Page 1

Instructions

Trabon

Divider Valves

312497P

For series progressive, oil and grease lubrication. For Professional Use Only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Keep these instructions.

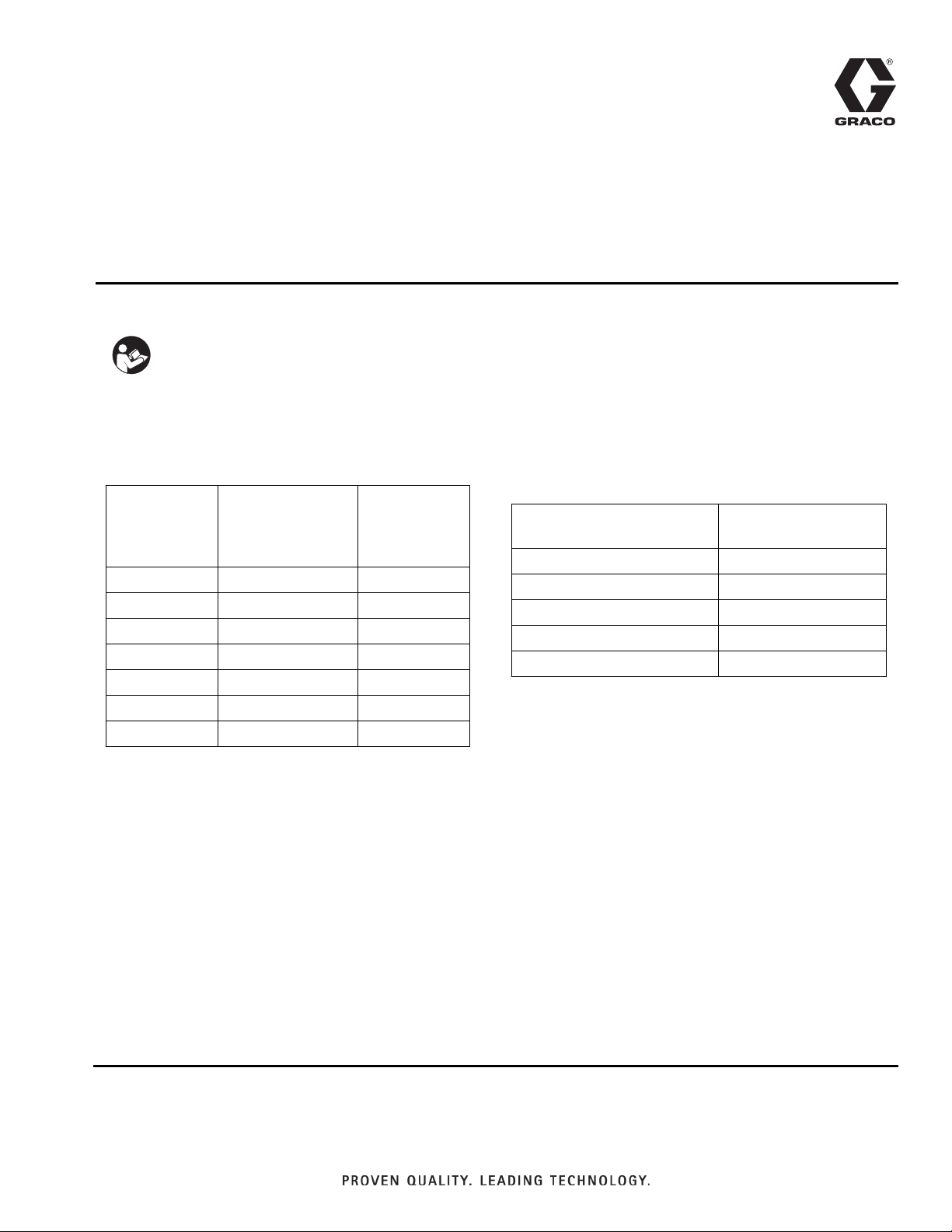

Models/Maximum Pressure

Table 1: Maximum Pressure Lube Points Table 2: MGO Series-Flo Divider Maximum

Maximum

Operating

Pressure kPSI

Divider Type

MD 3.0 (20.7, 207) 2

MJ 2.0 (13.8, 138) 8

MSP/MSPSS 3.5 (24.1, 241) 8

MHH 7.5 (51.7, 517) 8

MX 3.0 (20.7, 207) 10

MXP 3.0 (20.7, 207) 10

MGO See Table 2 11

(MPa, bar)

Maximum

Sections

Operating Pressures

Maximum Operating

Pressure kPSI (MPa, bar)

6.0 (41.4, 414) 3 to 7

5.5 (37.9, 379) 8

4.0 (27.6, 276) 9

4.5 (31.0, 310) 10

4.0 (27.6, 276) 11

Number of Sections

EN

Page 2

Warnings

Warnings

The following Warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point symbol alerts you to a general warning and hazard symbols refer to procedure-specific risks. Refer back to

these Warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

2 312497P

Page 3

Setup

a

b

b

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Verify pump feeding valve is stopped and disconnected from, or locked out of it’s driver.

2. Using a wrench, slowly loosen inlet nut.

3. Then, using a wrench, slowly loosen each port nut.

NOTICE

Do not install a divider valve into a system rated for

more than the valve’s maximum operating pressure.

This type of installation could result in o-ring damage

and cause the divider valve to leak.

To install the divider valve in your system:

1. Determine an appropriate, remote mounting location.

2. Install a rupture to atmosphere fitting with a blow-out

disk that is rated for 7,500 psi (52 MPa, 517 bar) or

less between the force feed lubricator pump and

master divider valve inlet.

3. Install an analog pressure gauge at the inlet to the

divider valve.

4. Install a slow or no cycle shutdown in one of the piston enclosure plugs. Program it to shut down after

no more than 180 seconds without a complete

cycle.

5. Torque. See Table 4 on page 15.

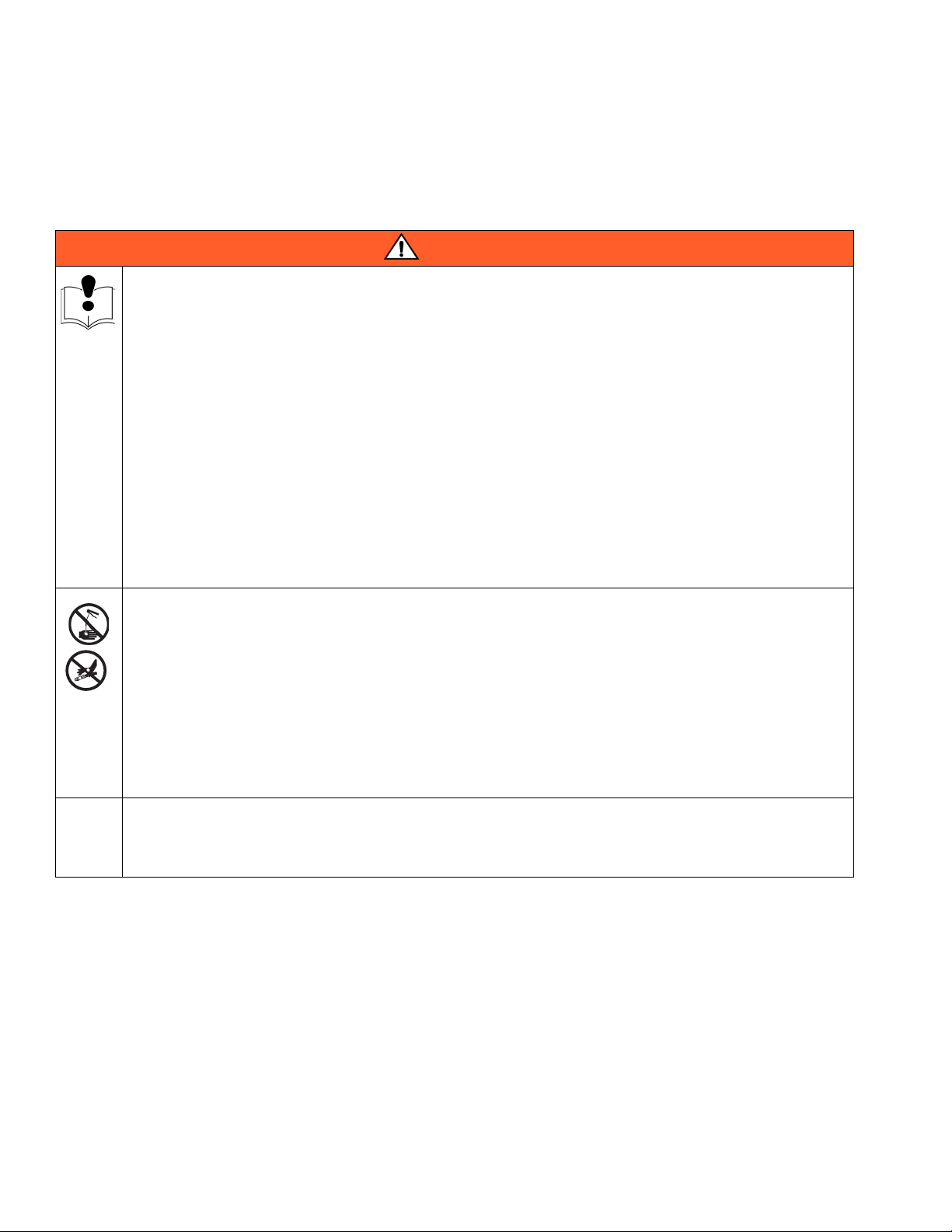

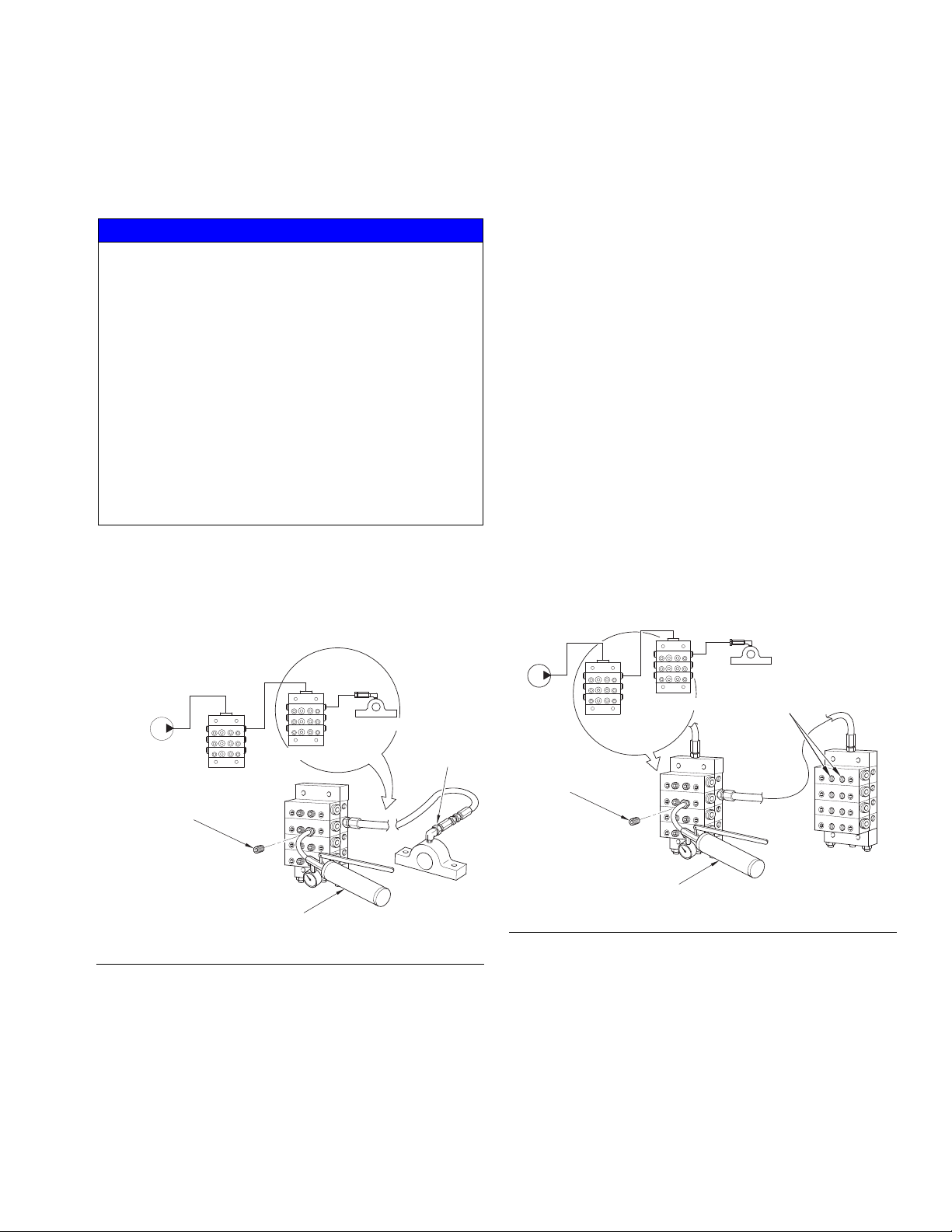

Setup

The divider valve is shipped ready to install in your system. It has been factory-tested and should not require

any additional modification.

For MJ and MX series valves only

installed between every valve section (b) of the block

assembly to prevent leaking.

: Gaskets (a) must be

As long as lubricant is supplied under pressure to the

inlet section of the divider assembly, valves sections will

continue to operate in a progressive manner. Divider

assemblies always follow a constant discharge pattern.

Whenever lubricant flow ceases, the valving pistons will

stop. When flow resumes, it will start again at the same

point in the discharge cycle.

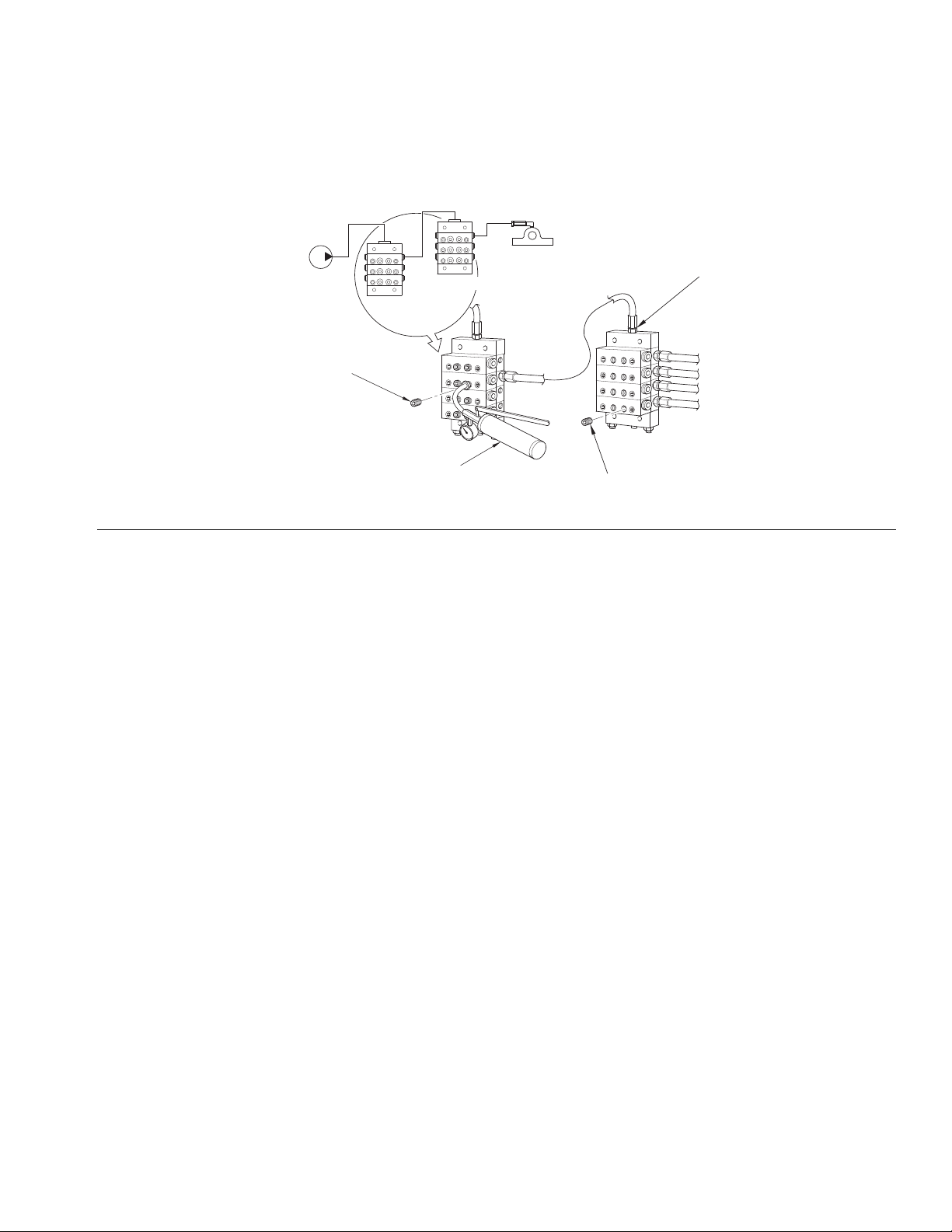

FIG. 1

312497P 3

Page 4

Setup

A

B

C

D

E

F

G

H

TI11102

Piston

Enclosure/End

Enclosure Plug Gasket

Piston

Indicator

Indicator Port Plug

Port

O-Rings

Check

Valve

Plug

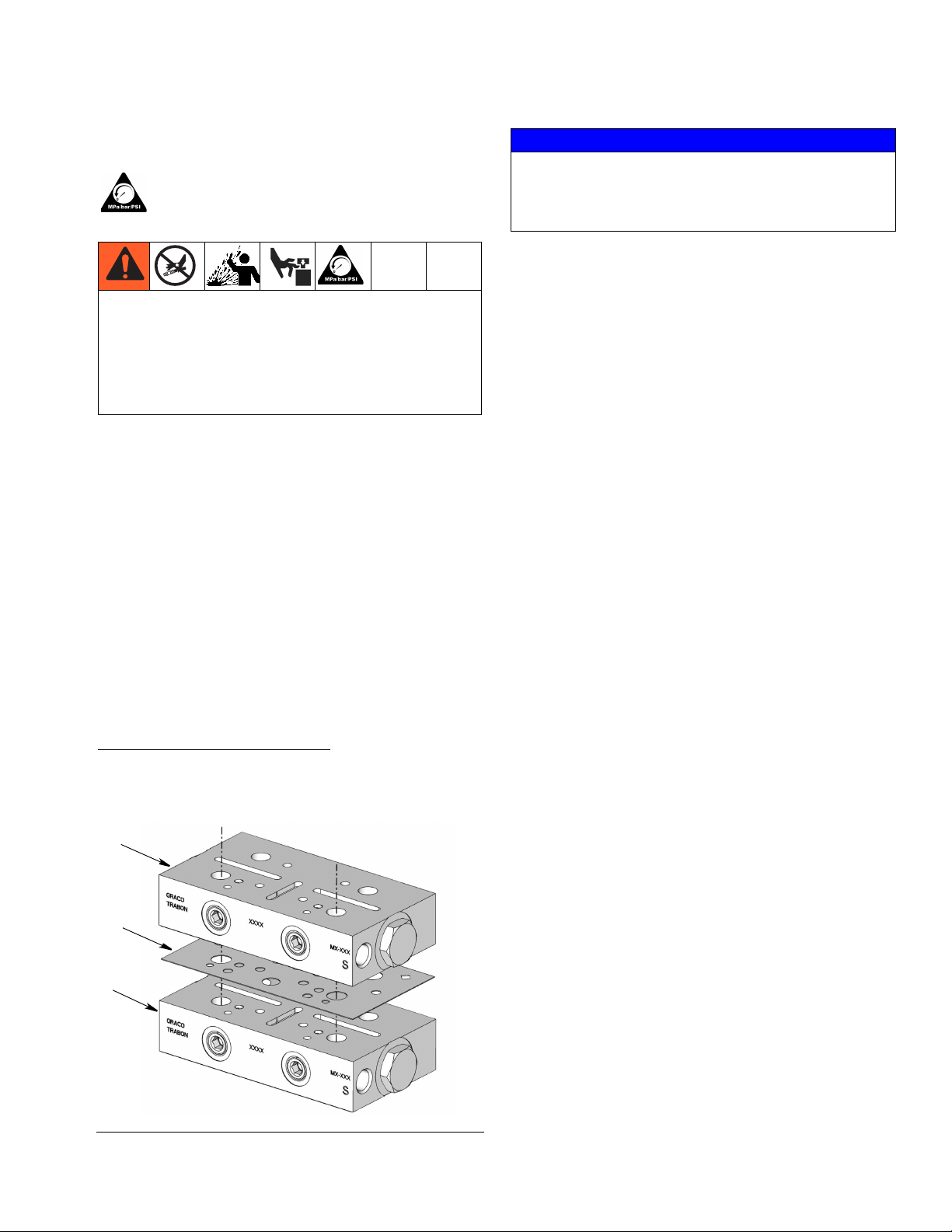

Component Identification

Divider Valves

A Series-Flo type divider valve is a manifold proportioning device consisting of an inlet and end section plus a

minimum of three valve sections. The divider valve is

manifolded together with tie rods and nuts. A master

divider valve is the first divider valve downstream from

the lube pump. A secondary divider valve is any divider

valve receiving lubricant from the master divider valve.

Valve Sections (MSP, MHH and MXP

modular-type, divider valves, only)

Valve sections (three or more required per manifold)

contain a piston specially fitted to that section, built in

outlet check valves and various passageways that,

working with the piston, meters and valves the flow of

lubricant (F

IG. 3).

FIG. 2

Key:

A Valve Section

B Inlet Section

C Indicator / Port Plug

D Crossport Plate

E End Plug

F Subplates with Outlet Ports

G End Section

H Tie Rod Nut

Table 3: Typical Divider Valve

Combinations

MASTER SECONDARY

MJ MD Machine tools, Printing,

MSP MJ, MSP Machine tools, Textile,

MX, MXP MX, MXP, MSP Cranes, Presses, Steel

MGO MX Levellers, Shears,

TYPE OF

APPLICATION

Wire Forging &

Packaging Machinery

Glass & Can Machinery,

Mobile Equipment

Mills, etc.

Conveyors, etc.

FIG. 3

Valve sections may be manufactured to require one or

two lube outlets. Stamping located on the face of each

section indicates:

• the style of divider valve section, i.e., MSP, MX,

etc.,

• the discharge per piston stroke expressed in

thousandths of cubic inches (35 = .035 in

3

)

and,

• the number of lube outlets required (S = single,

one outlet only; T = twin, two lube outlets

required).

4 312497P

Page 5

Setup

TI11098

MASTER

HAND PUMP

BLEED HOSE

REMOVE INDICATOR

OR PORT PLUG

SECONDARY

LUBE POINT

HERE

TI11099

MASTER

SECONDARY

LUBE POINT

REMOVE INDICATOR

OR PORT PLUG

HAND PUMP

BLEED

ALL PORTS

THROUGH

Prefilling Lubricant Distributor Lines

Follow the following procedure exactly as written, in the

order written.

NOTICE

• The initial startup and operation is the most critical

operating period for a newly installed machine in

terms of potential for being damaged by unremoved/unfiltered lubricant contaminants and lack of

adequate lubrication. Proper prefilling of lubrication

system ensures that lubricant is immediately available to every lube point during machine startup,

protecting them from damage.

• Use only clean oil filtered to the SAE -recommended cleanliness level of ISO 18/14 (ISO Standard 4406) when prefilling a system. The

manufacturers of the machine tool and its component bearings should be consulted to ensure that

the ISO 18/14 cleanliness level is adequate.

Filling Secondary-to-Lube Point Lines

3. In order to verify when lubricant is flowing and has

reached the end of the lube line, loosen the connector at the lube point of the line that is to be filled.

4. Stroke the hand pump until air-free lubricant is

observed flowing from the end of the lube line.

5. Tighten the lube line connector at the lube point, but

do not replace the port plugs or performance indicators into the ports on the front of the working section.

6. Repeat steps 1-5 for each of the other lube lines

connected to the other outlet ports in the secondary

divider valve assembly and for any other secondary

divider assemblies in the system.

NOTE: Do not replace any of the performance indicators or port plugs removed in Step 1 until the line-filling

procedure described in Section 2 (Filling Master

-to-Secondary Lube Lines) has been completed.

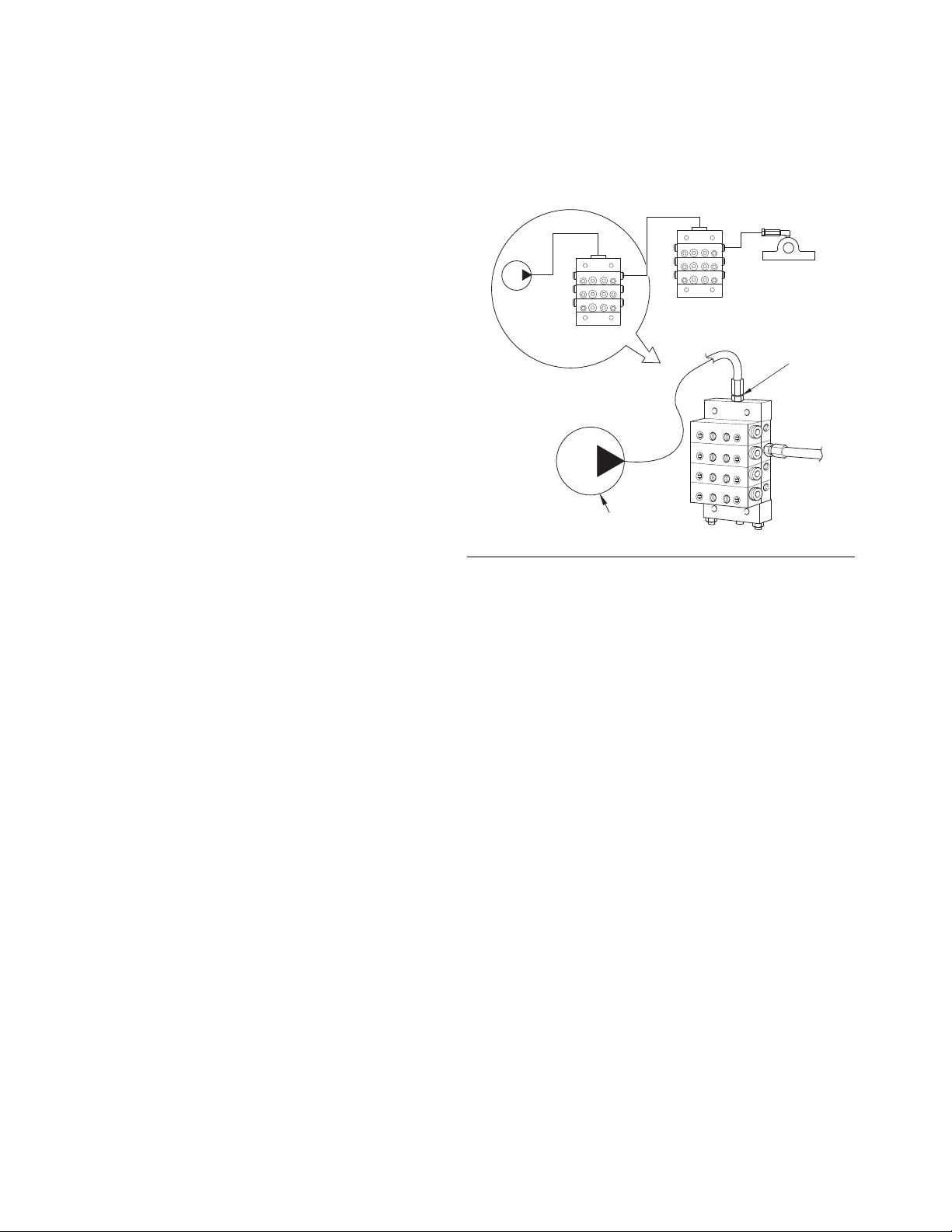

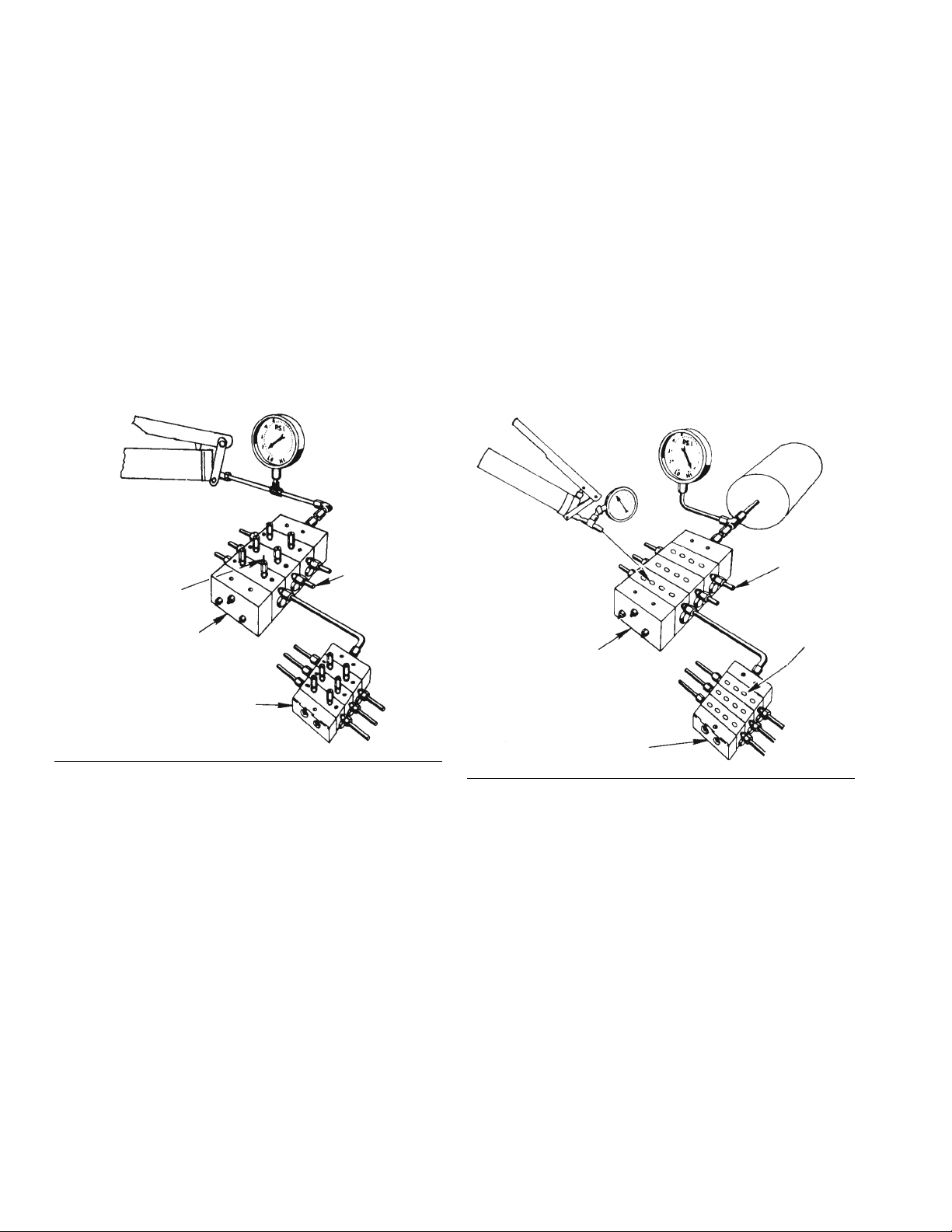

Filling Master-to-Secondary Lube Lines

Refer to FIG. 5. when performing this procedure.

Refer to FIG. 4. when performing this procedure

.

FIG. 4

1. Remove port plugs or performance indicators from

2. Connect a hand pump filled with clean, filtered lubri-

all of the indicator ports on front of secondary

divider valves.

cant to the indicator port closest to the first line to be

filled that corresponds to the output port that is feeding the line to be filled.

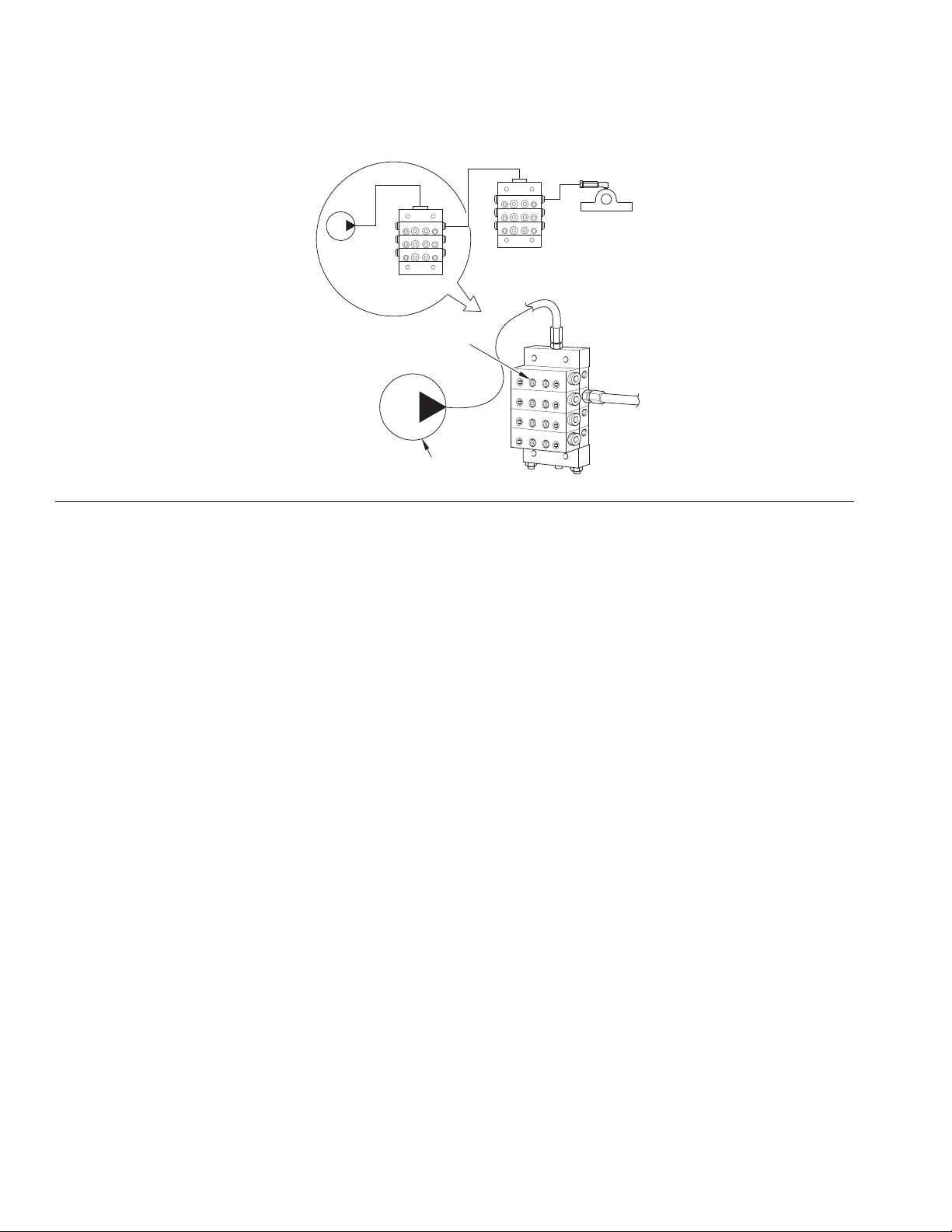

FIG. 5

1. Remove the port plugs or performance indicators

from all the indicator ports on the front of the master

divider valve.

2. Connect a hand pump filled with clean, filtered lubricant to the indicator port closest to the lube output

port that is feeding the line to the secondary divider

valve.

3. Stroke the hand pump to fill the line between the

master divider valve and secondary divider valve.

312497P 5

Page 6

Setup

TI11000

MASTER

BLEED

SECONDARY

LUBE POINT

HERE

CYCLE PUMP

4. Continue to stroke the pump until the lubricant

purges all the air out of the internal passages of the

secondary divider valve and lubricant flows freely

from all indicator ports with no evidence of included

air.

5. Reinstall the port plugs or performance indicators in

their respective positions in the secondary divider

valve. Do not replace the port plugs or performance

indicators in the master divider valve yet.

6. Repeat Steps 1-5 for each of the other lube lines

between the master divider valve and all other secondary divider valves.

NOTE: Do not replace any of the performance indicators or port plugs removed in Step 1 from the master

divider valve assembly until the air-purging procedure

described in Section 3 (Filling Master Divider Valve) has

been completed.

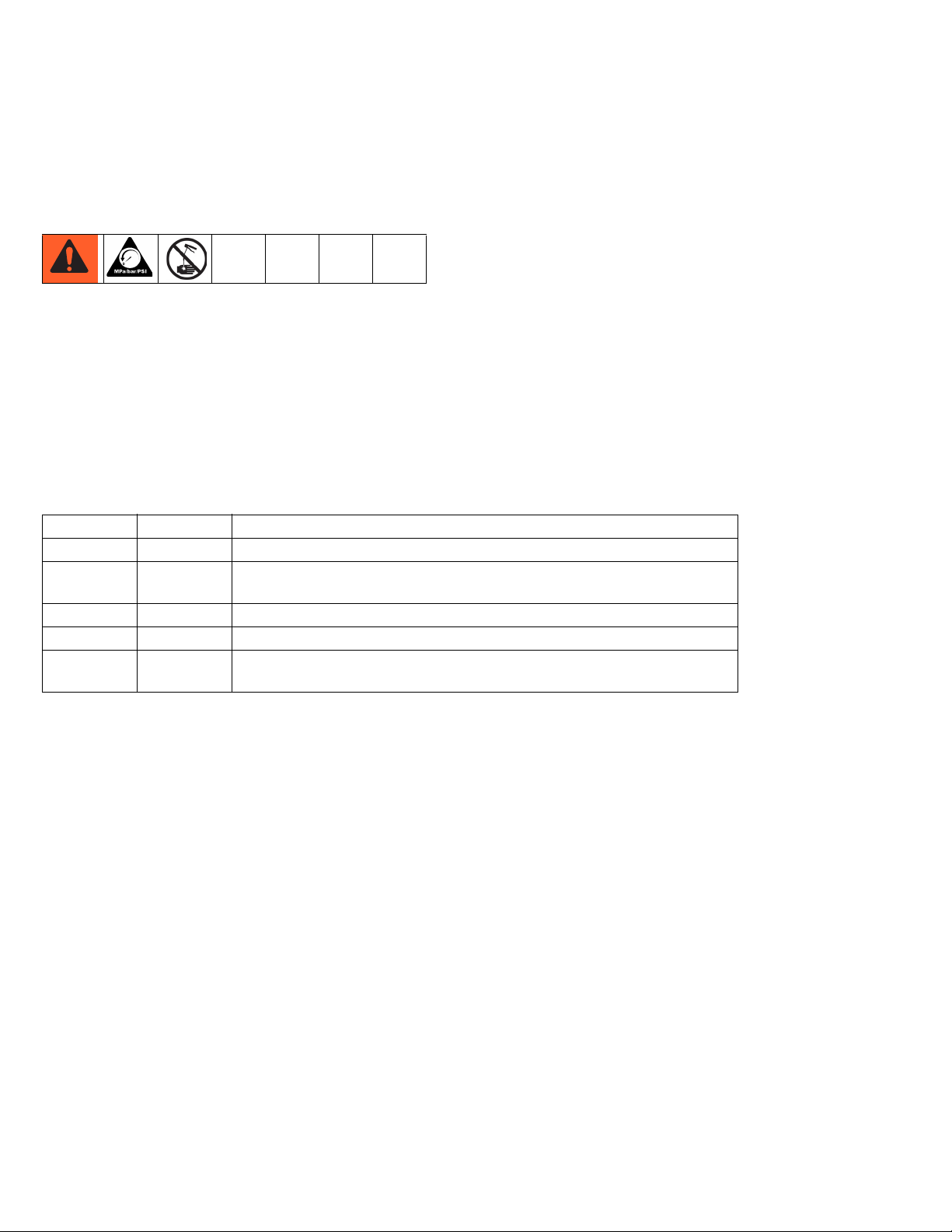

Filling Master Divider Valve

Refer to FIG. 6. when performing this procedure.

FIG. 6

1. Verify that all port plugs or performance indicators

have been removed from all indicator ports in the

master divider valve.

2. Verify that the system pump is properly connected

to the inlet port of the master divider valve.

3. Cycle the system pump sufficiently to fill the main

feeder line between the pump and the master

divider valve and the lubricant is observed being

discharged from all of the indicator ports on the front

of the master divider valve with no evidence of

included air.

4. Reinstall the master divider valve port plugs or performance indicators into their respective positions.

6 312497P

Page 7

Repair

Repair

General Repair Instructions

• Before performing any repair procedures, relieve

pressure, page 3.

• Pressure test distribution blocks yearly or every

8000 hours. Replace seals and divider valves as

necessary.

Page Section Air purging after:

8 1 Replacing line between a secondary divider valve and lube point.

9 2 Replacing a line between the master divider valve and a secondary

divider valve.

10 3 Replacing a line between pump and master divider valve.

11 4 Adding or replacing any component in a master divider valve assembly.

12 5 Adding or replacing any component in module in a secondary divider

valve assembly.

Purging Air From the System

Before machine operation is resumed following maintenance or repair, manual system air purging must be performed.

There are several air purging procedures available

depending upon the maintenance or repair procedure.

NOTE: Use only clean oil filtered to the SAE -recommended cleanliness level of ISO 18/14 (ISO Standard

4406) when prefilling a system. The manufacturers of

the machine tool and its component bearings should be

consulted to ensure that the ISO 18/14 cleanliness level

is adequate.

312497P 7

Page 8

Repair

TI11098

MASTER

HAND PUMP

BLEED HOSE

REMOVE INDICATOR

OR PORT PLUG

SECONDARY

LUBE POINT

HERE

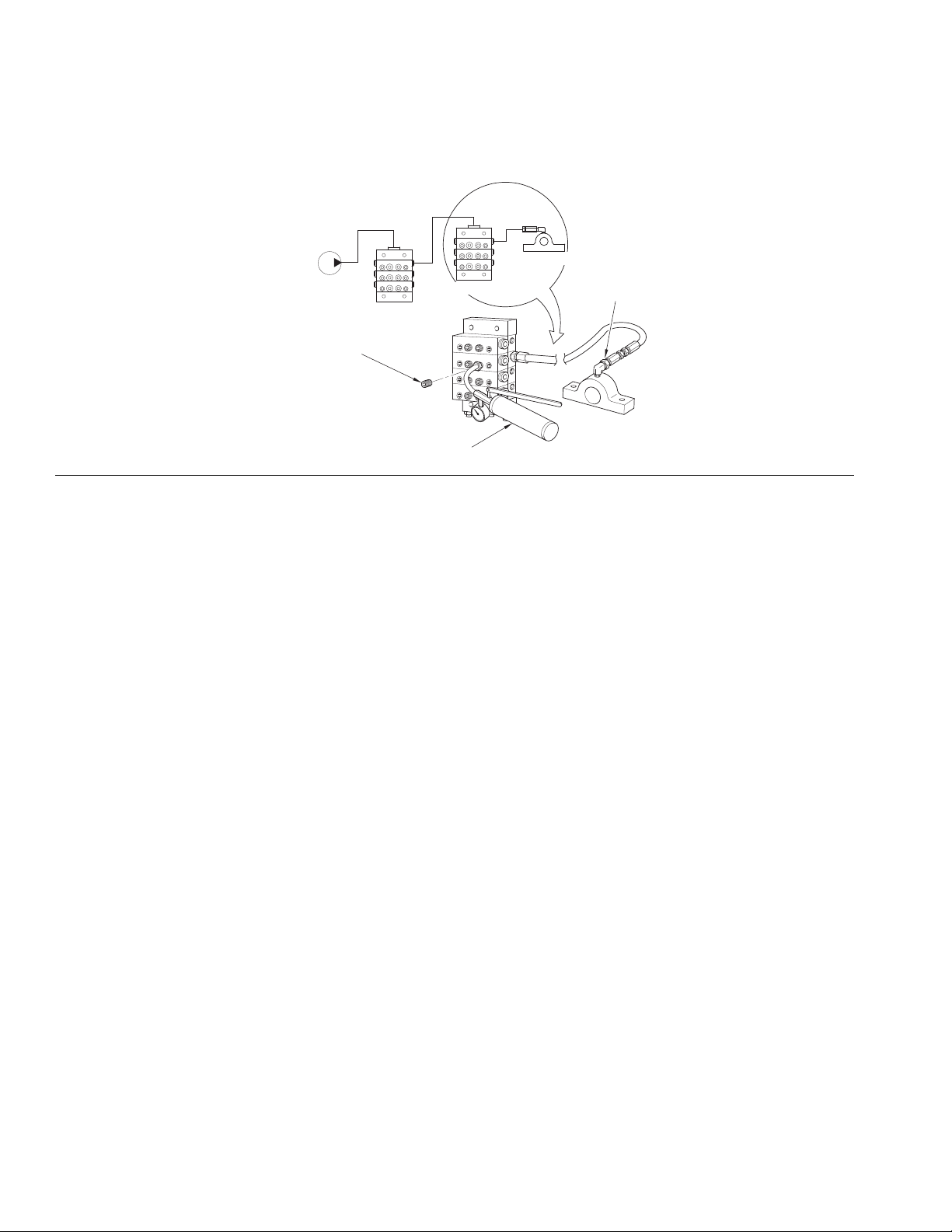

Section 1: Purging Air from Secondary Divider Valve Lube-to-Lube Point Lines

FIG. 7

Steps 1-6, refer to FIG. 7.

1. Install the line from the secondary divider valve to

the lube point, but do not completely tighten the

connection at the lube point.

2. Remove the performance indicator port plug or the

performance indicator from the working valve section on the secondary divider valve assembly corresponding to the outlet port and the line connected to

the lube point.

3. Attach a hand pump filled with clean, filtered lubricant to the port on the secondary divider valve that

was opened in Step 2.

4. Operate the hand pump until air-free lubricant is

observed flowing from the line at the lubrication

point.

5. Tighten the fitting at the lubrication point while lubricant is still flowing.

6. Remove the hand pump and reinstall the performance indicator or indicator port plug removed in

Step 2.

NOTE: If check valves were not installed at the lubrication point, lubricant may continually drain out of the line

when the secondary port is open. Therefore, when

check valves are not used, the method for bleeding this

line is to tighten the line at both ends and repeatedly

cycle the secondary divider valve via hand pump operation until lubricant, free of air, flows from the lubrication

point

8 312497P

Page 9

Section 2: Purging Air from Master to Secondary Divider Valve Lube Lines

TI11113

MASTER

HAND PUMP

REMOVE INDICATOR

OR PORT PLUG

SECONDARY

LUBE POINT

BLEED HERE

FIRST

AFTER BLEEDING INLET,

REMOVE ALL INDICATORS

OR PORT PLUGS AND BLEED

ALL PORTS

Repair

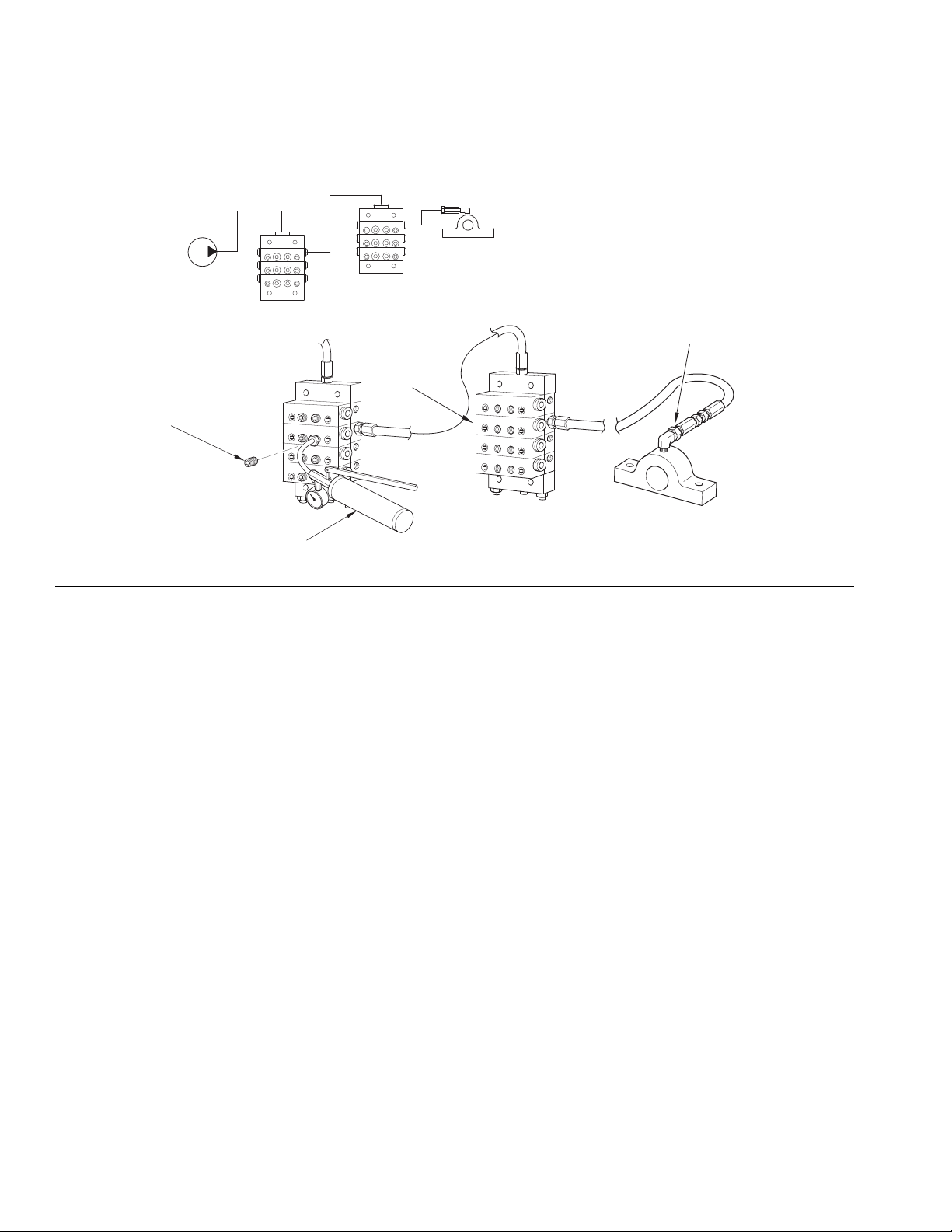

FIG. 8

Steps 1- 9, refer to FIG. 8.

1. Install the lines from the master divider valve to the

secondary divider valve, but do not completely

tighten the connection at the secondary divider

valve’s inlet.

2. Remove the performance indicator port plug or the

performance indicator from the working valve section on the master divider valve assembly corresponding to the outlet port and the line connected to

the secondary valve.

3. Attach a hand pump filled with clean, filtered lubricant on the master divider valve that was opened in

Step 2.

4. Operate the hand pump until air-free lubricant is

observed flowing freely from the secondary valve’s

lube inlet connector.

5. Tighten the fitting at the secondary valve’s inlet

while lubricant is still flowing.

6. Remove all of the indicators or indicator port plugs

from the secondary divider valve’s working sections.

7. Operate the hand pump again until air-free lubricant

is observed flowing out of all the secondary divider

valve’s indicator ports.

8. Reinstall all of the performance indicators or port

plugs in the secondary divider valve while lubricant

is still flowing from the ports.

9. Remove the hand pump and reinstall the performance indicator or indicator plug removed in Step 2

into the master divider working valve’s open port.

The system is now ready for operation.

312497P 9

Page 10

Repair

TI11114

BLEED THROUGH

SECONDARY

MASTER

ALL PORTS

SYSTEM PUMP

LUBE POINT

Section 3: Purging Air from Pump to Master Divider Valve Lines

FIG. 9

Steps 1-3, refer to FIG. 9.

1. Install the line from the system pump to the master

divider valve, but do not completely tighten the connection at the master valve’s lube inlet.

2. Cycle the system pump until air-free lubricant is

observed flowing from the line at the master divider

valve’s lube inlet.

3. Tighten the fitting at the lube inlet port while lubricant is still flowing.

The system is now ready for operation.

10 312497P

Page 11

Section 4: Purging Air After Adding or Replacing a Master Divider Valve Module

TI11116

BLEED

SECONDARY

MASTER

HAND PUMP

LUBE POINT

DISCONNECT

LINE

HERE

NEW VALVE

BLOCK

Repair

FIG. 10

Steps 1-7, refer to FIG. 10.

1. Install the new or replacement module into the master divider valve assembly. Also connect the tubing

or hoses to the appropriate secondary divider

valve(s) or lubrication point(s) if the new/replacement module is a base section.

2. Do not completely tighten the connection(s) at the

secondary divider valve’s inlet or at lubrication

points.

3. Disconnect and remove the line from the pump at

the inlet of the master divider valve.

4. Attach a hand pump filled with clean, filtered lubricant to the inlet port on the master divider valve.

5. Operate the hand pump until air-free lubricant is

observed flowing from each secondary valve’s lube

inlet connector and/or each lubrication point’s connector.

6. Tighten the fitting at the secondary valve inlet or at

the lubrication port while lubricant is still flowing.

7. Remove the hand pump and reconnect the system

pump to the inlet of the master divider valve.

The system is now ready for operation.

312497P 11

Page 12

Repair

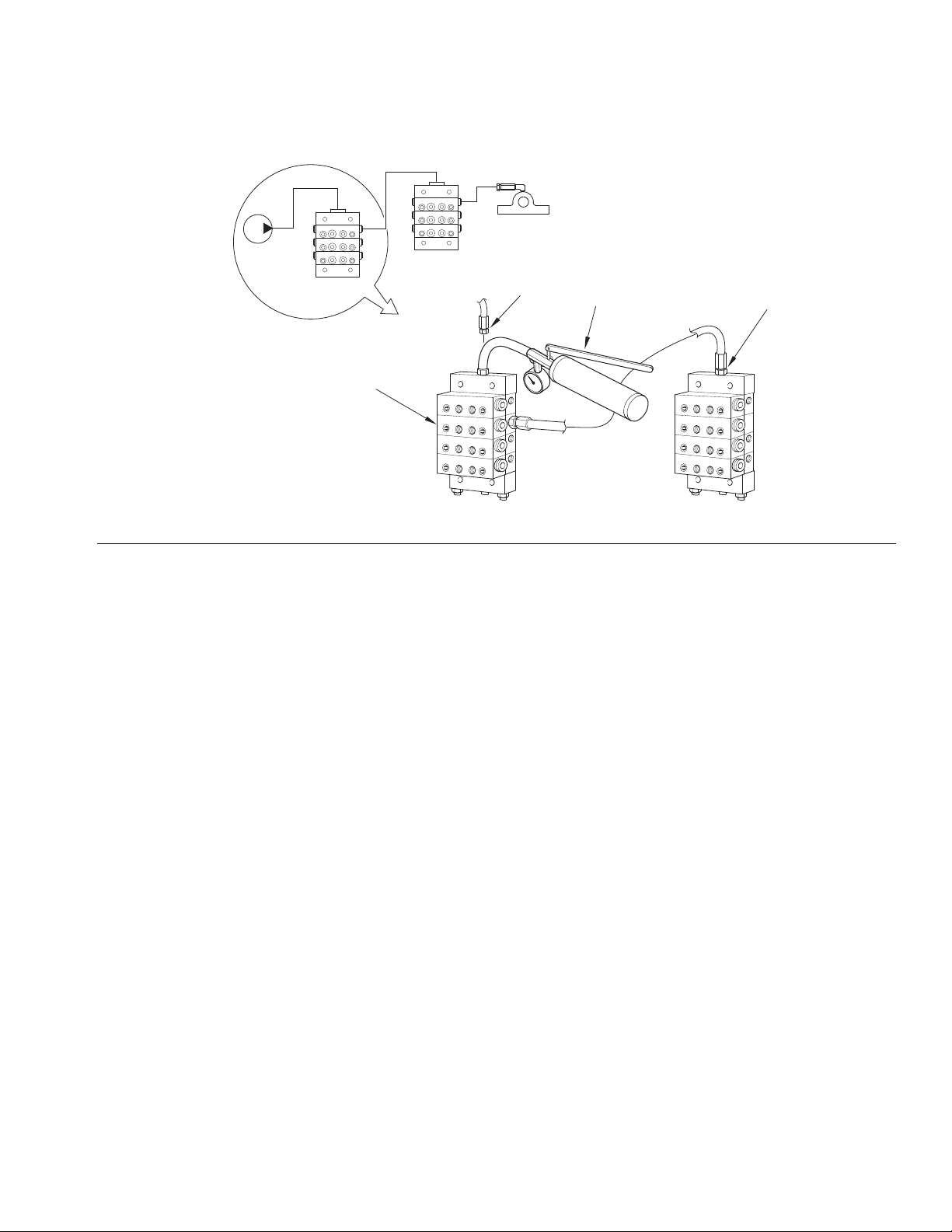

TI11115

MASTER

HAND PUMP

BLEED HOSE

REMOVE INDICATOR

OR PORT PLUG

SECONDARY

LUBE POINT

HERE

NEW VALVE

BLOCK

BLEED

HERE

Section 5: Purging Air After Adding or Replacing a Secondary Divider Valve Module

FIG. 11

Steps 1-8, refer to FIG. 11.

1. Install the new or replacement module to the secondary divider valve assembly. Also connect the

tubing or hoses to the appropriate lubrication point if

the new/replacement module is a base section.

2. Do not completely tighten the connection(s) at the

lubrication point.

3. Remove the performance indicator or indicator port

plug from the working valve section on the secondary divider valve assembly corresponding to the outlet port and line connected to a particular lube point.

4. Attach a hand pump filled with clean, filtered lubricant to the port on the secondary divider valve that

was opened in Step 3.

5. Operate the hand pump until air-free lubricant is

observed flowing from the loosened connector at

the lube point.

6. Tighten the fitting at the lube point while lubricant is

still flowing.

7. Repeat Steps 3 - 6 for any additional lubrication

points connected to the new module.

8. Remove the hand pump and reinstall the performance indicator or port plug removed in Step 3 into

the secondary divider valve’s open port.

The system is now ready for operation.

12 312497P

Page 13

Repair

Locating and Repairing Blockages

Blocks will cause a higher than normal pumping pressure. Depending on the application or system design,

this blockage will usually result in a complete loss of

lubricant flow into the total system and no bearing will be

receiving lubrication.

The loss of flow due to a blockage is first indicated with

the higher than normal system pressure that is developed by the pump as it attempts to overcome this blockage. Higher pressure is limited, isolated and signaled

through the use of various performance indicators, reset

and relief, incorporated into the system design.

Performance Indicators

Performance indicators are pressure-sensitive devices

that pinpoint excessive pressure in the lubricating system.

These devices are installed in the indicator ports of

divider valves, signal a fault either by causing an indicator pin to protrude or by releasing lubricant into the

atmosphere.

NOTE: Never block a lube outlet that is designed to discharge lubricant.

Reset Indicator with Memory

Reset indicators stop lube system operation when a

fault occurs. These devices can be used in either master

or secondary divider valves.

When a lube line becomes blocked, the resultant high

pressure pushes the indicator pin through the opening in

the cap. The high pressure prevents the affected divider

valve piston from completing its cycle, causing a pressure backup through the divider valve which trips a pressure switch upstream from the valve and shuts off the

pump.

The indicator pin remains extended until it is reset manually. This helps locate the lube line that is blocked.

Rupture Indicator

Rupture indicators are used on MSP/MH divider valve

applications where lube system pressure exceed 2500

psi (17 MPa, 172 bar). The high pressure from the lube

line blockage causes a disc to rupture. The lubricant

then forces an indicator to protrude, locating the blockage. The high pressure backs up through the system

and trips a switch to shut the system off. When the fault

is corrected, the disc must be replaced and the pin reset

manually.

Automatic Relief Indicator

An automatic relief indicator pinpoints lube line blockage

but allows the lube system to continue supplying lubricant to points that are not blocked. They are used primarily in secondary divider valves. The excessive

pressure created by line blockage moves a piston,

enabling the lubricant to escape through a vent. When

the pressure is relieved, the spring resets the piston.

Because these devices permit the lube system to keep

operating when a lube point is blocked, a separate pressure switch connected to an audible alarm should be

used to warn of high pressure.

Locating and Repairing Blockages

1. Make a visual inspection of the system. Check for

crushed lines or improper divider valve installation.

2. Verify that each divider valve outlet required to discharge lubricant can do so and that no pipe plugs

have been installed in an outlet designed to serve a

bearing or another divider valve.

3. Use a manual pump with a gauge. Fill the pump with

clean, filtered lubricant. Connect the manual pump

to the inlet of the master divider valve and slowly

operate pump. If system will not cycle freely, below

1500 psi, see Master Divider Valve Equipped with

Performance Indicator [Step 4a (below)].

NOTE: Use only clean oil filtered to the SAE -recommended cleanliness level of ISO 18/14 (ISO Standard

4406) when prefilling a system. The manufacturers of

the machine tool and its component bearings should be

consulted to ensure that the ISO 18/14 cleanliness level

is adequate.

312497P 13

Page 14

Repair

HAND PUMP

LUBE

INDICATOR PIN UP

MASTER

SECONDARY

OUTLETS

DIVDER

VALVE

DIVIDER

VALVE

TI11103

TI11104

HAND PUMP

SYSTEM PUMP

MASTER

DIVDER

VALVE

SECONDARY

DIVIDER

VALVE

LUBE

OUTLETS

INDICATOR

PORT

PLUGS

REMOVED

4a. Master Divider Valve Equipped With Performance

Indicator

With manual pump connected to the master divider

valve as outlined in Locating Blockages, Step 3,

raise pressure to 2000 psi (14 MPa, 138 bar). The

indicators in the indicator ports will signal the location of the blockage. An indicator in the up position

indicates pressure is in that outgoing line and signals the blockage is in the area being served from

this outlet (F

IG. 12).

If no indicator pins are protruding, the blockage is in

the master divider valve.

NOTE:

• If all indicator port plugs are removed, the master

will not cycle. Blockage is in this divider valve.

• When indicator port plug of a blocked area is

removed, a small shot of trapped lubricant will usually surge out of this outlet as the inlet pressure on

the divider valve drops.

• If testing (Step 4) indicates a blockage in the master

divider valve, this divider valve must be disassembled and cleaned. See Clean Divider Valve, Step 7,

page 15.

FIG. 12

4b. Master Divider Valve Equipped Without Performance

Indicator

1) With manual pump connected to the master

2) Remove, one at a time, each indicator port plug

3) If pressure drops and the master cycles freely

14 312497P

divider valve as outlined in Locating Blockages,

Step 3, raise pressure to 2000 psi (14 MPA, 138

bar).

and attempt to operate manual pump after each

plug is removed. Do not exceed 2000 psi (14

MPa, 138 bar)

after an indicator port plug is removed, then

blockage is downstream in the area that is

being served from that outlet. See Locating

Blockages, Step 3.

FIG. 13

5. If in Step 4, a blockage has been indicated

downstream of the master divider valve, install a

manual pump in the indicator port of the master

divider valve that is common to the blocked area.

(See F

IG. 13).

a. Proceed to downstream secondary divider valve

and remove all indicator port plugs.

b. Slowly operate manual pump. If lubricant can be

discharged freely through each of the indicator

ports of this divider valve, the blockage is not in

the supply line or the divider valve. Go to step 6.

If lubricant is not freely discharged through open

indicator ports of the second divider valve, the

blockage is in this divider valve or its supply

line. Disconnect supply line at secondary inlet

Page 15

Repair

HAND PUMP

SYSTEM PUMP

MASTER

DIVDER

VALVE

SECONDARY

DIVIDER

VALVE

LUBE

OUTLET

INDICATOR PORT

PLUGS REMOVED

BEARING

LUBE OUTLETS

Inlet

10T

20S

10T

30S

End

fitting and slowly operate manual pump to verify

location. If blockage is in this divider valve, go to

step 7.

NOTE: Dirt and foreign material will damage lubricating

equipment. Perform all service and disassembly under

the cleanest possible conditions.

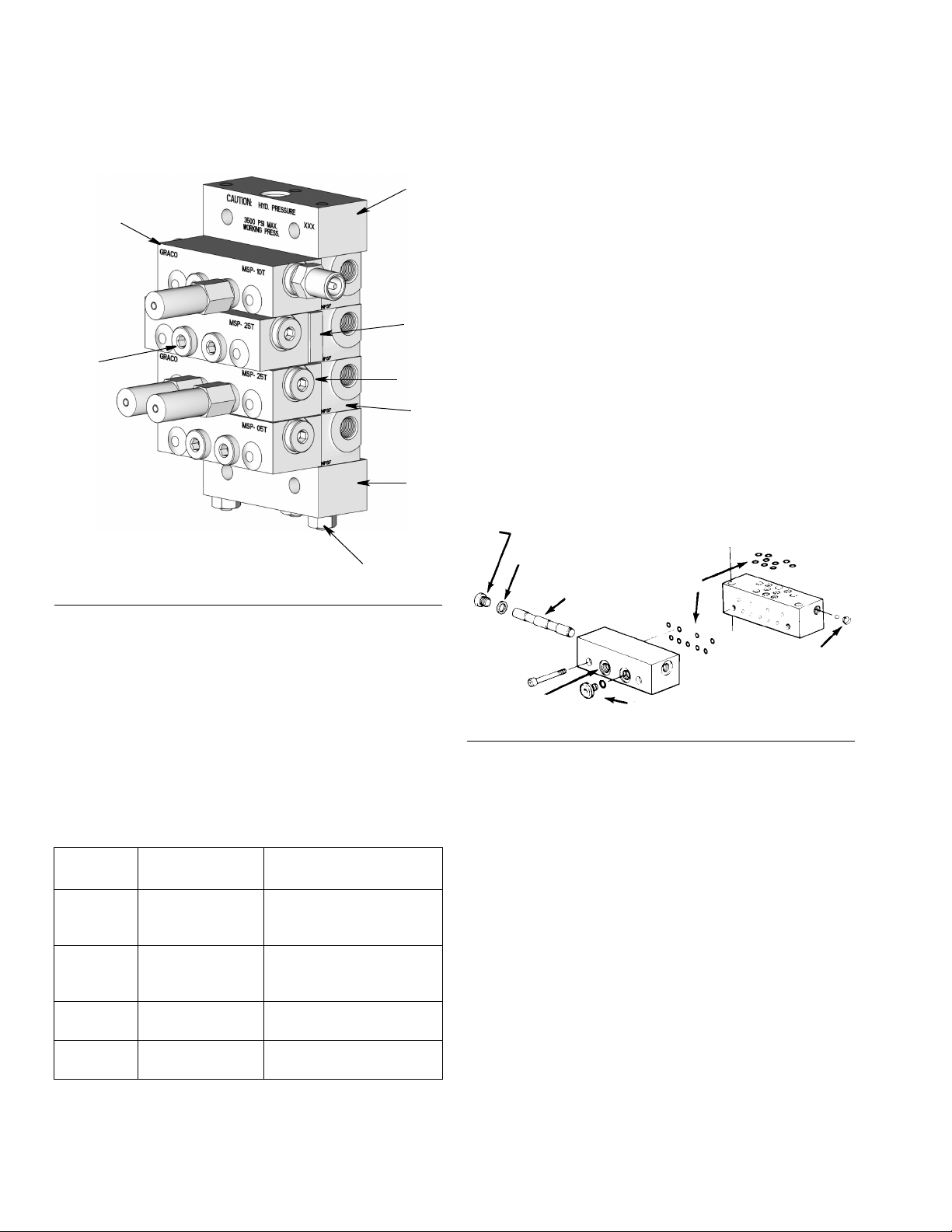

a. Before disassembling any divider valve, make a

sketch noting the arrangement of Valve Sections. For example: INLET 10T - 20S - 10T 30S - END (F

IG. 15). Also remove end plugs

only and try to move each piston back and forth

without removing the piston from the valve section.

FIG. 15

NOTICE

Do not insert hard metal objects into piston bore (i.e.,

punches, screwdrivers, etc.). Hard metal objects can

damage the surface and cause divider valves to leak

fluid. Use a brass rod and hand pressure only.

FIG. 14

6. Install manual pump into each indicator port of sec-

7. Clean Divider Valve

Table 4: Torque Values (*see FIG. 2, page 4)

Tie Rod Nuts 12 (16.3) - 5-8 (6.8-10.9) 23 (31.2) 6-9 (8.1-12.2) 12 (16.3) 5-8 (6.8-10.9)

Indicator Plugs* 6-7

End Plugs* 11-13

Valve Section

Mounting Screw

312497P 15

ondary divider valve in turn and slowly operate

pump (F

IG. 14). If high pressure exists, blockage

has been located. Look for crushed line, tight

bearing, improperly drilled fittings and/or lube

inlet port. Correct as necessary.

Assembly Torque ft-lbs (N.m)

MJ MD MSP/MH MX MXP MGO MSD-SST

(8.1-9.5)

(14.9-17.6)

- - 8-9

15 (20.3) 8-9

(10.9-12.2)

- 12-15

(16.3-20.3)

(10.9-12.2)

b. If all pistons move freely and there is no indica-

tion of a more serious problem, replace end

plugs.

c. Using a new gasket, tighten and torque as indi-

cated in Table 4 (below).

18 (24.4) 12-15

(16.3-20.3)

46 (62.4) 46-50

(62.4-67.8)

- 12-13

(16.3-17.6)

6-8

(8.1-10.9)

15 (20.34) 6-8 (8.1-10.9)

-8-9

5-7 (6.8-9.5)

(10.9-12.2)

Page 16

Repair

d. Clean sections and pistons in suitable clean sol-

vent until all lubricant has been removed.

e. Use compressed air to dry and blow out all ports

thoroughly.

A small metal probe should be used to make

sure all passages are clean and open.

Inspect cylinder bore and piston carefully for

scratches, score marks or other damage.

NOTE: If either piston or cylinder bore is damaged, a

new section must be installed. All pistons are selectively

fitted to the bore for proper clearance. Be sure to reinstall piston only into the valve section from which it was

removed.

f. If divider valve section and piston both appear

in good condition, reassemble section making

certain piston slides smoothly but snugly in cylinder bore.

Separation Blockage

If a hard wax or soap-like material is found in the Valve

Section, grease separation is occurring. This means that

the oil is being squeezed from the grease at normal system operating pressure and the grease thickener is

being deposited in the divider valve. Cleaning the

divider valve will only temporarily solve the problem.

Consult your lubricant supplier for recommendations on

alternate lubricants and your local Graco/Trabon distributor to verify compatibility with centralized lubricating

systems.

If all indictor port plugs are removed, master will not

cycle. Blockage is in this divider valve.(F

IG. 12).

g. Repeat cleaning and inspection of each section.

After all sections have been cleaned, blown out,

inspected and found to be in good condition,

reassemble divider valve using notes and

sketches (Step 7) as a reference.

NOTE:

• Always use new gaskets.

• Test operation of divider valve using manual pump.

Contamination Blockage

If dirt, foreign material or any other form of contamination is found in a divider valve, cleaning that divider

valve will only temporarily solve contamination blockage

problems. The source of the contamination must be

eliminated for satisfactory service.

The system filtering method must be investigated, filter

elements should be inspected and cleaned if necessary.

The reservoir filling method should be reviewed to eliminate any chance of foreign material entering the reservoir during filling.

16 312497P

Page 17

MD Series

1

1.19

(30.2

0.87

(22.0)

0.28

(7.11)

1.21

(30.9)

1.19

(30.2

0.87

(22.0)

0.28

(7.11)

1.21

(30.9)

1/8”OUTLET

LUBE INLET

1/8” OUTLET

3.12

(79.3)

3.00

(76.2)

Assembly

Bolts

0.25

(6.3)

1.25

(31.7)

1.75

(44.4)

2.12

(53.9)

0.40

(10.7)

0.28

(7.11) Dia. 2-Mtg. Holes

1.19

(30.2)

0.87

(22.0)

0.28

(7.11)

1.46

(37.0)

OUTLET

,5"%).,%4

v/54,%4-$/NLY

CYCLE INDICATOR

PIN (OPTIONAL)

ti11472

MD Series

Technical Data

Material Steel

Pressure (max) 3,000 psi (20.7 MPA,

206.8 bar)

Lubricant Oil or grease

Net Weight (approx.) 1-lb. 8 oz (0.68 kg)

Volume (Lubricant to cycle

divider valve one complete cycle)

MD-2, MD-3, MD-4

MD-6

0.080 in.3 (1.31 ccm)

0.060 in.3 (0.98 ccm)

Torque Ratings

Assembly Bolts

Enclosure Plugs

8-9 ft. lbs (10.9-12.2 N.m)

11-13 ft. lbs (14.9-17.6

N.m)

Indicator Plug

Outlet Plugs

15 ft. lbs (20.3 N.m)

6-7 ft. lbs. (8.1-9.5 N.m)

Parts

Ref Part No. Description

1 562656 VALVE, feeder, MD 2

562657 VALVE, feeder, MD 3

562658 VALVE, feeder, MD 4

562659 VALVE, feeder, MD 6

562653 VALVE, feeder, MD 2, IND

562654 VALVE, feeder, MD 3, IND

562655 VALVE, feeder, MD 4, IND

563270 VALVE, feeder, MD 2, IND/Switch

563271 VALVE, feeder, MD 3, IND/Switch

564356 VALVE, feeder, MD 4, IND/Switch

Dimensions

312497P 17

Page 18

MJ Series

3.23

(82.2)

1.06

(26.9)

.750

(19.0)

CYCLE INDICATOR PIN (OPTIONAL)

INDICATOR OUTLET

.750

(19.0)

1.37

(34.9)

1.09

(27.7)

4 MTG. HOLES

.270 (6.8)

.858

(21.79)

LUBE

OUTLET

B

.250

(6.3)

.582 TYPICAL

(14.7)

2.54

(64.5)

2.12

(53.9)

.687

(17.4)

A

ti11474

MJ Series

Technical Data Dimensions

Material Plated

Pressure (max) 2,000 psi (13.8 MPa, 137.9

bar)

Lubricant Oil or grease up to NLGI

Grade 1

Max Operating Temperature

Max Cycle Rate With

Cycle Pin

Net Weight (approx.)

3 section divider valve

4 section divider valve

5 section divider valve

6 section divider valve

7 section divider valve

8 section divider valve

Torque Ratings

Tie Rod Nut

Enclosure Plug

Outlet Port Plugs

200°F (93°C)

60 CPM

1-lb. 15 oz (0.88 kg)

2 lbs. 5 oz (1.04 kg)

2 lbs. 11 oz (1.21 kg)

3 lbs. 1 oz (1.38 kg)

3 lbs. 7 oz (1.55 kg)

3 lbs. 13 oz (1.72 kg)

12 ft. lbs (16.3 N.m)

11-13 ft. lbs (14.9-17.6

N.m)

6-7 ft. lbs. (8.1-9.5 N.m)

18 312497P

Page 19

Parts

2

1

6

5

4

3

Ref Part No. Description

1* 562500 VALVE, assembly, MJ 5S

562501 VALVE, assembly, MJ 10S

562502 VALVE, assembly, MJ 15S

562503 VALVE, assembly, MJ 5T

562504 VALVE, assembly, MJ 10T

562505 VALVE, assembly, MJ 15T

562508 VALVE, assembly, IND MJ 10S

562512 VALVE, assembly, IND MJ 10S Left

562510 VALVE, assembly, IND MJ 10 T

562513 VALVE, assembly, IND MJ 10T Left

562509 VALVE, assembly, IND MJ 15S

562511 VALVE, assembly, IND MJ 15T

564205 VALVE, assembly, IND MJ 15T Left

2* 560643 INLET, CRS, MJ

3* 560645 END, CRS, MJ

4 557515 ROD, tie, MJ 3 (3 required)

557516 ROD, tie, MJ 4 (3 required)

557517 ROD, tie, MJ 5 (3 required)

557518 ROD, tie, MJ 6 (3 required)

557519 ROD, tie, MJ 7 (3 required)

557520 ROD, tie, MJ 8 (3 required)

5 556371 NUT, tie rod, 1/4-28 (3 required)

6 557514 GASKET, feeder, MJ

*Component is shipped with gasket

MJ Series

312497P 19

Page 20

MSP Series

MSP Series

Technical Data

Material Corrosion Protected Steel (optional: Type 303 Stainless

Steel)

Pressure (max)

Zero Leak Inlet

Shunt/Shutoff Inlet

Ambient Temperature (max) 140°F (60°C)

Lubricant

Zero Leak Inlet

Shunt/Shutoff Inlet

New Weight (approx.)

Carbon Steel

3 section divider valve assembly

4 section divider valve assembly

5 section divider valve assembly

6 section divider valve assembly

7 section divider valve assembly

8 section divider valve assembly

Stainless Steel

3 section divider valve assembly

4 section divider valve assembly

5 section divider valve assembly

6 section divider valve assembly

7 section divider valve assembly

8 section divider valve assembly

Torque Ratings

Mounting Screw

Enclosure Plugs

Indicator Port Plug

Bleed Screws

Tie Rod Nut

1500 psi (10.3 MPa, 103.4 bar)

3000 psi (20.7 MPa, 206.8 bar)

Oil Only - up to 5000 SUS, requires 25 micron (min) filtration

Oil and fluid grease - filter oil through 25 micron filter and

grease through 100 micron mesh strainer

5.9 lbs (2.7 kg)

7.3 lbs (3.3 kg)

8.7 lbs (4.0 kg)

10.2 lbs (4.6 kg)

11.6 lbs (5.6 kg)

13.0 lbs (5.9 kg)

8.2 lbs (3.7 kg)

9.9 lbs (4.5 kg)

11.7 lbs (5.3 kg)

13.5 lbs (6.2 kg)

15.2 lbs (6.9 kg)

16.9 lbs (7.7 kg)

8-9 ft. lbs (10.9-12.2 N.m)

6-8 ft. lbs (8.1-9.5 N.m)

5-7 ft. lbs (6.8-9.5 N.m)

1-2 ft. lbs. (1.4-2.7 N.m)

5-8 ft. lbs. (6.8-10.9 N.m)

20 312497P

Page 21

Dimensions

ti11478

CROSSPORT PLATE (OPTIONAL)

MSP Series

312497P 21

Page 22

MSP Series

Parts

Ref Part No. Description

1 562711 VALVE, assembly MSP 05S

562712 VALVE, assembly MSP 10S

562713 VALVE, assembly MSP 15S

562714 VALVE, assembly MSP 20S

562715 VALVE, assembly MSP 25S

562716 VALVE, assembly MSP 30S

562717 VALVE, assembly MSP 35S

562718 VALVE, assembly MSP 40S

562720 VALVE, assembly MSP 05T

562721 VALVE, assembly MSP 10T

562722 VALVE, assembly MSP 15T

562723 VALVE, assembly MSP 20T

562724 VALVE, assembly MSP 25T

562725 VALVE, assembly MSP 30T

562726 VALVE, assembly MSP 35T

562727 VALVE, assembly MSP 40T

562729 VALVE, assembly IND MSP 20S

562730 VALVE, assembly IND MSP 25S

562731 VALVE, assembly IND MSP 30S

562732 VALVE, assembly IND MSP 35S

562733 VALVE, assembly IND MSP 40S

562734 VALVE, assembly IND left MSP 20S

562735 VALVE, assembly IND left MSP 25S

562736 VALVE, assembly IND left MSP 30S

562737 VALVE, assembly IND left MSP 35S

562738 VALVE, assembly IND left MSP 40S

562739 VALVE, assembly IND MSP 20T

562740 VALVE, assembly IND MSP 25T

562741 VALVE, assembly IND MSP 30T

562742 VALVE, assembly IND MSP 35T

562743 VALVE, assembly IND MSP 40T

562744 VALVE, assembly IND left MSP 20T

562745 VALVE, assembly IND left MSP 25T

562746 VALVE, assembly IND left MSP 30T

562747 VALVE, assembly IND left MSP 35T

562748 VALVE, assembly IND left MSP 40T

24B474 VALVE, assembly, MSP 05S - SST

562755 VALVE, assembly, MSP 10S - SST

24B475 VALVE, assembly, MSP 15S - SST

562756 VALVE, assembly, MSP 20S - SST

24B476 VALVE, assembly, MSP 25S - SST

24B477 VALVE, assembly, MSP 30S - SST

24B478 VALVE, assembly, MSP 35S - SST

562757 VALVE, assembly, MSP 40S -SST

24B479 VALVE, assembly, MSP 05T - SST

562758 VALVE, assembly, MSP 10T - SST

24B480 VALVE, assembly, MSP 15T - SST

562759 VALVE, assembly, MSP 20T - SST

24B481 VALVE, assembly, MSP 25T - SST

24B482 VALVE, assembly, MSP 30T -SST

24B483 VALVE, assembly, MSP 35T - SST

562760 VALVE, assembly, MSP 40T - SST

2 24B497 BLOCK, base, MSP, NPTF, SST

563425 BLOCK, base, MSP NPSF

563447 BLOCK, base, MSP, BSPP

563451 BLOCK, base, MSP, SAE

563479 BLOCK, base, MSP w/No outlets

24N369 BLOCK, base, MSP, BSPP, SST

Ref Part No. Description

3 560919 BLOCK, inlet, MSP, NPSF

560936 BLOCK, inlet, MSP, BSPP

560943 BLOCK, inlet, MSP, SAE

560976 BLOCK, inlet, MSP, ISO 6149

563421 BLOCK, inlet, MSP, NPSF, w/bleed

563422 BLOCK, inlet, MSP SAE w/bleed

15Y070 BLOCK, inlet, MSP, NPTF, SST

16P368 BLOCK, inlet, MSP, BSPP, SST

4 563279 BLOCK, MSP end w/alt inlet

563424 BLOCK, end, MSP

24B498 BLOCK, end, MSP, SST

5 563469 KIT, crossport bar, right

563470 KIT, crossport bar, left

563471 KIT, crossport bar, both

24R631 KIT, crossport, MSP, LH/RH, sst

24R632 KIT, crossport, MSP, RH, sst

24R633 KIT, crossport, MSP, LH, sst

6 563472 KIT, singling bar

7 562660 VALVE, assembly bypass, standard MSP

8 557731 ROD, tie, 3 section, MSP (3 required)

557732 ROD, tie, 4 section, MSP (3 required)

557733 ROD, tie, 5 section, MSP (3 required)

557734 ROD, tie, 6 section, MSP (3 required)

557735 ROD, tie, 7 section, MSP (3 required)

557736 ROD, tie, 8 section, MSP (3 required)

557738 ROD, tie, 9 section, MSP (3 required)

557739 ROD, tie, 10 section, MSP (3 required)

557740 ROD, tie, 11 section, MSP (3 required)

126247 ROD, tie, 3 section, MSP, SST

126248 ROD, tie, 4 section, MSP, SST

126249 ROD, tie, 5 section, MSP, SST

126250 ROD, tie, 6 section, MSP, SST

126251 ROD, tie, 7 section, MSP, SST

126252 ROD, tie, 8 section, MSP, SST

9 556371 NUT, 1/4 - 28 (3 required)

558633 NUT, SST 1/4 - 28 light hex (3 required)

22 312497P

Page 23

MSP Series

1

3

5 or 6

2

4

8

9

7

312497P 23

Page 24

MHH Series

MHH Series

Technical Data

Material Steel Body (corrosion protected) Steel Piston (honed fit)

Pressure (max) 7,500 psi (52 MPa, 517 bar) for Petroleum or Synthetic

Oil - fluoroelastomer O-rings

Lubricant Petroleum or synthetic oil only

Maximum Operating Temperature

Fluoroelastomer O-rings (557722) 350°F (163°C)

Maximum Cycle Rate Without Cycle Pin 200 CPM

Net Weight (approx.)

3 section divider valve assembly

4 section divider valve assembly

5 section divider valve assembly

6 section divider valve assembly

7 section divider valve assembly

8 section divider valve assembly

Torque Ratings

Mounting Screw

Enclosure Plugs

Indicator Port Plug

Bleed Screws

Tie Rod Nut

5.9 lbs (2.7 kg)

7.3 lbs (3.3 kg)

8.7 lbs (4.0 kg)

10.2 lbs (4.6 kg)

11.6 lbs (5.6 kg)

13.0 lbs (5.9 kg)

8-9 ft. lbs (10.9-12.2 N.m)

6-8 ft. lbs (8.1-9.5 N.m)

5-7 ft. lbs (6.8-9.5 N.m)

1-2 ft. lbs. (1.4-2.7 N.m)

5-8 ft. lbs. (6.8-10.9 N.m)

24 312497P

Page 25

Dimensions

INDICATOR PORT

(TYPICAL)

,

MOUNTING SCREW

(TYPICAL)

LUBE

INLET

.281 (7.137) DIA

(4) MTG HOLES

3.000

(76.2)

1.750

(44.4)

"A"

2.188

(55.56)

1.656

(42.06)

1.500

(38.1)

.781

(19.9)

1.125

(28.58)

.406

(10.31)

.734

(18.85)

OUTLET IS PLUGGED

ON ONE SIDE WHEN

WORKING SECTION IS

SINGLED

LUBE

OUTLET

(TYPICAL)

PISTON ENCLOSURE PLUG (TYPICAL)

TIE ROD AND NUT

(TYPICAL)

.28

(7.1)

.484

(12.3)

.484

(12.3)

.625

(15.9)

.922 (TYP)

(23.41)

",%%$3#2%73

ti11480

MHH Series

312497P 25

Page 26

MHH Series

3

5 or 6

2

4

8

9

7

1

Parts

Ref Part No. Description

1 562679 VALVE, assembly MHH 06S

562680 VALVE, assembly MHH 09S

562681 VALVE, assembly MHH 12S

562682 VALVE, assembly MHH 18S

562683 VALVE, assembly MHH 24S

562684 VALVE, assembly MHH 30S

562685 VALVE, assembly MHH 06T

562686 VALVE, assembly MHH 09T

562687 VALVE, assembly MHH 12T

562688 VALVE, assembly MHH 18T

562689 VALVE, assembly MHH 24T

562690 VALVE, assembly MHH 30T

2 563425 BLOCK, base, MHH, NPSF

563447 BLOCK, base, MHH, BSPP

563451 BLOCK, base, MHH, SAE

563479 BLOCK, base, MHH w/no outlets

3 560919 BLOCK, inlet, MHH, NPSF

560936 BLOCK, inlet, MHH, BSPP

560943 BLOCK, inlet, MHH, SAE

560976 BLOCK, inlet, MHH, ISO 6149

Ref Part No. Description

563421 BLOCK, inlet, MHH, NPSF, w/bleed

563422 BLOCK, inlet, MHH SAE w/bleed

4 563279 BLOCK, MHH end w/alt inlet

563424 BLOCK, end, MHH

5 563469 KIT, crossport bar, right

563470 KIT, crossport bar, left

563471 KIT, crossport bar, both

6 563472 KIT, singling bar

7 562660 VALVE, assembly bypass

8 557731 ROD, tie, 3 section (3 required)

557732 ROD, tie, 4 section (3 required)

557733 ROD, tie, 5 section (3 required)

557734 ROD, tie, 6 section (3 required)

557735 ROD, tie, 7 section, (3 required)

557736 ROD, tie, 8 section (3 required)

557738 ROD, tie, 9 section (3 required)

557739 ROD, tie, 10 section (3 required)

557740 ROD, tie, 11 section (3 required)

9 556371 NUT, 1/4 - 28 (3 required)

26 312497P

Page 27

MXP Series

Technical Data

Material Zinc Plated Steel

Pressure (max) 3,000 psi (20.7 MPa, 206.8 bar)

Lubricant Oil or grease

Maximum Operating Temperature 350°F (177°C)

Maximum Cycle Rate With Cycle Pin 60 CPM

Maximum Cycle Rate Without Cycle Pin or With Prox

Cycle Switch

Net Weight (approx.)

3 section divider valve assembly

4 section divider valve assembly

5 section divider valve assembly

6 section divider valve assembly

7 section divider valve assembly

8 section divider valve assembly

9 section divider valve assembly

10 section divider valve assembly

Torque Ratings

Tie Rod Nut

Enclosure Plugs

Indicator Plug

Valve Section Mounting Screw

200 CPM

18-lb. 2 oz (8.3 kg)

22 lbs. 6 oz (10.2 kg)

26 lbs. 9 oz (12.2 kg)

31 lbs. 3 oz (14.2 kg)

35 lbs. 6 oz (16.2 kg)

39 lbs. 9 oz (18.1 kg)

44 lbs. 3 oz (20.1 kg)

48 lbs. 6 oz (22.1 kg)

6-9 ft. lbs (8.1-12.2 N.m)

48 +/- 2 ft. lbs (2.7 N.m)

12 -15 ft. lbs (16.3-20.3 N.m)

12-13 ft. lbs. (16.3-17.6 N.m)

MXP Series

312497P 27

Page 28

MXP Series

,5"%).,%4

).$)#!4/20/24

,5"%/54,%4

/04)/.!,

#2/330/240,!4%/04)/.!,

ti11477

Dimensions

28 312497P

Page 29

Parts

3

5

2

4

7

8

6

1

MXP Series

Ref Part No. Description

1 562813 VALVE, twin, .025 MXP

562814 VALVE, twin, .050 MXP

562815 VALVE, twin, .075 MXP

562816 VALVE, twin, .100 MXP

562817 VALVE, twin, .125 MXP

562818 VALVE, twin, .150 MXP

562819 VALVE, single, .025 MXP

562820 VALVE, single, .050 MXP

562821 VALVE, single, .075 MXP

562822 VALVE, single, .100 MXP

562823 VALVE, single, .125 MXP

562824 VALVE, single, .150 MXP

562825 VALVE, twin, .050 MXP w/indicator

562826 VALVE, twin, .075 MXP w/indicator

562827 VALVE, twin, .100 MXP w/indicator

562828 VALVE, twin, .125 MXP w/indicator

562829 VALVE, twin, .150 MXP w/indicator

562830 VALVE, single, .050 MXP w/indicator

562831 VALVE, single, .075 MXP w/indicator

562832 VALVE, single, .100 MXP w/indicator

562833 VALVE, single, .125 MXP w/indicator

562834 VALVE, single, .150 MXP w/indicator

Ref Part No. Description

2 563519 BLOCK, BSPLT interm MXP 1/4 NPSF

563521 BLOCK, BSPLT interm MXP SAE

563522 BLOCK, BSPLT interm MXP 1/4 BSPP

563479 BLOCK, base, MSP/MHH w/no outlets

3 15R994

15R993

561029

4 563518 BLOCK, end, machine MX

5 563524 KIT, MXP, crossport bar, left

563525 KIT, MXP, crossport bar, right

563526 KIT, MXP, crossport bar, both

6 15R997 BLOCK, bypass, MXP

7 557766 ROD, tie, 3 section, MXP (3 required)

557767 ROD, tie, 4 section, MXP (3 required)

557768 ROD, tie, 5 section, MXP (3 required)

557769 ROD, tie, 6 section, MXP (3 required)

557770 ROD, tie, 7 section, MXP (3 required)

557771 ROD, tie, 8 section, MXP (3 required)

557772 ROD, tie, 9 section, MXP (3 required)

563520 ROD, tie, 10 section, MXP (3 required)

8 555406 NUT, 5/16 - 24 light hex (3 required)

BLOCK, inlet, MXP

BODY, inlet, MXP

BLOCK, sect MXP inlet BSPP thread

312497P 29

Page 30

MGO Series

MGO Series

Technical Data

Material Zinc Plated Steel and Phosphate Coated Cast Iron

Pressure (max)

3-7 section divider valve assembly 6000 psi (41 MPa, 414 bar)

8 section divider valve assembly 5500 psi (38 MPa, 379 bar)

9 section divider valve assembly 5000 psi (34 MPa, 345 bar)

10 section divider valve assembly 4500 psi (31 MPa, 310.3 bar)

11 section divider valve assembly 4000 psi (27 MPa, 27.6 bar)

Lubricant Oil or grease

Maximum Operating Temperature 200°F (93°C)

Maximum Cycle Rate With Cycle Pin 60 CPM

Maximum Cycle Rate Without Cycle Pin or With Prox

Cycle Switch

Net Weight (approx.)

3 section divider valve assembly 45-lb. (20.41 kg)

4 section divider valve assembly 53 lbs. 5 oz (24.18 kg)

5 section divider valve assembly 61 lbs. 10 oz (27.95 kg)

6 section divider valve assembly 70 lbs. 15 oz (32.17 kg)

7 section divider valve assembly 80 lbs. 4 oz (36.40 kg)

8 section divider valve assembly 89 lbs. 9 oz (40.62 kg)

9 section divider valve assembly 98 lbs. 14 oz (44.84 kg)

10 section divider valve assembly 108 lbs. 3 oz (49.07 kg)

11 section divider valve assembly 117 lbs. 8 oz (53.40 kg)

Torque Ratings

Tie Rod Nut 12 ft. lbs (16.3 N.m)

Enclosure Plug 15 ft. lbs (20.3 N.m)

Outlet Port Plug 6-8 ft. lbs (8.1-10.9 N.m)

Valve Section Mounting Screw 12-13 ft. lbs. (16.3-17.6 N.m)

200 CPM

30 312497P

Page 31

Dimensions

).,%4

/54,%43

).$)#!4/20/243

MGO Series

312497P 31

Page 32

MGO Series

3

1

2

5

6

4

5

Parts

Ref Part No. Description

1 562570 VALVE, MGO, assembly 150S SAE

562571 VALVE, MGO, assembly 300S SAE

562572 VALVE, MGO, assembly 450S SAE

562573 VALVE, MGO, assembly 600S SAE

562574 VALVE, MGO, assembly 150T SAE

562575 VALVE, MGO, assembly 300TS SAE

562576 VALVE, MGO, assembly 450T SAE

562577 VALVE, MGO, assembly 600T SAE

562578 VALVE, MGO, assembly 150S SAE IND

562579 VALVE, MGO, assembly 300S SAE IND

562580 VALVE, MGO, assembly 450S SAE IND

562581 VALVE, MGO, assembly 6000S SAE IND

562582 VALVE, MGO, assembly 150T SAE IND

562583 VALVE, MGO, assembly 300T SAE IND

562584 VALVE, MGO, assembly 450T SAE IND

562585 VALVE, MGO, assembly 600T SAE IND

2 563277 INLET,

3 563278 END

4 560591 ROD, tie, short MGO 3 (2 required)

560592 ROD, tie, short MGO 4 (2 required)

560593 ROD, tie, short MGO 5 (2 required)

560594 ROD, tie, short MGO 6 (2 required)

560595 ROD, tie, short MGO 7 (2 required)

560596 ROD, tie, short MGO 8 (2 required)

560597 ROD, tie, short MGO 9 (2 required)

560598 ROD, tie, short MGO 10 (2 required)

5 560600 ROD, tie, long MGO 3 (2 required)

560601 ROD, tie, long MGO 4 (2 required)

560602 ROD, tie, long MGO 5 (2 required)

560603 ROD, tie, long MGO 6 (2 required)

15U857 ROD, tie, long MGO 7 (2 required)

560604 ROD, tie, long MGO 8 (2 required)

560605 ROD, tie, long MGO 9 (2 required)

560606 ROD, tie, long MGO 10 (2 required)

6 555406 NUT, tie rod 3/8 - 24 lock (8 required)

32 312497P

Page 33

MX Series

Technical Data

Material Plated Steel

Pressure (max) 3,000 psi (21 MPa, 206.8 bar)

Lubricant Oil or grease

Maximum Operating Temperature 200°F (93°C)

Maximum Cycle Rate With Cycle Pin 60 CPM

Maximum Cycle Rate Without Cycle Pin 200 CPM

Net Weight (approx.)

3 section divider valve assembly

4 section divider valve assembly

5 section divider valve assembly

6 section divider valve assembly

7 section divider valve assembly

8 section divider valve assembly

9 section divider valve assembly

10 section divider valve assembly

Torque Ratings

Tie Rod Nut

Enclosure Plug

Outlet Port Plugs

21-lb. 6 oz (9.69 kg)

25 lbs. 10 oz (11.62 kg)

29 lbs. 14 oz (13.55 kg)

34 lbs. 2 oz (15.47 kg)

38 lbs. 6 oz (17.40 kg)

42 lbs. 12 oz (19.39 kg)

47 lbs. 2 oz (21.37 kg)

51 lbs. 8 oz (23.26 kg)

30 ft. lbs (40.7 N.m)

48 ft. lbs (65.1 N.m)

18 ft. lbs. (24.4 N.m)

MX Series

312497P 33

Page 34

MX Series

v/54,%4

ti11476

Dimensions

34 312497P

Page 35

Parts

3

1

6

2

4

5

Ref Part No. Description

1* 562514 VALVE, MX assembly 25S

562515 VALVE, MX assembly 25T

562516 VALVE, MX assembly 50S

562517 VALVE, MX assembly 50T

562538 VALVE, MX assembly 75S

562539 VALVE, MX assembly 75T

562540 VALVE, MX assembly 100S

562541 VALVE, MX assembly 100T

562542 VALVE, MX assembly 125S

562543 VALVE, MX assembly 125T

562545 VALVE, MX assembly 150S

562546 VALVE, MX assembly 150T

562528 VALVE, MX assembly 50S IND LH

562518 VALVE, MX assembly 50S IND RH

562533 VALVE, MX assembly 50T IND LH

562523 VALVE, MX assembly 50T IND RH

562529 VALVE, MX assembly 75S IND LH

562519 VALVE, MX assembly 75S IND RH

562534 VALVE, MX assembly 75T IND LH

562524 VALVE, MX assembly 75T IND RH

562530 VALVE, MX assembly 100S IND LH

562520 VALVE, MX assembly 100S IND RH

562569 VALVE, MX assembly 100T IND LH

562525 VALVE, MX assembly 100T IND RH

562531 VALVE, MX assembly 125S IND LH

562521 VALVE, MX assembly 125S IND RH

562535 VALVE, MX assembly 125T IND LH

562526 VALVE, MX assembly 125T IND RH

562532 VALVE, MX assembly 150S IND LH

562522 VALVE, MX assembly 150S IND RH

562536 VALVE, MX assembly 150T IND LH

562527 VALVE, MX assembly 150T IND RH

2* 560620 BLOCK, inlet

3* 563287 BLOCK, end

4 557488 ROD, tie, MX 3 (4 required)

557489 ROD, tie, MX 4 (4 required)

557490 ROD, tie, MX 5 (4 required)

557491 ROD, tie, MX 6 (4 required)

557492 ROD, MX 7 (4 required)

557493 ROD, tie, MX 8 (4 required)

560576 ROD, tie, MX 9 (4 required)

560577 ROD, tie, MX 10 (4 required)

5 557494 NUT, tie rod 3/8 - 24 lock (8 required)

6 557509 GASKET feeder, MX

MX Series

*Component shipped with gasket

312497P 35

Page 36

Accessories

Accessories

Tube Clips

Clips are plated and provided with 17/64” (6.75 mm)

mounting holes.

Part No. Description

557324 Holds 1 - 1/4” (6.35 mm) OD tube

558711 Holds 1 - 3/8” (9.52 mm) OD tube

558710 Holds 3 - 1/4” (6.35 mm) OD tube

Mounting Bars

Part No. Description

560920 MSP, 1/2” (12.7 mm) thick, 1/4-20 thread

561101 MJ, 1/2” (12.7 mm) thick, 10-24 thread

561102 MX and MXP, 1/2” (12.7 mm) thick, 5/16-18

threads, two sets of mounting holes

563465 KIT, mounting bar, includes 2 mounting bars,

4 screws, washers and lock washers

Mounting Brackets

All mounting brackets include screws, lock washers and

nuts.

Part No. Description

563435 MSP and MH, M-3 and M-4, 1/8” (3.175 mm)

thick, top mounting.

563436 MSP and MH, M5 and M-6, 1/8” (3.175 mm)

thick, top mounting

563437 MSP and MH, M7 and M-8, 1/8” (3.175 mm)

thick, top mounting

563438 MSP and MH, M-3 and M-4, 1/8” (3.175 mm)

thick, side mounting.

563439 MSP and MH, M5 and M-6, 1/8” (3.175 mm)

thick, side mounting

563440 MSP and MH, M7 and M-8, 1/8” (3.175 mm)

thick, side mounting

Performance Indicators

Performance indicators are pressure sensitive devices that signals a fault when there is excessive build up of pressure in a series progressive lubricating system. A fault is identified by either causing a pin to protrude or by releasing

lubricant to the atmosphere.

Reset Indicator with Memory

Reset Indicators stop lube system operation when a fault occurs. They can be used in either master or secondary

divider valves. Fault is indicated when a pin protrudes through the opening in the cap and is manually reset.

Description

Pressure PSI

(MPa, bar)

250 (2, 17) 563231 563252 NA 563239 NA NA

500 (3, 34) 563232 563253 563246 563240 NA NA

750 (5, 51) 563233 563254 NA 563241 NA NA

1000 (7, 69) 563234 563255 563247 563242 NA 24B495

1500 (10, 103) 563235 563256 563248 563243 564200 24B496

2000 (14, 138) 563236 563257 NA 563244 NA 24N373

2500 (17, 172) 563237 563258 563249 563245 NA NA

3000 (21, 207) NA 563261 NA NA NA NA

5000 (34, 344) NA 563262 NA NA NA NA

36 312497P

1/8” NPTF

MJ, MH, MS, MXP

1/8” NPSF

w/O-Ring

MH, MS, MXP

Nickel Plated

1/8” NPTF

MJ, MH, MS, MXP

1/4” NPTF

MX Only

7/8” SAE

w/O-Ring

MGO

1/8 NPSF

w/O-Ring

MSP SST

Page 37

Accessories

Automatic Relief Indicator

Automatic Relief Indicators pinpoint lube line blockage but allow the lube system to continue to supply lubrication to

points that are not blocked. They are used primarily in secondary divider valves. When needed, pressure is relieved

through a vent. When pressure is relieved the spring resets the piston. Because these indicators permit the lube system to continue operating when a lube point is blocked, a separate pressure switch connected to an audible or visual

alarm should be used to warn of high pressure.

Description

Pressure PSI (MPa, bar) Color*

1/8” NPTF

MJ, MH, MSP,

MXP

750 (5, 51) + 20% Blue 563163 563170 563156 24N945

1000 (7, 69) +

1250 (9, 86) +

1500 (10, 103) +

2000 (14, 138) +

2500 (17, 172) +

3000 (34, 344) +

* Color provided for reference only to aid in selection of replacement indicator. Indicators used to be identified by the color of the

spring retainer located in the end of the indicator.

20% Green 563164 563171 563157 NA

20% Yellow 563165 563172 NA NA

20% Red 563166 563173 563158 24N948

20% Orange 563167 563174 563159 24N949

20% Aluminum 563168 563175 563160 24N951

24% Purple 563169 563176 563161 24N952

1/8” NPSF

w/O-Ring

MH, MSP, MXP

1/4” NPTF

MX Only

1/8 NPT w/O-Ring

MSP SST

Rupture Indicator - MH Divider Valves Only

Rupture Indicators are only used on MH divider valve applications where lube system pressures exceed 2500 psi.

The high pressure from a lube line blockage causes a disc to rupture. The lubricant then forces an indicator pin to

protrude, locating the blockage. The high pressure backs up through the system and trips a switch to shut the system

off. When the fault is corrected, the disc must be replaced the pin reset manually.

Description

Pressure PSI (MPa, bar)

1/8” - 27 NPTF

1/8” - 27 NPSF

w/O-Ring

Disc Color

2800 (19, 193) + 20% 563228 563229 Green 557422

3700 (26, 255) +

4600 (32, 317) +

5500 (38, 379) +

6400 (44, 441) +

7300 (50, 503) +

8200 (57, 565) +

20% 563220 563221 Yellow 557423

20% 564355 563222 Red 557424

20% 563223 563224 Orange 557425

20% 563225 563226 Pink 557427

20% 563227 NA Blue 557428

20% NA NA Purple 557429

Replacement Disc

3/8” Diameter

312497P 37

Page 38

Accessories

Rupture-to-Atmosphere Indicator

Rupture-to-Atmosphere Indicators are standard on all Graco pumps. When the pressure reaches a predetermined

pressure setting, the pressure disc ruptures, venting lubricant into the atmosphere and relieving pressure.

Description

Pressure PSI* (MPa, Bar)

900 (6.2, 62) NA 557431 Black NA

1450 (10, 100) 563179 557433 Yellow 563962

1750 (12, 121) 563182 557434 Red 563963

2050 (14, 141) 563183 557435 Orange 563964

2350 (16, 162) 563184 557436 Aluminum 563965

2650 (18, 183) NA 557437 Pink NA

2950 (20, 203) 563185 557438 Blue 563966

3250 (22, 224) NA 557439 Purple NA

900 (6.2, 62) NA 555788 Black 563952

1450 (10, 100) NA 557423 Yellow 563954

1750 (12, 121) 564059 557424 Red 563955

2050 (14, 141) NA 557425 Orange 563956

2350 (16, 162) 563191 557426 Aluminum 563957

2650 (18, 183) NA 557427 Pink 563958

2950 (20, 203) 563192 557428 Blue 563959

3250 (22, 224) 563193 557429 Purple 563960

5000 (34, 344) 563194 557430 Brown 563961

3700 (26, 255) 564476 557423 Yellow 563954

4600 (32, 317) 563216 557424 Red 563955

5500 (38, 379) 563217 557425 Orange 563956

6400 (44, 441) 563218 557427 Pink 563958

7300 (50, 503) 563219 557428 Blue 563959

8200 (57, 565) NA 557429 Purple 563960

9500 (66, 655) NA NA Gray NA

Complete Assembly Replacement Disc Color Blowout Disc

1/4” NPTF Fittings 11/16” Diameter Quantity = 6

1/8” NPTF Fittings 3/8” Diameter Quantity = 25

High Pressure

1/8” NPTF Fittings

3/8” Diameter

Quantity = 25

Rupture-to-Atmosphere Indicator with Spud Assembly

A Spud Assembly is available to return vented lubricant to the reservoir by way of a tube. A high pressure switch is

recommended to provide an audible or visual warning alarm that height system pressure has occurred.

Description

Pressure PSI* (MPa, bar)

1450 (10, 100) 563186 557433 Yellow

1750 (12,121) 563187 557434 Red

2350 (16, 162) 563188 557436 Aluminum

*All pressures have a tolerance of + 500 psi (3.4 MPa, 34.5 bar)

38 312497P

Complete Assembly Replacement Disc Color

Page 39

Rupture Discs

All discs are 11/16” diameter.

Description

Pressure PSI*

(MPa, bar)

Single Disc Disc Color Quantity 6/package

900 (6.2 62) 557431 Black NA

1175 (8.1, 81) 557432 Green NA

1450 (10, 100) 557433 Yellow 563962

1750 (12, 121) 557434 Red 563963

2050 (14, 141) 557435 Orange 563964

2350 (16, 162) 557436 Aluminum 563965

2650 (18, 183) 557437 Pink NA

2950 (20, 203) 557438 Blue 563966

3250 (22, 224) 557439 Purple NA

*All pressures have a tolerance of + 500 psi (3.4 MPa, 34.5 bar)

Singling and Crossporting Bar Assemblies

Accessories

Singling Kits externally convert a “T” (Twin Outlet) section to an “S” (Single Outlet) section.

Crossporting Kits externally combine the output of two (2) adjacent sections.

Part Numbers

Divider Single Kit

MJ 562915 562914 562914 NA 557359 557403 NA NA

MHH 563469 563469 563470 563471 NA NA 122276 556514

MSP 563469 563469 563470 563471 NA NA 122276 556514

MS (Nickel) NA NA NA NA NA NA NA NA

MX 562916 562917 562917 NA 557511 557512 NA NA

MXP NA 563525 563524 563526 NA NA 557773 555601

MXP (Nickel) NA NA NA NA NA NA NA NA

MGO NA NA NA NA NA NA NA NA

Right Side Left Side 4Rside

Gasket

Upper Seal

(Bar Type)

Gasket

Lower Seal

(Bar Type)

90 Duro

Fluoroelastomer

O-Ring (plate

Type)

Valve Block

Mounting

Screw-Long

Cycle Indicators

Cycle Indicators provide a means of visually monitoring lube flow thru the system.

The pin type cycles in and out when lubricant is flowing. Movement of the pin is caused by the piston (the two are

attached) so that when the piston moves the indicator pin in and out once, the entire divider valve has cycled.

Valve Series O-Ring Sealed

MS/MHH 563251

MX/MXP 563260

MGO NA

312497P 39

Page 40

Accessories

Cycle Counters - Part No.: 563444

The purpose of a cycle counter is to give assurance that the lubricant is flowing thru the system. Every “count” indicates one complete cycle of the divider valve. Visual inspection and/or recording of counts provides a constant check

on the performance of your lubricant system and the pump. The Cycle Counter can be used on any MJ, MS, MH, MX

and MXP divider valve assembly.

Cycle Switches

The function of a Cycle Switch is to electrically give assurance that the lubricant is flowing through the system. Actuated by a cycle pin, the switch can be wired to various controls.

NOTE: The cycle switch MUST be attached to a section that is equipped with a cycle indicator pin.

Part Numbers

Series Flo Divider Valves MJ MS/MH MS (Nickel) MX MXP MGO

Cycle Switch and Bracket Assembly

SPDT

Replacement Switch 557781 557781 557781 557781 557781 557781

Cycle Switch and Bracket Assembly

DPDT

Replacement Switch NA NA NA NA NA NA

Replacement Bracket for either

SPDT or DPDT Switch Assembly

Moisture Resistant Cycle Switch

with 6-foot Cable and Bracket

Assembly SPDT

Replacement Switch with 6-foot

Cable

563272 563272 563272 563272 563272 563269

Electrical Ratings: 15 amps at 125, 250 and 480 VAC; 1/2 amp at 125 VDC, 1/4

amp at 250 VDC, 6.0 amp at 24 VDC Non-Inductive

564357 564357 564537 564357 564537 NA

Electrical Ratings: 10 amps at 125 or 250 VAC; 0.3 amp at 125 VDC or 0.15 amp

at 250 VDC

557546 557546 557546 557546 557546 560573

563273 563273 563273 563273 563273 NA

Electrical Ratings: 5 amps at 125 or 250 VAC; Wire Code for Moisture Resistant

Switch: BK (Com), Red (N.C), WH (N.O.), GN (Ground)

557782 557782 557782 557782 557782 NA

40 312497P

Page 41

Accessories

Proximity Cycle Switches

The Proximity Cycle Switches are magnetically operated single throw switches that sense the movement of the

divider valve piston when it is cycling. Each proximity cycle switch provides a signal that is used to monitor the system. There are 3 different types of switches available.

Reed Type Proximity Switch: Can be used with oil applications only for MS, MH and MGO divider valves at pressures up to 518 bar (7500 psi, 52 MPa) at cycle rates under 60 cycles per minute.

Field Sensitive Magnetic Proximity Switch: Dry contact, ceramic magnet operated switch. Used at pressures that

do not exceed 242 bar (3500 psi, 24 MPa) at cycle rates up to 200 cycles per minute. Used in MS/MH, MX/MXP and

MGO divider valves. An explosion proof version for MS/MH divider valves is available.

Magnetic Operated Proximity Switch: Not limited to valve size. Miniature snap-action switch is tripped by attraction

of internal magnet to the moving divider piston. Can be used at pressures up to 518 bar (7500 psi) at cycle rates that

do not exceed 150 cycles per minute.

Description

Unattached Reed Type (oil only)

10mA @ 120VAC

24 mA @ 24VDC

10,000,000 Cycle Life

Field Sensitive Magnetic Type

3-pin and 5-pin (AC only)

2A @ 120/240 VAC

4-pin (DC only) 0.1A @ 28VDC

150,000,000 Cycle Life

Magnetic Type with LED’s

5A @ 24 VDC

10,000,000 Cycle Life

Magnetic Type

5A @ 24VDC

5A @ 120/240 VAC

10,000,000 Cycle Life

Field Sensitive Magnetic Type

No.

of Pins

1/2 NPT with

Leads

(Explosion

Proof)

3

5

4 O-Ring 557747 557747 558939 558939 563495

Pigtail Lead

(Explosion

Proof)

3 O-Ring 563478 563478 NA NA NA

5 O-Ring 563477 563477 NA NA NA

3 Gasket* NA NA 563486 563486 NA

5 O-Ring 563484 563484 564400 564400 NA

Pigtail Lead

(Explosion

Proof)

Type

Seal

O-Ring 563427 563427 NA NA NA

O-Ring 557741 557741 563476 563476 563970

Gasket* NA NA NA NA NA

O-Ring 557746 557746 564399 564399 NA

Gasket* NA NA NA NA NA

O-Ring 557745 557745 564401 564401 NA

O-Ring 563485 563485 NA NA NA

MS MH MX MXP MGO

Part Number

25 mA @ 24VDC

M12 x 1, 4-pin (DC only)

10,000,000, cycle life

*Consult your distributor for availability.

312497P 41

4 O-Ring 563500 563501 NA NA NA

Page 42

Accessories

Proximity Switch Connection Cables

Connection Cables for:

3-Pin Proximity Switch 5-Pin Proximity Switch

Connector Length - ft (m) Part No. Connector Length - ft (m) Part No.

Straight 6 (1.83) 558021 Straight 6 (1.83) 558023

Straight 12 (3.66) 558022 Straight 12 (3.66) 558024

NA NA NA 90° 6 (1.83) 558965

4-Pin Proximity Switch

Straight 7 (2.13) 568738 NA NA NA

Base Section Sub Assemblies

Part No. Description

24N382 PLATE, base, MSP, NPTF, 3 sect, SS

24N383 PLATE, base, MSP, NPTF, 4 sect, SS

24N384 PLATE, base, MSP, NPTF, 5 sect, SS

24N385 PLATE, base, MSP, NPTF, 6 sect, SS

24N386 PLATE, base, MSP, NPTF, 7 sect, SS

24N387 PLATE, base, MSP, NPTF, 8 sect, SS

24N388 PLATE, base, MSP, BSPP, 3 sect, SS

24N389 PLATE, base, MSP, BSPP, 4 sect, SS

24N390 PLATE, base, MSP, BSPP, 5 sect, SS

24N391 PLATE, base, MSP, BSPP, 6 sect, SS

24N392 PLATE, base, MSP, BSPP, 7 sect, SS

24N393 PLATE, base, MSP, BSPP, 8 sect, SS

42 312497P

Page 43

Notes

Notes

312497P 43

Page 44

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2009, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312497

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised December 2014

Loading...

Loading...