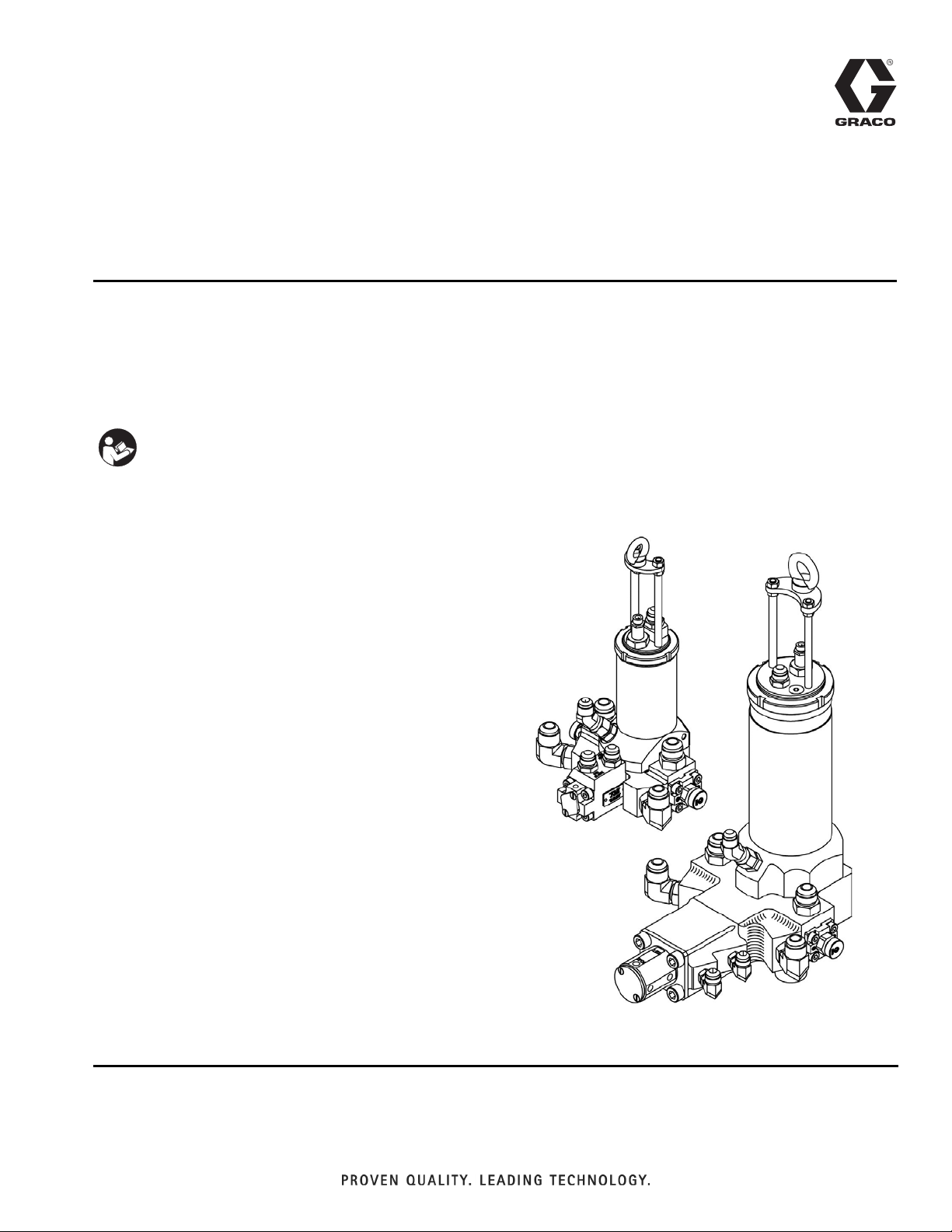

Page 1

Operation - Maintenance

312753E

L-Head

For dispensing controlled ratio shots of resin and isocyanate.

3000 psi (20.6 MPa, 206 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for model information.

EN

Page 2

Models

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Isocyanate Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . . . 5

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . 5

Keep Components A and B Separate . . . . . . . . . . 5

Foam Resins with 245 fa Blowing Agents . . . . . . . 5

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hydraulic & Chemical Hose Installation . . . . . . . 7

Bleeding Air from Hydraulic Fluid Lines . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . 9

Nozzle Grip Assembly Removal and Cleaning . 10

Nozzle Grip Assembly Installation . . . . . . . . . . . 11

Cleanout Plunger Proximity

Switch Replacement . . . . . . . . . . . . . . . . . 12

Material Plunger Proximity

Switch Replacement . . . . . . . . . . . . . . . . . 14

Cleanout Plunger Stroke Adjustment . . . . . . . . 17

Pour Nozzle Maintenance . . . . . . . . . . . . . . . . . 19

Pour Nozzle Removal and Installation . . . . . . . . 20

Step Seal and Scraper Seal Replacement . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Models 5/8, 6/10, 10/14 . . . . . . . . . . . . . . . . . . . 24

Models 13/20 and 16/25 . . . . . . . . . . . . . . . . . . 26

Orifice Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Additional Tools and Accessories . . . . . . . . . . . 29

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 32

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 32

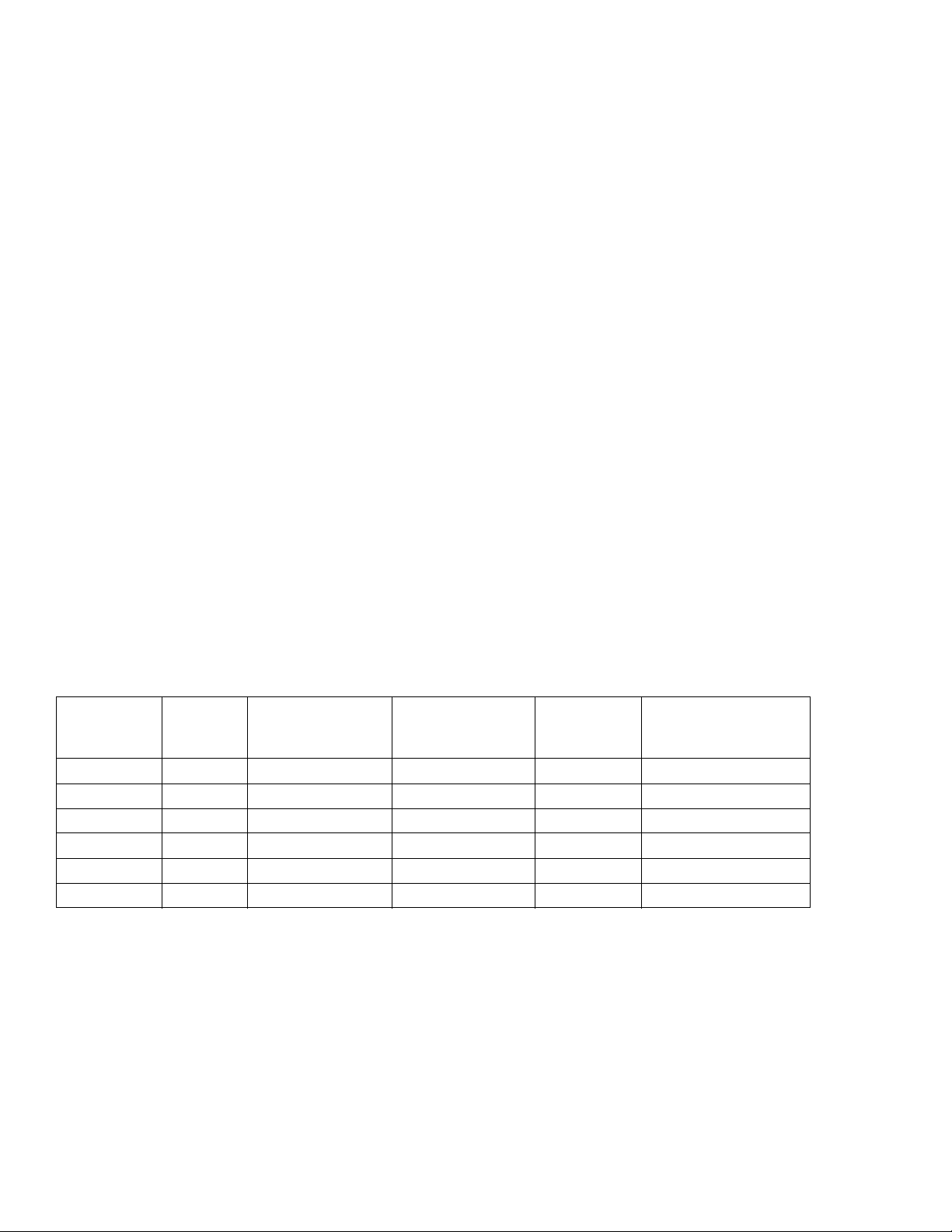

Models

Maximum Working

CE

Model

20.20.5/8 ✔ 5 8 2 3000 (20.6, 206)

20.20.6/10 ✔ 6 10 2 3000 (20.6, 206)

20.20A.6/10 6 10 2 3000 (20.6, 206)

20.20.10/14 ✔ 10 14 2 3000 (20.6, 206)

20.20.13/20 ✔ 13 20 2 3000 (20.6, 206)

20.20.16/25 ✔ 16 25 2 3000 (20.6, 206)

Approved

Impingement

Chamber ID (mm)

Exiting

Chamber ID (mm)

Number of

Streams

Pressure

psi (MPa, bar)

2 312753E

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

312753E 3

Page 4

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

4 312753E

Page 5

Isocyanate Hazard

Isocyanate Hazard

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

• Keep the ISO lube pump reservoir filled with Graco

Throat Seal Liquid (TSL), Part 206995. The lubricant creates a barrier between the ISO and the

atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always park pumps when you shutdown.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Keep Components A and B Separate

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (isocyanate) and component B (resin) parts.

Foam Resins with 245 fa Blowing Agents

New foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

312753E 5

Page 6

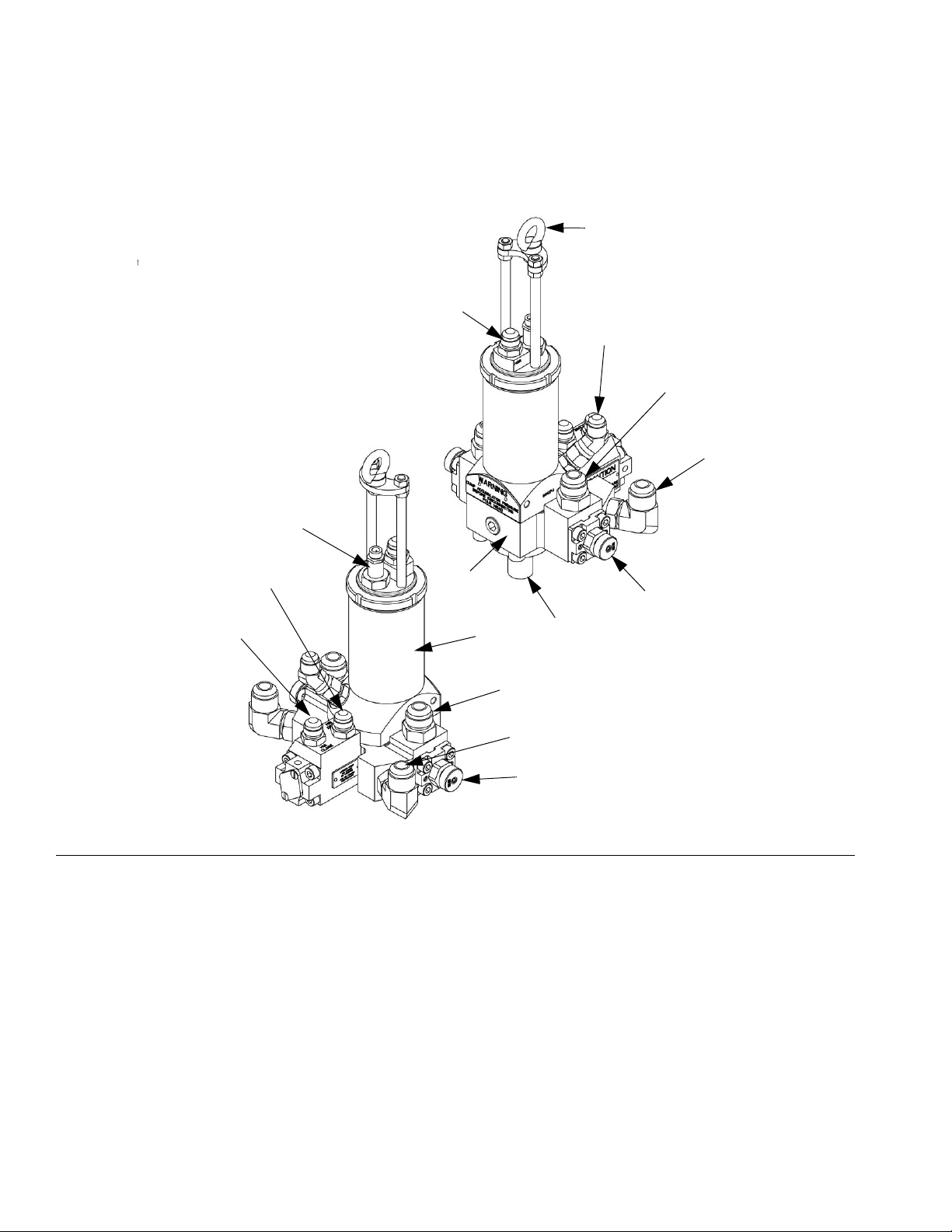

Component Identification

Component Identification

A

Q

B

C

D

N

FIG. 1: L-Head

Key:

AEye Bolt

B Cleanout Plunger Open Fitting

C Resin Close Fitting

D Resin Open Fitting

E Resin Nozzle Grip Assembly

F Pour Nozzle

G MixHead Body

H

P

G

E

J

F

K

L

M

H Cleanout Plunger Proximity Switch

J Cleanout Cylinder Housing

K Iso Close Fitting

L Iso Open Fitting

M Iso Nozzle Grip Assembly

N Material Plunger Close Fitting

P Material Plunger Open Fitting

Q Cleanout Plunger Close Fitting

6 312753E

Page 7

Installation

Installation

When hoisting the MixHead from an overhead position, always lift by the top eyebolt.

Handle the MixHead with care. The internal moving

parts are precisely machined for proper alignment.

Any disturbance of this alignment may result in MixHead failure.

Hydraulic & Chemical Hose Installation

Do not come into contact with Isocyanate. See Isocyanate Hazard on page 5.

NOTICE

The person performing the installation must understand the operation of the MixHead hydraulic power

source and chemical flow system.

Before disconnecting a chemical fitting or nozzle grip

assembly, turn off the proportioner, bleed the chemical pressure to ZERO, and allow the fluid to cool.

Install Hydraulic Hose

The fittings are identified on the MixHead body and the

hoses are color-coded to aid in identification and proper

installation.

When connecting the hoses, do not allow any dirt or foreign matter to enter the lines.

See FIG. 1 on page 6.

After mounting the MixHead, install the hydraulic and

chemical hoses as follows:

1. Install the hydraulic hoses for the cleanout plunger

to the fittings on the MixHead as follows:

a. Install the “close” hose to the Cleanout Plunger

Close Fitting (Q).

b. Install the “open” hose to the Cleanout Plunger

Open Fitting (B).

2. Install the hydraulic hoses for the material plunger to

the hydraulic fittings on the MixHead as follows:

a. Install the “close” hose to the Material Plunger

Close Fitting (N).

Before Disconnecting Hydraulic Fitting or

Proximity Switch

• Turn off the hydraulic pump

• Depressurize the hydraulic system

• Allow the fluid to cool

b. Install the “open” hose to the Material Plunger

Open Fitting (P).

Follow hydraulic fluid lines air purging procedure

carefully to avoid skin injection hazard.

Before Disconnecting a Chemical Fitting or

Nozzle Grip Assembly

• Turn off the proportioner

• Bleed the chemical pressure to ZERO

• Allow the fluid to cool

312753E 7

3. Purge all air from the hydraulic fluid lines using the

procedure in the Bleeding Air from Hydraulic

Fluid Lines section on page 8.

4. Manually cycle the cleanout plunger back and forth

to check for proper operation. Check for hydraulic

leaks and retighten fittings as required. Make sure

the proximity switch is securely tightened and making contact, and then return the cleanout plunger to

the “retract” position.

Page 8

Installation

5. Manually cycle the material plunger back and forth

to check for proper operation. Check for hydraulic

leaks and retighten fittings as required. Make sure

the proximity switch is securely tightened and making contact, and then return the material plunger to

the closed/recirculation position.

NOTICE

Before connecting the chemical hoses, make sure the

hydraulic hoses are properly connected and the cleanout plunger and material plunger have been tested

for proper operation. Failure to do so may result in

chemical cross-contamination of the MixHead and

proportioning system.

6. Install the chemical hoses to the fittings on the MixHead as follows:

a. Install the isocyanate “close” hose to the Iso

Close Fitting (K).

b. Install the isocyanate “open” hose to the Iso

Open Fitting (L).

c. Install the resin “close” hose to the Resin Close

Fitting (C).

4. Use a bucket to catch the hydraulic fluid, and lay

down a drop cloth to catch spilled hydraulic fluid.

The hydraulic fluid motor must be off and the manual

unloading valve must be completely open before proceeding to the next step to avoid high pressure

spraying of hydraulic fluid.

5. At the “close” port of the material plunger (N),

loosen the hydraulic hose very slowly, allow all pressurized air to escape, then tighten the hose.

6. Move the cleanout plunger to the “extend” position.

At the “close” port of the cleanout plunger (Q),

loosen the hydraulic hose very slowly, allow all pressurized air to escape, then tighten the hose.

7. Move the cleanout plunger to the “retract” position.

At the “open” port of the cleanout plunger (B),

loosen the hydraulic hose very slowly, allow all pressurized air to escape, and then tighten the hose.

Install Chemical Hose

d. Install the resin “open” hose to the Resin Open

Fitting (D).

7. Recirculate both chemical lines until the pressures

stabilize.

8. Pressurize the MixHead and check for chemical

leaks.

Bleeding Air from Hydraulic Fluid Lines

1. Start the hydraulic fluid motor to build pressure in

the hydraulic lines.

2. Turn off the hydraulic fluid motor.

3. Open the manual unloading valve all the way.

An assistant is required for the following steps.

8. With the cleanout plunger in the “retract” position,

open the material plunger by manually energizing

the hydraulic directional valve.

9. Have an assistant bleed out any air at the “open”

port of the material plunger (P).

10. Hold the material plunger in the open/pour position

until the “open” port has been completely bled of air

and the hydraulic hose has been securely tightened,

then return the material plunger to the closed position.

8 312753E

Page 9

Maintenance

All maintenance must be done with pressure relieved

and the power switched off and locked out, unless

otherwise noted.

Maintenance Schedule

Service Action Frequency Reference

Maintenance

Apply cleanout plunger lubrication Flush mesamoll into the

cleanout bore

Inspect for hydraulic and chemical

leaks

Inspect proximity switch wires for

open exposure

Inspect pour nozzle bore Clean as needed Weekly See page 20

Inspect adjustment stem, injection

nozzle, and nozzle grip for blockage

and erosion

Replace seals as needed Daily See page 7

Replace cord set/switch as

needed

Replace parts as needed Weekly See page 10

Daily See page 20

Weekly See pages 12, 14

312753E 9

Page 10

Maintenance

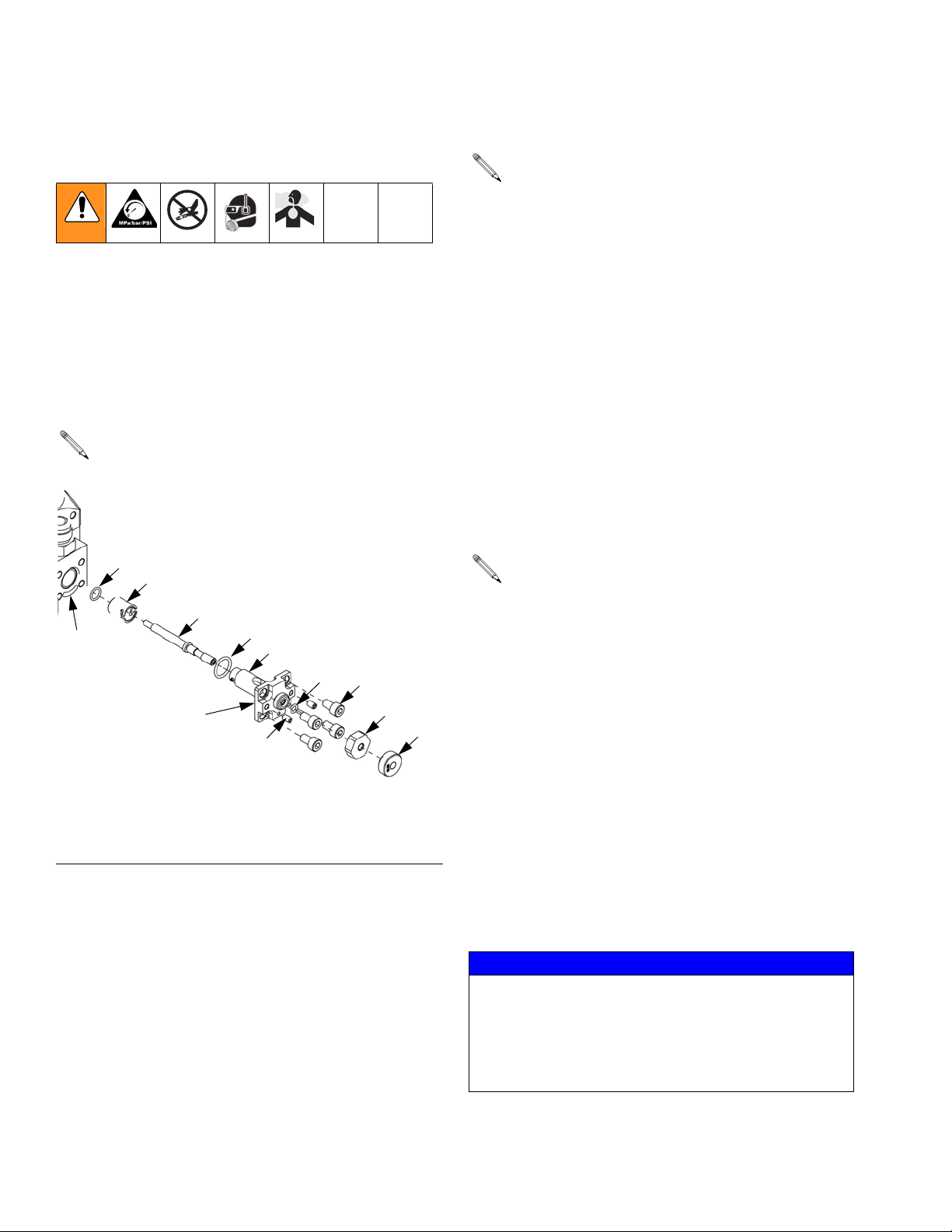

Nozzle Grip Assembly Removal and Cleaning

The nozzle grip assembly must be removed, disassembled and cleaned whenever disconnecting the chemical

hoses, replacing the internal o-rings, and/or changing

the injection nozzle and adjustment stem. It is advisable

to maintain a supply of spare nozzle grips, adjustment

stems, hex o-ring seats, locknuts, and the necessary

screws and o-rings.

See Parts List on page 25.

3

18

Nozzle Grip Assembly for models

5/8, 6/10, 10/14 shown

Tools Required

See Additional Tools and Accessories on

page 29.

• Nozzle ejector

• 5/32 in. hex key

• M3 hex key for M6 set screws

• 1 in. open-end wrench

• Torque wrench with M6 hex for M8 SHC screws

Nozzle Grip Removal

1. Bleed all chemical pressures to zero.

2. Remove one of the M8 socket head cap screws (13)

from the nozzle grip assembly and reinsert it at least

two full turns.

This screw is a safety stop for the nozzle grip

should any pressure be left in the system.

17

FB

FA

Key:

FA Roll Pin (pressed into nozzle grip, not shown)

FB Slot for roll pin

IG. 2:

F

2

9

4

14

13

3. Unscrew the other three M8 screws (13) from the

nozzle grip. Try pulling and pushing the assembly in

and out of its bore to ensure that no pressure exists.

5

6

a. If it will not come out, turn the two M6 set

screws (14) contained in the nozzle grip clockwise to separate it.

b. If the nozzle grip assembly will not come out

with the set screws fully extended into the MixHead body, replace the M6 set screws (14) with

longer M6 cap screws, and continue to move

the nozzle grip assembly out of the MixHead

body with the cap screws until the nozzle grip

assembly can be removed by hand.

NOTICE

Whenever a chemical hose is disconnected, immediately remove its associated nozzle grip assembly and

flush all chemical from the assembly and the MixHead

bore. Exposure to atmospheric moisture will cause

the remaining chemical in the nozzle grip assembly to

harden, making removal from the MixHead difficult.

10 312753E

Page 11

Maintenance

4. Using a clockwise twisting motion, pull the entire

nozzle grip assembly out of the MixHead body.

5. If the injection nozzle will not come out with the nozzle grip assembly, use the nozzle ejector tool to

remove the injection nozzle. See Additional Tools

and Accessories on page 29.

Nozzle Grip Cleaning

6. Flush remaining chemical and dirt from the nozzle

grip bore and mating surface of the MixHead body.

7. Disassemble the nozzle grip assembly and soak the

metal parts in solvent.

8. Clean the parts thoroughly,

9. Inspect for damage and/or wear and replace as

required.

10. Inspect the three o-rings (2, 3, 4) and replace as

required.

Nozzle Grip Assembly Installation

6. With the roll pin (FA) on the nozzle grip (9) in place

and lined up with the slot (FB) in the MixHead body,

insert the nozzle grip into the MixHead body.

7. Install the four M8 screws (13) hand tight.

8. Use a torque wrench to alternately tighten each

screw 1/2 turn at a time to 180 in-lb of torque.

The roll pin in the nozzle grip allows only one

method of insertion, ensuring that the chemical

openings in the nozzle grip and MixHead body will

be correctly aligned. Do not insert a nozzle grip

without the roll pin in place, or the nozzle grip may

be installed upside down in the body, causing the

chemical entering the MixHead to accumulate at

the nozzle grip and clog it.

9. Thread the two set screws (14) into the nozzle grip

until the screws contact the MixHead body.

10. Apply Lubriplate grease to the small o-ring (4) and

insert it into the nozzle grip (9).

11. Install and tighten down the hex o-ring seat (5) onto

the nozzle grip (9).

12. Install and hand tighten the locknut (6).

13. Recirculate all chemical lines until the pressures

stabilize.

See FIG. 2 on page 10.

With all parts clean and dry, assemble and install the

nozzle grip assembly as follows.

1. Lightly coat the injection needle (17) with Lubriplate

grease. Screw the injection needle (17) into the nozzle grip (9) until the shoulder of the injection needle

bottoms out in the nozzle grip counterbore.

2. Lightly coat the medium o-ring (3) with Lubriplate

grease and install on the end of the injection

nozzle (18).

3. Mount the injection nozzle (18) on the nozzle

grip (9).

4. Lightly coat the large o-ring (2) with Lubriplate

grease and install on the nozzle grip (9).

5. Lubricate the nozzle grip (9) with Lubriplate grease.

14. Pressurize the MixHead and check for chemical

leaks.

15. Set the desired impingement pressure.

a. Loosen the locknut.

b. Turn the adjustment stem until the desired

impingement pressure is achieved.

c. Retighten the locknut.

312753E 11

Page 12

Maintenance

Cleanout Plunger Proximity Switch Replacement

• Do not operate the MixHead unless all proximity

switches are in place and the proximity switch

alarm is operational and armed.

• A shock hazard or unpredictable machine operation

could occur if the proximity switch is separated from

its mating cord set, or if either the proximity switch

or its mating cord set are used with a different

switch or cord set.

The proximity switch on the cleanout plunger is a

high-pressure switch that extends directly into the

hydraulic fluid. The quick-disconnect feature on the

switch allows easy replacement of a failed or damaged

switch or cord set.

Tools Required

• 1 in. open-end wrench

Cord Set Replacement

See FIG. 3 on page 12.

1. Disconnect the cord set (BA) from the machine at

the Amphenol connector (BB).

2. Unscrew the knurled knob at the end of the cord

set (BA) and disconnect the cord set from the proximity switch (BC) on the MixHead.

3. Match up the keys on the cord set (BA) with the keyways on the proximity switch (BC), insert the cord

set into the proximity switch, and tighten the knurled

knob.

4. Connect the cord set (BA) to the machine at the

Amphenol connector (BB).

F

IG. 3

BA

BB

BC

BD

Key:

BA Proximity Switch Cord Set

BB Amphenol

BC Cleanout Plunger Proximity Switch

BD O-ring

®

Connector

12 312753E

Page 13

Proximity Switch Replacement

See FIG. 3 on page 12.

1. Turn OFF the hydraulic fluid motor, bleed the

hydraulic pressure to zero and allow the fluid to

cool.

2. Disconnect the cord set (BA) from the machine at

the Amphenol connector (BB).

3. Unscrew the knurled knob at the end of the cord

set (BA) and disconnect the cord set from the proximity switch (BC) on the MixHead.

4. Unscrew the proximity switch (BC) from the MixHead using the open-end wrench.

5. The replacement proximity switch will have an

o-ring (BD) already in position. Be sure to install the

switch (BC) with the o-ring (BD) in place.

Maintenance

6. Carefully screw the replacement proximity switch

(BC) back into the MixHead by hand and tighten

with the wrench.

7. Ensure the o-ring (BD) forms a leak-proof seal.

8. Match the keys on the cord set with the keyways on

the proximity switch, insert the cord set into the

proximity switch and tighten the knurled knob.

9. Connect the cord set (BA) to the machine at the

Amphenol connector (BB).

10. Purge all air from the hydraulic fittings. See step 3

on page 7.

312753E 13

Page 14

Maintenance

Material Plunger Proximity Switch Replacement

Do not operate the MixHead unless all proximity

switches are in place and the proximity switch alarm

is operative and armed.

Tools Required

• M2.5 hex key for M4 flat head screws

• Metric wrench (13mm)

• Proximity Switch gauge

• Gauge M1978-1: Models 5/8, 6/10, 10/14

• Gauge MU1140: Models 13/20, 16/25

See FIG. 4 on page 15 for models 5/8, 6/10, and

10/14. See F

16/25.

1. Turn OFF the hydraulic fluid motor and chemical

motor.

2. Disconnect the old proximity switch (CA, DA) from

the machine at the Amphenol connector.

3. Remove the two M4 flat head screws from the cover

plate on the material plunger housing (CH) or sensor cap (DH), depending on which model you have.

Remove the cover plate. Wipe the inside bore clean

of any dirt and hydraulic oil.

4. The position of the material plunger (CG, DF) can

be determined by observing its relationship to the

proximity switch within the material plunger housing/sensor cap. The material plunger will be in a

sensing position for the open/pour position, and in a

non-sensing position for the closed/recirculation

position.

5. While holding the conduit (CB, DB) of the old proximity switch stationary with one hand, loosen the

adapter (CC, DC) from the jam nut (CE, DD) with

the other hand. Loosen the jam nut and

lock-washer (CD, DE) on the proximity switch from

the material plunger housing/sensor cap. Remove

the proximity switch by unscrewing it from the

tapped hole.

IG. 5 on page 16 for models 13/20 and

6. Insert the sensor gauge (CF, DG) into the material

plunger housing/sensor cap.

7. Install the replacement proximity switch into the

appropriate threaded hole in the material plunger

housing/sensor cap as follows.

Models 5/8, 6/10, 10/14:

See FIG. 4 on page 15.

a. Thread the replacement proximity switch (CA)

until it contacts the flat cutout on the sensor

gauge (CF).

b. Maintain this position by tightening the

lock-washer (CD) and jam nut (CE) on the

threads of the proximity switch against the

material plunger housing (CH), with the

lock-washer between the jam nut and the material plunger housing.

c. While holding the conduit (CB) stationary,

tighten the adapter (CC) by hand until it contacts the jam nut (CE).

d. Remove the sensor gauge (CF) from the mate-

rial plunger housing (CH).

e. This step will ensure a clearance of

0.010-0.015 in. (0.254-0.381 mm) between the

material plunger (CG) and proximity

switch (CA).

Models 13/20 and 16/25:

See FIG. 5 on page 16.

a. Thread the replacement proximity switch (DA)

into the sensor cap (DH) until it contacts the

outer diameter of the sensor gauge (DG).

b. Maintain this position by tightening the lock

washer (DE) and jam nut (DD) on the threads of

the proximity switch against the sensor cap, with

the lock washer between the jam nut and the

sensor cap.

14 312753E

Page 15

Maintenance

c. While holding the conduit (DB) stationary,

tighten the adapter (DC) by hand until it contacts the jam nut (DD).

d. Remove the sensor gauge (DG) from the sen-

sor cap (DH).

e. This step will ensure a clearance of

0.010-0.015 in. (0.254-0.381 mm) between the

material plunger (DF) and proximity switch (DA).

8. Reinstall the cover plate to the material plunger

housing/sensor cap using the two M4 flat head

screws.

9. Connect the proximity switch to the machine at the

Amphenol connector.

1

CF

CA

CC

CD

CB

CE

1

Set Proximity Switch to make contact here on models 5/8, 6/10, 10/14.

2

0.010-0.015 in. (0.254-0.381 mm)

FIG. 4: Material Proximity Switch - Models 5/8, 6/10, 10/14

2

CG

CH

Key:

CA Proximity Switch

CB Conduit

CC Adapter

CD Lock-washer

CE 8 mm Jam Nut

312753E 15

CF Sensor Gauge M1978-1

CG Material Plunger

CH Material Plunger Cylinder Housing

Page 16

Maintenance

DF

DA

1

DC

DE

DB

DD

1

0.010-0.015 in. (0.254-0.381 mm)

FIG. 5: Material Proximity Switch - Models 13/20 and 16/25.

Key:

DA Proximity Switch

DB Conduit

DC Adapter

DD 8 mm Jam Nut

DE Lock-washer

DF Material Plunger

DG Sensor Gauge MU1140

DH Sensor Cap

DG

DH

16 312753E

Page 17

Cleanout Plunger Stroke Adjustment

The cleanout plunger stroke is properly set during factory assembly so that the cleanout plunger completely

clears the impingement chamber during a pour. Usually,

no adjustment is needed. However, for some applications where the chemical flow is on the lower end of the

MixHead flow range, improved mixing may be achieved

by adjusting the cleanout plunger so that it partially

blocks the impingement chamber leading into the exiting

chamber.

Tools Required

•Steel rod

• Hook spanner wrench

3. Loosen the shaft nut from the cylinder housing by

Maintenance

In the following step, there must be no hydraulic pressure in the system when loosening the shaft nut from

the cylinder housing.

turning counterclockwise with the proper hook spanner wrench.

Adjusting Plug

Shaft Nut

• Wrench MU1063: Models 5/8, 6/10, 10/14

• Wrench MU1080: Models 13/20 and 16/25

1. Relieve hydraulic pressure to zero and allow the

fluid to cool.

2. Record the original position of the adjusting plug in

relationship to the cylinder housing. This is done to

establish a reference point for restoring the cleanout

plunger to its original setting and for determining the

position of the cleanout plunger relative to the

impingement chamber.

a. Accurately measure and record the distance

that the adjusting plug extends above the shaft

nut.

b. Record the number of exposed threads of the

adjusting plug.

Adjusting

Plug

NOTICE

In the following step, do not exceed the following number of complete revolutions of the adjusting plug from

its original factory setting:

• Models 20.20.5/8 and 20.20.6/10: One

• Models 20.20.10/14: Two

• Models 20.20.13/20: Three

• Models 20.20.16/25: Four

Exceeding the above limits may result in chemical

cross-contamination of the MixHead due to complete

blockage of the impingement chamber.

Shaft Nut

312753E 17

Page 18

Maintenance

4. Place the steel rod between the two tie rods on top

of the adjusting plug and carefully turn the adjusting

plug clockwise to a desired position within the range

listed above. One complete turn moves the adjusting plug 0.078 in. (1.9812 mm).

5. Lock the adjusting plug into position by tightening

the shaft nut against the cylinder housing with a

hook spanner.

6. Purge all air from the hydraulic fittings. See step 3

on page 7.

18 312753E

Page 19

Maintenance

Pour Nozzle Maintenance

With proper maintenance, the L-Head is capable of performing thousands of pours without the need for removing and cleaning the pour nozzle. However, the use of

fast-reacting chemicals will require more frequent pour

nozzle removal and cleaning. The faster the chemical

reaction, the more frequent the need to clean the pour

nozzle. This is due to hardening of the chemicals before

the cleanout plunger can clean the bore. A sticking cleanout plunger is a good indication that the pour nozzle

must be cleaned. Use the following maintenance practices to help minimize cleanout plunger sticking:

Cleanout Plunger Lubrication

If the MixHead is to be left idle for any period of time, the

cleanout plunger should be lubricated before leaving.

1. Retract the cleanout plunger to the open/pour position.

Cleanout Plunger Retract Routine

During operation, periodic lubrication with mesamoll

may be all that is required to prevent sticking. However,

in cases where sticking is a continual problem, the cleanout plunger retract routine may be utilized.

In the retract routine, the cleanout plunger is retracted

as soon as it is permissible after each shot, to ensure

that the scraper seal has a chance to remove the foam

from the cleanout plunger while the foam is still wet.

Contact Graco technical service to learn more about the

cleanout plunger retract routine. Some modifications to

the software timing are required to incorporate this procedure.

2. Run a fine-grade wire brush up and down the cleanout bore to remove any loose foam.

3. Bring the cleanout plunger to the closed position,

and completely submerge the pour nozzle in a cup

of mesamoll plasticizer.

4. Cycle the cleanout plunger.

5. The mesamoll will be sucked up into the MixHead,

providing the lubrication between the cleanout

plunger and the bore it rides in.

6. Cycle the cleanout plunger several more times to

ensure that all of the remaining foam is removed,

and then leave the cleanout plunger in the

open/pour position.

312753E 19

Page 20

Maintenance

Pour Nozzle Removal and Installation

Tools Required

• Torque wrench with M6 and M8 sockets

• Fine-grade wire brushes on air tool

1. Cycle the cleanout plunger to the open/pour position.

2. Remove the socket head cap screws holding the

pour nozzle to the MixHead body, and remove the

nozzle. If there is resistance, lightly tap the nozzle

with a soft hammer until it breaks free from the MixHead body.

3. Thoroughly clean the external surface and the bore

of the pour nozzle of all foam and foreign matter

using fine grade wire brushes. Soak the nozzle in

solvent if necessary.

Step Seal and Scraper Seal Replacement

NOTICE

Do not attempt to replace the step seal and/or scraper

seal yourself.

Replacement of the step seal and the scraper seal

should be considered only when a hydraulic leak develops out of the pour nozzle, or when an excessive

amount of foam is getting into the hydraulics of the cleanout plunger.

MixHeads requiring step seal and/or scraper seal

replacement must be returned to Graco for rebuilding.

4. Thoroughly clean the external mounting surface of

the MixHead body using fine grade wire brushes.

Cycle the cleanout plunger forward to the

closed/non-pour position.

5. Carefully install the pour nozzle onto the cleanout

plunger and into position on the MixHead body.

Install and finger-tighten the screws. Cycle the cleanout plunger several times to ensure proper alignment of the pour nozzle. Leave the cleanout plunger

in the closed/non-pour position after cycling.

NOTICE

Proper alignment of the cleanout plunger within the

bore of the pour nozzle is critical to the life of the MixHead.

6. Using a torque wrench, alternately tighten the three

socket head cap screws a half-turn at a time to

180 in-lb.

20 312753E

Page 21

Troubleshooting

Troubleshooting

Any individual working with the equipment must be

knowledgeable in the necessary safety procedures.

Unless otherwise noted, all electrical troubleshooting

must be done with the incoming power switched off

and locked out at the source.

Symptom Probable Cause(s) Corrective Actions Reference

Chemical Crossover Seal failure on Material

Plunger

Fracture of Material

Plunger

Cleanout Plunger did not

retract during pour

Improper customer adjustment on stroke of Cleanout

Plunger

Hydraulic leak out of Pour

Nozzle

Chemical leak out of Pour

Nozzle

Galled Cleanout Plunger Send in MixHead for repair

Worn Step Seal Send in MixHead for repair

Worn Seal on Material

Plunger

Fractured Tip on Material

Plunger

Cleanout Proximity Switch

Damaged Switch Remove and test Switch

not working

Damaged Cord Set Remove and test Cord Set

Material Proximity Switch

Damaged Switch Remove and test Switch

not working

Improper clearance

between Switch and Material Plunger

Cleanout Plunger sticks in

bore

Poor lubrication maintenance of Cleanout Plunger

Build-up of foam in Pour

Nozzle

Galled Cleanout Plunger Send in MixHead for repair

Foam is curing on Cleanout Plunger before

scraper seal can remove it

Send in MixHead for repair

Send in MixHead for repair

Send in MixHead for repair

Send in MixHead for repair

Send in MixHead for repair

Send in MixHead for repair

Replace as needed

Replace as needed

Replace as needed

Reset clearance using sensor gauge

Lubricate Cleanout

Plunger on a daily basis

Remove and clean Pour

Nozzle

Try Plunger Retract Routine

See page 12

See page 12

See page 14

See page 14

See page 20

See page 20

Contact Graco

312753E 21

Page 22

Troubleshooting

Symptom Probable Cause(s) Corrective Actions Reference

Hydraulic leak around

Cleanout Plunger Proximity

Switch

Hydraulic leak out of sensing area of Material

Damaged o-ring Replace o-ring See page 12

Proximity Switch not tightened down onto Adjusting

plug

Improper sealing Replace with Polypak seal

Tighten Proximity Switch

against Adjusting Plug to

compress seal

See page 12

Contact Graco

and modify Sensor Cap

Plunger

Chemical leak out of Nozzle Grip Assembly

Cleanout Plunger falls out Fractured Cleanout

Loose Hex o-ring Seat Replace o-ring See Maintenance, page 9.

Damaged o-ring Seat Replace o-ring(s) See Maintenance, page 9.

Send in MixHead for repair

Plunger

Excessive amount of foam

in hydraulics

Worn Scraper Seal Send in MixHead for repair

Badly scored or galled

Send in MixHead for repair

Cleanout Plunger

Chemical pressure rise

during pour- one side only

Incorrect orifice size of

Injection Nozzle

Partial blockage in orifice

Replace with proper orifice

See page 10

size(s)

Remove blockage See page 10

of Injection Nozzle

Partial blockage in Nozzle

Remove blockage See page 10

Grip

Incorrect Injection Nozzle/Adjustment Stem size

Use matching Nozzle and

Stem sizes

See Technical Data,

page 31

combination

Chemical pressure rise

during pour- both sides

Chemical pressure drop

during pour- one or both

Cleanout Plunger partially

blocking impingement

chamber

Runner and/or Aftermixer

too small

Restriction exists in return

loop from MixHead to Tank

Adjust Cleanout Plunger

stroke to clear impingement chamber

Enlarge Runner and/or

Aftermixer

Remove restriction in

return loop

See page 17

sides

Injection Nozzle stuck in

body

Exposure to air has hardened chemical remaining

Remove Injection Nozzle

using nozzle ejector tool

See page 10

around Injection Nozzle

Mounting Holes stripped

out of body

Chemical or hydraulic leak

around fitting

Erosion of Adjustment

Stem Tip and Orifice of

Injection Nozzle

Poor quality foam at lower

output

Incorrect mounting of Mix-

Send in MixHead for repair

Head

Damaged o-ring Replace o-ring

Damaged fitting Replace fitting

Chemical attack of steel

parts or wear by abrasive

Replace with Carbide

Adjustment Stems and

Injection Nozzles

Incorrect Orifice size of

Injection Nozzle

Approaching lower limit of

MixHead throughput

Replace with smaller Orifice size

Adjust stroke of Cleanout

Plunger

See page 10, and Techni -

cal Data on page 31

See page 24

See page 24

22 312753E

Page 23

Troubleshooting

312753E 23

Page 24

Parts

Parts

Models 5/8, 6/10, 10/14

10

11

16

15

1

3

18

17

2

7

8

12

14

9

4

13

5

6

24 312753E

Page 25

Parts List

Ref. Part No. Description Qty

1 0135-910 O-RING 1

2*† --- O-RING 1

3*† --- O-RING 1

4*† --- O-RING 1

5 M0450 SEAT, hex o-ring 1

6 M0454-2 LOCKNUT 1

7 M362-3 COVER, sensor 1

8---

---

---

--9 M1051-1 GRIP, nozzle 1

10 M24017 SWITCH, material plunger proximity 1

11 M24022 CORD SET, cleanout plunger proximity switch 1

12 MA1009 SCREW, socket head cap 3

13 MA1755 SCREW, socket head cap 4

14 MA1759 SCREW, socket head cap 2

15 MA1769 SCREW, flat head machine 2

16 MS4086 SWITCH, cleanout plunger proximity 1

17† --- NEEDLE, injection, L style 1

18† --- NOZZLE, L Injection 1

NOZZLE, pour (20.20.5/8)

NOZZLE, pour (20.20.6/10)

NOZZLE, pour (20.20A.6/10)

NOZZLE, pour (20.20.10/14)

Parts

1

1

1

1

* Part included in Nozzle Grip Assembly Seal Kit MK1490, which can be purchased separately.

† Part included in Orifice Kits listed on page 28.

--- Parts not available for individual sale.

312753E 25

Page 26

Parts

Models 13/20 and 16/25

110

111

116

101

115

107

108

112

103

118

117

102

114

109

104

113

105

106

26 312753E

Page 27

Parts List

Ref Part No. Description Qty

101 0135-910 O-RING 1

102*† --- O-RING 1

103*† --- O-RING 1

104*† --- O-RING 1

105 M0450 SEAT, hex o-ring 1

106 M0454-2 LOCKNUT 1

107 M375-3 COVER, sensor 1

108 ---

--109 M1051-1 GRIP, nozzle 1

110 M24017

M24018

111 M24022 CORD SET, cleanout plunger proximity switch 1

112 MA1800 SCREW, socket head cap 4

113 MA1755 SCREW, socket head cap 4

114 MA1759 SCREW, socket head cap 2

115 MA1769 SCRW, flat head machine 2

116 MS4086 SWITCH, cleanout plunger proximity 1

117† --- NEEDLE, injection, L style 1

118† --- NOZZLE, L Injection 1

NOZZLE, pour (13/20)

NOZZLE, pour (16/25)

SWITCH, material plunger proximity (male)

SWITCH, material plunger proximity (female)

Parts

1

1

1

1

* Parts included in Nozzle Grip Assembly Seal Kit MK1490, which can be purchased separately.

† Part included in Orifice Kits listed on page 28.

--- Parts not available for individual sale.

312753E 27

Page 28

Parts

Orifice Kits

EB

EC

Key:

EA L-injection Nozzle

EB L-style Injection Needle

EC O-ring

ED O-ring, fluoroelastomer

EE O-ring, fluoroelastomer

F

IG. 6: L-Head Orifice Kit

Kit Numbers

Orifice size (mm) Kit

Calibrate M0934A-4

0.25 247761

0.45 247762

0.5 247763

0.75 247764

0.80 247765

0.85 247766

1.00 247767

1.10 247811

1.20 247848

1.25 247858

1.30 247859

1.40 247860

1.50 247861

1.60 247862

1.65 247863

1.70 247864

1.75 247865

1.80 247866

1.90 247867

2.00 247868

2.40 247869

3.20 247870

3.60 247871

4.20 247872

5.00 247873

5.60 247874

ED

EA

EE

Orifice Selection

This section is provided to give an approximate orifice size needed for a given application. There is no

guarantee that this formula will give you the correct

orifice.

To help choose the correct orifice for your application,

use the following equation to find a suggested ‘effective’

orifice size.

D F 0.324⁄()P Sg 62.4××()×=

D = Orifice Diameter (mm)

F = Flow through orifice (pounds / second)

P = Dispensing Pressure for Chemical (psi)

Sg = Specific Gravity of Chemical

The calculated “D” is the suggested orifice size in millimeters. Round to the nearest available orifice size to get

the suggested orifice for the application.

28 312753E

Page 29

Additional Tools and Accessories

Part No. Description Qty

MU1079 EJECTOR, nozzle 1

M1978-1* GAUGE, sensor (5/8, 6/10, 10/14) 1

MU1140† GAUGE, sensor (13/20, 16/25) 1

MU1063* WRENCH, hook spanner (5/8, 6/10, 10/14) 1

MU1080† WRENCH, hook spanner (13/20, 16/25)) 1

MU1064*† HEX L-KEY, 3 mm, long arm 1

MU1066*† HEX L-KEY, 6mm, long arm 1

MU1069*† HEX KEY, 5/32 in., 6 in. 1

MU1154*† HEX L-KEY, 3/8 in., long arm 1

MU1155*† WRENCH, open end, 1 in., 15 deg 1

MU1067† HEX L-KEY, 8 mm, long arm 1

* Included in L-Head Tool Kit MK1184 for models 5/8,

6/10, and 10/14. Kit can be purchased separately

† Included in L-Head Tool Kit MK1223 for models 13/20

and 16/25. Kit can be purchased separately

Parts

312753E 29

Page 30

Parts

30 312753E

Page 31

Technical Data

Technical Data

Proximity Switch Electrical Requirements . . . . Cleanout Piston: 50 mA @24VDC

Material Piston: 60 mA @ 16 VDC

Fittings (See F

Max Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 lb (19.5 kg)

Wetted Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel, Trivalent Chromium Plated Carbon Steel,

IG. 1 on page 6) . . . . . . . . . . . . . Iso Close Fitting (K):

1/2 BSPP X 1-1/16 JIC CONNECT,

1-1/16-12 F JIC x 3/4-16 JIC

Resin Close Fitting (C):

1/2 BSPP X 1-1/16 JIC CONNECT,

1-1/16-12 F JIC x 7/8-14 JIC

Iso Open Fitting (L):

1/2 BSPP x 1-1/16-12 ELBOW,

1-1/16-12 F JIC x 3/4-16 JIC

Resin Open Fitting (D):

1/2 BSPP x 1-1/16-12 ELBOW,

1-1/16-12 F JIC x 7/8-14 JIC

Cleanout Plunger Open Fitting (B):

3/8 BSPP x 3/4-16 JIC NIPPLE,

3/4-16 JIC x 3/4-16 JIC (SW) 45

PTFE, Perifluorinated and EPDM O-rings

312753E 31

Page 32

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-746-1334 Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312753

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised June 2013

Loading...

Loading...