Page 1

Operation

1:1 Extruder

310726H

Supply, metering and dispense system for 5 gallon (20 Liter) pails. For professional use

only.

Not approved for use in European explosive atmosphere locations.

Part No. 965119

1:1 Extruder President® Check-Mate® 200 System, carbon steel

Part No. 570135

1:1 Extruder President® Check-Mate® 200 System, stainless steel

2000 psi (14 MPa, 140 bar) Pump Maximum Working Pressure

90 psi (621 kPa, 6.3 bar) Pump Maximum Air Inlet Pressure

150 psi (1 MPa, 10 bar) Ram Maximum Air Inlet Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Table Of Contents

EN

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . .5

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dispensing Mixed Material . . . . . . . . . . . . . . . . . . . . . .5

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Part No. 965119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Part No. 965119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Part No. 570135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Part No. 570135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 10

Part No. 570135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Part No. 965119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mounting Footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Part No. 570135 and 965119 . . . . . . . . . . . . . . . . . . . 11

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . .12

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground equipment and conductive objects in work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Comply with all applicable safety regulations.

2 310726H

Page 3

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

310726H 3

Page 4

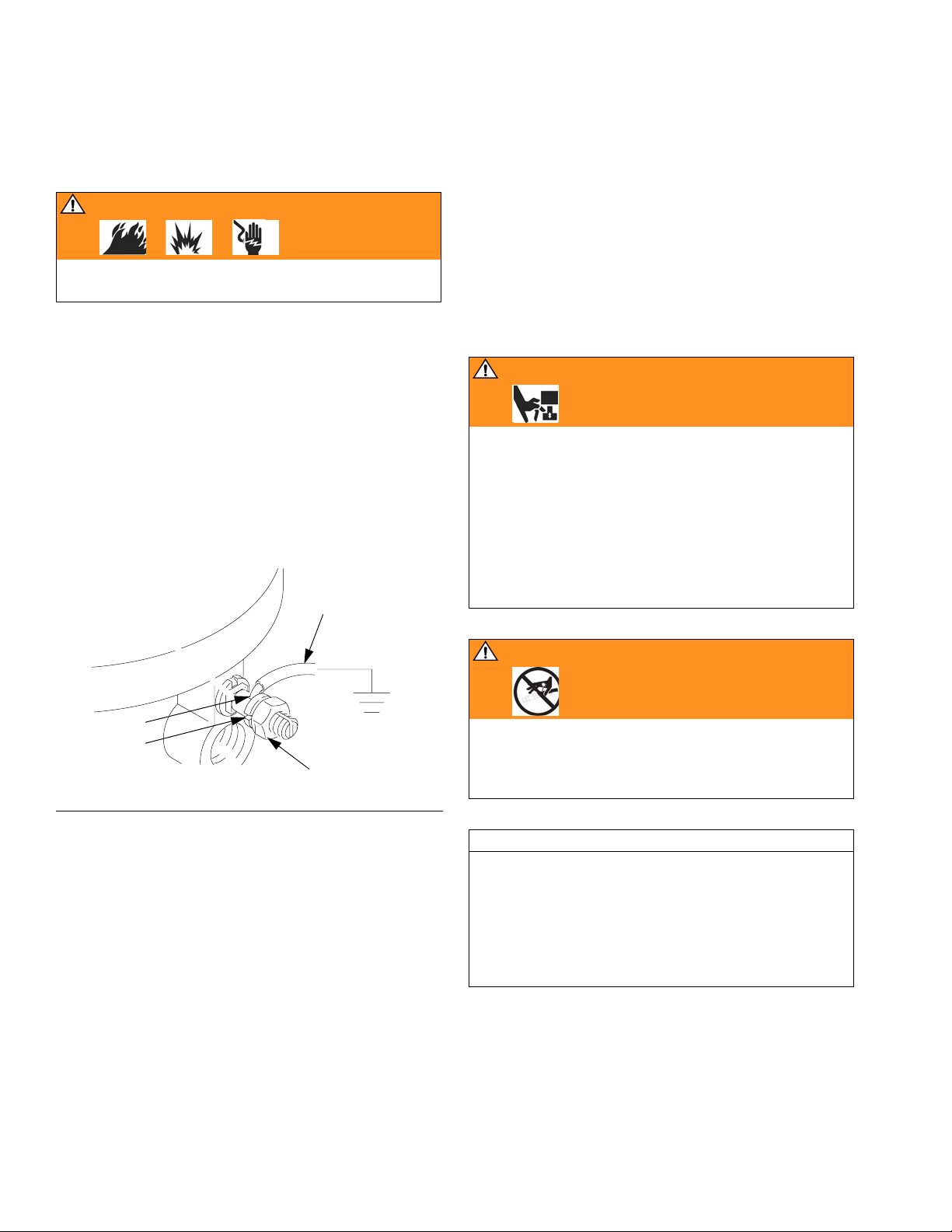

Grounding

Grounding

WARNING

Your system must be grounded. Read warnings, page

2.

Pump: use ground wire and clamp. Loosen grounding

lug locknut (A) and washer (B). Insert 12 gauge minimum ground wire end (D) into lug slot (C) and tighten

locknut securely. Connect ground clamp to a true earth

ground.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray

gun/dispense valve firmly to the side of a grounded

metal pail, then trigger the gun/valve.

Operation

WARNING

Air and fluid hoses: use only electrically conductive

hoses. Check electrical resistance of hoses once a

week. Refer to the hose tag or contact supplier for maximum resistance limits. If total resistance to ground

exceeds limits, replace hose immediately.

D

C

B

A

F

IG. 1

Air compressor: follow manufacturer’s recommenda-

tions.

Spray gun / Dispense valve: ground through connection to a properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Keep your fingers, hands, and tools away from the

priming piston and the air motor piston during operation and whenever the pump air and fluid pressure is

not fully relieved. The pump priming piston extends

below the foot valve during operation and could pinch

or amputate your fingers or hands as it moves up into

the cylinder.

Be sure all moving part shields are installed and safety

devices are operating properly before each use.

WARNING

Tighten all fluid connections securely before each use.

High pressure fluid can dislodge a loose coupling or

allow high pressure spray to be emitted from the coupling.

CAUTION

Never operate one pump alone. Do not disconnect

one pump or allow a pump to run out of material. The

system is designed to have both pumps run together.

Running one pump alone puts too much stress on the

hardware that connects the air motor to the displacement pumps and could cause the hardware to fracture.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

4 310726H

Page 5

Operation

Pressure Relief Procedure

WARNING

Follow Pressure Relief Procedure when you stop

dispensing and before cleaning, checking, or servicing

equipment. Read warnings, page 2.

1. Engage trigger lock.

2. Turn off air to the pump air motor.

3. Disengage the trigger lock.

4. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun to relieve pressure.

5. Engage the trigger lock.

6. Open all fluid drain valves in the system, having a

waste container ready to catch drainage. Leave

drain valve(s) open until you are ready to dispense

again.

6. Stand clear of the pumps. Turn the ram control to

DOWN. When the ram plates enter the pails and

material comes out the vents, close the vent valves.

Set the ram down pressure to at least 50 psi (345

kPa, 3.4 bar). More pressure can be used for high

viscosity materials.

7. Remove the mixer if one is installed.

8. Open the outlet valves on the hoses.

9. Set the President air motor regulator to 40 psi (276

kPa, 2.8 bar). Slowly open the pump control air

valve just until the pumps start moving. (Some air

will escape while the valve is partially open.) When

the pumps are primed and filling the hoses, the

pump control air valve can be fully opened. When

both materials are coming through the outlets free

of test oil, close the dispense valve.

Dispensing Mixed Material

1. Install a mixer on the outlet valve.

2. Set pump motor valve to the ON position.

7. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

Initial Startup

1. Connect a 1/2 in. (12.7 mm) air hose to the main air

inlet connection.

2. Connect the dispense valve kit.

3. Raise the pneumatic ram:

a. Turn the ram control to UP.

b. Turn the ram air regulator up until the pumps

begin to rise.

4. Open a pail of component A and B. Place the pails

in their proper spots on the frame assembly pail levelers. Hook the pail handles over the nearby frame

bolts.

3. Open dispense valve. Adjust President air motor

regulator from 40–120 psi (0.28–0.8 MPa, 2.8–8

bar) to obtain desired flow rate.

Shutdown

When you are done dispensing, remove the disposable

mixer, and wipe off the outlet. Depending on what type

of material you are dispensing, it may be better to leave

the mixer on until the next time you use the equipment,

or it may be necessary to not only wipe off the outlet but

to seal it from air. Part No. 551327 plastic disposable

caps are available for this purpose.

5. Open the pail ram plate vent valves.

310726H 5

Page 6

Part No. 965119

Part No. 965119

23 43,75

78

61

13

50

35

18,26

48

29

11,10

51

27

49

36

13

15

41

28

73,72,71

81

32

45

42

2

16

1

38

Front View

14

52

53

67

39

70

59

74

47

25

76

12

62

37

40

68

69

58

20

5

3

33

30

7

17,15

4

24

60

9

34

12

57

58

23

19

22

8

54

7

6

14

21,86

55,87,88

56

58

6 310726H

Side View

Page 7

Part No. 965119

Part No. 965119

Ref.

No. Part No. Description Qty.

1 100060 SCREW, cap hex head 3

2 100018 WASHER, lock spring 3

3 100122 NIPPLE, close 1

4 113264 CROSS, pipe 1

5 100361 PLUG, pipe 1

6 108638 TEE, pipe 2

7 100840 ELBOW, street 2

8 100896 FITTING, bushing pipe 2

9 100960 GAUGE, press air 1

10 101533 WASHER, spring lock 6

11 101535 NUT, full hex 6

12 103475 TEE, pipe 3

13 625077 ROD, tie 1:1 extruder 6

14 101959 ELBOW, cprsn male 2

15 102814 GAUGE, press fluid 2

16 104594 SCREW, cap 8

17 100206 BUSHING, pipe 2

18 208391 VALVE, ball 2

19 156684 UNION, adapter 2

20 156823 UNION, swivel 1

21 156971 NIPPLE, short 2

22 157191 FITTING, adapter; 1/2 npt x 3/4 npt 2

23 158212 BUSHING 3

25 158683 FITTING, elbow 90° 1

26 100195 NIPPLE, pipe 2

27 184100 NUT, coupling 2

28 184160 ROD, adapter 2

29 184131 COLLAR, coupling 4

30 171937 REGULATOR, air 1

31 206995 FLUID, TSL 1 qt. 1

32 24B229 MOTOR, Air pres 1

33 511174 FITTING, airline 1

34 220179 VALVE, check 2

35 222771 PUMP, shovel 2

36 222812 PLATE, wiper, 5 gallon 2

37 502524 FITTING, connector tube 1

38 512004 CYLINDER, air/ 2” stroke 2

39 512171 SCREW, machine, socket HD 2

40 590385 TUBE, poly-flo 10

41 623533 PLATE, pail/ram 2

42 624909 PLATE, tie 1:1 Extrud. Checkmate 1

43 167646 BEAM, ram 1

45 624913 ROD, tie ram 1:1 extruder 2

47 902413 KIT, repair 1

48 947917 FRAME, pail locator 1

49 257461 RAM, 55 gal, bare 3 in. pneumatic 1

50 948617 YOKE, extruder 1:1 1

51 513649 BEARING, cam follower 2

52 100128 WASHER, lock 1

53 513623 SCREW, cap socket HD 1

54 C19391 FITTING, elbow 1

55 513004 VALVE, directional air 1/4 in. NPT 1

Ref.

No. Part No. Description Qty.

56 512910 MUFFLER, polyethylene 1/4 in.

NPT

57 113034 FITTING, tube, straight 1

58 205437 COUPLING, hose 4

59 162449 FITTING, nipple reducing 1

60 206727 VALVE, release air 2

61 061132 HOSE, nylon 20

62 109209 NUT, lock hex 6

65▲ 180233 LABEL, warning 4

66▲ 513106 LABEL, warning 1

67 624944 SPACER, pump 1

68 208048 HOSE, coupled 1

69 102478 STRAP, tie wiring 10

70 166361 EMBLEM, Graco 1

71 100004 SCREW, cap hex head 4

72 100731 WASHER 4

73 100133 WASHER, lock 4

74 625286 SHIELD, yoke 1:2 extruder 1

75 189559 CAP, end 2

76 15W561 UNION, swivel 90° 1

77 184119 WRENCH, packing nut 1

78 165188 EMBLEM, Graco 1

81 100451 COUPLING 2

86 C12509 HOSE, 1/4 OD 1

87 107445 SCREW, cap 2

88 100016 WASHER, lock 2

Repair Parts

207385 Motor Seal Kit

222785 Throat Packing Kit (UHMW & PTFE)

222786 Throat Packing Kit (PTFE)

222784 Pump Seal Kit (Less Throat)

184101 Replacement Rod

184106 Replacement Cylinder

222798 Inlet Seat Kit (Seat & O-ring)

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

1

310726H 7

Page 8

Part No. 570135

Part No. 570135

41

35

11,10

66

13

50

27

28

15

49

48

36

73,72,71

13

2

29

51

39

93

33

43,75

3

74

70

37

94

47

33

61

69

60

92,89

5

62

40

25

52

53

67

65

97

95

59

87

96

1

32

45

42

16

38

Front View

14

20

4

60

9

7

17,15

12

34

88

Side View

8 310726H

54

7

6

14

54,22

55,23,24

56

57

30

Page 9

Part No. 570135

Part No. 570135

Ref.

No. Part No. Description Qty.

1 100060 SCREW, cap hex head 3

2 100018 WASHER, lock spring 3

3 100122 NIPPLE, close 1

4 113264 CROSS, pipe 1

5 100361 PLUG, pipe 1

6 108638 TEE, pipe 1

7 100840 ELBOW, street 6

9 100960 GAUGE, press air 1

10 101533 WASHER, spring lock 6

11 101535 NUT, full hex 6

12 502570 FITTING, tee 1/2 NPT 2

13 625077 ROD, tie 1:1 extruder 2

14 101959 ELBOW, cprsn male 2

15 513432 GAUGE, press fluid SST 2

16 104594 SCREW, cap 8

17 102022 BUSHING, pipe 2

20 156823 UNION, swivel 1

22 C12509 HOSE, 1/4 OD 1

23 107445 SCREW, cap 2

24 100016 WASHER, lock 2

25 158683 FITTING, elbow 90° 1

27 184100 NUT, coupling 2

28 184160 ROD, adapter 2

29 184131 COLLAR, coupling 4

30 171937 REGULATOR, air 1

31 206995 FLUID, TSL 1 qt. (not shown) 1

32 24B229 MOTOR, air president 1

33 511174 FITTING, airline 2

34 501603 VALVE, check 1/2 in. NPT SST 2

35 222814 PUMP, shovel SST 2

36 222909 PLATE, wiper, 5 gallon 2

37 502524 FITTING, connector tube 1

38 512004 CYLINDER, air/ 2 in. stroke 2

39 512171 SCREW, machine, socket HD 2

40 590385 TUBE, poly-flo 10

41 623533 PLATE, pail/ram 2

42 624909 PLATE, tie 1:1 Extrud. Checkmate 1

43 167646 BEAM, ram 1

45 624913 ROD, tie ram 1:1 extruder 2

47 902413 KIT, repair 1

48 947917 FRAME, pail locator 1

49 257461 RAM, 55 gal, bare 3 in. pneumatic 1

50 948617 YOKE, extruder 1:1 1

51 513649 BEARING, cam follower 2

52 100128 WASHER, lock 1

53 513623 SCREW, cap socket HD 1

54 C19391 FITTING, elbow 1

55 513004 VALVE, directional air 1/4 in. NPT 1

56 512910 MUFFLER, polyethylene 1/4 in.

NPT

57 113034 FITTING, hose, straight 1

59 162449 FITTING, nipple reducing 1

60 206727 VALVE, release air 2

Ref.

No. Part No. Description Qty.

61 208048 HOSE, coupled 1

62 109209 NUT, lock hex 6

65▲ 180233 LABEL, warning 4

66▲ 513106 LABEL, warning 1

67 624944 SPACER, pump 1

69 102478 STRAP, tie wiring 10

70 166361 EMBLEM, Graco 1

71 100004 SCREW, cap hex head 4

72 100731 WASHER 4

73 100133 WASHER, lock 4

74 625286 SHIELD, yoke 1:1 extruder 1

75 189559 CAP, end 2

87 C20432 FITTING, cross pipe 1

88 552049 COUPLING, 1/2 in. NPT SST 2

89 100206 BUSHING, pipe 1

92 111697 PLUG, pipe 1

93 104172 FITTING, tube 2

94 590332 TUBE, poly-flo5/32ID x 1/4OD 15

95 158212 BUSHING 1

96 15W561 UNION, swivel 90° 1

97 165188 EMBLEM, Graco 1

98 184119 WRENCH, packing nut (not shown) 1

Repair Parts

207385 Motor Seal Kit

222785 Throat Packing Kit (UHMW & PTFE)

222786 Throat Packing Kit (PTFE)

222784 Pump Seal Kit (Less Throat)

184101 Replacement Rod

184106 Replacement Cylinder

222798 Inlet Seat Kit (Seat & O-ring)

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

1

310726H 9

Page 10

Technical Specifications

Technical Specifications

Part No. 570135

Mix ratio by volume . . . . . . . . . . . . . . . . . 1:1

Pressure Ratio (Fluid/Air) . . . . . . . . . . . . . 22:1

Volume Output per cycle . . . . . . . . . . . . . 2.9 fl. oz.

Air Motor Diameter. . . . . . . . . . . . . . . . . . Ø4.25

Air Consumption. . . . . . . . . . . . . . . . . . . . 10 cfm

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 npsm(f)

Fluid Outlets . . . . . . . . . . . . . . . . . . . . . . 1/2 or 3/8 npt(f)

Wetted Parts . . . . . . . . . . . . . . . . . . . . . . Stainless Steel, PTFE, UHMW

Maximum Air Working Pressure . . . . . . . . . 90 psi (6.3 bar, .63 mPa)

Maximum Temperature . . . . . . . . . . . . . . . Ambient

Maximum Fluid Working Pressure . . . . . . . 2000 psi (140 bar, 14.0 mPa)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . 500 lbs (227 kg)

Polyethylene

Part No. 965119

Mix Ratio by Volume . . . . . . . . . . . . . . . . . 1:1

Pressure Ratio (fluid/air) . . . . . . . . . . . . . 22:1

Volume Output per cycle . . . . . . . . . . . . . 2.9 fl. oz.

Air Motor Diameter. . . . . . . . . . . . . . . . . . Ø4.25

Air Consumption. . . . . . . . . . . . . . . . . . . . 10 cfm

Air Inlet. . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 npsm(f)

Fluid Outlets . . . . . . . . . . . . . . . . . . . . . . 1/2 or 3/8 npt(f)

Wetted Parts . . . . . . . . . . . . . . . . . . . . . . Carbon Steel, Stainless Steel, Duc-

tile Iron, Zinc and Nickel Plating,

PTFE, UHMW Polyethylene

Maximum Air Working Pressure . . . . . . . . . 90 psi (6.3 bar, .63 mPa)

Maximum Temperature . . . . . . . . . . . . . . . Ambient

Maximum Fluid Working Pressure . . . . . . . 2000 psi (140 bar, 14.0 mPa)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . 500 lbs (227 kg)

10 310726H

Page 11

Mounting Footprint

Part No. 570135 and 965119

Mounting Footprint

42

2

.56 Holes

2

25

310726H 11

Page 12

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2003, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 310726

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised March 2013

Loading...

Loading...