Page 1

Instructions - Parts List

®

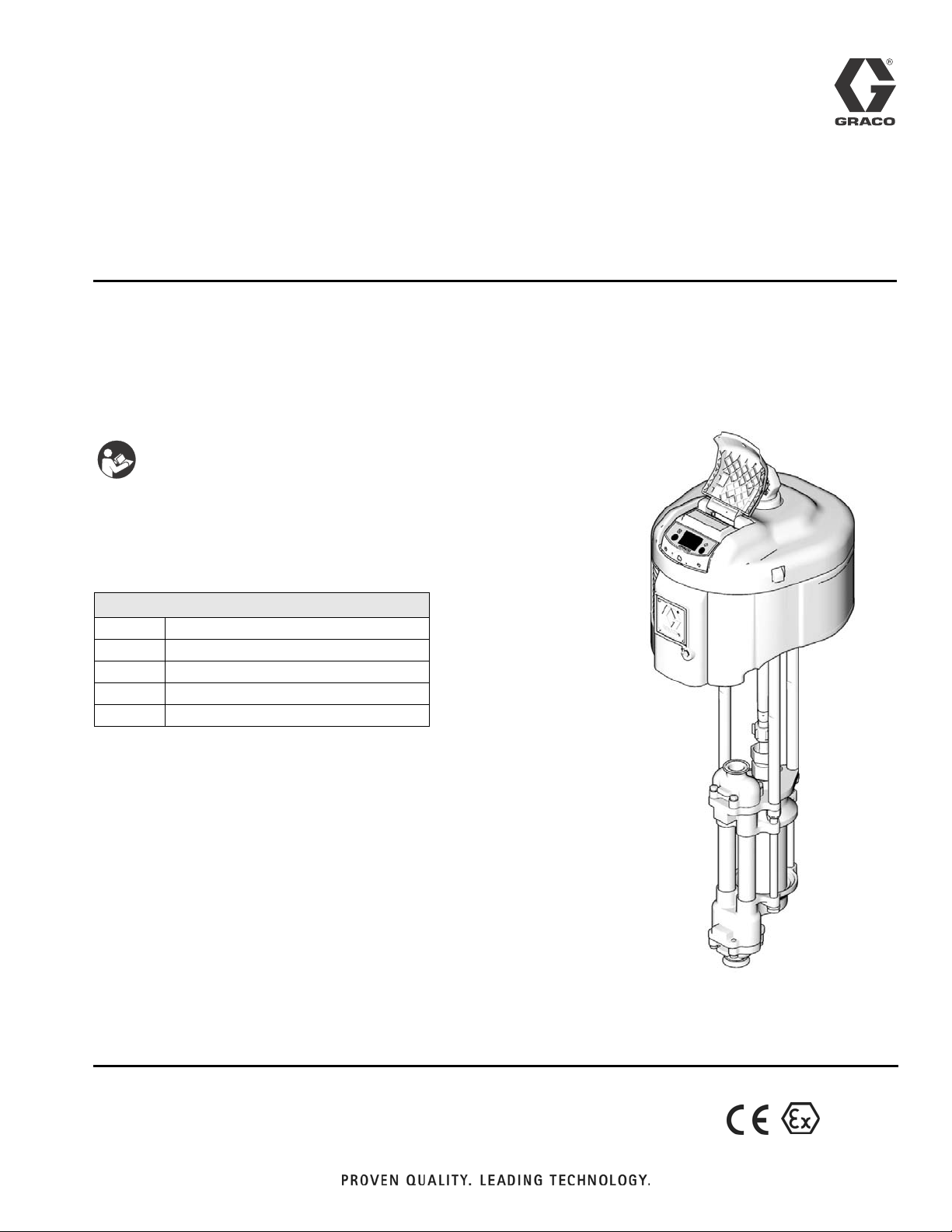

High-Flo

Designed for low pressure, medium volume circulation of finishing materials.

Do not use with caustics, acids, abrasive line strippers, and other similar fluids.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for Table of Contents and page 3 for

List of Models.

See page 25 for Maximum Working Pressures.

Related Manuals

Part No. Description

311238 NXT Air Motor manual

308330 Viscount I Plus Hydraulic Motor manual

311690 High-Flo Lower manual

308048 Viscount II Hydraulic Motor manual

Pumps

311211M

ENG

Patent Pending

NXT Air-Powered

Pump Shown

TI8354a

II 2 G

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

NXT Air-Powered Pumps . . . . . . . . . . . . . . . . . . 3

Viscount I Plus Hydraulic-Powered Pumps . . . . . 3

Viscount II Hydraulic Powered Pumps . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Air-Powered Pumps . . . . . . . . . . . . . . . . . . . 8

Hydraulic-Powered Pumps . . . . . . . . . . . . . . 8

All Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

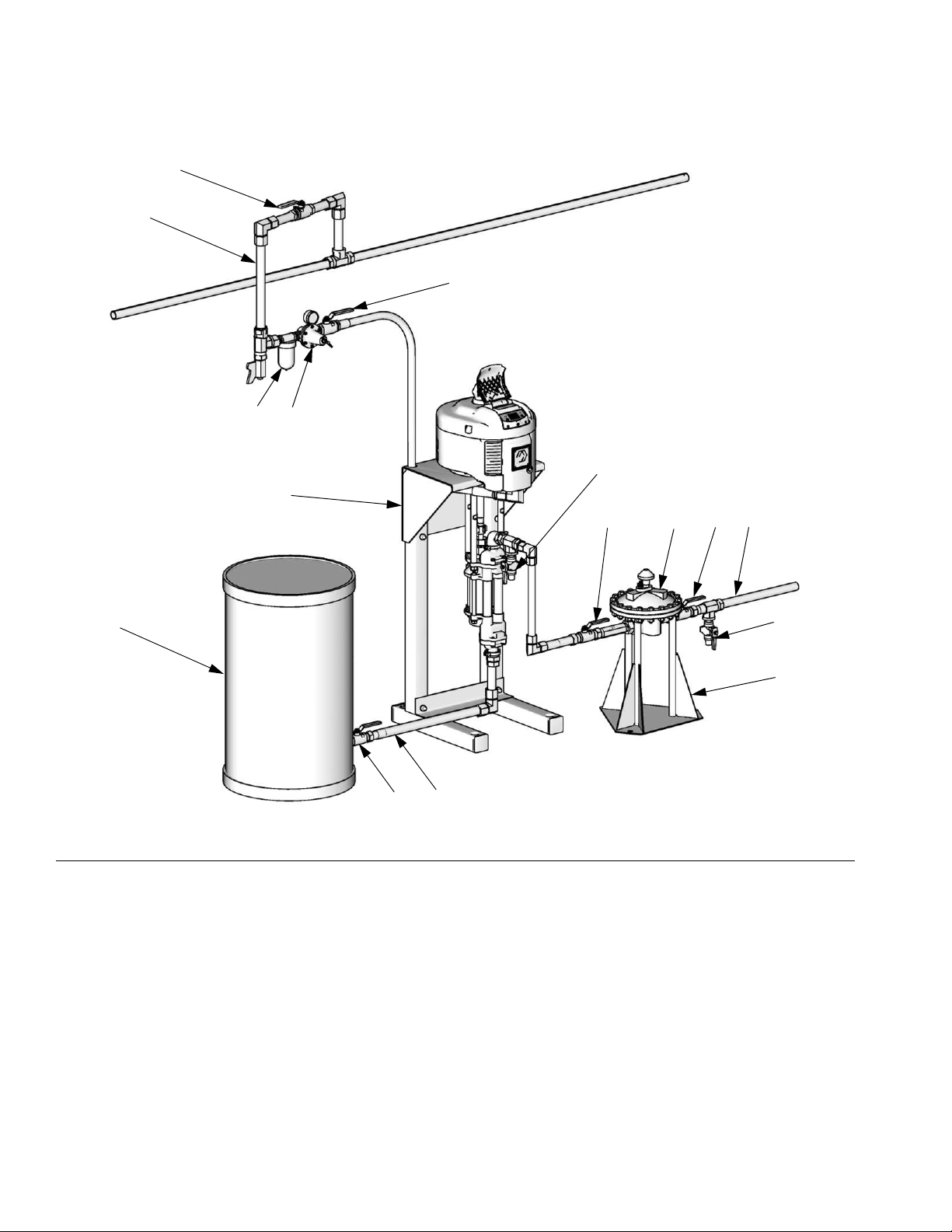

Air-Powered Pumps Typical Installation . . . . . . 10

Hydraulic-Powered Pumps Typical Installation . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . 12

Flush Before Using Equipment . . . . . . . . . . . . . 12

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pump Operation . . . . . . . . . . . . . . . . . . . . . . . . 12

Stop the Pump at the Bottom of Its Stroke . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preventive Maintenance Schedule . . . . . . . . . . 13

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Air Line Filter . . . . . . . . . . . . . . . . . . . . . . . 13

Hydraulic Power Supply Check . . . . . . . . . . 13

Mix Tank Volume . . . . . . . . . . . . . . . . . . . . . 13

Packing Nut Tightness . . . . . . . . . . . . . . . . 13

Excessive Leaking at Throat . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Disconnect the Lower . . . . . . . . . . . . . . . . . . . . 15

Reconnect the Lower . . . . . . . . . . . . . . . . . . . . . 15

Reassemble the Coupling Rod and Tie Rods

to the Motor . . . . . . . . . . . . . . . . . . . . . . . . . 16

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

NXT Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Common Parts . . . . . . . . . . . . . . . . . . . . . . 18

Parts That Vary by Model . . . . . . . . . . . . . . 19

Viscount I Plus Pumps . . . . . . . . . . . . . . . . . . . . 21

Common Parts . . . . . . . . . . . . . . . . . . . . . . 21

Parts That Vary by Model . . . . . . . . . . . . . . 21

Viscount II 460 Pumps . . . . . . . . . . . . . . . . . . . . 22

Common Parts . . . . . . . . . . . . . . . . . . . . . . 22

Parts That Vary by Model . . . . . . . . . . . . . . 22

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Pump Mounting Hole Diagram . . . . . . . . . . . . . . . 24

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

NXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Viscount I Plus Pumps . . . . . . . . . . . . . . . . . . . . 25

Viscount II Pumps . . . . . . . . . . . . . . . . . . . . . . . 25

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 26

Air-Powered Pumps . . . . . . . . . . . . . . . . . . . . . . 26

Hydraulic Powered Pumps . . . . . . . . . . . . . . . . 28

Viscount II 460 Pumps . . . . . . . . . . . . . . . . . . . . 29

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 30

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 30

2 311211M

Page 3

Models

Models

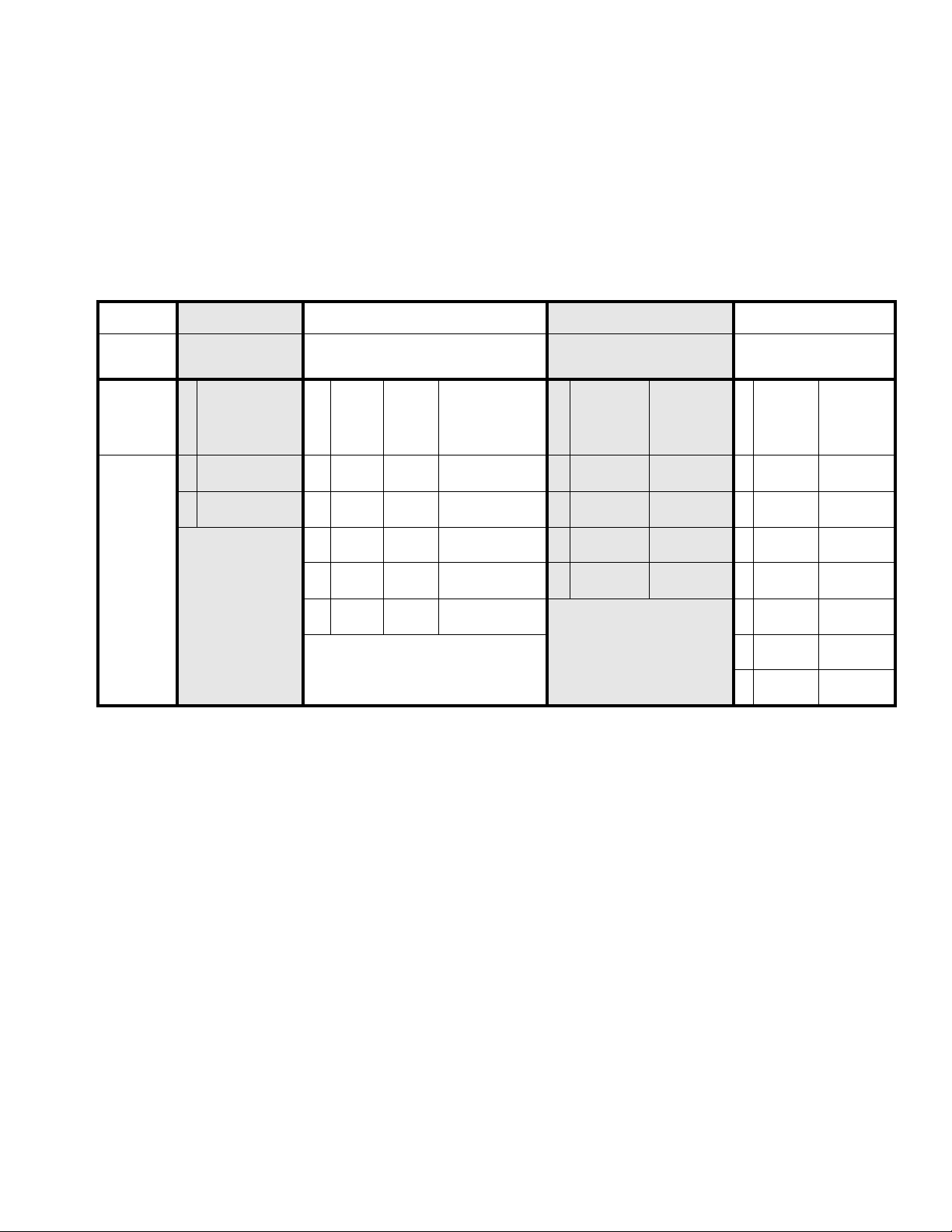

NXT Air-Powered Pumps

Your model number is marked on the pump identification plate located toward the rear of the air motor. To determine

the model number of your pump from the following matrix, select the six digits which describe your pump. The first

digit is always J for circulation pumps. The remaining five digits define the construction. For example, a circulation

pump with carbon steel construction, a 2.0:1 ratio, low noise exhaust, no communication option, npt fittings, and

chrome rod and cylinder is model number JC20L1. To order replacement parts, see page 18.

J C20 L1

First

Digit

J

(all

circulation

pumps)

Second Digit Third and Fourth Digit Fifth Digit Sixth Digit

Maximum

Fluid

Motor

Material

C Carbon Steel 20 2200 2000 200 (1.4, 14.0) L Low Noise none 1 npt Chromex/

S Stainless Steel 30 2200 1500 300 (2.1, 21.0) M Low Noise

Size

35 3400 2000 340 (2.3, 23.0) R Remote none 3 bspp* Chromex/

40 2200 1000 400 (2.8, 28.0) S Remote

45 3400 1500 460 (3.2, 32.0)

XX = X.X:1 ratio 7 npt Chromex/

Lower

Size

Pressure

psi (MPa, bar) Exhaust

Communi-

cation Fittings

™

DataTrak

DataTrak

2 npt Chromex/

™

4 bspp* Chromex/

5 tri-

clamp

6 tri-

clamp

Rod and

Cylinder

Chrome

MaxLife

Chrome

MaxLife

Chromex/

Chrome

Chromex/

MaxLife

Nitride

311211M 3

Page 4

Models

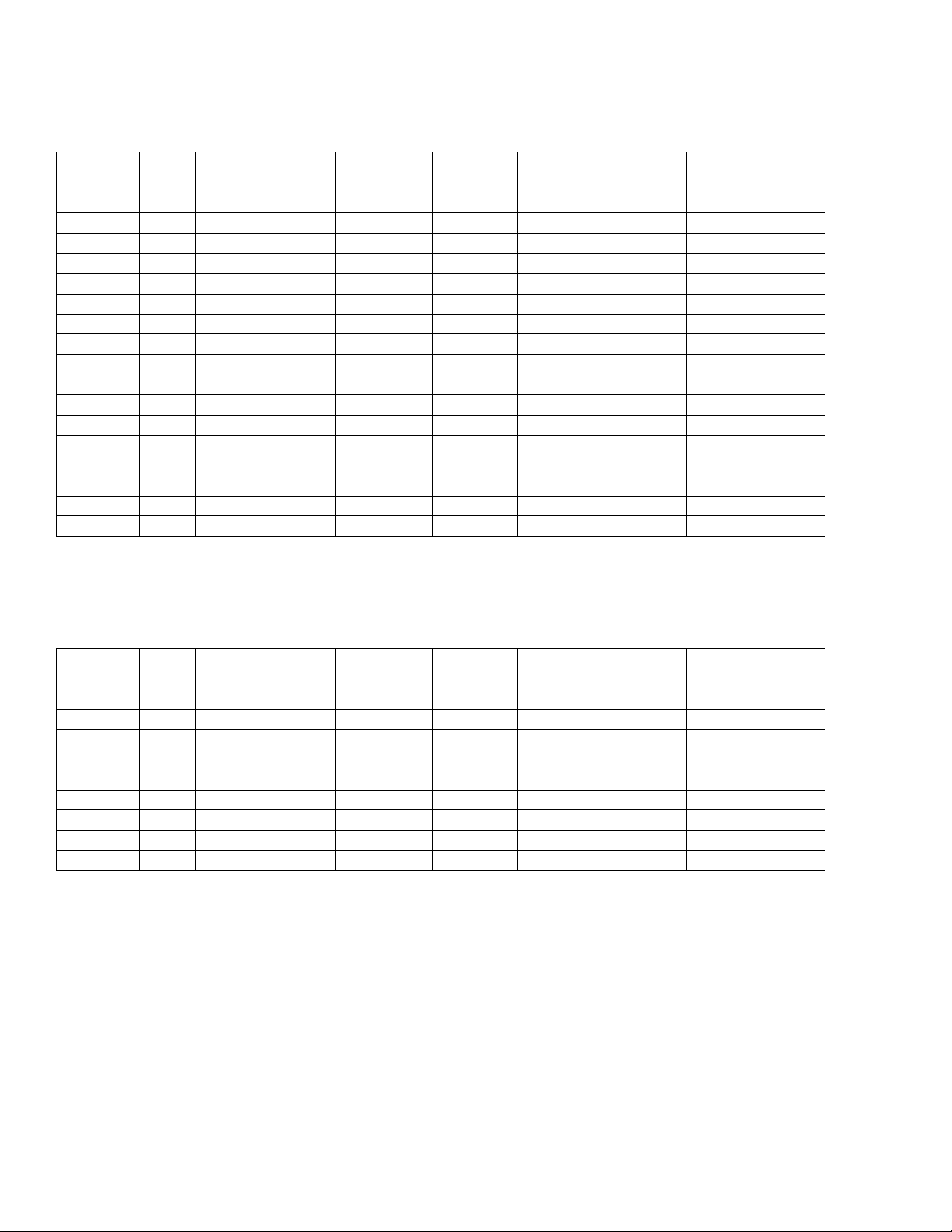

Viscount I Plus Hydraulic-Powered Pumps

Maximum Pump

Working Pressure

Model No. Series

253642 A 300 (2.1, 21) npt sst Chromex Chrome 253033

253643 A 225 (1.6, 16) npt sst Chromex Chrome 253034

24E787 A 300 (2.1, 21) npt sst Chromex Chrome 24E783

24E788 A 225 (1.6, 16) npt sst Chromex Chrome 24E784

253644 A 300 (2.1, 21) npt sst Chromex MaxLife 253568

253645 A 225 (1.6, 16) npt sst Chromex MaxLife 253569

253646 A 300 (2.1, 21) npt cst Chromex Nitride 253061

253647 A 225 (1.6, 16) npt cst Chromex Nitride 253062

253648 A 300 (2.1, 21) bspp* sst Chromex Chrome 253423

253649 A 225 (1.6, 16) bspp* sst Chromex Chrome 253085

253650 A 300 (2.1, 21) bspp* sst Chromex MaxLife 253398

253651 A 225 (1.6, 16) bspp* sst Chromex MaxLife 253397

253652 A 300 (2.1, 21) tri-clamp sst Chromex Chrome 253520

253653 A 225 (1.6, 16) tri-clamp sst Chromex Chrome 253521

253654 A 300 (2.1, 21) tri-clamp sst Chromex MaxLife 253523

253655 A 225 (1.6, 16) tri-clamp sst Chromex MaxLife 253524

psi (MPa, bar)

Connection

Style Material

Rod

Material

Cylinder

Material

High-Flo Lower

(see manual 311690)

*BSPP models require inlet and outlet seals to perform optimally. See Accessories, page 9.

Viscount II Hydraulic Powered Pumps

Maximum Pump

Working Pressure

Model No. Series

247355 A 460 (3.2, 32) npt sst Chromex Chrome 253035

24E786 A 460 (3.2, 32) npt sst Chromex Chrome 24E785

247356 A 460 (3.2, 32) npt cs Chromex Chrome 253063

247357 A 460 (3.2, 32) bspp* sst Chromex Chrome 253086

247358 A 460 (3.2, 32) bspp* sst Chromex MaxLife 253396

247359 A 460 (3.2, 32) tri-clamp sst Chromex Chrome 253522

247360 A 460 (3.2, 32) tri-clamp sst Chromex MaxLife 253525

247361 A 460 (3.2, 32) npt sst Chromex MaxLife 253570

*BSPP models require inlet and outlet seals to perform optimally. See Accessories, page 9.

psi (MPa, bar)

Connection

Style Material

Rod

Material

Cylinder

Material

High-Flo Lower

(see manual 311690)

4 311211M

Page 5

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

311211M 5

Page 6

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

6 311211M

Page 7

Installation

Installation

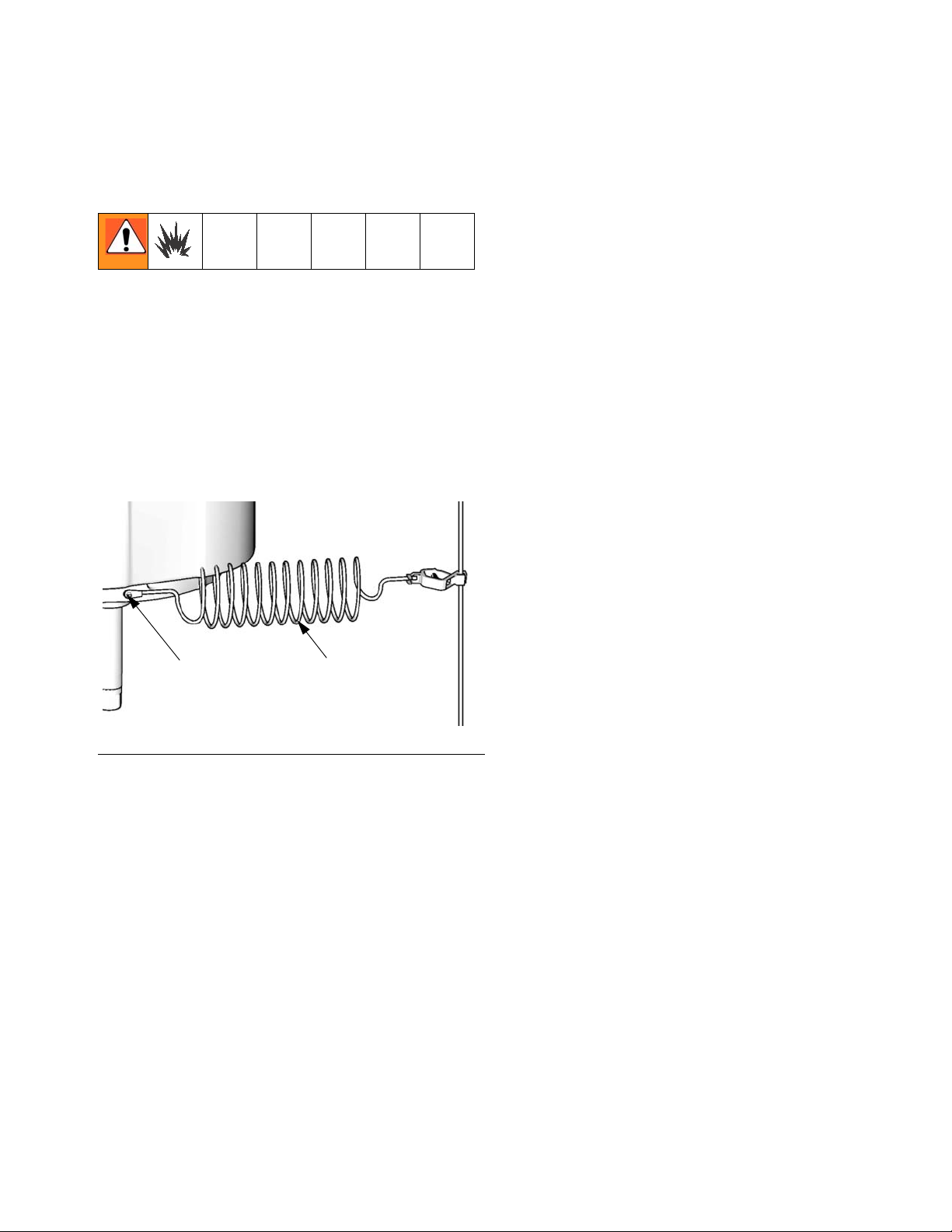

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

Pump: Use a ground screw (Z) and lockwasher on the

motor to attach ground wire 244524 (Y). Tighten the

screw securely. Connect the other end of the ground

wire to a true earth ground. See F

IG. 1.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

Z Y

TI8250a

FIG. 1

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check the

electrical resistance of hoses. If total resistance to

ground exceeds 29 megohms, replace hose immediately.

Air compressor: follow manufacturer’s recommendations.

Hydraulic power supply: follow manufacturer’s recommendations.

Surge tank: use a ground wire and clamp.

Spray gun: ground through a connection to a properly

grounded fluid hose and pump.

Fluid supply container: follow local code.

311211M 7

Page 8

Installation

Accessories

Install the following accessories in the order shown in

F

IG. 2 and FIG. 3, using adapters as necessary.

Air-Powered Pumps

For typical installation, see FIG. 2 on page 10.

Accessory Air Control Kits are available for the NXT

Air Motor. The kits include a master air valve, air

regulator, and filter. Order the kits separately. See

manual 311239 for more information.

Air Line

• Bleed-type master air valve (M): required in your

system to relieve air trapped between it and the air

motor when the valve is closed.

Trapped air can cause the pump to cycle unexpectedly,

which could result in serious injury from splashing or

moving parts.

Hydraulic-Powered Pumps

For typical installation, see FIG. 3 on page 11.

Hydraulic Power Supply

CAUTION

The hydraulic power supply must be kept clean at all

to avoid damage to the motor and hydraulic power

supply.

1. Blow out hydraulic lines with air and flush thoroughly before connection to the motor.

2. Plug hydraulic inlets, outlets, and line ends when

disconnecting them for any reason.

Be sure the power supply can provide sufficient power to

the motor. Be sure the power supply is equipped with a

suction filter to the hydraulic pump.

Hydraulic Supply Line

• For Viscount I Plus motors, the hydraulic inlet

on the motor is 3/4 in., 37° flare. Use a minimum 1/2 in. (13 mm) ID hydraulic supply line

(K).

Be sure the valve is easily accessible from the pump

and located downstream from the air regulator. Be sure

the air bleed hole points away from the operator.

The air motor is rated to 100 psi (0.7 MPa, 7.0 bar). If

you will apply more than 100 psi (0.7 MPa, 7.0 bar) to

the system, install a safety relief valve between the

bleed-type master air valve and the air motor.

• Pump air regulator (L): to control pump speed and

outlet pressure. Locate close to the pump.

• Air line filter (K): removes harmful dirt and mois-

ture from compressed air supply.

• Second bleed-type air valve (M): isolates air line

accessories for servicing. Locate upstream from all

other air line accessories.

• For Viscount II motors, use a minimum 13 mm

(1/2 in.) ID supply line supply line (K). The

motor has a 3/4 npt(f) hydraulic oil supply fitting.

• Supply line shutoff valve (S): isolates the motor

when servicing the system. See F

• Hydraulic fluid pressure gauge (P): monitors the

hydraulic oil pressure to the motor to avoid overpressurizing the motor or lower.

• Pressure- and temperature-compensated flow

control valve (T): prevents the motor from running

too fast, which can damage it.

• Pressure reducing valve (N), which has a drain

line (M) running to the return line (K): controls the

hydraulic pressure to the motor.

IG. 3.

8 311211M

Page 9

Installation

Hydraulic Return Line

• For Viscount I Plus motors, the hydraulic outlet

on the motor is 7/8 in., 37° flare. Use a minimum 5/8 in. (16 mm) ID hydraulic return line

(J).

• For Viscount II motors, use a minimum 22 mm

(7/8 in.) ID return line (J). The motor has a 1 in.

npt(f) hydraulic oil return fitting.

• Return line shutoff valve (R): isolates the motor

when servicing the system.

CAUTION

To avoid damage to the pump, never use the return

line shutoff valve to control the hydraulic flow. Do not

install any flow control devices on the hydraulic return

line.

• Return fluid filter (J): removes residue from the

hydraulic fluid to help keep the system running

smoothly (10 micron size).

All Pumps

Fluid Line

• Fluid filter: with a 60 mesh (250 micron) stainless

steel element to filter particles from the fluid as it

leaves the pump.

• Fluid drain valve (U): required in your system, to

relieve fluid pressure in the hose and gun.

• Fluid shutoff valve (D): shuts off fluid flow.

• Fluid pressure regulator: for more precise adjust-

ment of the fluid pressure.

• Gun or valve: to dispense fluid.

• Fluid line swivel: for easier gun movement.

• Suction kit: enables the pump to draw fluid from a

container.

• Inlet and outlet seals: prevent leakage in BSPP

models. Order 193423 for 1-1/2 in. inlet seal and

193422 for 1-1/4 in. outlet seal.

311211M 9

Page 10

Installation

Air-Powered Pumps Typical Installation

M

J

M

KL

B

N

GNDD

E

A

D

FIG. 2: Typical Installation

Key:

A Mix Tank

B Pump Stand

C Fluid Supply Line; 1-1/2 in. (38 mm) minimum diameter

D Fluid Shutoff Valve

E Fluid Line; 1 in. (25 mm) minimum diameter

F Surge Tank Stand

G Surge Tank

H Ground Wire (required, see page 7 for installation)

J Air Supply Line

K Air Line Filter

L Air Regulator and Gauge

M Bleed-Type Master Air Valve (required)

N Fluid Drain Valve (required)

F

C

TI8398a

10 311211M

Page 11

Hydraulic-Powered Pumps Typical Installation

Installation

K

A

L

M

E

S

N

P

E

R

T

J

U

D

B

G

D

U

C

D

FIG. 3: Typical Installation

Key:

AMix Tank

B Pump Stand

C Fluid Supply Line; 1-1/2 in. (38 mm) minimum diameter

D Fluid Shutoff Valve

E Fluid Line; 1 in. (25 mm) minimum diameter

F Surge Tank Stand

G Surge Tank

J 10 Micron Return Filter

K Hydraulic Return Line; 5/8 in. (16 mm) minimum diameter

L Hydraulic Supply Line; 1/2 in. (13 mm) minimum diameter

MDrain Line

N Pressure Reducing Valve

P Hydraulic Pressure Gauge

R Return Line Shutoff Valve

S Supply Line Shutoff Valve

T Flow Control Valve

F

TI8399a

U Fluid Drain Valve (required)

Y Ground Wire (required see page 7 for installation)

311211M 11

Page 12

Operation

Operation

Pressure Relief Procedure

1. Engage trigger lock.

2. Air-Powered Pumps only: Close the bleed-type

master air valve.

Hydraulic-Powered Pumps only: Shut off the

hydraulic supply line valve (S) first, then the return

line valve (R).

3. Disengage the trigger lock.

4. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun to relieve pressure.

5. Engage the trigger lock.

6. Open all fluid drain valves in the system, having

waste containers ready to catch drainage. Leave the

drain valves open until you are ready to spray again.

7. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen the tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

Pump Operation

• In a circulation system, the pump operates continuously until the power supply is shut off.

CAUTION

Do not allow the pump to run quickly for a long period

of time as this may damage the packings.

• In a direct-supply system, the pump starts

when the gun is opened, and stops when the

gun is closed.

• Perform a stall test periodically to ensure the

piston seal is in good working condition and

prevent system overpressurization:

• Close the fluid shutoff valve (D) closest to the

pump on the downstroke and be sure that the

pump stalls. Open the fluid shutoff valve to

restart the pump. Close the fluid shutoff valve

(D) closest to the pump on the upstroke and be

sure that the pump stalls.

Stop the Pump at the Bottom of

CAUTION

Hydraulic-Powered Pumps only: When shutting down

the hydraulic system, always shut off the hydraulic

supply line shutoff valve (S) first, and then the return

line shutoff valve (R) to prevent overpressurizing the

motor or its seals. When starting the hydraulic system, open the return line shutoff valve first.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Flushing, page 13.

Trigger Lock

Always engage the trigger lock when you stop spraying

to prevent the gun from being triggered accidentally by

hand or if dropped or bumped.

12 311211M

Its Stroke

Relieve the pressure when you stop the pump for any

reason. Stop the pump on the downstroke, before the air

motor changes over.

CAUTION

Failure to stop the pump at the bottom of its stroke

allows fluid to dry on the piston rod, which can cause

damage to the throat packings when the pump is

restarted.

Hydraulic-Powered Pumps only: Always shut off the

supply line shutoff valve (S) first, and then the

return line shutoff valve (R). This is to prevent overpressurizing the motor or its seals.

Page 13

Maintenance

Maintenance

Preventive Maintenance Schedule

The operating conditions of your particular system

determine how often maintenance is required. Establish

a preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your system.

Your maintenance schedule should include the following:

Flushing

• Flush before shutting down the system for an

extended period of time.

• Flush before repairing the pump, if possible.

• Flush before fluid can dry out, settle, or set up

in the equipment.

Air Line Filter

Drain and clean as necessary.

Excessive Leaking at Throat

If you see excessive leaking at the throat, tighten the

packing nut (21), see F

lem, replace the throat packings, piston rod, or both See

manual 311690.

NXT Air-Powered

Pump Shown

1

packing nut

1

Torque to 15-20 ft-lb (20-27 N•m).

F

IG. 4

IG. 4. If this does not fix the prob-

TI8354a

Hydraulic Power Supply Check

Carefully follow the hydraulic power supply manufacturer's recommendations on reservoir and filter cleaning,

and periodic changes of hydraulic fluid.

Mix Tank Volume

Don't let the mix tank run dry. When the tank is empty,

the pump demands more power as it tries to suck in

some fluid. This causes the pump to run too fast, which

can seriously damage the pump.

Packing Nut Tightness

Check the packing nut (21) tightness every few days at

startup and then weekly throughout the life of the throat

seal. The packing nut should be tight enough to stop

leakage, but no tighter. See F

To check the adjustment of the packing nut, stop the

pump and relieve fluid pressure. Loosen the packing nut

until it turns freely. Tighten the nut firmly and then turn

the nut another 1/4 turn. If you have a torque wrench,

tighten the packing nut to 30 ft-lb (40 N•m), then back off

and re-tighten to 15-20 ft-lb (20-27 N•m).

IG. 4.

311211M 13

Page 14

Troubleshooting

Troubleshooting

1. Relieve the pressure.

2. Check all possible problems and solutions before

disassembling pump.

PROBLEM CAUSE SOLUTION

Pump output low on both strokes. Restricted air or hydraulic supply lines. Clear any obstructions; be sure all shutoff

valve are open; increase pressure, but do

not exceed maximum working pressure.

Exhausted fluid supply. Refill and reprime pump.

Clogged fluid outlet line, valves, etc. Clear.

Worn piston packing. Replace. See lower manual 311690.

Pump output low on only one stroke. Held open or worn ball check valves. Check and repair.

Worn piston packings. Replace. See lower manual 311690.

Pump operates erratically. Exhausted fluid supply. Refill and reprime pump.

Held open or worn ball check valves. Check and repair.

Worn piston packing. Replace. See lower manual 311690.

Excessive hydraulic fluid supply pressure

to Viscount motor.

Pump will not operate. Restricted air or hydraulic supply lines. Clear any obstructions; be sure all shut

Exhausted fluid supply. Refill and reprime pump.

Clogged fluid outlet line, valves, etc. Clear.

Damaged air motor or hydraulic motor. See air motor manual 311238 or hydrau-

Fluid dried on piston rod. Disassemble and clean pump. See lower

Pump will not prime Suction line clogged. Clear. Flush more frequently.

Held open or worn ball check valves. Check and repair.

Piston assembled with wrong nut. Use only the large, round, special nut.

Excessive throat leakage. Worn piston rod or throat packings. Replace. See lower manual 311690.

Pump will not stall when fluid is shut off. Warn ball check valves. Check and repair.

Worn piston packing. Replace. See lower manual 311690.

See Viscount I Plus motor manual

308330 or Viscount II manual 308048.

off valves are open; increase pressure,

but do not exceed maximum working

pressure.

lic motor manual 308330 or 308048.

manual 311690. In future, stop pump at

bottom of stroke.

14 311211M

Page 15

Repair

• To service the lower, see manual 311690.

Repair

tie rods. Tighten the locknuts and torque to 50-55

ft-lb (68-75 N•m).

• To service the air motor, see manual 311238.

• To service the Viscount I Plus hydraulic motor,

see manual 308330.

• To service the Viscount II hydraulic motor, see

manual 308048.

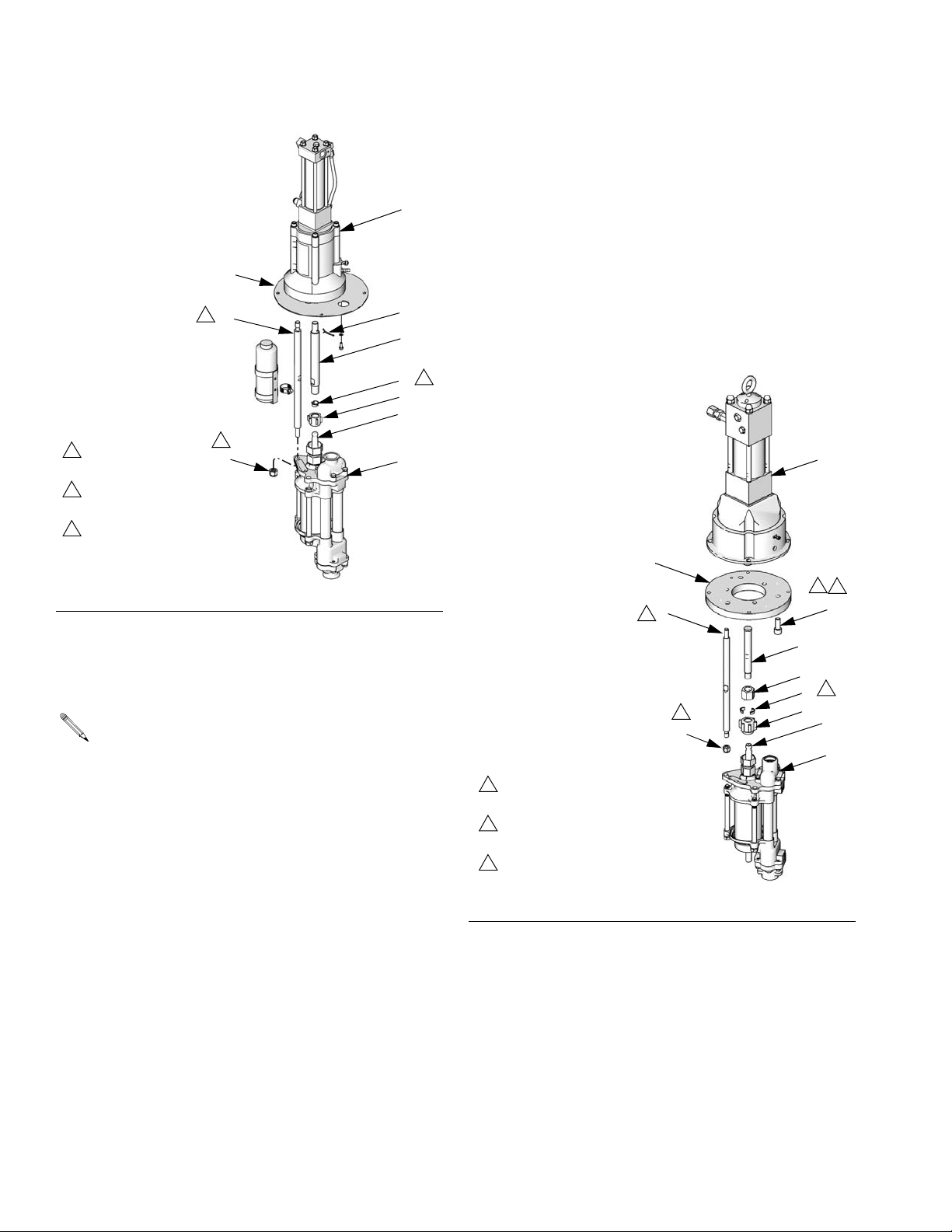

Disconnect the Lower

To service the lower, follow the procedure on this page,

and disassemble the pump as described in manual

311690. To disconnect pump from an electric circulation

assembly, EPXXXX, see manual 311594.

In stand or wall-mounted installations, you do not

have to remove the entire pump from its mounting.

1. Relieve the pressure, see Pressure Relief Procedure page 12.

2. Disconnect the hoses from the lower and plug the

ends to prevent fluid contamination.

3. Loosen the coupling nut (K) and remove the collars

(G). Remove the coupling nut from the piston rod

(H). Unscrew the locknuts (B) from the tie rods (C).

Pull the lower (D) off the motor (E). See F

F

IG. 6.

IG. 5 and

3. Insert the collars (G) into the coupling nut (K).

Tighten the coupling nut onto the piston rod (H) and

torque to 90-100 ft-lb (122-135 N•m).

4. Flush and test the pump before reinstalling it in the

system. Connect hoses and flush the pump. While it

is pressurized, check for smooth operation and

leaks. Adjust or repair as necessary before reinstalling in the system. Reconnect the pump ground wire

before operating.

NXT Pump

E

Shown

F

2

C

3

G

1

Torque to 90-100 ft-lb

(122-135 N•m).

2

Torque to 50-60 ft-lb

(68-81 N•m).

3

Apply lubricant.

3

2

B

1

K

H

D

Reconnect the Lower

FIG. 5

TI8394b

If the coupling rod (F) and tie rods (C) have been

disassembled from the motor, see Reassemble the

Coupling Rod and Tie Rods to the Motor on page

16.

1. Assemble the coupling nut (K) to the piston rod (H).

2. Orient the lower (D) to the motor (E). Position the

lower on the tie rods (C). Lubricate the threads of

the tie rods. Screw the tie rod locknuts (B) onto the

311211M 15

Page 16

Repair

Viscount I Plus

Pump Shown

3

4. Align the lower (D) with the tie rods (C) and loosely

install the tie rod locknuts (B).

5. Insert the collars (G) and screw the coupling nut (K)

onto the coupling rod (F) and torque to 90-100 ft-lb

E

(122-135 N•m).

6. For Viscount I Plus pumps, torque the holding the

J

adapter plate (J) to the motor (E) to 15-17 ft-lb

(20-23 N•m). For Viscount I Plus and Viscount II

pumps, torque the tie rod locknuts (B) to 50-55 ft-lb

C

A

F

(68-75 N•m).

1

G

K

H

1

Torque to 90-100 ft-lb

(122-135 N•m).

2

Torque to 50-55 ft-lb

(68-75 N•m).

3

Lubricate threads.

F

IG. 6

2

B

D

TI7674b

Reassemble the Coupling Rod and Tie Rods to the Motor

Use this procedure only if the coupling rod (F) and

tie rods (C) have been disassembled from the

motor, to ensure proper alignment of the motor

shaft to the piston rod.

1. Loosen, but do not remove, the screws holding the

adapter plate (J) to the motor (E), on Viscount I Plus

pumps. See F

screw (N) to 50-55 ft-lb (68-75 N•m) into motor (E).

2. Screw the tie rods (C) into the adapter plate (J) and

torque to 50-55 ft-lb (68-75 N•m). On Viscount I Plus

pumps, the tie rods will engage threaded holes in

the base of the motor. Viscount II pumps will engage

into the adapter plate (J).

IG. 6. For Viscount II pumps, torque

Viscount II 460

Pump Shown

1

Torque to 90-100 ft-lb

(122-135 N•m).

2

Torque to 50-55 ft-lb

(68-75 N•m).

3

Lubricate threads.

FIG. 7

E

J

3

2

F

M

1

G

K

TI10466a

N

H

D

C

3

2

B

3. Fill the cavity in the bottom of the motor shaft with

grease. Screw the coupling rod (F) into the motor

shaft until the pin holes align. Install the pin (A) in

the first hole from the end of the coupling. On Viscount II pumps, torque the coupling nut (M) into the

motor shaft.

16 311211M

Page 17

Repair

311211M 17

Page 18

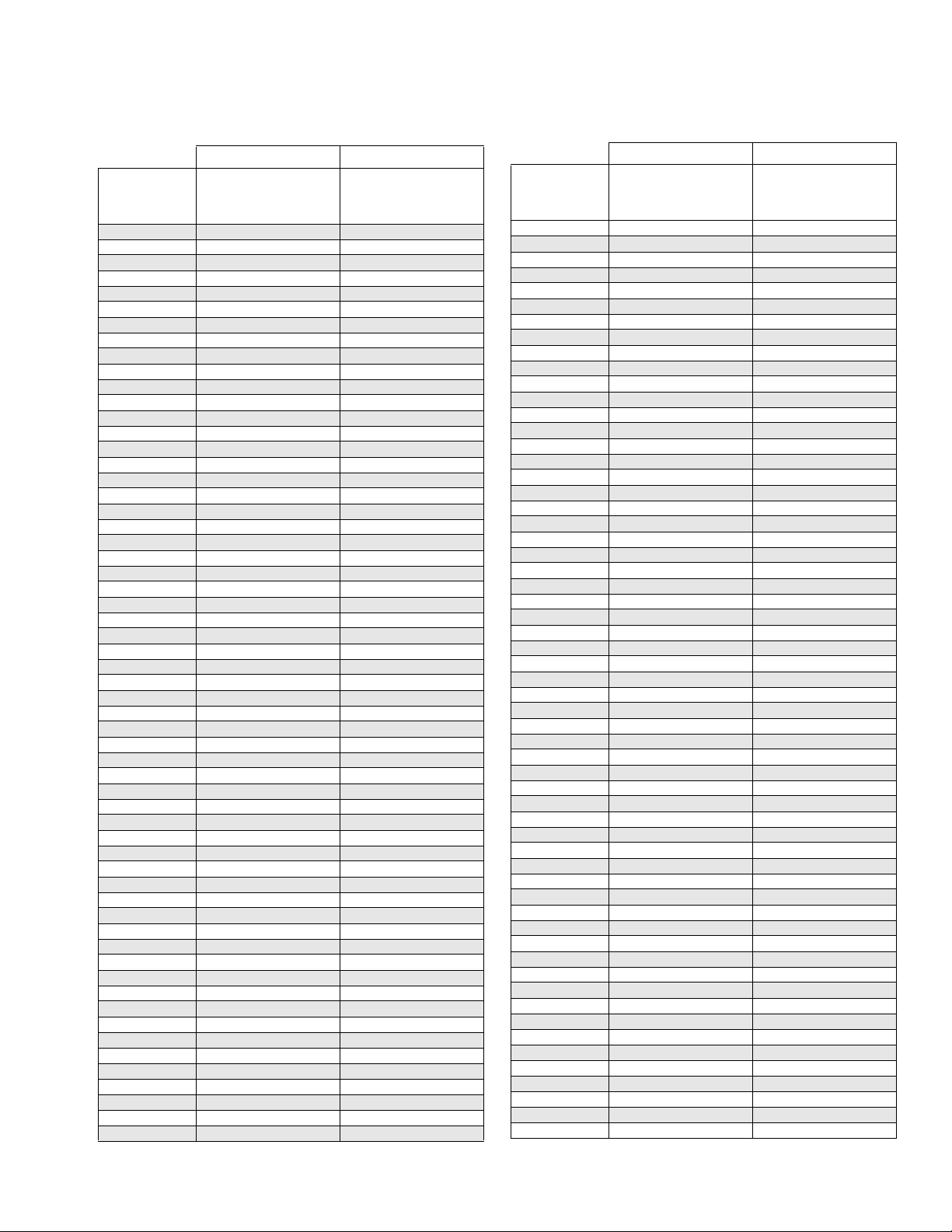

Parts

Parts

NXT Pumps

101

Common Parts

Ref.

No. Description Part No. Qty.

101 MOTOR, NXT, see manual 311238 see table,

page 19

102 LOWER, High-Flo, see manual 311690 see table,

page 19

103 NUT, coupling 184059 1

104 COLLAR, coupling 184128 2

105 ADAPTER, coupling 15H369 1

106 TIE ROD, 14.25 in. (362 mm) between

shoulders

107 NUT, lock, hex; 9/16-12 unc 108683 3

108 COVER, moisture 247362 1

15G924 3

1

1

106

107

108

105

104

103

102

TI8394b

18 311211M

Page 19

Parts That Vary by Model

Parts

101 102

Air-Powered

Pump

(see page 3)

JC20L1 N22LN0 253063

JC20M1 N22LT0 253063

JC30L7 N22LN0 253062

JC30M7 N22LT0 253062

JC35L1 N34LN0 253063

JC35M1 N34LT0 253063

JC40L7 N22LN0 253061

JC40M7 N22LT0 253061

JC45L7 N34LN0 253062

JC45M7 N34LT0 253062

JS20L1 N22LN0 253035

JS20L2 N22LN0 253570

JS20L3 N22LN0 253086

JS20L4 N22LN0 253396

JS20L5 N22LN0 253522

JS20L6 N22LN0 253525

JS20M1 N22LT0 253035

JS20M2 N22LT0 253570

JS20M3 N22LT0 253086

JS20M4 N22LT0 253396

JS20M5 N22LT0 253522

JS20M6 N22LT0 253525

JS20R1 N22RN0 253035

JS20R2 N22RN0 253570

JS20R3 N22RN0 253086

JS20R4 N22RN0 253396

JS20R5 N22RN0 253522

JS20R6 N22RN0 253525

JS20S1 N22RT0 253035

JS20S2 N22RT0 253570

JS20S3 N22RT0 253086

JS20S4 N22RT0 253396

JS20S5 N22RT0 253522

JS20S6 N22RT0 253525

JS30L1 N22LN0 253034

JS30L2 N22LN0 253569

JS30L3 N22LN0 253085

JS30L4 N22LN0 253397

JS30L5 N22LN0 253521

JS30L6 N22LN0 253524

JS30M1 N22LT0 253034

JS30M2 N22LT0 253569

JS30M3 N22LT0 253085

JS30M4 N22LT0 253397

JS30M5 N22LT0 253521

JS30M6 N22LT0 253524

JS30R1 N22RN0 253034

JS30R2 N22RN0 253569

JS30R3 N22RN0 253085

JS30R4 N22RN0 253397

JS30R5 N22RN0 253521

JS30R6 N22RN0 253524

JS30S1 N22RT0 253034

JS30S2 N22RT0 253569

JS30S3 N22RT0 253085

JS30S4 N22RT0 253397

JS30S5 N22RT0 253521

JS30S6 N22RT0 253524

JS35L1 N34LN0 253035

NXT Air Motor

(see manual 311238)

High-Flo Lower

(see manual 311690)

101 102

Air-Powered

Pump

(see page 3)

JS35L2 N34LN0 253570

JS35L3 N34LN0 253086

JS35L4 N34LN0 253396

JS35L5 N34LN0 253522

JS35L6 N34LN0 253525

JS35M1 N34LT0 253035

JS35M2 N34LT0 253570

JS35M3 N34LT0 253086

JS35M4 N34LT0 253396

JS35M5 N34LT0 253522

JS35M6 N34LT0 253525

JS35R1 N34RN0 253035

JS35R2 N34RN0 253570

JS35R3 N34RN0 253086

JS35R4 N34RN0 253396

JS35R5 N34RN0 253522

JS35R6 N34RN0 253525

JS35S1 N34RT0 253035

JS35S2 N34RT0 253570

JS35S3 N34RT0 253086

JS35S4 N34RT0 253396

JS35S5 N34RT0 253522

JS35S6 N34RT0 253525

JS40L1 N22LN0 253033

JS40L2 N22LN0 253568

JS40L3 N22LN0 253423

JS40L4 N22LN0 253398

JS40L5 N22LN0 253520

JS40L6 N22LN0 253523

JS40M1 N22LT0 253033

JS40M2 N22LT0 253568

JS40M3 N22LT0 253423

JS40M4 N22LT0 253398

JS40M5 N22LT0 253520

JS40M6 N22LT0 253523

JS40R1 N22RN0 253033

JS40R2 N22RN0 253568

JS40R3 N22RN0 253423

JS40R4 N22RN0 253398

JS40R5 N22RN0 253520

JS40R6 N22RN0 253523

JS40S1 N22RT0 253033

JS40S2 N22RT0 253568

JS40S3 N22RT0 253423

JS40S4 N22RT0 253398

JS40S5 N22RT0 253520

JS40S6 N22RT0 253523

JS45L1 N34LN0 253034

JS45L2 N34LN0 253569

JS45L3 N34LN0 253085

JS45L4 N34LN0 253397

JS45L5 N34LN0 253521

JS45L6 N34LN0 253524

JS45M1 N34LT0 253034

JS45M2 N34LT0 253569

JS45M3 N34LT0 253085

JS45M4 N34LT0 253397

JS45M5 N34LT0 253521

JS45M6 N34LT0 253524

NXT Air Motor

(see manual 311238)

High-Flo Lower

(see manual 311690)

311211M 19

Page 20

Parts

101 102

Air-Powered

Pump

(see page 3)

JS45R1 N34RN0 253034

JS45R2 N34RN0 253569

JS45R3 N34RN0 253085

JS45R4 N34RN0 253397

JS45R5 N34RN0 253521

JS45R6 N34RN0 253524

JS45S1 N34RT0 253034

JS45S2 N34RT0 253569

JS45S3 N34RT0 253085

JS45S4 N34RT0 253397

JS45S5 N34RT0 253521

JS45S6 N34RT0 253524

NXT Air Motor

(see manual 311238)

High-Flo Lower

(see manual 311690)

20 311211M

Page 21

Viscount I Plus Pumps

101

111

Parts

Common Parts

Ref.

No. Description Part No. Qty.

101 MOTOR, Viscount 1+, see manual

308330

102 LOWER, High-Flo, see manual 311690 see table,

103 TIE ROD, 14.25 in. (362 mm) between

shoulders

104 NUT, lock, hex; 9/16-12 unc 108683 3

105 NUT, coupling 184059 1

106 COLLAR, coupling 184128 2

107 PIN, cotter 100103 1

108 ADAPTER, coupling 15H838 1

109 SCREW, cap 100001 4

110 WASHER, lock 100214 4

111 PLATE, adapter 189206 1

261466 1

below

15G924 3

Parts That Vary by Model

1

103

104

107

110

109

108

106

105

102

Hydraulic-Powered Pump

(see page 3)

253642 253033

253643 253034

24E787 24E783

24E788 24E784

253644 253568

253645 253569

253646 253061

253647 253062

253648 253423

253649 253085

253650 253398

253651 253397

253652 253520

253653 253521

253654 253523

253655 253524

102

High-Flo Lower

(see manual 311690)

TI7674b

311211M 21

Page 22

Parts

Viscount II 460 Pumps

103

101

Common Parts

Ref.

No. Description Part No. Qty.

101 MOTOR, Viscount II, see manual

308048

102 LOWER, High-Flo, see manual 311690 see table,

103 TIE ROD, 14.25 in. (362 mm) between

shoulders

104 NUT, lock, hex; 9/16-12 unc 108683 3

105 NUT, coupling 184059 1

106 COLLAR, coupling 184128 2

108 ADAPTER, coupling 15K736 1

109 SCREW, cap, socket hd C19789 3

110 NUT, coupling 183079 1

111 BRACKET, mounting 120558 1

223646 1

below

15G924 3

Parts That Vary by Model

1

111

103

104

110

106

105

108

109

102

Hydraulic-Powered Pump

(see page 3)

247355 253035

24E786 24E785

247356 253063

247357 253086

247358 253396

247359 253522

247360 253525

247361 253570

102

High-Flo Lower

(see manual 311690)

TI10467a

22 311211M

Page 23

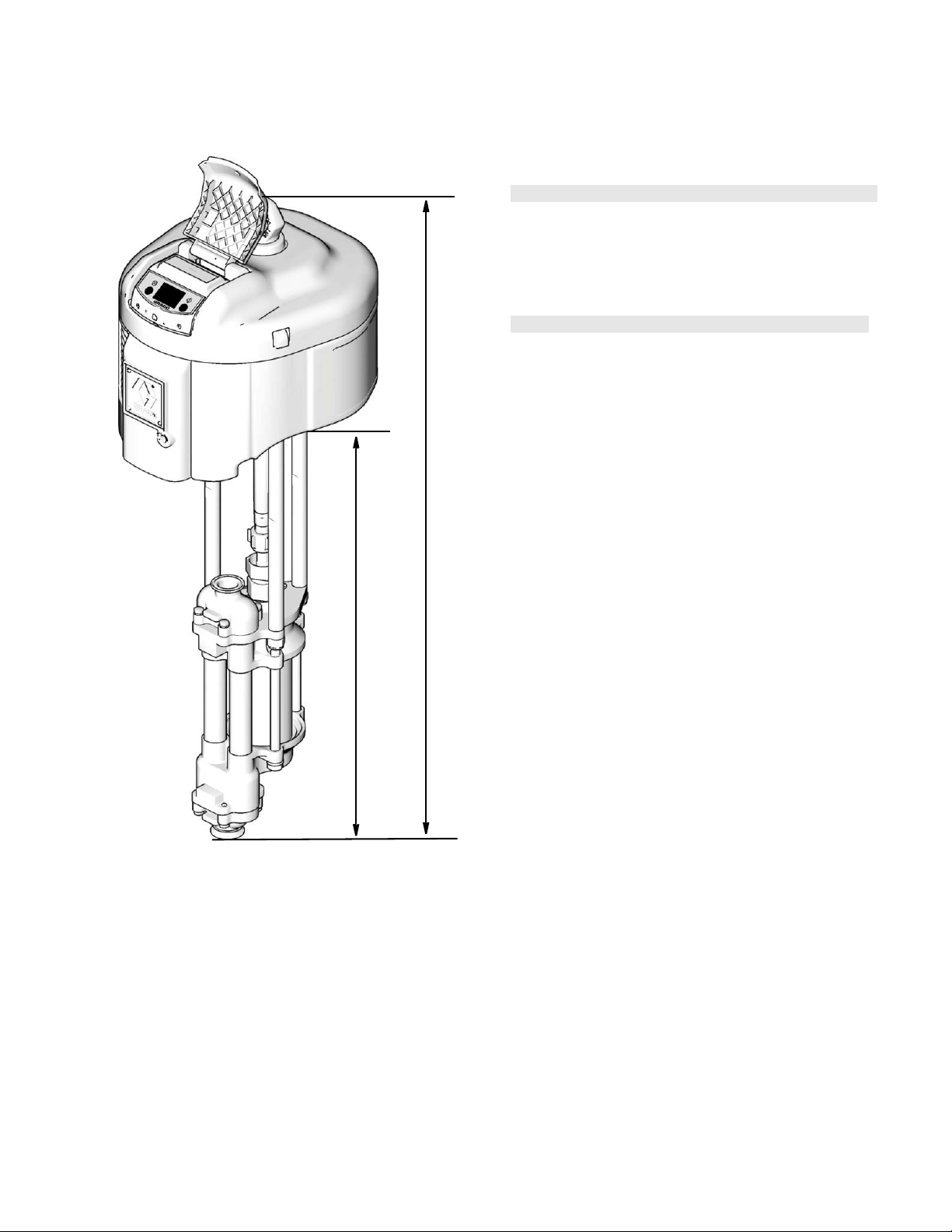

Dimensions

Dimensions

A

Air-Powered Pumps

Approx.

B

Pump ModelAin. (mm)

NXT cst 45.60 (1158) 28.78 (731) 96 (43)

in. (mm)

Weight

lb (kg)

Hydraulic-Powered Pumps

Approx.

A

Pump Model

Viscount I Plus cst 49.00 (1245) 28.78 (731) 76 (35)

Viscount II 53.72 (1365) 28.78 (731) 144 (65)

in. (mm)

B

in. (mm)

Weight

lb (kg)

TI8354a

B

311211M 23

Page 24

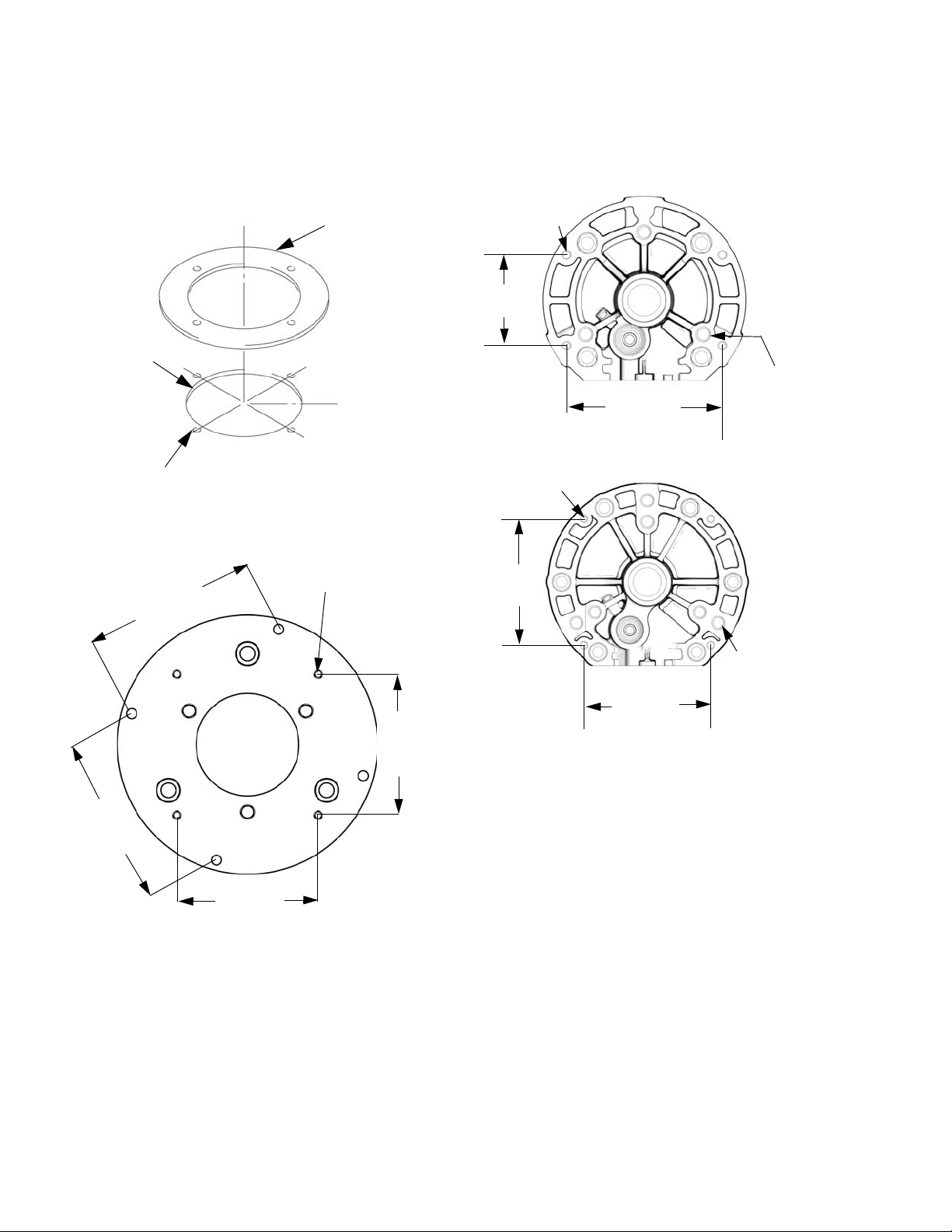

Pump Mounting Hole Diagram

)

Pump Mounting Hole Diagram

Viscount I Plus Models

9.75 in.

(247.7 mm)

Four 0.44 in. (11.1 mm)

diameter holes on 10.5 in.

bolt circle

Viscount II Models

7.43 in.

(188 mm)

Gasket

161806

4X 3/8-16 UNC - 2B

Four 3/8-16

Mounting Holes

3.938 in.

(100 mm)

Four 3/8-16

Mounting Holes

6.186 in.

(157 mm)

NXT 2200

6.750 in.

(172 mm)

NXT 3400

Three 5/8-11 Tie

Rod Holes

5.906 in. (150 mm

x 120° Bolt Circle

TI8071A

7.43 in.

(188 mm)

6.186 in.

(157 mm)

6.186 in.

(157 mm)

6.186 in.

(157 mm)

Six 5/8-11 Tie

Rod Holes

8.000 in. (203 mm)

x 120° Bolt Circle

5.906 in. (150 mm)

x 120° Bolt Circle

TI8070A

24 311211M

Page 25

Technical Data

NXT

Fluid Flow at

Maximum

Working Pressure

Model

JX20XX 200 (1.4, 14)

JX30XX 300 (2.1, 21) 23 (88) 2.6 (0.7)

JX35XX 350 (2.4, 24) 32 (121) 1.9 (0.5)

JX40XX 400 (2.8, 28) 17 (64) 3.6 (0.9)

JX45XX 450 (3.1, 31) 23 (88) 2.6 (0.7)

psi (MPa, bar)

See 311238 for Sound information.

Viscount I Plus Pumps

Air Operating

Range

psi (MPa, bar) Air Consumption

100 (0.7, 7.0) See Performance Chart

60 cycles per

minute

gpm (lpm)

32 (121) 1.9 (0.5)

Pump Cycles

per Gallon

(Liter)

Technical Data

Maximum

Fluid

Temperature

Rating

°F (°C)

150° (66°)

Maximum

Working

Pressure

Model

253642 300 (2.1, 21)

253643 225 (1.6, 16) 20 (74) 3.1 (0.8)

24E787 300 (2.1, 21) 14 (54) 4.2 (1.1)

24E788 225 (1.6, 16) 20 (74) 3.1 (0.8)

253644 300 (2.1, 21) 14 (54) 4.2 (1.1)

253645 225 (1.6, 16) 20 (74) 3.1 (0.8)

253646 300 (2.1, 21) 14 (54) 4.2 (1.1)

253647 225 (1.6, 16) 20 (74) 3.1 (0.8)

253648 300 (2.1, 21) 14 (54) 4.2 (1.1)

253649 225 (1.6, 16) 20 (74) 3.1 (0.8)

253650 300 (2.1, 21) 14 (54) 4.2 (1.1)

253651 225 (1.6, 16) 20 (74) 3.1 (0.8)

253652 300 (2.1, 21) 14 (54) 4.2 (1.1)

253653 225 (1.6, 16) 20 (74) 3.1 (0.8)

253654 300 (2.1, 21) 14 (54) 4.2 (1.1)

253655 225 (1.6, 16) 20 (74) 3.1 (0.8)

psi (MPa, bar)

Maximum

Hydraulic Working

Pressure

psi (MPa, bar)

1500 (10.3, 103)

Hydraulic Oil

Consumption

See Performance

Chart

Maximum

Hydraulic

Motor Fluid

Temperature

134°F (54°C)

Fluid Flow at

60 cycles per

minute

gpm (lpm)

14 (54) 4.2 (1.1)

per Gallon

Pump

Cycles

(Liter)

Viscount II Pumps

Model

247355

24E786

247356

247357

247358

247359

247360

247361

Maximum

Working

Pressure

psi (MPa, bar)

460 (3.2, 32) 1200 (8.3, 83)

Maximum

Hydraulic Working

Pressure

psi (MPa, bar)

Hydraulic Oil

Consumption

See Performance

Chart

Maximum

Hydraulic

Motor Fluid

Temperature

134°F (54°C) 31.7 (120) 1.89 (0.50) 150°F (66°C)

Fluid Flow at

60 cycles per

minute

gpm (lpm)

Pump

Cycles

per Gallon

(Liter)

Maximum

Fluid

Temperature

Rating

150°F (66°C)

Maximum

Fluid

Temperature

Rating

311211M 25

Page 26

Performance Charts

Performance Charts

Air-Powered Pumps

Fluid Outlet Pressure - Black Curves

To find Fluid Outlet Pressure (psi/MPa/bar) at a specific fluid

flow (gpm/lpm) and operating air pressure (psi/MPa/bar):

1. Locate desired flow along bottom of chart.

2. Follow vertical line up to intersection with selected fluid

outlet pressure curve (black).

3. Follow left to scale to read fluid outlet pressure.

Key:

A 100 psi (0.7 MPa, 7.0 bar) air pressure

B 70 psi (0.49 MPa, 4.9 bar) air pressure

C 40 psi (0.28 Mpa, 2.8 bar) air pressure

2200cc NXT Air Motor, 1000cc High-Flo Lower

CYCLES PER MIN.

10.0

(37.9)

39

12.0

(45.4)

45

SCFM (m

70 (1.96)

60 (1.68)

50 (1.40)

40 (1.12)

30 (0.84)

20 (0.56)

10 (0.28)

0 (0.0)

14.0

(53.0)

gpm

(lpm)

3

/min.)

AIR FLOW

0

0.0

(0.0)

7

A

B

C

2.0

(7.0)

psi (MPa, bar)

450 (3.1, 31)

400 (2.8, 28)

350 (2.4, 24)

300 (2.1, 21)

250 (1.7, 17)

200 (1.4, 14)

150 (1.0, 10)

100 (0.7, 7)

FLUID PRESSURE

50 (0.3, 3)

0 (0, 0)

14

20 26 33

A

B

C

4.0

6.0

(15.0)

(22.5)

(30.0)

FLUID FLOW

8.0

Air Consumption - Gray Curves

To find Pump Air Consumption (scfm or m3/min.) at a specific

fluid flow (gpm/lpm) and air pressure (psi/MPa/bar):

1. Locate desired flow along bottom of chart.

2. Read vertical line up to intersection with selected air consumption curve (dashes).

3. Follow left to scale to read air consumption.

2200cc NXT Air Motor, 1500cc High-Flo Lower

CYCLES PER MIN.

psi (MPa, bar)

300 (2.1, 21)

05

A

250 (1.7, 17)

200 (1.4, 14)

150 (1.0, 10)

100 (0.7, 7)

FLUID PRESSURE

50 (0.3, 3)

0 (0, 0)

0.0

(0.0)

B

C

2.0

(7.0)

10

15

A

B

C

4.0

6.0

(22.5)

8.0

(30.0)

(15.0)

FLUID FLOW

20 24

10.0

(37.9)

28

12.0

(45.4)

32

SCFM (m

50 (1.40)

45 (1.26)

40 (1.12)

35 (0.98)

30 (0.84)

25 (0.7)

20 (0.56)

15 (0.42)

10 (0.28)

5 (0.14)

0 (0.0)

14.0

(53.0)

gpm

(lpm)

3

/min.)

AIR FLOW

26 311211M

Page 27

Performance Charts

2200cc NXT Air Motor, 2000cc High-Flo Lower

CYCLES PER MIN.

21

12.0

(45.4)

24

SCFM (m

40 (1.12)

35 (0.98)

30 (0.84)

25 (0.7)

20 (0.56)

15 (0.42)

10 (0.28)

5 (0.14)

0 (0.0)

14.0

(53.0)

gpm

(lpm)

0 (0, 0)

0

0.0

(0.0)

A

B

C

2.0

(7.0)

psi (MPa, bar)

250 (1.7, 17)

200 (1.4, 14)

150 (1.0, 10)

100 (0.7, 7)

50 (0.3, 3)

FLUID PRESSURE

4

8

14

11

17

A

B

C

4.0

6.0

8.0

(15.0)

(22.5)

(30.0)

10.0

(37.9)

FLUID FLOW

3400cc NXT Air Motor, 2000cc High-Flo Lower

3

/min.)

AIR FLOW

3400cc NXT Air Motor, 1500cc High-Flo Lower

CYCLES PER MIN.

15

0 (0, 0)

0

0.0

(0.0)

A

B

C

2.0

(7.0)

psi (MPa, bar)

500 (3.5, 35)

450 (3.1, 31)

400 (2.8, 28)

350 (2.4, 24)

300 (2.1, 21)

250 (1.7, 17)

200 (1.4, 14)

150 (1.0, 10)

100 (0.7, 7)

FLUID PRESSURE

50 (0.3, 3)

10

5

4.0

(15.0)

FLUID FLOW

A

B

C

6.0

(22.5)

20

8.0

(30.0)

24

10.0

(37.9)

28

12.0

(45.4)

32

SCFM (m

80 (2.24)

70 (1.96)

60 (1.68)

50 (1.4)

40 (1.12)

30 (0.84)

20 (0.56)

10 (0.28)

0 (0.0)

14.0

(53.0)

gpm

(lpm)

3

/min.)

AIR FLOW

4

0 (0, 0)

0

0.0

(0.0)

A

B

C

2.0

(7.0)

psi (MPa, bar)

350 (2.4, 24)

300 (2.1, 21)

250 (1.7, 17)

200 (1.4, 14)

150 (1.0, 10)

100 (0.7, 7)

FLUID PRESSURE

50 (0.3, 3)

CYCLES PER MIN.

11

8

14

17

A

B

C

4.0

6.0

8.0

(15.0)

(22.5)

FLUID FLOW

(30.0)

10.0

(37.9)

21 24

12.0

(45.4)

SCFM (m

60 (1.68)

50 (1.4)

40 (1.12)

30 (0.84)

20 (0.56)

10 (0.28)

0 (0.0)

14.0

(53.0)

gpm

(lpm)

3

/min.)

AIR FLOW

311211M 27

Page 28

Performance Charts

Hydraulic Powered Pumps

Viscount I Plus 225 Pumps

Viscount I Plus 300 Pumps

28 311211M

Page 29

Viscount II 460 Pumps

Performance Charts

Viscount II 460 - MR4Ball - 2000cc

Performance @ 600 1050 1200 PSIG

CYCLES PER MIN.

450 (3.1, 31)

400 (2.8, 28)

350 (2.4, 24)

300 (2.1, 21)

250 (1.7, 17)

200 (1.4, 14)

150 (1.0, 10)

100 (0.7, 7)

FLUID PRESSURE, psi (MPa, bar)

Key:

A High PSIG

B Mid PSIG

C Low PSIG

50 (0.3, 3)

0 (0, 0)

048121620

A

B

C

2.0

4.0

6.0

8.0

0.0

(0.0)

(7.0)

(15.0)

(22.5)

FLUID FLOW, gpm (lpm)

(30.0)

10.0

(37.9)

24 28

12.0

(45.4)

14.0

(53.0)

32

16.0

(60.6)

36

18.0

(68.1)

8

7

6

5

4

OIL FLOW (gpm)

3

2

1

0

311211M 29

Page 30

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 311211

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2006, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 3/2010

Loading...

Loading...