Page 1

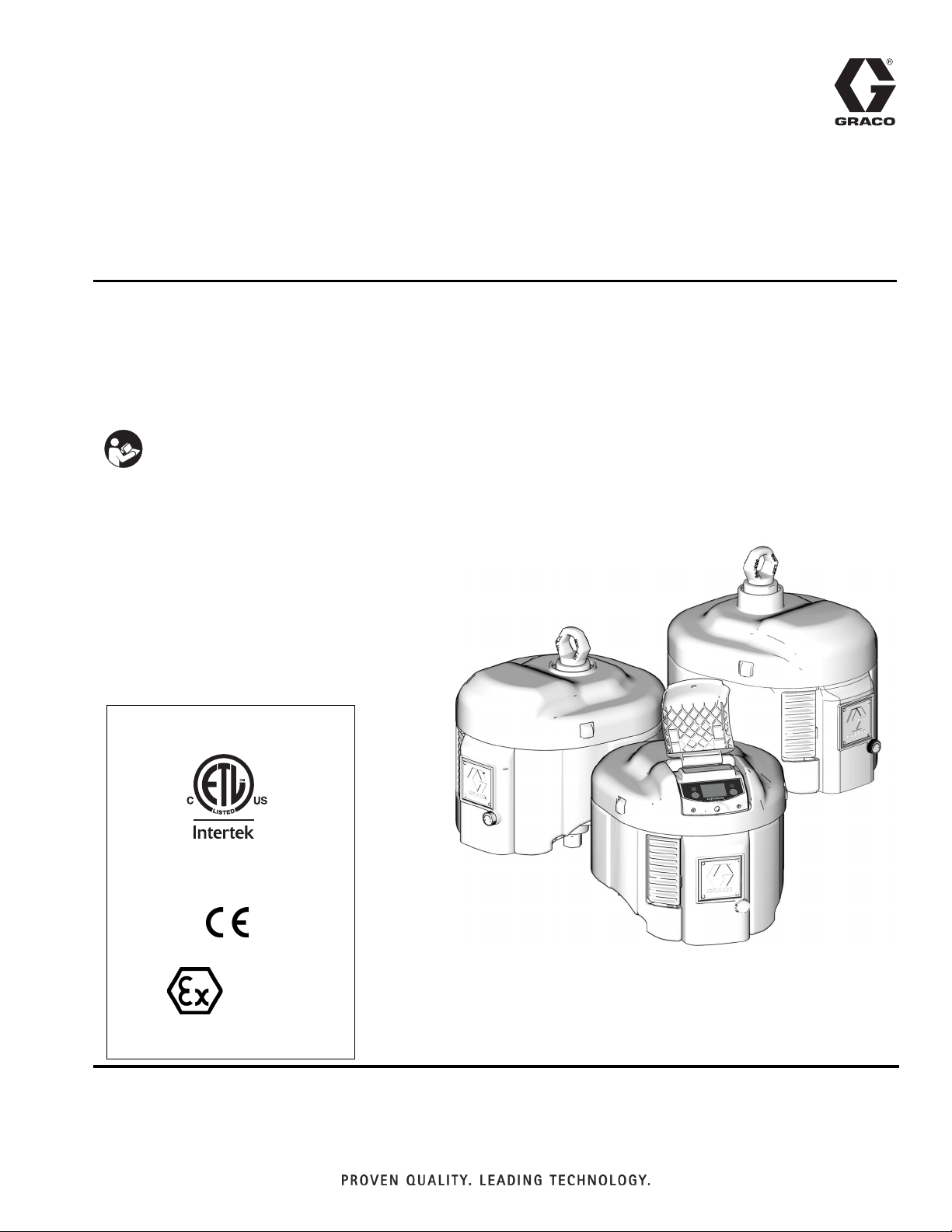

Instructions-Parts

®

NXT

For use with high performance finishing and coating pumps in hazardous or

non-hazardous locations. For professional use only.

100 psi (0.7 MPa, 7.0 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 3 for model information.

Air Motor

With Linear Sensor

Standard

311238ZAJ

EN

Models with DataTrak™ display

include agency approvals listed below.

9902471

Class I, Div 1

Group D T3A

0359

II 1 G

Ex ia IIA T3 Ga

ITS13ATEX27862X

™

With DataTrak

Updated technical information and repair videos are available at

www.graco.com. Click on “Tech Support”, and then enter “NXT” in the

“Search by Keyword” field.

TI8621a

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Air Motor Part No. Matrix . . . . . . . . . . . . . . . . . . . . . . . 3

Air Motor Part Nos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . 7

De-icing Control (F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Integrated Air Control Module Accessory . . . . . . . . . . . 8

Motor Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DataTrak Controls and Indicators . . . . . . . . . . . . . . . . . 10

DataTrak Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Replace the DataTrak Module Battery or Fuse . . . . . .14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Preventive Maintenance Schedule . . . . . . . . . . . . . . . 19

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . 19

Air Valve Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cylinder and Piston Repair . . . . . . . . . . . . . . . . . . . . . 23

Poppet Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Replace the Linear Sensor (if present) . . . . . . . . . . . . 27

Remote DataTrak Connection Kit NXT406 . . . . . . . . . 28

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

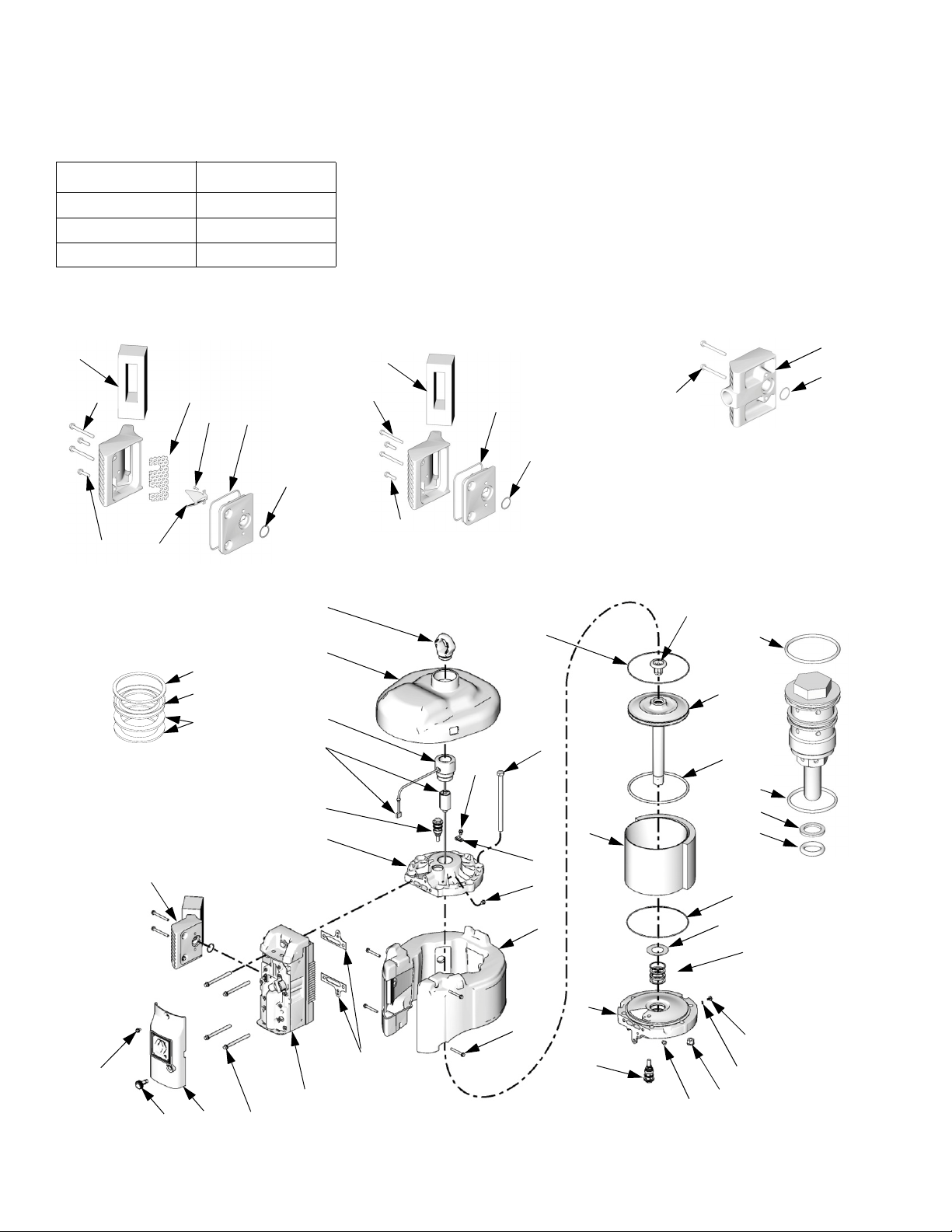

Air Motor Parts Drawing

(Shown with DataTrak and Low Noise Exhaust) . 29

Air Motor Parts Drawing

(Shown with Linear Sensor) . . . . . . . . . . . . . . . . .30

NXT Model 2200 Air Motors . . . . . . . . . . . . . . . . . . . . 31

NXT Model 3400 Air Motors . . . . . . . . . . . . . . . . . . . . 33

NXT Model 6500 Air Motors . . . . . . . . . . . . . . . . . . . . 35

Air Motor Parts Drawing

(for use with Remote DataTrak) . . . . . . . . . . . . . . 37

Air Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

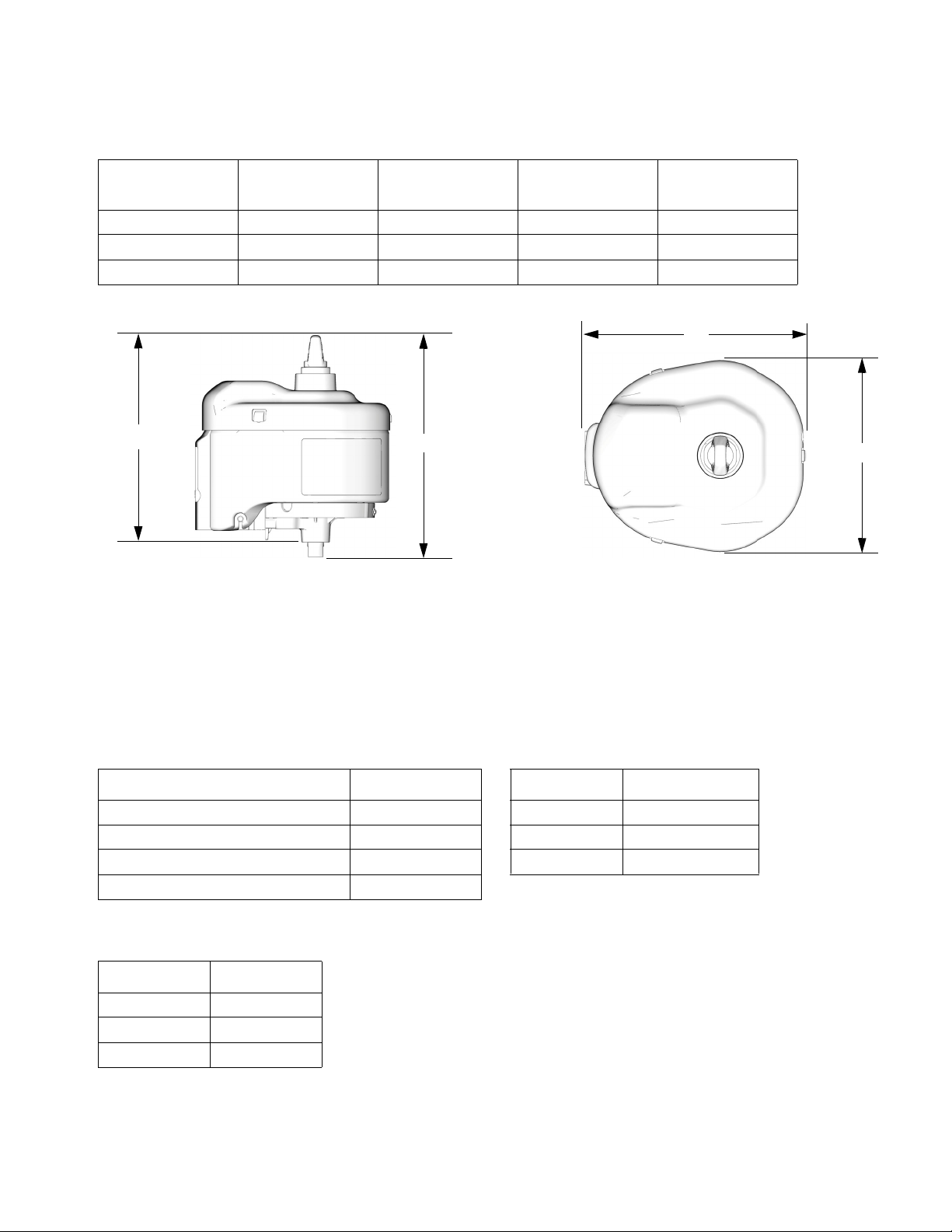

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mounting Hole Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . 42

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . 48

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

2 311238ZAJ

Page 3

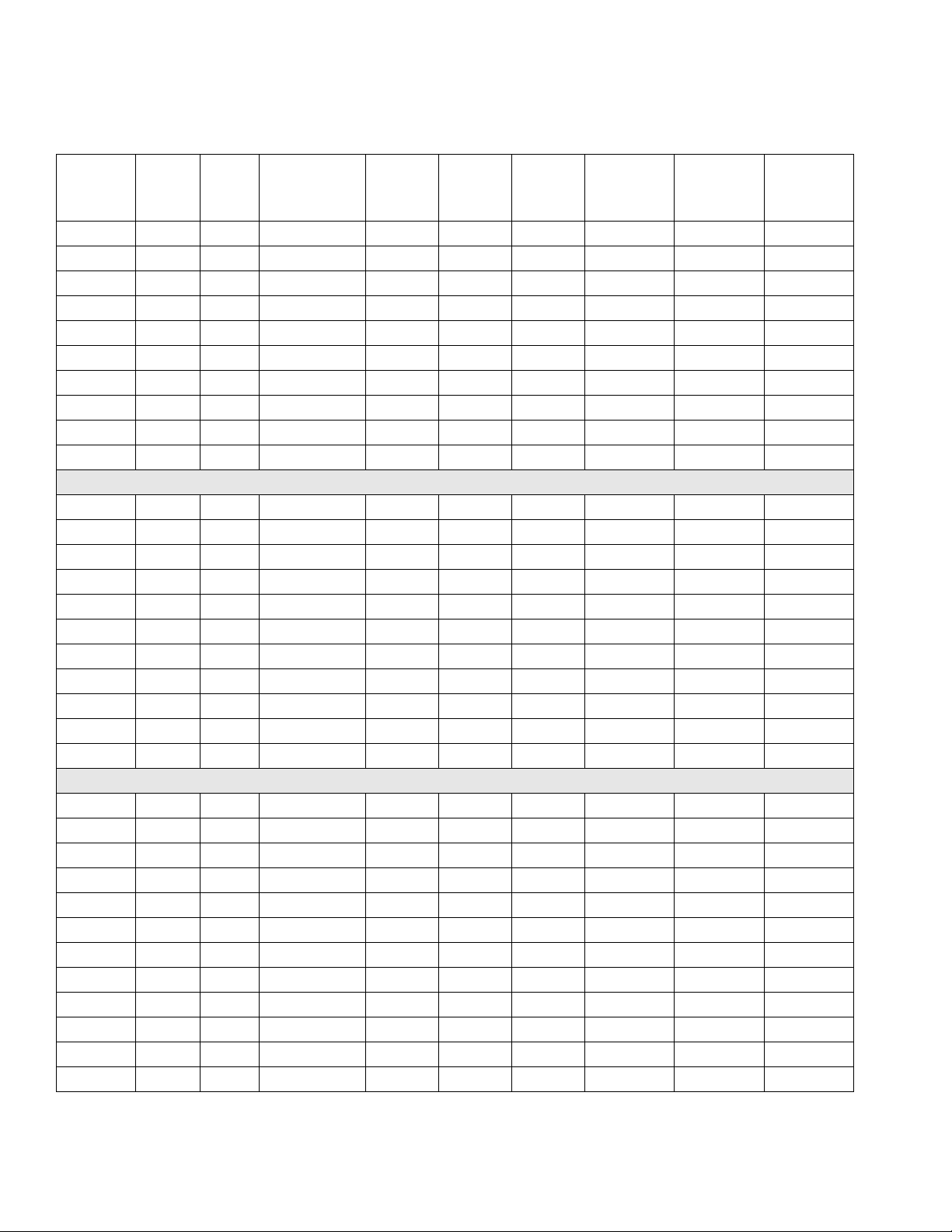

Models

Models

Air Motor Part No. Matrix

Check your motor’s identification plate (ID) for the 6-digit part number of your motor. Use the

following matrix to define the construction of your motor, based on the six digits. For example, Motor Part No. N65DT0 represents an NXT motor (N), 6500 cc per stroke (6 5), with

de-icing exhaust (D) and DataTrak monitoring (T). The last digit (0) is unassigned.

N6 5 D T 0

ID

First Digit

(Motor)

N (NXT

Air Motor)

Remote exhaust models have a 1 in. npt(f) exhaust

outlet, allowing installation of a muffler or plumbing

to route exhaust to a remote location.

Remote DataTrak models do not have the DataTrak

display on the motor. An external plug connects to

systems using a remote display interface. See

pages 37-38 for parts.

Second and Third Digits

(motor size in cc per stroke)

65 6500 D De-icing N None 0 None

34 3400 L Low noise T DataTrak 2

22 2200 R Remote exhaust

Fourth Digit

(Exhaust Type)

(see note below)

Do not operate the remote exhaust air motor without a

plumbed exhaust line or muffler installed.

Fifth Digit

(Data Monitoring)

R Remote DataTrak

H Linear Sensor

Sixth Digit

(unassigned)

assigned

311238ZAJ 3

Page 4

Models

Air Motor Part Nos.

Air

Motor

Part No. Series

NXT

Model

Piston

Diameter,

in. (mm) De-Ice

N22DN0 L 2200 6.0 (152)

N22DT0 L 2200 6.0 (152)

N22DH0 L 2200 6.0 (152)

N22LN0 L 2200 6.0 (152)

N22LT0 L 2200 6.0 (152)

N22LR0 L 2200 6.0 (152)

N22LH0 L 2200 6.0 (152)

N22RN0 L 2200 6.0 (152)

N22RT0 L 2200 6.0 (152)

N22RH0 L 2200 6.0 (152)

N34DN0 L 3400 7.5 (191)

N34DT0 L 3400 7.5 (191)

N34DH0 L 3400 7.5 (191)

N34LN0 L 3400 7.5 (191)

N34LN2 L 3400 7.5 (191)

N34LT0 L 3400 7.5 (191)

N34LR0 L 3400 7.5 (191)

N34LH0 L 3400 7.5 (191)

N34RN0 L 3400 7.5 (191)

N34RT0 L 3400 7.5 (191)

N34RH0 L 3400 7.5 (191)

Low

Noise

Remote

Exhaust

Includes

DataTrak

™

Includes

Remote

DataTrak

™

Includes

Linear

Sensor

✔

✔✔

✔✔

✔

✔✔

✔✔

✔✔

✔

✔✔

✔✔

✔

✔✔

✔✔

✔

✔

✔✔

✔✔

✔✔

✔

✔✔

✔✔

N65DN0 L 6500 10.375 (264)

N65DT0 L 6500 10.375 (264)

N65DH0 L 6500 10.375 (264)

N65LN0 L 6500 10.375 (264)

N65LN2 L 6500 10.375 (264)

N65LT0 L 6500 10.375 (264)

N65LR0 L 6500 10.375 (264)

N65LH0 L 6500 10.375 (264)

N65RN0 L 6500 10.375 (264)

N65RT0 L 6500 10.375 (264)

N65RH0 L 6500 10.375 (264)

257055 L 6500 10.375 (264)

✿

Air motor includes potted linear sensor approved for use in hazardous locations, but only when it is used with XM

✔

✔✔

✔✔

✔

✔

✔✔

✔✔

✔✔

✔

✔✔

✔✔

✔✔✿

plural component sprayers.

4 311238ZAJ

Page 5

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. Refer

back to these Warnings. Additional, product-specific warnings may be found throughout the body of this manual

where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SPECIAL CONDITIONS FOR SAFE USE

Equipment must comply with the following conditions to avoid a hazardous condition which can cause

fire or explosion.

• All label and marking material must be cleaned with a damp cloth (or equivalent).

• The electronic monitoring system is required to be grounded. See Grounding instructions.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like

just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin

and cause serious injury.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

311238ZAJ 5

Page 6

Related Manuals

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equip-

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

WARNING

ment, follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

component. See Technical Data in all equipment manuals.

all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

Graco replacement parts only.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

Related Manuals

Component manuals in U.S. English:

Manual Description

311239 Integrated Air Control

Modules Instructions-Parts

311486 DataTrak Conversion Kit Instructions-Parts

312148 NXT Air Motor Mounting

Conversion Instructions-Parts

3A0293 AIr Controls Instructions-Parts

406656 NXT135 Air Valve Seal Kit

406657 NXT144 Air Valve Rebuild Kit

406658 Air Motor Repair Kits

406820 NXT145 Replacement Kit

6 311238ZAJ

Page 7

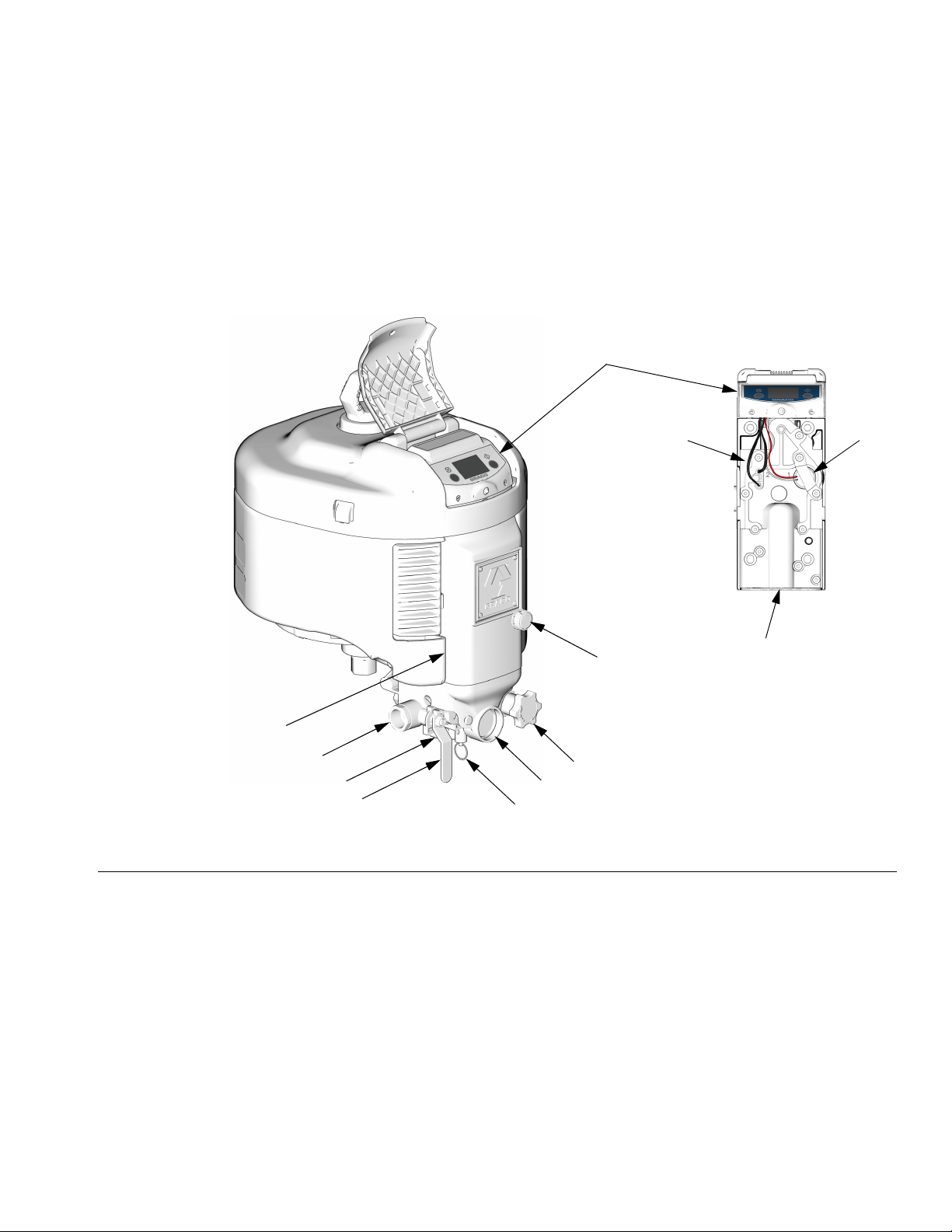

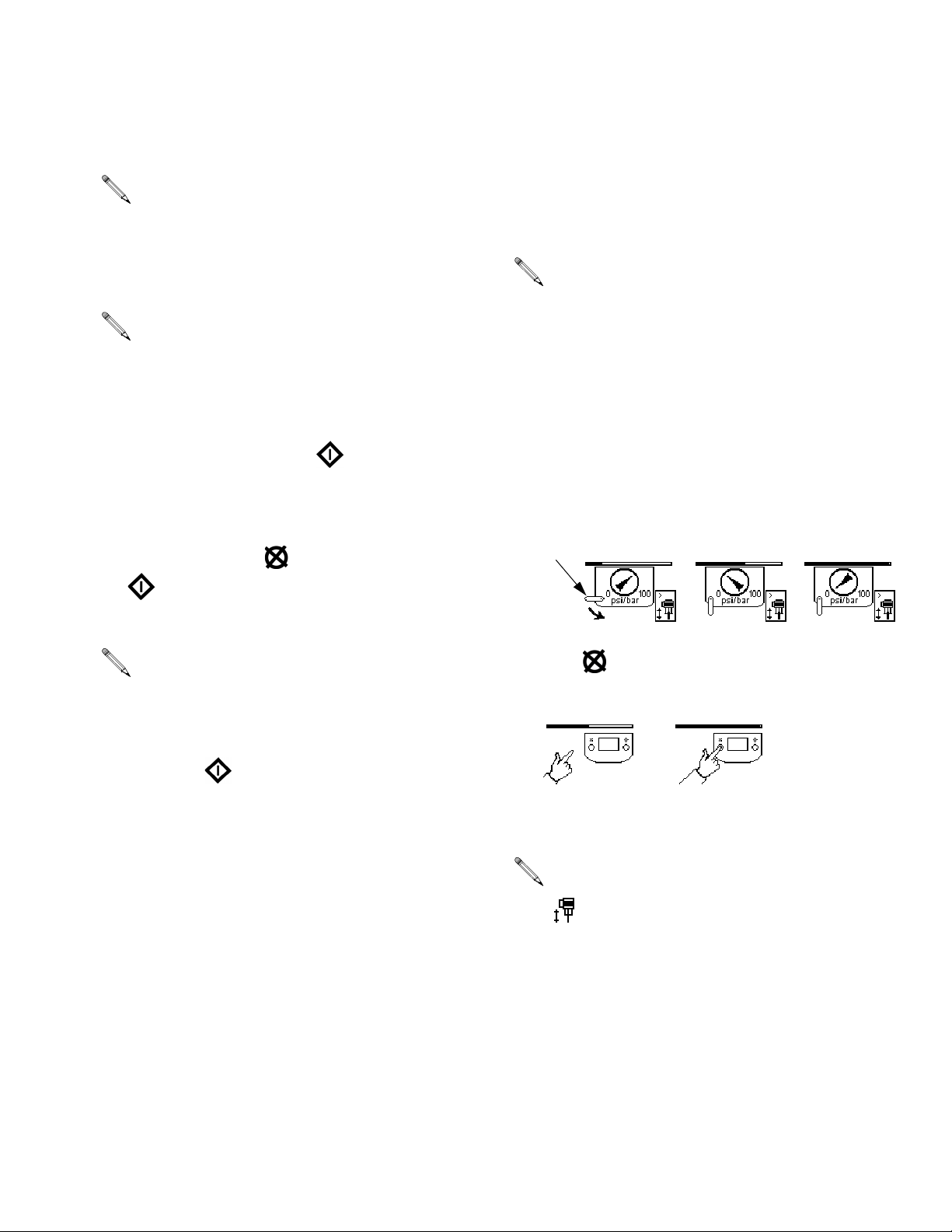

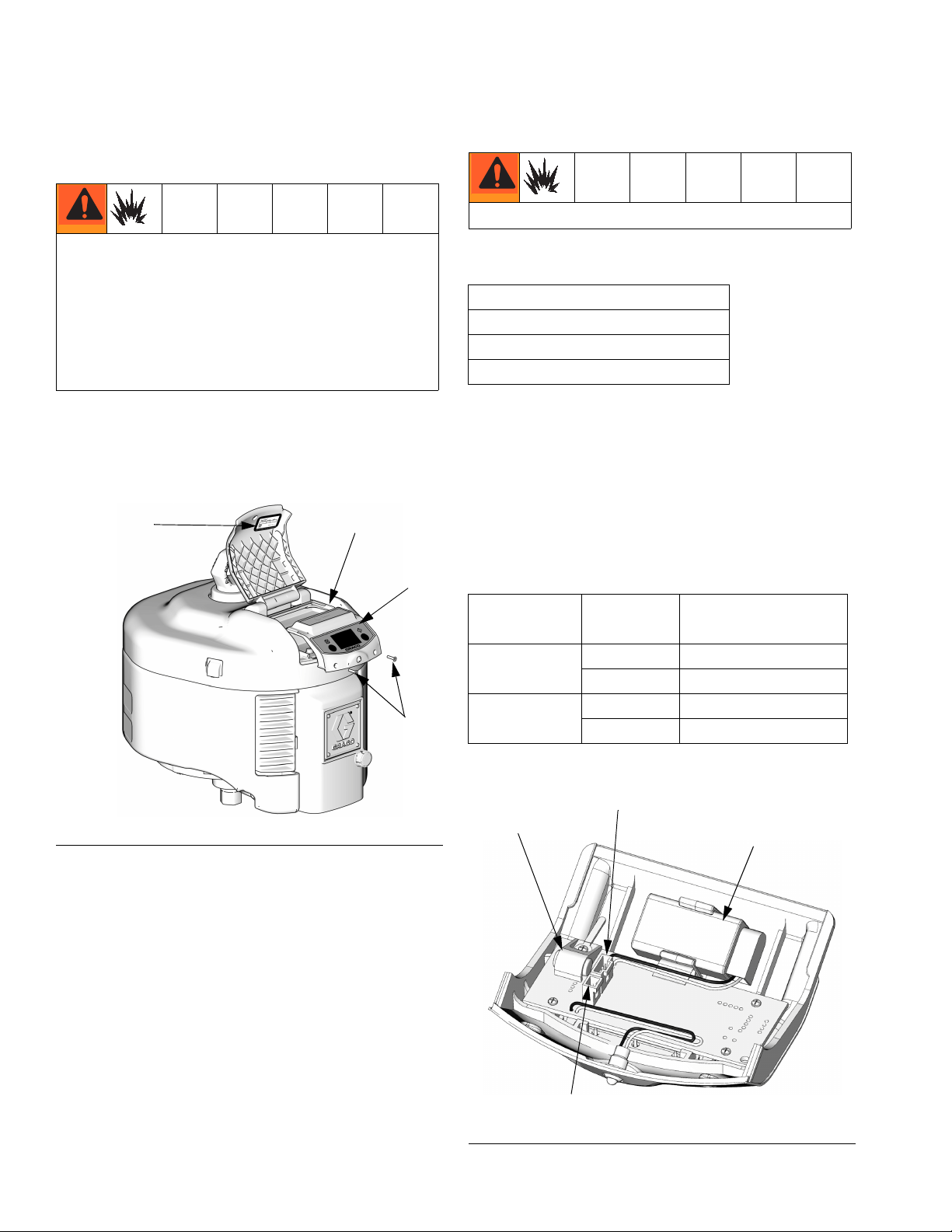

Component Identification

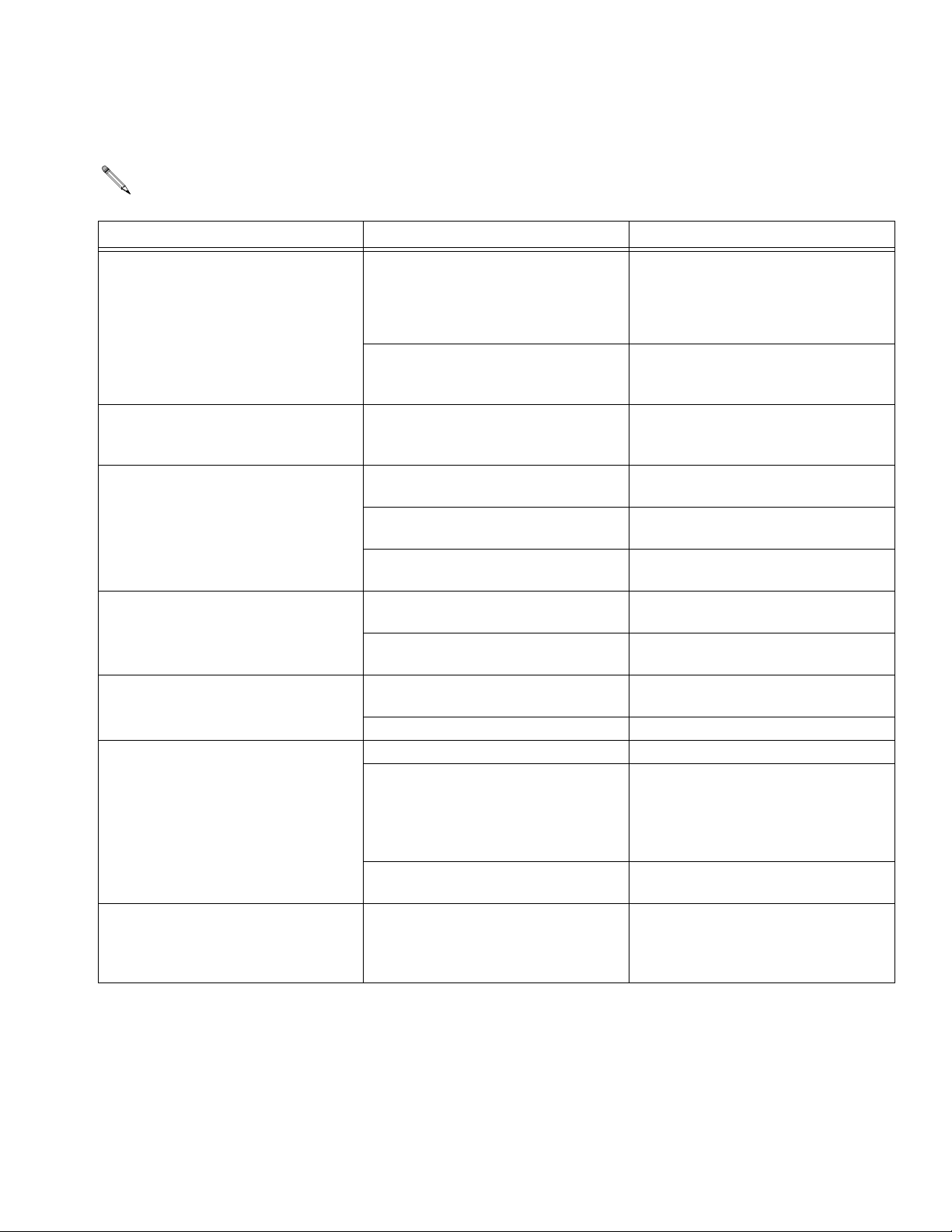

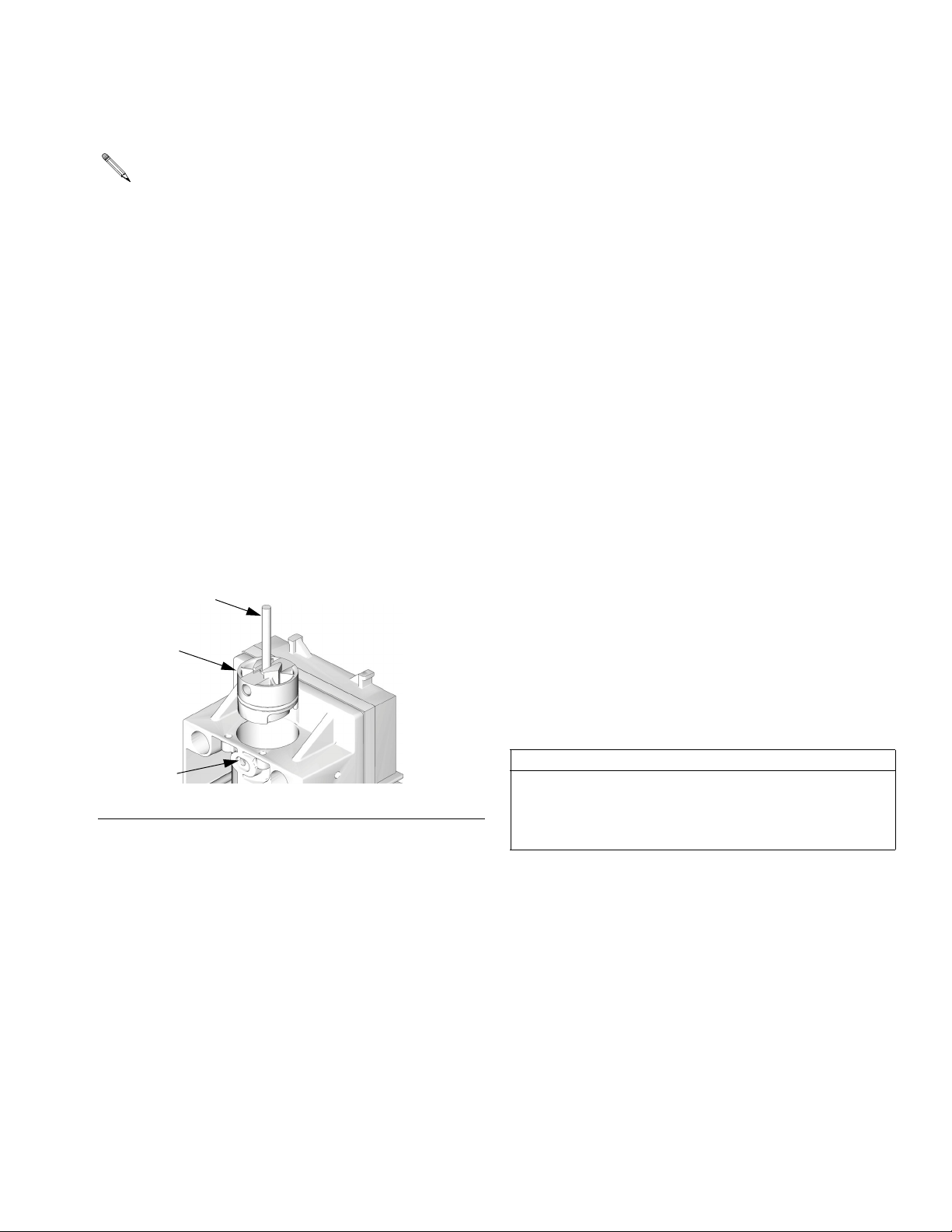

Key for FIG. 1

Component Identification

A Air Inlet, 3/4 npt(f)

B Bleed-Type Master Air Valve

C Air Regulator Adjustment Knob

D Air Pressure Gauge

E Air Filter (out of view; located at rear of air control kit)

F De-icing Control

G Air Valve (behind cover)

H DataTrak module (see pages 9-14; not present on all

models)

J Runaway Solenoid (component 1)

K DataTrak Sensors (component 2)

L Air Valve Inlet Port, 3/4 npt(f)

M Safety Relief Valve

H

KJ

TI7759a

F

L

Detail With Air Valve

Cover Removed

G

A

E

B

M

C

D

TI8233b

FIG. 1: Component Identification (Model Shown with DataTrak Module and Accessory Air Control Kit)

311238ZAJ 7

Page 8

Component Identification

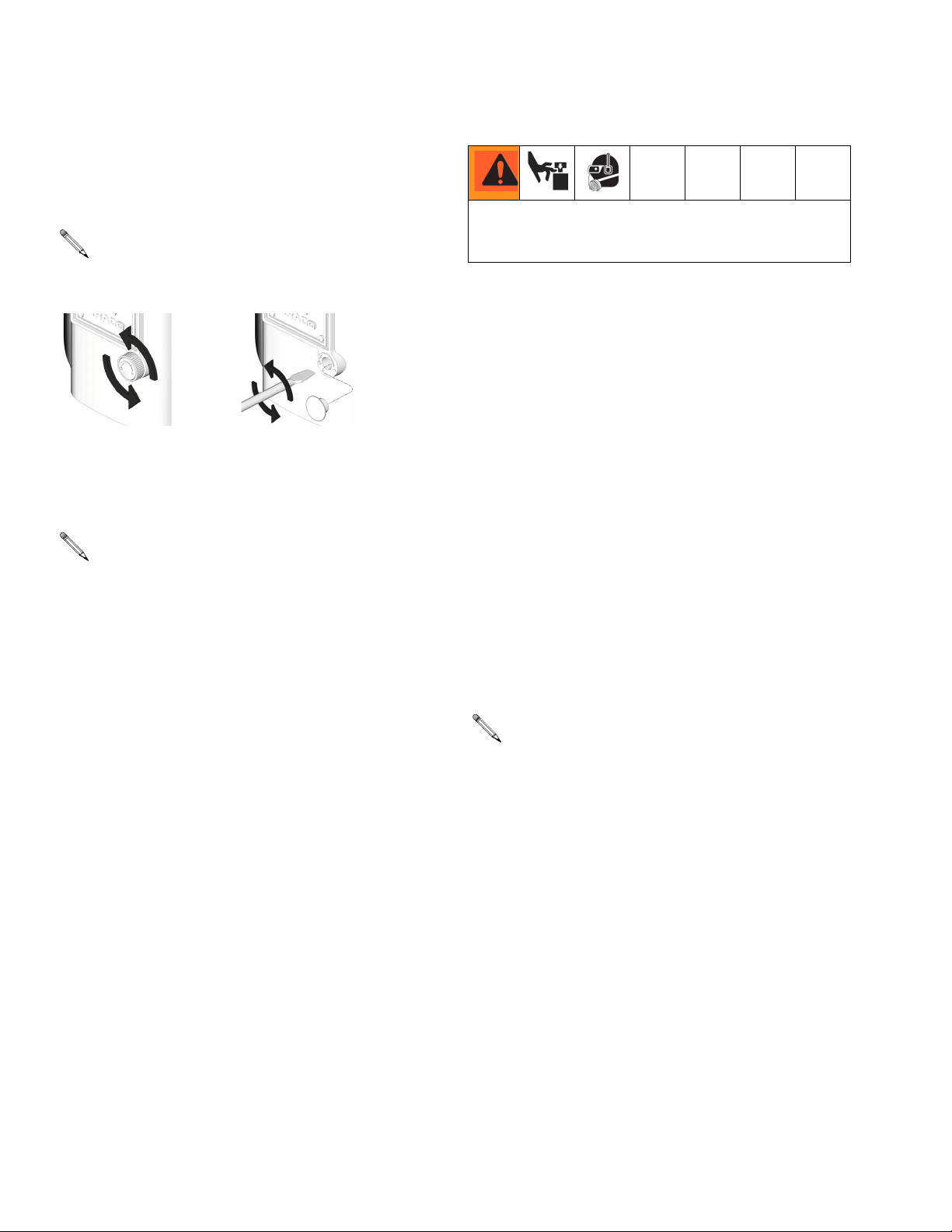

De-icing Control (F)

Open with knob or flat blade screwdriver to reduce icing.

If needed, adjust enough warm feed air bleed to eliminate icing.

Low noise models have exhaust baffles that can

accumulate ice easily.

TI8802aTI8159b

Integrated Air Control Module Accessory

Accessory Air Control Kits include air line components in an integrated assembly. Order the kits separately. See manual 311239 for installation

instructions.

Bleed-type Master Air Valve (B)

Trapped air can cause the pump to cycle unexpectedly,

which could result in serious injury from splashing or

moving parts.

• Required in your system to relieve air trapped

between it and the air motor when the valve is

closed.

• Be sure the valve is easily accessible from the

pump and located downstream from the air regulator.

Air Regulator (C)

Adjusts air pressure to the motor and fluid outlet pressure of pump. Locate it close to the pump. Install a

gauge (D) to read air pressure.

Safety Relief Valve (M)

Automatically opens to relieve air pressure, to prevent

pump overpressurization.

• NXT011 with locking air regulator and 110 psi

(0.76 MPa, 7.6 bar) relief valve

• NXT031 with locking air regulator and 75 psi

(0.51 MPa, 5.1 bar) relief valve

• NXT021 with non-locking air regulator and 110

psi (0.76 MPa, 7.6 bar) relief valve.

Air Filter (E)

Removes harmful dirt from compressed air supply.

Graco recommends using an air filter with a minimum measurement of 40 micron.

8 311238ZAJ

Page 9

Grounding

Motor Lubrication

Graco does not require lubrication beyond the grease

installed at the factory or through regular maintenance.

With good quality compressed air and normal ambient

conditions NXT air motors will run millions of cycles

without additional lubrication.

However, if any of the following criteria apply to your

system, you will benefit from installing a 3/4 in. air line

lubricator in the air line before the air motor or from

occasionally adding oil to an air filter cup.

• Air supply does not contain any oil.

• Air supply is very wet.

• Air supply is very dry.

• Air motor is run at low air pressure.

• Air motor is run in unusually hot or cold environments.

Areas that benefit from lubrication:

• main piston o-rings(17),

• sliding valve spool(119/108), and

• motor detent assembly (113).

Add Accessory Air Lubricator

If using an air motor with integrated air controls, add an

accessory airline lubricator❄ to the motor inlet. The oil

will move through the air filter.

Depending on air quality you may need to change

the air filter more frequently.

❄

Graco offers airline lubricators for NXT air motors.

Order 214848 (1/2 in.) for NXT 2200 and NXT 3400

air motors. Order 214849 (3/4 in.) for NXT 6500 air

motors.

If using an air motor without integrated air controls, add

a standard type filter/regulator/lubricator that is sized for

the specific air motor, such as 217073 (3/4 in.) or

217072 (1/2 in.).

Grounding

Add Lubrication

The three methods for adding lubrication are described

below.

Lubricate Air Valve

Perform these steps annually, or more often depending

on your duty cycle, air pressure, and air quality. Use a

high quality lithium-based grease.

1. Remove the 10 air valve cover screws (124) and air

valve cover (112).

2. Grease all visible moving parts, especially detent

(113) and valve pistons (119).

Lubricate Air Filter Bowl

If using a motor with integrated air controls, add 50-75

ml of oil to the air filter bowl and run the motor for a few

minutes at a fast cycle rate. The oil will move through

the air valve and main piston.

The equipment must be grounded to reduce the risk of

static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

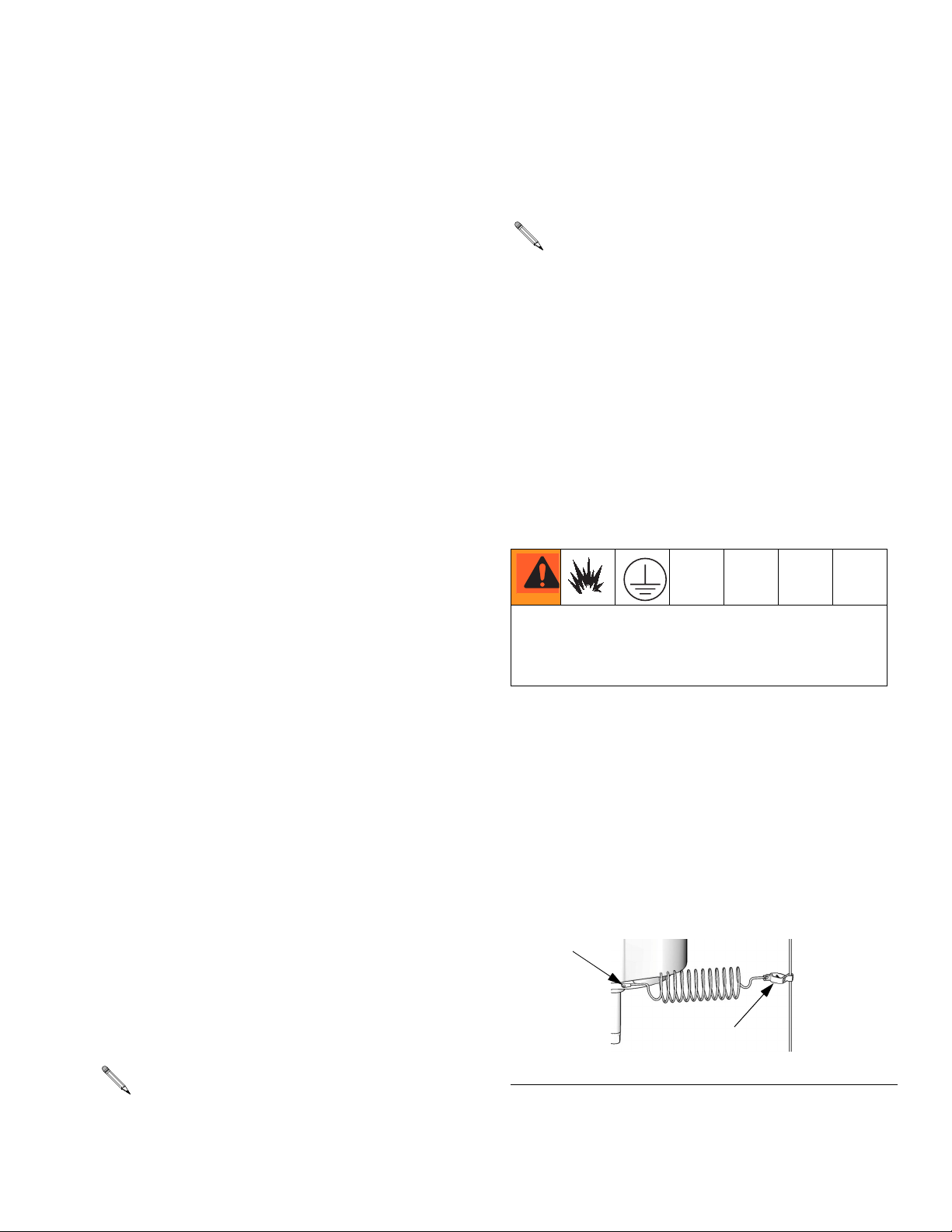

See F

IG

. 2. Use the ground screw (60) and lockwasher

(61) to attach Part No. 244524 Ground Wire (GW) at the

rear of the air motor. Tighten the screw securely. Connect the other end of the ground wire to a true earth

ground.

60, 61

GW

TI8250a

F

IG

It is normal for some oil to come out through the

exhaust.

311238ZAJ 9

. 2. Ground Wire

Page 10

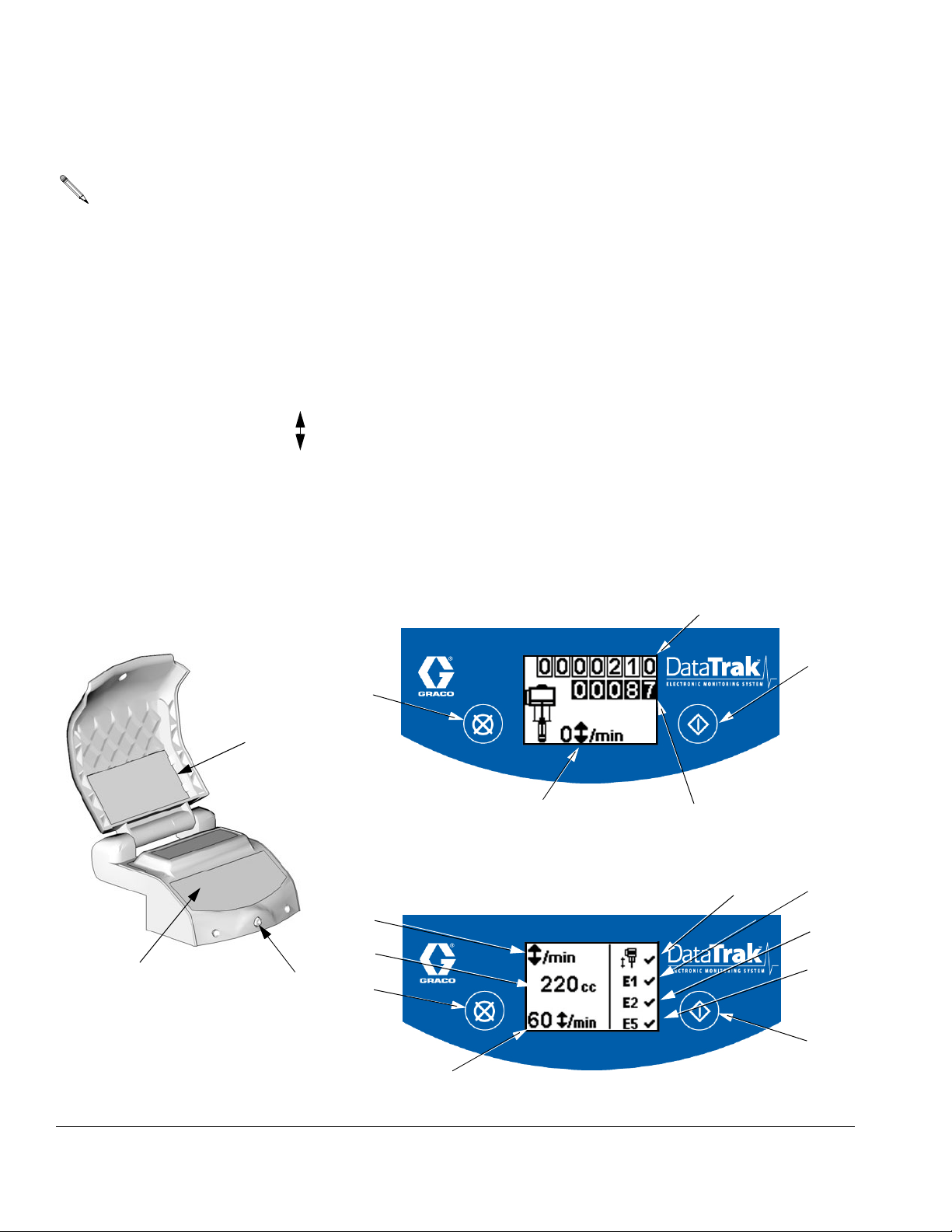

DataTrak Controls and Indicators

DataTrak Controls and Indicators

DataTrak is included with certain models. See page 3 for a list of models featuring DataTrak.

It is recommended that a 3/4 in. air line lubricator be used with DataTrak models.

For remote DataTrak models, see your system operation manuals.

To prevent damage to the soft key buttons, do not press the buttons with sharp objects such as pens, plastic

cards, or fingernails.

Key for FIG. 3

T Runaway Limit, in cycles per minute (user settable;

00=OFF)

U Lower Displacement (user settable)

V Flow Rate Units (user settable to gpm [US],

gpm [Imperial], oz/min [US], oz/min [Imperial], l/min, or

cc/min)

W LED (fault indicator when lit)

X Diagnostic Reference Card (see T

Y Display

/min,

ABLE

1, page 13)

RK

X

PF Prime/Flush Key (Enables Prime/Flush mode. While in

Prime/Flush mode, runaway protection is disabled and

the batch totalizer [BT] will not count.)

RK Reset Key (Resets faults. Press and hold for 3 seconds to

clear the batch totalizer.)

CF Cycle/Flow Rate

BT Batch Totalizer

GT Grand Totalizer

RT Runaway Toggle (enable/disable)

UT E1 Toggle

DT E2 Toggle

ST E5 Toggle

Run Mode

GT

PF

CF BT

TI8622b

Y; See Details at right.

TI8215a

W

RK

Setup Mode

RT

V

U

UT

DT

ST

PF

T

TI8623b

FIG. 3. DataTrak Controls and Indicators

10 311238ZAJ

Page 11

DataTrak Operation

DataTrak Operation

DataTrak is included with certain models. See page

3 for a list of models featuring DataTrak.

For remote DataTrak models, see your system

operation manuals. See pages 37-38 for parts.

The DataTrak display (Y) will turn off after 1 minute

to save battery life. Press any key to wake up the

display.

Setup Mode

1. See FIG. 3. Press and hold for 5 seconds until

Setup menu appears.

2. To enter settings for runaway, lower size, and flow

rate units, and to enable runaway, E1, E2, and E5

error options, press to change the value, then

to save the value and move the cursor to the

next data field.

Run Mode

Runaway

The runaway control should be tested regularly. To

test, go to Setup Mode and set value to 1 (one).

Pump should stop in six cycles.

1. See FIG. 3. If pump runaway occurs, the runaway

solenoid will actuate, stopping the pump. The LED

(W) will flash and the display (Y) will indicate a runaway condition (see Table 1).

2. To reset runaway monitor, close master air valve

(B). Wait for air to completely bleed off the air motor

before going to step 3. The screen will change to

indicate this, as shown below.

B

When runaway, E1, E2, and E5 error options are

enabled, a ✓ will appear on the setup screen. See

F

IG

. 3.

3. Move the cursor to the E5 error enable option field,

then press once more to exit Setup mode.

3. Press to clear the diagnostic code and reset the

runaway solenoid.

4. Open master air valve (B) to restart pump.

To disable runaway monitoring, go to setup mode

and set runaway value to 0 (zero) or toggle (RT) off

(see F

IG

. 3).

311238ZAJ 11

Page 12

DataTrak Operation

Prime/Flush

1. See FIG. 3. To enter Prime/Flush mode, press any

key to wake up the display, then press . The

Prime/Flush symbol will appear in the display and

the LED will flash .

2. While in Prime/Flush mode, runaway protection is

disabled and the batch totalizer (BT) will not count.

3. To exit Prime/Flush mode, press any key to wake

up the display, then press . The Prime/Flush

symbol will disappear from the display and the LED

will stop flashing.

Counter/Totalizer

See FIG. 3. The last digit of the batch totalizer (BT) represents tenths of gallons or liters. To reset the totalizer,

press any key to wake up the display, then press and

hold for 3 seconds.

Display

See FIG. 3. The display (Y) will turn off after 1 minute of

inactivity in Run mode or 3 minutes in Setup mode.

Press any key to wake up the display.

DataTrak will continue to count cycles when display

is off.

Diagnostics

DataTrak can diagnose several problems with the

pump. When the monitor detects a problem, the LED

IG

(W, F

on the display. See Table 1.

To acknowledge the diagnosis and return to the normal

operating screen, press once to wake up the display, and once more to clear the diagnostic code

screen.

. 3) will flash and a diagnostic code will appear

If flow rate is set to both totalizers will dis-

play the number of pump cycles.

/min,

12 311238ZAJ

Page 13

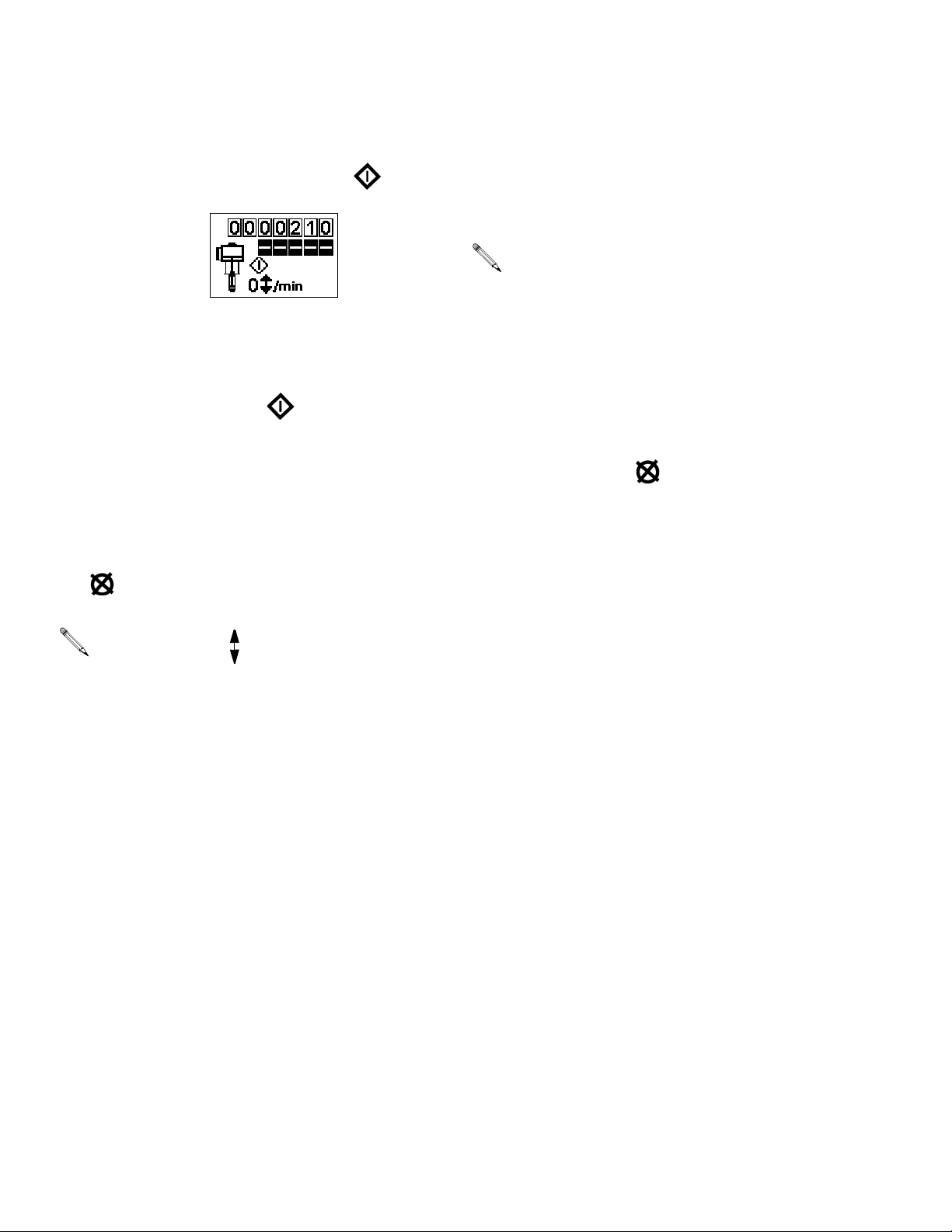

Table 1: Diagnostic Codes

DataTrak Operation

Symbol Code

No.

E-1 Diving Up Leak during upstroke. Worn piston valve or packings.

E-2 Diving Down Leak during downstroke. Worn intake valve.

E-3 Low Battery Battery voltage too low to stop

E-4 Service

Code Name Diagnosis Cause

Runaway Pump running faster than set runaway

limit.

runaway.

Problem with stopping runaway. • Damaged solenoid.

Component 1

• Increased air pressure.

• Increased fluid output.

• Exhausted fluid supply.

• Low battery. To replace battery, see

page 14.

• Disable Runaway mode until battery

is replaced; see page 11.

• Damaged valve carriage.

E-4 Disconnected

Solenoid

E-5 Service

Component 2

E-6 Blown Fuse Fuse is blown. • Faulty solenoid or solenoid wiring.

Solenoid is disconnected. • Solenoid unplugged.

• Damaged solenoid wires.

Problem with sensing valve movement. • Sensors unplugged.

• Sensors mounted incorrectly.

• Damaged sensors.

• Damaged valve carriage.

• Extreme temperatures (above 140°F

[60°C]).

• Disable Runaway mode until fault is

corrected and fuse is replaced. See

pages 11 and 14.

311238ZAJ 13

Page 14

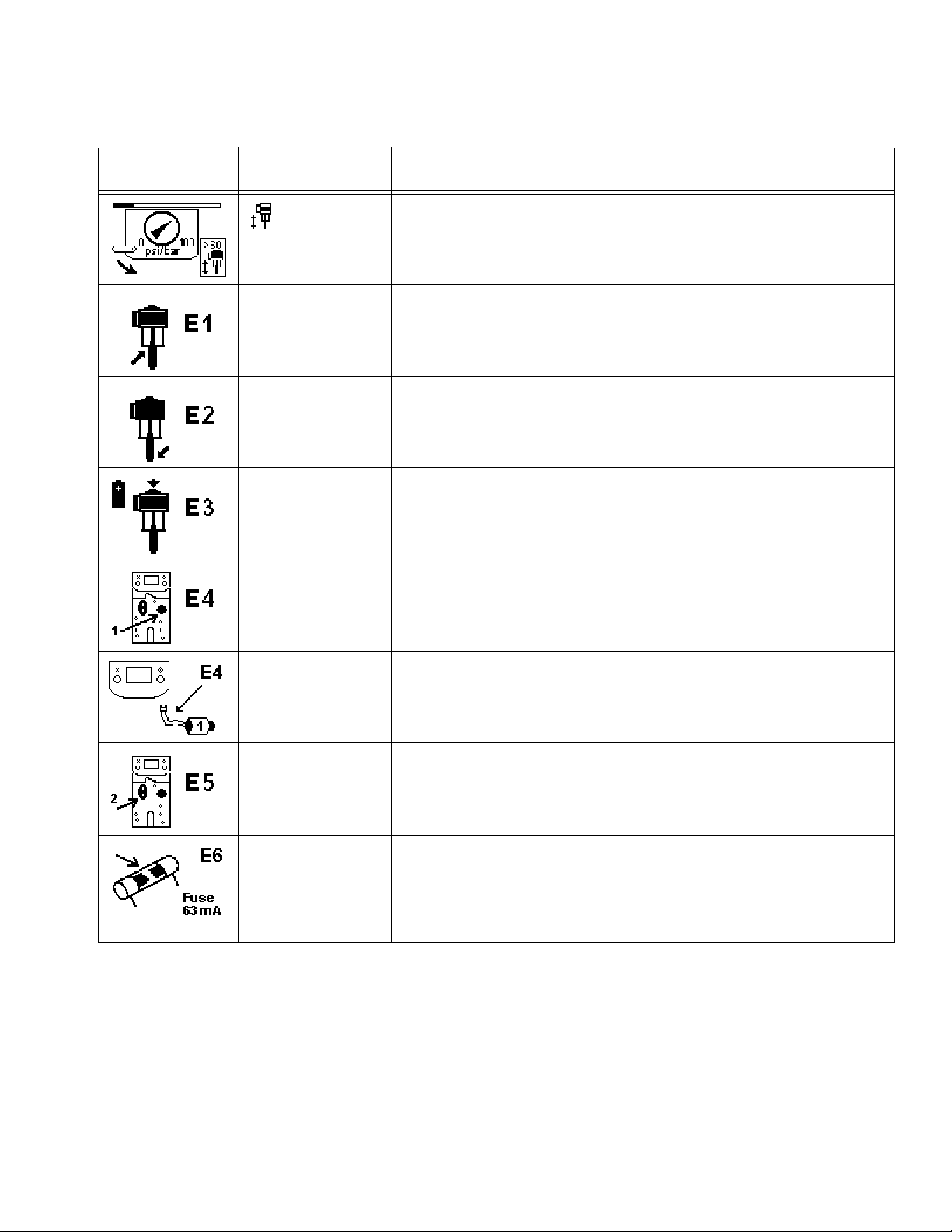

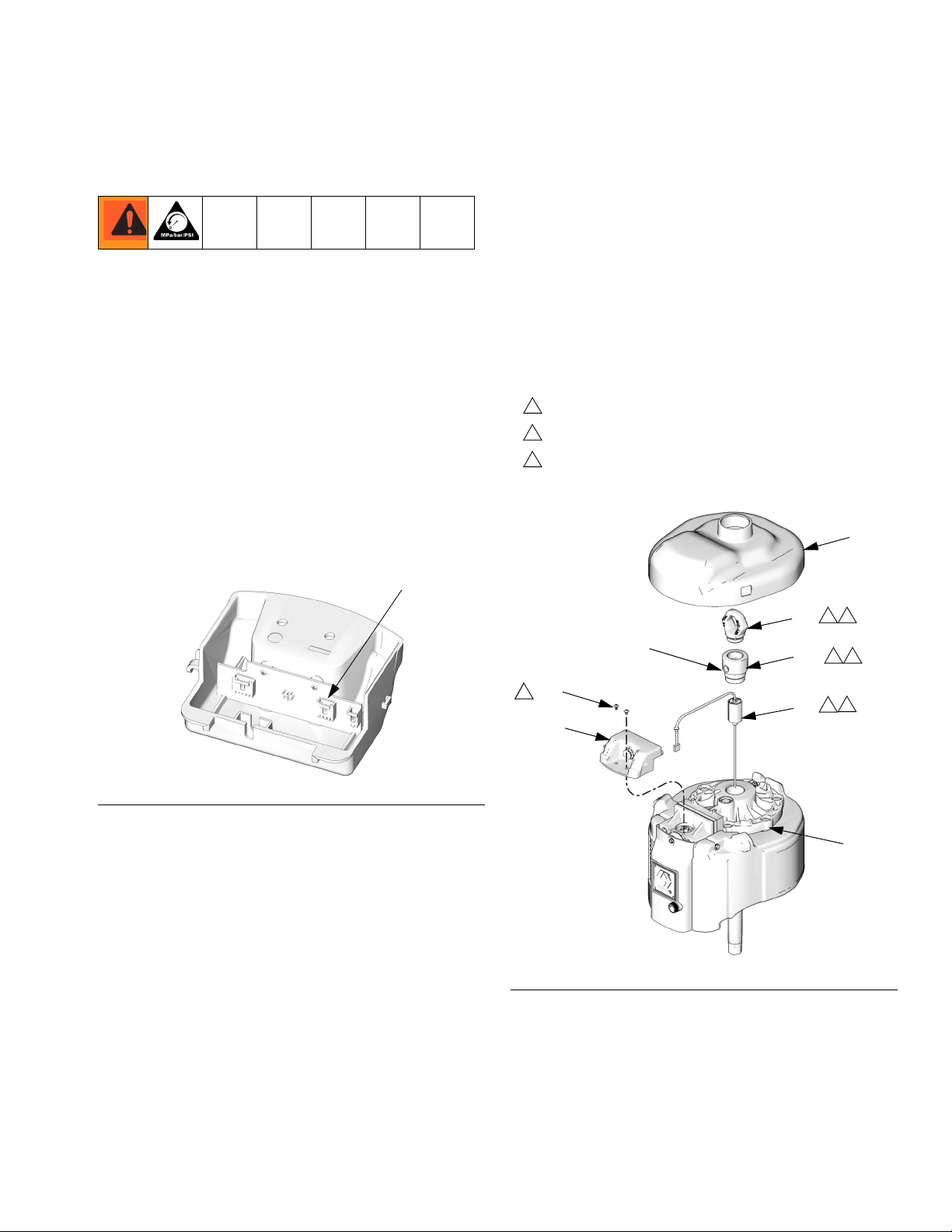

DataTrak Operation

Replace the DataTrak Module Battery or Fuse

To reduce the risk of fire and explosion, the battery

and fuse must be replaced in a non-hazardous location.

Use only an approved replacement battery, shown in

Table 2, and an approved fuse, shown in Table 3.

Use of an unapproved battery or fuse will void

Graco’s warranty and Intertek and Ex approvals.

1. Remove two screws (135). Carefully slide the DataTrak module (131) out of the housing (132). See

F

IG

. 4.

4.

To replace the battery,

disconnect the used bat-

tery and replace with an approved battery.

Use only a Graco-approved replacement fuse (131a).

Table 2: Approved Batteries

Energizer alkaline # 522

Varta alkaline # 4922

Ultralife lithium # U9VL

Duracell alkaline # MN1604

5.

To replace the fuse (131a):

a. Remove the screw, metal strap, and plastic

holder.

Series

132

Letter

131

135

TI8216c

F

IG

. 4. Remove DataTrak Module

2. Disconnect the runaway solenoid and sensor cables

from the module board. See F

IG

. 5.

3. Take the DataTrak module (131) to a non-hazardous location.

b. Pull the fuse away from the board.

c. Replace with a new fuse (131a).

Table 3: Approved Fuses

DataTrak

Part No. Series* Fuse Required

289822 A or B 24C580

C and later 24V216

All other part

numbers

A 24C580

B and later 24V216

* FIG. 4 shows where to find the Series letter.

Sensor Cable Connection

Fuse (131a)

Battery

TI7757a

Solenoid Cable Connection

F

IG

. 5. DataTrak Battery and Fuse Location

14 311238ZAJ

Page 15

Troubleshooting

Also see the troubleshooting section in the Integrated Air Control Modules manual 311239.

Problem Cause Solution

Air motor will not run. Damaged main air valve spool or

poppets.

Rebuild main air valve. See page

19. Replace poppets (12). See page

26.

Troubleshooting

DataTrak solenoid engaged. Runaway occurred (DataTrak models

only).

Air continuously exhausting around

air motor shaft on up stroke.

Air continuously exhausting from

muffler on up and down strokes.

Air motor “bounces” at top of stroke. Damaged bottom poppet. Replace bottom poppet (12). See

Air motor “bounces” at bottom of

stroke.

Slow motor reversal. Plugged poppet muffler. Remove muffler (58) and clean.

Icing on muffler. Air motor operating at high pressure

Damaged air motor shaft seal. Replace air motor shaft seal (7),

De-icing control is open. Close de-icing control with knob or

Damaged air valve carriage, plate,

or seal.

Damaged or worn motor piston

o-ring.

Bottom valve to motor gasket

leaking.

Damaged top poppet. Replace top poppet (12). See page

Top valve to motor gasket leaking. Replace gasket (46).

Leaking signal air from poppet (12),

gaskets (46), exhaust cover gasket

(102), carriage cover gasket (106),

piston valve (119), piston valve stop

(110), or sleeve seal (109).

Valve assembly is dry and sticky. Add oil to air filter cup or add an air

or high cycle rate with high moisture

content air.

See Runaway on page 11.

leather backup packings (8), and

retaining ring (9). See page 23.

flat blade screwdriver.

Replace the carriage (108), plate

(105), or seal (104). See page 21.

Replace piston o-ring (17). See

page 23.

page 26.

Replace gasket (46).

26.

Replace leaking part or gasket.

line oiler.

Reduce pressure, cycle rate, or duty

cycle of motor, or open de-icing control with knob or flat blade screwdriver.

311238ZAJ 15

Page 16

Troubleshooting

Problem Cause Solution

Icing inside motor. Air motor operating at high pressure

or high cycle rate with high moisture

content air.

Reduce pressure, cycle rate, or duty

cycle of motor, or open de-icing control with knob or flat blade screwdriver. Reduce dew point of

compressed air with a moisture

coalescing filter or an air dryer.

Motor muffler restriction.

Air constantly exhausting from top or

Poppet pin or seat leaking. Disassemble, clean, and lubricate

bottom poppet muffler (58).

Air exhausting from poppet muffler

(58) on only the up stroke or only the

down stroke.

Air motor stops or pauses at end of

stroke.

Poppet (12), o-ring (12d), backup

o-ring (12c) is missing or there are

too many.

Poppet (12) is plugged or excessively leaking air.

Detent (113) is jammed. Clean and lubricate detent (113); or

Piston valve seal damaged or

installed backward on piston valve

(119).

Retaining clip on piston valve (119)

folded over and catching in bore on

cylinder sleeve (109).

Valve body (103) is cracked due to

screws (123) being over-torqued.

(Applies only to air motors built prior

to 2008.)

End cap gasket (46) is leaking

between pressure port and poppet

signal port.

Air valve assembly (40) is dry. Friction is high due to dry, compressed

air.

Air motor will not run at any pressure.

DataTrak runaway solenoid stopped

air motor. Piston valve (119) and air

cup assembly (108) not releasing

from solenoid (140) pin.

Red LED is flashing. Air motor is in prime/flush mode.

Air motor is displaying a diagnostic

code.

If using a low noise motor, remove

low-noise baffle in muffler.

poppet valve pin; see page 26. If

problem still is not resolved, replace

poppet.

Replace one or both o-rings.

Replace top poppet if air is exhausting on down stroke.

Replace bottom poppet if air is

exhausting on up stroke.

Replace poppet (12).

replace.

Replace piston valve (119).

Fix or replace piston valve (119).

Replace valve body (103)or entire

air valve assembly (40).

Replace gasket (46)

Disassemble air valve assembly

(40) and grease or lubricate air. See

Motor Lubrication, page 9.

Clean and lubricate bores and seals

of piston valve (119), air cup assembly (108), and detent (113).

Press to return to normal operation. See Prime/Flush, page 12.

See Diagnostics, page 12.

16 311238ZAJ

Page 17

Problem Cause Solution

Minimum air operation pressure is

too high. (For series E-G air motors,

minimum pressure is over 26 psi

(0.18 MPa, 1.8 bar). For series H

and later air motors, minimum pressure is over 16 psi (0.11 MPa, 1.1

bar).)

Friction build-up due to a dry air

valve assembly (40).

Fluid pump is binding because

pump packings are swelling or are

dirty.

See causes for “Air motor stops or

pauses at end of stroke.”

Troubleshooting

See Motor Lubrication, page 9.

Replace pump packings.

See solutions for “Air motor stops or

pauses at end of stroke.”

311238ZAJ 17

Page 18

Troubleshooting

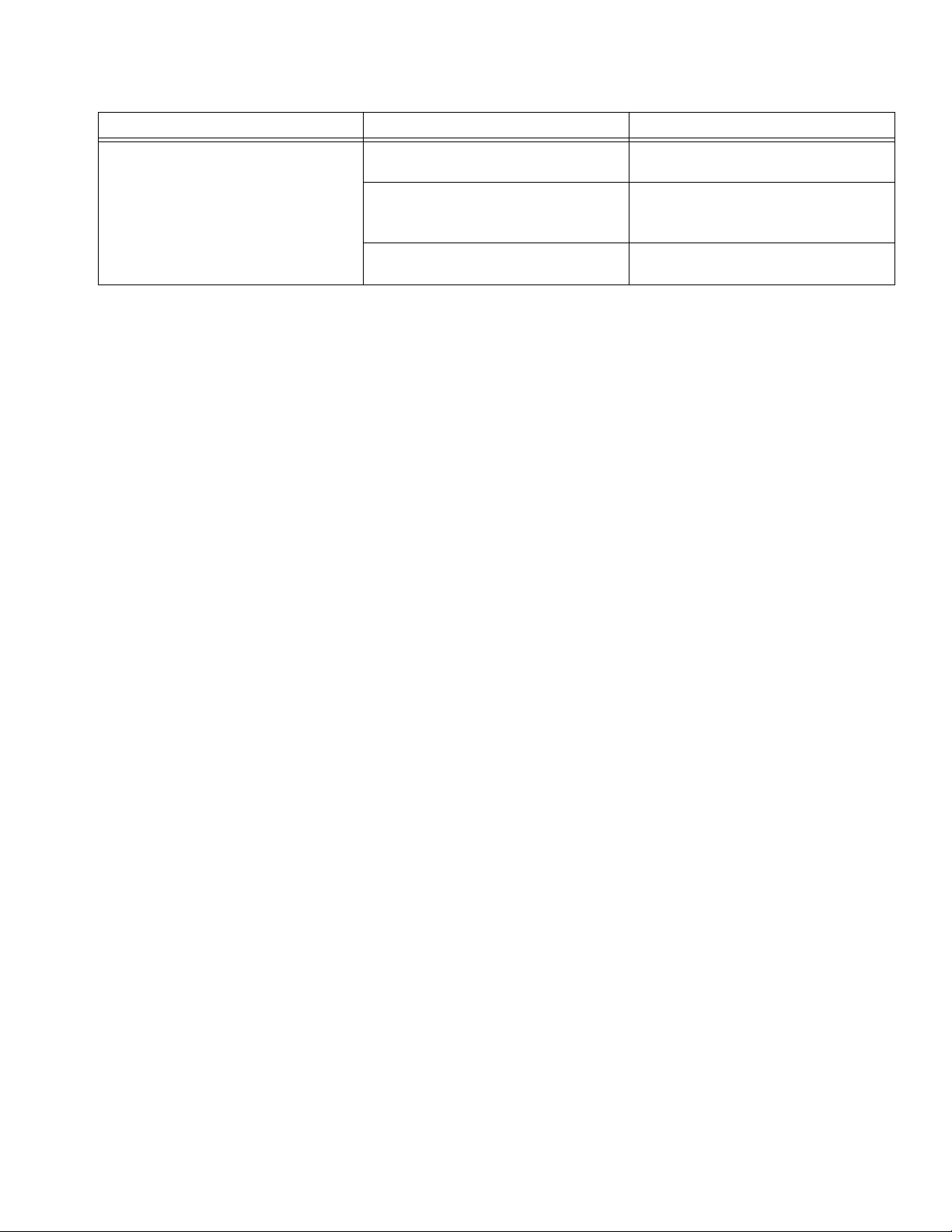

Air Valve

Seals

Air Valve

Spool

Air Valve

Slide Plate

Air Valve

Seals

Poppet

TI8624a

Poppet Piston Shaft SealsPiston O-ring

FIG. 6. Cutaway View, Standard and DataTrak Models

Linear Sensor

Poppet

Air Valve

Seals

Air Valve

Spool

Air Valve

Slide Plate

Air Valve

Seals

TI8066b

Poppet Piston Shaft SealsPiston O-ring

IG

. 7. Cutaway View, Models with Linear Sensor

F

18 311238ZAJ

Page 19

Repair

Repair

Preventive Maintenance Schedule

The operating conditions of your particular system

determine how often maintenance is required. Establish

a preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your system.

Tools Required

• Flat blade screwdriver

• Phillips screwdriver

• 3/4 in. socket wrench

• 9/16 in. socket wrench

• 3/8 in. socket wrench

• Torque wrench

4. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun to relieve pressure.

5. Engage the trigger lock.

6. Open all fluid drain valves in the system, having a

waste container ready to catch drainage. Leave

drain valve(s) open until you are ready to spray

again.

7. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

Air Valve Repair

Remove the Air Valve

•Grease

• Thread adhesive

Pressure Relief Procedure

Trapped air can cause the pump to cycle unexpectedly,

which could result in serious injury from skin injection or

moving parts.

Do not lift or move motor while pressurized.

1. Engage the trigger lock.

2. Close the bleed-type master air valve.

3. Disengage the trigger lock.

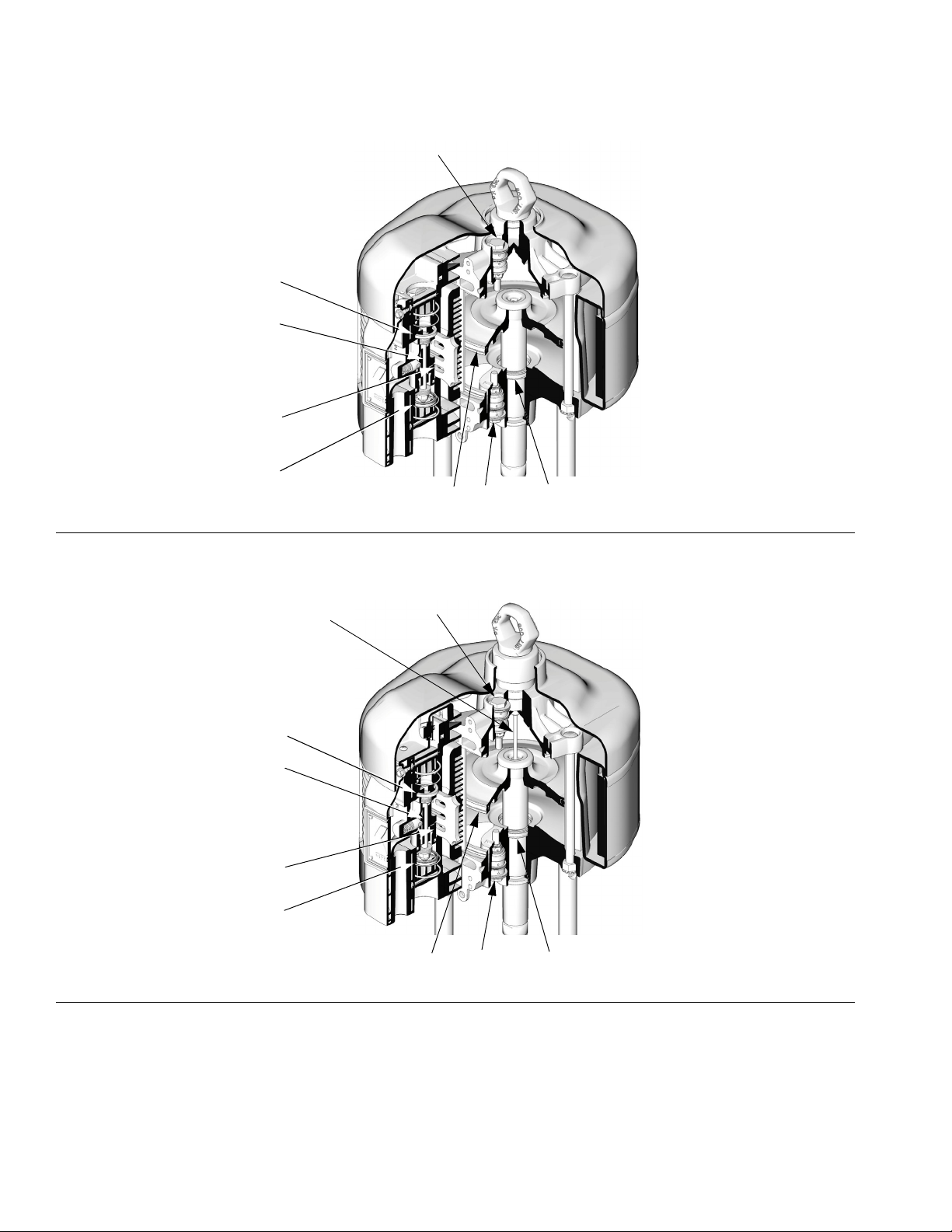

1. Stop the pump at the middle of its stroke. Relieve

the pressure, page 19.

2. Disconnect the air line to the motor.

IG

3. See F

FIG. 8. Remove the Top Cover

4. See F

5. For motors with DataTrak or the linear sensor:

. 8. Pry off the top cover (30).

30

IG

. 9. Remove the outer valve cover (47).

TI8218b

311238ZAJ 19

Page 20

Repair

a. DataTrak Models: Remove the two screws

(135). Carefully remove the DataTrak module

(131), see page 14. Disconnect the runaway

solenoid and sensor cables from the module

board. Remove the two screws (134) and carefully slide the housing (132) off the air valve.

b. Linear Sensor Models: Remove the screws

(134) and carefully slide the housing (132) off

the air valve. Disconnect the sensor cable from

the circuit board. See F

IG

. 15 on page 27.

c. Remote DataTrak Models: When removing the

outer cover (47), carefully slide the remote wire

harness and grommet from the slot in the cover.

See F

IG

. 17 on page 28.

6. Remove the screws (43 and 41). Remove the air

valve (40) by grasping the top and bottom and rotating the valve out from the right side, to pull the

exhaust housing (E) out of the muffler (15). Replace

the gaskets (46).

7. To repair the air valve, go to Disassemble the Air

Valve, page 21. To install a complete new air valve,

continue with step 8.

8. Lubricate the gaskets (46) and ensure they align

with the holes at the back of the air valve (40).

Install the air valve. Install the screws (41) and

torque to 20 ft-lb (27.1 N•m). Thread the screws (43)

in by hand, then fully tighten them against the muffler (15).

9. For motors with DataTrak or the linear sensor:

a. DataTrak Models: Carefully slide the housing

(132) onto the air valve. Thread the screws

(134) in by hand, then torque to 100 in-lb (11.3

N•m). Reattach the solenoid and sensor cables

to the DataTrak module (131), see page 14.

Carefully slide the module back into the housing

(132). Reinstall the two screws (135).

b. Linear Sensor Models: Reconnect the sensor

cable to the circuit board. See F

IG

. 15, page 27.

Carefully slide the housing (132) onto the air

valve. Thread the screws (134) in by hand, then

torque to 100 in-lb (11.3 N•m).

c. Remote DataTrak Models: When installing the

outer cover (47), carefully slide the remote wire

harness and grommet into the slot in the cover.

See F

IG

. 17 on page 28.

10. Reinstall the top cover (30).

11. Reconnect the air line to the motor.

134

6

5

Apply lubricant.

6

Thread in by hand, then torque to

100 in-lb (11.3 N•m).

11

Torque to 20 ft-lb (27.1 N•m).

17

Fully tighten against muffler (15).

135

131

E

41

11

47

F

IG

. 9. Remove the Air Valve (Model Shown with DataTrak Module)

43

132

40

17

15

43

46

5

17

TI8217c

20 311238ZAJ

Page 21

Repair

Disassemble the Air Valve

Air Valve Seal Repair Kit NXT135 is available. Parts

included in the kit are marked with a symbol (†).

Kits include the latest part and gasket improvements; use all the parts in the kit.

Air Valve Rebuild Kit NXT144 is available. Parts

included in the kit are marked with a symbol (‡).

Kits include the latest part and gasket improvements; use all the parts in the kit.

1. Perform steps 1-6 under Remove the Air Valve,

page 19.

IG

2. See F

cover (112), spring-loaded detent (113), gasket

(106), and de-icing control (145).

3. See F

their holes (J). Invert the pins and slide the heads

into the slots on the piston stops (110). Use the pins

to pull the piston stops out.

. 11. Remove the screws (124), carriage

IG

. 10. Remove the retainer pins (111) from

6. Carefully remove the sleeves (109). Inspect the

seals (109a) and the inside surface of the sleeves

and housing (103) for wear or damage.

7. Remove the carriage (108) and carriage detent

(107).

8. Remove the screws (123), retainers (117), valve

plate (105), and seal (104).

9. Inspect the ramp (107), carriage (108), plate (105),

body (103), and seal (104) for damage or cracks.

Reassemble the Air Valve

1. Install a new gasket (102†‡) between valve body

(103) and exhaust cover (101).

2. Lubricate the valve plate (105‡). Install the seal

(104†‡) and plate (105‡) in the valve body (103).

Thread the screws (123) and retainers (117) in by

hand, then evenly torque to 21-23 ft-lb (28.5-31.1

N•m). Lubricate the sealing face of the carriage

(108‡). Install the carriage and ramp (107‡).

111

110

J

F

IG

. 10. Remove Piston Stops

4. See F

IG

. 11. Rotate the piston valve assembly (119)

TI7758a

so the pins (P) are accessible. Raise the spring (S)

and push one pin out. Push one end of the piston

valve out the top of the valve body (103) and the

other end out the bottom. Do not permanently distort

the springs (S).

5. Inspect the piston and seals. If damaged, replace

the piston valve assembly (119). The open seal lip

must face to the center.

3. Lubricate o-rings (109a) on sleeves (109‡). Install

the sleeves. Lubricate the inside surfaces.

4. Lubricate pistons and seals of piston valve assembly (119) with lithium grease. Install one end of the

piston valve assembly in the valve body (103).

Rotate the piston so the pin holes are accessible.

Install the other end and secure with the pin (P) and

spring (S).

CAUTION

Do not permanently distort the springs. The springs

must be completely tight against the piston valve

assembly (119) to prevent interference. Ensure the

two spring wire ends are not on one side of the clip.

311238ZAJ 21

Page 22

Repair

5. Lubricate o-rings (110a). Install the piston stop

(110) and retainer pins (111).

IG

6. See F

. 11. Lubricate and install the spring-loaded

detent (113‡), gasket (106†‡), carriage cover (112),

and screws (124). Torque to 130 in-lb (4.7 N•m), following the pattern shown in Inset 11a.

9

6

2

4

8

5

1

3

7

10

NXT145

Inset 11a. Torque Pattern

110

1

110a

1

‡109

1

109a

1

119 (Ref)

1

7. See F

ensure they align with the holes at the back of the

air valve (40). Install the air valve. Install the screws

(41) and torque to 20 ft-lb (27.1 N•m). Thread the

screws (43) in by hand, then fully tighten them

against the muffler (15).

8. For motors with DataTrak or the linear sensor, reinstall the modules, see step 9, page 20.

1

Apply high quality lithium grease.

2

Important: Do not permanently distort spring (S). Spring must

be completely tight against piston (119) to prevent interference.

5

Torque to 130 in-lb (4.7 N•m).

7

Thread in by hand, then torque to 21-23 ft-lb (28.5-31.1 N•m).

†‡106111 103

1

IG

. 9, page 20. Lubricate the gaskets (46) and

102†‡

1

101

S

2

P

1

‡113

138

◆

◆

112

139

144

140 †‡142

1

8

8

124

5

F

IG

. 11. Air Valve Repair (NXT107 Shown)

145

1

1

1

109a

‡109

110a

1

110

119

1

107‡

108‡

104†‡

1

105‡

117

123

7

1

TI11295b

22 311238ZAJ

Page 23

Repair

Cylinder and Piston Repair

Air Motor Seal Repair Kits are available. See the

parts lists on pages 31, 33, and 35 for the correct

kit for your size motor. Parts included in the kits are

marked with an asterisk (*). For the best results,

use all the parts in the kit.

Disassemble the Air Motor

1. Stop the pump at the middle of its stroke. Relieve

the pressure, page 19.

2. Disconnect the air line to the motor.

3. See F

4. For motors with DataTrak or the linear sensor:

IG

. 8 on page 19. Pry off the top cover (30).

a. DataTrak Models: Remove the two screws

(135). Carefully remove the DataTrak module

(131), see page 14. Disconnect the runaway

solenoid and sensor cables from the module

board. Remove the two screws (134) and carefully slide the housing (132) off the air valve.

b. Linear Sensor Models: Remove the screws

(134) and carefully slide the housing (132) off

the air valve. Disconnect the sensor cable from

the circuit board. See F

IG

. 15 on page 27.

5. Remove the outer valve cover (47). See F

6. Remove the four screws (43) and the muffler (15).

7. Remove the top two air valve screws (41). Loosen

but do not remove the bottom two screws (41). Tilt

the air valve (40) to make disassembly easier.

8. Remove the tie bolts (13). Using a rubber mallet, hit

the underside of the top cap (1) to separate. Lift the

top cap off the motor.

9. Disconnect the air motor from the lower (see your

separate pump manual). Leave the piston shaft

adapter (A) attached to the shaft (S).

10. Push the piston assembly (4) out the top of the cylinder (2).

11. Inspect the piston o-ring (17). Check the piston (4)

and piston shaft (S) for scoring or damage. The

replacement piston (4) includes the piston, shaft (S),

adapter (A), and bumper (10).

12. Remove the cylinder (2). Check the inner surface for

scoring or other damage. Replace if damaged.

13. Remove the bumper (59), retaining ring (9), backup

packings (8), and v-packing (7) from the bottom

cover (3). Inspect these parts for wear or damage.

Inspect the bearing (B) in place (slight scoring is

acceptable). If the bearing is damaged, replace the

bottom cover (3).

IG

. 12.

311238ZAJ 23

Page 24

Repair

5

5

5

10

*17

4

10

S

13

A

12

5 9

43

17

41

11

47

40

TI8219C

46*

FIG. 12. Air Motor Repair

2

18*

5

1

13

43

46*

12

5109

17

59

9*

18

5

7*

18

*8

5

18

5

B

Linear Sensor

1

Models

TI8220a

12

5 9

3

14

5

Apply high quality lithium grease.

9

Torque to 30-36 ft-lb (40.6-48.8 N•m).

10

Torque to 38-42 ft-lb (51.3-56.7 N•m).

Use 3/8 in. drive socket to fit in recess.

11

Torque to 20 ft-lb (27.1 N•m).

17

Fully tighten against muffler (15).

Installation order: two leather o-rings (8), one u-cup

18

(7) facing up, and one spiral ring (9). Installation order

changed with series H air motors.

24 311238ZAJ

Page 25

Repair

Reassemble Air Motor

1. See FIG. 12. Install two backup packings (8*), and

then v-packing (7*) with the lips facing up. Then

install the retaining ring (9*) in the bottom cover (3).

Lubricate the packings. Install the bumper (59).

Prior to series H air motors the u-cup (7) was

installed between the leather packings (8).

2. Install the o-ring (17*) on the piston (4). Ensure the

piston bumper (10) is in place.

It is normal for the o-ring (17*) to seem too large.

3. Install the piston assembly on the bottom cover (3),

carefully sliding the adapter (A) and shaft (S)

through the packings.

4. Grease the inside of the cylinder (2). Place the cylinder (2) over the piston (4). Be careful not to damage

the o-ring (17*). Slowly work the o-ring into the

groove, compressing it until the cylinder slides over.

10. Reinstall the muffler (15). Fully tighten the screws

(43) against the muffler.

11. Reinstall the outer valve cover (47).

12. For motors with DataTrak or the linear sensor:

a. DataTrak Models: Carefully slide the housing

(132) onto the air valve. Thread the screws

(134) in by hand, then torque to 100 in-lb (11.3

N•m). Reattach the solenoid and sensor cables

to the DataTrak module (131), see page 14.

Carefully slide the module back into the housing

(132). Reinstall the two screws (135).

b. Linear Sensor Models: Reconnect the sensor

cable to the circuit board. See F

IG

. 15, page 27.

Carefully slide the housing (132) onto the air

valve. Thread the screws (134) in by hand, then

torque to 100 in-lb (11.3 N•m).

13. Reinstall the top cover (30).

14. Reconnect the air line to the motor.

It is normal for the o-ring (17*) to seem too large to

fit into the cylinder.

5. Carefully place the top cap on the cylinder (2) so the

flat edge aligns with the flat edge of the bottom

cover (3). Install the tie bolts (13) hand tight.

6. Using new gaskets (46), reinstall the valve assembly with the top two air valve screws (41) and torque

to 20 ft-lb (27.1 N•m). Install the bottom two air

valve screws (41) tight to align the end caps (1) and

bottom cover (3). Then loosen the two bottom

screws (41).

7. Torque end cap tie bolts (13) evenly to 38-42 ft-lb

(51.3-56.7 N•m).

8. Retighten the bottom two air valve screws (41) and

torque to 20 ft-lb (27.1 N•m).

9. Reconnect the air motor to the lower (see your separate pump manual).

See Accessories, page 41, for a list of available

adapters to connect the NXT motor to various

Graco lowers.

311238ZAJ 25

Page 26

Repair

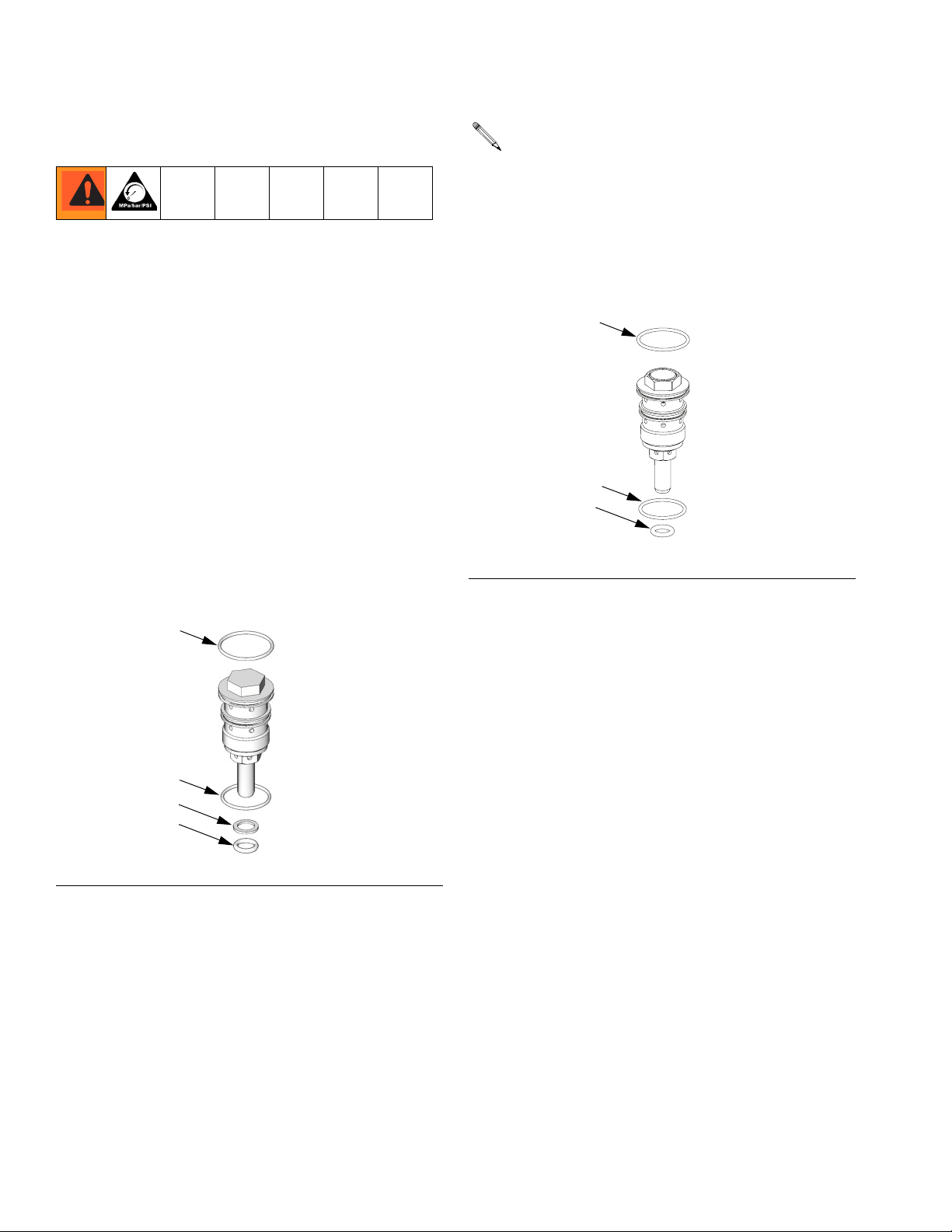

Poppet Repair

1. Stop the pump at the middle of its stroke. Relieve

the pressure, page 9.

2. Disconnect the air line to the motor.

3. See F

4. See F

5. Inspect the poppet o-rings (12a, 12b, 12d) and

6. Lubricate the poppet assemblies (12) and reinstall

IG

. 8 on page 19. Pry off the top cover (30).

IG

. 13. Unscrew the poppet assemblies (12).

The small o-rings (12c, 12d) may not come out with

the poppet assemblies. Be sure to remove them

from the top cap (1) or bottom cover (3).

backup (12c). Replace damaged o-rings, or replace

the entire poppet assembly.

in the top cap (1) and bottom cover (3). Torque to

30-36 ft-lb (40.6-48.8 N•m).

Poppets were upgraded in mid-2009 for improved

sealing and earlier actuation. New style poppets

can be used in older air motors, but do not use the

back-up o-ring (12c).

If you order a replacement poppet NXT100, you will

automatically receive a new style poppet.

12b

12a

12d

F

IG

. 14. New Style Poppet Detail

12b

12a

12c

12d

FIG. 13. Original Poppet Detail

TI7750b

26 311238ZAJ

Page 27

Repair

Replace the Linear Sensor (if present)

1. Stop the pump at the middle of its stroke. Relieve

the pressure, page 9.

2. Disconnect the air line to the motor.

3. See F

4. Hold the adapter (33) with a wrench to keep it from

5. Remove the screws (134) and carefully slide the

IG

. 8 on page 19. Pry off the top cover (30).

turning, and unscrew the lift ring (21). See F

IG

. 16.

housing (132) off the air valve. Disconnect the sensor cable from the circuit board. See F

IG

. 15.

Sensor Cable

Connection

10. Thread the sensor cable through the hole (H) in the

side of the adapter, and reconnect it to the circuit

board. See F

IG

. 15, page 27. Carefully slide the

housing (132) onto the air valve. Thread the screws

(134) in by hand, then torque to 100 in-lb (11.3

N•m).

11. Apply thread adhesive to the lift ring (21). Hold the

adapter (33) with a wrench to keep it from turning,

and torque the lift ring to 30-36 ft-lb (40.6-48.8 N•m).

12. Reinstall the top cover (30).

13. Reconnect the air line to the motor.

6

Thread in by hand, then torque to 100 in-lb (11.3 N•m).

8

Apply adhesive.

9

Torque to 30-36 ft-lb (40.6-48.8 N•m).

30

TI8075a

FIG. 15. Sensor Cable Connection

6. Thread the cable back through the hole (H) in the

side of the adapter (33) and extend it out the top of

the adapter.

7. Unscrew the adapter (33) and sensor (35). Lift the

sensor straight up out of the air motor.

8. Apply thread adhesive to the new sensor housing.

Screw the sensor (35) into the top cap (1). Torque to

30-36 ft-lb (40.6-48.8 N•m).

9. Apply thread adhesive to the adapter (33). Extend

the sensor cable straight up out the top of the

adapter, then screw the adapter into the top cap (1).

Torque to 30-36 ft-lb (40.6-48.8 N•m).

H

134

6

132

FIG. 16. Replace the Linear Sensor

21

33

35

8 9

8 9

8

TI7756c

9

1

311238ZAJ 27

Page 28

Repair

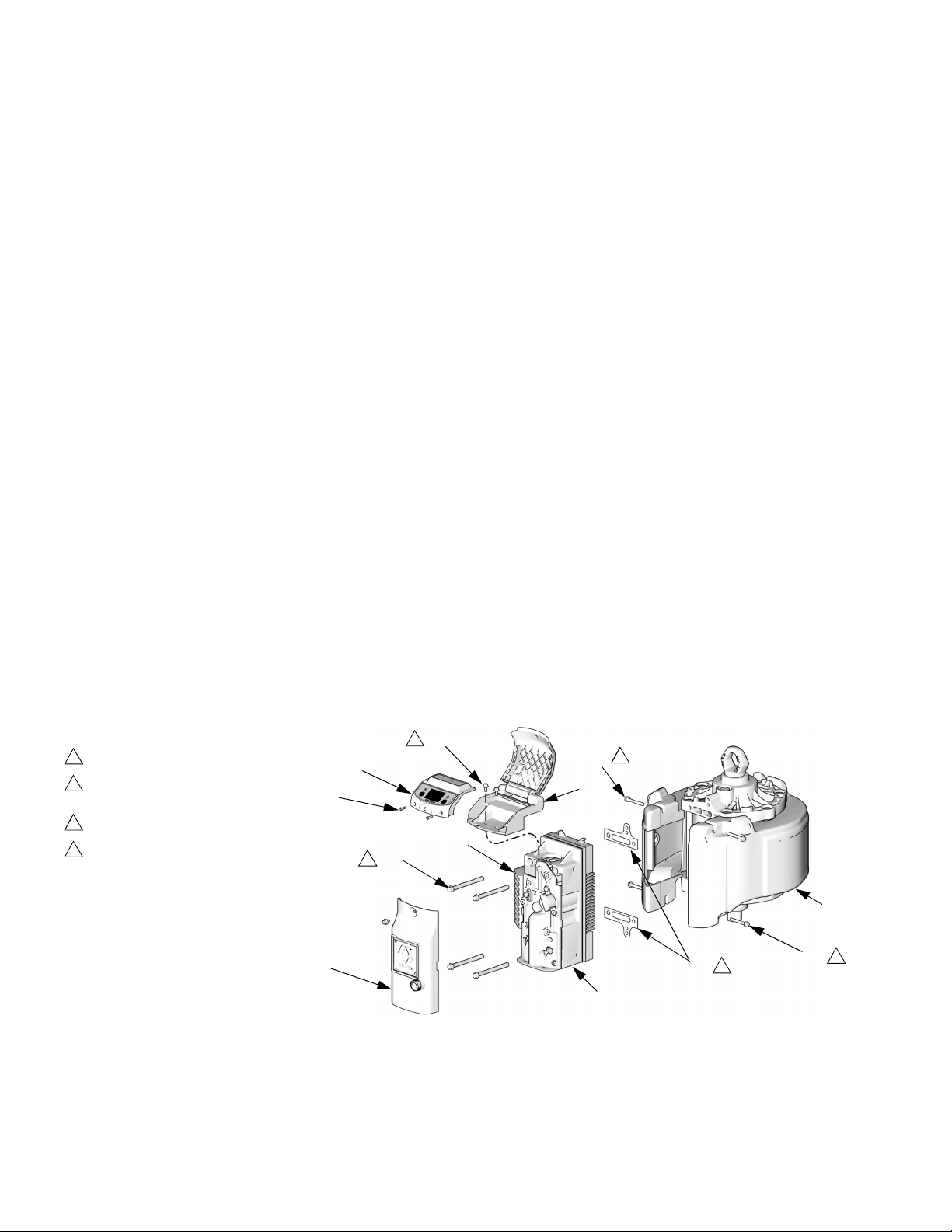

Remote DataTrak Connection Kit NXT406

A

1. Stop the pump during the upstroke. Follow the

Pressure Relief Procedure, page 19.

2. Disconnect the air line to the motor.

3. Pry off the top cover. Remove the air valve cover

and discard.

4. Install the reed switch sensor (139) and secure with

the screw (124) and o-ring (144). See F

nect the reed switch sensor cable (R) to the remote

DataTrak wire harness (76).

5. Route the wires to the top of the air valve. Install the

wire strain relief (74) with screw (45) and washer

(75) onto the reed switch sensor about 2 in. (50 mm)

behind the connection (C).

6. Route the remote DataTrak wire harness (76) down

the front of the air valve and carefully slide the

grommet (G) into the slot (S) of the new air valve

cover (47). There should be about 3 in. (76 mm) of

wire extending out of the air valve cover.

7. Install the new air valve cover (47) with the screw

(45), positioning the wire harness (76) so it will not

be pinched.

IG

. 17. Con-

124

144

139

IG

. 17. Remote DataTrak Connection Kit

F

45

75

74

C

76

R

45

47GS

TI10949A

8. Reinstall the top cover (A).

9. Reconnect the air line to the motor.

10. Plug the cable from the remote DataTrak module

into the wire harness (76).

See your system operation manuals for complete

remote DataTrak instructions.

28 311238ZAJ

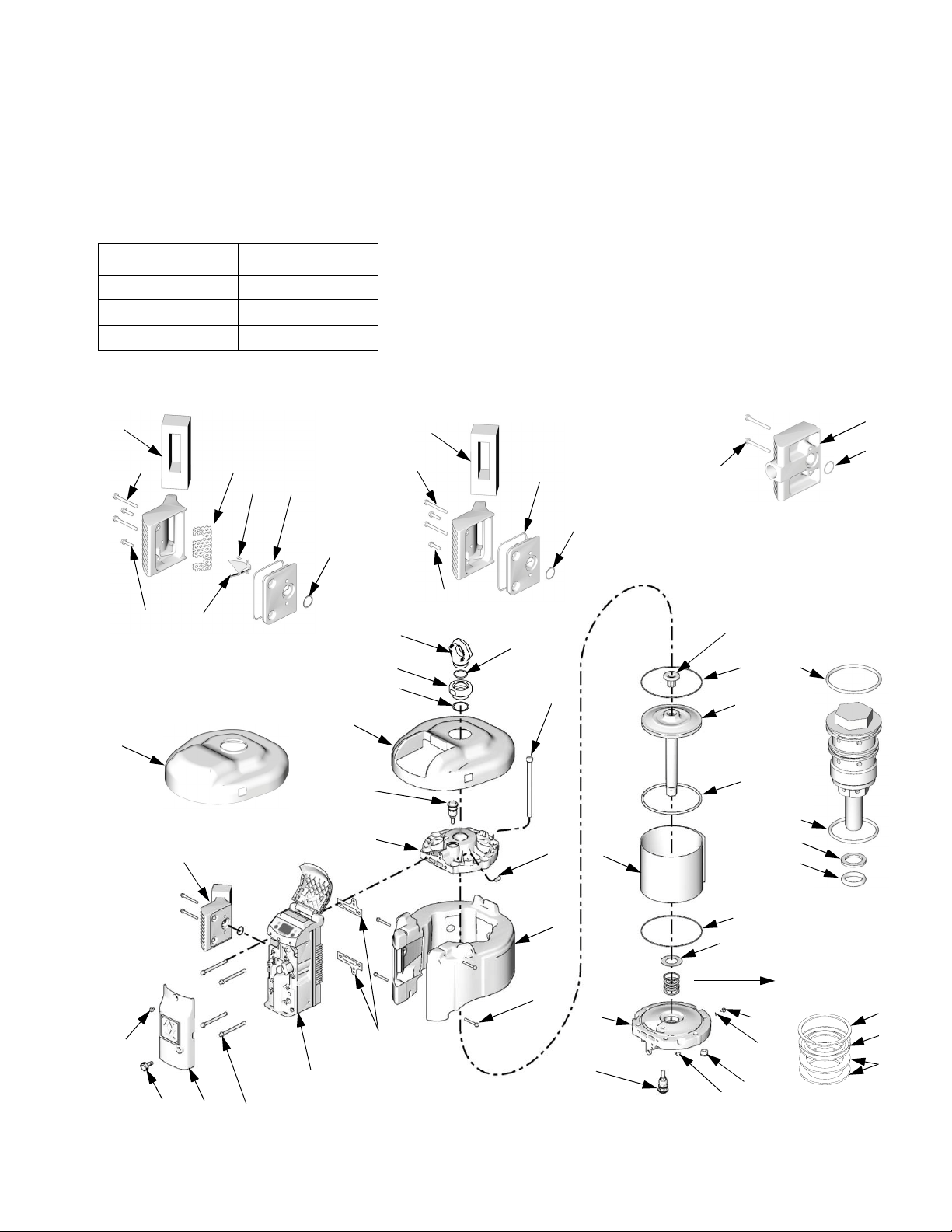

Page 29

Parts

Air Motor Parts Drawing (Shown with DataTrak and Low Noise Exhaust)

Air Motor Model Parts List Page

NXT Model 2200 31

NXT Model 3400 33

NXT Model 6500 35

Parts

56

44

25

Top Cover (30) Detail for

Models without DataTrak

30

See Exhaust

Details Above

63

55

54

56

57

TI9421b

TI8620a

20

30

12

De-Ice Exhaust (22) DetailLow Noise Exhaust (24) Detail

56

44

25

21

65

64

1

57

TI9422b

66

13

58

20

2

Remote Exhaust (23) Detail

23

20

44

TI8801a

Poppet (12)

10

18*

4

17*

†12c

Detail

(see page 26)

12b

12a

12d

TI7750b

15

18*

59

Packing

43

}

3

45

40

41

47

62

311238ZAJ 29

46*

12

58

Order Detail

60

61

14

9*

7*

8*

TI8214d

Page 30

Parts

Air Motor Parts Drawing (Shown with Linear Sensor)

Air Motor Model Parts List Page

NXT Model 2200 31

NXT Model 3400 33

NXT Model 6500 35

Remote Exhaust (23) DetailDe-Ice Exhaust (22) DetailLow Noise Exhaust (24) Detail

56

44

63

55

57

20

44

56

57

44

20

23

20

TI8801a

25

54

Packing

Order Detail

See Exhaust

Details Above

9*

7*

8*

TI9421b

21

30

33

35

12

25

TI9422b

Poppet (12)

Detail

10

*18

13

45

1

2

36

58

15

}

(see page 26)

12b

4

17*

112a

†12c

112d

TI7750b

18*

59

See Packing

Order Detail

3

43

45

40

62

47

30 311238ZAJ

41

46*

12

58

60

61

14

TI7748e

Page 31

NXT Model 2200 Air Motors

Parts

NXT Model 2200 Common Parts

Ref. Part Description Qty

1 15F955 COVER, top 1

2 NXT204 CYLINDER 1

3 NXT202 COVER, bottom 1

4 NXT201 PISTON ASSEMBLY 1

7* 161562 PACKING, V-block; nitrile 1

8* 15H610 PACKING, backup; leather 2

9* 16A026 RING, retaining 1

10 NXT106 BUMPER, piston; includes magnet 1

12 NXT100 POPPET; includes items 12a-12d 2

12a

12b . O-RING; buna-N 1

12c† . O-RING, backup; buna-N 1

12d . O-RING; buna-N 1

13 119050 BOLT, hex hd; 1/2-13 x 8 in.

NXT101

. O-RING; buna-N 1

(203 mm)

Ref. Part Description Qty

14 15F639 NUT, with lockwasher; 1/2-13 4

15 NXT203 MUFFLER 1

17* 123196 O-RING, piston; nitrile 1

18* 15F449 O-RING, end cap; nitrile 2

20★ 119990 O-RING; buna-N 1

21 15F931 RING, lift 1

41 120088 SCREW; 3/8-16 x 4 in. (101 mm) 4

43 120091 SCREW, thread forming; 1/4-20 x 2

in. (51 mm)

44 120092 SCREW, thread forming; 1/4-20 x

2-1/2 in. (63 mm)

46* 253476 GASKET 1

47 287844 COVER, valve, outer 1

51▲ 15F674 LABEL, safety 1

52▲ 15F973 LABEL, safety 1

4

58 120206 MUFFLER, poppet 2

59 277366 BUMPER 1

60 116343 SCREW, ground; M5 x 0.8 1

61 111307 WASHER, lock; 5 mm 1

62 NXT112 KNOB, de-ice 1

4

2

311238ZAJ 31

Page 32

Parts

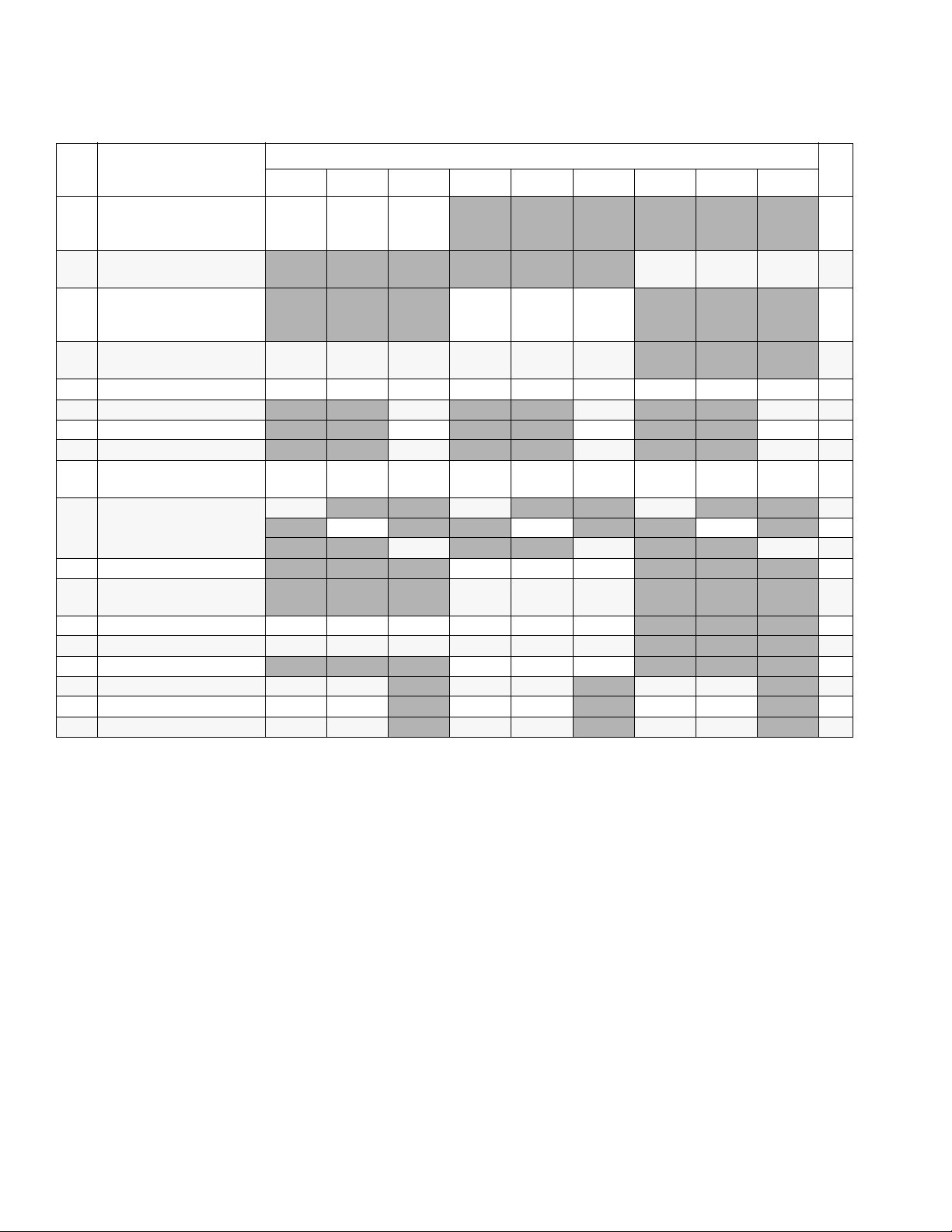

NXT Model 2200 Varying Parts

Air Motor Part Numbers

Ref. Description

22 KIT, de-ice exhaust,

includes items 20, 25, 44,

56, 57

23 KIT, remote exhaust;

includes items 20, 44

24 KIT, low noise exhaust;

includes items 20, 22, 25,

44, 54, 55, 56, 57, 63

25 SCREW, machine, hex

hd; 1/4-20 x 1 in. (25 mm)

30 COVER, top 15G377 15G576 15G379 15G377 15G576 15G379 15G377 15G576 15G379 1

33 ADAPTER, lift ring 15F772 15F772 15F772 1

35 SENSOR ASSEMBLY 287839 287839 287839 1

36 GUIDE, strain relief 120143 120143 120143 1

40 AIR VALVE ASSEMBLY;

see page 38

45 SCREW, thread-forming;

1/4-20 x 1/2 in. (13 mm)

54★ DEFLECTOR

55★ SCREW, thread-forming;

1/4-20 x 1/2 in. (13 mm)

56 SEAL, exhaust 15H190 15H190 15H190 15H190 15H190 15H190

57★ GASKET; buna-N 15K345 15K345 15K345 15K345 15K345 15K345 1

63★ DIFFUSER, exhaust

64 O-RING 108014 108014 108014 108014 108014 108014 1

65 ADAPTER, lift ring 16D001 16D001 16D001 16D001 16D001 16D001 1

66 O-RING C20987 C20987 C20987 C20987 C20987 C20987 1

NXT110 NXT110 NXT110

NXT105 NXT105 NXT105 1

NXT104 NXT104 NXT104 1

120730 120730 120730 120730 120730 120730 2

NXT107 NXT108 NXT109 NXT107 NXT108 NXT109 NXT107 NXT108 NXT109 1

107257 107257 107257 1

107257 107257 107257 3

107257 107257 107257 4

15H179 15H179 15H179 1

107257 107257 107257 2

15G689 15G689 15G689 1

QtyN22DN0 N22DT0 N22DH0 N22LN0 N22LT0 N22LH0 N22RN0 N22RT0 N22RH0

1

1

▲

Replacement Danger and Warning labels, tags, and cards are available at no cost.

* Parts included in Repair Kit NXT200 (purchase separately).

★

Parts included in Low Noise Exhaust Conversion Kit NXT111 (purchase separately).

IG

† Only used on original poppets (see F

. 13) made prior to mid-2009.

32 311238ZAJ

Page 33

NXT Model 3400 Air Motors

Parts

NXT Model 3400 Common Parts

Ref. Part Description Qty

1 15F954 COVER, top 1

2 NXT304 CYLINDER 1

3 NXT302 COVER, bottom 1

4 NXT301 PISTON ASSEMBLY 1

7* 161562 PACKING, V-block; nitrile 1

8* 15H610 PACKING, backup; leather 2

9* 16A026 RING, retaining 1

10 NXT106 BUMPER, piston; includes magnet 1

12 NXT100 POPPET; includes items 12a-12d 2

12a

12b . O-RING; buna-N 1

12c† . O-RING, backup; buna-N 1

12d . O-RING; buna-N 1

13 119050 BOLT, hex hd; 1/2-13 x 8 in.

NXT101

. O-RING; buna-N 1

(203 mm)

Ref. Part Description Qty

14 15F639 NUT, with lockwasher; 1/2-13 6

15 NXT303 MUFFLER 1

17* 122434 O-RING, piston; nitrile 1

18* 15F449 O-RING, end cap; nitrile 2

20★ 119990 O-RING; buna-N 1

21 15F931 RING, lift 1

41 120088 SCREW; 3/8-16 x 4 in. (101 mm) 4

43 120091 SCREW, thread forming; 1/4-20 x 2

in. (51 mm)

44 120092 SCREW, thread forming; 1/4-20 x

2-1/2 in. (63 mm)

46* 253476 GASKET 1

47 287844 COVER, valve, outer 1

51▲ 15F674 LABEL, safety 1

52▲ 15F973 LABEL, safety 1

6

58 120206 MUFFLER, poppet 2

59 277366 BUMPER 1

60 116343 SCREW, ground; M5 x 0.8 1

61 111307 WASHER, lock; 5 mm 1

62 NXT112 KNOB, de-ice 1

4

2

311238ZAJ 33

Page 34

Parts

NXT Model 3400 Varying Parts

Air Motor Part Numbers

N34LN0

Ref. Description

22 KIT, de-ice exhaust,

includes items 20, 25, 44,

56, 57

23 KIT, remote exhaust;

includes items 20, 44

24 KIT, low noise exhaust;

includes items 20, 22, 25,

44, 54, 55, 56, 57

25 SCREW, machine, hex

hd; 1/4-20 x 1 in. (25 mm)

30 COVER, top 15G556 15G575 15G558 15G556 15G575 15G558 15G556 15G575 15G558 1

33 ADAPTER, lift ring 15F772 15F772 15F772 1

35 SENSOR ASSEMBLY

36 GUIDE, strain relief 120143 120143 120143 1

40 AIR VALVE ASSEMBLY;

see page 38

45 SCREW, thread-forming;

1/4-20 x 1/2 in. (13 mm)

54★ DEFLECTOR 15H179 15H179 15H179 1

55★ SCREW, thread-forming;

1/4-20 x 1/2 in. (13 mm)

56 SEAL, exhaust 15H190 15H190 15H190 15H190 15H190 15H190

57★ GASKET; buna-N 15K345 15K345 15K345 15K345 15K345 15K345 1

63★ DIFFUSER, exhaust 15G689 15G689 15G689 1

64 O-RING 108014 108014 108014 108014 108014 108014 1

65 ADAPTER, lift ring 16D001 16D001 16D001 16D001 16D001 16D001 1

66 O-RING C20987 C20987 C20987 C20987 C20987 C20987 1

NXT110 NXT110 NXT110

120730 120730 120730 120730 120730 120730 2

287839 287839 287839 1

NXT107 NXT108 NXT109 NXT107 NXT108 NXT109 NXT107 NXT108 NXT109 1

107257 107257 107257 1

107257 107257 107257 3

107257 107257 107257 4

N34LN2 N34LT0 N34LH0 N34RN0 N34RT0 N34RH0

NXT105 NXT105 NXT105 1

NXT104 NXT104 NXT104 1

107257 107257 107257 2

QtyN34DN0 N34DT0 N34DH0

1

1

▲

Replacement Danger and Warning labels, tags, and cards are available at no cost.

* Parts included in Repair Kit NXT300 (purchase separately).

★

Parts included in Low Noise Exhaust Conversion Kit NXT111 (purchase separately).

† Only used on original poppets (see F

IG

. 13) made prior to mid-2009.

34 311238ZAJ

Page 35

Parts

NXT Model 6500 Air Motors

NXT Model 6500 Common Parts

Ref. Part Description Qty

1 15F953 COVER, top 1

2 NXT604 CYLINDER 1

3 NXT602 COVER, bottom 1

4 NXT601 PISTON ASSEMBLY 1

7* 161562 PACKING, V-block; nitrile 1

8* 15H610 PACKING, backup; leather 2

9* 16A026 RING, retaining 1

10 NXT106 BUMPER, piston; includes magnet 1

12 NXT100 POPPET; includes items 12a-12d 2

12a

12b . O-RING; buna-N 1

12c† . O-RING, backup; buna-N 1

12d . O-RING; buna-N 1

13 119050 BOLT, hex hd; 1/2-13 x 8 in.

NXT101

. O-RING; buna-N 1

(203 mm)

Ref. Part Description Qty

14 15F639 NUT, with lockwasher; 1/2-13 6

15 NXT603 MUFFLER 1

17* 122675 O-RING, piston; nitrile 1

18* 15F448 O-RING, end cap; nitrile 2

20★ 119990 O-RING; buna-N 1

21 15F931 RING, lift 1

41 120088 SCREW; 3/8-16 x 4 in. (101 mm) 4

43 120091 SCREW, thread forming; 1/4-20 x 2

in. (51 mm)

44 120092 SCREW, thread forming; 1/4-20 x

2-1/2 in. (63 mm)

46* 253476 GASKET 1

47 287844 COVER, valve, outer 1

51▲ 15F674 LABEL, safety 1

52▲ 15F973 LABEL, safety 1

58 120206 MUFFLER, poppet 2

59 277366 BUMPER 1

60 116343 SCREW, ground; M5 x 0.8 1

6

61 111307 WASHER, lock; 5 mm 1

62 NXT112 KNOB, de-ice 1

4

2

311238ZAJ 35

Page 36

Parts

NXT Model 6500 Varying Parts

Air Motor Part Numbers

N65LN0

Ref. Description

22 KIT, de-ice exhaust,

includes items 20, 25,

44, 56, 57

23 KIT, remote exhaust;

includes items 20, 44

24 KIT, low noise exhaust;

includes items 20, 22,

25, 44, 54, 55, 56, 57

25 SCREW, machine, hex

hd; 1/4-20 x 1 in. (25

mm)

30 COVER, top 16R866 16R868 15F880 16R866 16R868 15F880 16R866 16R868 15F880 15F880 1

33 ADAPTER, lift ring 15F772 15F772 15F772 15F772 1

35 SENSOR ASSEMBLY

36 GUIDE, strain relief 120143 120143 120143 120143 1

40 AIR VALVE ASSEM BLY;

see page 38

45 SCREW, thread-form-

ing; 1/4-20 x 1/2 in. (13

mm)

54★ DEFLECTOR

55★ SCREW, thread-form-

ing; 1/4-20 x 1/2 in. (13

mm)

56 SEAL, exhaust 15H190 15H190 15H190 15H190 15H190 15H190

57★ GASKET; buna-N 15K345 15K345 15K345 15K345 15K345 15K345 15K345 1

63★ DIFFUSER, exhaust

NXT110 NXT110 NXT110

120730 120730 120730 120730 120730 120730 120730 2

287839 287839 287839 256893 1

NXT107 NXT108 NXT109 NXT107 NXT108 NXT109 NXT107 NXT108 NXT109 NXT109 1

107257 107257 107257 1

107257 107257 107257 3

107257 107257 107257 107257 4

N65LN2 N65LT0 N65LH0 N65RN0 N65RT0 N65RH0 257055

NXT110 1

NXT105 NXT105 NXT105 1

NXT104 NXT104 NXT104 1

15H179 15H179 15H179 1

107257 107257 107257 2

15H190 1

15G689 15G689 15G689 1

64 O-RING 108014 108014 108014 108014 108014 108014 1

65 ADAPTER, lift ring 16D001 16D001 16D001 16D001 16D001 16D001 1

66 O-RING C20987 C20987 C20987 C20987 C20987 C20987 1

QtyN65DN0 N65DT0 N65DH0

▲

Replacement Danger and Warning labels, tags, and cards are available at no cost.

* Parts included in Repair Kit NXT600 (purchase separately).

★

Parts included in Low Noise Exhaust Conversion Kit NXT111 (purchase separately).

IG

† Only used on original poppets (see F

. 13) made prior to mid-2009.

36 311238ZAJ

Page 37

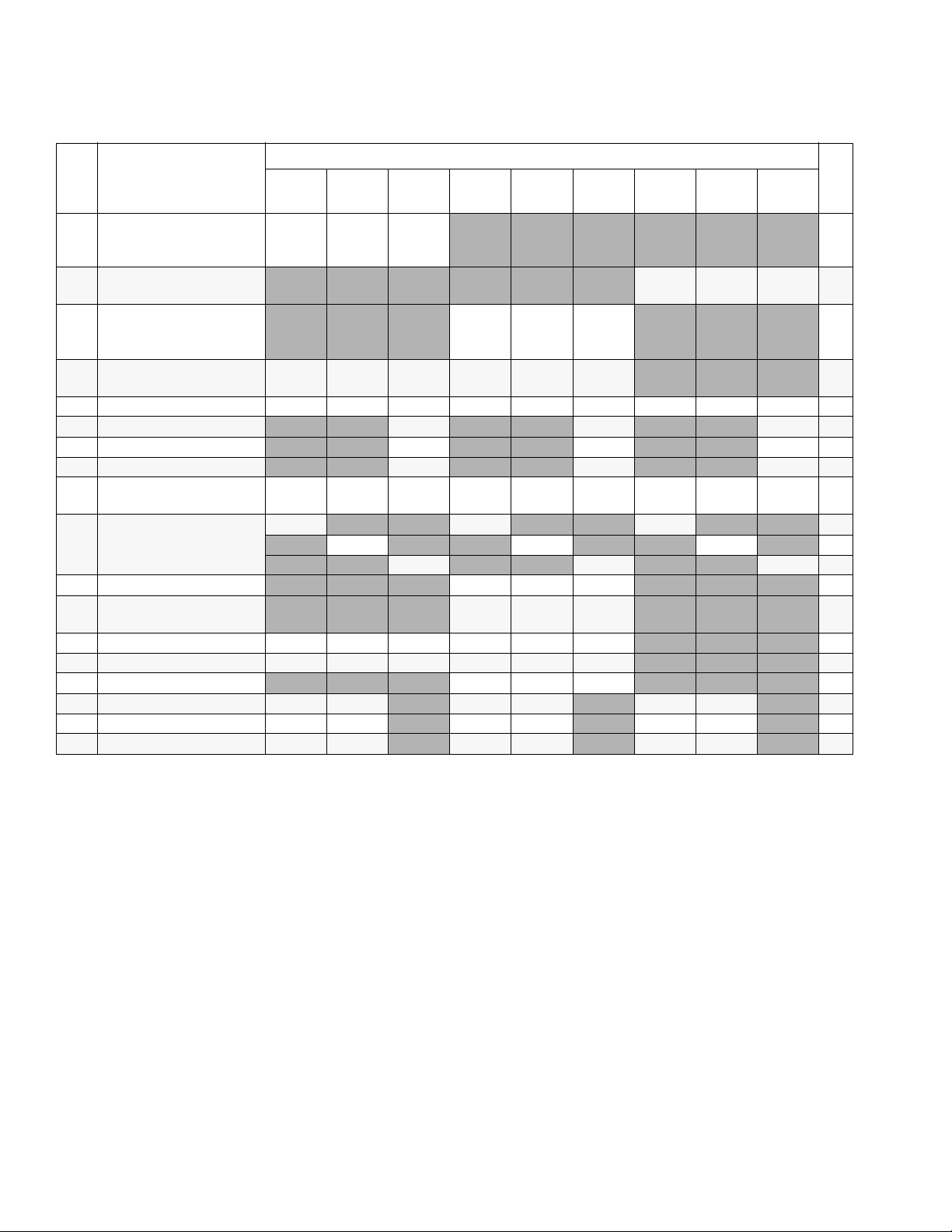

Air Motor Parts Drawing (for use with Remote DataTrak)

Air Motor Models

N22LR0

N34LR0

N65LR0

Low Noise Exhaust (24) Detail

56

Parts

44

25

See Exhaust

Details Above

76

45

62

54

47

63

55

41

57

TI9421b

40

45

75

74

20

30

12

1

21

65

64

46*

66

43

13

58

15

12

Poppet (12)

10

18*

4

17*

2

18*

59

3

60

61

14

58

Detail

(see page 26)

12b

12a

†12c

12d

TI7750b

Packing

Order Detail

9*

7*

8*

TI10948B

311238ZAJ 37

Page 38

Parts

Air Motor Parts List (for use with Remote DataTrak)

Air Motor Models

N22LR0

N34LR0

N65LR0

The parts listed below are common to all NXT Model Air Motors using the remote DataTrak. Parts which vary by air

motor are found in the table at the bottom of this page.

Ref. Part Description Qty

7* 161562 PACKING, V-block; nitrile 1

8* 15H610 PACKING, backup; leather 2

9* 16A026 RING, retaining 1

10 NXT106 BUMPER, piston; includes magnet 1

12 NXT100 POPPET; includes items 12a-12d 2

12a

12b . O-RING; buna-N 1

NXT101

12c† . O-RING, backup; buna-N 1

12d . O-RING; buna-N 1

13 119050 BOLT, hex hd; 1/2-13 x 8 in. (203 mm) 4

14 15F639 NUT, with lockwasher; 1/2-13 4

18* 15F449 O-RING, end cap; nitrile 2

20★ 119990 O-RING; buna-N 1

21 15F931 RING, lift 1

24 NXT104 KIT, low noise exhaust; includes items

25 120730 SCREW, machine, hex hd; 1/4-20 x 1

40 NXT107 AIR VALVE ASSEMBLY; see page 38 1

41 120088 SCREW; 3/8-16 x 4 in. (101 mm) 4

43 120091 SCREW, thread forming; 1/4-20 x 2 in.

44 120092 SCREW, thread forming; 1/4-20 x 2-1/2

. O-RING; buna-N 1

20, 25, 44, 54, 55, 56, 57, 63

in. (25 mm)

(51 mm)

in. (63 mm)

Ref. Part Description Qty

45 107257 SCREW, thread-forming; 1/4-20 x 1/2

46* 253476 GASKET 1

47◆ 15M568 COVER, valve, outer 1

51▲ 15F674 LABEL, safety 1

54★ 15H179 DEFLECTOR 1

55★ 107257 SCREW, thread-forming; 1/4-20 x 1/2

56 15H190 SEAL, exhaust 1

57★ 15K345 GASKET; buna-N 1

58 120206 MUFFLER, poppet 2

59 277366 BUMPER 1

60 116343 SCREW, ground; M5 x 0.8 1

61 111307 WASHER, lock; 5 mm 1

1

62 n/a PLUG 1

63★ 15G689 DIFFUSER, exhaust 1

64 108014 O-RING 1

5

65 16D001 ADAPTER, lift ring 1

66 C20987 O-RING 1

74◆ 121162 CLIP, strain relief 1

75◆ 117018 WASHER 1

4

76◆ 15M573 WIRE HARNESS, remote 1

2

in. (13 mm)

in. (13 mm)

4

2

Air Motor Part Numbers

Ref. Description

1 CAP, top 15F955 15F954 15F953 1

2 CYLINDER NXT204 NXT304 NXT604 1

3 COVER, bottom NXT202 NXT302 NXT602 1

4 PISTON ASSEMBLY; includes item 10 NXT201 NXT301 NXT601 1

15 MUFFLER NXT203 NXT303 NXT603 1

17* O-RING, piston; nitrile 123196 122434 122675 1

30 COVER, top 15G377 15G556 16R866 1

▲

Replacement Danger and Warning labels, tags, and cards are available at no cost.

QtyN22LR0 N34LR0 N65LR0

* Parts included in Repair Kits NXT200 (N22LR0), NXT300 (N34LR0), NXT600 (N65LR0). Purchase separately.

★

Parts included in Low Noise Exhaust Conversion Kit NXT111 (purchase separately).

◆

Parts included in Remote DataTrak Kit NXT406 (purchase separately). Kit also includes items 139 and 144 (see page 39).

IG

† Only used on original poppets (see F

. 13) made prior to mid-2009.

Parts designated n/a are not available separately.

38 311238ZAJ

Page 39

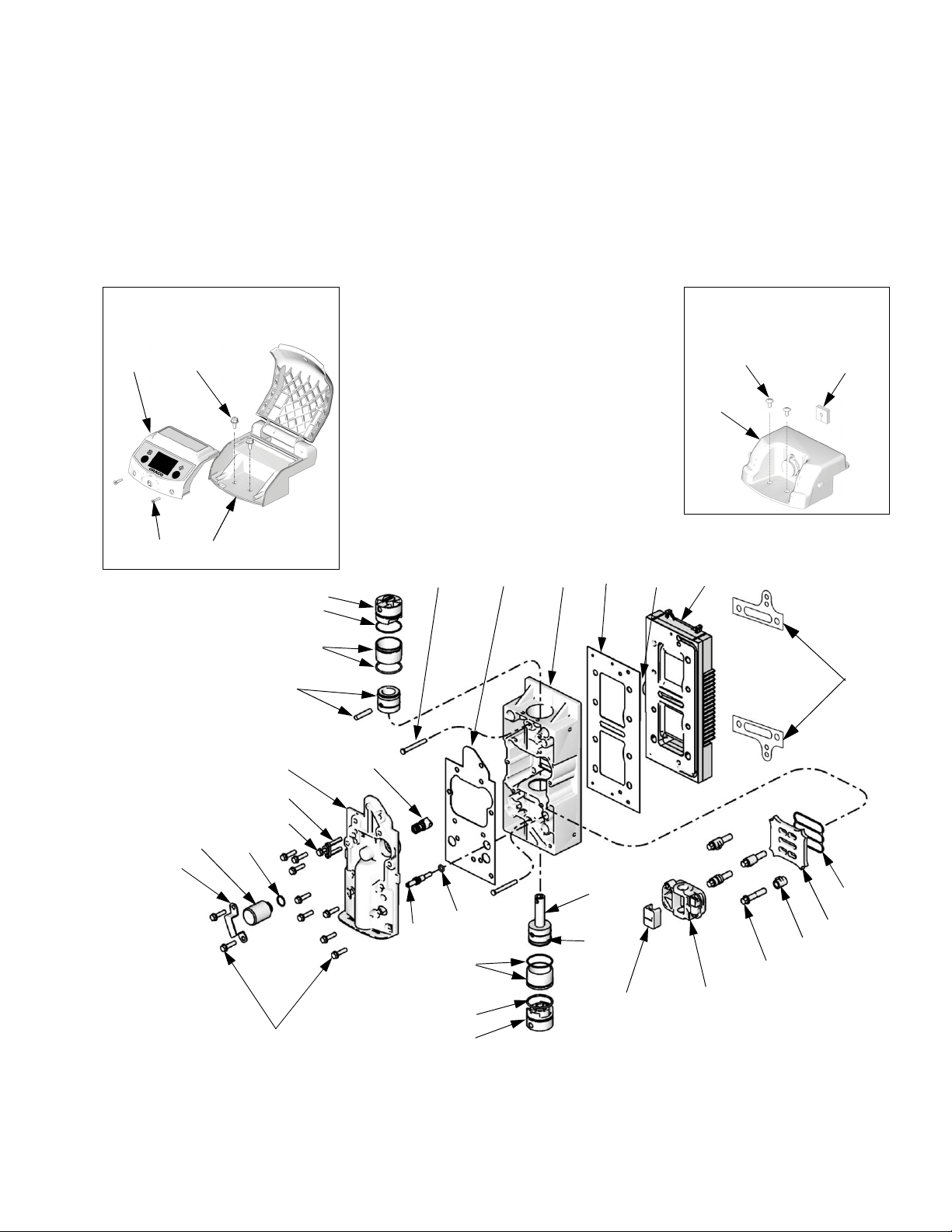

Air Valve

Part NXT107 Bare Air Valve

Part NXT108 Air Valve with DataTrak Module

Part NXT109 Air Valve with Junction Box

Parts

Detail of Part NXT108

with DataTrak Module

131

135

134

132

119 (Ref)

TI8618a

110

†‡110a

‡109

†‡106111 103

102†‡

20†‡

Detail of Part NXT109

with Junction Box

134

136

133

TI8619a

101

148†‡

‡113

◆

◆

112

139

144

140 †‡142

138

119

145a†‡

145

‡109

†‡110a

124

311238ZAJ 39

110

119a†

107‡

123

108‡

104†‡

105‡

117

TI11295b

Page 40

Parts

Part NXT107 Bare Air Valve

Part NXT108 Air Valve with DataTrak Module (shown)

Part NXT109 Air Valve with Junction Box Housing

Ref. Part Description Qty

20†‡ 119990 O-RING; buna-N 1

101 15X996 COVER, exhaust 1

102†‡ 15H633 GASKET, exhaust cover 1

103 15H394 BODY, valve 1

104†‡ 15F435 SEAL, plate, valve; nitrile 1

105‡ 15F438 PLATE, valve 1

106†‡ 15H634 GASKET, carriage cover 1

107‡ 15G055 CARRIAGE, detent, ramp 1

108‡ NXT138 CARRIAGE, air cup 1

109‡ NXT140 SLEEVE, cylinder; with o-ring 2

110 NXT141 STOP, valve piston; with o-ring 2

110a†‡108014 O-RING, plug, spool 2

111 15F440 PIN, end cap retainer 2

112 16A038 COVER, valve 1

113‡ NXT145 DETENT, spring-loaded (series H air

motors or valve covers; marked with

117 15G905 RETAINER, valve plate 4

119‡ NXT142 VALVE, piston 1

119a†‡ n/a SEAL, u-cup, piston, spool 1

123 120089 SCREW, 3/8-16 x 1-3/4 in. (44 mm) 4

124 120730 SCREW, machine, hex washer hd;

120730 SCREW, machine, hex washer hd;

131 NXT402 MODULE, DataTrak; includes items

131a n/a . FUSE; 63 mA; NXT108 only, see

132 NXT401 HOUSING, DataTrak; includes items

133 NXT411 JUNCTION BOX ASSEMBLY; includes

134 107257 SCREW, thread forming; 1/4-20 x 1/2

“B”)

11

1/4-20 x 1 in. (25 mm); NXT108 and

NXT109

10

1/4-20 x 1 in. (25 mm); NXT107

131a and 135; NXT108 only

Table 3 on page 14

134 and 135; NXT108 only

items 134 and 136; NXT109 only

in. (13 mm); NXT108 and NXT109 only

Ref. Part Description Qty

135 120279 SCREW, thread forming; #6 x 5/8 in.

136 15G225 GROMMET, junction box; NXT109 only 1

138 15G790 CLIP, solenoid 1

139◆ NXT404 SENSOR, reed switch; includes items

140 NXT403 SOLENOID; 7 Vdc; includes items 138

277355 PLUG, solenoid port; NXT107 and

142†‡ 104130 O-RING; buna-N; NXT107 and NXT109

144◆ 118605 O-RING; nitrile; NXT108 and NXT109

1

145 NXT102 CONTROL, de-icing; with knob and

145a†‡159589 O-RING, stem, bleed 1

147 15G722 CARD, diagnostic, multilingual;

148†‡ 253476 GASKET, end caps, pair 1

†

Parts included in Air Valve Seal Repair Kit NXT135 (pur-

(16 mm); NXT108 only

144 and 124 (qty 1); NXT108 and

NXT109 only

and 124 (qty 2); NXT108 only

NXT109 only

only

only

o-ring

NXT108 only

chase separately).

‡

1

Parts included in Air Valve Rebuild Kit NXT144 (purchase

separately) for series H (and later) air motors; marked with

“B” on cover (112); see Disassemble the Air Valve, page

1

1

21.

◆

Parts included in Remote DataTrak Kit NXT406 (purchase

separately). Kit also includes items 74, 75, and 76 (see

1

2

page 37).

Parts designated n/a are not available separately.

2

1

1

1

1

1

1

1

40 311238ZAJ

Page 41

Dimensions

Air Motor

Model A, inch (mm) B, inch (mm) C, inch (mm) D, inch (mm)

NXT Model 2200 15.6 (394) 16.8 (427) 15.4 (391) 12.4 (315)

NXT Model 3400 15.5 (394) 16.7 (424) 16.1 (409) 14.0 (356)

NXT Model 6500 15.9 (404) 17.1 (434) 18.9 (480) 16.2 (411)

C

Dimensions

A

B

Accessories

Motor/Lower Adapters

The following adapters are available as accessories to

connect an NXT air motor to a Graco lower.

Lower Adapter

High-Flo 15H369

Dura-Flo 600, 750, 900, and 1200 15H370

Dura-Flo 1800 and 2400 15H371

Xtreme 15H392

Air Line Lubricators

D

TI7773ATI7772A

DataTrak Conversion Kits

To convert standard NXT air motors to include DataTrak

module.

Air Motor Conversion Kit

NXT 2200 NXT206

NXT 3400 NXT306

NXT 6500 NXT606

111897 Threaded Muffler

1 in. npt(m). For use with remote exhaust manifold.

Air Motor Lubricator

NXT 2200 214848

NXT 3400 214848

NXT 6500 214849

311238ZAJ 41

Integrated Air Control Modules

See Integrated Air Control Modules manual 311239.

Air Control

See Air Controls manual 3A0293.

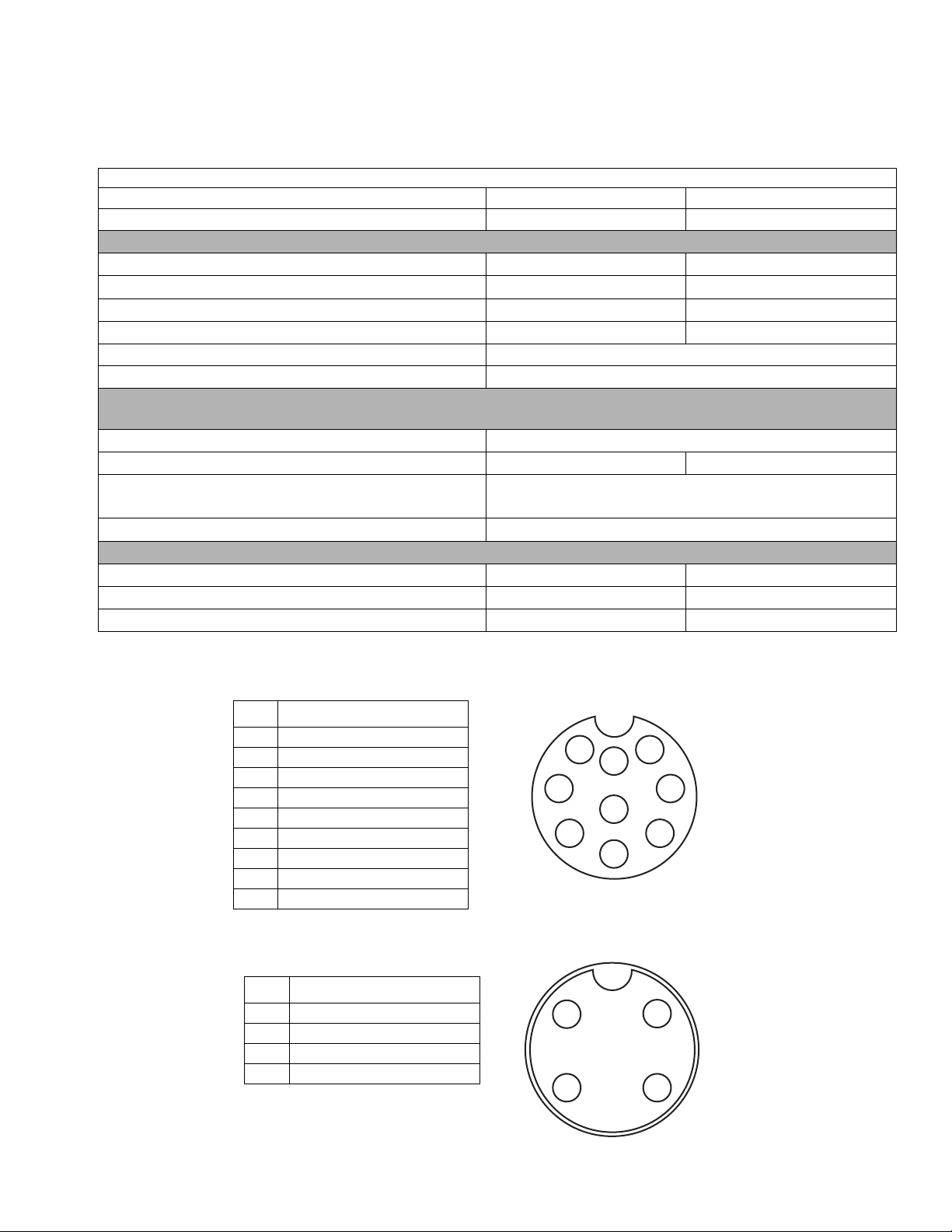

Page 42

Mounting Hole Diagrams

Mounting Hole Diagrams

Four 3/8-16

Mounting Holes

3.938 in.

(100 mm)

Four 3/8-16

Mounting Holes

6.186 in.

(157 mm)

NXT Model 2200

6.750 in.

(172 mm)

NXT Model 3400

Three 5/8-11 Tie Rod Holes,

5.906 in. (150 mm) x 120° Bolt Circle

TI8071A

Four 3/8-16

Mounting Holes

6.186 in.

(157 mm)

6.186 in.

(157 mm)

NXT Model 6500

6.186 in.

(157 mm)

Six 5/8-11 Tie Rod Holes,

8.000 in. (203 mm) x 120° Bolt Circle

5.906 in. (150 mm) x 120° Bolt Circle

TI8070A

Three 5/8-11 Tie Rod Holes,

8.000 in. (203 mm) x 120° Bolt Circle

TI8069A

42 311238ZAJ

Page 43

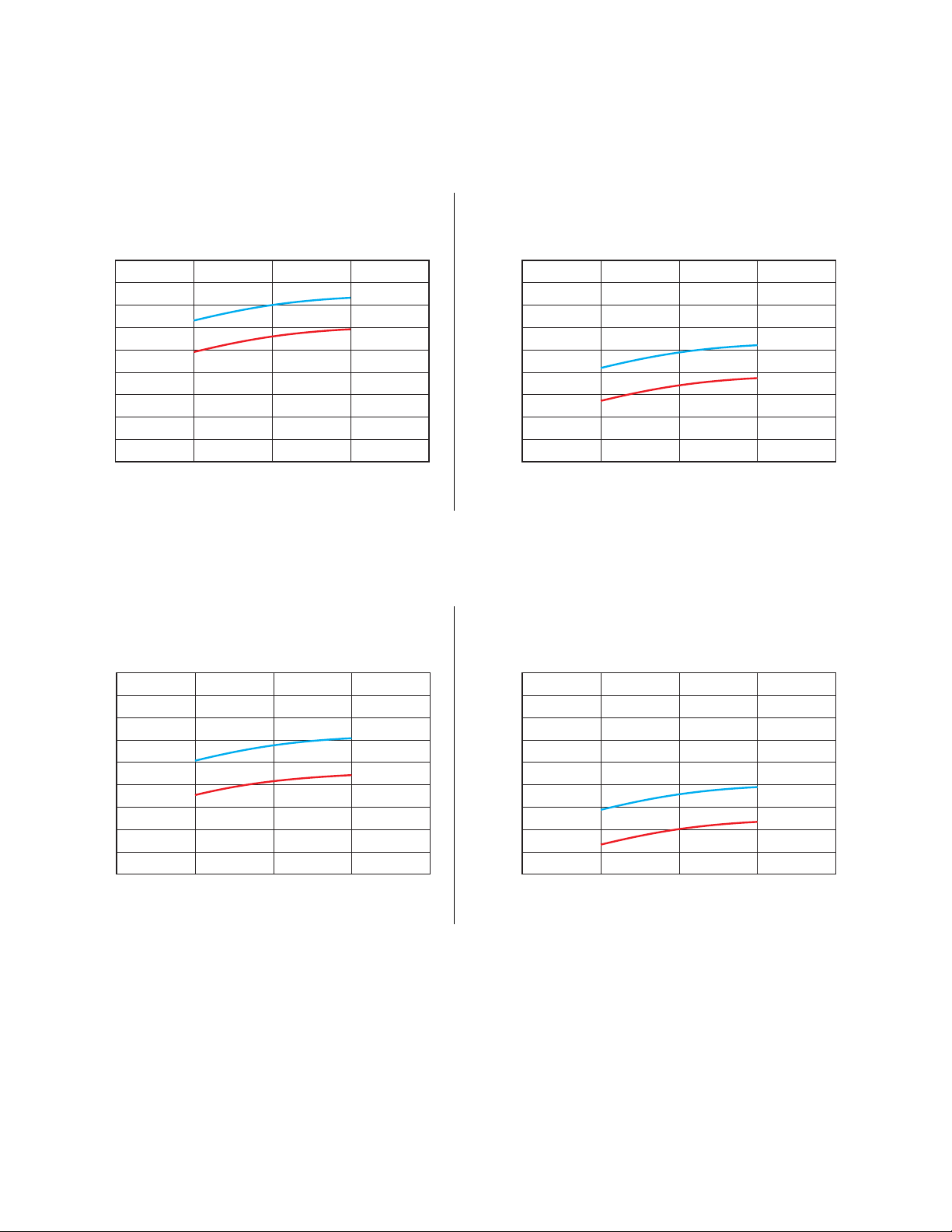

Technical Data

Technical Data

NXT Air Motor

US Metric

Maximum air inlet pressure 100 psi 0.7 MPa, 7.0 bar

Air motor piston diameter

NXT Model 6500:

NXT Model 3400:

NXT Model 2200:

Stroke length 4.75 in. 120 mm

Air Inlet Size 3/4 npt(f)

Remote exhaust outlet size (remote models only) 1 in. npt(f)

Maximum motor speed

(Do not exceed maximum recommended speed of fluid pump, to prevent premature pump wear)

Operating temperature range 32-140°F 0-60°C

Materials of construction Aluminum, ductile iron, stainless steel, carbon steel, acetal,

Seals and packings Nitrile rubber

Weight

NXT Model 6500:

NXT Model 3400:

NXT Model 2200:

10.375 in. 264 mm

7.5 in. 191 mm

6.0 in. 152 mm

60 cycles per minute

polyethylene, Santoprene

69 lb 31 kg

50 lb 23 kg

46 lb 21 kg

®

, alloy steel, polypropylene

Santoprene® is a registered trademark of the Monsanto Company.

Pin-Out Information for Motor with Linear Sensor

Description

Pin

15V Common

2 Voltage Out

3 +5V Supply

4 Shield

5 Extend High Pin

6 Retract High Pin

7 Bottom SW Signal

8 Top SW Signal

9Common

Pin-Out Information for Motor with Remote DataTrak Connector

Description

Pin

1 Bottom SW Signal

2 Top SW Signal

3Common

4 Shield

1

7

9

TI9239A

4

1