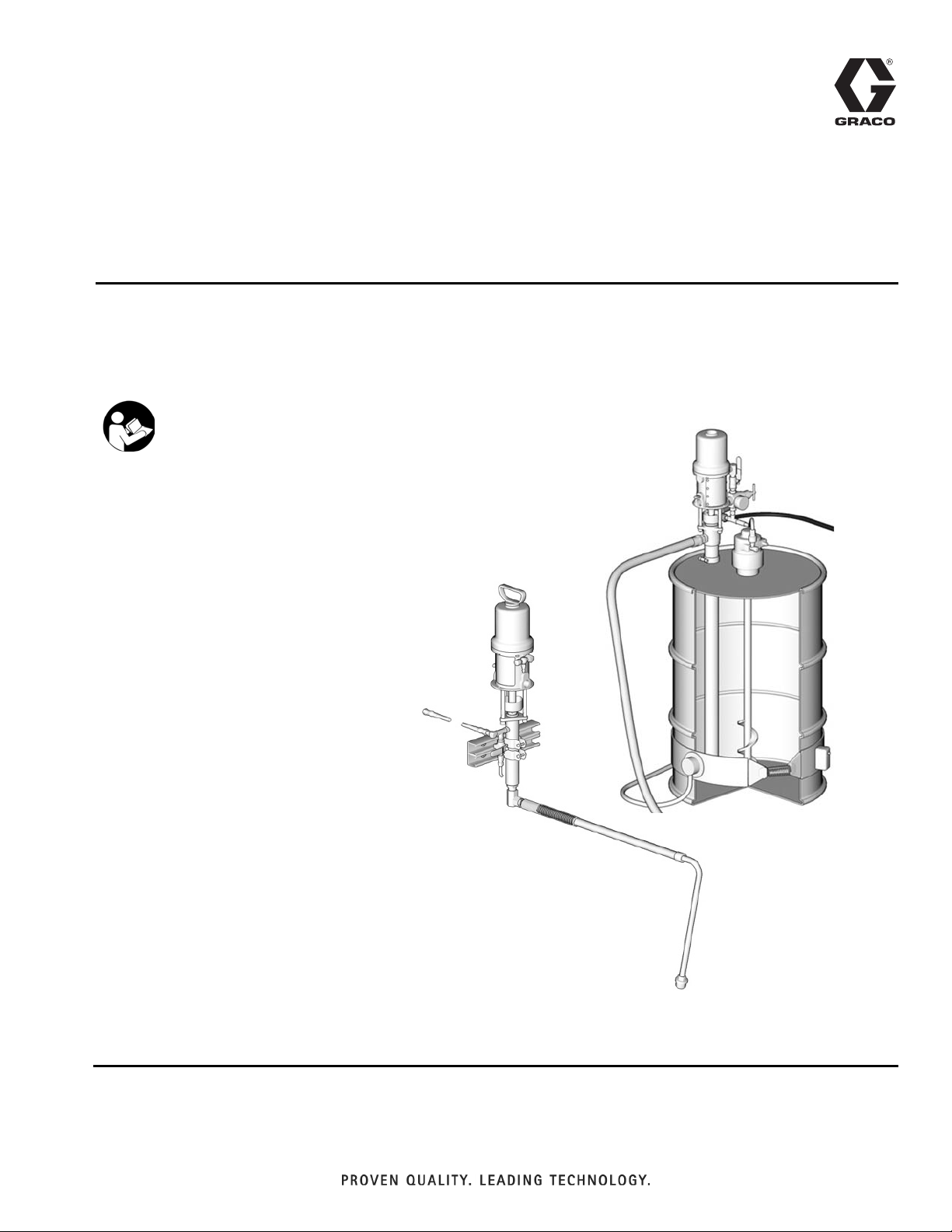

Page 1

Instruction - Parts

Feed and

Solvent Flush Kits

For use with proportioner systems. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for model information, including

maximum working pressure.

Agitator kit 248824 and

Feed pump kit 248825 shown

310863M

EN

Solvent flush kit

248826 shown

TI5726

TI5675

Page 2

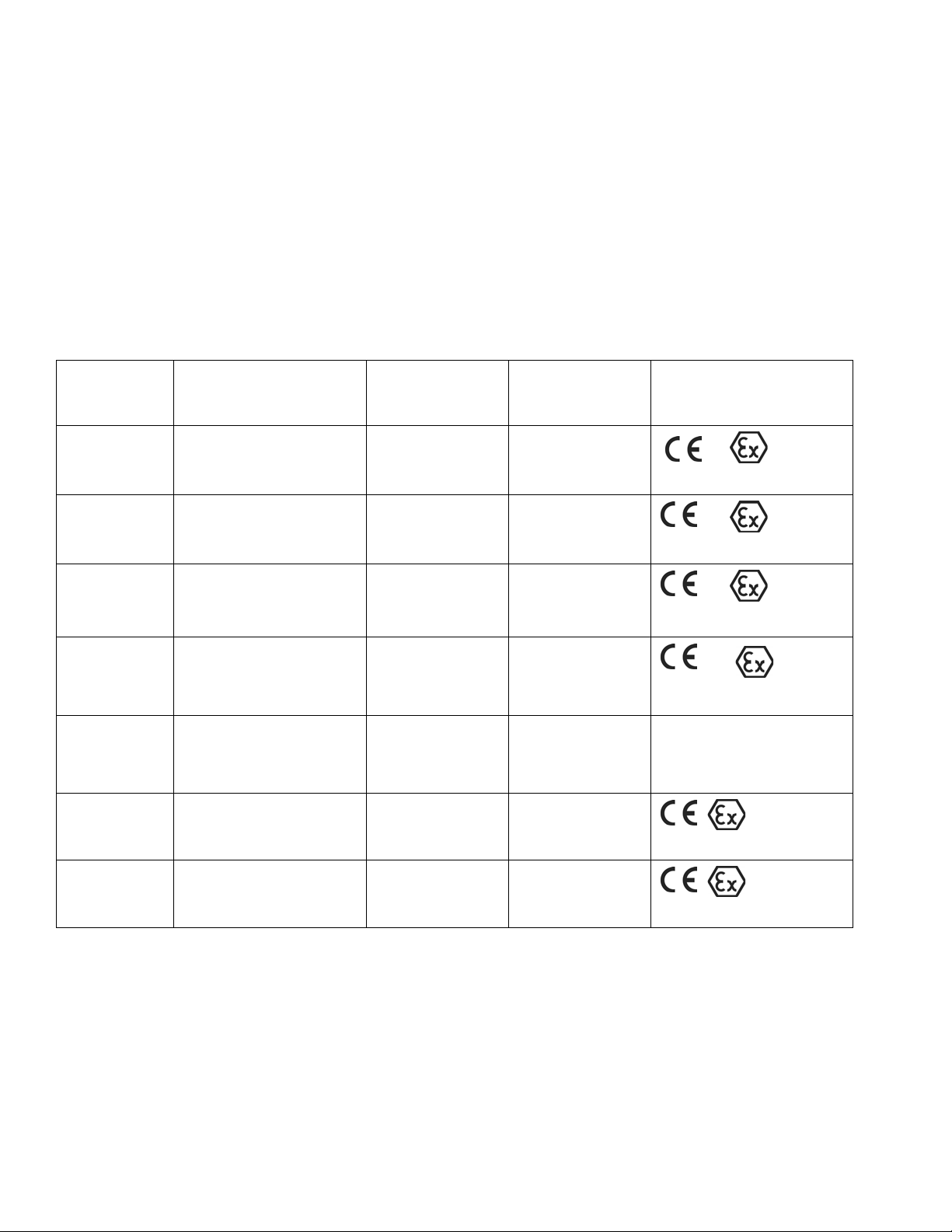

Pump Kits

Contents

Pump Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation/Maintenance . . . . . . . . . . . . . . . . . . . . . . 8

Pump Kits

Complete

Package

(fluid and air) Description

248824 Agitator kit with air con-

nection

248825

Monark

®

5:1 feed pump,

drum size

248826

Monark

®

23:1°

wall-mount, pail size, solvent flush kit

248885

Monark

®

23:1 5-gallon,

pail-mount, solvent flush

kit

Maximum Air

Wor king

Pressure

100 psi

(0.7 MPa, 7 bar)

180 psi

(1.2 MPa, 12 bar)

120 psi

(0.8 MPa, 8 bar)

120 psi

(0.8 MPa, 8 bar)

Troubleshooting/Repair . . . . . . . . . . . . . . . . . . . . . . 8

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 16

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maximum Fluid

Working

Pressure Approvals

NA

ll 1/2 G c T3

Agitator 224854

ITS03ATEX11226

900 psi

(6.2 MPa, 62 bar)

0359

Pump 218956

ll 1/2 G c T2

ITS03ATEX11228

2760 psi

(19 MPa, 190 bar)

0359

Pump 223596

ll 1/2 G c T3

ITS03ATEX11228

2760 psi

(19 MPa, 190 bar)

0359

Pump 223596

ll 1/2 G c T3

ITS03ATEX11251

248951

OBSOLETE

(replaced by

258980)

258980

262393

Merkur

®

40:1

wall-mount, pail size, solvent flush kit

Merkur

®

45:1

wall-mount, solvent flush

kit

®

Merkur

45:1

machine-mount, solvent

flush kit; XP systems

100 psi

(0.7 MPa, 7 bar)

100 psi

(0.7 MPa, 7 bar)

100 psi

(0.7 MPa, 7 bar)

4000 psi

(28 MPa, 280 bar)

4500 psi

(31 MPa, 310 bar)

4500 psi

(31 MPa, 310 bar)

ll 2 G c T3 (200°C)

Pump 262287

ll 2 G c T3 (200°C)

Pump 262392

2 310863M

Page 3

Manual Conventions

WARNING

Hazard Symbol

WARNING: a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Warnings in the instructions usually include a symbol

indicating the hazard. Read the general Warnings

section for additional safety information.

CAUTION

CAUTION: a potentially hazardous situation which, if

not avoided, may result in property damage or

destruction of equipment.

Note

Manual Conventions

Additional helpful information.

310863M 3

Page 4

Warnings

Warnings

The following general warnings are related to the safe setup, use, grounding, maintenance, and repair of this equipment. Additional more specific warnings may be found throughout the text of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground equipment and conductive objects in work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD -

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or overbend hoses or use hoses to pull equipment.

• Comply with all applicable safety regulations.

4 310863M

Page 5

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

310863M 5

Page 6

Installation

Installation

If this equipment is used in a Hydra-Cat™ or Xtreme

™

proportioning package, see manual 310794.

Mix

2. Install feed kits

1. Install solvent flush kit

a. See FIG. 1. Install pump using mounting

bracket (202) and hardware supplied.

Mount bracket on wall, back of proportioner stand, or cart.

For wall mount, ensure that wall is strong enough to

support weight of equipment, fluid, hoses, and

stress caused during operation. Mount at a convenient height for operation and maintenance, and so

suction hose is not stretched tight. Ensure that

equipment is level.

b. Connect suction hose (207) to elbow

(206) at pump inlet. Place suction tube

in container of solvent.

a. See FIG. 2. Install feed pump (101) in

drum and secure with bung adapter

(BA).

b. Install air control kit (104).

c. Screw swivel union (103) into pump fluid

outlet. Connect hose (102) to swivel.

Connect other end of hose to proportioner.

101

104

103

102

BA

202

206

207

F

IG. 2: Feed Pump

TI5675

F

IG. 1: Solvent Flush Kit

6 310863M

TI5674

Page 7

Installation

3. Install agitator kit

a. See FIG. 3. Install agitator (1) in drum.

b. Screw air line fitting (2a) into agitator

inlet. Connect air line coupler (2b) into

fitting (2a).

2a

2b

5. Grounding

WARNING

Your system must be grounded. Read warnings, page

4.

• Proportioner pump: follow instructions in propor-

tioner operation manual.

• Air and fluid hoses: use only electrically conductive hoses.

• Air compressor: follow manufacturer’s recommendations.

• Spray gun: ground through connection to a properly grounded fluid hose and pump.

• Feed pumps and solvent pump: follow instructions in feed pump manual.

1

• Object being sprayed: follow local code.

FIG. 3: Agitator Kit

4. Connect air lines

a. Shut off air valves at feed pumps.

b. Connect air lines to quick disconnect fit-

tings at feed pump and agitator.

TI5514

• Solvent pails used when flushing: follow local

code. Use only conductive metal pails, placed on a

grounded surface. Do not place the pail on a nonconductive surface, such as paper or cardboard,

which interrupts grounding continuity.

• To maintain grounding continuity when flushing

or relieving pressure: hold metal part of the spray

gun/dispense valve firmly to the side of a grounded

metal pail, then trigger the gun/valve.

6. Flush Before Using

Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Flushing the System in the proportioner operation

manual.

310863M 7

Page 8

Operation/Maintenance

Operation/Maintenance

Refer to separate pump and agitator manuals for operation and maintenance instructions. See parts lists beginning on page 9 for manual numbers.

Troubleshooting/Repair

Refer to separate pump and agitator manuals for operation and maintenance instructions. See parts lists beginning on page 9 for manual numbers.

8 310863M

Page 9

Parts

Part No. 248824, Agitator Kit with Air

Connection

Parts

Ref.

No. Part No. Description Qty.

1 224854 AGITATOR, helix; see 308175 1

2 249002 KIT, air line, agitator 1

2a 169969 FITTING, air line

2b 208536 COUPLER, air line

2c 203266 HOSE, coupled, air

2d 104984 TEE, pipe, 1/4 npt

2e 156971 NIPPLE, short, 1/4 npt

Part No. 248825, Feed Kit, 5:1 Monark

Ref.

No. Part No. Description Qty.

101 218956 PUMP, Monark 5:1; see 307044 1

102 217382 HOSE, coupled, 10 ft (3.05 m) x

3/4 id

103 157785 FITTING, swivel, 3/4 npsm (m x f) 1

104 248829 REGULATOR KIT, air, feed pump 1

2e

2d

2c

2b

1//8 npt

1

2a

2 - 11-1/2 npt

TI5515

101

1

103

102

104

air inlet fitting

1/4 npt

TI5674

310863M 9

Page 10

Parts

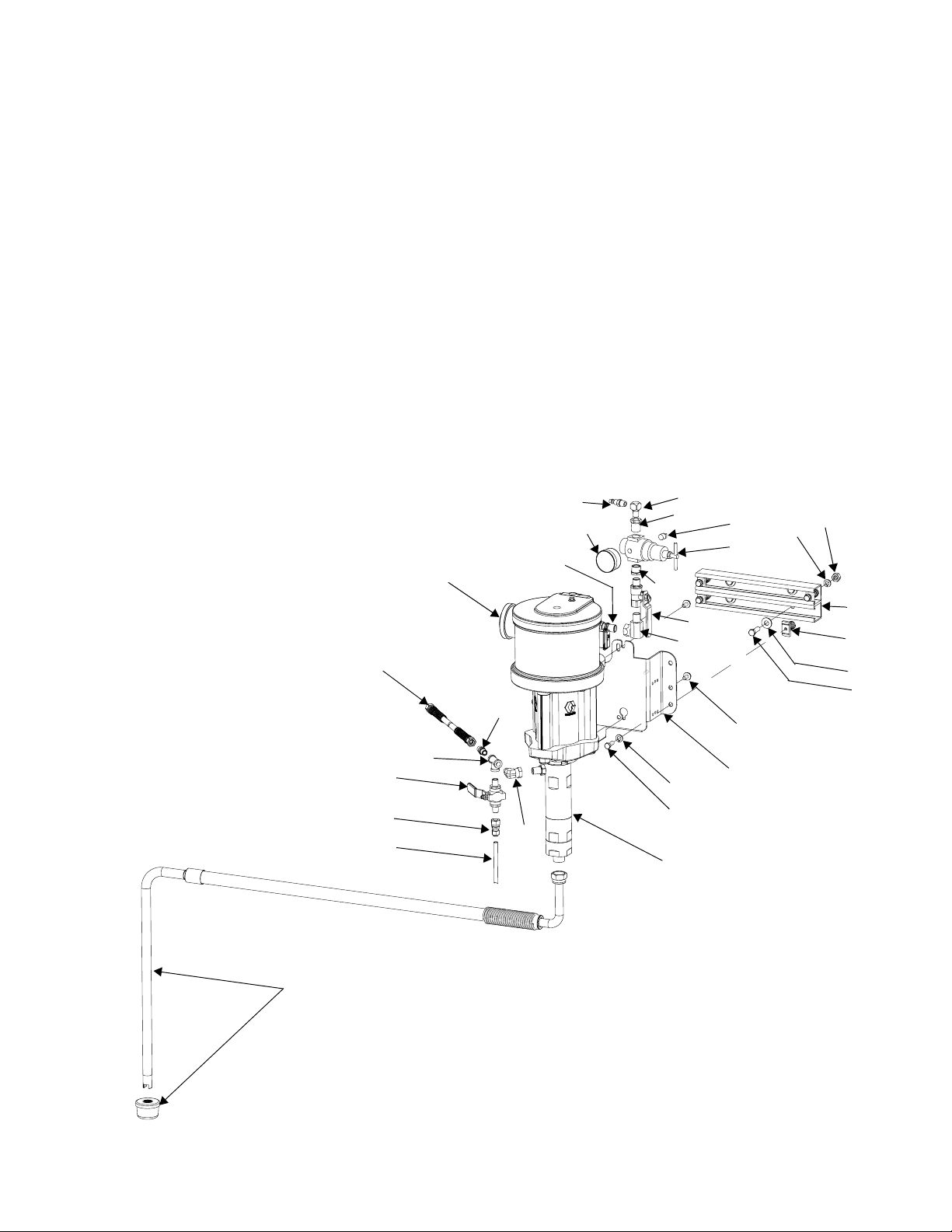

Part No. 248826, Solvent Flush Kit

Ref.

No. Part No. Description Qty.

201 223596 PUMP, Monark, 23:1 (chrome); see

307619

202 15E737 SUPPORT, clamp, solvent pump 1

203 164259 ELBOW, street 1

204 169969 FITTING, air line 1

205 206264 VALVE, needle 1

206 156589 FITTING, union, adapter, 90° 1

207 244354 HOSE, suction, (5-gallon pail) 1

208 187651 STRAINER, 3/4-16 unf 1

209 157350 ADAPTER, 3/8 npt x 1/4 npt 1

1/4 npsm outlet

Ref.

No. Part No. Description Qty.

210 104984 TEE, pipe 1

1

211 223541 HOSE, coupled, 50 ft (15.24 m) 1

213 100004 SCREW, cap, hex head 4

214 100132 WASHER, flat 4

215 100052 WASHER, lock 4

216 101213 NUT, full, hex 4

217 15E756 CLAMP, unistrut mount, Monark 2

218 156971 NIPPLE, short 1

219 100840 ELBOW, street 1

220 238635 VALVE, ball, cs 1

221 205447 COUPLING, hose 1

222 061132 HOSE, nylon, wpr 225, 4 ft (1.22 m) 1

223 100896 FITTING, bushing, pipe 1

201

203

202

205

204

216

211

218

219

220

221

222

210

209

206

223

215

217

214

213

207

208

10 310863M

TI5676

Page 11

Part No. 248885, Solvent Pump, 5 Gallon Pail-Mount

Parts

Ref.

No. Part No. Description Qty.

301 240435 COVER, pail 1

302 223596 PUMP, Monark, 23:1 (chrome); see

307619

303 100644 SCREW, cap, socket head 2

304 100016 WASHER, lock 2

305 155699 ELBOW, street 1

306 114337 FITTING, nipple, cs, straight 1

307 114478 TUBE, flare, riser tube, sst 1

308 192889 FITTING, bulkhead 1

309 114830 WASHER, flat 1

310 102300 NUT 1

311 157350 ADAPTER, 3/8 npt x 1/4 npt 1

312 104984 TEE, pipe 1

313 100840 ELBOW, street 1

314 101962 SCREW, set, socket head 2

315 101108 PAIL, metal, 5 gallon 1

Ref.

No. Part No. Description Qty.

319 114575 PLUG, button 1

320 114371 KNOB, screw 3

1

321 238909 WIRE, grounding assembly 1

322 187190 STRAINER 1

327 223756 HOSE, coupled, 15 ft (4.57 m) 1

328 156971 NIPPLE, short 2

329 223541 HOSE, coupled, 50 ft (15.24 m) 1

330 200991 HOSE, coupled, 10 ft (3.05 m) not

shown

331 164259 ELBOW, street 1

332 206264 VALVE, needle 1

333 169969 FITTING, air line 1

340 238635 VALVE, ball, cs 1

341 205447 COUPLING, hose 1

342 061132 HOSE, nylon, wpr 225, 4 ft (1.22 m) 1

332

302

333

331

1

1/4 npsm outlet

329

327

328

313

340

341

342

321

328

311

312

309

310

307

322

308

303

304

305

319

314

320

301

306

315

TI5730

310863M 11

Page 12

Parts

Part No. 248951, Solvent Flush Kit, Merkur

Ref.

No. Part No. Description Qty.

401 233900 SPRAYER, Merkur; see 309463 1

402 15E737 SUPPORT, clamp, solvent pump 1

403 100450 SCREW, cap, hex head 4

404 100023 WASHER, flat 4

405 100896 FITTING, bushing, pipe 1

406 244354 HOSE, suction, (5-gallon pail) 1

407 156589 FITTING, union, adapter, 90° 1

408 187651 STRAINER, 3/4-16 unf 1

409 150287 COUPLING 1

410 104984 TEE, pipe 1

1/4 npsm outlet

418

411

417

Ref.

No. Part No. Description Qty.

411 223541 HOSE, coupled, 50 ft (15.24 m) 1

412 15E889 NUT, clamp, unistrut mount 4

413 100004 SCREW, cap, hex head 4

414 100132 WASHER, flat 4

415 100133 WASHER, lock 8

416 100131 NUT, full hex 4

417 156971 NIPPLE, short 1

418 100840 ELBOW, street 2

419 238635 VALVE, ball, cs 1

420 205447 COUPLING, hose 1

421 061132 HOSE, nylon, wpr 225, 4 ft (1.22 m) 1

422 100176 BUSHING, hex 1

423 248829 AIR REGULATOR KIT, feed pump 1

401

412

404

414

409410

422

413

415

403

415

402

416

408

TI5728

406

419

420

421

405

407

air inlet fitting

1/4 npt

423

12 310863M

Page 13

Part No. 258980, Solvent Flush Kit, 45:1 Merkur

Ref.

No. Part No. Description Qty.

501 262287 PUMP, solvent; see manual 312794 1

501a LW050A LOWER, 50cc; see manual 312792 1

501b M12LN0 MOTOR, 1200cc; see manual 312796 1

501c 15T795 PLATE, wall mount 1

501d 111799 SCREW, cap, hex hd 4

501e 116395 FITTING, swivel, elbow 1

501f 256421 KIT, suction tube; includes hose and

strainer

255871 HOSE, siphon, assembly 1

181073 STRAINER, inlet; 1/2-14 npsm 1

501g 100081 BUSHING, pipe 2

501h 166469 NIPPLE, pipe, hex 1

504 15E737 SUPPORT, clamp, solvent pump 1

505 100132 WASHER, flat 4

506 100004 SCREW, cap, hex hd 4

507 100133 WASHER, lock 8

1

Parts

Ref.

No. Part No. Description Qty.

508 100131 NUT, full hex 4

509 100450 SCREW, cap, hex hd 4

510 15E889 NUT, clamp, mount, unistrut 4

512 104984 FITTING, tee, pipe 1

513 156971 FITTING, nipple, short 1

514 H42550 HOSE, coupled, 1/4 x 50 ft (15.24 m) 1

515 214037 VALVE, ball, cs 1

516 205447 COUPLING, hose 1

517 061132 HOSE, nylon, wpr 225, 4 ft (1.22 m) 1

520 155494 FITTING, swivel, 90° 1

521 113333 VALVE, ball, vented, 0.375 1

522 101689 GAUGE, pressure, air 1

523 104266 REGULATOR, air 1

524 100206 BUSHING, pipe 1

525 100840 FITTING, elbow, street 1

526 169970 FITTING, line air 1

529 100509 PLUG, pipe 1

514

516

517

515

512

501b

501g, 501h

513

501e

526

522

527

525

524

520

507

509

501a

521

529

523

501d

501c

508

507

504

510

505

506

501f

r_258980_310863_12d

310863M 13

Page 14

Parts

Part No. 262393, Solvent Flush Kit, 45:1

Merkur

Ref.

No. Part No. Description Qty.

601 262392 PUMP, solvent, 6 in, 50cc; with suction

601a LW050A LOWER, 50cc; see manual 312792 1

601b M12FN0 MOTOR, 1200cc; see manual 312796 1

601c 156589 FITTING, union, adapter, 90°; 3/4 nptf x

601d 100505 BUSHING, pipe, 3/4 npt(m) x 3/8 npt (f) 1

601e 156849 PIPE, nipple; 3/8-18 npt 1

601f 245082 KIT, suction, tube; includes hose and

244675 HOSE, siphon, assembly 1

218798 STRAINER, inlet; 1/2-14 npsm 1

601g 100081 BUSHING, pipe 1

601h 157350 ADAPTER, 1

601j 111799 SCREW, cap, hex hd 4

601k 116395 FITTING, swivel, elbow 1

602 104984 FITTING, tee, pipe 1

603 156971 FITTING, nipple, short 1

604 H42503 HOSE, coupled, 1/4 ID; 3 ft (1 m) 1

605 214037 VALVE, ball, cs 1

606 205447 COUPLING, hose 1

607 061132 HOSE, nylon; 4 ft (1.2 m) 1

608 24F126 MODULE, air controls; see parts list 1

610 16F537 HOSE, COUPLED, 6 ft (1.8 m) 1

611 15B772 HOSE, air, 18 in. (457.2mm); not shown 1

614 194958 STRAP, tie; not shown 3

601b

hose; see manual 312794

3/4 npsw

strainer

601g

601h

610

Part No. 24F126, Air Control Module

Ref.

No. Part No. Description Qty.

701 24F125 PANEL, air controls 1

702 15T500 GAUGE, pressure, air, 1/8 1

1

703 15T536 REGULATOR, air, 3/8 npt 1

704 16F810 PANEL, nut, steel 1

705 114362 VALVE, ball, air 1

706 15T498 FITTING, 90°, swivel, 5/32 x 1/8

1

708 113498 VALVE, safety, 110 psi 1

709 15T937 FITTING, elbow, swivel 1/4 npt x

1

710 155699 FITTING, elbow, street 2

711 164672 ADAPTER 2

713 054753 TUBE, nylon, black; 3/4 ft. 1

718 108296 SCREW, hex washer, hd 4

719 109544 FITTING, elbow 1

718

702

npt(f)

5/32

706

711

703

710

709

air flow

708

705

1

1

719

601k

601a

601c

601d

601e

601f

601j

603

602

605

606

607

r_262393_310863_1a

604

704

701

711

710

r_262393_310863_2a-1

14 310863M

Page 15

Parts

310863M 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211, Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2004, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 310863

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised July 2013

Loading...

Loading...