Page 1

Operation - Maintenance

™

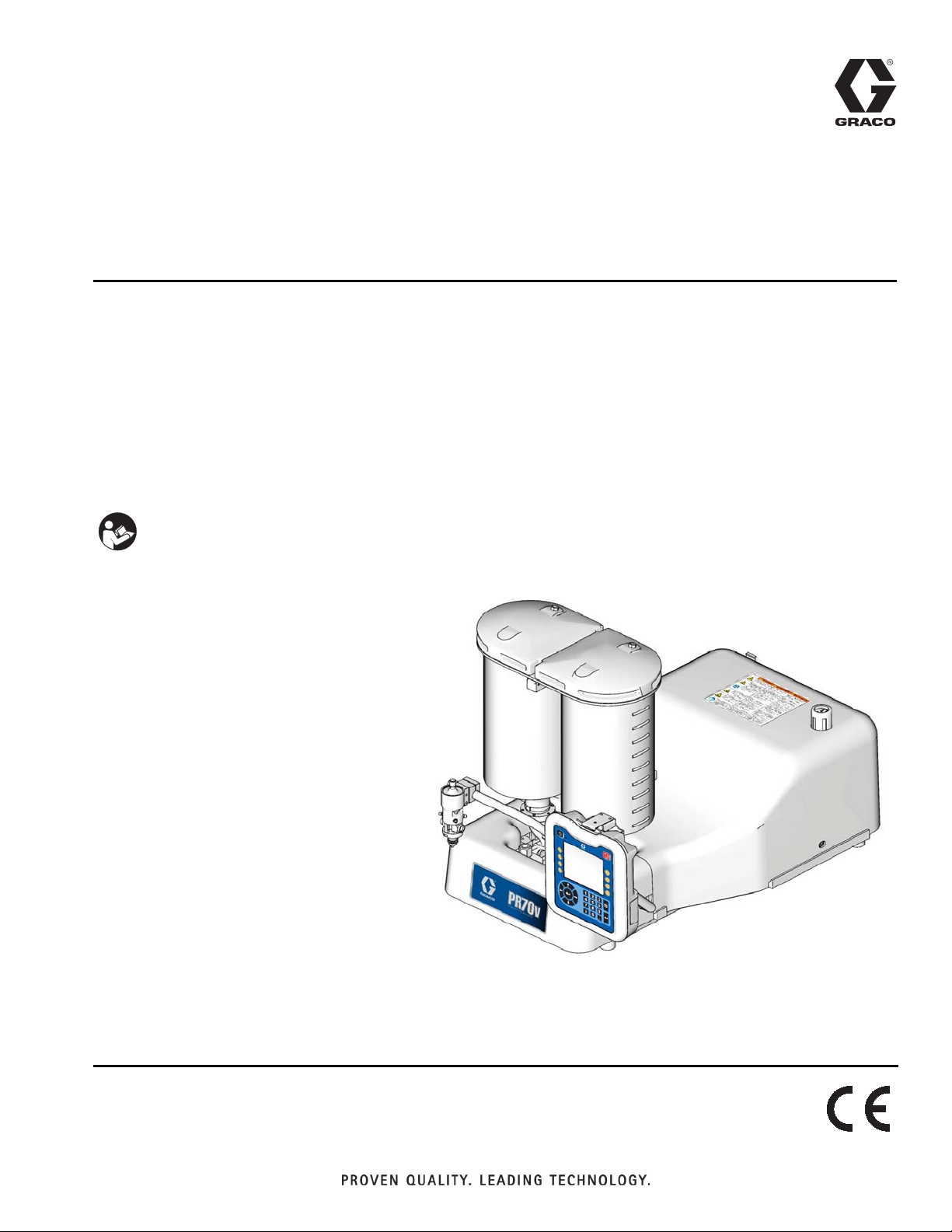

PR70

with Advanced Display Module

Fixed or variable ratio systems. For accurate metering, mixing, and dispensing of

two-component materials. For professional use only.

Not approved for use in European explosive atmosphere locations.

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

Important Safety Instructions

Read all warnings and instructions in all supplied manuals. Save these instructions.

and PR70v

™

312759R

EN

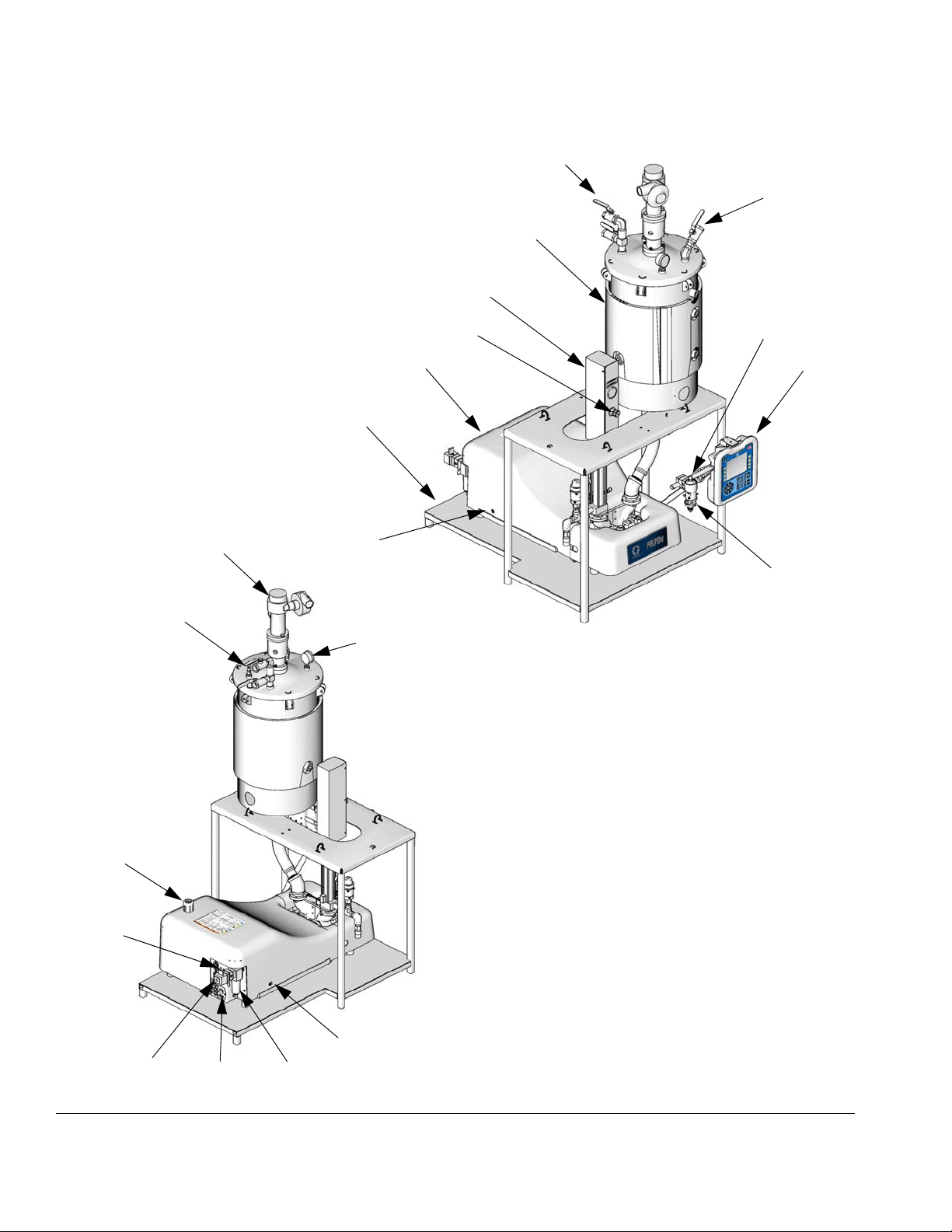

PR70v Shown with Advanced Display Module

ti12385b

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Configurator . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Component Identification . . . . . . . . . . . . . . . . . . . 13

Advanced Display Module (ADM) . . . . . . . . . . . 15

Screen Navigation Diagram . . . . . . . . . . . . . . . . . 16

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Machine Installation . . . . . . . . . . . . . . . . . . . . . 17

Tank Refill Kit 256577 Installation . . . . . . . . . . . 19

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . 22

Edit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Piston Position Calibration . . . . . . . . . . . . . . . . 37

Prime the Dispense Head . . . . . . . . . . . . . . . . . 39

Phasing Adjustment . . . . . . . . . . . . . . . . . . . . . 40

Adjust Dispense Valve Snuff Back . . . . . . . . . . 42

Adjust Open Dispense Valve (ODV) Timing . . . 43

Calibrate Dispense Weight Ratio (PR70v only) 44

Shot Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 47

Flow Meter Calibration . . . . . . . . . . . . . . . . . . . 48

Dispense Verification . . . . . . . . . . . . . . . . . . . . . 48

External Control Interface Setup . . . . . . . . . . . . 49

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Operation Screens . . . . . . . . . . . . . . . . . . . . . . 53

Auto-Refill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Temperature Control . . . . . . . . . . . . . . . . . . . . . 63

Purge Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

USB Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Download Procedure . . . . . . . . . . . . . . . . . . . . . 64

Pressure Relief

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Clean the Pump Shafts . . . . . . . . . . . . . . . . . . . 66

Disassemble and Clean the Dispense Head . . . 66

Flush Pneumatic Air Motor 82/0216/11 . . . . . . . 67

Lubricate Pneumatic Air Motor . . . . . . . . . . . . . 67

Lubricate Gear Box of Pneumatic Air Motor

01/0368-1/11 . . . . . . . . . . . . . . . . . . . . . . . . 67

Install Upgrade Token . . . . . . . . . . . . . . . . . . . . 68

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Machine with On-Board Tanks . . . . . . . . . . . . . . 78

Machine with Off-Board Tanks . . . . . . . . . . . . . . 79

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 82

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 82

2 312759R

Page 3

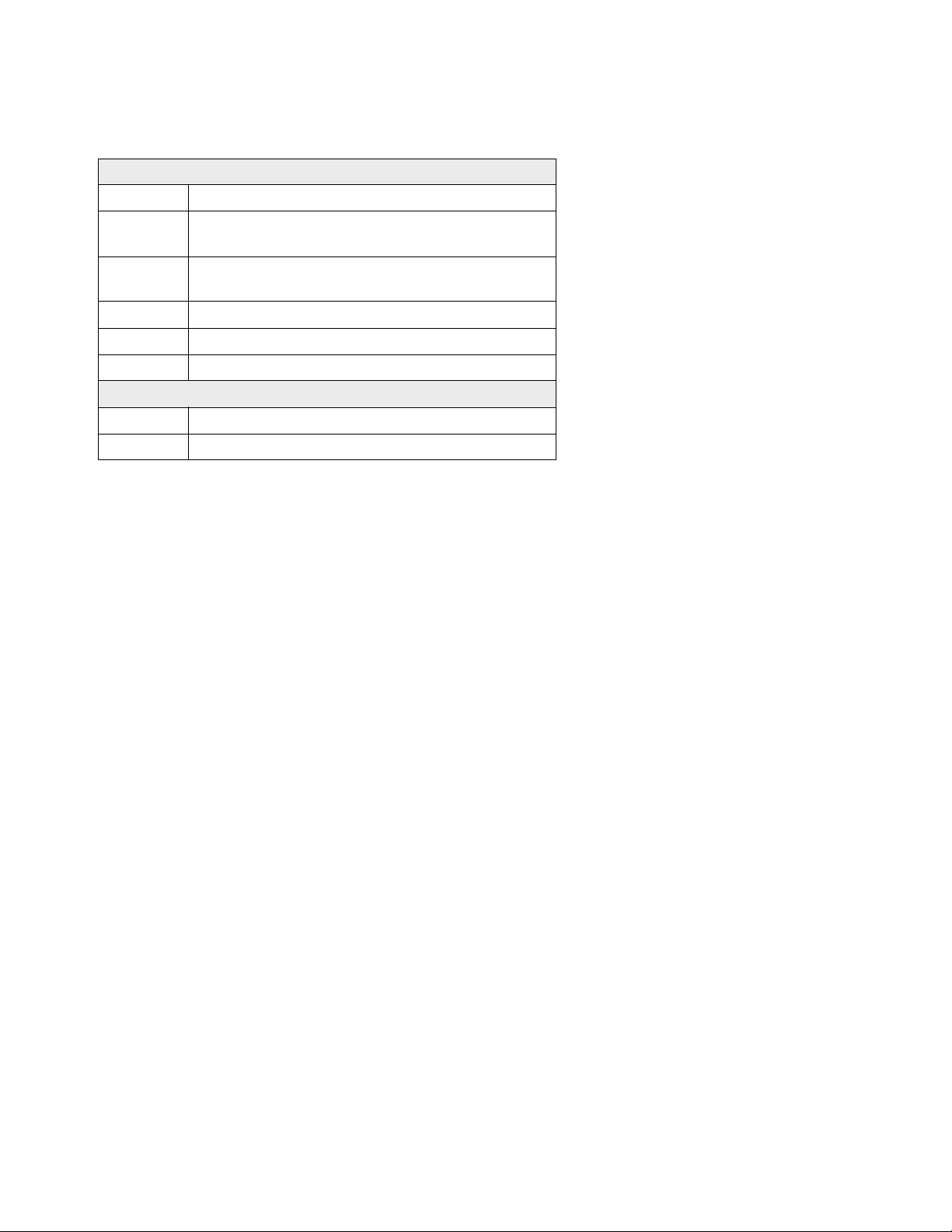

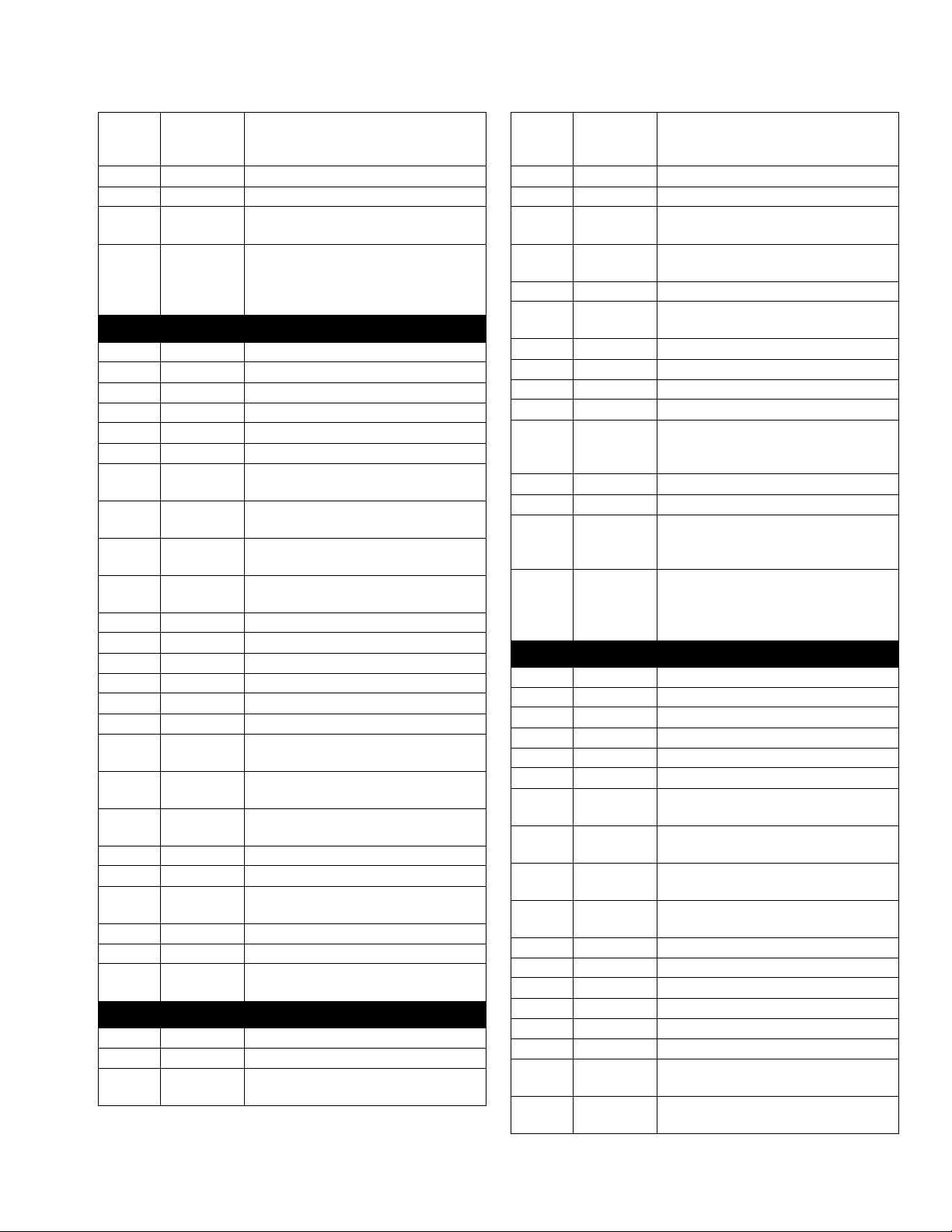

Related Manuals

PR70 and PR70v Operation and Parts Manuals

Part Description

3A0429 PR70 with Standard Display Module Operation and

Maintenance Manual

312759 PR70 and PR70v with Advanced Display Module

Operation and Maintenance Manual

312760 PR70 and PR70v Repair and Parts Manual

312394 PR70 and PR70v Feed Systems Manual

312761 PR70v Integrated Heat Instructions - Parts Manual

MD2 Dispense Valve Manual

Part Description

312185 MD2 Dispense Valve Instructions and Parts Manual

Related Manuals

312759R 3

Page 4

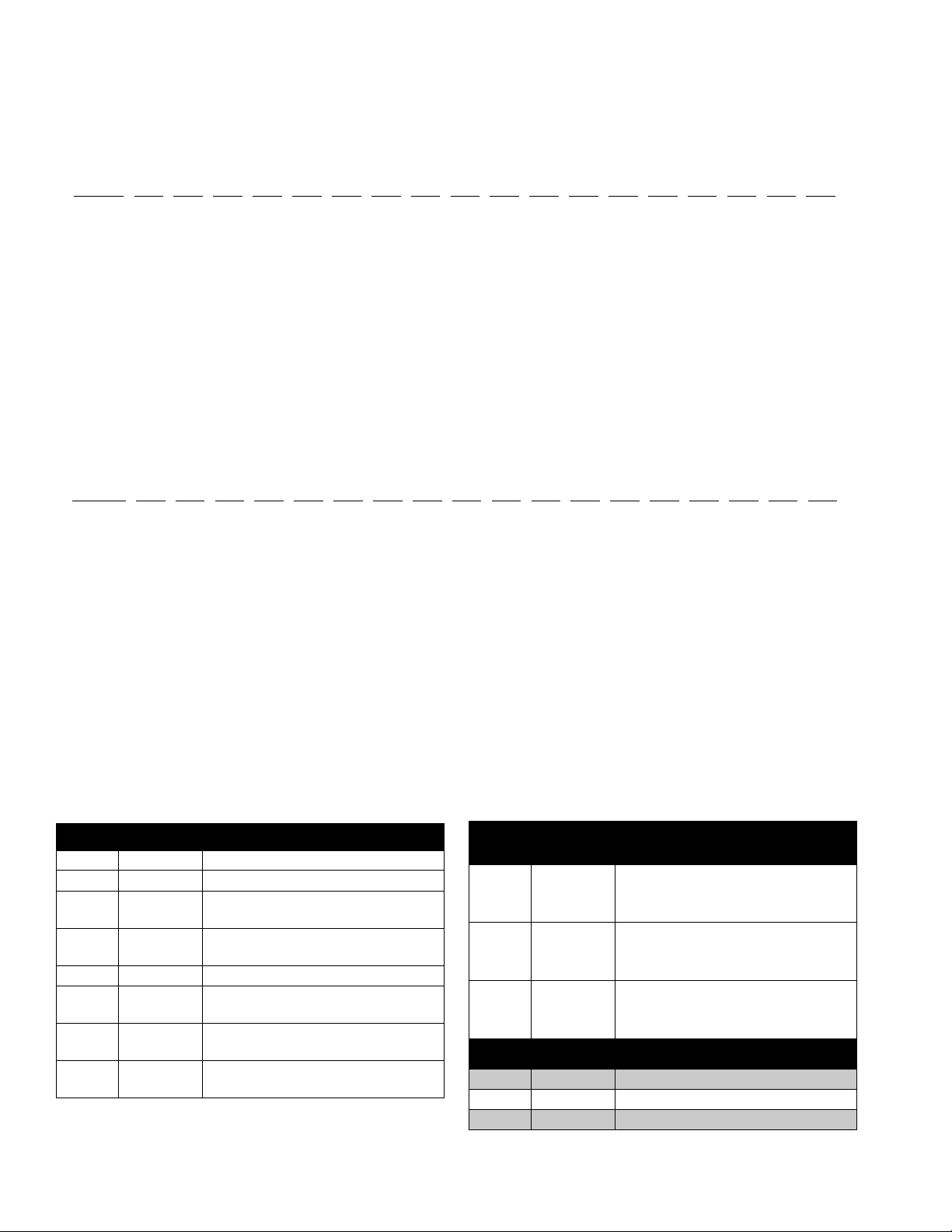

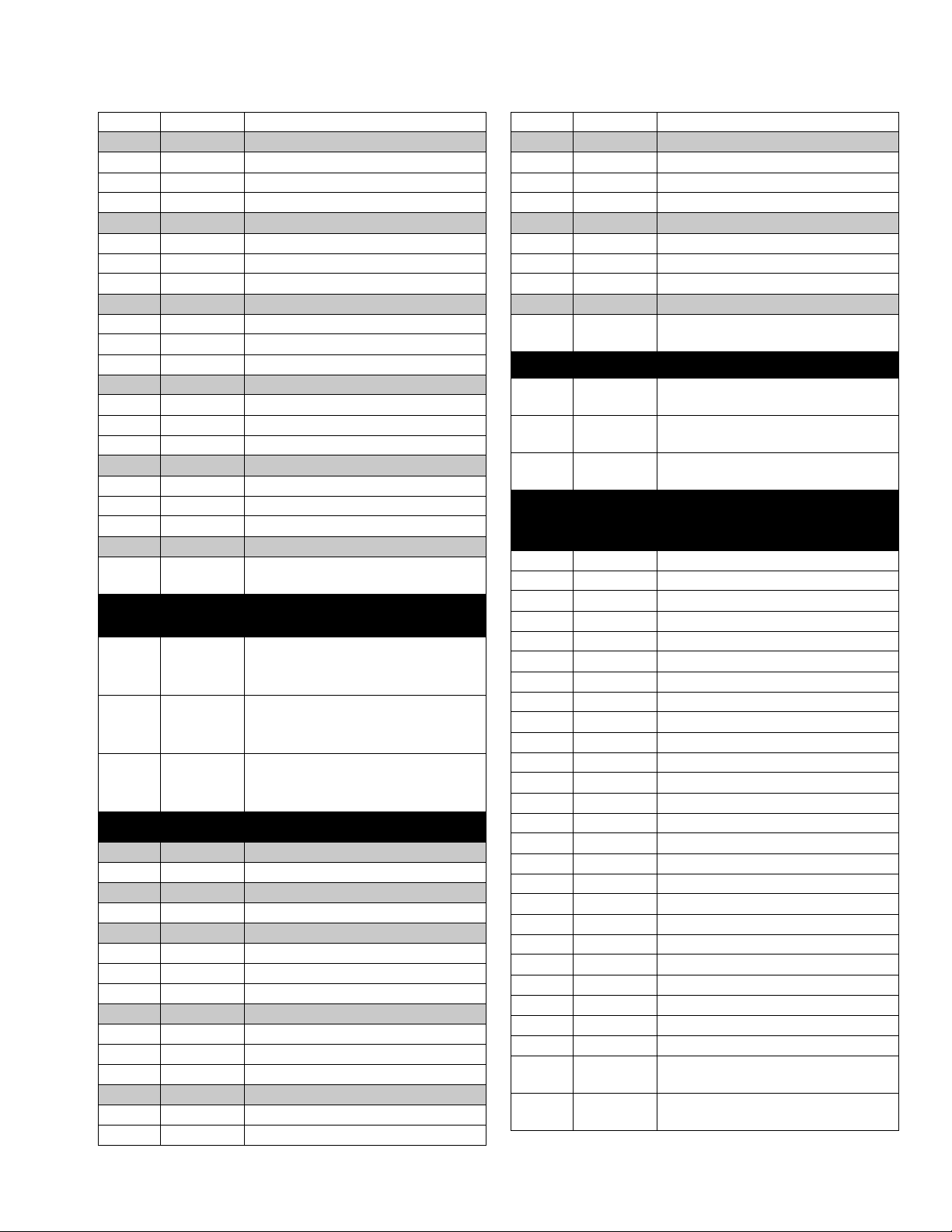

Product Configurator

Product Configurator

PR7F------------------

Code: A B-C D-E F G-H I-J K L M N O P Q R S T U V

Air Motor

High Volume Side Piston

Low Volume Side Piston

Controls

High Volume Side Hose

Low Volume Side Hose

Dispense Valve

Mixer

Applicator Mounting

Power Cord

Flow Monitoring

High Volume Side Tank

High Volume Side Tank Cover

Low Volume Side Tank

Low Volume Side Tank Cover

Tank Level Sensors

Heat Zone Controller

An example of the product configurator would be the following configurator code.

PR7F-J -A5-A5-E-A6-A6- 3- 1- 2-A-N- 3-N-H-N- 6-N-N

Code: A B-C D-E F G-H I-J K L M N O P Q R S T U V

Air Motor

High Volume Side Piston

Low Volume Side Piston

Controls

High Volume Side Hose

Low Volume Side Hose

Dispense Valve

Mixer

Applicator Mounting

Power Cord

Flow Monitoring

High Volume Side Tank

High Volume Side Tank Cover

Low Volume Side Tank

Low Volume Side Tank Cover

Tank Level Sensors

Heat Zone Controller

Off-Board Tank Stand

Off-Board Tank Stand

The following part number fields apply for the PR70 and PR70v part numbering configurator fields. Shaded items

listed in the configurator table below are “Super Standard” items that are typically stocked and provide the best delivery dates.

Code A Part Air Motor

A LC0262 PR70 with 3.0 in. (4.56 mm) Air Motor

B LC0264 PR70 with 4.5 in. (10.26 mm) Air Motor

C LC0263 PR70 with 3.0 in. (4.56 mm) Air Motor

and Hydracheck

D LC0265 PR70 with 4.5 in. (10.26 mm) Air Motor

and Hydracheck

F LC0242 PR70v with 3.0 in. (4.56 mm) Air Motor

G LC0244 PR70v with 4.5 in. (10.26 mm) Air

Motor

H LC0243 PR70v with 3.0 in. (4.56 mm) Air Motor

and Hydracheck

J LC0245 PR70v with 4.5 in. (10.26 mm) Air

Motor and Hydracheck

4 312759R

Code B Part

A LC1___ Nylon Piston, Stainless Steel Metering

B LC2___ UHMWPE Piston, Stainless Steel

C LC3___ UHMWPE Piston, Ceramic Metering

Code C Part High Volume Piston Size (mm2)

1 80, Available in Nylon Only

2 100, Available in Nylon Only

3 120, Available in Nylon Only

High Volume Side Piston and

Metering Tube Material

Tube (last three digits of part number

is the mm

Metering Tube (last three digits of part

number is the mm

Tube (last three digits of part number

is the mm

2

piston size)

2

2

piston size)

piston size)

Page 5

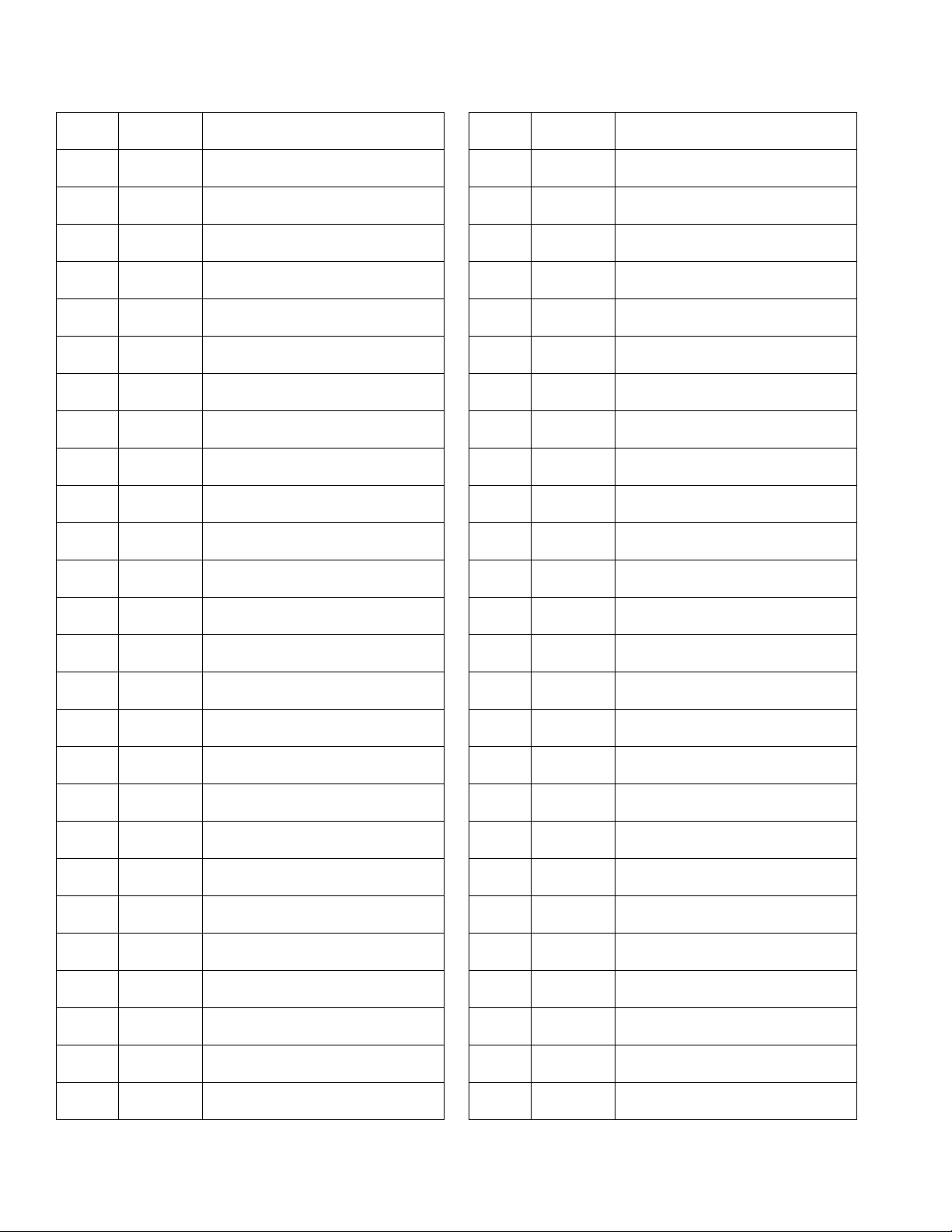

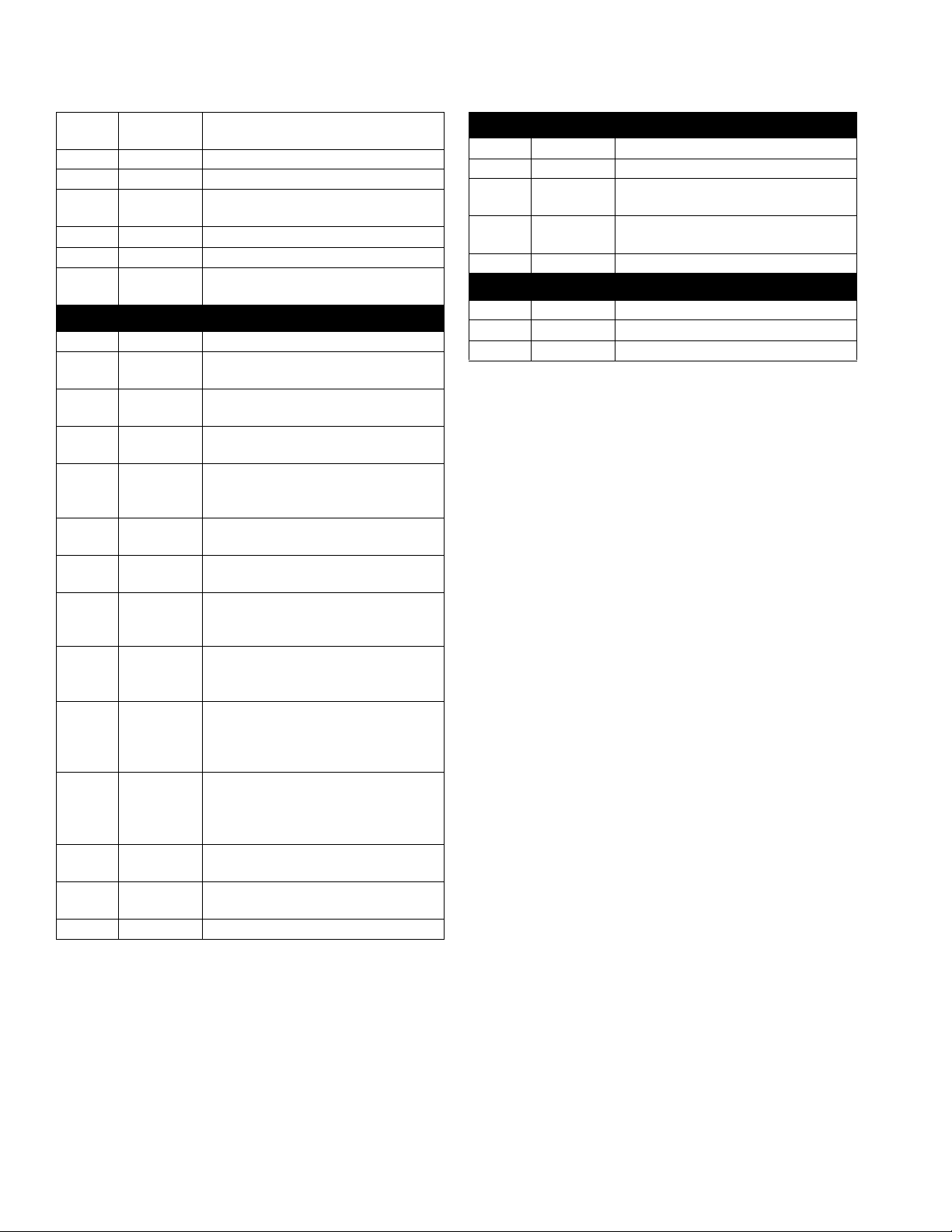

Product Configurator

4 140, Available in Nylon Only

5 160

6 180

7 200

8 220

9 240

A 260

B 280

C 300

F 320

G 360

H 400

J 440

L 480

M 520

R 560

S 600

T 640

U 720

W 800

X 880

Y 960

Z Custom High Volume side, consult fac-

tory (stainless steel only)

Low Volume Side Piston and

Code D Part

Metering Tube Material

A LC1___ Nylon Piston, Stainless Steel Metering

Tube (last three digits of part number

is the mm2 piston size)

B LC2___ UHMWPE Piston, Stainless Steel

Metering Tube (last three digits of part

2

number is the mm

piston size)

C LC3___ UHMWPE Piston, Ceramic Metering

Tube (last three digits of part number

2

is the mm

piston size)

Code E Part Low Volume Side Piston Size (mm2)

1 80, Available in Nylon Only

2 100, Available in Nylon Only

3 120, Available in Nylon Only

4 140, Available in Nylon Only

5 160

6 180

7 200

8 220

9 240

A 260

B 280

C 300

F 320

G 360

H 400

J440

L 480

M520

R560

S600

T 640

U720

W800

X880

Y 960

Z Custom Low Volume side, consult fac-

tory (stainless steel only)

Code F Par t Controls

B LC0272 Standard Display Module with 1 Fluid

Control Module

D LC0274 Advanced Display Module with 1 Fluid

Control Module

E LC0275 Advanced Display Module with 2 Fluid

Control Modules

Codes

G-H,

I-J

Part

High Volume Hose /

Low Volume Hose

A1 LC0801 3/16 in. (4.8 mm) - 2.5 ft (0.6 m)

A2 LC0802 3/16 in. (4.8 mm) - 10 ft (3.0 m)

A3 LC0803 3/16 in. (4.8 mm) - 15 ft (4.6 m)

A4 LC0804 1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

A5 LC0805 1/4 in. (6.5 mm) - 10 ft (3.0 m)

A6 LC0806 1/4 in. (6.5 mm) - 15 ft (4.6 m)

A7 LC0807 3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

A8 LC0808 3/8 in. (9.5 mm) - 10 ft (3.0 m)

A9 LC0809 3/8 in. (9.5 mm) - 15 ft (4.6 m)

AA LC0810 1/2 in. (13 mm) - 2.5 ft (0.6 m)

AB LC0811 1/2 in. (13 mm) - 10 ft (3.0 m)

AC LC0812 1/2 in. (13 mm) - 15 ft (4.6 m)

AG LC0813 3/4 in. (19 mm) - 10 ft (3.0 m)

AH LC0814 3/4 in. (19 mm) - 15 ft (4.6 m)

B4 LC0881 Heated, 1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

B5 LC0882 Heated, 1/4 in. (6.5 mm) - 10 ft (3.0 m)

B6 LC0883 Heated, 1/4 in. (6.5 mm) - 15 ft (4.6 m)

B7 LC0884 Heated, 3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

B8 LC0885 Heated, 3/8 in. (9.5 mm) - 10 ft (3.0 m)

B9 LC0886 Heated, 3/8 in. (9.5 mm) - 15 ft (4.6 m)

BA LC0887 Heated, 1/2 in. (13 mm) - 2.5 ft (0.6 m)

BB LC0888 Heated, 1/2 in. (13 mm) - 10 ft (3.0 m)

BC LC0889 Heated, 1/2 in. (13 mm) - 15 ft (4.6 m)

BG LC0890 Heated, 3/4 in. (19 mm) - 10 ft (3.0 m)

BH LC0891 Heated, 3/4 in. (19 mm) - 15 ft (4.6 m)

C1 LC0161 Recirculating, On-Board Tanks,

3/16 in. (4.8 mm) - 2.5 ft (0.6 m)

C2 LC0162 Recirculating, On-Board Tanks,

3/16 in. (4.8 mm) - 10 ft (3.0 m)

312759R 5

Page 6

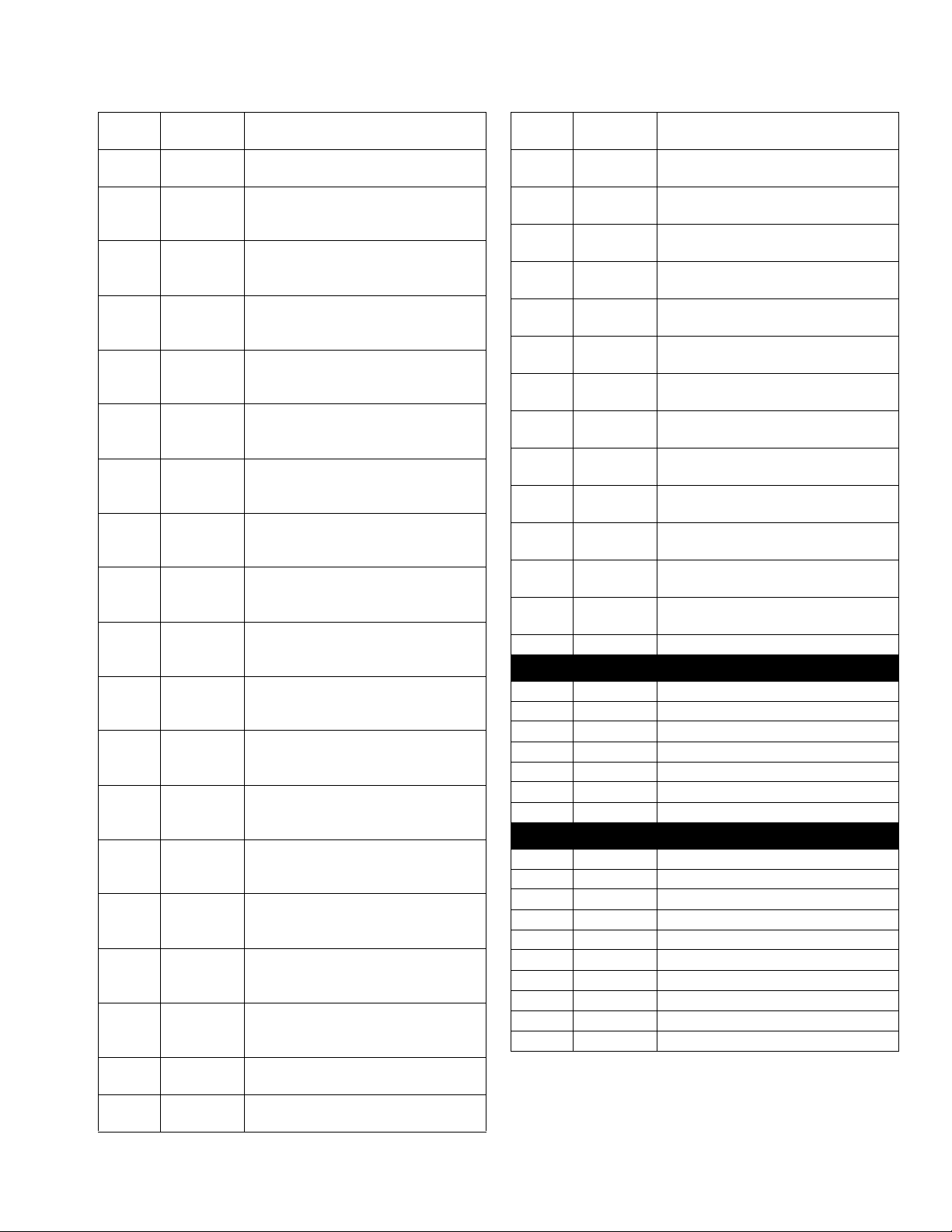

Product Configurator

C3 LC0163 Recirculating, On-Board Tanks,

3/16 in. (4.8 mm) - 15 ft (4.6 m)

C4 LC0164 Recirculating, On-Board Tanks,

1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

C5 LC0165 Recirculating, On-Board Tanks,

1/4 in. (6.5 mm) - 10 ft (3.0 m)

C6 LC0166 Recirculating, On-Board Tanks,

1/4 in. (6.5 mm) - 15 ft (4.6 m)

C7 LC0167 Recirculating, On-Board Tanks,

3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

C8 LC0168 Recirculating, On-Board Tanks,

3/8 in. (9.5 mm) - 10 ft (3.0 m)

C9 LC0169 Recirculating, On-Board Tanks,

3/8 in. (9.5 mm) - 15 ft (4.6 m)

CA LC0170 Recirculating, On-Board Tanks,

1/2 in. (13 mm) - 2.5 ft (0.6 m)

CB LC0171 Recirculating, On-Board Tanks,

1/2 in. (13 mm) - 10 ft (3.0 m)

CC LC0172 Recirculating, On-Board Tanks,

1/2 in. (13 mm) - 15 ft (4.6 m)

CD LC0173 Recirculating, On-Board Tanks,

3/4 in. (19 mm) - 10 ft (3.0 m)

CE LC0174 Recirculating, On-Board Tanks,

3/4 in. (19 mm) - 15 ft (4.6 m)

D1 LC0175 Recirculating, Off-Board Tanks,

3/16 in. (4.8 mm) - 2.5 ft (0.6 m)

D2 LC0176 Recirculating, Off-Board Tanks,

3/16 in. (4.8 mm) - 10 ft (3.0 m)

D3 LC0177 Recirculating, Off-Board Tanks,

3/16 in. (4.8 mm) - 15 ft (4.6 m)

D4 LC0178 Recirculating, Off-Board Tanks,

1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

D5 LC0179 Recirculating, Off-Board Tanks,

1/4 in. (6.5 mm) - 10 ft (3.0 m)

D6 LC0180 Recirculating, Off-Board Tanks,

1/4 in. (6.5 mm) - 15 ft (4.6 m)

D7 LC0181 Recirculating, Off-Board Tanks,

3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

D8 LC0182 Recirculating, Off-Board Tanks,

3/8 in. (9.5 mm) - 10 ft (3.0 m)

D9 LC0183 Recirculating, Off-Board Tanks,

3/8 in. (9.5 mm) - 15 ft (4.6 m)

DA LC0184 Recirculating, Off-Board Tanks,

1/2 in. (13 mm) - 2.5 ft (0.6 m)

DB LC0185 Recirculating, Off-Board Tanks,

1/2 in. (13 mm) - 10 ft (3.0 m)

DC LC0186 Recirculating, Off-Board Tanks,

1/2 in. (13 mm) - 15 ft (4.6 m)

DD LC0187 Recirculating, Off-Board Tanks,

3/4 in. (19 mm) - 10 ft (3.0 m)

DE LC0188 Recirculating, Off-Board Tanks,

3/4 in. (19 mm) - 15 ft (4.6 m)

E1 LC0190 Recirculating, Heated, On-Board

Tanks, 1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

E2 LC0191 Recirculating, Heated, On-Board

Tanks, 1/4 in. (6.5 mm) - 10 ft (3.0 m)

E3 LC0192 Recirculating, Heated, On-Board

Tanks, 1/4 in. (6.5 mm) - 15 ft (4.6 m)

E4 LC0193 Recirculating, Heated, On-Board

Tanks, 3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

E5 LC0194 Recirculating, Heated, On-Board

Tanks, 3/8 in. (9.5 mm) - 10 ft (3.0 m)

E6 LC0195 Recirculating, Heated, On-Board

Tanks, 3/8 in. (9.5 mm) - 15 ft (4.6 m)

E7 LC0196 Recirculating, Heated, On-Board

Tanks, 1/2 in. (13 mm) - 2.5 ft (0.6 m)

E8 LC0197 Recirculating, Heated, On-Board

Tanks, 1/2 in. (13 mm) - 10 ft (3.0 m)

E9 LC0198 Recirculating, Heated, On-Board

Tanks, 1/2 in. (13 mm) - 15 ft (4.6 m)

EA LC0199 Recirculating, Heated, On-Board

Tanks, 3/4 in. (19 mm) - 10 ft (3.0 m)

EB LC0200 Recirculating, Heated, On-Board

Tanks, 3/4 in. (19 mm) - 15 ft (4.6 m)

F1 LC0201 Recirculating, Heated, Off-Board

Tanks, 1/4 in. (6.5 mm) - 2.5 ft (0.6 m)

F2 LC0202 Recirculating, Heated, Off-Board

Tanks, 1/4 in. (6.5 mm) - 10 ft (3.0 m)

F3 LC0203 Recirculating, Heated, Off-Board

Tanks, 1/4 in. (6.5 mm) - 15 ft (4.6 m)

F4 LC0204 Recirculating, Heated, Off-Board

Tanks, 3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

F5 LC0205 Recirculating, Heated, Off-Board

Tanks, 3/8 in. (9.5 mm) - 10 ft (3.0 m)

F6 LC0206 Recirculating, Heated, Off-Board

Tanks, 3/8 in. (9.5 mm) - 15 ft (4.6 m)

F7 LC0207 Recirculating, Heated, Off-Board

Tanks, 1/2 in. (13 mm) - 2.5 ft (0.6 m)

F8 LC0208 Recirculating, Heated, Off-Board

Tanks, 1/2 in. (13 mm) - 10 ft (3.0 m)

F9 LC0209 Recirculating, Heated, Off-Board

Tanks, 1/2 in. (13 mm) - 15 ft (4.6 m)

FA LC0210 Recirculating, Heated, Off-Board

Tanks, 3/4 in. (19 mm) - 10 ft (3.0 m)

FB LC0211 Recirculating, Heated, Off-Board

Tanks, 3/4 in. (19 mm) - 15 ft (4.6 m)

GA LC0400 High Pressure, 3/8 in. (9.5 mm) - 2.5 ft

(0.6 m)

GB LC0401 High Pressure, 3/8 in. (9.5 mm) - 10 ft

(3.0 m)

GC LC0402 High Pressure, 3/8 in. (9.5 mm) - 15 ft

(4.6 m)

GD LC0403 High Pressure, 1/2 in. (13 mm) - 2.5 ft

(0.6 m)

GE LC0404 High Pressure, 1/2 in. (13 mm) - 10 ft

(3.0 m)

GF LC0405 High Pressure, 1/2 in. (13 mm) - 15 ft

(4.6 m)

6 312759R

Page 7

Product Configurator

GH LC0406 High Pressure, 3/4 in. (19 mm) - 10 ft

(3.0 m)

GJ LC0407 High Pressure, 3/4 in. (19 mm) - 15 ft

(4.6 m)

GK LC0432 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

GL LC0433 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 10 ft (3.0 m)

GM LC0434 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 15 ft (4.6 m)

GQ LC0435 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 2.5 ft (0.6 m)

GR LC0436 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 10 ft (3.0 m)

GS LC0437 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 15 ft (4.6 m)

GT LC0438 High Pressure, Recirculating,

On-Board Tanks,

3/4 in. (19 mm) - 10 ft (3.0 m)

GU LC0439 High Pressure, Recirculating,

On-Board Tanks,

3/4 in. (19 mm) - 15 ft (4.6 m)

GW LC0440 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 2.5 ft (0.6 m)

GX LC0441 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 10 ft (3.0 m)

GY LC0442 High Pressure, Recirculating,

On-Board Tanks,

3/8 in. (9.5 mm) - 15 ft (4.6 m)

G1 LC0443 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 2.5 ft (0.6 m)

G2 LC0444 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 10 ft (3.0 m)

G3 LC0445 High Pressure, Recirculating,

On-Board Tanks,

1/2 in. (13 mm) - 15 ft (4.6 m)

G4 LC0446 High Pressure, Recirculating,

On-Board Tanks,

3/4 in. (19 mm) - 10 ft (3.0 m)

G5 LC0447 High Pressure, Recirculating,

On-Board Tanks,

3/4 in. (19 mm) - 15 ft (4.6 m)

HA LC0472 High Pressure, Heated, 3/8 in. (9.5

mm) - 2.5 ft (0.6 m)

HB LC0473 High Pressure, Heated, 3/8 in. (9.5

mm) - 10 ft (3.0 m)

HC LC0474 High Pressure, Heated, 3/8 in. (9.5

mm) - 15 ft (4.6 m)

HF LC0475 High Pressure, Heated, 1/2 in. (13

mm) - 2.5 ft (0.6 m)

HG LC0476 High Pressure, Heated, 1/2 in. (13

mm) - 10 ft (3.0 m)

HJ LC0477 High Pressure, Heated, 1/2 in. (13

mm) - 15 ft (4.6 m)

HL LC0478 High Pressure, Heated, 3/4 in. (19

mm) - 10 ft (3.0 m)

HM LC0479 High Pressure, Heated, 3/4 in. (19

mm) - 15 ft (4.6 m)

HQ LC0480 High Pressure, Heated, 3/8 in. (9.5

mm) - 2.5 ft (0.6 m)

HR LC0481 High Pressure, Heated, 3/8 in. (9.5

mm) - 10 ft (3.0 m)

HS LC0482 High Pressure, Heated, 3/8 in. (9.5

mm) - 15 ft (4.6 m)

HT LC0483 High Pressure, Heated, 1/2 in. (13

mm) - 2.5 ft (0.6 m)

HU LC0484 High Pressure, Heated, 1/2 in. (13

mm) - 10 ft (3.0 m)

HX LC0485 High Pressure, Heated, 1/2 in. (13

mm) - 15 ft (4.6 m)

HY LC0486 High Pressure, Heated, 3/4 in. (19

mm) - 10 ft (3.0 m)

H2 LC0487 High Pressure, Heated, 3/4 in. (19

mm) - 15 ft (4.6 m)

NN --- Not required

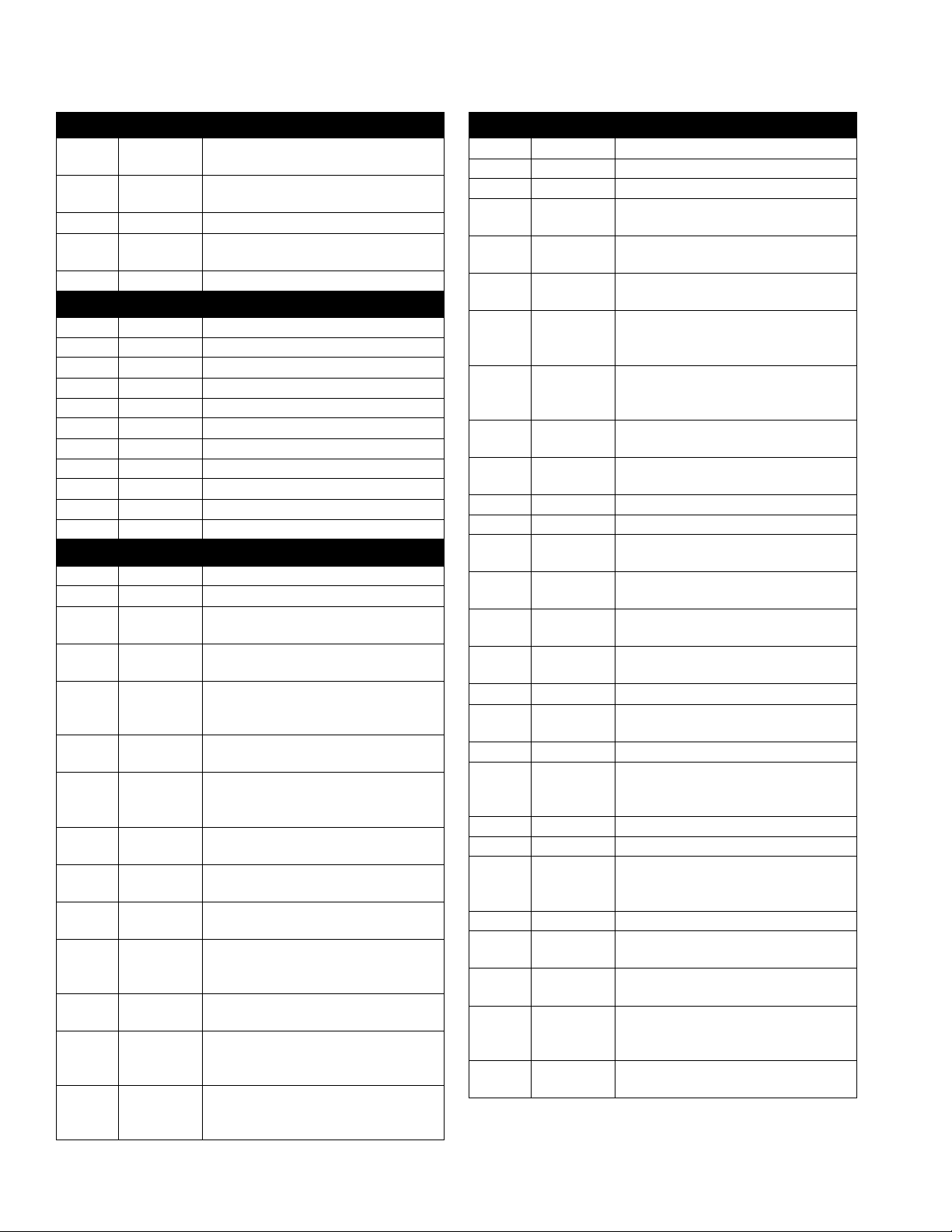

Code K Part Dispense Valve

NN/ANone

2 255179 MD2, Valve Only with 1:1 Nose

3 255181 MD2, Valve Only with 10:1 Nose

4 LC0120 MD2, Handheld with 1:1 Nose

5 LC0122 MD2, Handheld with 10:1 Nose

6 LC0121 MD2, Lever with 1:1 Nose

7 LC0123 MD2, Lever with 10:1 Nose

Code L Par t Mixer Type

NN/ANone

1 LC0063 3/16 in. (4.8 mm) x 32

2 LC0057 1/4 in. (6.4 mm) x 24

3 LC0058 3/8 in. (9.5 mm) x 24

4 LC0059 3/8 in. (9.5 mm) x 36

5 LC0060 3/8 in. (9.5 mm) Combo

6 LC0062 1/4 in. (6.4 mm) x 24 Luer Lock

7 LC0061 3/16 in. (4.8 mm) x 32 Luer Lock

8 LC0295 1/2 in. (12.7 mm) x 24

9 LC0296 1/2 in. (12.7 mm) x 36

312759R 7

Page 8

Product Configurator

Code M Part Applicator Mounting

N LC0294 None, Customer Mount Controls and

Applicator

1 LC0292 Mast Mount, Controls & MD2 Applica-

tor Machine Mounted

2 LC0293 Mast Mount, Controls Only

3 256439 Tank Stand Mount, Controls & MD2

Applicator Machine Mounted

4 256438 Tank Stand Mount, Controls Only

Code N Part Power Cord Option

1 121055 120VAC North American Cord Set

2 121054 10A, 250V US Cord Set

3 121056 10A, 250V Continental europe

4 121057 10A, 250V U.K./Ireland

5 121058 10A, 250V Israel

6 124864 10A, 250V Australia

7 124861 10A, 250V Italy

8 124863 10A, 250V Switzerland

9 124862 10A, 250V Denmark

A 121060 10A, 250V India

B N/A Heat Controller Option

Code O Part Flow Monitoring

N LC0041 None

1 257433 Pressure Transducer

2 LC0302 Two 0.5 gpm Flow Meters, No Pres-

sure Transducers

3 LC0305 Two 1.0 gpm Flow Meters, No Pres-

sure Transducers

4 LC0303 One 1.0 gpm Flow Meter, One

0.5 gpm Flow Meter, No Pressure

Transducers

5 LC0307 Two 2.0 gpm Flow Meters, No Pres-

sure Transducers

6 LC0306 One 2.0 gpm Flow Meter, One

1.0 gpm Flow Meter, No Pressure

Transducers

7 LC0304 One 2.0 gpm Flow Meter, One 0.5 gpm

Flow Meter, No Pressure Transducers

A LC0312 Two 0.5 gpm Flow Meters, With Pres-

sure Transducers

B LC0315 Two 1.0 gpm Flow Meters, With Pres-

sure Transducers

C LC0313 One 1.0 gpm Flow Meter, One

0.5 gpm Flow Meter, With Pressure

Transducers

D LC0317 Two 2.0 gpm Flow Meters, With Pres-

sure Transducers

E LC0316 One 2.0 gpm Flow Meter, One

1.0 gpm Flow Meter, With Pressure

Transducers

F LC0314 One 2.0 gpm Flow Meter, One 0.5 gpm

Flow Meter, With Pressure Transduc-

ers

Code P Part High Volume Side Tank

NN/ANone

1 256896 No Tanks, 1 1/2 in. npt flange

2 255241 8 L, Twin Polyethylene Tanks and Lids

3 255250 8 L, Twin Polyethylene Tanks and Lids,

One 120V Agitator

4 255251 8 L, Twin Polyethylene Tanks and Lids,

Two 120V Agitators

5 255281 8 L, Twin Polyethylene Tanks and Lids,

with Shut-Off Valves

6 255282 8 L, Twin Polyethylene Tanks and Lids,

One 120V Agitator, with Shut-Off

Valves

7 255283 8 L, Twin Polyethylene Tanks and Lids,

Two 120V Agitators, with Shut-Off

Valves

8 LC0235★ 7.5 L, Stainless Steel, High Level Sen-

sors

9 LC0236★ 7.5 L, Stainless Steel, High Level Sen-

sors, with Shut-Off Valve

A LC0013★ 3 L, Stainless Steel

B LC0012★ 7.5 L, Stainless Steel

C 255285★ 3 L, Stainless Steel, with Shut-Off

Valve

D LC0156 8 L, Twin Polyethylene Tanks and Lids,

One Pneumatic Agitator

E LC0157 8 L, Twin Polyethylene Tanks and Lids,

Two Pneumatic Agitator

F 255284★ 7.5 L, Stainless Steel, with Shut-Off

Valve

G LC0254★ 7.5 L, Stainless Steel, 240V Heat

H LC0255★ 7.5 L, Stainless Steel, 240V Heat,

with Shut-Off Valve

J LC0054 30 L, Stainless Steel

K LC0158 8 L, Twin Polyethylene Tanks and Lids,

One Pneumatic Agitator, with Shut-Off

Valves

L LC0259 30 L, Stainless Steel, 240V Heat

M LC0055 60 L, Stainless Steel

P LC0159 8 L, Twin Polyethylene Tanks and Lids,

Two Pneumatic Agitators, with

Shut-Off Valves

R LC0260 60 L, Stainless Steel, 240V Heat

S LC0126 8 L, Twin Polyethylene Tanks and Lids,

One 240V Agitator

T LC0127 8 L, Twin Polyethylene Tanks and Lids,

Two 240V Agitators

U LC0128 8 L, Twin Polyethylene Tanks and Lids,

One 240V Agitator, with Shut-Off

Valves

V LC0238★ 7.5 L, Stainless Steel, High Level Sen-

sors, 240V Heat, with Shut-Off Valve

8 312759R

Page 9

Product Configurator

W LC0129 8 L, Twin Polyethylene Tanks and Lids,

Two 240V Agitators, with Shut-Off

Val ves

X LC0160 Accumulator, Fluoroelastomer

Y LC0297 Accumulator, EP

Z LC0237★ 7.5 L, Stainless Steel, High Level Sen-

sors, 240V Heat

--- ★ When ordering tanks for spare or

replacement parts, refer to Parts section of the PR70 and PR70v Feed Systems manual.

Code Q Part High Volume Side Tank Cover

N N/A None

1 LC0018 On-Board Dust Cover

2 LC0019 On-Board Clamp Down

3 LC0020 On-Board Vacuum De-gas

4 LC0021 On-Board Agitate 120VAC 50/60 Hz

5 LC0022 On-Board Agitate 240VAC 50/60 Hz

6 LC0023 On-Board Agitate 120 VAC 50/60 Hz

and De-gas

7 LC0024 On-Board Agitate 240 VAC 50/60 Hz

and De-gas

8 LC0025 On-Board 120VAC 50/60 Hz, De-gas

and Fill-Port

9 LC0026 On-Board 240 VAC 50/60 Hz, De-gas

and Fill-Port

A LC0142 Off-Board Clamp Down - 30L

B LC0101 Off-Board Clamp Down - 60L

C LC0043 Off-Board Vacuum De-gas - 30L

F LC0102 Off-Board Vacuum De-gas - 60L

G LC0047 Off-Board Electric Agitator - 30L

H LC0048 Off-Board Electric Agitator - 60L

K LC0147 Off-Board Vacuum De-gas, Pneu-

matic Agitator, Fill Port, Slinger - 60 L

M LC0051 Off-Board Vacuum De-gas, Electric

Agitator, Fill Port, Slinger - 30 L

R LC0052 Off-Board Vacuum De-gas, Electric

Agitator, Fill Port, Slinger - 60 L

S LC0130 On-Board, Pneumatic Agitate

T LC0131 On-Board, Pneumatic Agitate, De-gas

U LC0132 On-Board, Pneumatic Agitate, De-gas,

Fill Port

V LC0142 Off-Board Pneumatic Agitator - 30 L

W LC0143 Off-Board Pneumatic Agitator - 60 L

Z LC0146 Off-Board Vacuum De-gas, Pneu-

matic Agitator, Fill Port, Slinger - 30 L

Code R Part Low Volume Side Tank

N N/A None

1 256896 No Tanks, 1 1/2 in. npt flange

8 LC0235★ 7.5 L, Stainless Steel, High Level Sen-

sors

9 LC0236★ 7.5 L, Stainless Steel, High Level Sen-

sors,

with Shut-Off Valve

A LC0013★ 3 L, Stainless Steel

B LC0012★ 7.5 L, Stainless Steel

C 255285★ 3 L, Stainless Steel, with Shut-Off

Valve

F 255284★ 7.5 L, Stainless Steel, with Shut-Off

Valve

G LC0254★ 7.5 L, Stainless Steel, 240V Heat

H LC0255★ 7.5 L, Stainless Steel, 240V Heat,

with Shut-Off Valve

J LC0054 30 L, Stainless Steel

L LC0259 30 L, Stainless Steel, 240V Heat

M LC0055 60 L, Stainless Steel

R LC0260 60 L, Stainless Steel, 240V Heat

V LC0238★ 7.5 L, Stainless Steel, High Level Sen-

sors,

240V Heat, with Shut-Off Valve

X LC0160 Accumulator, Fluoroelastomer

Y LC0297 Accumulator, EP

Z LC0237★ 7.5 L, Stainless Steel, High Level Sen-

sors,

240V Heat

--- ★ When ordering tanks for spare or

replacement parts, refer to Parts section of the PR70 and PR70v Feed Systems manual.

Code S Part Low Volume Side Tank Covers

NN/ANone

1 LC0018 On-Board Dust Cover

2 LC0019 On-Board Clamp Down

3 LC0020 On-Board Vacuum De-gas

4 LC0021 On-Board Agitate 120VAC 50/60 Hz

5 LC0022 On-Board Agitate 240VAC 50/60 Hz

6 LC0023 On-Board Agitate 120 VAC 50/60 Hz

and De-gas

7 LC0024 On-Board Agitate 240 VAC 50/60 Hz

and De-gas

8 LC0025 On-Board 120VAC 50/60 Hz, De-gas

and Fill-Port

9 LC0026 On-Board 240 VAC 50/60 Hz, De-gas

and Fill-Port

A LC0142 Off-Board Clamp Down - 30L

B LC0101 Off-Board Clamp Down - 60L

C LC0043 Off-Board Vacuum De-gas - 30L

F LC0102 Off-Board Vacuum De-gas - 60L

G LC0047 Off-Board Electric Agitator - 30L

H LC0048 Off-Board Electric Agitator - 60L

K LC0147 Off-Board Vacuum De-gas, Pneu-

matic Agitator, Fill Port, Slinger - 60 L

M LC0051 Off-Board Vacuum De-gas, Electric

Agitator, Fill Port, Slinger - 30 L

312759R 9

Page 10

Product Configurator

R LC0052 Off-Board Vacuum De-gas, Electric

Agitator, Fill Port, Slinger - 60 L

S LC0130 On-Board, Pneumatic Agitate

T LC0131 On-Board, Pneumatic Agitate, De-gas

U LC0132 On-Board, Pneumatic Agitate, De-gas,

Fill Port

V LC0142 Off-Board Pneumatic Agitator - 30 L

W LC0143 Off-Board Pneumatic Agitator - 60 L

Z LC0146 Off-Board Vacuum De-gas, Pneu-

matic Agitator, Fill Port, Slinger - 30 L

Code T Part Tank Level Sensors

N N/A None

2 LC0278 Polyethylene Tanks - Low Level Sen-

sors Only

3 LC0279 Two 7.5 L Stainless Steel Tanks - Low

Level Sensors Only

4 LC0282 Two 30 L or 60 L Stainless Steel Tanks

- Low Level Sensors Only

5 LC0281 7.5 L Stainless Steel - Low Level Sen-

sors Only, and 30 L or 60 L Stainless

Steel - Low Level Sensors Only

6 LC0280 Accumulator Sensors, and 7.5 L Low

Level Sensors

7 LC0283 Accumulator Sensors, and 30 L or

60 L Low Level Sensors

9 LC0284 Two 7.5 L Stainless Steel Tanks - High

and Low Level Sensors with Refill

Logic

A LC0287 Two 30 L or 60 L Stainless Steel Tanks

- High and Low Level Sensors with

Refill Logic

B LC0286 7.5 L Stainless Steel - Low Level Sen-

sors, and

30 L or 60 L Stainless Steel - High and

Low Level Sensors with Refill Logic

C LC0289 7.5 L Stainless Steel - High and Low

Level Sensors with Refill Logic, and

30 L or 60 L Stainless Steel - High and

Low Level Sensors with Refill Logic

D LC0285 Accumulator Sensors, and 7.5 L High

and Low Level Sensors

E LC0288 Accumulator Sensors, and 30 L or

60 L High and Low Level Sensors

G N/A Two Sets of Accumulator Sensors

Code U Part Heat Zone Controller

NN/ANone

C LC0250 1 Tank or 1 Hose

D LC0251 2 Tanks, 1 Tank and 1 Hose, or 2

Hoses

E LC0252 2 Tanks and 1 Hose, or 1 Tank and 2

Hoses

F LC0253 2 Tanks and 2 Hoses

Code V Part Off-Board Tank Stands

NN/ANone

2 LC0103 PR70 Tank Stand

3 LC0247 PR70v Tank Stand

10 312759R

Page 11

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

312759R 11

Page 12

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

12 312759R

Page 13

Component Identification

Component Identification

101

103

106

105

111

110

104

102

ti13389b

119

Key:

101 Tanks

102 Dispense Head

103 Snuff Back Adjustment Knob

104 Advanced Display Module

105 System Air Pressure Regulator

106 System Air Pressure Relief

Switch

107 Power Switch

108 Water Separator

109 Air Inlet

110 Shield Locking Screws

111 Machine Shield

112 Agitator

119 Flow Meters

ti13388b

109

107

108

110

FIG. 1:PR70v with On-Board Tanks and Other Options

312759R 13

Page 14

Component Identification

113

116

101

117

105

106

113

112

115

110

114

111

ti12388b

118

103

104

102

ti12387b

Key:

101 Tanks

102 Dispense Head

103 Snuff Back Adjustment Knob

104 Advanced Display Module

105 System Air Pressure Regulator

106 System Air Pressure Relief Switch

107 Power Switch

108 Water Separator

109 Air Inlet

110 Shield Locking Screws

111 Machine Shield

112 Agitator

113 De-gas Valve Tree

114 Tank Air Pressure Gauge

115 Tank Stand

116 Refill Port

117 Accumulator

118 Accumulator Air Pressure Regulator

110

109

107

108

FIG. 2: PR70v with Off-Board Tank, Accumulator, and Other Options

14 312759R

Page 15

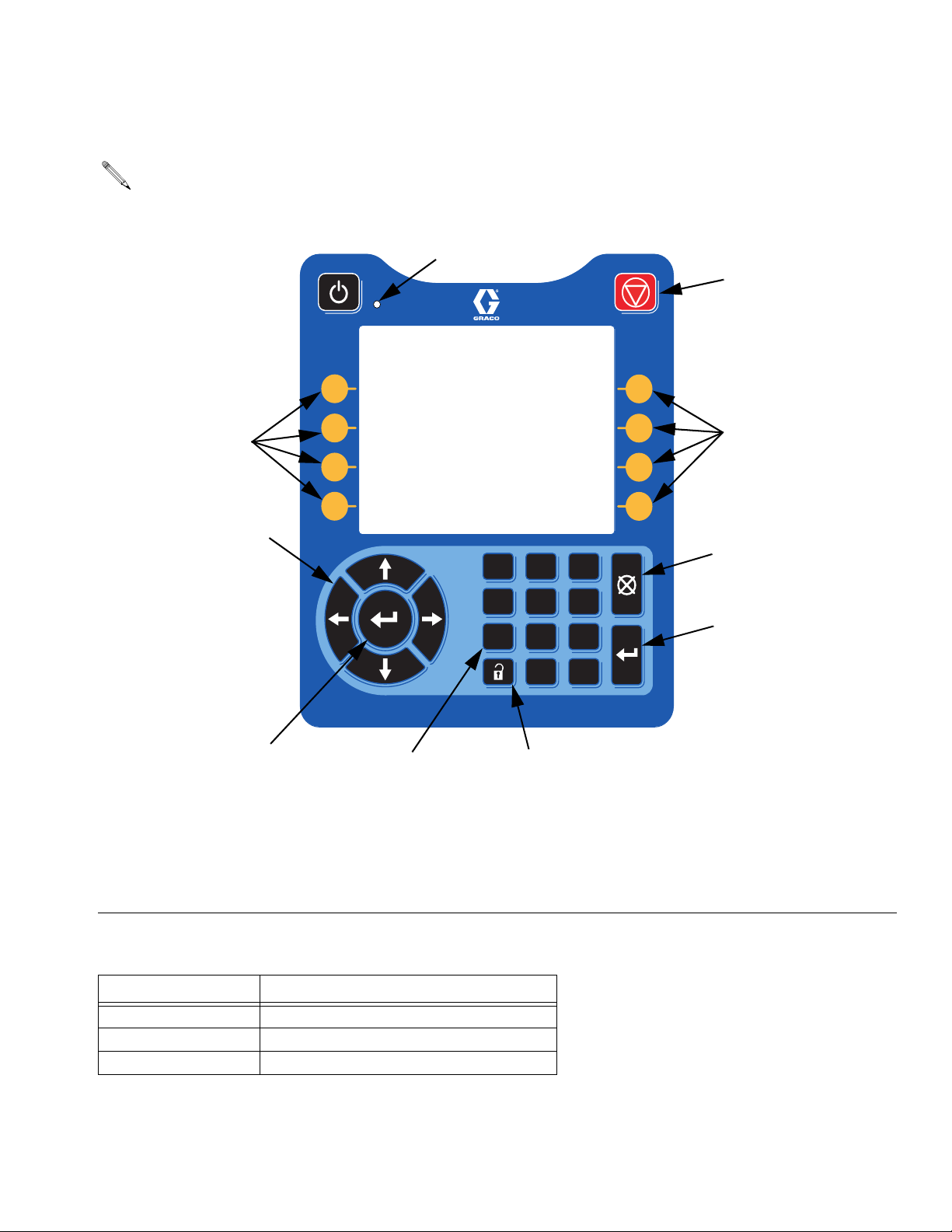

Advanced Display Module (ADM)

If an invalid key is pressed, the Advanced Display

Module will sound three quick beeps to notify the

user.

AJ

Component Identification

AB

AC

AD

AG

Key:

AB Machine Disable Mode Key

AC Soft Keys

AD Directional Keypad

AE Numeric Keypad

AE

AC

AF

1 2 3

4 5 6

AG

7 8 9

0 .

AH

AF Abort/Cancel Key

AG Enter Key

AH Alternate Setup/Operation Screens

AJ Module Status LED

IG. 3

F

Module Status LED Diagnostics

State Description

Solid Green System enabled, valid mode selected

Flashing Yellow System disabled (setup screens)

Solid Yellow System disabled (operation screens)

312759R 15

Page 16

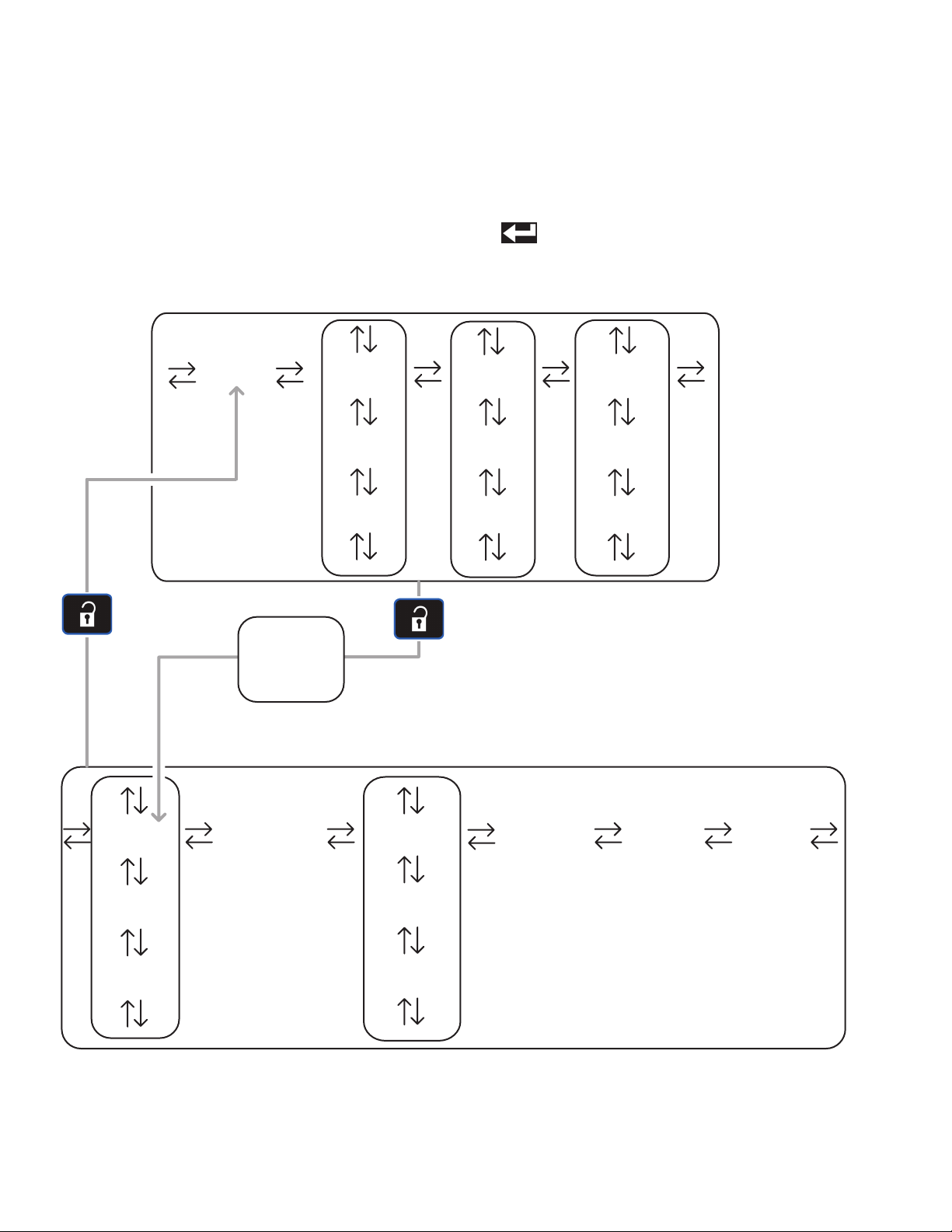

Screen Navigation Diagram

Screen Navigation Diagram

The black arrows in the diagram denote which arrow on

the directional keypad to press to move to the respective

screen.

Operation Screens

Home Data #1 Events #1

Data #2

Data #... Errors #... Events #...

If the password is enabled, the password will need to be

entered to access the Setup screens. Use the numeric

keypad to enter the password then press the Enter but-

ton ( ).

Errors #1

Errors #2 Events #2

Password

Entry

(if enabled)

Setup Screens

CalibrationEdit #1 Advanced System

Edit #2

Edit #... Options #...

Options #1

Options #2

Manual

16 312759R

Page 17

Grounding

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current. This product is equipped with a cord having a

grounding wire with an appropriate grounding plug. The

plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Improper installation of the grounding plug is able to

result in a risk of electric shock. When repair or replacement of the cord or plug is required, do not connect the

grounding wire to either flat blade terminal. The wire

with insulation having an outer surface that is green with

or without yellow stripes is the grounding wire. Do not

modify the plug provided; if it does not fit the outlet, have

the proper outlet installed by a qualified electrician. Only

connect the product to an outlet having the same configuration as the plug. Do not use an adapter with this

product.

access to compressed air and AC power and is well

ventilated.

2. Place the machine on the designated location. Allow

the machine to rest on the rubber feet provided.

Mount Machine, if Needed

3. Remove the shield locking screws (110) on both

sides then remove the protective shield.

4. Attach the frame to the selected location by installing fasteners (not provided with unit) through the

four mounting holes. See F

Variable Ratio

IG. 4.

ti12712a

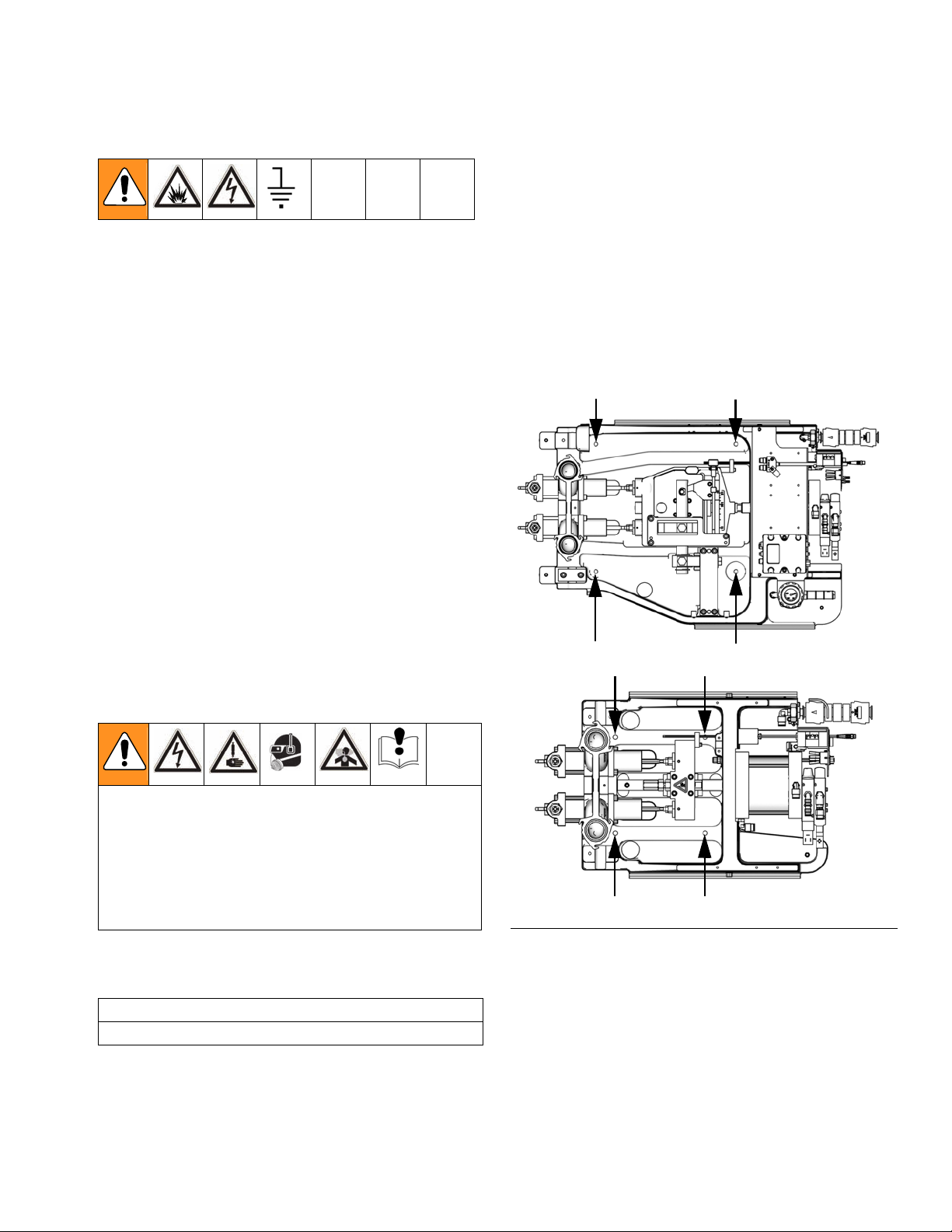

Installation

Avoid contact with electrical inter-connects when

connecting electric power to the machine. Avoid contact with Krytox on the pump shaft, PE tank lid, and

PE tank lid gasket. Contact with Krytox causes

flu-like symptoms. Read all manufacturer’s warning

and material MSDS to know the specific hazards of

the material used.

Machine Installation

CAUTION

Do not lift the machine by the tanks.

Locate Machine

1. Locate a bench top or open floor area to mechanically mount the machine. Ensure the location has

Fixed Ratio

ti12713a

FIG. 4: Mounting Holes

Connect Pressurized Air Input

5. Connect a compressed airline to the air inlet (109)

in the back of the machine.

312759R 17

Page 18

Installation

Electrical Requirements

Improper wiring may cause electric shock or other

serious injury if work is not performed properly. Have

a qualified electrician perform any electrical work. Be

sure your installation complies with all National, State

and Local safety and fire codes.

6. Using the power cord provided, connect AC power

(100-240V, 50/60 Hz, single-phase) to the machine.

Ground System

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

7. The machine is grounded through the power cord.

• Be sure that the plug is plugged into an outlet that is

properly installed and grounded in accordance with

all local codes and ordinances.

• Only connect the product to an outlet having the

same configuration as the plug.

Flush the System

8. The machine is tested at the factory with mineral oil.

Flush the machine before first use.

18 312759R

Page 19

Installation

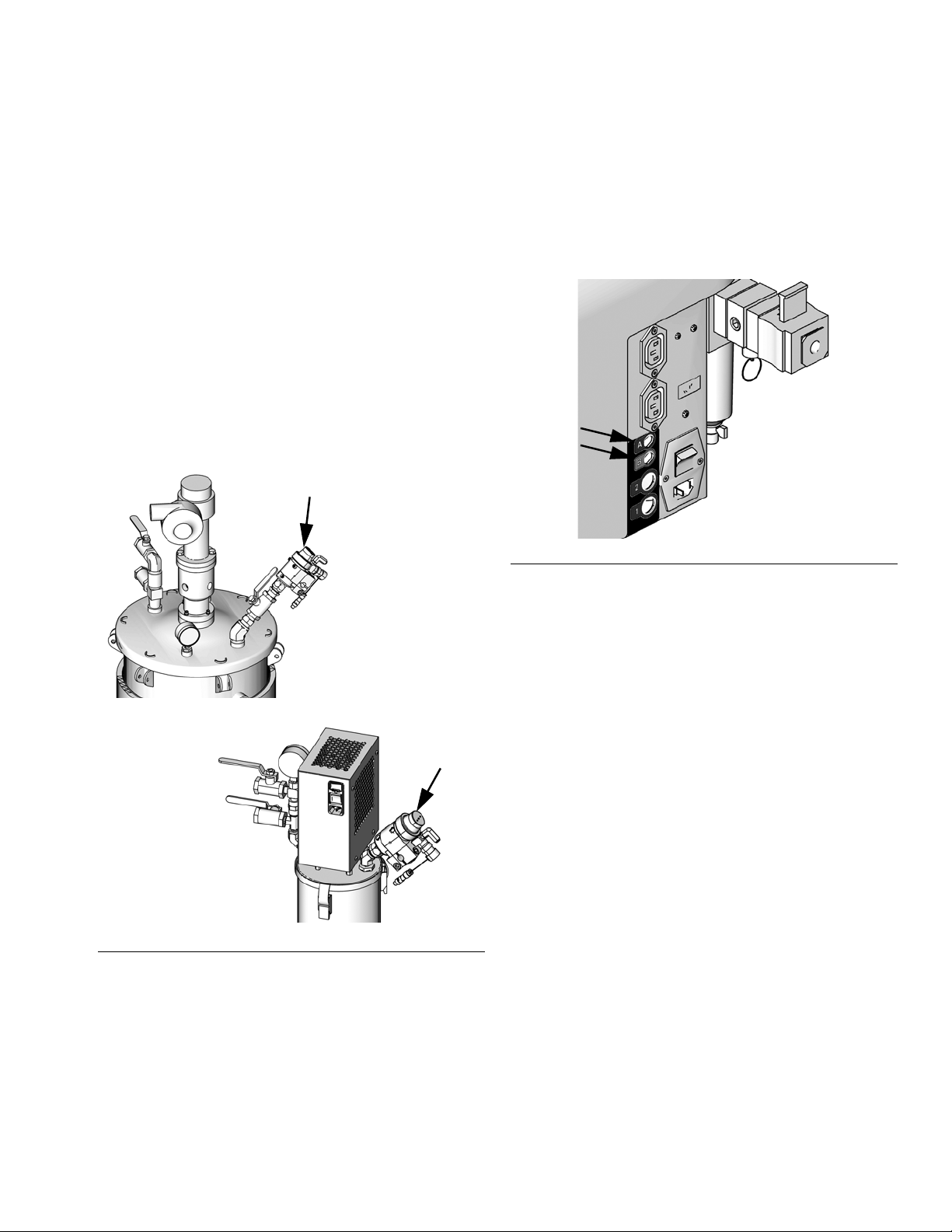

Tank Refill Kit 256577 Installation

The tank refill kit is shipped uninstalled. The tank refill kit

can be installed on the lid of the tank or on the side of

the tank. See F

Install the tank refill kit in the tank lid if using heat or agitation or if a slinger blade is installed in the tank. Install

the tank refill kit in the side of the tank if using thicker

materials. Pouring thick materials into the tank from the

lid can result in air added to the material. For all other

applications, install the tank refill kit in either location.

Tank Refill Kit Lid Installation

1. Use PTFE tape and the fittings supplied to install

the refill kit. See F

IG. 5 and FIG. 7.

IG. 5.

2. For tank refill kits installed on the A side tank,

plug the tank refill kit power cord into the “A” connector located at the back of the machine. See F

6.

For tank refill kits installed on the B side tank,

plug the tank refill kit power cord into the “B” connector located at the back of the machine. See F

6.

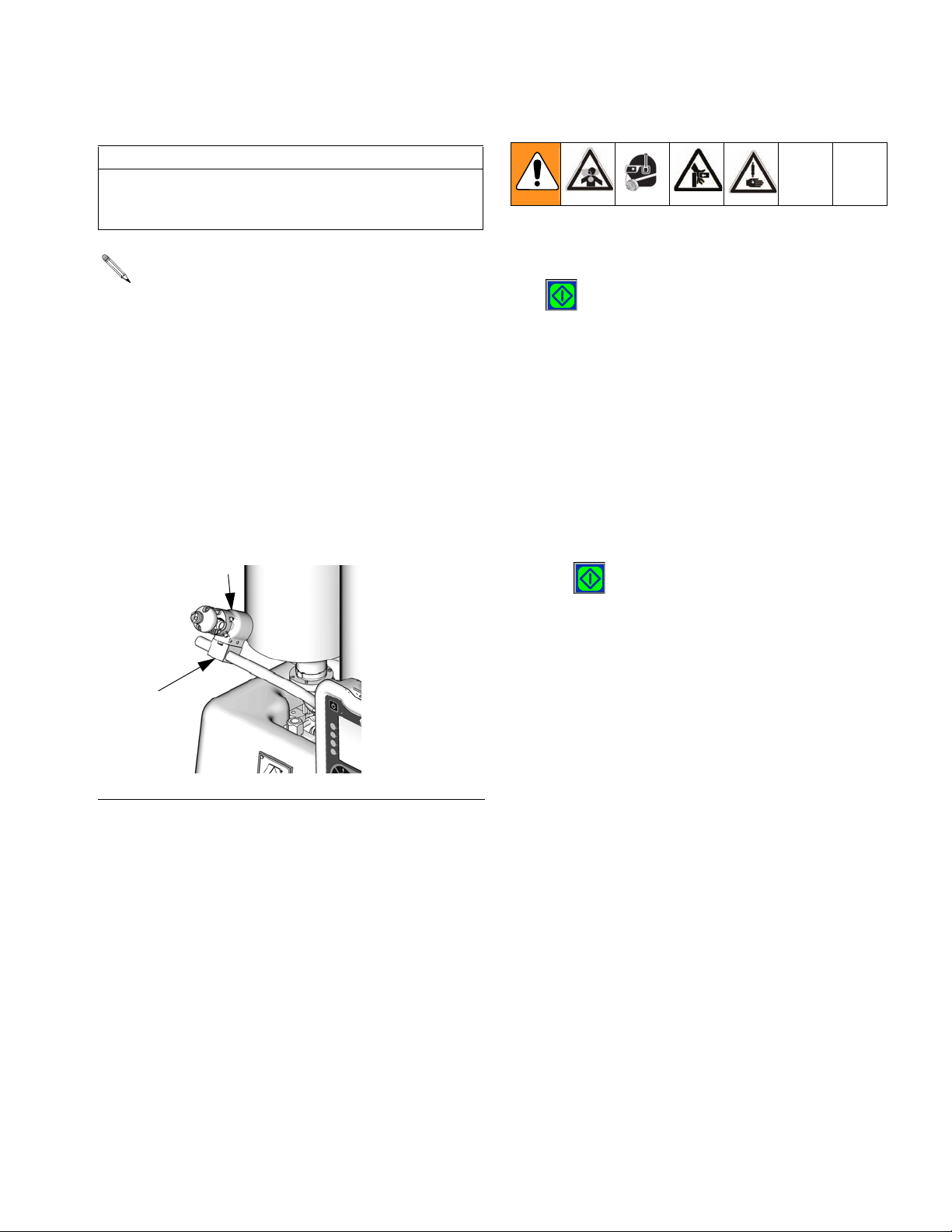

ti12583a

F

IG. 6: Tank Refill Kit Power Source

IG.

IG.

7.5 L Tanks

F

IG. 5: Tank Lid Installation

30 L or 60 L Tanks

ti13386a

ti13387a

312759R 19

Page 20

Installation

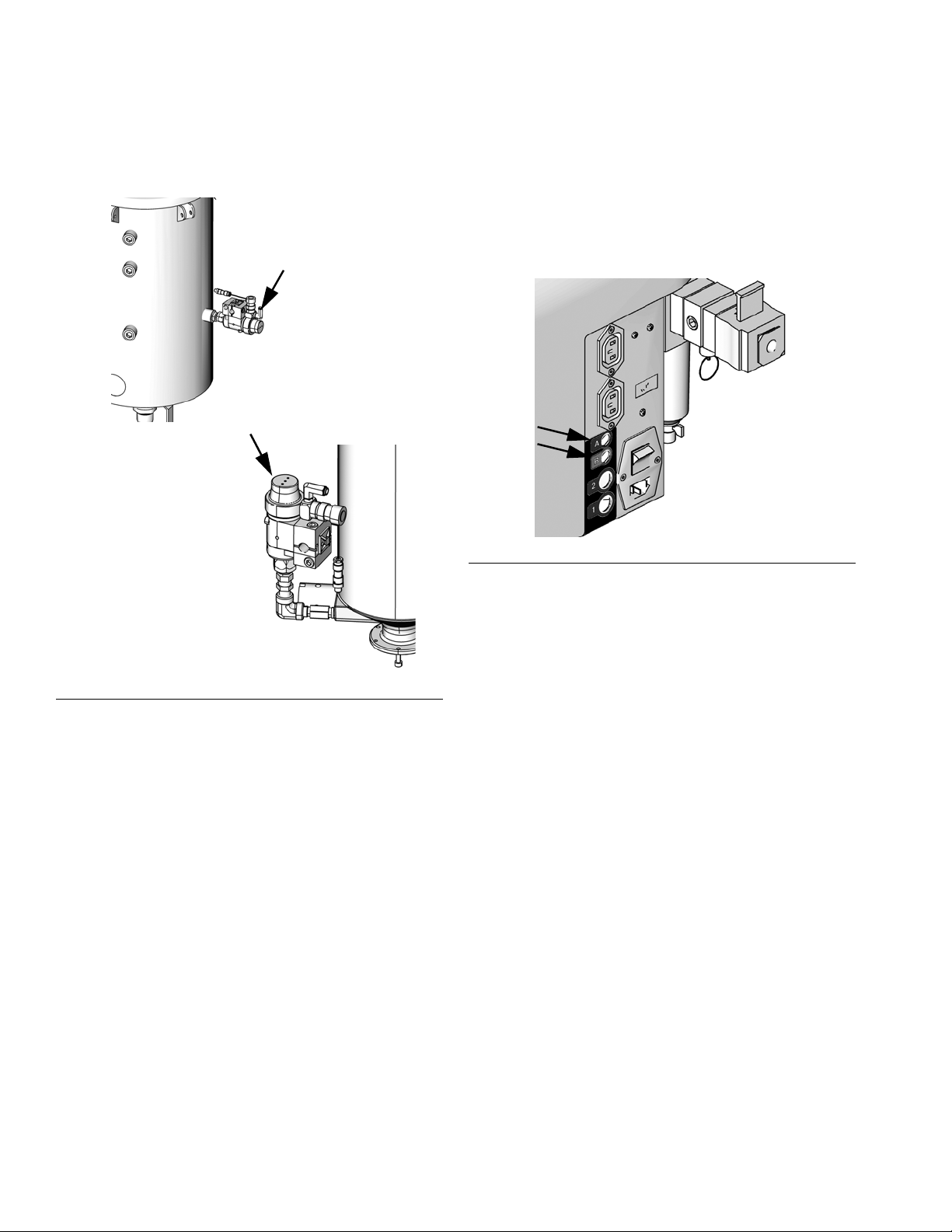

Tank Refill Kit Side Installation

1. Use PTFE tape and the fittings supplied to install

the refill kit as shown in F

ti13385a

7.5 L Tanks

IG. 7.

30 L or 60 L Tanks

2. For tank refill kits installed on the A side tank,

plug the tank refill kit power cord into the “A” connector located at the back of the machine. See F

8.

For tank refill kits installed on the B side tank,

plug the tank refill kit power cord into the “B” connector located at the back of the machine. See F

8.

ti12583a

F

IG. 8: Tank Refill Kit Power Source

IG.

IG.

F

IG. 7: Side Installation

ti12591b

20 312759R

Page 21

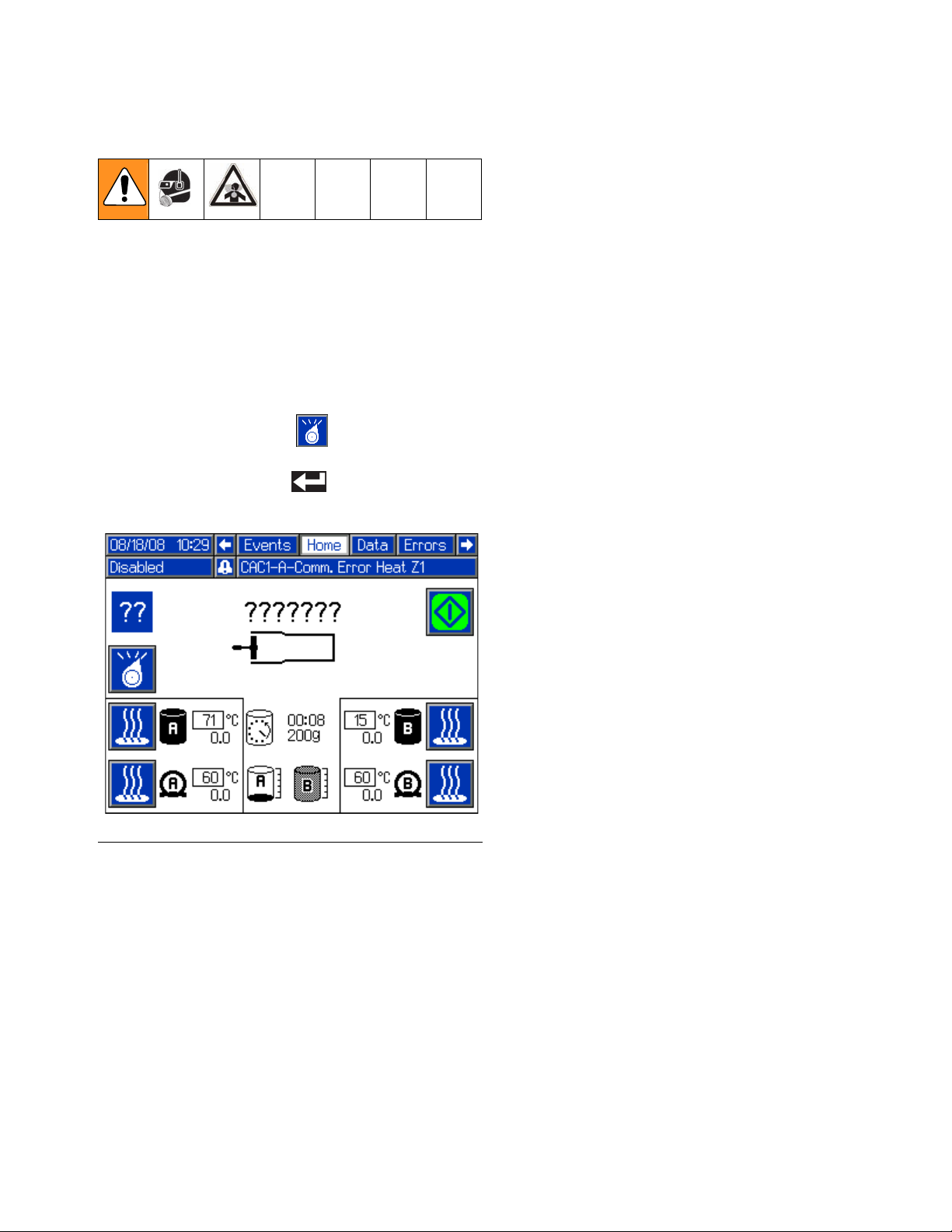

Startup

1. Locate power switch (107) at rear of machine and

turn power on. The display module will automatically

turn on and begin to load.

2. Slide the system air pressure relief switch (106) up.

It is the yellow tab at the left, rear of the machine.

The hole in the tab should not be showing.

3. If the machine is in Disabled Mode, press the Select

Operating Mode button ( ) repeatedly to exit

Disabled mode and to select a new operating mode.

Press the Enter button ( ) to accept the new

operating mode.

Startup

FIG. 9: Disabled Mode

312759R 21

Page 22

Setup

Setup

Setup Screens

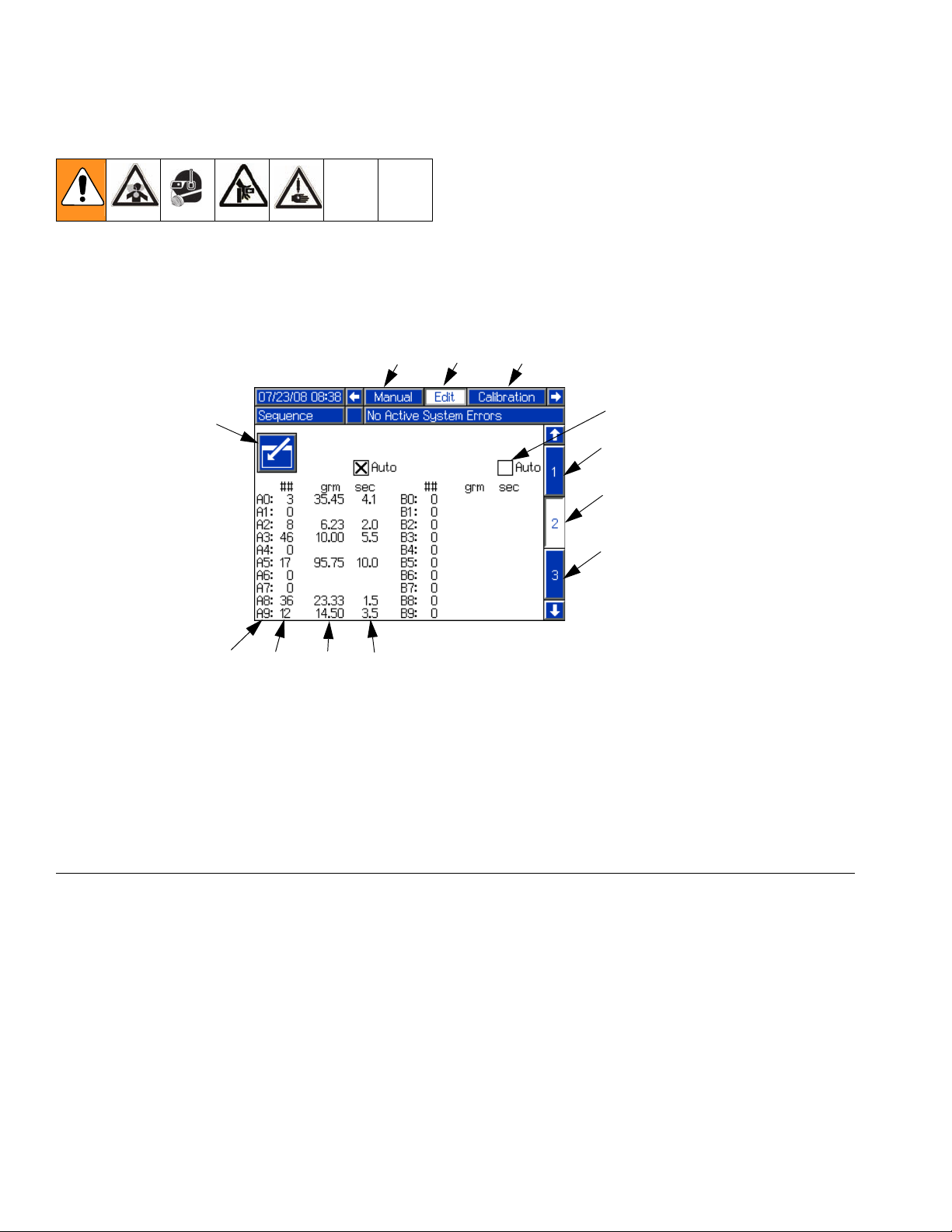

Edit Screens

GA

GC GEGD GF

Key:

GA Enter/Exit Screen button

GB Active Screen Name

GC Shot Number (Edit Screen #1) or

Sequence Position (Edit Screens

#2-#5)

GD Shot Number (Edit Screens #2-#5

only)

GE Shot Size

GH

GB

GF Delay Between Shots (Edit Screens

#2-#5 only)

GG Enable/Disable Auto Sequencing

Mode (Edit Screens #2-#5 only)

GH Adjacent Screen Names

GJ Active Screen Number

GK Adjacent Screen Numbers

GH

Edit Screen #2 Shown

GG

GK

GJ

GK

FIG. 10

Enter/Exit Screen Button

Many screens use the Enter/Exit Screen button (GA).

When scrolling through screens using the arrow keys,

the information in each screen can be seen but not

changed. To change the information in a screen that has

the Enter/Exit Screen button (GA), first press the

Enter/Exit Screen button to enter the screen. Once in

the screen, use the arrow keys to navigate and use the

arrow keys, number keys, and enter key as applicable to

change the values.

22 312759R

Page 23

Setup

Overview

There are five Edit screens. Edit Screen #1 is the Shot

Editing screen and Edit Screens #2-#5 are Sequence

Editing screens. Edit Screen #1 shows Shot #1 through

Shot #50. Each shot has a defined shot size that is measured in grams.

Edit Screens #2-#5 show Sequence A through

Sequence G. Each sequence has ten positions; shown

as A0 to A9 in F

IG. 10. Each of the ten positions in the

sequence uses one of the Shot Numbers (GD) defined

in Edit Screen #1. The third column in F

IG. 10 shows the

shot sizes (GE) for the selected Shot Numbers.

When operating in Sequence mode and a shot in the

sequence is finished, the machine will automatically

select the next position in the sequence that uses a Shot

Number with a non-zero shot size.

When operating in Sequence mode, there is an option to

allow the machine to automatically perform all of the

shots in the sequence with a preset delay between

shots. The delay between Shots (GF) is shown in the

fourth column. This process is called Auto-Sequencing.

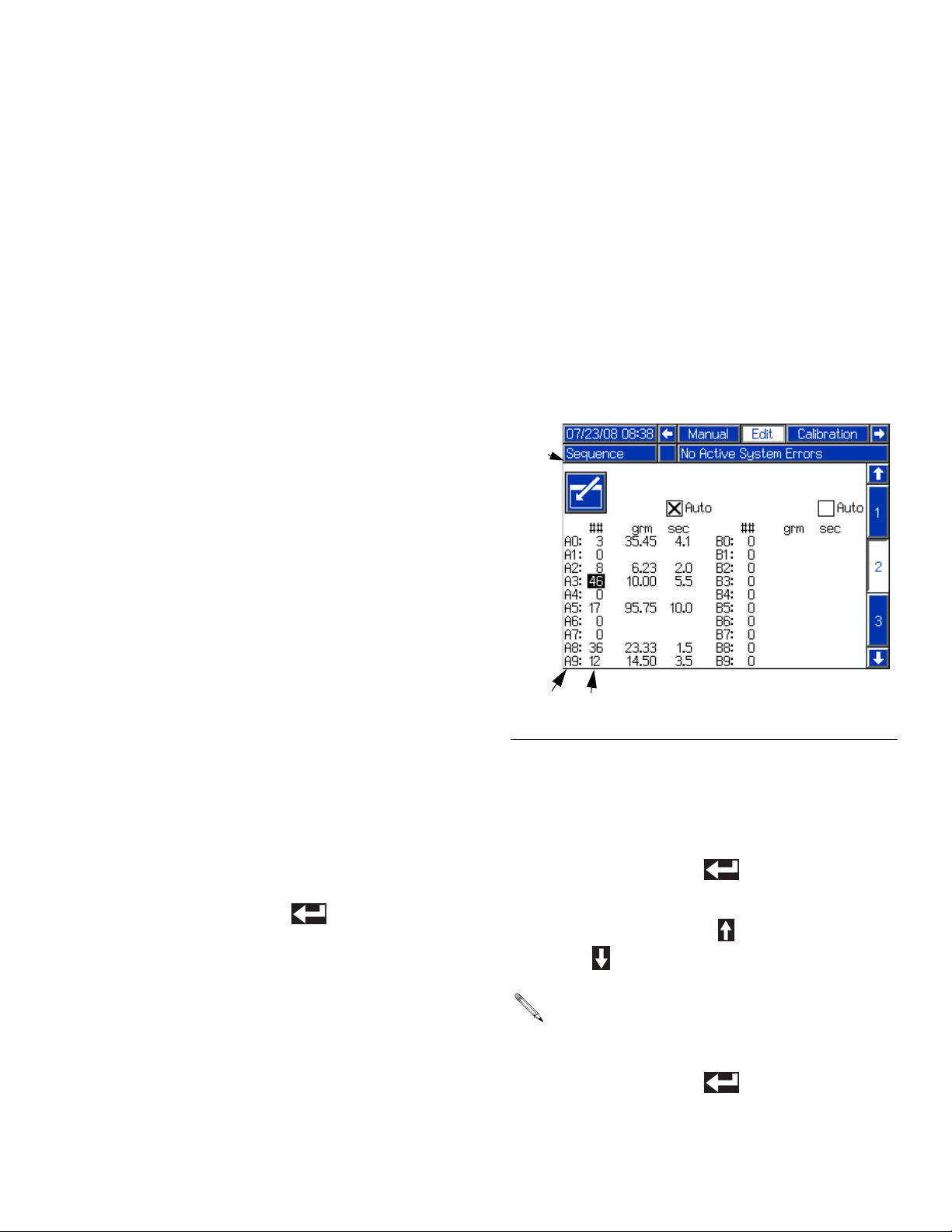

Edit Shot Sequence

To change which Shot Numbers (GD) from Edit Screen

#1 are used in a sequence, use the following procedure.

1. Navigate to the Edit Screen that contains the

Sequence to be changed. See the list below, then

see Screen Navigation Diagram, page 16.

• Sequences A and B are on Edit Screen #2

• Sequences C and D are on Edit Screen #3

• Sequences E and F are on Edit Screen #4

• Sequence G is on Edit Screen #5

2. Press the Enter/Exit Screen button (GA) to enter the

screen.

GA

Edit Shot Size

To edit the defined shot size (GE) for a certain shot

number using Edit Screen #1, use the following procedure.

1. Navigate to the Edit Screen #1. See Screen Navi-

gation Diagram, page 16.

2. Press the Enter/Exit Screen button (GA) to enter the

screen.

3. Use the arrow keys to navigate to the shot size for

the Shot Number to be changed.

4. Use the numeric keypad to enter the desired shot

size in grams.

5. Press the Enter button ( ) to accept the shot

size and exit editing mode.

6. Press the Enter/Exit Screen button (GA) to exit the

screen.

GC

GD

FIG. 11: Edit Shot Number in Sequence

3. Each Sequence Position (GC) uses a Shot

Number (GD). Use the arrow keys to navigate to the

Shot Number for the sequence position to be

changed.

4. Press the Enter button ( ) to enter editing

mode.

5. Use the Up Arrow button ( ) or the Down Arrow

button ( ) to change the Shot Number.

Only Shot Numbers with non-zero shot sizes will be

available for selection.

6. Press the Enter button ( ) to accept the Shot

Number and exit editing mode.

312759R 23

Page 24

Setup

7. Press the Enter/Exit Screen button (GA) to exit the

screen.

Edit Auto-Sequencing

To edit whether the machine automatically performs all

shots in a sequence, use the following procedure.

1. Navigate to the Edit Screen that contains the

Sequence to be changed. See Screen Navigation

Diagram, page 16.

2. Press the Enter/Exit Screen button (GA) to enter the

screen.

GG

GA

b. Use the numeric keypad to enter the desired

delay time in seconds.

c. Press the Enter button ( ) to accept the

delay and exit editing mode.

7. Press the Enter/Exit Screen button (GA) to exit the

screen.

GF

F

IG. 12: Turn Auto-Sequencing On/Off

3. Use the arrow keys to navigate to the Enable/Disable Auto Sequencing Mode (GG) box for the

sequence position to be changed.

4. Press the Enter button ( ) to add or remove the

“X” from the box.

5. Navigate away from the Enable/Disable Auto

Sequencing Mode (GG) box to accept the change.

6. If Auto-Sequencing is enabled, the delay between

shots can be changed.

a. Navigate to the delay between shots (GF) for

the Sequence Position to be changed.

The delay shown in a given Sequence Position row

is the delay prior to beginning the next shot in the

sequence.

24 312759R

Page 25

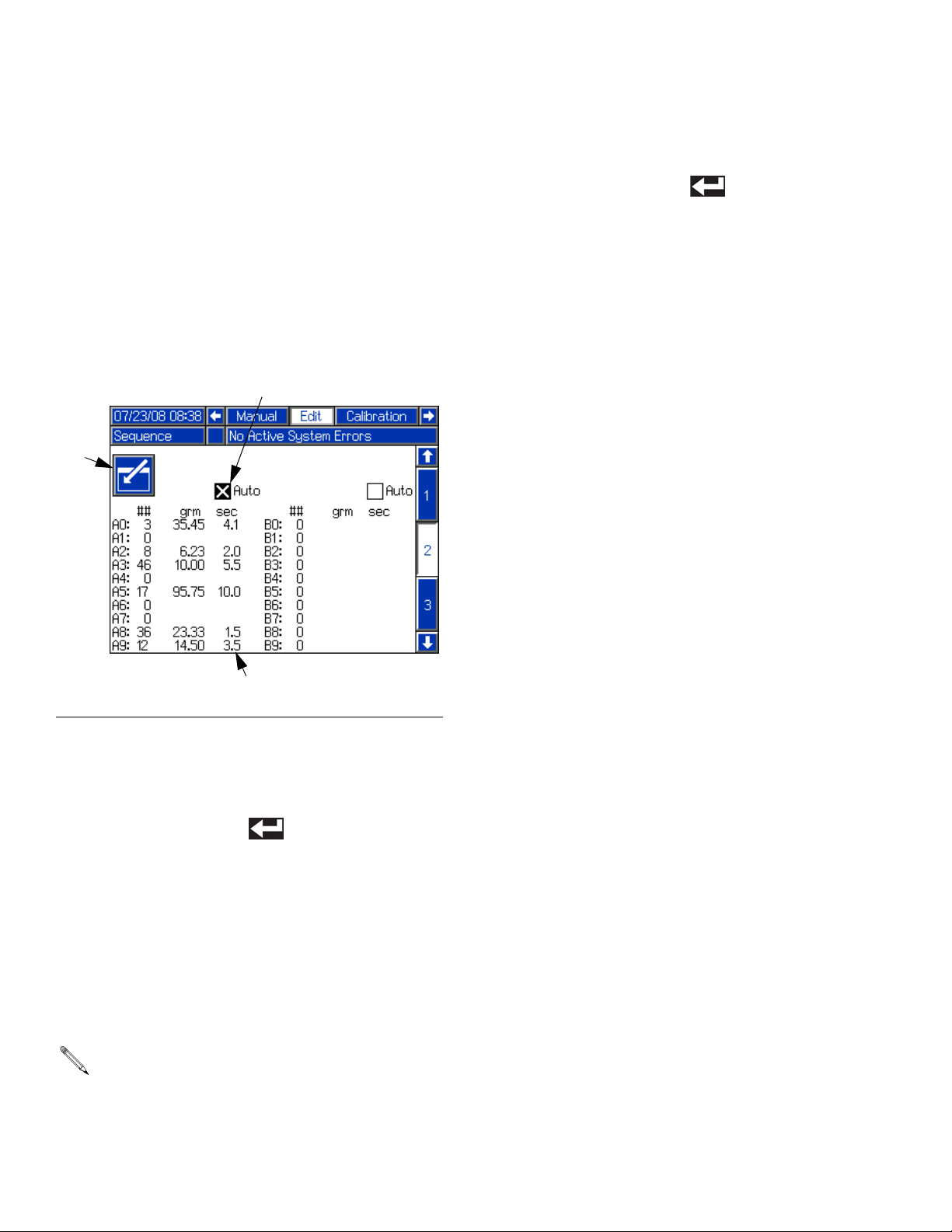

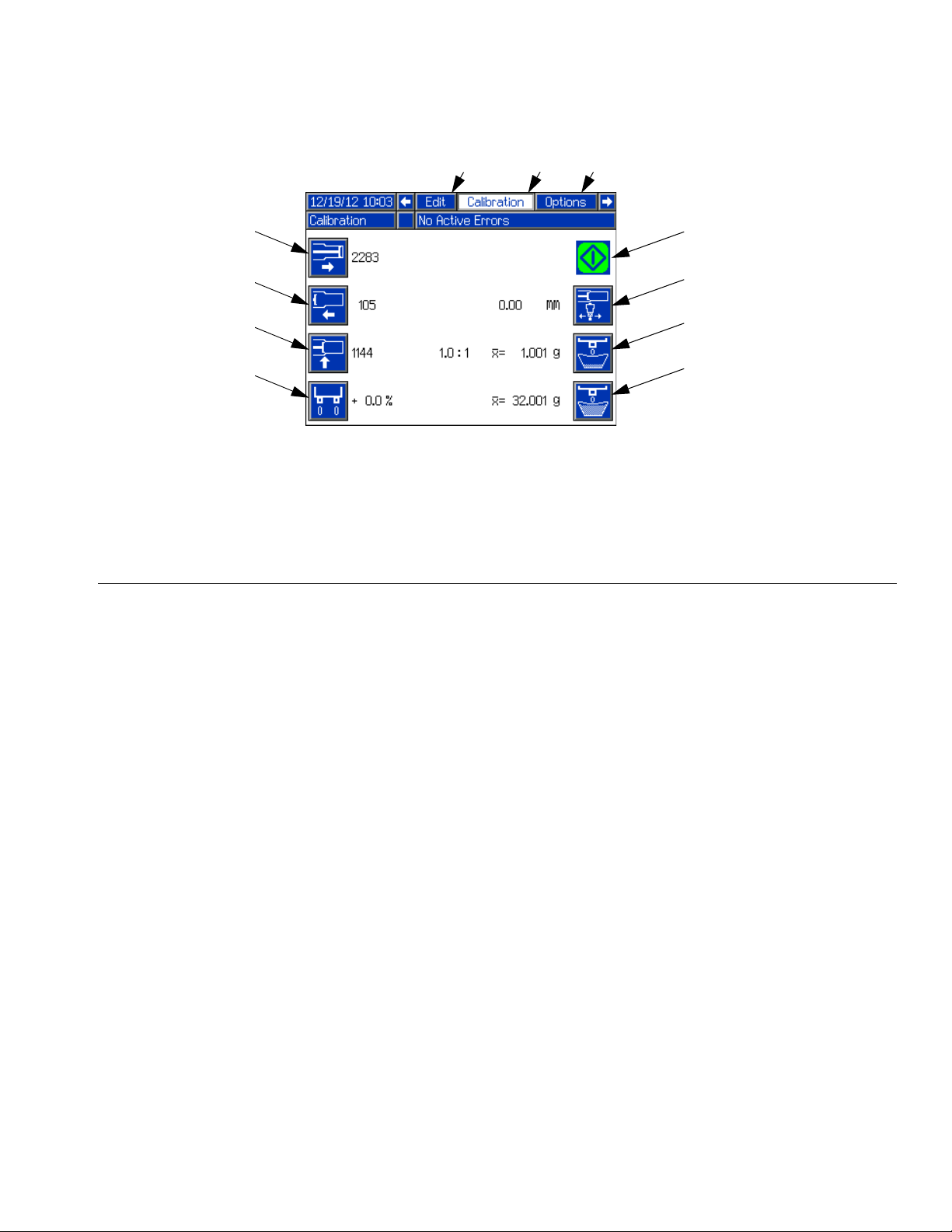

Calibration Screen

Setup

F

IG. 13

FB

FC

FD

FE

Key:

FA Start/Stop Shot

FB Update Piston Extended Position

FC Update Piston Retracted Position

FD Update Piston Engaged Position

FE Piston Phasing

FK

FJ

FK

FA

FF

FG

FH

FF Adjust Open Dispense Valve Timing

FG Initiate Small Calibration Shot

FH Initiate Large Calibration Shot

FJ Active Screen Name

FK Adjacent Screen Names

See Piston Position Calibration on page 37, Phasing

Adjustment on page 40, Adjust Open Dispense

Valve (ODV) Timing on page 43, and Shot Calibration

on page 47 for Calibration Screen use.

312759R 25

Page 26

Setup

Options Screens

Fluid Options, Screen #1

HB

HA

HC

HD

HE

HK

HL

HM

HN

Key:

HA Enter/Exit Screen

HB Purge Timer Enable/Disable

HC Purge Timer Delay

HD Purge Timer Shot Size

HE Purge Timer Alarm (seconds)

HF Recirculation Timer Enable/Disable

HG Recirculation Timer Delay

HH Recirculation Timer Shot Size

HJ Recirculation Timer Alarm (seconds)

HS

HR

HS

HF

HG

HU

HH

HJ

HT

HV

HU

HK Low Level Sensors Enable/Disable

(For FCMB Systems)

HL Tank A High Level Sensor Options

HM Tank B High Level Sensor Options

HN Maximum Fill Time

HR Active Screen Name

HS Adjacent Screen Names

HT Active Screen Number

HU Adjacent Screen Numbers

HV Pressure Units of Measure Selection

F

IG. 14

Recirculation and Purge Timers The Purge Timer and Recirculation Timer behave in a

similar way, with a certain shot size (HD, HH) being exe-

To use Recirculation mode, 3-way ball valves must

be installed at the dispense head. Fluid lines must

be installed going from the ball valves back to the

tank.

cuted after the timer delay (HC, HG) has elapsed. The

difference is that the purge timer operates with the dispense valve open so a purge shot is executed. The

recirculation timer operates with the dispense valve

closed so when the shot is executed no material is dispensed.

Both timers feature an adjustable alarm to warn the user

that the piston drive block is to begin moving. The alarm

setting is the number of seconds before the shot is to be

When Recirculation mode is enabled, both recircula-

executed.

tion ball valves must be turned to return material

back to the tank. Only turning one valve may result in

a pressure imbalance exceeding the machine’s maximum working pressure.

26 312759R

Page 27

Setup

Level Sensors

See the Feed Systems manual referenced at the

beginning of this manual for Vacuum Auto-Fill procedure.

The Low Level Sensors can be enabled or disabled. Disabling the low level sensors disables low level alarms. If

the Low Level Sensors are disabled, the tank icons on

the Home screen will be grayed out.

With High Level Sensors installed, auto-Refill can be

used. The High Level Sensors have multiple Auto-Refill

modes ranging in function.

• High Level Auto-Refill refills the tank when material is below the high level sensor. This mode is recommended for applications with temperature

control.

• Empty Auto-Refill refills the tank when a low level

condition is seen.

• Manual Auto-Refill requires the user to initiate tank

refill.

• Monitor High Level mode simply displays the current fluid level on the Home screen. This selection

should be chosen only if low level sensors are

installed for the respective tank.

2. Use the arrow keys to navigate to the item to be

changed.

3. Use the numeric keypad to enter the new value.

4. Press the Enter button ( ) to accept the new

value.

5. Press the Enter/Exit Screen button (GA) to enter the

screen.

Edit High Level Sensor Drop-Down Boxes

1. Press the Enter/Exit Screen button (GA) to enter the

screen.

2. Use the arrow keys to navigate to the item to be

changed.

3. Press the Enter button ( ) to open the

drop-down menu.

4. Use the up and down arrow keys to select the new

value.

5. Press the Enter button ( ) to accept the new

value.

6. Press the Enter/Exit Screen button (GA) to enter the

screen.

• Accumulator mode refills the accumulators automatically when a low level condition is seen.

Maximum Fill Time

The Maximum Fill Time (HN) function allows the user to

specify a maximum amount of time for refilling the tank.

If after the input amount of time the tanks are not full, an

alarm will be displayed.

Enable/Disable Timers and Low Level Sensors

1. Press the Enter/Exit Screen button (HA).

2. Use the arrow keys to navigate to the item to be

changed.

3. Press the Enter button ( ) to enable or disable

the selected item.

Edit Numeric Values

1. Press the Enter/Exit Screen button (GA) to enter the

screen.

312759R 27

Page 28

Setup

Heat Options, Screen #2

JA

Key:

JA Enter/Exit Screen

JB Enable/Disable Tank Heater Zone

JC Zone Number Used for Tank Heat Control

JD Tank Heat High Temperature Alarm

JE Tank Heat Temperature Setpoint

JF Tank Heat Low Temperature Alarm

JG Tank Heat Blanket Temperature Setpoint

JH Enable/Disable Hose Heater Zone

JP

JN

JP

JB

JC

JD

JS

JE

JF

JG

JR

JH

JJ

JK

JS

JL

JM

JJ Zone Number Used for Hose Heater Control

JK Hose Heater High Temperature Alarm

JL Hose Heater Temperature Setpoint

JM Hose Heater Low Temperature Alarm

JN Active Screen Name

JP Adjacent Screen Names

JR Active Screen Number

JS Adjacent Screen Numbers

F

IG. 15

The Heat Options Setup Screen includes options for the

tank and hose heaters. Each tank and hose heater can

be enabled and disabled and each have their own settings.

Zone Numbers

Each tank and hose heater is assigned to a specific

“zone” number. The zone number refers to the zone

number on the Integrated Heat Assembly. Each zone

number has a label above it. See F

IG. 16.

The zone number specified for each option on the Heat

Options Setup Screen needs to match how the system

is connected. For instance, if tank A is connected to

zone #1, then zone #1 needs to be selected for tank A

heat.

Zone #4

Zone #3

Zone #2

Zone #1

Assembly

LC0253 Shown

ti12593a

FIG. 16: Integrated Heat Assembly, Zone Numbers

Temperature Settings

Each tank and hose heater has a high and low temperature alarm and a temperature setpoint. The tanks also

have a blanket heater temperature setpoint.

An alarm will sound when the material temperature is

outside of the range given by the high and low temperature setpoints. also, dispensing may be disabled

depending on the selections made in the System

Options Setup Screen, see page 30.

28 312759R

Page 29

Setup

Enable/Disable Heat Options

All heat options can be enabled or disabled. All options

that are installed should be enabled and all that are not

installed should be disabled. All enabled heat options

can be turned on and off from the Home Screen, see

page 53. To enable or disable heat options, perform the

following procedure.

1. Press the Enter/Exit Screen button (JA).

2. Use the arrow keys to navigate to the item to be

changed.

3. Press the Enter button ( ) to enable or disable

the selected item.

4. Navigate away from the Enable/Disable field to

accept the change.

Change Zone Number

To change a zone number, the applicable tank or hose

heater must be disabled.

1. Press the Enter/Exit Screen button (JA).

Edit Temperature Settings

1. Press the Enter/Exit Screen button (JA) to enter the

screen.

2. Use the arrow keys to navigate to the item to be

changed.

3. Use the numeric keypad to enter the desired temperature in the displayed units (Celsius or Fahrenheit).

4. Press the Enter button ( ) to accept the new

value and exit editing mode.

5. Press the Enter/Exit Screen button (JA) to exit the

screen.

2. Disable all heat options that will have their zone

number changed.

3. Change zone number for all heat options just disabled.

No two zones may have the same zone number

assigned at any point. To change a heat option

zone number to a zone number already assigned to

another heat option, the existing assignment must

first be changed to either another zone number

or “--”.

a. Use the arrow keys to navigate to the Heat

Option Zone field (JC, JJ).

b. Press the Enter button ( ) to enter editing

mode.

c. Use the Up Arrow button ( ) or the Down

Arrow button ( ) to change the item value.

d. Press the Enter button ( ) to exit editing

mode.

312759R 29

Page 30

Setup

System Options, Screen #3

F

IG. 17

LA

LB

LC

LD

LE

LF

LG

LH

LN

Key:

LA Enter/Exit Screen

LB Disable Dispensing Option

LC Disable Modifying Shot Sizes Option

LD Disable Erasing Counters Option

LE Disable Changing Temperature Setpoint

Option

LF Enable Piston Auto-Retract Option

LG Low Temperature Disables Dispense

Option

LK

LJ

LK

LM

LL

LM

LH Silent Mode Option

LJ Active Screen Name

LK Adjacent Screen Names

LL Active Screen Number

LM Adjacent Screen Numbers

LN Disables Pump Stationary During

Dispense Timeout Error

Primary Run Screen Options

These options disable certain functions on the Home

Screen. Some of the functions can be performed using

the setup screens. When using these options, it is recommended that the Setup screens are protected by a

password; see Advanced Setup Screen, page 34.

• Disable Dispensing disables dispensing from the

Home screen.

• Disable Modifying Shot Sizes disables editing

shot size definitions from the Home screen.

• Disable Erasing Counters disables erasing shot

counters on the Data screen.

• Disable Changing Temperature Setpoint disables

changing the temperature setpoint from the Home

screen.

Miscellaneous Options

• Enable Piston Auto Retract enables the piston to

automatically retract after every shot when in Operator (Manual) mode. Normally the piston only

retracts after it completes the entire stroke.

• Low Temperature Disables Dispense disables

dispensing if the material temperature is below the

low temperature setpoint.

• Silent Mode disables all audible alerts.

Enable/Disable Options

1. Press the Enter/Exit Screen button (LA) to enter the

screen.

2. Use the arrow keys to navigate to the item to be

changed.

3. Press the Enter button ( ) to enable or disable

the selected item.

4. Navigate away from the Enable/Disable field to

accept the change.

5. Press the Enter/Exit Screen button (LA) to exit the

screen.

30 312759R

Page 31

Dispense Check Options, Screen #4

Setup

PA

PB

PC

PD

PE

PF

PG

Key:

PA Enter/Exit Screen

PB Change in Velocity

PC Change in Pressure

PD Change in Ratio or Volume

PE Ratio Type (Volume or Weight)

PF A Side Flow Meter Calibration Factor

PJ

PH

PJ

PL

PK

PL

PG B Side Flow Meter Calibration Factor

PH Active Screen Name

PJ Adjacent Screen Names

PK Active Screen Number

PL Adjacent Screen Numbers

F

IG. 18

Change in Velocity, Change in Pressure, Change in

Ratio or Volume

NOTE: The machine must have pressure transducers

installed for Change in Pressure to be available. The

machine must have flow meters installed for Change in

Ratio or Volume to be available. The Change in Velocity

function is available on all machines. If a non-zero value

is entered for an unavailable function, an error will be

displayed.

During machine calibration the machine measures and

obtains base values for piston speed, fluid pressure, and

fluid ratio or volume. The machine also records when

the pressure rises for each side, to get a base value for

phasing.

NOTE: The pressure transducers are designed to work

with the hoses available in the PR70 configurator. If they

are used with other hoses, unexpected alarms may

occur.

When any of these three dispense check features are

enabled by entering a value other than zero, the

machine will compare the value seen during each dispense to the values measured during calibration. If the

values are farther than the input percentage from the

calibration values, an error is shown after the dispense.

See Error Codes on page 71. This warning signals the

user of a less than optimal dispense or possible

machine malfunction.

The available input values for Change in Velocity and

Change in Pressure are 0 (off), 20, 40, or 60 percent.

The acceptable input value for Change in Ratio or Vol-

ume are 0 (off), or 1 through 10 percent. If an invalid

number is entered, it will automatically be rounded to the

nearest valid entry.

312759R 31

Page 32

Setup

Ratio Type

Fluid ratio can be monitored as either weight-ratio or volume-ratio. If the ratio type selected is “Volume”, the calibration factor for each installed flow meter must be

entered in the calibration factor fields (PF, PG). The calibration factor is found on the flow meter data sheet

shipped with the machine.

After each shot, the ratio for that shot will be shown on

the Home screen. If weight-ratio is selected, the ratio will

be shown to the left of the piston position graphic. If volume-ratio is selected, the ratio will be shown to right of

the piston position graphic.

32 312759R

Page 33

Flow Meter Calibration, Screen #5

Setup

RF

RARA

RB

RC

RD

RE

RH

Key:

RA Enter/Exit Screen

RB Average Calibration Weight

RC Material Weight Entry

RD Cycles per Gram

RE Total Cycles

RF A Side Information

RK

RJ

RG B Side Information

RH A to B Weight Ratio

RJ Active Screen Name

RK Adjacent Screen Names

RL Active Screen Number

RM Adjacent Screen Numbers

RK

RG

RM

RL

RM

F

IG. 19

Proper calibration of the flow meters ensures that ratio

and weight monitoring perform optimally. Flow meter

calibration is only necessary if the ratio type selected on

Options Screen #4 is “Volume”. After the flow meter calibration factors are entered in Options Screen #4, the

machine will accurately measure volume and the material weight dispensed counters will start tracking dispenses.

See Flow Meter Calibration on page 48.

312759R 33

Page 34

Setup

Advanced Setup Screen

KL

KC

KD

KE

KF

KG

KH

KJ

KK

Key:

KA Language Selection

KB Temperature Units Selection

KC Date Format

KD Month

KE Day

KF Four Digit Year

KG Hours (24 Hour Clock)

KN

KM

KN

KA

KB

KH Minutes

KJ Numeric Password

(four digits allowed)

KK Screen Saver

KL Enter/Exit Screen

KM Active Screen Name

KN Adjacent Screen Names

F

IG. 20

Password

If a password other than “0” is entered, the password is

automatically enabled. The password protects entry into

the setup screens. With the password enabled, the

restricted user may still be able to change shot sizes,

erase counters, or modify temperatures depending on

the options enabled on the System Options Setup

Screen. To prohibit the restricted user from changing

these settings, enable the appropriate options; see Sys-

tem Options, Screen #3 on page 30.

Screen Saver

The screen saver turns off the screen backlighting after

the given number of minutes. To disable the screen

saver, press any button.

Languages

The language selection feature will change the language of all text on the display module. Available languages are English, Spanish, French, German,

Chinese, Japanese, Korean, Russian, and Italian.

Date Formats

There are three available formats: MM/DD/YY,

DD/MM/YY, and YY/MM/DD.

Edit Settings

1. Press the Enter/Exit Screen button (KL) to enter the

screen.

2. Use the arrow keys to navigate to the item to be

changed.

3. For numeric entries, use the numeric keypad to

enter the new value.

For non-numeric settings, press the Enter button

( ) then use the Up Arrow button ( ) and the

Down Arrow button ( ) to change the selection.

4. Press the Enter button ( ) to accept the new

value or selection and exit editing mode.

34 312759R

Page 35

System Data Screen

Setup

MM

MA

Key:

MA Enter/Exit Screen

MB Current Machine Cycles Counter

MC Total Machine Cycles Counter

MD Advanced Display Module Software

Version

ME Fluid Control Module #1 Software

Version

MF Fluid Control Module #2 Software

Version

MG Temperature Control Module -

Zone #1 Software Version

ML

MM

MB

MC

MN

MP

MD

ME

MF

MG

MH

MJ

MK

MH Temperature Control Module -

Zone #2 Software Version

MJ Temperature Control Module -

Zone #3 Software Version

MK Temperature Control Module -

Zone #4 Software Version

ML Active Screen Name

MM Adjacent Screen Names

MN Resettable material weight counter

MP Non-resettable material weight

counter

F

IG. 21

Software Version

Software version will read “0.00.000” if component cannot be seen by the ADM. This is the result of the component not being installed or a communication error.

Machine Cycles

A machine cycle is one full extension and retraction of

the machine piston. The Current Machine Cycles Counter is resettable and the Total Machine Cycles Counter is

the number of cycles since the ADM was installed.

Reprogramming the ADM will not reset the Total

Machine Cycles counter.

Reset Current Machine Cycles Counter

1. Press the Enter/Exit Screen button (MA) to enter the

screen. The Current Machine Cycles count will be

highlighted.

2. Press the Enter button ( ) to reset the Current

Machine Cycles counter.

3. Press the Enter/Exit Screen button (MA) to exit the

screen.

312759R 35

Page 36

Setup

Manual Screen

EHEJ EJ

EA

EB

EC

1

ED

1

1

Valve will open for approximately two seconds.

EG

EF

EE

Key:

EA Extend Piston Command

EB Retract Piston Command

EC Tank A Refill Valve Command Open

ED Tank B Refill Valve Command Open

EE Dispense Valve Command Close

EF Dispense Valve Command Open

EG Revert to Automatic Dispense Valve Operation

EH Active Screen Name

EJ Adjacent Screen Names

F

IG. 22

The Manual screen overrides control of some machine

actions. This can be useful in troubleshooting. To perform any of the available machine actions shown on the

Manual screen, press the appropriate button.

36 312759R

Page 37

Setup

Edit Settings

• Edit Display Settings:

See Advanced Setup Screen, page 34.

• Edit Shots and Sequences:

See Edit Screens, page 22.

• Edit Recirculation and Purge Timers:

See Fluid Options, Screen #1, page 26.

• Edit Level Sensor Settings:

See Fluid Options, Screen #1, page 26.

• Edit Temperature Control Settings:

See Heat Options, Screen #2, page 28.

• Edit System Options:

See System Options, Screen #3, page 30.

Piston Position Calibration

Prepare Machine for Calibration

1. Ensure that both piston shafts are screwed all the

way into the drive block.

2. Ensure there is a sufficient amount of material in the

tanks.

3. Navigate to the Calibration screen. See Screen

Navigation Diagram, page 16.

4. Place a waste container under the dispense valve to

capture any dispensed material.

5. Ensure system air pressure relief switch (106) is in

the up position and the system air pressure

regulator (105) shows air pressure in the system.

Extended Piston Position

6. With air pressure applied to the machine, press the

Extend Piston button ( ).

F

IG. 23: Calibration Screen

The position sensor assigns a numeric value to the location of the piston. Higher numbers indicate the piston is

extended and lower numbers indicate the piston is

retracted.

The Piston Position Calibration procedure teaches the

machine the location of the most extended piston posi-

tion ( ), the most retracted piston position ( ),

and the position where the piston engages the pump

cylinder ( ).

Perform the Piston Position Calibration procedure when

first setting up the machine. Also perform this procedure

if the linear position sensor, piston, or any electronic

component has been replaced.

7. Press the Start/Stop Shot button ( ). The piston

will fully extend and a number 3600-3900 should be

displayed. If a number significantly different from

3600-3900 is displayed, ensure the air cylinder air

line connections are not switched and that the linear

position sensor is installed correctly.

If the piston does not extend after pressing the

Start/Stop Shot button ( ) the air pressure may

need to be increased. Use system air pressure

regulator (105) to increase the air pressure in increments of 10 psi until the piston activates. Material

will be dispensed when adequate pressure is

achieved.

8. Press the Enter button ( ) to accept the new

value or press the Abort/Cancel button ( ) to

keep the previous value.

312759R 37

Page 38

Setup

Retracted Piston Position

9. With air pressure applied to the machine, press the

Retract Piston button ( ).

10. Press the Start/Stop Shot button ( ). The piston

will fully retract and a number from 1250 to 1600 will

be displayed next to the Retract Piston button. If a

number outside of this range is displayed, ensure

the air cylinder air line connections are not switched

and that the linear position sensor is properly

installed.

11. Press the Enter button ( ) to accept the value or

press the Abort/Cancel button ( ) to keep the

previous value.

Engaged Piston Position

Manually Move the Piston Drive Block

In the steps below, ensure pressure is off or piston

may activate and pinch fingers against machine

block.

a. Press down the system air pressure relief

switch (106).

b. Remove machine cover.

c. With no air pressure in the system manually

push the piston drive block until the piston

engages the cylinder and resists movement. A

number from 2000 to 2400 will be displayed.

If a number outside of this range is displayed,

ensure the air cylinder air line connections are not

switched and that the linear position sensor is properly installed.

12. Use air pressure regulator to decrease air pressure

in the system to zero.

13. Place a clean waste container under the dispense

valve.

14. Press the Engage Piston button ( ).

15. With no air pressure in the system, press the

Start/Stop Shot button ( ).

16. Move the piston drive block until it just begins to

engage the cylinder using one of the following methods. No material should be dispensed.

Use Air Pressure to Move Piston Drive Block

a. Use the air pressure regulator to slowly

increase air pressure in the system until the piston drive block begins to extend and encounters

the cylinder entrance. A number from 2000 to

2400 will be displayed.

d. Lift the system air pressure relief switch (106) to

enable system pressure.

17. Ensure there is no material in the waste container

under dispense valve. The piston block moved too

far and caused material to be dispensed if there is

material in the waste container. Go back to step 12

if the piston moved too far.

18. Press the Enter button ( ) to accept the value or

press the Abort/Cancel button ( ) to keep the

previous value.

Prepare Machine for Operation

19. Adjust the system air pressure regulator (105) to

increase air pressure to standard operating pressure for your application.

20. Navigate to the Home screen. See Screen Naviga-

tion Diagram, page 16.

If a number outside of this range is displayed,

ensure the air cylinder air line connections are not

switched and that the linear position sensor is properly installed.

38 312759R

Page 39

Setup

Prime the Dispense Head

CAUTION

If the dispense head is not primed, chemical crossover may occur resulting in cured material in the dispense head, hoses, and/or pumps.

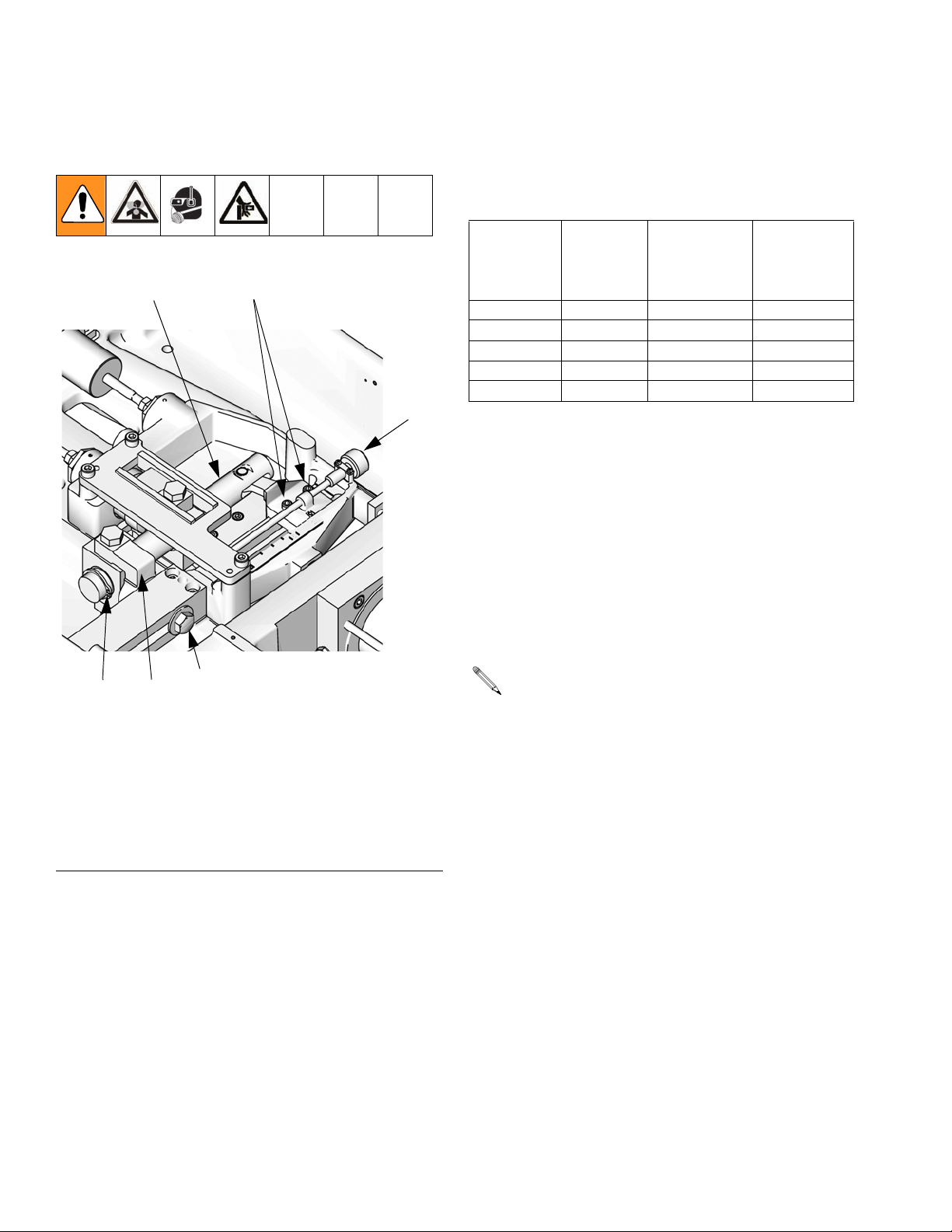

See FIG. 24.

1. Remove static mixer from the dispense head (102) if

installed.

2. Turn snuff-back adjustment knob (103) fully clockwise. This will prevent the dispense valve from closing between priming shots.

3. Use a 4 mm hex key to loosen the screws (102a)

holding the dispense head in place.

4. Rotate dispense head (102) so the tip is above the

fluid input hoses.

102

8. Select a large size shot.

9. Hold a waste container at the end of the dispense

head (102) and press the Start/Stop Shot button

( ) or the footswitch.

10. Repeat the previous step until no air comes out of

the dispense valve.

11. If phasing adjustments and ratio checking are not

required, use the following procedure to attach the

static mixer.

a. Attach the static mixer with the dispense head

pointed up.

b. Hold waste container at end of dispense

head (102) and press the Start/Stop Shot button

( ) or the footswitch.

102a

ti12391a

F

IG. 24: Prime Dispense Head

5. Use a 4 mm hex key to tighten screws (102a) holding dispense head in place.

6. Route the fluid hoses connected to the dispense

head so they are always below the dispense head.

This ensures any air in the hoses will travel to the

dispense head.

7. Navigate to the Home Screen. See Screen Naviga-

tion Diagram, page 16.

c. Repeat the previous steps until static mixer has

been purged of air.

12. Use a 4 mm hex key to loosen screws (102a) holding dispense head in place.

13. Rotate dispense head back to normal dispensing

position.

14. Use a 4 mm hex key to tighten the screws (102a)

holding the dispense head in place.

15. Adjust snuff back to proper setting for operation.

See Adjust Dispense Valve Snuff Back on

page 42.

312759R 39

Page 40

Setup

Phasing Adjustment

F