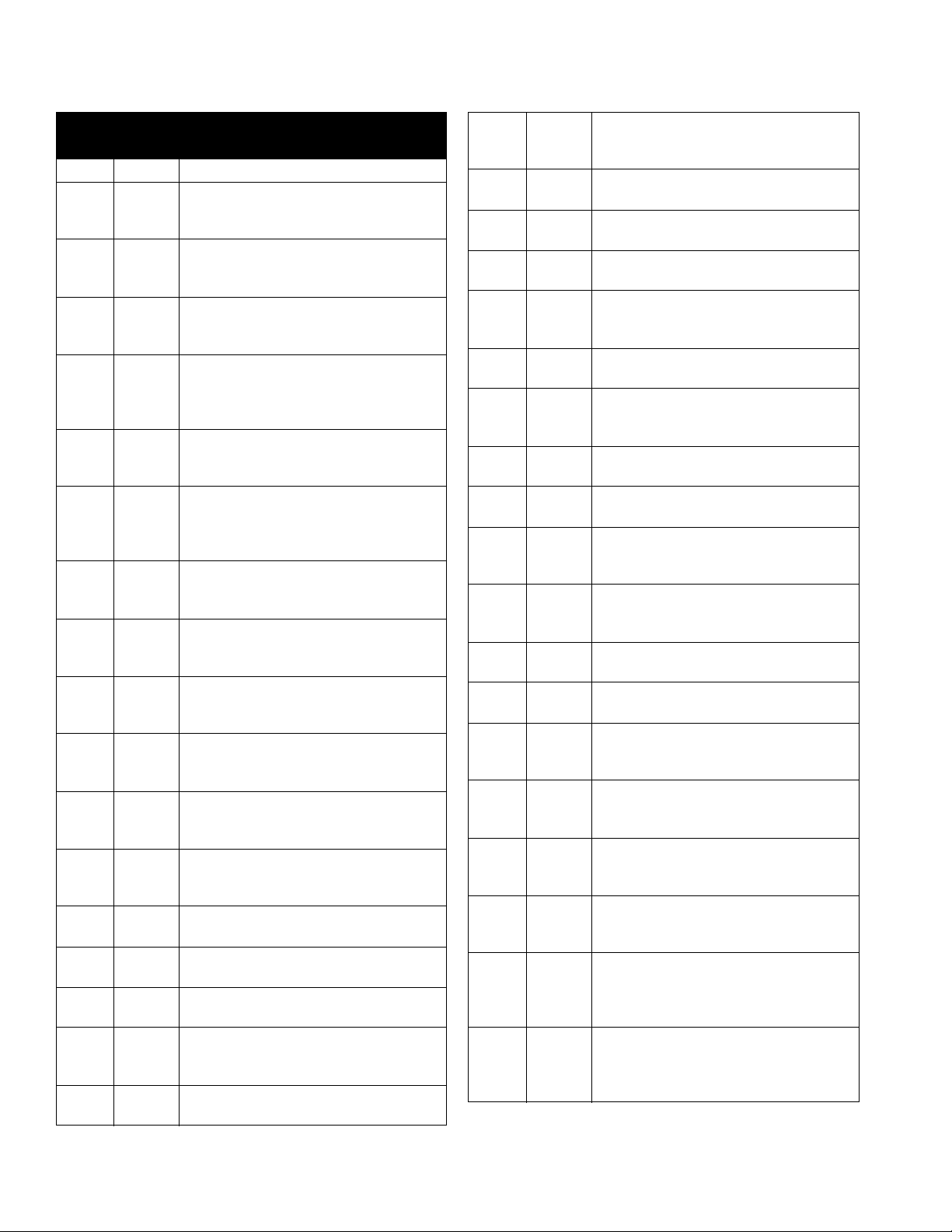

Product Configurator

Code

Q-R

NH - None

01 U90715 160 ft, 2000 psi, (3) 3/8 with Fluid Temper-

02 U90453 210 ft, 2000 psi, (4) 3/8 with Fluid Temper-

03 U90454 310 ft, 2000 psi, (6) 3/8 with Fluid Temper-

04 U90670 310 ft, 2000 psi, (5) 3/8 with Fluid Temper-

05 U90455 410 ft, 2000 psi, (8) 3/8 with Fluid Temper-

06 U90680 410 ft, 2000 psi, (7) 3/8 with Fluid Temper-

07 U90716 160 ft, 2000 psi, (3) 3/8 with Fluid Temper-

08 U90456 210 ft, 2000 psi, (4) 3/8 with Fluid Temper-

09 U90681 310 ft, 2000 psi, (6) 3/8 with Fluid Temper-

10 U90457 310 ft, 2000 psi, (5) 3/8 with Fluid Temper-

11 U90682 410 ft, 2000 psi, (8) 3/8 with Fluid Temper-

12 U90458 410 ft, 2000 psi, (7) 3/8 with Fluid Temper-

13 U90717 160 ft, 2000 psi, (3) 3/8 with Fluid Temper-

14 U90465 210 ft, 2000 psi, (4) 3/8 with Fluid Temper-

15 U90466 310 ft, 2000 psi, (6) 3/8 with Fluid Temper-

16 U90683 310 ft, 2000 psi, (5) 3/8 with Fluid Temper-

17 U90467 410 ft, 2000 psi, (8) 3/8 with Fluid Temper-

Part Heated Hoses

ature Sensor, No Scuff-Guard,

Non-assembled

ature Sensor, No Scuff-Guard,

Non-assembled

ature Sensor, No Scuff-Guard,

Non-assembled

ature Sensor, (1) 3/8 No Fluid Temperature Sensor, No Scuff-Guard,

Non-assembled

ature Sensor, No Scuff-Guard,

Non-assembled

ature Sensor, (1) 3/8 No Fluid Temperature Sensor, No Scuff-Guard,

Non-assembled

ature Sensor, Scuff-Guard, Non-assembled

ature Sensor, Scuff-Guard, Non-assembled

ature Sensor, Scuff-Guard, Non-assembled

ature Sensor, (1) 3/8 No Fluid Temperature Sensor, Scuff-Guard, Non-assembled

ature Sensor, Scuff-Guard, Non-assembled

ature Sensor, (1) 3/8 No Fluid Temperature Sensor, Scuff-Guard, Non-assembled

ature Sensor, No Scuff-Guard, Assembled

ature Sensor, No Scuff-Guard, Assembled

ature Sensor, No Scuff-Guard, Assembled

ature Sensor, (1) 3/8 No Fluid Temperature Sensor, No Scuff-Guard, Assembled

ature Sensor, No Scuff-Guard, Assembled

18 U90684 410 ft, 2000 psi, (7) 3/8 with Fluid Temper-

ature Sensor, (1) 3/8 No Fluid Temperature Sensor, No Scuff-Guard, Assembled

19 U90718 160 ft, 2000 psi, (3) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Assembled

20 U90468 210 ft, 2000 psi, (4) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Assembled

21 U90685 310 ft, 2000 psi, (6) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Assembled

22 U90469 310 ft, 2000 psi, (5) 3/8 with Fluid Temper-

ature Sensor, (1) 3/8 No Fluid Temperature Sensor, Scuff-Guard, Assembled

23 U90686 410 ft, 2000 psi, (8) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Assembled

24 U90470 410 ft, 2000 psi, (7) 3/8 with Fluid Temper-

ature Sensor, (1) 3/8 No Fluid Temperature Sensor, Scuff-Guard, Assembled

25 U90719 160 ft, 3500 psi, (3) 3/8 with Fluid Temper-

ature Sensor, No Scuff-Guard, Assembled

26 U90471 210 ft, 3500 psi, (4) 3/8 with Fluid Temper-

ature Sensor, No Scuff-Guard, Assembled

27 U90472 310 ft, 3500 psi, (4) 1/2 with Fluid Temper-

ature Sensor, (2) 3/8 with Fluid Temperature Sensor, No Scuff-Guard, Assembled

28 U90473 410 ft, 3500 psi, (6) 1/2 with Fluid Temper-

ature Sensor, (2) 3/8 with Fluid Temperature Sensor, No Scuff-Guard, Assembled

29 U90720 160 ft, 3500 psi, (3) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Assembled

30 U90474 210 ft, 3500 psi, (4) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Assembled

31 U90475 310 ft, 3500 psi, (4) 1/2 with Fluid Temper-

ature Sensor, (2) 3/8 with Fluid Temperature Sensor, Scuff-Guard, Assembled

32 U90476 410 ft, 3500 psi, (6) 1/2 with Fluid Temper-

ature Sensor, (2) 3/8 with Fluid Temperature Sensor, Scuff-Guard, Assembled

33 U90721 160 ft, 3500 psi, (4) 3/8 with Fluid Temper-

ature Sensor, No Scuff-Guard,

Non-assembled

34 U90459 210 ft, 3500 psi, (4) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Non-assembled

35 U90460 310 ft, 3500 psi, (4) 1/2 with Fluid Temper-

ature Sensor, (2) 3/8 with Fluid Temperature Sensor, No Scuff-Guard,

Non-assembled

36 U90461 410 ft, 3500 psi, (6) 1/2 with Fluid Temper-

ature Sensor, (2) 3/8 with Fluid Temperature Sensor, No Scuff-Guard,

Non-assembled

8 312765B

Page 9

Product Configurator

37 U90722 160 ft, 3500 psi, (4) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Non-assembled

38 U90462 210 ft, 3500 psi, (4) 3/8 with Fluid Temper-

ature Sensor, Scuff-Guard, Non-assembled

39 U90463 310 ft, 3500 psi, (4) 1/2 with Fluid Temper-

ature Sensor, (2) 3/8 with Fluid Temperature Sensor, Scuff-Guard, Non-assembled

40 U90464 410 ft, 3500 psi, (6) 1/2 with Fluid Temper-

ature Sensor, (2) 3/8 with Fluid Temperature Sensor, Scuff-Guard, Non-assembled

41 U90857 (2) 160 ft, 2000 psi, (3) 3/8 with Fluid Tem-

perature Sensor, No Scuff-Guard,

Non-assembled

42 U90861 (2) 160 ft, 2000 psi, (3) 3/8 with Fluid Tem-

perature Sensor, Scuff-Guard,

Non-assembled

43 U90865 (2) 160 ft, 2000 psi, (3) 3/8 with Fluid Tem-

perature Sensor, No Scuff-Guard, Assembled

44 U90869 (2) 160 ft, 2000 psi, (3) 3/8 with Fluid Tem-

perature Sensor, Scuff-Guard, Assembled

45 U90858 (2) 210 ft, 2000 psi, (4) 3/8 with Fluid Tem-

perature Sensor, No Scuff-Guard,

Non-assembled

46 U90862 (2) 210 ft, 2000 psi, (4) 3/8 with Fluid Tem-

perature Sensor, Scuff-Guard,

Non-assembled

47 U90866 (2) 210 ft, 2000 psi, (4) 3/8 with Fluid Tem-

perature Sensor, No Scuff-Guard, Assembled

48 U90870 (2) 210 ft, 2000 psi, (4) 3/8 with Fluid Tem-

perature Sensor, Scuff-Guard, Assembled

49 U90859 (2) 310 ft, 2000 psi, (6) 3/8 with Fluid Tem-

perature Sensor, No Scuff-Guard,

Non-assembled

50 U90860 (2) 310 ft, 2000 psi, (5) 3/8 with Fluid Tem-

perature Sensor, (1) 3/8 No Fluid Temperature Sensor, No Scuff-Guard,

Non-assembled

51 U90863 (2) 310 ft, 2000 psi, (6) 3/8 with Fluid Tem-

perature Sensor, Scuff-Guard,

Non-assembled

52 U90864 (2) 310 ft, 2000 psi, (5) 3/8 with Fluid Tem-

perature Sensor, (1) 3/8 No Fluid Temperature Sensor, Scuff-Guard,

Non-assembled

53 U90867 (2) 310 ft, 2000 psi, (6) 3/8 with Fluid Tem-

perature Sensor, No Scuff-Guard, Assembled

54 U90868 (2) 310 ft, 2000 psi, (5) 3/8 with Fluid Tem-

perature Sensor, (1) 3/8 No Fluid Temperature Sensor, No Scuff-Guard, Assembled

55 U90871 (2) 310 ft, 2000 psi, (6) 3/8 with Fluid Tem-

perature Sensor, Scuff-Guard, Assembled

56 U90872 (2) 310 ft, 2000 psi, (5) 3/8 with Fluid Tem-

perature Sensor, (1) 3/8 No Fluid Temperature Sensor, Scuff-Guard, Assembled

Code S Part Breathable Air System

N-None

B U91014 One 300 ft Breathing System, Includes

One Mask, Lens, One 300 ft Hose, Hose

Hanger, Service Kit

D U91015 Two 300 ft Breathing Systems, Includes

(2) Masks, (50) Lens, (2) 300 ft Hoses, (2)

Hose Hangers, (1) Service Kit

312765B 9

Page 10

Warnings

Warnings

For complete warnings for installed components,

see supplied manuals. See Related Manuals on

page 3.

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

10 312765B

Page 11

Warnings

WARNING

WARNINGWARNINGWARNING

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon

monoxide can cause death. Do not operate in an enclosed area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

312765B 11

Page 12

Component Identification

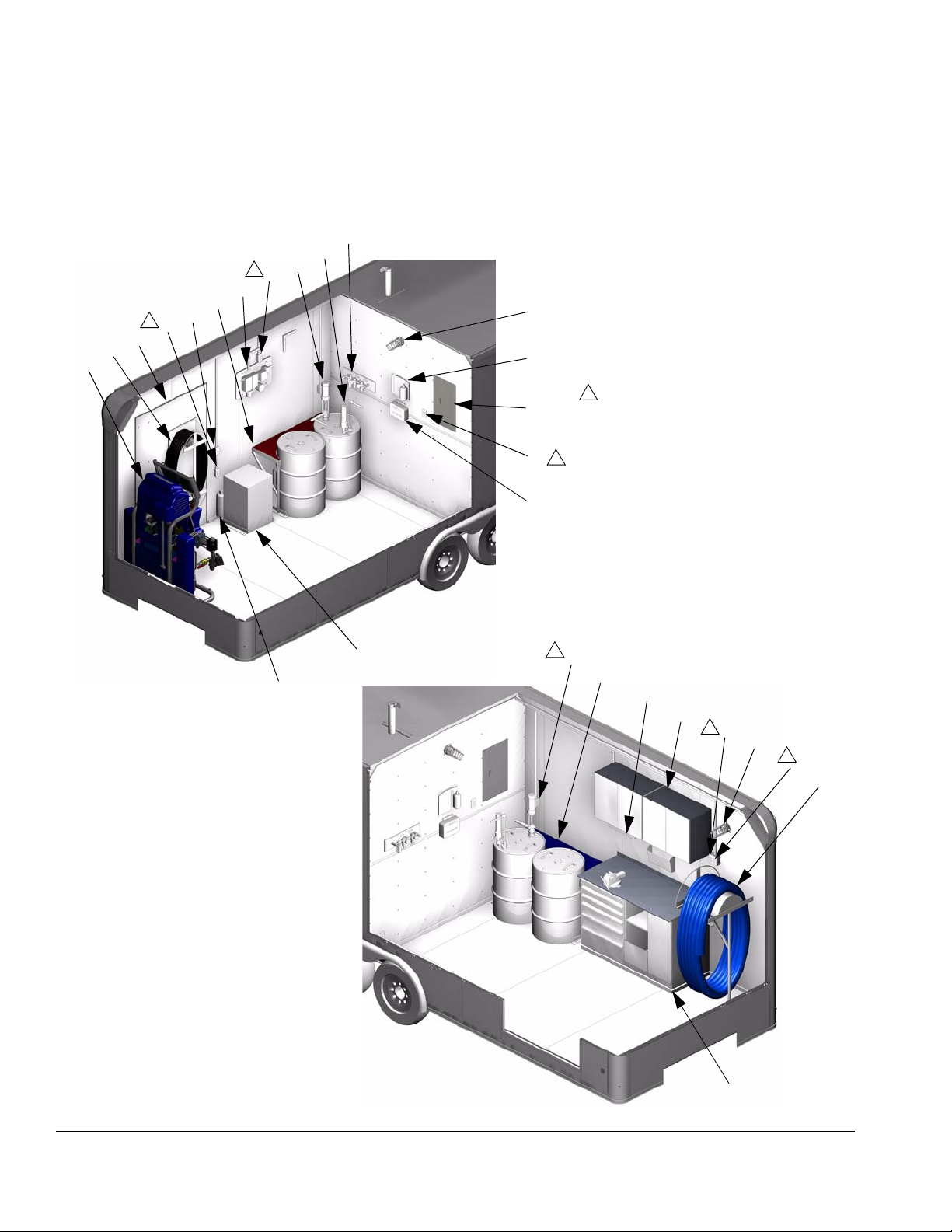

Component Identification

20 ft Trailer

F

K

L

1

V

E

C

S

1

V

T

D

A

J

G

R

W

H

H

1

See Power Sources on page 19 for a closer

view of which outlets Shore Power supplies.

Generator Power supplies all outlets.

1

Key:

N

A Proportioner

BAir Dryer

C Chemical Drums and Rack

D Breathable Air Hose and Rack

E Breathing Air Filter System

F Air Regulators Assembly

G Emergency Eye Wash Station

H First Aid Kit

J 120V Lights

K Agitator

L Pump (Stick Pump shown)

M Work Bench and Cabinets

N Fire Extinguisher

P Heated Hoses and Rack

R Electrical Panel

SLight Switch

TDoor

U Fluorescent Light

V Outlet powered only by Generator

Power

W Outlet powered by both Generator

Power and Shore Power

TI12886a

1

B

V

C

U

M

W

1

J

1

V

P

TI12887a

M

FIG. 1: Main Room

12 312765B

Page 13

20 ft Trailer, continued

J

AE

W

1

S

Component Identification

AB

AD

AA

AF

TI12888b

N

AC

1

See Power Sources on page 19 for a closer view of which outlets

Shore Power supplies. Generator Power supplies all outlets.

Key:

AA Generator

AB Air Conditioner

AC Air Compressor

AD Main Breaker

AE Shore Power Extension Cord

AF Shore/Generator Power Switch

FIG. 2: Generator Room

312765B 13

Page 14

Component Identification

Single Proportioner 28 ft Trailer and Truck Box

M

G

H

V

2

C

1

P

T

R

W

2

M

D

28 ft Trailer Shown

Key:

A Proportioner

BAir Dryer

C Chemical Drums and Rack

D Breathable Air Hose and Rack

E Breathing Air Filter System

F Air Regulators Assembly

G Emergency Eye Wash Station

H First Aid Kit

J 120V Lights

K Agitator

L Pump (Stick Pump shown)

M Work Bench and Cabinets

N Fire Extinguisher

P Heated Hoses and Rack

R Electrical Panel

S Light Switch

TDoor

U Fluorescent Light

V Outlet powered only by Generator

Power

W Outlet powered by both Generator

Power and Shore Power

TI12883a

V

2

E

J

K

L

2

V

C

1

U

F

B

28 ft Trailer Shown

1

The 18 ft truck box has a two-drum chemical rack instead of a three-drum

chemical rack. All other truck boxes have a three drum chemical rack.

2

See Power Sources on page 19 for a closer view of which outlets Shore Power

supplies. Generator Power supplies all outlets.

J

A

V

2

S

TI12884a

N

FIG. 3: Main Room

14 312765B

Page 15

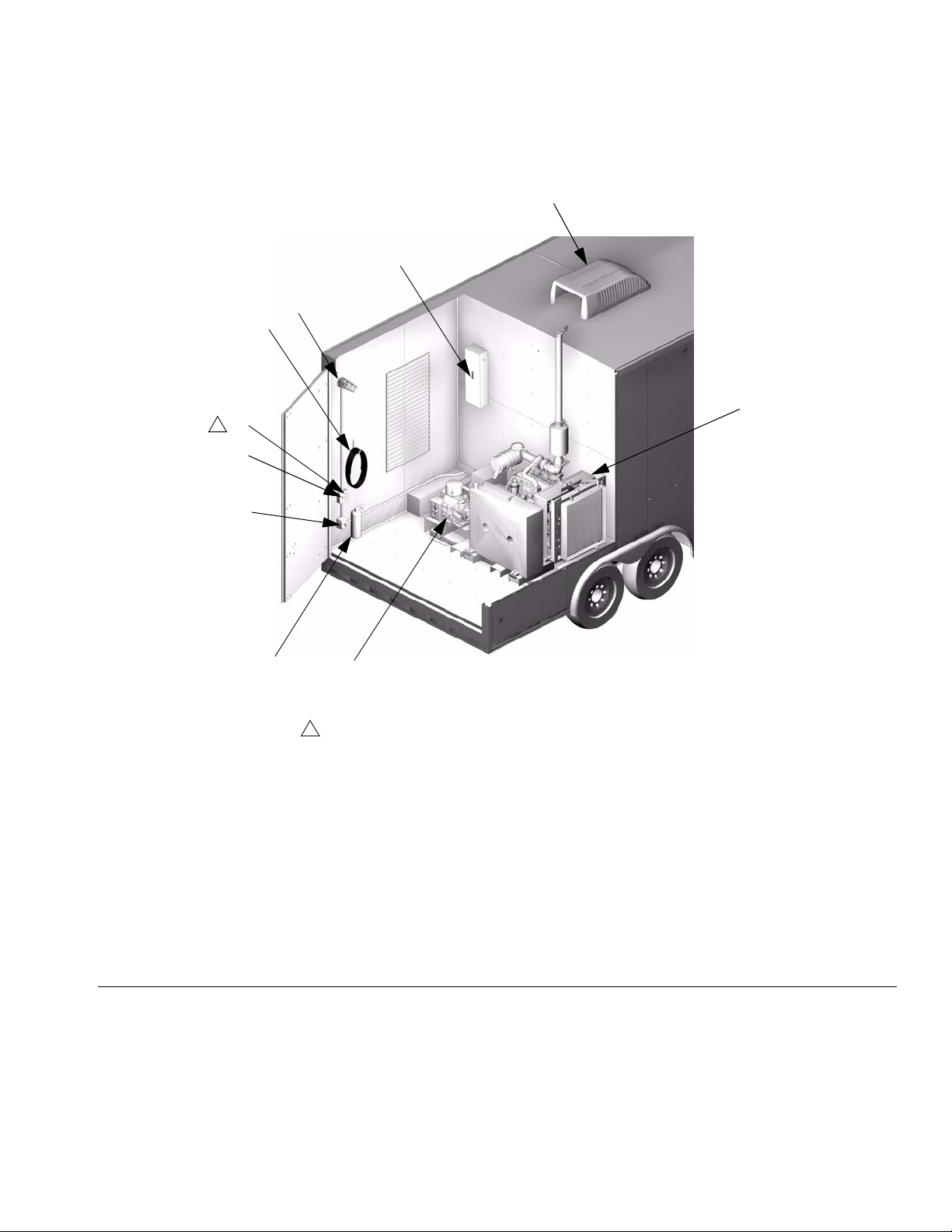

Single Proportioner 28 ft Trailer

and Truck Box continued

AB

J

AD

AE

W

2

S

Component Identification

AA

1

AF

28 ft Trailer Shown

FIG. 4: Generator Room

N

1

Only the 28 ft trailer has the gooseneck area.

2

See Power Sources on page 19 for a closer view of which outlets

Shore Power supplies. Generator Power supplies all outlets.

AC

Key:

AA Generator

AB Air Conditioner

AC Air Compressor

AD Main Breaker

AE Shore Power Extension Cord

AF Shore/Generator Power Switch

TI12885b

312765B 15

Page 16

Component Identification

Dual Proportioner 28 ft Trailer and 20-28 ft Truck Box

A

G

H

V

1

D

C

P

T

TI12889a

R

W

1

A

1

See Power Sources on page 19 for a closer

view of which outlets Shore Power supplies.

Generator Power supplies all outlets.

20 ft Truck Box Shown

Key:

A Proportioner

BAir Dryer

C Chemical Drums and Rack

D Breathable Air Hose and Rack

E Breathing Air Filter System

F Air Regulators Assembly

G Emergency Eye Wash Station

H First Aid Kit

J 120V Lights

K Agitator

L Pump (Stick Pump shown)

M Tool Box and Cabinets

N Fire Extinguisher

P Heated Hoses and Rack

R Electrical Panel

S Light Switch

T Door

U Fluorescent Light

V Outlet powered only by Generator

Power

W Outlet powered by both Generator

Power and Shore Power

M

U

F

20 ft Truck Box Shown

1

V

E

J

K

L

1

V

D

J

C

P

T

V

1

S

TI12890a

N

FIG. 5: Main Room

16 312765B

Page 17

Dual Proportioner 28 ft Trailer

and 20-28 ft Truck Box,

continued

20 ft Truck Box Shown

AB

B

AD

AE

W

1

S

Component Identification

AJ

AA

FIG. 6: Generator Room

AF

N

TI12891b

AC

1

See Power Sources on page 19 for a closer view of which outlets

Shore Power supplies. Generator Power supplies all outlets.

Key:

AA Generator

AB Air Conditioner

AC Air Compressor

AD Main Breaker

AE Shore Power Extension Cord

AF Shore/Generator Power Switch

AG Air Tank

312765B 17

Page 18

Grounding

Grounding

See grounding procedure and related warnings in

supplied manuals. See Related Manuals on page 3.

The trailer must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

When grounding the trailer, ground to one of the bolt

holes on the rear, side of generator block. See F

Have a qualified electrician connect the grounding wire

to the generator. Check with national electric code for

grounding of mobile electric units. Be sure your installation complies with all National, State, and Local safety

and fire codes.

IG. 7.

Transporting Trailer

• Do not run generator while trailer is in motion.

• Do not exceed the gross vehicle weight requirement. See Technical Data on page 45.

• See warnings in trailer manual. See Related Man-

uals on page 3.

1. Read trailer manual before transporting or loading

the trailer. See Related Manuals on page 3.

2. Follow Pressure Relief Procedure, page 26.

3. Follow Short-Term Shutdown procedure, page 28.

4. Ensure that drums are properly secured into drum

holders. Tighten drum straps to ensure that they

don’t move during transport.

5. Lock tool cabinet and secure all loose articles in

trailer.

F

IG. 7: Generator Grounding Point

6. Ensure all hoses are completely in trailer/truck box

and on support racks.

7. Shut and lock all trailer doors.

TI12895a

18 312765B

Page 19

Setup

Setup

See setup procedure and related warnings in supplied manuals. See Related Manuals on page 3.

Power Sources

The trailer has two options for power sources. Generator

Power uses the electricity provided by the generator to

provide power to all of the components and outlets in the

trailer except for the 12V lights. Shore Power uses electricity from an external source, supplied through the

Shore Power extension cord, to provide power to certain

outlets in the trailer.

NOTE: Shore Power outlets are labeled with a plaque.

Outlets Powered by Shore Power in 20 ft Trailers

• The left two outlets of the 4-gang outlet in the main

room, on the driver side wall of the trailer

• The two-plug outlet in the main room to the left of

the electrical panel, on the partition wall

• The outlet (W) in the generator room

TI12887a

FIG. 8: Outlets Powered by Shore Power in

20 ft Trailers

TI12888b

312765B 19

Page 20

Setup

Outlets Powered by Shore Power in 28 ft Trailer and

Modified Truck Boxes

• The two-plug outlet in the main room to the left of

the electrical panel, on the partition wall

• The outlet (W) in the generator room

Single Proportioner,

20 ft Trailer Shown

TI12883a

F

IG. 9: Outlets Powered by Shore Power in

28 ft Trailers

TI12885b

20 312765B

Page 21

Setup

Shore Power

Shore Power can be used to provide power to certain

outlets in the trailer. The powered outlets can be used to

run low amperage items.

1. Turn main breaker off.

2. Turn generator off.

3. Turn Shore/Generator Power Switch (AF) to the

“OFF” position. See F

Shore Power

IG. 10

F

IG. 10.

Generator Power

TI13945a

Generator Power

When using Generator Power, all outlets in the trailer

are hot, including Shore Power outlets.

1. Turn off main breaker.

2. Turn Shore/Generator Power Switch (AF) to the

“OFF” position. See F

Shore Power

IG. 12

F

3. Start generator. See Startup instructions on

page 24.

IG. 12.

Generator Power

TI13945a

4. Route Shore Power extension cord (AE) out of the

trailer through the outlet in the floor below the Shore

Power rack.

5. Plug Shore Power extension cord (AE) into a

grounded 110 V outlet.

6. Turn Shore/Generator Power Switch (AF) to the

“SHORE” position. See F

IG. 11.

Shore Power

Generator Power

TI13943a

FIG. 11: Shore Power Setup

4. Turn Shore/Generator Power Switch (AF) to the

“GEN” position. See F

IG. 13.

Shore Power

Generator Power

TI13394a

IG. 13: Generator Power Setup

F

5. Turn on main breaker in the generator room.

7. Turn on main breaker.

312765B 21

Page 22

Setup

Air Regulators Assembly

The left air pressure regulator on the air regulators

assembly (F) supplies air to the transfer pump and

should be set according to air inlet recommendations in

the transfer pump manual. Pump fluid outlet pressure

may vary based on air inlet pressure. Verify the fluid outlet pressure meets proportioner fluid inlet recommendations in Proportioner manual. See Related Manuals on

page 3.

The right air pressure regulator supplies air to gun via

the proportioner and should be set according to air inlet

recommendations in the gun manual. See Related

Manuals on page 3. Verify both regulators are set correctly. Fill ISO pump lube reservoir as required.

Hose Connections

See Simplified Pneumatic Schematic on page 38,

and Simplified Fluid Schematics on page 40.

For more information, see Heated Hose manual and Circulation and Return Tube Kits manual listed in Related

Manuals section on page 3.

Feed System

See setup instructions and related warnings in supplied manuals. See Related Manuals on page 3.

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (isocyanate) and component B (resin) parts. Always use

the red drum rack for ISO and the blue drum rack for

resin.

1. Install drums into rack (C). Tighten drum straps.

2. Install drum lids if included.

3. Install agitator, stick pumps, and/or riser tubes if

included.

4. Attach feed system hoses.

Proportioner and Gun

See Proportioner and Gun manuals for related setup

instructions. See Related Manuals on page 3.

22 312765B

Page 23

Air Conditioning

1. Verify Air Conditioning breaker is in the “ON” position.

2. See setup instructions in Air Conditioning manual.

See Related Manuals on page 3.

Breathable Air System

See setup instructions and related warnings in supplied manuals. See Related Manuals on page 3.

1. Verify breathing air filter system is plugged in.

2. Set setup instructions in Breathable Air System

manual. See Related Manuals on page 3.

Setup

Band Heaters

See setup instructions and related warnings in supplied manuals. See Related Manuals on page 3.

NOTICE

Band heaters may char material if temperature setting is too high.

1. Wrap the band heaters around the drums and connect velcro straps to hold the heaters in place.

2. Verify the band heater power cable is plugged in.

3. See setup instructions in Band Heaters manual.

See Related Manuals on page 3.

312765B 23

Page 24

Startup

Startup

See startup instructions and related warnings in

supplied manuals. See Related Manuals on page 3.

Prepare for Generator Startup

1. Ensure main breaker for the generator is in the OFF

position. The main breaker is the only breaker

located in the generator room.

2. Turn Shore/Generator Power Switch (AF) to the

“GEN” position.

3. With trailer level, check fuel, oil, and coolant fluid

levels on generator.

NOTICE

To prevent damage to spray machine and generator,

do not run generator out of fuel. Follow shut down

procedure on page 28 when fuel level is getting low.

Start Generator

NOTE: Refer to generator operator’s manual for cold

weather startup instructions.

8. Press and hold bypass button.

4. Check oil in compressor.

5. Check oil level in lube cup on air regulators assembly.

6. Close water bleed valve on compressor.

7. Ensure proportioner is turned off.

TI12894a1

FIG. 14: Generator Bypass Button

9. Turn ignition switch to start position until engine

starts.

10. Release ignition switch and bypass button.

11. Wait at least five minutes after starting generator for

readout on digital voltage/amp meter in main room

to stabilize.

24 312765B

Page 25

Start Trailer Components

12. Turn on main breaker in the generator room.

13. Verify voltage and frequency displayed on the digital

voltage/amp meter. With engine at normal operating

temperature and not under load, voltage should be

220V +/- 1% and frequency should be

60Hz +5%/-2%.

14. Start proportioner. See Proportioner manual for

instructions, see Related Manuals on page 3.

15. Start compressor.

For all non-screw compressors, engage starter.

Verify readout on air pressure gauge on compressor.

For screw compressors, open ball valve on compressor. See F

IG. 15.

Startup

TI12894a

F

IG. 15: Screw Compressor Ball Valve

16. Verify air dryer is on. See Related Manuals on

page 3.

17. Turn on agitators and pumps. See Related Manu-

als on page 3.

Foam Resins with 245fa Blowing Agents

New foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially if agitated. Maintain proper temperature inside

trailer.

18. If required, see Related Manuals on page 3 for

other non-Graco component startup instructions.

312765B 25

Page 26

Pressure Relief Procedure

Pressure Relief Procedure

Chemical Pressure Relief

1. Turn off feed pumps and agitators if used.

See pressure relief procedure and related warnings

in supplied manuals. See Related Manuals on

page 3.

Generator pressure must be relieved prior to performing

generator maintenance or repair. See generator manual.

Air Pressure Relief

1. For rotary compressors, open ball valve on compressor. See F

For all other compressors, open service valve on

compressor.

IG. 16.

2. Turn off proportioner.

3. Relieve pressure in gun and perform gun shutdown

procedure. See Gun manual. See Related Manuals

on page 3.

4. Relieve pressure in proportioner. See Proportioner

manual. See Related Manuals on page 3.

Hydraulic Pressure Relief

Only the Hydraulic Reactor has hydraulic pressure. See

the Hydraulic Reactor manual for hydraulic pressure

relief procedure.

TI12894a

F

IG. 16: Rotary Compressor Ball Valve

2. For dual proportioner Spray Rigs, open water

bleed valve located on the bottom of the air

tank (AG).

26 312765B

Page 27

Operation

See operation instructions and related warnings in

supplied manuals. See Related Manuals on page 3.

Trailer Interior Lights

120V Lights

The trailer interior lights on the walls and the fluorescent

light under the cabinet (if installed) can be powered by

either Generator or Shore Power. To use these lights,

setup Generator Power or Shore Power, see Setup on

page 19. There is one light switch for the 120V lights in

each room.

Operation

12V Lights

NOTE: Modified truck boxes will only include 12V lights

if the customer-provided truck box comes with 12V

lights.

The trailer interior lights on the ceiling are powered by

the truck through the 7-way connector. To use the 12V

lights, connect the trailer 7-way connector to the truck.

There is one main light switch for the 12V lights in each

room. There is also a switch on each light.

312765B 27

Page 28

Shutdown

Shutdown

8. Run generator unloaded for at least two minutes to

allow engine to cool. See generator operator’s manual for details.

See shutdown instructions and related warnings in

supplied manuals. See Related Manuals on page 3.

Short-Term Shutdown

1. Turn off proportioner. Refer to proportioner manual

for shutdown procedure. See Related Manuals on

page 3.

2. Relieve chemical pressure. See Pressure Relief

Procedure on page 26.

3. Properly seal supply drums.

4. Ensure desiccant dryer is in proper working condition.

5. Turn off air compressor.

• For screw compressors, close the ball valve.

See F

IG. 17, ball valve is shown open.

9. Turn generator ignition switch to the off position.

10. Turn Shore/Generator Power Switch (AF) to the

“OFF” position.

Long-Term Shutdown

NOTE: Perform long-term shutdown when Spray Rig will

not be used for longer than 90 days.

1. Follow steps 1 through 7 of Short-Term Shutdown.

2. Flush pump, feed system hoses, proportioner, and

spray gun with mesamoll or compatible solvent. Follow flushing procedure in each component’s manual. See Related Manuals on page 3.

NOTICE

Isocyanate crystallization may result if proper flushing is not performed.

3. Remove pumps, agitators, and supply hoses from

feed system.

TI12894a

IG. 17: Screw Compressor Ball Valve

F

• For all other compressors, turn switch on

starter to the off position.

6. Relieve air pressure. See Pressure Relief Proce-

dure on page 26.

7. Turn off main breaker.

4. Clean agitator with mesamoll or compatible solvent.

5. Cap off the drums to provide air-tight seal.

6. Turn Shore/Generator Power Switch (AF) to the

“OFF” position.

7. Follow long-term storage procedure in compressor

manual.

8. Follow long-term storage procedure in generator

manual.

28 312765B

Page 29

Maintenance

See maintenance instructions and related warnings

in supplied manuals. See Related Manuals on

page 3.

NOTE: Follow suggested maintenance schedule for all

components in their respective owner’s manuals. See

Related Manuals on page 3.

Troubleshooting

Maintenance

See troubleshooting instructions and related warnings in supplied manuals. See Related Manuals on

page 3.

Contact your authorized Graco distributor for service and repairs.

Problem Cause Solution

Component will not turn on Component is not plugged in • Plug in the component

Component is plugged into a Generator Power supplied outlet and Generator Power is not selected

OR

Component is plugged into a Shore

Power supplied outlet and Shore

Power is not selected

Component breaker is off 1. Check for tripped breaker.

• Plug component into a hot outlet.

See Setup on page 19 for a list

of which outlets are powered by

Generator Power and Shore

Power.

2. Remove cause of tripped

breaker.

3. Turn breaker on.

312765B 29

Page 30

Simplified Electrical Schematics

Simplified Electrical Schematics

NOTE: Modified truck box wiring varies by trailer.

Main Breaker, All Trailers

1

3

BA

BA

BB

BA

3

Key:

BA Current Transformer

BB Grounding Block

1

Connects to Generator Electrical Cabinet. See

Generator manual for wiring information.

2

Connects to Electrical Panel. See Electrical Panel wiring

for your trailer configuration.

3

Wire is only used on 3-phase models.

3

2

FIG. 18: Main Breaker, All Trailers

30 312765B

Page 31

Power Supply, All Trailers

Connects to

120V light (J)

2

Simplified Electrical Schematics

Connects to

2

outlet (V)

Light Switch

Shore/Generator

Power Switch

Shore Power Extension Cord

Outlet

1

Connects to generator

breaker in electrical panel

1

See Electrical Panel wiring figure for your trailer

configuration.

2

See Trailer wiring figure for your trailer configuration.

FIG. 19: Power Supply, All Trailers

312765B 31

Page 32

Simplified Electrical Schematics

Electrical Panel

1-phase 20 ft and 28 ft Single Proportioner Trailers

To Outlet (V)

To Outlet (V)

To Shore/Generator

Power Switch (AF)

To Outlet (V)

Optional To Air

Conditioner (AB)

2

To Proportioner (A)

2

2

3

2

2

2 To Outlet (V)

2 To Outlet (V)

1

1

Connects to Main Breaker. See Main Breaker wiring, FIG. 18 on page 30.

2

See Trailer Wiring figure for your trailer configuration.

3

See Power Supply wiring, F

IG. 19 on page 31.

FIG. 20: Electrical Panel, 1-phase 20 ft and 28 ft Single Proportioner 28 ft Trailers

32 312765B

Page 33

3-phase 20 ft and 28 ft Single Proportioner Trailers

Simplified Electrical Schematics

To Outlet (V, W)

To O ut le t ( V )

To Shore/Generator

Power Switch (AF)

To O ut le t ( V )

Optional To Air

Conditioner (AB)

2

To Proportioner (A)

2

2

3

2

2

2

To Outlet (V)

2

To Outlet (V)

1

1

Connects to Main Breaker. See Main Breaker wiring,

IG. 18 on page 30.

F

2

See Trailer Wiring figure for your trailer configuration.

3

See Power Supply wiring, F

IG. 19 on page 31.

FIG. 21: Electrical Panel, 3-phase 20 ft and 28 ft Single Proportioner Trailers

312765B 33

Page 34

Simplified Electrical Schematics

Dual Proportioner 28 ft Trailers

To Proportioner (A)

2

To Proportioner (A)

2

To Outlet (V)

To O ut le t ( V )

To Shore/Generator

Power Switch (AF)

To A ir

Conditioner (AB)

2

2

2

3

2 To Outlet (V)

To Outlet (V)

2

2 To Outlet (V)

1

1

Connects to Main Breaker. See Main Breaker wiring,

IG. 18 on page 30.

F

2

See Trailer Wiring figure for your trailer configuration.

3

See Power Supply wiring, F

IG. 19 on page 31.

FIG. 22: Electrical Panel, Dual Proportioner 28 ft Trailers

34 312765B

Page 35

Trailer Wiring

20 ft Trailers

NOTE: Dashed lines indicate items on other side of wall.

Simplified Electrical Schematics

J

J

3

AD

S

W

AF

2

W

1

R

Items located on driver side

wall in Generator Room

V

V

V

J

Partition Wall

U

S

4

T

W

A

Main Room Passenger Side Wall Main Room Driver Side Wall

1

See Electrical Panel wiring figure for your trailer

configuration.

2

See Power Supply wiring, F

3

See Main Breaker wiring, F

4

The wire is routed through this light switch but the wire is

not connected to the light switch.

IG. 19 on page 31.

IG. 18 on page 30.

W

V

Key:

A Proportioner

BAir Dryer

C Chemical Drums and Rack

D Breathable Air Hose and Rack

E Breathing Air Filter System

F Air Regulators Assembly

G Emergency Eye Wash Station

HFirst Aid Kit

J 120V Lights

K Agitator

F

IG. 23: Trailer Wiring, 20 ft Trailers

312765B 35

L Pump (Stick Pump shown)

M Work Bench and Cabinets

N Fire Extinguisher

P Heated Hoses and Rack

R Electrical Panel

SLight Switch

T Door

U Fluorescent Light

V Outlet powered only by Generator

Power

W Outlet powered by both Generator

Power and Shore Power

AA Generator

AB Air Conditioner

AC Air Compressor

AD Main Breaker

AE Shore Power Extension Cord

AF Shore/Generator Power Switch

Page 36

Simplified Electrical Schematics

Single Proportioner 28 ft Trailer

NOTE: Dashed lines indicate items on other side of wall.

U

J

W

AD

R

1

3

J

V

V

W

S

2

AF

V

Partition Wall

Main Room Driver Side Wall Main Room Passenger Side Wall

1

See Electrical Panel wiring figure for your trailer

configuration.

2

See Power Supply wiring, F

3

See Main Breaker wiring, F

4

The wire is routed through the outlet but the wire is not

connected to the outlet.

IG. 19 on page 31.

IG. 18 on page 30.

J

V

4

A

V

S

Key:

A Proportioner

BAir Dryer

C Chemical Drums and Rack

D Breathable Air Hose and Rack

E Breathing Air Filter System

F Air Regulators Assembly

G Emergency Eye Wash Station

H First Aid Kit

J 120V Lights

KAgitator

F

IG. 24: Trailer Wiring, Single Proportioner 28 ft Trailers

36 312765B

L Pump (Stick Pump shown)

M Work Bench and Cabinets

N Fire Extinguisher

P Heated Hoses and Rack

R Electrical Panel

S Light Switch

T Door

U Fluorescent Light

V Outlet powered only by Generator

Power

W Outlet powered by both Generator

Power and Shore Power

AA Generator

AB Air Conditioner

AC Air Compressor

AD Main Breaker

AE Shore Power Extension Cord

AF Shore/Generator Power Switch

Page 37

Dual Proportioner 28 ft Trailers

NOTE: Dashed lines indicate items on other side of wall.

U

Simplified Electrical Schematics

AD

J

3

V

V

J

W

R

1

V

Main Room Driver Side Wall Main Room Passenger Side Wall

Key:

A Proportioner

BAir Dryer

C Chemical Drums and Rack

D Breathable Air Hose and Rack

E Breathing Air Filter System

F Air Regulators Assembly

G Emergency Eye Wash Station

H First Aid Kit

J 120V Lights

KAgitator

A

Partition Wall

1

See Electrical Panel wiring figure for your trailer

configuration.

2

See Power Supply wiring, F

3

See Main Breaker wiring, F

4

The wire is routed through the outlet but the wire is not

connected to the outlet.

L Pump (Stick Pump shown)

M Work Bench and Cabinets

N Fire Extinguisher

P Heated Hoses and Rack

R Electrical Panel

S Light Switch

T Door

U Fluorescent Light

V Outlet powered only by Generator

Power

IG. 19 on page 31.

IG. 18 on page 30.

2

W

A

S

2

AF

V

W Outlet powered by both Generator

Power and Shore Power

AA Generator

AB Air Conditioner

AC Air Compressor

AD Main Breaker

AE Shore Power Extension Cord

AF Shore/Generator Power Switch

J

4

V

S

F

IG. 25: Trailer Wiring, Dual Proportioner 28 ft Trailers

312765B 37

Page 38

Simplified Pneumatic Schematic

Simplified Pneumatic Schematic

Single Proportioner Trailers/Truck Boxes

To P um p ( L)

Air Regulators

Assembly (F)

To Proportioner (A)

Air Dryer (B)

To P u m p ( L)

From Air

Compressor (AC)

In

Out

Breathing Air Filter

System (E)

FIG. 26

38 312765B

Page 39

Dual Proportioner Trailers/Truck Boxes

Air Dryer (B)

Simplified Pneumatic Schematic

To P u m p ( L)

Air Regulators

Assembly (F)

To P um p ( L )

In

Out

To Breathing Air Fil-

ter System (E)

From Air

Compressor (AC)

Air Tank (AG)

Water Bleed

Val ve

To Proportioner (A)

FIG. 27

312765B 39

To Proportioner (A)

Page 40

Simplified Fluid Schematics

Simplified Fluid Schematics

Single Proportioner Trailers/Truck Boxes

See Circulation and Return Tube Kits manual. See

Related Manuals on page 3.

Dual Proportioner Trailers/Truck Boxes

CB

CB

CB

L

CA

CB

CG

Top View of Drums

L

CD

CE

CE

Key:

CA Iso Drum

CB Iso Fluid Line

CC Iso Recirculation Valve

CD Resin Drum

CB

CE

CG

CE

CE Resin Fluid Line

CF Resin Recirculation Valve

CG Proportioner Manifold

FIG. 28: Gun Circulation

40 312765B

Page 41

Dual Proportioner Trailers/Truck Boxes, continued

CE

CB

Simplified Fluid Schematics

CF

CC

CB

CC

CF

CE

Key:

CA Iso Drum

CB Iso Fluid Line

CC Iso Recirculation Valve

CD Resin Drum

CA

CB

Top View of Drums

CE

CD

CE Resin Fluid Line

CF Resin Recirculation Valve

CG Proportioner Manifold

FIG. 29: System Circulation

312765B 41

Page 42

Simplified Fluid Schematics

Dual Proportioner Trailers/Truck

Boxes, continued

CE

CF

CC

CC

CF

CB

CE

L

Top View of Drums

L

CA

CD

CB

CE

CB

CB

CG

CB

CE

CG

CE

CE

CB

FIG. 30: Machine Circulation

Key:

CA Iso Drum

CB Iso Fluid Line

CC Iso Recirculation Valve

CD Resin Drum

CE Resin Fluid Line

CF Resin Recirculation Valve

CG Proportioner

42 312765B

Page 43

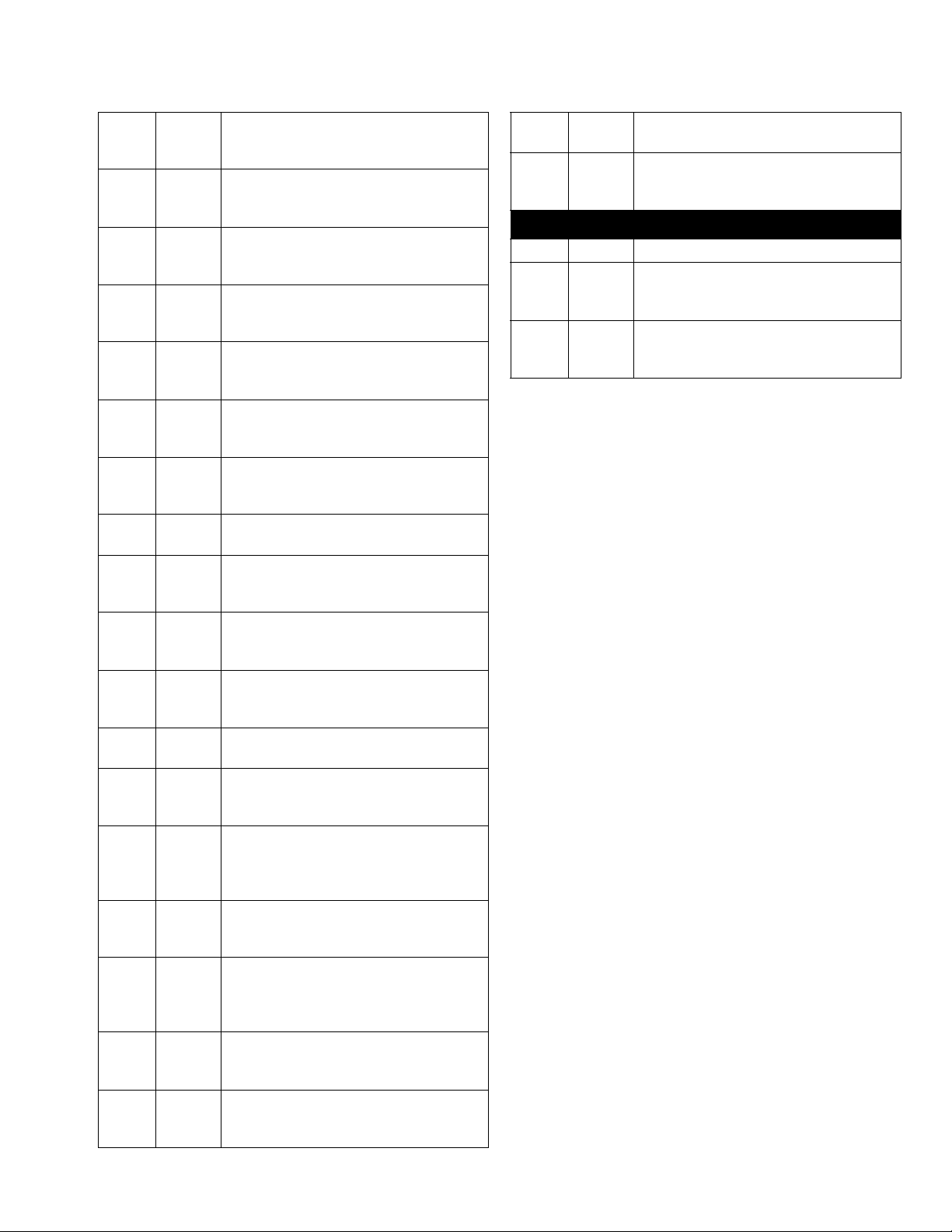

Dimensions

Dimensions

D

C

28 ft Trailer Shown

A

TI12881a

FIG. 31: Top View

312765B 43

Page 44

Dimensions

28 ft Trailer Shown

B

E

TI12882a

IG. 32: Side View

F

Ref

20 ft Trailer

in. (cm)

28 ft Trailer

in. (cm)

A (width) 102 (259) 102 (259)

B (height,

trailer

level)

Without Air

Conditioning

With Air

Conditioning

129 (328) 129 (328)

135 (343) 135 (343)

C (length) 240.5 (612) 340 (864)

D (hitch length) 52 (132) 27 (69)

E (hitch height, trailer level) 21.25 (54)

32 to 42

(81 to 107)

Modified

Tru ck Box

Var ies

44 312765B

Page 45

Technical Data

Technical Data

NOTE: See Related Manuals on page 3.

Voltage, Frequency 230V, 60 Hz

Generator Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 kW, 1-phase or 3-phase (see Product Configurator

on page 4)

Trailer Maximum Weight Capacity . . . . . . . . . . . . . . . . . . See tag on trailer

Trailer Weight OEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See original Graco documents shipped with trailer

Wetted Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Related Manuals on page 3

Maximum Air Working Pressure . . . . . . . . . . . . . . . . . . . . 120 psi (0.8 MPa, 8.2 bar)

See component manuals for component Maximum Air

Working Pressure

Maximum Fluid Working Pressure . . . . . . . . . . . . . . . . . . Fluid Supply Lines from

Drum to Proportioner . . . . . . . . 500 psi (3.4 MPa, 34 bar)

Fluid Recirculation Lines . . . 3500 psi (24 MPa, 241 bar)

See component manuals for component Maximum Fluid

Working Pressure

312765B 45

Page 46

Graco Ohio Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Ohio Information

TO PLACE AN ORDER,

Toll Free: 1-800-746-1334 or Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

contact your Graco distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 312765

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO OHIO INC. 8400 PORT JACKSON AVE NW, NORTH CANTON, OH 44720

Copyright 2009, Graco Ohio Inc. is registered to ISO 9001

www.graco.com

Rev 3/2009

Loading...

Loading...