Page 1

Repair - Parts

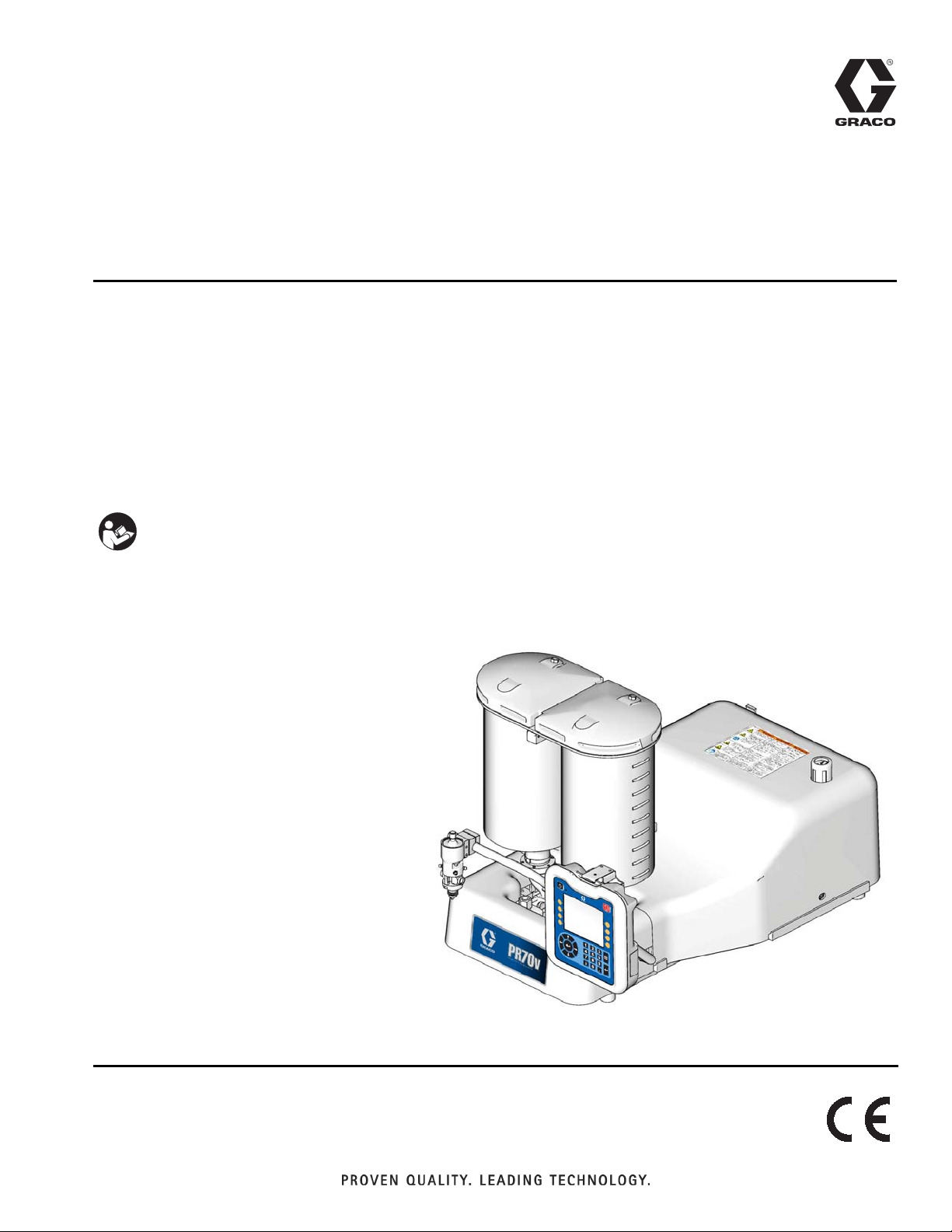

PR70 and PR70v

312760S

Two Component Liquid Dispensing Systems

Fixed or variable ratio systems. For accurate metering, mixing, and dispensing of

two-component materials. For professional use only.

Not approved for use in European explosive atmosphere locations.

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

Important Safety Instructions

Read all warnings and instructions in all

supplied manuals. Save these instructions.

EN

PR70v Shown with Advanced Display Module

ti12385b

Page 2

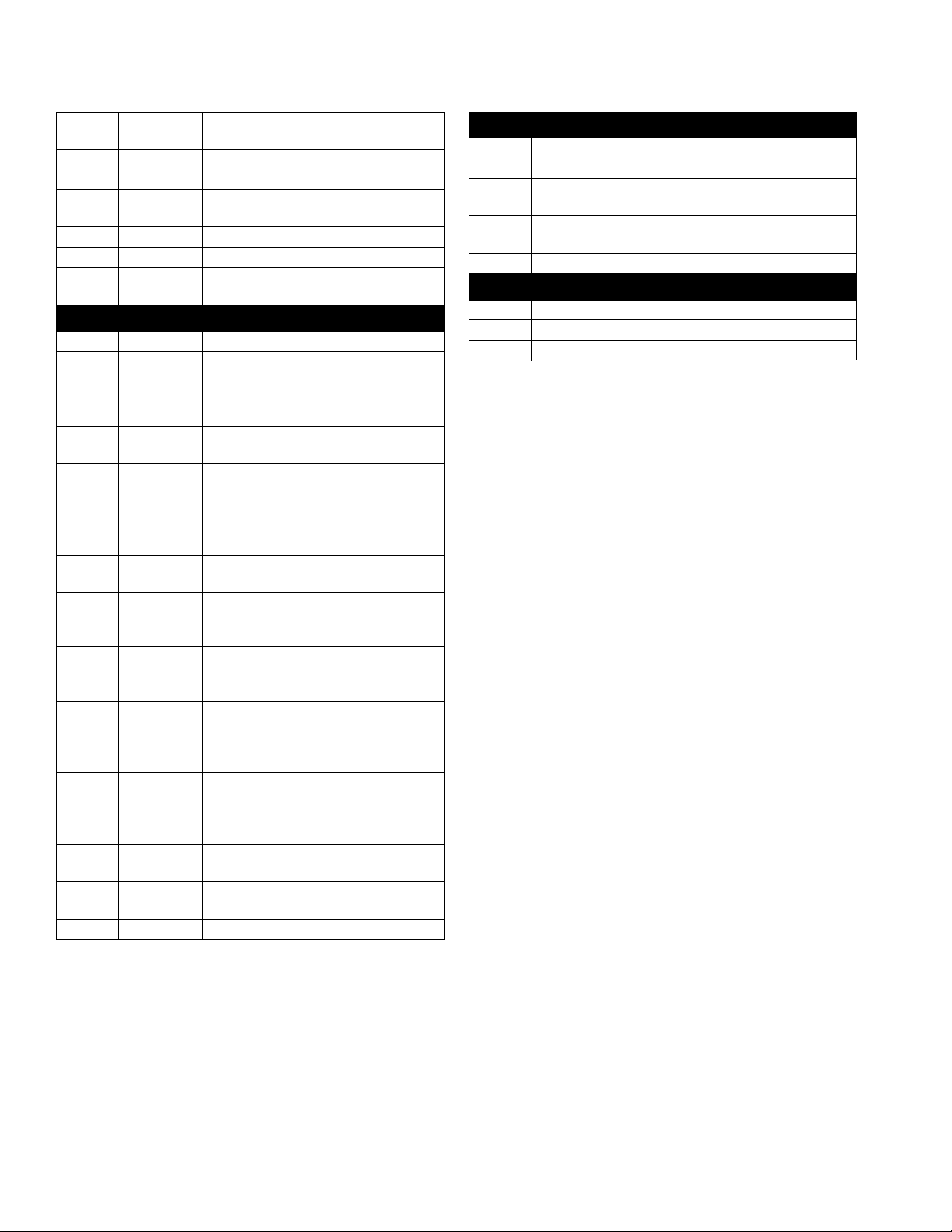

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Configurator . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 14

Models with Advanced Display Module . . . . . . . 14

Models with Standard Display Module . . . . . . . 14

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Error Codes

(Advanced Display Module) . . . . . . . . . . . . 18

Error Codes

(Standard Display Module) . . . . . . . . . . . . . 23

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . 25

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

HydraCheck Kit Installation . . . . . . . . . . . . . . . . 29

Air Cylinder Kit Installation . . . . . . . . . . . . . . . . 31

Rear Pump Rebuild Kit Installation . . . . . . . . . . 33

Piston/Cylinder Replacement Kit Installation . . 35

Check Valve Rebuild Kit Installation . . . . . . . . . 36

Piston Plug Installation . . . . . . . . . . . . . . . . . . . 37

Pressure Transducer Installation . . . . . . . . . . . . 37

Flow Meter Installation . . . . . . . . . . . . . . . . . . . 38

Fluid Control Module Replacement . . . . . . . . . . 39

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . 40

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Fixed Ratio Base, LC0262, LC0263, LC0264,

LC0265 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Fixed Ratio Frame Sub-Assembly, LC0290 . . . . 44

Fixed Ratio Drive Block Assembly, LC0107 . . . . 45

Variable Ratio Base, LC0242, LC0243, LC0244,

LC0245 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Variable Ratio Frame Sub-Assembly, LC0232 . . 49

Air Cylinder, LC0110, LC0111, LC0230, LC0231 52

Pump Sub-Assembly, LC0112 . . . . . . . . . . . . . . 54

Control Bracket, LC0240, LC0261 . . . . . . . . . . . 56

Incoming Power Bracket, LC0239 . . . . . . . . . . . 58

Piston Package . . . . . . . . . . . . . . . . . . . . . . . . . 60

Nylon and UHMW Piston Replacement Kits . . . 63

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Applicator Mounting . . . . . . . . . . . . . . . . . . . . . . 65

Dispense Valve . . . . . . . . . . . . . . . . . . . . . . . . . 66

Mixers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Hose Packages . . . . . . . . . . . . . . . . . . . . . . . . . 69

Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Flow Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . 77

Tank Stands, Assemblies LC0247 and LC0103 79

Heat Zone Assemblies . . . . . . . . . . . . . . . . . . . 79

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Machine with On-Board Tanks . . . . . . . . . . . . . . 82

Machine with Off-Board Tanks . . . . . . . . . . . . . . 83

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 86

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 86

2 312760S

Page 3

Related Manuals

PR70 and PR70v Operation and Parts Manuals

Part Description

3A0429 PR70 with Standard Display Module Operation and

Maintenance Manual

312759 PR70 and PR70v with Advanced Display Module

Operation and Maintenance Manual

312760 PR70 and PR70v Repair and Parts Manual

312394 PR70 and PR70v Feed Systems Manual

312761 PR70v Integrated Heat Instructions - Parts Manual

MD2 Dispense Valve Manual

Part Description

312185 MD2 Dispense Valve Instructions and Parts Manual

Related Manuals

312760S 3

Page 4

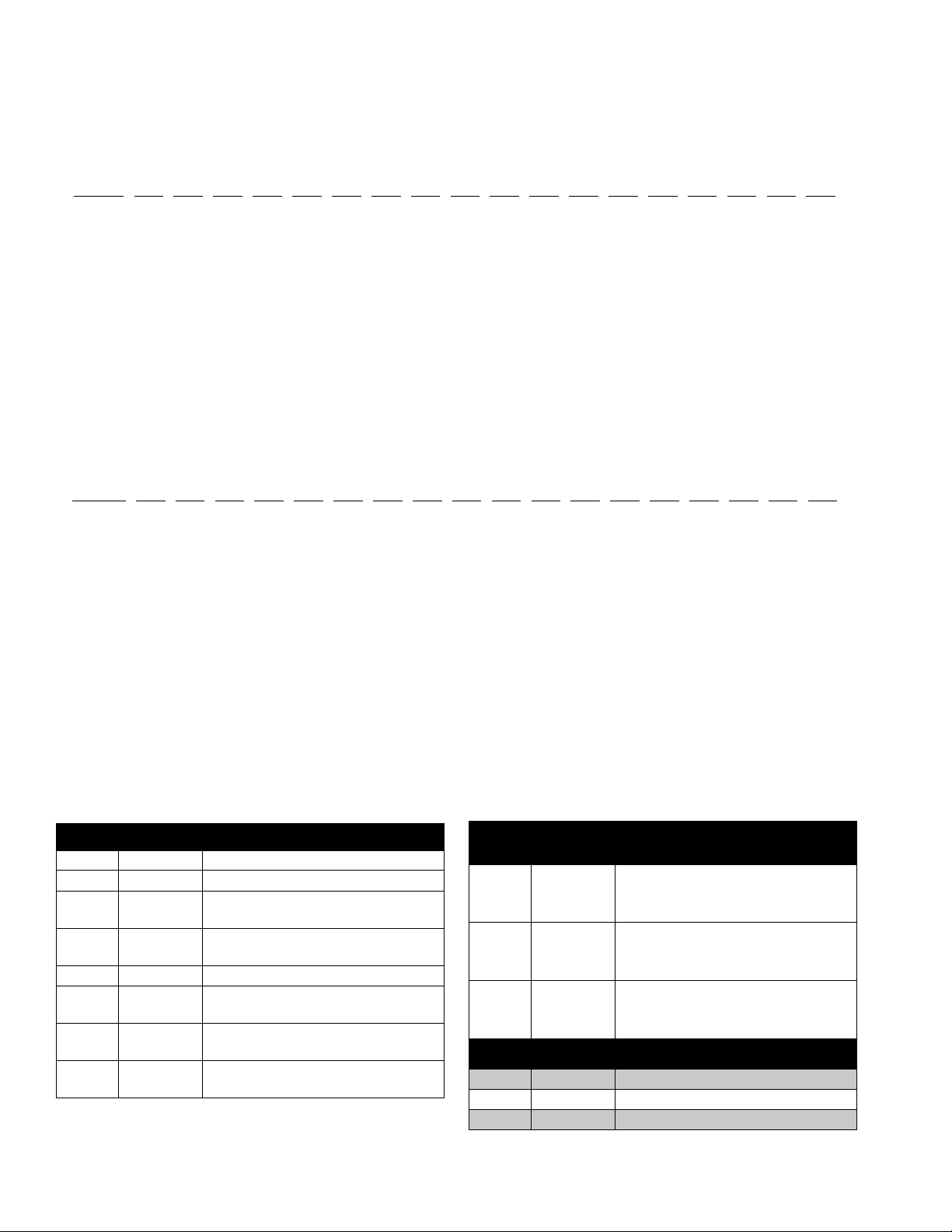

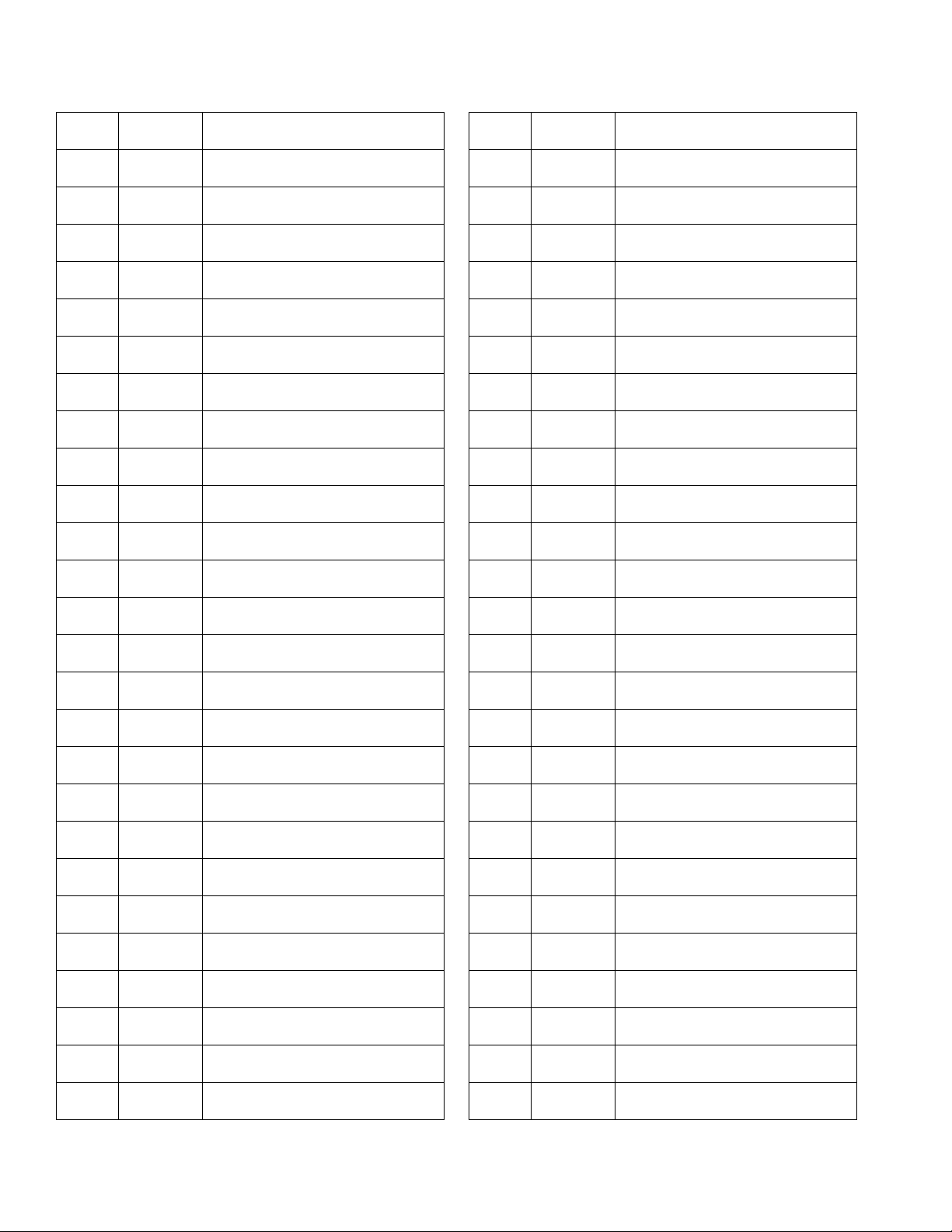

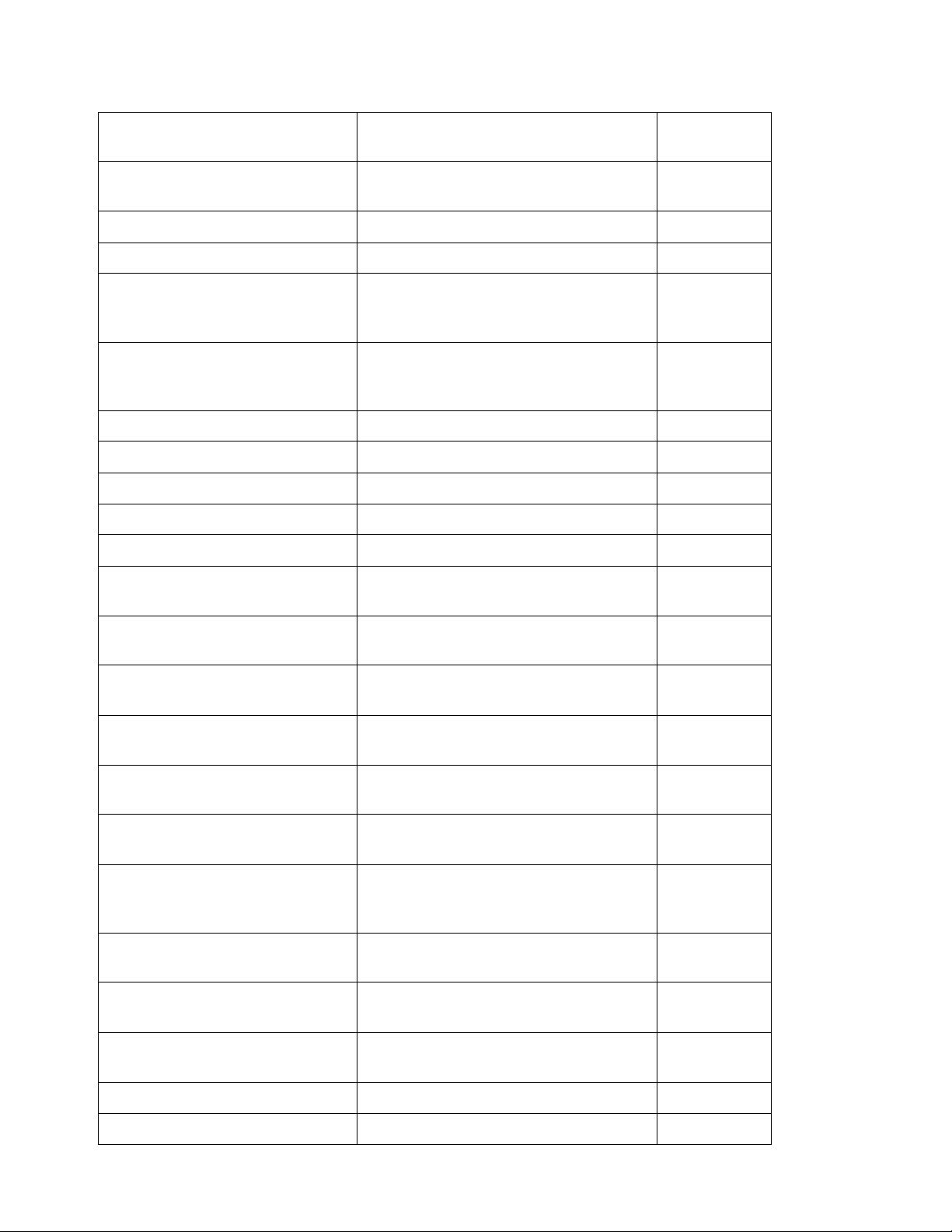

Product Configurator

Product Configurator

PR7F------------------

Code: A B-C D-E F G-H I-J K L M N O P Q R S T U V

Air Motor

High Volume Side Piston

Low Volume Side Piston

Controls

High Volume Side Hose

Low Volume Side Hose

Dispense Valve

Mixer

Applicator Mounting

Power Cord

Flow Monitoring

High Volume Side Tank

High Volume Side Tank Cover

Low Volume Side Tank

Low Volume Side Tank Cover

Tank Level Sensors

Heat Zone Controller

An example of the product configurator would be the following configurator code.

PR7F-J-A5-A5-E-A6-A6-3-1-2 -A-N- 3 -N-H-N- 6 -N-N

Code: A B-C D-E F G-H I-J K L M N O P Q R S T U V

Air Motor

High Volume Side Piston

Low Volume Side Piston

Controls

High Volume Side Hose

Low Volume Side Hose

Dispense Valve

Mixer

Applicator Mounting

Power Cord

Flow Monitoring

High Volume Side Tank

High Volume Side Tank Cover

Low Volume Side Tank

Low Volume Side Tank Cover

Tank Level Sensors

Heat Zone Controller

Off-Board Tank Stand

Off-Board Tank Stand

The following part number fields apply for the PR70 and PR70v part numbering configurator fields. Shaded items

listed in the configurator table below are “Super Standard” items that are typically stocked and provide the best delivery dates.

Code A Part Air Motor

A LC0262 PR70 with 3.0 in. (4.56 mm) Air Motor

B LC0264 PR70 with 4.5 in. (10.26 mm) Air Motor

C LC0263 PR70 with 3.0 in. (4.56 mm) Air Motor

and Hydracheck

D LC0265 PR70 with 4.5 in. (10.26 mm) Air Motor

and Hydracheck

F LC0242 PR70v with 3.0 in. (4.56 mm) Air Motor

G LC0244 PR70v with 4.5 in. (10.26 mm) Air

Motor

H LC0243 PR70v with 3.0 in. (4.56 mm) Air Motor

and Hydracheck

J LC0245 PR70v with 4.5 in. (10.26 mm) Air

Motor and Hydracheck

4 312760S

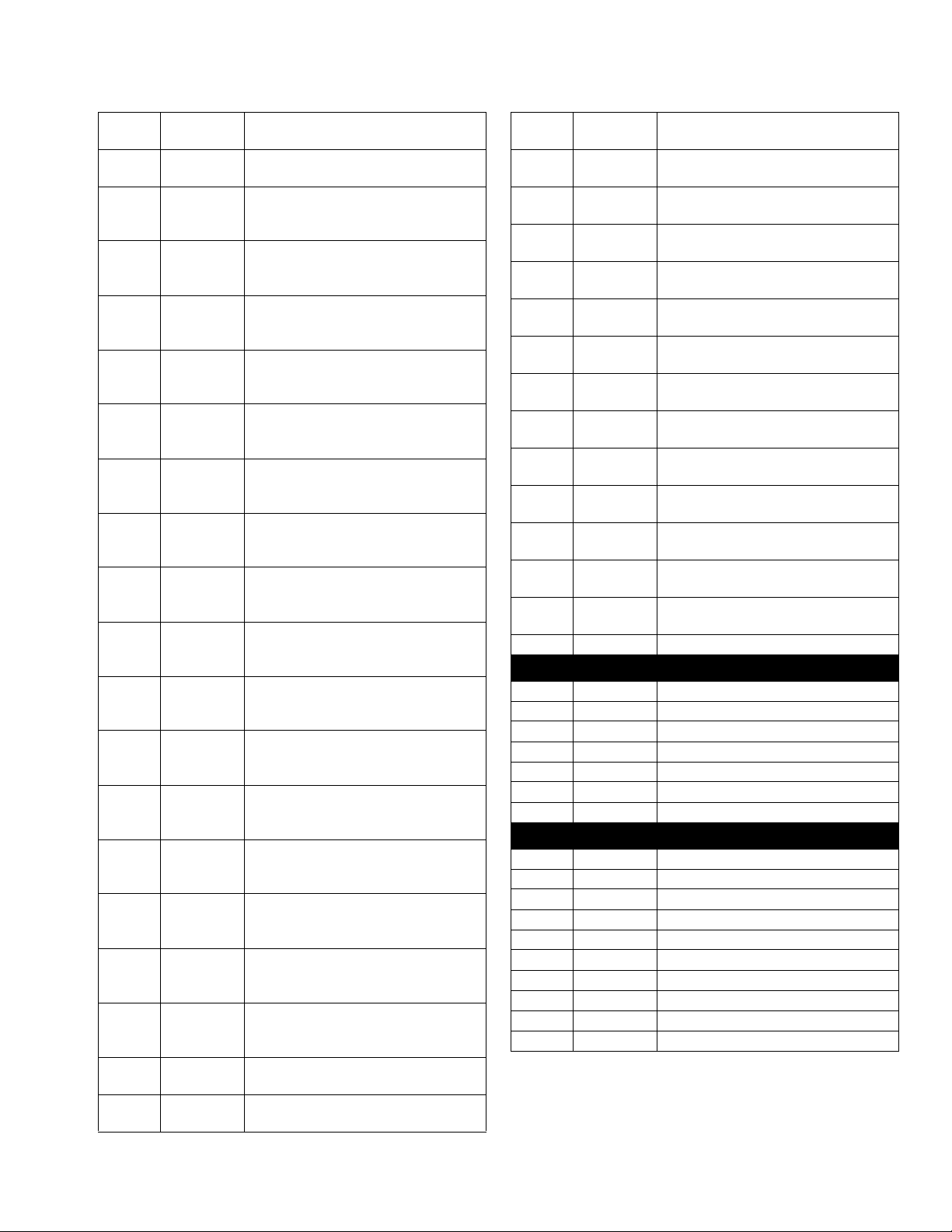

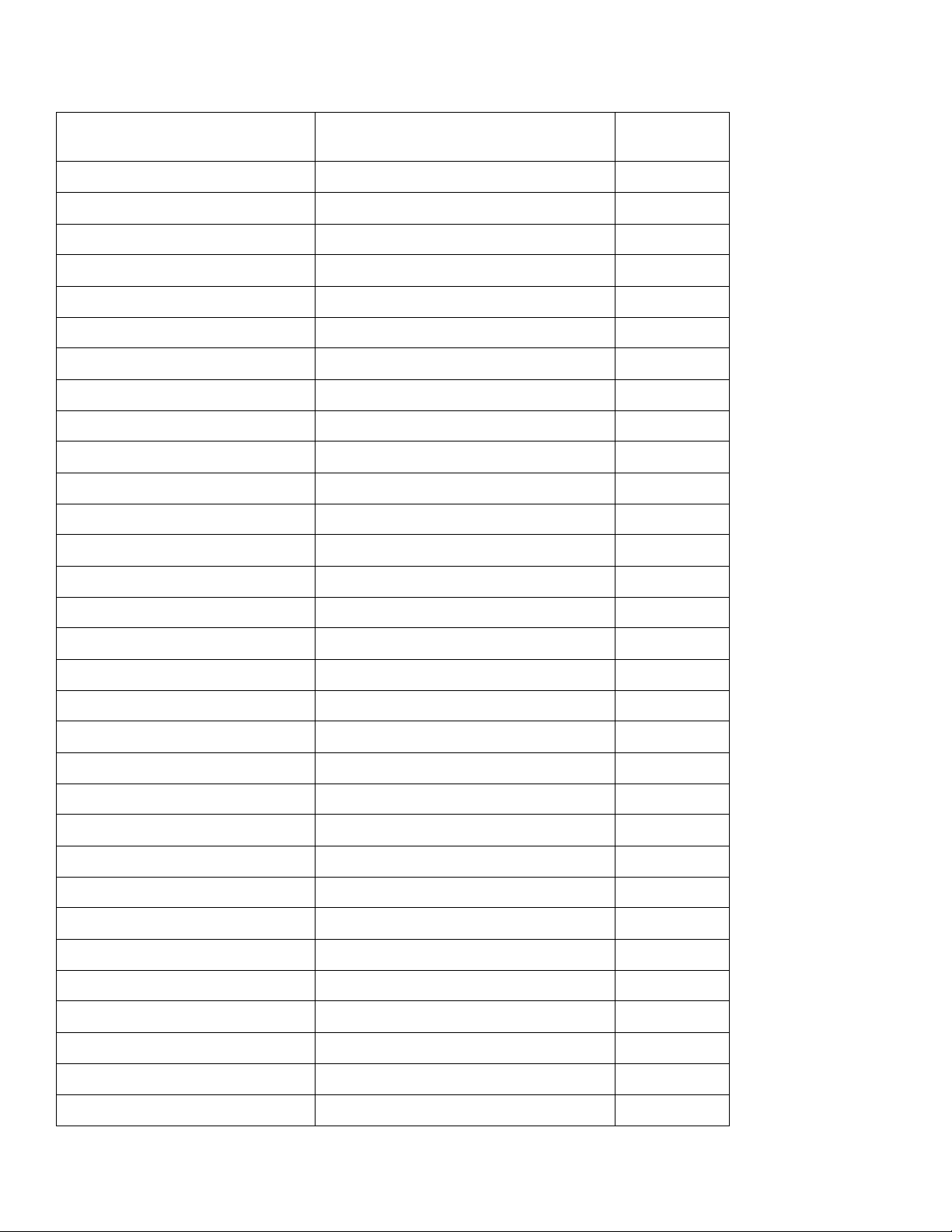

Code B Part

A LC1___ Nylon Piston, Stainless Steel Metering

B LC2___ UHMWPE Piston, Stainless Steel

C LC3___ UHMWPE Piston, Ceramic Metering

Code C Part High Volume Piston Size (mm2)

1 80, Available in Nylon Only

2 100, Available in Nylon Only

3 120, Available in Nylon Only

High Volume Side Piston and

Metering Tube Material

Tube (last three digits of part number

is the mm

Metering Tube (last three digits of part

number is the mm

Tube (last three digits of part number

is the mm

2

piston size)

2

2

piston size)

piston size)

Page 5

Product Configurator

4 140, Available in Nylon Only

5 160

6 180

7 200

8 220

9 240

A 260

B 280

C 300

F 320

G 360

H 400

J 440

L 480

M 520

R 560

S 600

T 640

U 720

W 800

X 880

Y 960

Z Custom High Volume side, consult fac-

tory (stainless steel only)

High Volume Side Piston and

Code D Part

Metering Tube Material

A LC1___ Nylon Piston, Stainless Steel Metering

Tube (last three digits of part number

is the mm2 piston size)

B LC2___ UHMWPE Piston, Stainless Steel

Metering Tube (last three digits of part

2

number is the mm

piston size)

C LC3___ UHMWPE Piston, Ceramic Metering

Tube (last three digits of part number

2

is the mm

piston size)

Code E Part Low Volume Side Piston Size (mm2)

1 80, Available in Nylon Only

2 100, Available in Nylon Only

3 120, Available in Nylon Only

4 140, Available in Nylon Only

5 160

6 180

7 200

8 220

9 240

A 260

B 280

C 300

F 320

G 360

H 400

J440

L 480

M520

R560

S600

T 640

U720

W800

X880

Y 960

Z Custom Low Volume side, consult fac-

tory (stainless steel only)

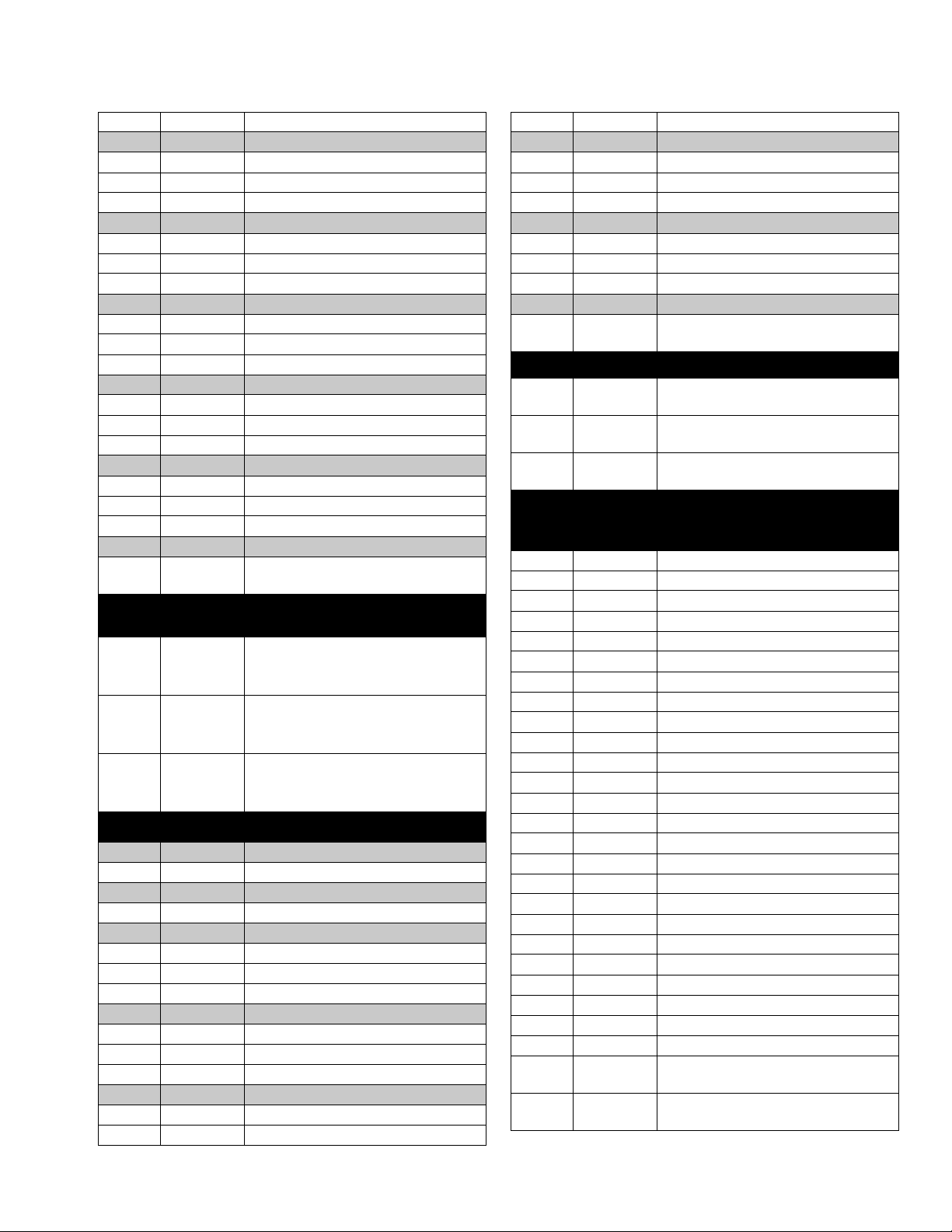

Code F Par t Controls

B LC0272 Standard Display Module with 1 Fluid

Control Module

D LC0274 Advanced Display Module with 1 Fluid

Control Module

E LC0275 Advanced Display Module with 2 Fluid

Control Modules

Codes

G-H,

I-J

Part

High Volume Hose /

Low Volume Hose

A1 LC0801 3/16 in. (4.8 mm) - 2.5 ft (0.6 m)

A2 LC0802 3/16 in. (4.8 mm) - 10 ft (3.0 m)

A3 LC0803 3/16 in. (4.8 mm) - 15 ft (4.6 m)

A4 LC0804 1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

A5 LC0805 1/4 in. (6.5 mm) - 10 ft (3.0 m)

A6 LC0806 1/4 in. (6.5 mm) - 15 ft (4.6 m)

A7 LC0807 3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

A8 LC0808 3/8 in. (9.5 mm) - 10 ft (3.0 m)

A9 LC0809 3/8 in. (9.5 mm) - 15 ft (4.6 m)

AA LC0810 1/2 in. (13 mm) - 2.5 ft (0.6 m)

AB LC0811 1/2 in. (13 mm) - 10 ft (3.0 m)

AC LC0812 1/2 in. (13 mm) - 15 ft (4.6 m)

AG LC0813 3/4 in. (19 mm) - 10 ft (3.0 m)

AH LC0814 3/4 in. (19 mm) - 15 ft (4.6 m)

B4 LC0881 Heated, 1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

B5 LC0882 Heated, 1/4 in. (6.5 mm) - 10 ft (3.0 m)

B6 LC0883 Heated, 1/4 in. (6.5 mm) - 15 ft (4.6 m)

B7 LC0884 Heated, 3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

B8 LC0885 Heated, 3/8 in. (9.5 mm) - 10 ft (3.0 m)

B9 LC0886 Heated, 3/8 in. (9.5 mm) - 15 ft (4.6 m)

BA LC0887 Heated, 1/2 in. (13 mm) - 2.5 ft (0.6 m)

BB LC0888 Heated, 1/2 in. (13 mm) - 10 ft (3.0 m)

BC LC0889 Heated, 1/2 in. (13 mm) - 15 ft (4.6 m)

BG LC0890 Heated, 3/4 in. (19 mm) - 10 ft (3.0 m)

BH LC0891 Heated, 3/4 in. (19 mm) - 15 ft (4.6 m)

C1 LC0161 Recirculating, On-Board Tanks,

3/16 in. (4.8 mm) - 2.5 ft (0.6 m)

C2 LC0162 Recirculating, On-Board Tanks,

3/16 in. (4.8 mm) - 10 ft (3.0 m)

312760S 5

Page 6

Product Configurator

C3 LC0163 Recirculating, On-Board Tanks,

3/16 in. (4.8 mm) - 15 ft (4.6 m)

C4 LC0164 Recirculating, On-Board Tanks,

1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

C5 LC0165 Recirculating, On-Board Tanks,

1/4 in. (6.5 mm) - 10 ft (3.0 m)

C6 LC0166 Recirculating, On-Board Tanks,

1/4 in. (6.5 mm) - 15 ft (4.6 m)

C7 LC0167 Recirculating, On-Board Tanks,

3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

C8 LC0168 Recirculating, On-Board Tanks,

3/8 in. (9.5 mm) - 10 ft (3.0 m)

C9 LC0169 Recirculating, On-Board Tanks,

3/8 in. (9.5 mm) - 15 ft (4.6 m)

CA LC0170 Recirculating, On-Board Tanks,

1/2 in. (13 mm) - 2.5 ft (0.6 m)

CB LC0171 Recirculating, On-Board Tanks,

1/2 in. (13 mm) - 10 ft (3.0 m)

CC LC0172 Recirculating, On-Board Tanks,

1/2 in. (13 mm) - 15 ft (4.6 m)

CD LC0173 Recirculating, On-Board Tanks,

3/4 in. (19 mm) - 10 ft (3.0 m)

CE LC0174 Recirculating, On-Board Tanks,

3/4 in. (19 mm) - 15 ft (4.6 m)

D1 LC0175 Recirculating, Off-Board Tanks,

3/16 in. (4.8 mm) - 2.5 ft (0.6 m)

D2 LC0176 Recirculating, Off-Board Tanks,

3/16 in. (4.8 mm) - 10 ft (3.0 m)

D3 LC0177 Recirculating, Off-Board Tanks,

3/16 in. (4.8 mm) - 15 ft (4.6 m)

D4 LC0178 Recirculating, Off-Board Tanks,

1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

D5 LC0179 Recirculating, Off-Board Tanks,

1/4 in. (6.5 mm) - 10 ft (3.0 m)

D6 LC0180 Recirculating, Off-Board Tanks,

1/4 in. (6.5 mm) - 15 ft (4.6 m)

D7 LC0181 Recirculating, Off-Board Tanks,

3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

D8 LC0182 Recirculating, Off-Board Tanks,

3/8 in. (9.5 mm) - 10 ft (3.0 m)

D9 LC0183 Recirculating, Off-Board Tanks,

3/8 in. (9.5 mm) - 15 ft (4.6 m)

DA LC0184 Recirculating, Off-Board Tanks,

1/2 in. (13 mm) - 2.5 ft (0.6 m)

DB LC0185 Recirculating, Off-Board Tanks,

1/2 in. (13 mm) - 10 ft (3.0 m)

DC LC0186 Recirculating, Off-Board Tanks,

1/2 in. (13 mm) - 15 ft (4.6 m)

DD LC0187 Recirculating, Off-Board Tanks,

3/4 in. (19 mm) - 10 ft (3.0 m)

DE LC0188 Recirculating, Off-Board Tanks,

3/4 in. (19 mm) - 15 ft (4.6 m)

E1 LC0190 Recirculating, Heated, On-Board

Tanks, 1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

E2 LC0191 Recirculating, Heated, On-Board

Tanks, 1/4 in. (6.5 mm) - 10 ft (3.0 m)

E3 LC0192 Recirculating, Heated, On-Board

Tanks, 1/4 in. (6.5 mm) - 15 ft (4.6 m)

E4 LC0193 Recirculating, Heated, On-Board

Tanks, 3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

E5 LC0194 Recirculating, Heated, On-Board

Tanks, 3/8 in. (9.5 mm) - 10 ft (3.0 m)

E6 LC0195 Recirculating, Heated, On-Board

Tanks, 3/8 in. (9.5 mm) - 15 ft (4.6 m)

E7 LC0196 Recirculating, Heated, On-Board

Tanks, 1/2 in. (13 mm) - 2.5 ft (0.6 m)

E8 LC0197 Recirculating, Heated, On-Board

Tanks, 1/2 in. (13 mm) - 10 ft (3.0 m)

E9 LC0198 Recirculating, Heated, On-Board

Tanks, 1/2 in. (13 mm) - 15 ft (4.6 m)

EA LC0199 Recirculating, Heated, On-Board

Tanks, 3/4 in. (19 mm) - 10 ft (3.0 m)

EB LC0200 Recirculating, Heated, On-Board

Tanks, 3/4 in. (19 mm) - 15 ft (4.6 m)

F1 LC0201 Recirculating, Heated, Off-Board

Tanks, 1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

F2 LC0202 Recirculating, Heated, Off-Board

Tanks, 1/4 in. (6.5 mm) - 10 ft (3.0 m)

F3 LC0203 Recirculating, Heated, Off-Board

Tanks, 1/4 in. (6.5 mm) - 15 ft (4.6 m)

F4 LC0204 Recirculating, Heated, Off-Board

Tanks, 3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

F5 LC0205 Recirculating, Heated, Off-Board

Tanks, 3/8 in. (9.5 mm) - 10 ft (3.0 m)

F6 LC0206 Recirculating, Heated, Off-Board

Tanks, 3/8 in. (9.5 mm) - 15 ft (4.6 m)

F7 LC0207 Recirculating, Heated, Off-Board

Tanks, 1/2 in. (13 mm) - 2.5 ft (0.6 m)

F8 LC0208 Recirculating, Heated, Off-Board

Tanks, 1/2 in. (13 mm) - 10 ft (3.0 m)

F9 LC0209 Recirculating, Heated, Off-Board

Tanks, 1/2 in. (13 mm) - 15 ft (4.6 m)

FA LC0210 Recirculating, Heated, Off-Board

Tanks, 3/4 in. (19 mm) - 10 ft (3.0 m)

FB LC0211 Recirculating, Heated, Off-Board

Tanks, 3/4 in. (19 mm) - 15 ft (4.6 m)

GA LC0400 High Pressure, 3/8 in. (9.5 mm) - 2.5 ft

(0.6 m)

GB LC0401 High Pressure, 3/8 in. (9.5 mm) - 10 ft

(3.0 m)

GC LC0402 High Pressure, 3/8 in. (9.5 mm) - 15 ft

(4.6 m)

GD LC0403 High Pressure, 1/2 in. (13 mm) - 2.5 ft

(0.6 m)

GE LC0404 High Pressure, 1/2 in. (13 mm) - 10 ft

(3.0 m)

GF LC0405 High Pressure, 1/2 in. (13 mm) - 15 ft

(4.6 m)

6 312760S

Page 7

Product Configurator

GH LC0406 High Pressure, 3/4 in. (19 mm) - 10 ft

(3.0 m)

GJ LC0407 High Pressure, 3/4 in. (19 mm) - 15 ft

(4.6 m)

GK LC0432 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

GL LC0433 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 10 ft (3.0 m)

GM LC0434 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 15 ft (4.6 m)

GQ LC0435 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 2.5 ft (0.6 m)

GR LC0436 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 10 ft (3.0 m)

GS LC0437 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 15 ft (4.6 m)

GT LC0438 High Pressure, Recirculating,

On-Board Tanks,

3/4 in. (19 mm) - 10 ft (3.0 m)

GU LC0439 High Pressure, Recirculating,

On-Board Tanks,

3/4 in. (19 mm) - 15 ft (4.6 m)

GW LC0440 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

GX LC0441 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 10 ft (3.0 m)

GY LC0442 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 15 ft (4.6 m)

G1 LC0443 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 2.5 ft (0.6 m)

G2 LC0444 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 10 ft (3.0 m)

G3 LC0445 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 15 ft (4.6 m)

G4 LC0446 High Pressure, Recirculating,

On-Board Tanks,

3/4 in. (19 mm) - 10 ft (3.0 m)

G5 LC0447 High Pressure, Recirculating,

On-Board Tanks,

3/4 in. (19 mm) - 15 ft (4.6 m)

HA LC0472 High Pressure, Heated, 3/8 in. (9.5

mm) - 2.5 ft (0.6 m)

HB LC0473 High Pressure, Heated, 3/8 in. (9.5

mm) - 10 ft (3.0 m)

HC LC0474 High Pressure, Heated, 3/8 in. (9.5

mm) - 15 ft (4.6 m)

HF LC0475 High Pressure, Heated, 1/2 in. (13

mm) - 2.5 ft (0.6 m)

HG LC0476 High Pressure, Heated, 1/2 in. (13

mm) - 10 ft (3.0 m)

HJ LC0477 High Pressure, Heated, 1/2 in. (13

mm) - 15 ft (4.6 m)

HL LC0478 High Pressure, Heated, 3/4 in. (19

mm) - 10 ft (3.0 m)

HM LC0479 High Pressure, Heated, 3/4 in. (19

mm) - 15 ft (4.6 m)

HQ LC0480 High Pressure, Heated, 3/8 in. (9.5

mm) - 2.5 ft (0.6 m)

HR LC0481 High Pressure, Heated, 3/8 in. (9.5

mm) - 10 ft (3.0 m)

HS LC0482 High Pressure, Heated, 3/8 in. (9.5

mm) - 15 ft (4.6 m)

HT LC0483 High Pressure, Heated, 1/2 in. (13

mm) - 2.5 ft (0.6 m)

HU LC0484 High Pressure, Heated, 1/2 in. (13

mm) - 10 ft (3.0 m)

HX LC0485 High Pressure, Heated, 1/2 in. (13

mm) - 15 ft (4.6 m)

HY LC0486 High Pressure, Heated, 3/4 in. (19

mm) - 10 ft (3.0 m)

H2 LC0487 High Pressure, Heated, 3/4 in. (19

mm) - 15 ft (4.6 m)

NN --- Not required

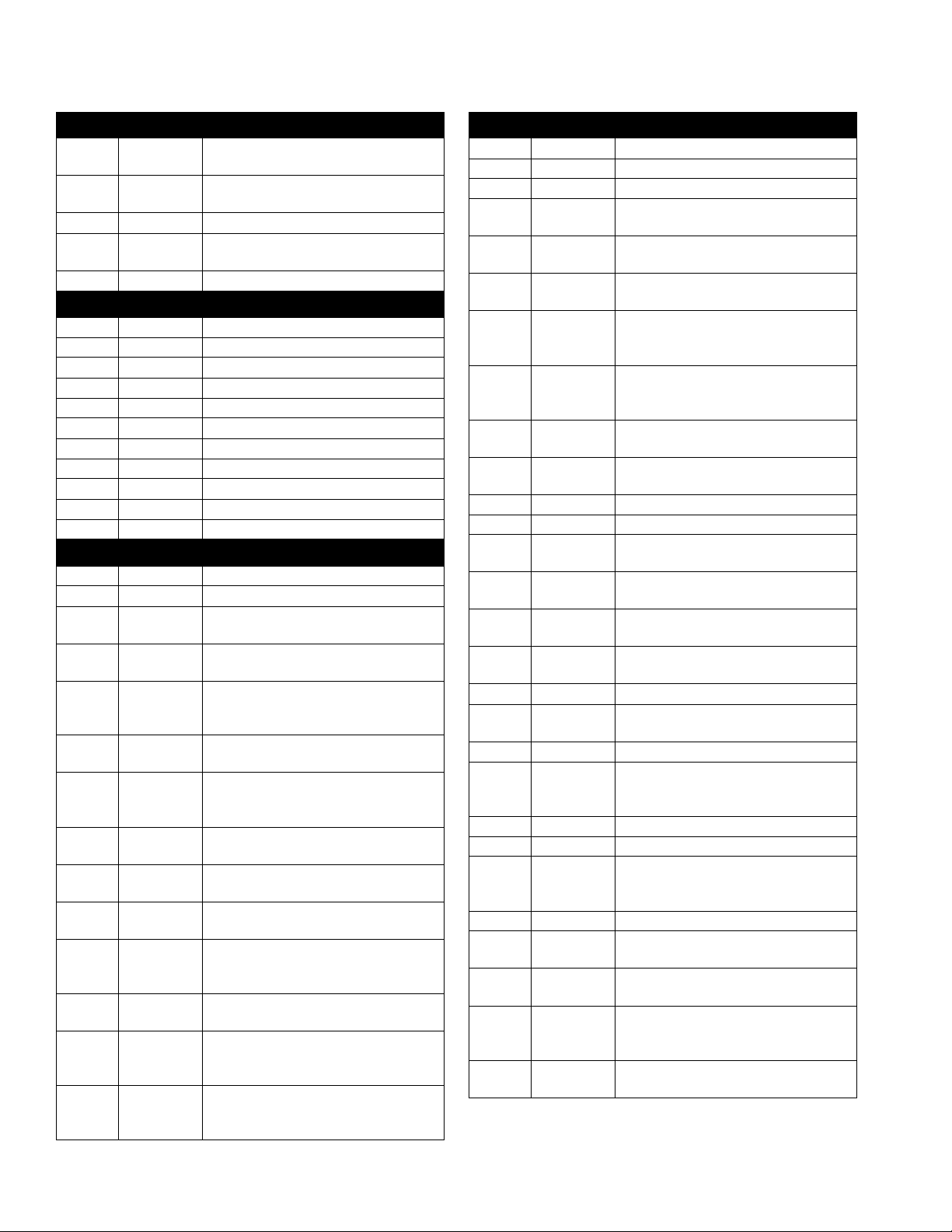

Code K Part Dispense Valve

NN/ANone

2 255179 MD2, Valve Only with 1:1 Nose

3 255181 MD2, Valve Only with 10:1 Nose

4 LC0120 MD2, Handheld with 1:1 Nose

5 LC0122 MD2, Handheld with 10:1 Nose

6 LC0121 MD2, Lever with 1:1 Nose

7 LC0123 MD2, Lever with 10:1 Nose

Code L Par t Mixer Type

NN/ANone

1 LC0063 3/16 in. (4.8 mm) x 32

2 LC0057 1/4 in. (6.4 mm) x 24

3 LC0058 3/8 in. (9.5 mm) x 24

4 LC0059 3/8 in. (9.5 mm) x 36

5 LC0060 3/8 in. (9.5 mm) Combo

6 LC0062 1/4 in. (6.4 mm) x 24 Luer Lock

7 LC0061 3/16 in. (4.8 mm) x 32 Luer Lock

8 LC0295 1/2 in. (12.7 mm) x 24

9 LC0296 1/2 in. (12.7 mm) x 36

312760S 7

Page 8

Product Configurator

Code M Part Applicator Mounting

N LC0294 None, Customer Mount Controls and

Applicator

1 LC0292 Mast Mount, Controls & MD2 Applica-

tor Machine Mounted

2 LC0293 Mast Mount, Controls Only

3 256439 Tank Stand Mount, Controls & MD2

Applicator Machine Mounted

4 256438 Tank Stand Mount, Controls Only

Code N Part Power Cord Option

1 121055 120VAC North American Cord Set

2 121054 10A, 250V US Cord Set

3 121056 10A, 250V Continental europe

4 121057 10A, 250V U.K./Ireland

5 121058 10A, 250V Israel

6 124864 10A, 250V Australia

7 124861 10A, 250V Italy

8 124863 10A, 250V Switzerland

9 124862 10A, 250V Denmark

A 121060 10A, 250V India

B N/A Heat Controller Option

Code O Part Flow Monitoring

N LC0041 None

1 257433 Pressure Transducer

2 LC0302 Two 0.5 gpm Flow Meters, No Pres-

sure Transducers

3 LC0305 Two 1.0 gpm Flow Meters, No Pres-

sure Transducers

4 LC0303 One 1.0 gpm Flow Meter, One

0.5 gpm Flow Meter, No Pressure

Transducers

5 LC0307 Two 2.0 gpm Flow Meters, No Pres-

sure Transducers

6 LC0306 One 2.0 gpm Flow Meter, One

1.0 gpm Flow Meter, No Pressure

Transducers

7 LC0304 One 2.0 gpm Flow Meter, One 0.5 gpm

Flow Meter, No Pressure Transducers

A LC0312 Two 0.5 gpm Flow Meters, With Pres-

sure Transducers

B LC0315 Two 1.0 gpm Flow Meters, With Pres-

sure Transducers

C LC0313 One 1.0 gpm Flow Meter, One

0.5 gpm Flow Meter, With Pressure

Transducers

D LC0317 Two 2.0 gpm Flow Meters, With Pres-

sure Transducers

E LC0316 One 2.0 gpm Flow Meter, One

1.0 gpm Flow Meter, With Pressure

Transducers

F LC0314 One 2.0 gpm Flow Meter, One 0.5 gpm

Flow Meter, With Pressure Transduc-

ers

Code P Part High Volume Side Tank

NN/ANone

1 256896 No Tanks, 1 1/2 in. npt flange

2 255241 8 L, Twin Polyethylene Tanks and Lids

3 255250 8 L, Twin Polyethylene Tanks and Lids,

One 120V Agitator

4 255251 8 L, Twin Polyethylene Tanks and Lids,

Two 120V Agitators

5 255281 8 L, Twin Polyethylene Tanks and Lids,

with Shut-Off Valves

6 255282 8 L, Twin Polyethylene Tanks and Lids,

One 120V Agitator, with Shut-Off

Valves

7 255283 8 L, Twin Polyethylene Tanks and Lids,

Two 120V Agitators, with Shut-Off

Valves

8 LC0235★ 7.5 L, Stainless Steel, High Level Sen-

sors

9 LC0236★ 7.5 L, Stainless Steel, High Level Sen-

sors, with Shut-Off Valve

A LC0013★ 3 L, Stainless Steel

B LC0012★ 7.5 L, Stainless Steel

C 255285★ 3 L, Stainless Steel, with Shut-Off

Valve

D LC0156 8 L, Twin Polyethylene Tanks and Lids,

One Pneumatic Agitator

E LC0157 8 L, Twin Polyethylene Tanks and Lids,

Two Pneumatic Agitator

F 255284★ 7.5 L, Stainless Steel, with Shut-Off

Valve

G LC0254★ 7.5 L, Stainless Steel, 240V Heat

H LC0255★ 7.5 L, Stainless Steel, 240V Heat,

with Shut-Off Valve

J LC0054 30 L, Stainless Steel

K LC0158 8 L, Twin Polyethylene Tanks and Lids,

One Pneumatic Agitator, with Shut-Off

Valves

L LC0259 30 L, Stainless Steel, 240V Heat

M LC0055 60 L, Stainless Steel

P LC0159 8 L, Twin Polyethylene Tanks and Lids,

Two Pneumatic Agitators, with

Shut-Off Valves

R LC0260 60 L, Stainless Steel, 240V Heat

S LC0126 8 L, Twin Polyethylene Tanks and Lids,

One 240V Agitator

T LC0127 8 L, Twin Polyethylene Tanks and Lids,

Two 240V Agitators

U LC0128 8 L, Twin Polyethylene Tanks and Lids,

One 240V Agitator, with Shut-Off

Valves

V LC0238★ 7.5 L, Stainless Steel, High Level Sen-

sors, 240V Heat, with Shut-Off Valve

8 312760S

Page 9

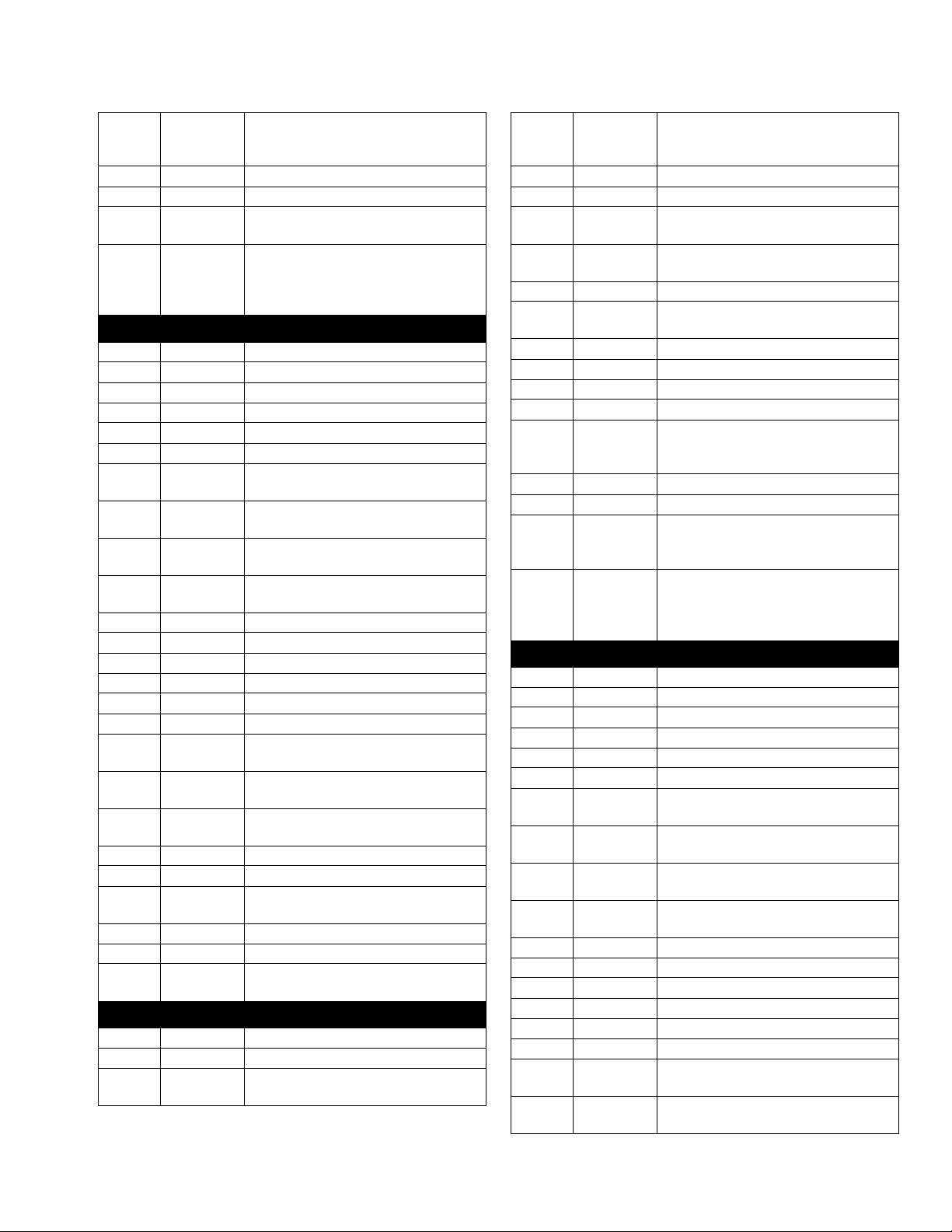

Product Configurator

W LC0129 8 L, Twin Polyethylene Tanks and Lids,

Two 240V Agitators, with Shut-Off

Val ves

X LC0160 Accumulator, Fluoroelastomer

Y LC0297 Accumulator, EP

Z LC0237★ 7.5 L, Stainless Steel, High Level Sen-

sors, 240V Heat

--- ★ When ordering tanks for spare or

replacement parts, refer to Parts section of the PR70 and PR70v Feed Systems manual.

Code Q Part High Volume Side Tank Cover

N N/A None

1 LC0018 On-Board Dust Cover

2 LC0019 On-Board Clamp Down

3 LC0020 On-Board Vacuum De-gas

4 LC0021 On-Board Agitate 120VAC 50/60 Hz

5 LC0022 On-Board Agitate 240VAC 50/60 Hz

6 LC0023 On-Board Agitate 120 VAC 50/60 Hz

and De-gas

7 LC0024 On-Board Agitate 240 VAC 50/60 Hz

and De-gas

8 LC0025 On-Board 120VAC 50/60 Hz, De-gas

and Fill-Port

9 LC0026 On-Board 240 VAC 50/60 Hz, De-gas

and Fill-Port

A LC0142 Off-Board Clamp Down - 30L

B LC0101 Off-Board Clamp Down - 60L

C LC0043 Off-Board Vacuum De-gas - 30L

F LC0102 Off-Board Vacuum De-gas - 60L

G LC0047 Off-Board Electric Agitator - 30L

H LC0048 Off-Board Electric Agitator - 60L

K LC0147 Off-Board Vacuum De-gas, Pneu-

matic Agitator, Fill Port, Slinger - 60 L

M LC0051 Off-Board Vacuum De-gas, Electric

Agitator, Fill Port, Slinger - 30 L

R LC0052 Off-Board Vacuum De-gas, Electric

Agitator, Fill Port, Slinger - 60 L

S LC0130 On-Board, Pneumatic Agitate

T LC0131 On-Board, Pneumatic Agitate, De-gas

U LC0132 On-Board, Pneumatic Agitate, De-gas,

Fill Port

V LC0142 Off-Board Pneumatic Agitator - 30 L

W LC0143 Off-Board Pneumatic Agitator - 60 L

Z LC0146 Off-Board Vacuum De-gas, Pneu-

matic Agitator, Fill Port, Slinger - 30 L

Code R Part Low Volume Side Tank

N N/A None

1 256896 No Tanks, 1 1/2 in. npt flange

8 LC0235★ 7.5 L, Stainless Steel, High Level Sen-

sors

9 LC0236★ 7.5 L, Stainless Steel, High Level Sen-

sors,

with Shut-Off Valve

A LC0013★ 3 L, Stainless Steel

B LC0012★ 7.5 L, Stainless Steel

C 255285★ 3 L, Stainless Steel, with Shut-Off

Valve

F 255284★ 7.5 L, Stainless Steel, with Shut-Off

Valve

G LC0254★ 7.5 L, Stainless Steel, 240V Heat

H LC0255★ 7.5 L, Stainless Steel, 240V Heat,

with Shut-Off Valve

J LC0054 30 L, Stainless Steel

L LC0259 30 L, Stainless Steel, 240V Heat

M LC0055 60 L, Stainless Steel

R LC0260 60 L, Stainless Steel, 240V Heat

V LC0238★ 7.5 L, Stainless Steel, High Level Sen-

sors,

240V Heat, with Shut-Off Valve

X LC0160 Accumulator, Fluoroelastomer

Y LC0297 Accumulator, EP

Z LC0237★ 7.5 L, Stainless Steel, High Level Sen-

sors,

240V Heat

--- ★ When ordering tanks for spare or

replacement parts, refer to Parts section of the PR70 and PR70v Feed Systems manual.

Code S Part Low Volume Side Tank Covers

NN/ANone

1 LC0018 On-Board Dust Cover

2 LC0019 On-Board Clamp Down

3 LC0020 On-Board Vacuum De-gas

4 LC0021 On-Board Agitate 120VAC 50/60 Hz

5 LC0022 On-Board Agitate 240VAC 50/60 Hz

6 LC0023 On-Board Agitate 120 VAC 50/60 Hz

and De-gas

7 LC0024 On-Board Agitate 240 VAC 50/60 Hz

and De-gas

8 LC0025 On-Board 120VAC 50/60 Hz, De-gas

and Fill-Port

9 LC0026 On-Board 240 VAC 50/60 Hz, De-gas

and Fill-Port

A LC0142 Off-Board Clamp Down - 30L

B LC0101 Off-Board Clamp Down - 60L

C LC0043 Off-Board Vacuum De-gas - 30L

F LC0102 Off-Board Vacuum De-gas - 60L

G LC0047 Off-Board Electric Agitator - 30L

H LC0048 Off-Board Electric Agitator - 60L

K LC0147 Off-Board Vacuum De-gas, Pneu-

matic Agitator, Fill Port, Slinger - 60 L

M LC0051 Off-Board Vacuum De-gas, Electric

Agitator, Fill Port, Slinger - 30 L

312760S 9

Page 10

Product Configurator

R LC0052 Off-Board Vacuum De-gas, Electric

Agitator, Fill Port, Slinger - 60 L

S LC0130 On-Board, Pneumatic Agitate

T LC0131 On-Board, Pneumatic Agitate, De-gas

U LC0132 On-Board, Pneumatic Agitate, De-gas,

Fill Port

V LC0142 Off-Board Pneumatic Agitator - 30 L

W LC0143 Off-Board Pneumatic Agitator - 60 L

Z LC0146 Off-Board Vacuum De-gas, Pneu-

matic Agitator, Fill Port, Slinger - 30 L

Code T Part Tank Level Sensors

N N/A None

2 LC0278 Polyethylene Tanks - Low Level Sen-

sors Only

3 LC0279 Two 7.5 L Stainless Steel Tanks - Low

Level Sensors Only

4 LC0282 Two 30 L or 60 L Stainless Steel Tanks

- Low Level Sensors Only

5 LC0281 7.5 L Stainless Steel - Low Level Sen-

sors Only, and 30 L or 60 L Stainless

Steel - Low Level Sensors Only

6 LC0280 Accumulator Sensors, and 7.5 L Low

Level Sensors

7 LC0283 Accumulator Sensors, and 30 L or

60 L Low Level Sensors

9 LC0284 Two 7.5 L Stainless Steel Tanks - High

and Low Level Sensors with Refill

Logic

A LC0287 Two 30 L or 60 L Stainless Steel Tanks

- High and Low Level Sensors with

Refill Logic

B LC0286 7.5 L Stainless Steel - Low Level Sen-

sors, and

30 L or 60 L Stainless Steel - High and

Low Level Sensors with Refill Logic

C LC0289 7.5 L Stainless Steel - High and Low

Level Sensors with Refill Logic, and

30 L or 60 L Stainless Steel - High and

Low Level Sensors with Refill Logic

D LC0285 Accumulator Sensors, and 7.5 L High

and Low Level Sensors

E LC0288 Accumulator Sensors, and 30 L or

60 L High and Low Level Sensors

G N/A Two Sets of Accumulator Sensors

Code U Part Heat Zone Controller

NN/ANone

C LC0250 1 Tank or 1 Hose

D LC0251 2 Tanks, 1 Tank and 1 Hose, or 2

Hoses

E LC0252 2 Tanks and 1 Hose, or 1 Tank and 2

Hoses

F LC0253 2 Tanks and 2 Hoses

Code V Part Off-Board Tank Stands

NN/ANone

2 LC0103 PR70 Tank Stand

3 LC0247 PR70v Tank Stand

10 312760S

Page 11

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

312760S 11

Page 12

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

12 312760S

Page 13

Warnings

312760S 13

Page 14

Grounding

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current. This product is equipped with a cord having a

grounding wire with an appropriate grounding plug. The

plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Improper installation of the grounding plug is able to

result in a risk of electric shock. When repair or replacement of the cord or plug is required, do not connect the

grounding wire to either flat blade terminal. The wire

with insulation having an outer surface that is green with

or without yellow stripes is the grounding wire. Do not

modify the plug provided; if it does not fit the outlet, have

the proper outlet installed by a qualified electrician. Only

connect the product to an outlet having the same configuration as the plug. Do not use an adapter with this

product.

5. Press the system air pressure relief switch down to

stop air supply and to vent air pressure in the

machine. It is the yellow tab at the left, rear of the

machine. The hole in the tab should be visible.

6. If necessary, run a lock through the hole to lock the

tab in place. This prevents the system air pressure

from being inadvertently enabled.

Models with Standard Display Module

With the machine in an idle state:

1. If the machine pistons are not fully retracted, retract

the pistons by pressing in the M1 screen. See

manual 3A0429 for more information.

2. Manually open the dispense valve by pressing the

third M1 soft key until the “ ” ICON is shown in the

Current DV field. See manual 3A0429 for more information.

Pressure Relief Procedure

Models with Advanced Display Module

1. Place a waste container below the dispense valve.

2. Navigate to the Manual screen.

3. Press the Open Dispense Valve button on the Manual screen to relieve chemical pressure.

4. Press the Machine Disable Mode button ( ).

3. Press the system air pressure relief switch down to

stop air supply and to vent air pressure in the

machine. It is the yellow tab at the left, rear of the

machine. The hole in the tab should be visible.

4. If necessary, run a lock through the hole to lock the

tab in place. This prevents the system air pressure

from being inadvertently enabled.

Shutdown

If the machine is to remain idle for an extended period of

time, perform the following steps.

1. Place a waste container below the dispense valve.

2. If installed, remove static mixer from the end of the

dispense valve.

14 312760S

Page 15

3. Place a container below the dispense valve and

activate a small shot to flush mixed material out of

the valve.

4. Relieve pressure. See Pressure Relief Procedure.

5. With a clean rag and cotton swabs, clean the end of

the dispense valve.

6. Install nightcap on the dispense valve.

Shutdown

312760S 15

Page 16

Troubleshooting

Troubleshooting

Before starting any troubleshooting procedures, perform

the following procedure.

1. Relieve pressure. See Pressure Relief Procedure,

page 14.

2. Disconnect AC power from the machine.

Problem Cause Solution

Display Module completely dark No power Verify rear AC Power switch is ON.

Fuse blown Replace machine fuses.

Loose connection Tighten 5-pin cable on Display Mod-

Bad display module Replace Display Module.

No or incorrect amount of material

dispensed from either side.

Piston stalled Input air reduced or removed Reconnect input air line to machine.

Significant material leaking from

pump rear seal

Ball valve closed (if installed) Open tank ball valve.

Tank empty Fill tank with material.

Tank clogged Verify no obstruction in the tank.

Air in material Prime the machine until the air is

Check valve malfunction Remove; clean or replace check

Piston worn or broken Remove and replace piston if worn.

Mixer blocked Replace static mixer.

Open Dispense Valve (ODV) adjustment too late

Blocked check valve Remove check valve; clean and

Air cylinder failure Remove air cylinder and reinstall air

Pump shaft worn Remove pump shaft assembly, and

3. Allow the machine to cool if the machine has a heat

control option.

Try the recommended solutions in the order given for

each problem to avoid unnecessary repairs. Verify all

circuit breakers, switches, and controls are properly set

and wiring is correct.

ule.

removed.

valve.

Increase air pressure regulator

adjustment.

Incorporate purge timer or decrease

purge timer delay to prevent mixer

blockage.

Readjust the ODV setting to occur

sooner.

replace.

cylinder parts as necessary.

reinstall rear pump rebuilt kit.

16 312760S

Page 17

Troubleshooting

Problem Cause Solution

Material dispensed not correct weight Specific gravity of one or more of the

Recalibrate machine.

two materials has changed since calibration

Machine air pressure has changed

since calibration.

Readjust air pressure regulator to

value used when machine was cali-

brated, or recalibrate machine.

Not enough material in one or more

tanks

Check tank levels; fill and prime as

necessary.

Mixer has slight obstruction Replace static mixer. Prime machine.

Check valve malfunction Remove check valve; clean or

replace as necessary.

Piston worn or broken Replace piston.

Machine dispensing off ratio One tank is empty Check tank levels. Add material if

necessary.

Tank ball valve closed Open tank ball valve. Prime machine.

Machine out of phase Rephase machine.

Check valve malfunction Remove check valve; clean or

replace as necessary.

Piston worn or broken Replace piston.

Pumps drawing material back from

valve hose

Check valve stuck open Remove check valve, clean or

replace as necessary.

312760S 17

Page 18

Troubleshooting

Error Codes (Advanced Display Module)

Code-Class-Event

Shown on Errors Screen Description

050X-A-Improper System Cal Improper Calibration 5

06CX-A-Invalid Key Token No or Invalid Key Token 4

A401-A-Over Current Z1 Heater Over Current, Zone #1 7

A402-A-Over Current Z2 Heater Over Current, Zone #2 7

A403-A-Over Current Z3 Heater Over Current, Zone #3 7

A404-A-Over Current Z4 Heater Over Current, Zone #4 7

A4C1-A-Fan Over Current Z1 High Relay 2 Current, Zone #1 7

A4C2-A-Fan Over Current Z2 High Relay 2 Current, Zone #2 7

A4C3-A-Fan Over Current Z3 High Relay 2 Current, Zone #3 7

A4C4-A-Fan Over Current Z4 High Relay 2 Current, Zone #4 7

A701-A-Heater Fault Z1 Unexpected Heater Current, Zone #1 7

A702-A-Heater Fault Z2 Unexpected Heater Current, Zone #2 7

A703-A-Heater Fault Z3 Unexpected Heater Current, Zone #3 7

System

Behavior Ref

A704-A-Heater Fault Z4 Unexpected Heater Current, Zone #4 7

A7C1-A-Fan Output Fault Z1 Unexpected Relay 2 Current, Zone #1 7

A7C2-A-Fan Output Fault Z2 Unexpected Relay 2 Current, Zone #2 7

A7C3-A-Fan Output Fault Z3 Unexpected Relay 2 Current, Zone #3 7

A7C4-A-Fan Output Fault Z4 Unexpected Relay 2 Current, Zone #4 7

B10X-A-Small Shot Request Less Than Minimum Shot Requested 5

CAC1-A-Comm. Error FCM 1 Communication Error, FCM3 #1 2

CAC1-A-Comm. Error FCM2 Communication Error, FCM3 #2 3

CAC1-A-Comm. Error Heat Z1 Communication Error, Heat Zone #1 1

CAC1-A-Comm. Error Heat Z2 Communication Error, Heat Zone #2 1

CAC1-A-Comm. Error Heat Z3 Communication Error, Heat Zone #3 1

CAC1-A-Comm. Error Heat Z4 Communication Error, Heat Zone #4 1

DEFX-A-Piston Timeout Piston Stroke Timeout 5

DJ0X-D-Linear Sensor Fault Bad Linear Position Sensor 6

F2A-Low Flow A Side Low A Side Fluid Flow, relative to calibra-

tion and user-input allowable variance.

6

18 312760S

Page 19

Troubleshooting

Code-Class-Event

Shown on Errors Screen Description

System

Behavior Ref

F2B-Low Flow B Side Low B Side Fluid Flow, relative to calibra-

tion and user-input allowable variance.

F2FX-D-Delta Velocity Minus Delta Velocity Minus 6

F3FX-D-Delta Velocity Plus Delta Velocity Plus 6

F6A-Flow Meter A Problem Flow Meter A Problem, or bad connection

between Fluid Control Module and Flow

Meter A

F6B-Flow Meter B Problem Flow Meter B Problem, or bad connection

between Fluid Control Module and Flow

Meter B

L2AX-D-Low Level Tank A Low Material Level, Tank A 6

L2BX-D-Low Level Tank B Low Material Level, Tank B 6

L2FX-D-Low Level Tank A/B Low Material Level, Both Tanks 6

L8AX-D-Refill Timeout A Auto Refill Failed, A Side 6

L8AX-D-Refill Timeout B Auto Refill Failed, B Side 6

6

6

6

P2AX-D-Low Pressure A A Side Low Pressure, relative to calibra-

tion and user-input allowable variance.

P2BX-D-Low Pressure B B Side Low Pressure, relative to calibra-

tion and user-input allowable variance.

P3AX-D-High Pressure A A Side High Pressure, relative to calibra-

tion and user-input allowable variance.

P3BX-D-High Pressure B B Side High Pressure, relative to calibra-

tion and user-input allowable variance.

P6AX-D-Pressure Fault A Problem with A Side Piston Pressure

Transducer or Transducer Connection

P6BX-D-Pressure Fault B Problem with B Side Piston Pressure

Transducer or Transducer Connection

P6DX-D-Pressure Fault A/B Problem with A and B Side Piston Pres-

sure Transducer or Transducer Connection

P7DX-D-Out of Phase Machine Out of Phase, relative to calibra-

tion and user-input allowable variance.

R2-A:B Ratio Low A:B Ratio is low, relative to calibration and

user-input allowable variance.

6

6

6

6

6

6

6

6

6

R3-A:B Ratio High A:B Ratio is high, relative to calibration

6

and user-input allowable variance.

T201-D-Low Material Temp Z1 Material Below Temperature, Zone #1 8

T202-D-Low Material Temp Z2 Material Below Temperature, Zone #2 8

312760S 19

Page 20

Troubleshooting

Code-Class-Event

Shown on Errors Screen Description

System

Behavior Ref

T203-D-Low Material Temp Z3 Material Below Temperature, Zone #3 8

T204-D-Low Material Temp Z4 Material Below Temperature, Zone #4 8

T401-A-High Material Temp Z1 Material Over Temperature, Zone #1 7

T402-A-High Material Temp Z2 Material Over Temperature, Zone #2 7

T403-A-High Material Temp Z3 Material Over Temperature, Zone #3 7

T404-A-High Material Temp Z4 Material Over Temperature, Zone #4 7

T4C1-A-Blanket Over Temp Z1 Blanket Over Temperature, Zone #1 7

T4C2-A-Blanket Over Temp Z2 Blanket Over Temperature, Zone #2 7

T4C3-A-Blanket Over Temp Z3 Blanket Over Temperature, Zone #3 7

T4C4-A-Blanket Over Temp Z4 Blanket Over Temperature, Zone #4 7

T601-A-Material RTD Fault Z1 Material RTD Fault, Zone #1 7

T602-A-Material RTD Fault Z2 Material RTD Fault, Zone #2 7

T603-A-Material RTD Fault Z3 Material RTD Fault, Zone #3 7

T604-A-Material RTD Fault Z4 Material RTD Fault, Zone #4 7

T6C1-A-Blanket RTD Fault Z1 Blanket RTD Fault, Zone #1 7

T6C2-A-Blanket RTD Fault Z2 Blanket RTD Fault, Zone #2 7

T6C3-A-Blanket RTD Fault Z3 Blanket RTD Fault, Zone #3 7

T6C4-A-Blanket RTD Fault Z4 Blanket RTD Fault, Zone #4 7

T801-A-No Heat Z1 No Temperature Rise, Zone #1 7

T802-A-No Heat Z2 No Temperature Rise, Zone #2 7

T803-A-No Heat Z3 No Temperature Rise, Zone #3 7

T804-A-No Heat Z4 No Temperature Rise, Zone #4 7

T901-A-Temp Switch Cutoff Z1 Over Temp Switch Open, Zone #1 7

T902-A-Temp Switch Cutoff Z2 Over Temp Switch Open, Zone #2 7

T903-A-Temp Switch Cutoff Z3 Over Temp Switch Open, Zone #3 7

T904-A-Temp Switch Cutoff Z4 Over Temp Switch Open, Zone #4 7

T9C1-A-Control Shutdown Z1 PCB Over Temperature, Zone #1 7

T9C2-A-Control Shutdown Z2 PCB Over Temperature, Zone #2 7

T9C3-A-Control Shutdown Z3 PCB Over Temperature, Zone #3 7

T9C4-A-Control Shutdown Z4 PCB Over Temperature, Zone #4 7

WM01-A-Current Fault Z1 High Relay 1 Current, Zone #1 7

20 312760S

Page 21

Troubleshooting

Code-Class-Event

Shown on Errors Screen Description

WM02-A-Current Fault Z2 High Relay 1 Current, Zone #2 7

WM03-A-Current Fault Z3 High Relay 1 Current, Zone #3 7

WM04-A-Current Fault Z4 High Relay 1 Current, Zone #4 7

WMC1-A-Control Fault Z1 Unexpected Relay 1 Current, Zone #1 7

WMC2-A-Control Fault Z2 Unexpected Relay 1 Current, Zone #2 7

WMC3-A-Control Fault Z3 Unexpected Relay 1 Current, Zone #3 7

WMC4-A-Control Fault Z4 Unexpected Relay 1 Current, Zone #4 7

System

Behavior Ref

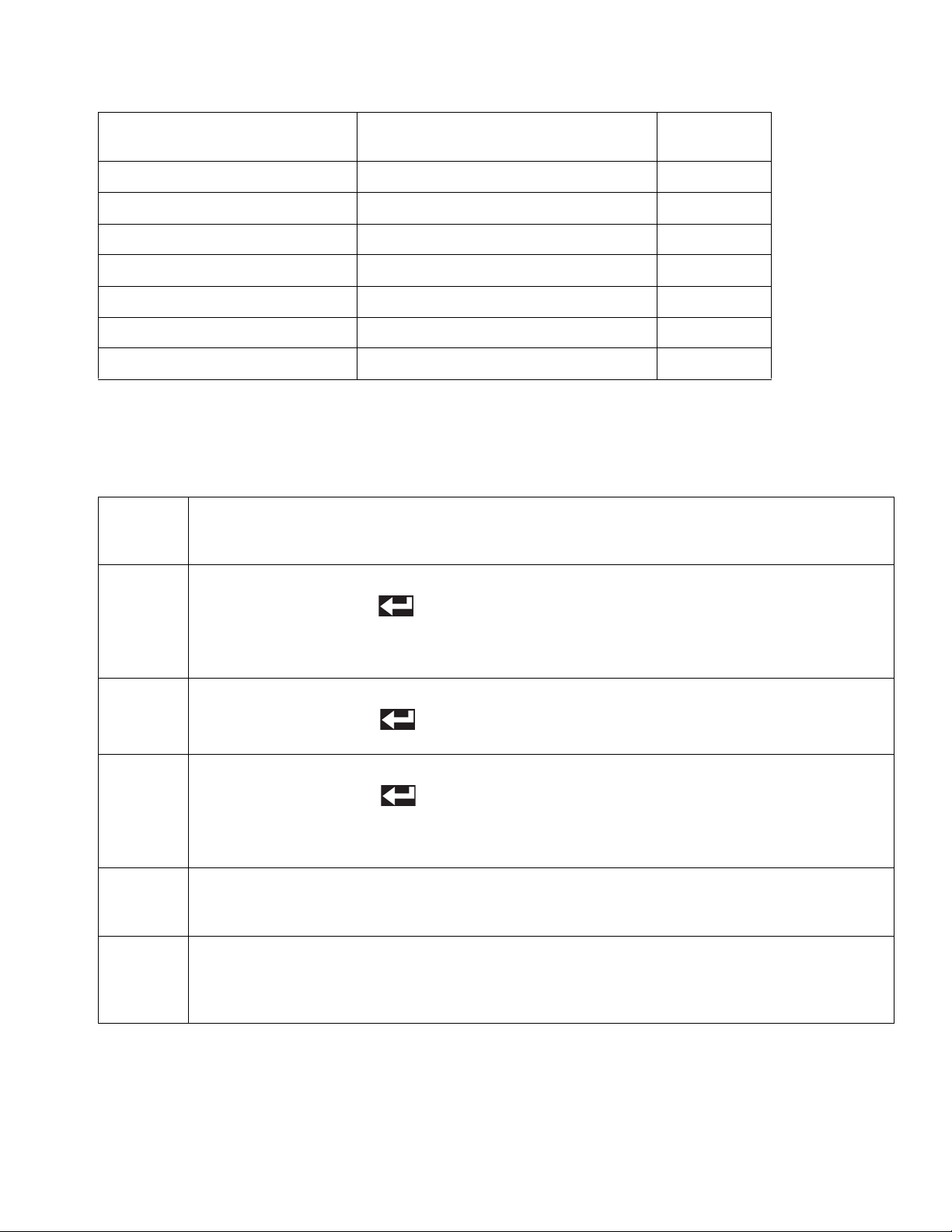

System Behavior Descriptions

NOTE: System behavior descriptions apply only to

Advanced Display Module errors.

System

Behavior

Reference System Behavior Description

When this error is generated, a pop-up with the error-code will be shown until it is acknowledged by

pressing the Enter button ( ). The heat control will be turned off, any auto-sequencing in progress

1

2

3

4

5

will be stopped, and the foot switch will be disabled until the error-code is acknowledged. When the

error condition is cleared, the heat control may be turned back on from the Home screen. This error

will not disable purge or recirculation operation.

When this error is generated, a pop-up with the error-code will be shown until it is acknowledged by

pressing the Enter button ( ). All physical machine operation will be disabled until the error condition is corrected. The display module can still be used but all machine commands sent will be ignored.

When this error is generated, a pop-up with the error-code will be shown until it is acknowledged by

pressing the Enter button ( ). Any auto-sequencing in progress will be stopped and the foot

switch will be disabled until the error-code is acknowledged. This error will not disable purge or recir-

culation operation. All features dependent on Fluid Control Module #2 will be disabled until the error

condition is corrected.

When this error is generated, a pop-up with the error-code will be shown continuously until the error

condition is corrected. The machine and display module are completely disabled until the error condition is corrected.

When this error is generated, a pop-up with the error-code will be shown. Any auto-sequencing, purge

timer or recirculation timer operation in progress will be stopped and the foot switch will be disabled

until the error-condition is cleared. The error-code pop-up will be shown until the error condition is

cleared. When the error condition is cleared, all options may be turned back on.

312760S 21

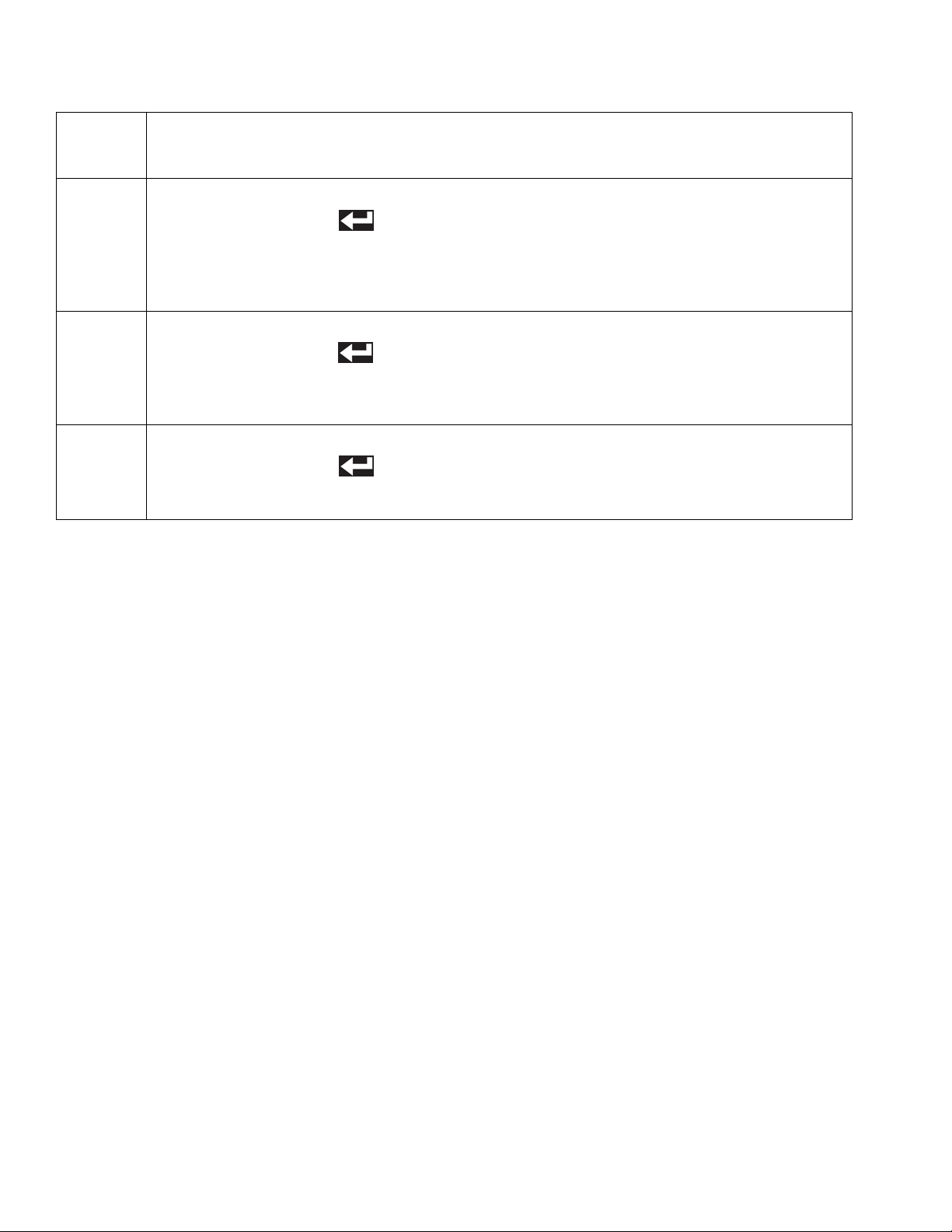

Page 22

Troubleshooting

System

Behavior

Reference System Behavior Description

When this error is generated, a pop-up with the error-code will be shown until it is acknowledged by

pressing the Enter button ( ). Any auto-sequencing in progress will be stopped, and the foot

6

switch will be disabled until the error-code is acknowledged. Once the error-code pop-up is acknowledged, the machine will return to normal operation The error will be shown in the Errors screen until

the condition is cleared. The error-code pop-up will not reappear unless the error condition is cleared

and then reappears. This error will not disable purge or recirculation operation.

When this error is generated, a pop-up with the error-code will be shown until it is acknowledged by

pressing the Enter button ( ). All heat options will be turned off, any auto-sequencing in progress

7

will be stopped, and the foot switch will be disabled until the error-code is acknowledged. When the

error condition is cleared, the heat control may be turned back on from the Home screen. This error

will not disable purge or recirculation operation.

When this error is generated, a pop-up with the error-code will be shown until it is acknowledged by

8

pressing the Enter button ( ). All heat options will remain on, any auto-sequencing in progress

will be stopped, and the foot switch will be disabled until the error-code is acknowledged. This error

will not disable purge or recirculation operation.

22 312760S

Page 23

Troubleshooting

Error Codes (Standard Display Module)

When the machine is operating and a fault is detected, it

will report the condition by generating an error code.

Error codes are typically generated when the machine is

idle after dispensing a shot.

When error codes are generated, a screen will be displayed which contains an animation sequence, the error

code number and an ICON symbol representing the

condition detected. The HMI will also output an error

code tone sequence. The tone sequence cannot be disabled.

When errors are generated, the machine will automatically be disabled and remain in an idle state until the

user acknowledges the condition. Any active purge timer

present prior to error code generation will be suspended, and will need re-started by requesting a shot

after the error is acknowledged.

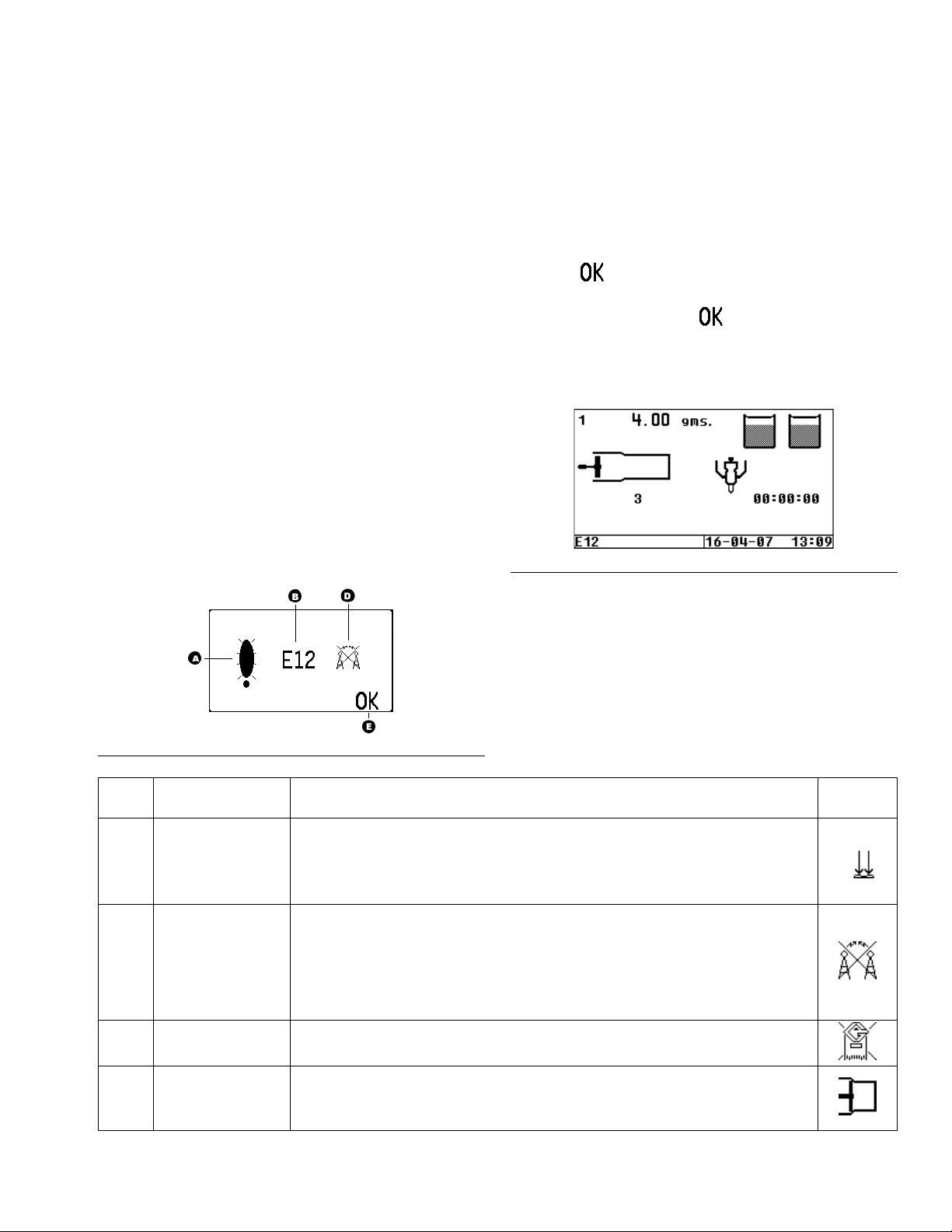

The following typical screen is generated when an error

code is generated:

Key:

A Error Code Animation Field

B Error Code Number Field

D Error Code ICON

E Error Code Acknowledgement ICON

When an error code is generated, the user will need to

acknowledge the condition by pressing the soft key

under the ICON.

After the user activates the key, the error number

shown in F

hand corner of the Run screen, while the condition is still

present.

FIG. 2: Typical Run Screen with Active Error Code

IG. 1, will be displayed on the bottom left

The example E12 number on the main run screen will

remain on the run screen as long as the error condition

exists. If the problem is corrected the example E12 number will be removed.

If more than 1 error code condition exists for the

machine, the corresponding “EXX” numbers will be

F

IG. 1: Typical Error Code Screen

Error

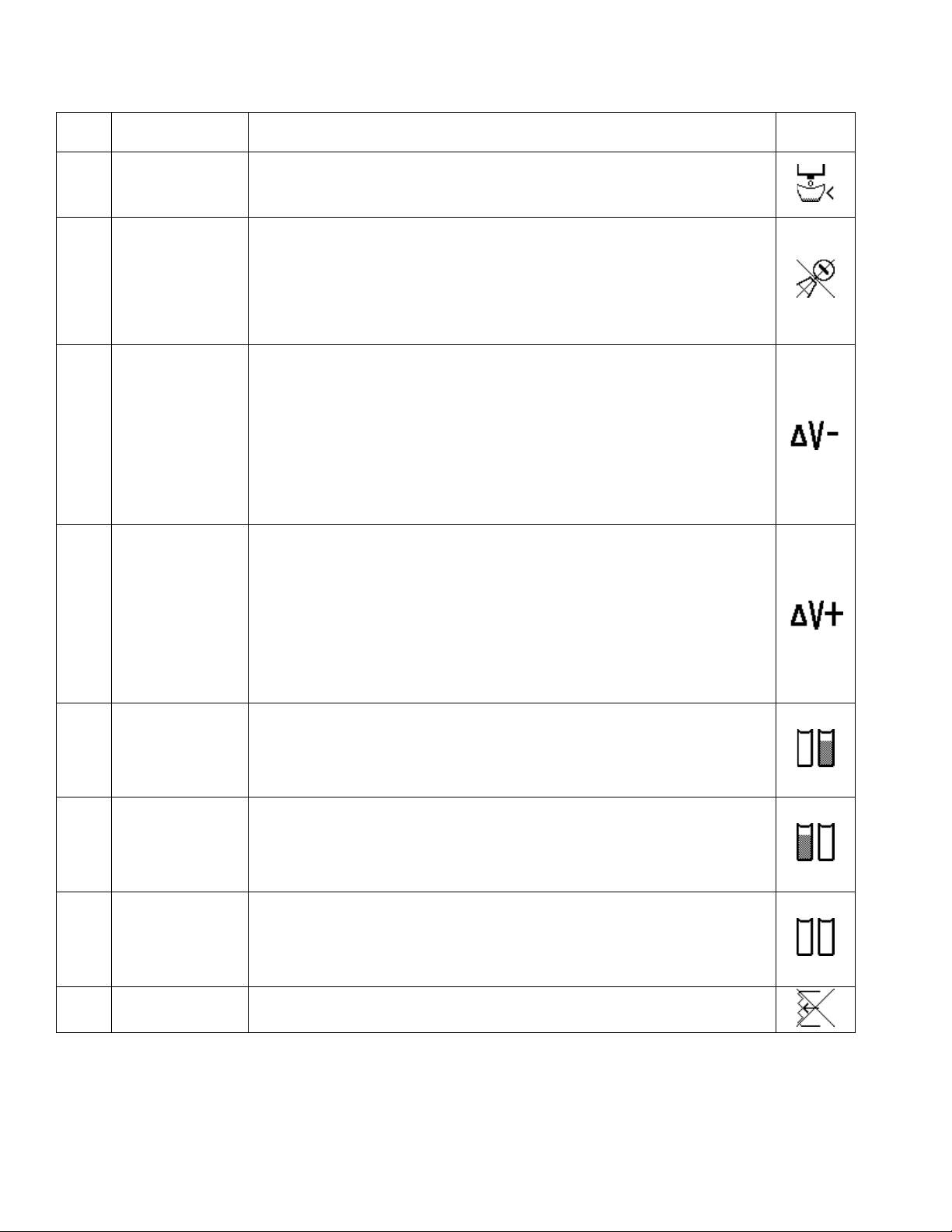

Code Title Cause, Details ICON

E11

E12

E13

E21

Stuck Key Error A key on membrane has been active (pressed) for > 30 seconds

continuously. Replace the HMI. This error code does not require user

acknowledgment and will clear itself automatically if the condition is

removed.

Communication

Error

No or Invalid Run

Token Error

Piston Stroke

Time-out Error

The Display module has lost communication with the Fluid Control Module.

Material dispensing will be disabled if this condition exists. Check

communication cables between the 2 electronic components, or check the

HMI and/or the Fluid Control Module.

This error will be regenerated continuously while the condition exists.

The Run Token in the FCM is missing (not installed), or does not have the

correct data.

A piston stroke action has taken > 55 seconds. Typically caused by no/too

little air pressure to the machine or a mechanical interference with the

piston has occurred. Check machine input line pressure.

listed on the bottom left corner, separated by commas.

312760S 23

Page 24

Troubleshooting

Error

Code Title Cause, Details ICON

E23

Less than

Minimum Shot

User has requested a shot < the minimum allowable size entered during

calibration. (< 15% of stoke, N/A in Operator Mode).

Requested Error

E24

Improper

Calibration Error

The calibration done on the machine is invalid, so the requested shot

cannot be executed. For instance, a Large Stroke Calibration Shot mass

which is less than the Short Stroke Calibration Shot mass (C4 screen) will

create this error code. If the wiring to the linear position transducer is

reversed this error will appear. If invalid piston positions are calibrated into

the machine (C1 screen) this error will appear.

E25

Delta Velocity

(“V”) Minus Error

The piston velocity is slower than the calibration velocity measured, by the

percentage amount selected by the user (20%, 40% or 60%). If the user

selects 0%, this monitoring or alarm feature is disabled.

If generated, shot size accuracy may be degraded. Typically the problem is

created when the machine pressure regulator is adjusted to different value

from when the machine was calibrated. Another less likely cause could be a

mechanical failure with dispensing (worn piston, etc.). This error will not be

generated for a purge shot or when the machine is in Operator mode.

E26

Delta Velocity

(“V”) Plus Error

The piston velocity is faster than the calibration velocity measured, by the

percentage amount selected by the user (20%, 40% or 60%). If the user

selects 0%, this monitoring or alarm feature is disabled.

E27

E28

E29

E50

Low Material

Level, Tank A

Alarm or Error

Low Material

Level, Tank B

Alarm or Error

Low Material

Level, Both Tanks

Alarm or Error

Bad Linear

Position Sensor

If generated, shot size accuracy may be degraded. Typically the problem is

created when the machine pressure regulator is adjusted to different value

from when the machine was calibrated. Another less likely cause could be a

mechanical failure with dispensing (worn piston, etc.). This error will not be

generated for a purge shot, or when the machine is in Operator mode.

Tank A is low (only generated if tank sensing is enabled). Fill tank A with

material.

Tank level errors will be generated after every shot if the condition still

exists.

Tank B is low (only generated if tank sensing is enabled). Fill tank B with

material.

Tank level errors will be generated after every shot if the condition still

exists.

Both tanks are low (only generated if tank sensing is enabled). Fill both

tanks with material.

Tank level errors will be generated after every shot if the condition still

exists.

There is a fault with the linear position sensor. Check wiring or replace.

24 312760S

Page 25

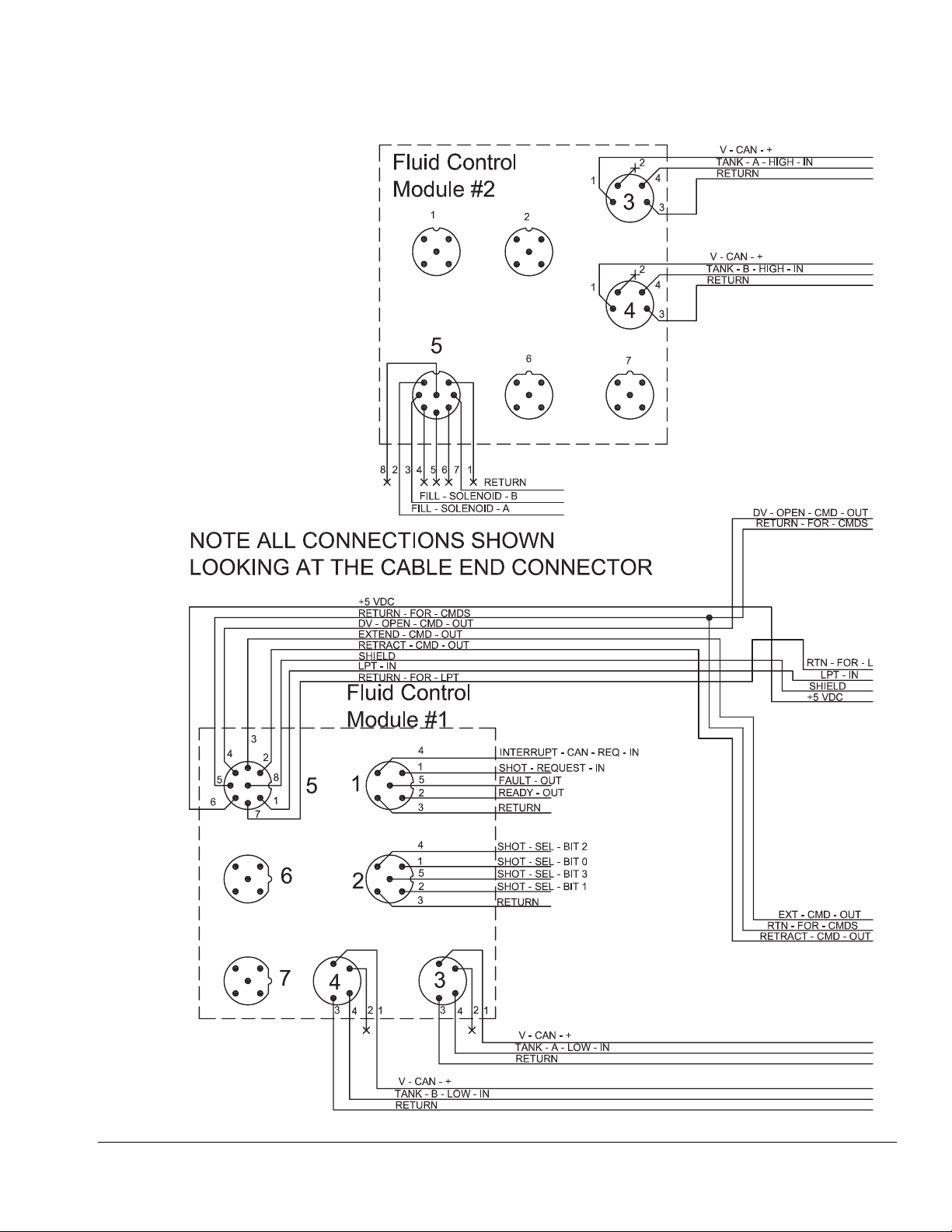

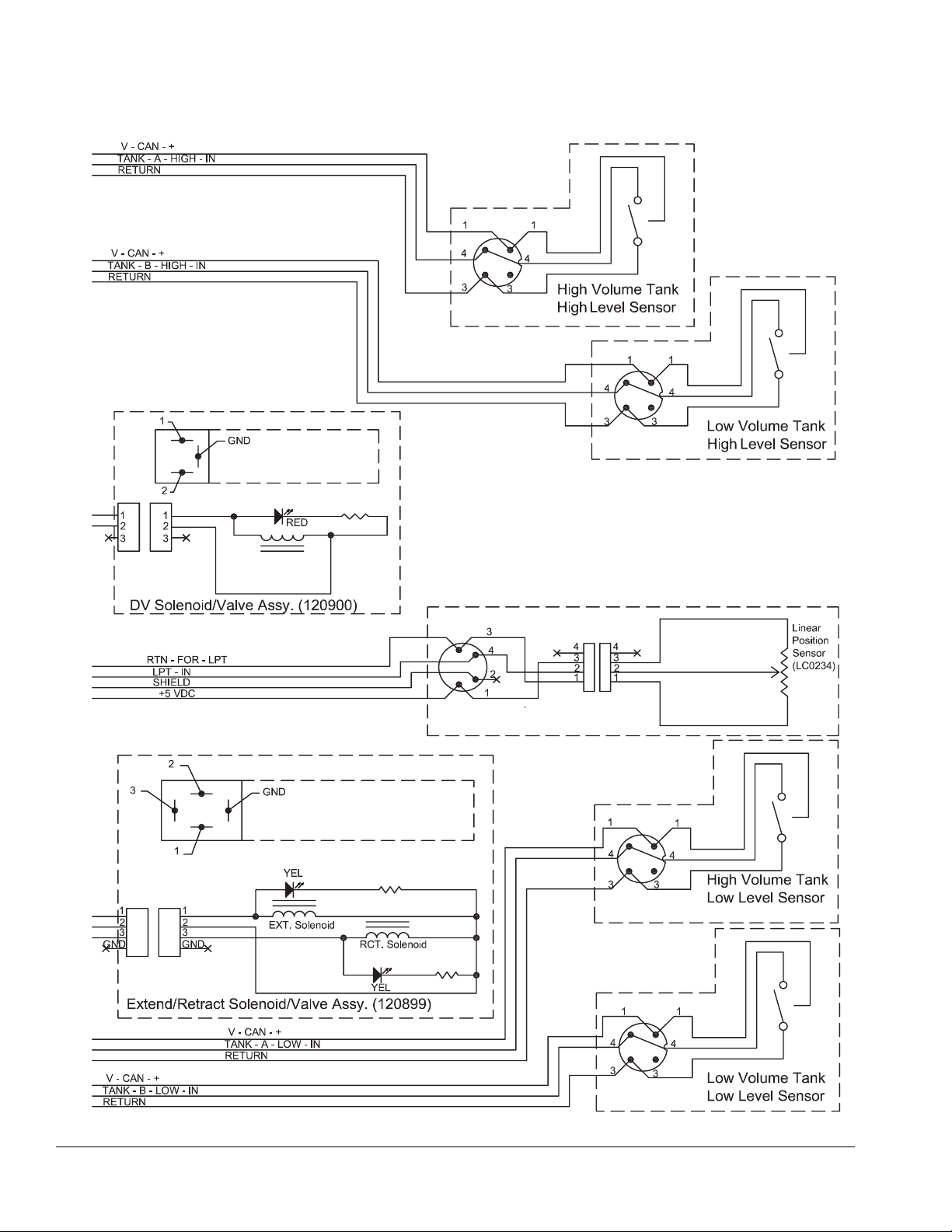

Electrical Schematics

NOTE: Fluid Control Module #2

sections apply only to models with

Advanced Display module

See F

IG. 6

Electrical Schematics

A

B

C

D

E

F

G

H

FIG. 3: Electrical Schematic - Page 1

See F

See F

J

K

L

M

IG. 6

IG. 6

N

P

R

S

T

U

V

W

X

312760S 25

Page 26

Electrical Schematics

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

S

T

U

V

W

X

FIG. 4: Electrical Schematic - Page 2

26 312760S

Page 27

Electrical Schematics

FIG. 6

IG. 6

F

F

F

IG. 6

IG. 6

FIG. 5: Electrical Schematic - Page 3

312760S 27

Page 28

Electrical Schematics

NOTE: See PR70 operation manual for Optional External Control Interface instructions.

Customer Supplied

Dry Contact/Relay

2

NOTE: Connector #2 is for use

with systems with an Advanced

Display Module only.

NOTE: View shown is looking at

pins on end of cable.

1

NOTE: Connector #1 is for use

with all systems.

NOTE: View shown is looking at

pins on end of cable.

1

2

5

4

3

1

2

5

4

3

Brown

Gray

Black

Blue

White

Brown

Gray

Black

Blue

White

SHOT REQUEST - INPUT

INTERRUPT - CAN - REQ - INPUT

SHOT SEL - BIT 0

SHOT SEL - BIT 3

Not Used

COMMON

SHOT SEL - BIT 1

FAULT OUTPUT

COMMON

READY - OUTPUT

Customer Supplied

Dry Contact/Relay

+24 VDC

+24 VDC

IG. 6: Electrical Schematic - Page 4

F

28 312760S

Page 29

Repair

HydraCheck Kit Installation

200b

1

203

200a

Repair

200d

200c

1

Torque to 85 in-lb (9.6 N•m).

FIG. 7: HydraCheck Installation - Variable Ratio Base

420

AA

ti12437a

100d

100b

103

104

ti12436a

F

IG. 8: HydraCheck Installation - Fixed Ratio Base

312760S 29

Page 30

Repair

The following procedure is the same for Fixed and

Variable Ratio bases, except where noted. See F

7 and F

IG. 8 for part references. See Kits on

IG.

page 80 for kit numbers.

NOTE: The HydraCheck kit is intended to be used with

low viscosity materials to minimize splashing. It is not

intended to be used as a timer or flow control device.

Prepare Machine for Kit Installation

1. Navigate to the Manual screen.

2. Press the Retract Piston Command button.

Install Adjustment Screw/Cap

9. On Variable Ratio models, loosely install hex

nut (200d) and adjustment screw (200c) onto the

variable ratio drive block (AA).

On Fixed Ratio models, loosely install hex

nut (100b) and adjustment cap (100d) onto the air

cylinder shaft (420).

3. Relieve system pressure. See Pressure Relief Pro-

cedure on page 14.

4. Remove shroud screws (2202, 2409). See F

on page 44 and F

IG. 21 on page 49.

5. Remove the shroud (117, 214). See F

page 42 and F

IG. 21 on page 49.

IG. 17

IG. 16 on

Install HydraCheck Shock

Be sure that system pressure is relieved and disabled before proceeding.

6. Install shock absorber (200a) through the opening in

the pump sub-assembly (203) with the groove for

the snap ring on the back of the pump assembly.

The shock absorber can be inserted through the

front or the back of the pump sub-assembly.

7. Install shock snap ring (included with shock, not

shown) onto the shock absorber (200a) in the

groove farthest from the pump sub-assembly.

Adjust the Adjustment Screw/Cap

10. Push the drive block (104, AA) forward until resistance is felt when it engages the cylinder. Make sure

the resistance is not due to shock absorber (200a)

contact with the adjustment screw (200c) or adjustment cap (100d).

11. Adjust the adjustment screw or adjustment cap until

it contacts the shock absorber.

12. On Variable Ratio models, hold the adjustment

screw (200c) in place and tighten the hex nut (200d)

against the drive block (AA).

On Fixed Ratio models, hold the adjustment

cap (100d) in place and tighten the hex nut (100b)

against the adjustment cap.

Prepare Machine for Operation

13. Lift the system air pressure relief switch to enable

system pressure. It is the yellow tab at the left, rear

of the machine.

8. Install set screw (200b) and torque to 85 in-lb

(9.6 N•m).

Adjust Shock Resistance

14. Execute a shot to see how the shock absorber

affects the speed of the drive block (104, AA).

15. The shock absorber has a numeric scale on one

side. Rotate the knob with the scale to a higher

value for more resistance. Rotate the knob to a

lower value for less resistance.

16. Repeat these steps until the desired resistance is

achieved.

30 312760S

Page 31

Air Cylinder Kit Installation

Repair

420

412

411

4

403

4

417

405

401

419

406

412

413

415

416

422

411

4

412

407

404

402

1

408

2

418

414

414

409

415

ti12490a

412

1

2

3

4

5

410

Torque to 41 in-lb (4.6 N•m).

Torque to 350 in-lb (39.5 N•m).

Torque to 100 ft-lb (135 N•m).

Coat all sliding surfaces with lubricant, part 115982.

Apply sealant tape to npt fittings.

See Kits on page 80 for kit numbers.

Prepare Machine for Kit Installation

1. Relieve pressure. See Pressure Relief Procedure,

page 14.

2. Shut down the machine. See Shutdown, page 14.

3. Disconnect the pressurized air input hose.

4. Remove shroud screws (2202, 2409). See F

on page 44 and F

IG. 21 on page 49.

5. Remove the shroud (117, 214). See F

page 42 and F

IG. 21 on page 49.

IG. 17

IG. 16 on

Disassemble the Air Cylinder

6. Remove the incoming power bracket (110) from the

machine by removing the two attachment

screws (109). See F

IG. 15 on page 41.

7. Remove the two solenoid valves (407, 408) from the

cylinder blind end block (418) by removing the three

socket head cap screws (402).

8. Use an open-end wrench to remove all hex

nuts (103, 100b, 100d) connecting the piston rod to

the drive block. See F

IG. 15 on page 41.

9. Remove the four screws (108) that attach the cylinder rod end block (417) to the frame. See F

IG. 15 on

page 41. Access the screws through the four holes

312760S 31

Page 32

Repair

in the blind end block (418) using a long allen

wrench.

10. Partially remove the air cylinder by pulling on the

cylinder from the back of the machine until the air

lines at the elbow fittings can be seen.

11. With the cylinder partially removed, disconnect the

airlines at the air cylinder elbow fittings.

12. Finish removing air cylinder.

13. On a bench, disassemble the air cylinder by removing the four long screws (404) that connect the two

cylinder blocks.

Clean and Inspect the Parts

14. Inspect the cylinder tube (416) and piston (419) for

scratches. Replace if necessary.

15. Using a clean dry cloth, remove any grease from the

inside of the tube (416), the outside of the

piston (419), and the cylinder rod (420).

16. Remove the two cylinder block o-rings (411) from

the blocks (417, 418) and replace.

17. Remove the piston o-ring (403) and replace.

18. Remove the cylinder rod (420) from the rod end

block (417).

them. Then torque the bolts to 350 in-lb (39.5 N•m)

in a crisscross pattern.

3

1

2

4

22. Insert the cylinder rod (420) through the hole in the

rod end cylinder block (417) and base frame.

23. Before the cylinder is completely in place, reconnect

the airlines to the cylinder block elbows fittings. Verify the correct airlines are connected.

24. Reinstall the four screws (108) that attach the cylinder rod end block (417) to the frame. See F

IG. 15 on

page 41.

25. Reinstall the hex nuts (103, 100b, 100d) to the cylinder rod (420) and torque to 100 ft-lb (135 N•m). See

F

IG. 15 on page 41.

26. Install the three screws (402) that attach the solenoid valves (407, 408) to the blind end block (418).

Torque to 41 in-lb (4.6 N•m).

19. Remove the rod o-ring (401) from the rod end

block (417) and replace.

20. Liberally apply high temperature lubricant grease

(part 115982) to the inside of the tube (416), the

outside of the piston (419), all the o-rings, and the

cylinder rod (420).

Re-Assemble the Air Cylinder

NOTICE

In the following step, the long screws must be tightened in a crisscross pattern. Failure to do so may

result in air cylinder damage.

21. Reinstall the four long screws (404) that attach the

two drive blocks (417, 418) by finger-tightening

Prepare Machine for Operation

27. Reattach the incoming power bracket (110) by reinstalling the two attachment screws (109). See F

IG.

15 on page 41.

28. Reconnect pressurized air input hose.

29. Operate the machine and ensure there are no air

leaks are found.

30. Install the shroud (117, 214). See F

47 and F

IG. 21 on page 49.

31. Install shroud screws (2202, 2409). See F

page 44 and F

IG. 21 on page 49.

IG. 20 on page

IG. 17 on

32. Calibrate the machine. See the appropriate operation manual referenced at the beginning of this manual for procedure.

32 312760S

Page 33

Rear Pump Rebuild Kit Installation

The pump shaft is installed with Krytox. Contact with

Krytox can lead to flu-like symptoms. The MSDS for

this material is available upon request.

Repair

See Kits on page 80 for kit numbers.

505

513

506

514

507

511

2

508

501

504

512

503

1

510

3

3

502

ti12491a

1

Torque to 350 in-lb (39.5 N•m).

2

Lube shaft with krytox grease prior to insertion into bearing.

3

Shaft seal (503) must be installed with open side facing the washer (512).

F

IG. 9

Prepare Machine for Kit Installation

1. Drain the pump.

• If ball valves are installed, close the ball

valves then take several shots.

• If ball valves are not installed, empty the

509

2. Relieve pressure. See Pressure Relief Procedure,

page 14.

3. Shut down the machine. See Shutdown, page 14.

4. Disconnect the pressurized air input hose.

tanks. Perform shots repeatedly until no material comes out of the dispense valve.

312760S 33

5. Remove shroud screws (2202, 2409). See F

on page 44 and F

IG. 21 on page 49.

IG. 17

Page 34

Repair

6. Remove the shroud (117, 214). See FIG. 16 on

page 42 and F

IG. 21 on page 49.

Disassemble the Rear Pump Assembly

7. Disconnect the pump shaft (511) from the drive

block.

a. Loosen the shaft locking nut (502).

b. Hold the drive block alignment rod (2302, 2419)

stationary with a wrench. See F

45 and F

IG. 22 on page 50.

IG. 18 on page

c. Turn the pump shaft (511) with a wrench.

d. Manually push the pump shaft (511) forward to

to separate the shaft from the drive block.

8. Remove the shaft lock nut (502).

9. Remove the two screws (505) that hold the pump

collar in place.

10. Remove the pump collar (509) from the pump

housing (507).

11. Slide the pump bearing housing (510) away from

the pump housing (507) to remove.

block. This will prevent the threads from damaging

the seal (503).

17. Slide the pump shaft through the hole in the bearing

housing.

18. Align the bearing housing in position next to the

pump housing.

19. Install the pump collar over the bearing housing.

20. Attach the pump housing using the two

screws (505) and torque to 350 in-lb (39.5 N•m).

21. Remove the masking tape from pump shaft (511).

22. Install the pump shaft lock nut (502) onto the pump

shaft (511).

23. Connect the pump shaft to the drive block alignment

rod (2302, 2419). See F

IG. 18 on page 45 and FIG.

22 on page 50. Screw the shaft completely into the

drive block.

24. Tighten the lock nut (502)

Prepare for Operation

25. Open the tank ball valves if installed.

26. Fill tanks.

12. Remove rear pump components from the pump

bearing housing (510).

Clean and Inspect the Parts

13. Using a clean dry cloth, remove any existing grease

from the bearing housing.

14. Apply new high temperature grease lubricant

(part 115982) to the inside of the pump bearing

housing (510), and the new rebuild components.

Assemble the Rear Pump Assembly

15. Install the new rebuild kit components into the bearing housing.

NOTICE

Be careful when installing the seal (503). Ensure

there is masking tape on the threads of the piston rod

and that the open side of the seal faces the piston rod

when it slides onto the rod.

16. Apply one layer of thin masking tape over the male

threads of the pump shaft that mates with the drive

27. Perform several shots to fill the pump with new

material.

28. Calibrate and phase the machine. See the appropriate operation manual referenced at the beginning of

this manual for procedure.

34 312760S

Page 35

Repair

Piston/Cylinder Replacement Kit Installation

See Piston Package on page 60 and Nylon and

UHMW Piston Replacement Kits on page 63 for

kit numbers.

606

1

601

606

605

603

602

604

ti12438a

1

The arrow imprinted on the cylinder points

toward the pump outlet.

7. Push the drive block (104, AA) forward until pistons

are fully extended. See F

IG. 7 and FIG. 8 on

page 29.

8. Use a wrench to prevent the pump shaft (511) from

rotating and remove the piston screw (605). See

F

IG. 9 on page 33.

9. Remove the piston (602) and any front or rear

washers (603) from the pump shaft (511). See F

IG.

9 on page 33.

10. Clean the washers.

Install Cylinder

11. Install the new piston and any front or rear washers.

12. Install the piston screw (605).

Tighten the piston screw until the piston stops rotating, then turn the screw an additional 1/4 turn.

13. Fully retract the piston.

Prepare Machine for Kit Installation

1. Drain the pump.

• If ball valves are installed, close the ball

valves then take several shots.

• If ball valves are not installed, empty the

tanks. Perform shots repeatedly until no material comes out of the dispense valve.

2. Relieve pressure. See Pressure Relief Procedure,

page 14.

3. Models with ADM: To prevent machine movement,

press the Machine Disable Mode key ( ).

Models with SDM: To prevent machine movement,

press the Red button

.

Disassemble Cylinder

4. Remove the four end cap screws (506). See F

IG. 9

on page 33.

5. Remove the pump end caps (508). See F

IG. 9 on

page 33. Allow the cap to hang by the hose.

14. Lubricate the new o-rings with high temperature

grease (part 115982).

15. Insert the lubricated o-rings (606) into the grooves

of the pump housing (507) and end caps (508). See

F

IG. 9 on page 33.

16. Install the cylinder between the pump housing (507)

and end cap (508). See F

IG. 9 on page 33.

17. Secure cylinder in place with the four end cap

screws (506). See F

IG. 9 on page 33.

Prepare Machine for Operation

18. Open the tank ball valves if installed.

19. Fill tanks.

20. Perform several shots to fill the pump housing (507)

with new material.

21. Calibrate and phase the machine. See the operation

manual referenced at the beginning of this manual

for procedure.

6. Remove the cylinder (601) and o-rings (606) from

the pump housing (507). See F

312760S 35

IG. 9 on page 33.

Page 36

Repair

Check Valve Rebuild Kit Installation

See Pump Sub-Assembly, LC0112, page 54 for

pump sub-assembly part references. See Kits on

page 80 for kit numbers.

Inner Radius

2101

2102

ti12565a

1

Side of seat with outside chamfer must face away

from ball. Side of seat with inner radius must face the

ball.

IG. 10: Check Valve Rebuild Kit

F

2103

Prepare Machine for Kit Installation

1. Relieve pressure. See Pressure Relief Procedure,

page 14.

2. Models with ADM: To prevent machine movement,

press the Machine Disable Mode key ( ).

Models with SDM: To prevent machine movement,

press the Red button

.

3. Place a waste container below the dispense valve to

catch any dispensed material.

4. Push the drive block (104, AA) forward until pistons

are fully extended. See F

IG. 7 and FIG. 8 on

page 29.

Outside

Chamfer

2104

1

the female threaded end of the check valve

housing (513).

9. Place the new check valve ball guide (2103) on a

bench with the open end up. Install the check valve

spring (2102) into the guide.

10. Install the check valve ball (2101) on top of the

spring (2101).

11. Place the seat (2104) on top of the check valve

ball (2101) with the outside chamfered side of the

seat facing away from the check valve ball.

12. Hold both ends of the assembled check valve

assembly and install the check valve into the

unthreaded end of the check valve housing (513)

with the ball end facing out. See F

IG. 9 on page 33.

13. Apply pressure to the valve to snugly fit the assembled check valve (514) into the check valve

housing (513). Fit the check valve seat (2104) into

the valve guide. See F

IG. 9 on page 33.

Verify when the assembled check valve (514) and

housing (513) are turned up-side down that the

contents of the check valve stay in place.

14. Use a wrench to insert the new valve and valve

housing into the pump end cap (508).

15. Install the material male hose fitting into the check

valve housing using a wrench.

16. Before operating the machine, activate a few shots

to purge any air present in the material hose lines.

17. Calibrate the machine if necessary. See the appropriate operation manual referenced at the beginning

of this manual for procedure.

5. Move the waste container to below the check

valve (514).

6. Disconnect the male hose fitting from the check

valve housing (513) by loosening the hose from the

housing. See Pump Sub-Assembly, LC0112,

page 54.

7. Remove the check valve housing (513) from the

pump endcap (508) by loosening the housing with a

wrench.

8. Remove the existing check valve (514) from the

housing by inserting a screwdriver or dowel rod into

36 312760S