Page 1

Parts

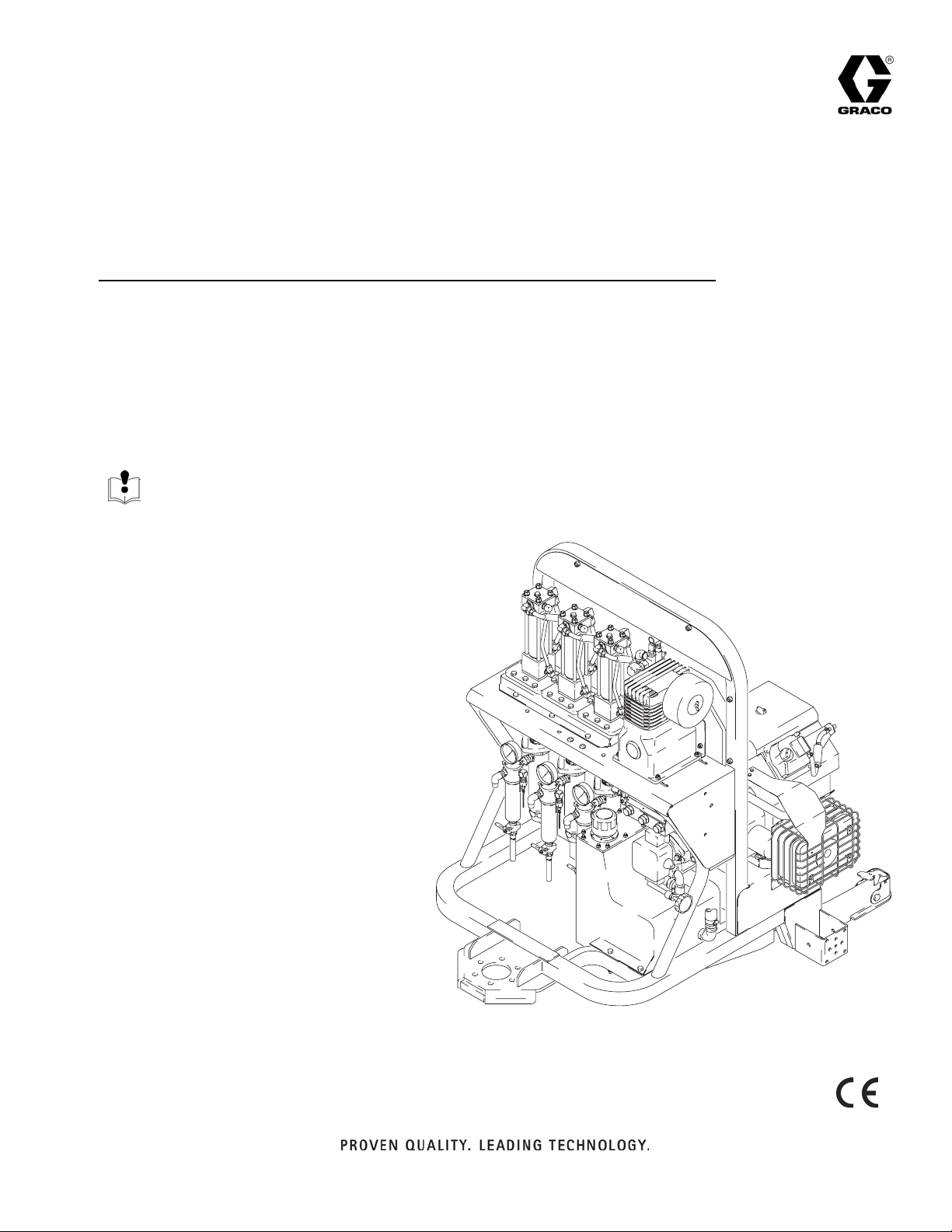

RoadLazer® Skid-Mount OEM

Striping Package

- For OEM use in customized line striper applications only -

Model 234672

Hydraulic Stainless Steel

2000 psi (138 bar) Maximum Working Pressure

Read warnings and instructions in this

manual and provided in Operation manual

308611

310664D

EN

Related Manuals

308612 - Bead Spray Gun

308613 - Auto Spray Gun

308616 - Programmable Skipline

308974 - Pump

ti4748a

Page 2

Contents

Manual Conventions

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

RoadLazer Line Striper Kit Components . . . . . . .5

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Pump System . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Engine System . . . . . . . . . . . . . . . . . . . . . . . . . .10

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Battery System . . . . . . . . . . . . . . . . . . . . . . . . . .12

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Manual Conventions

WARNING

Hazard Symbol

WARNING: a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Warnings in the instructions usually include a symbol

indicating the hazard. Read the general Warnings

section for additional safety information.

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Main Base Assembly (page 1 of 2) . . . . . . . . . . 14

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Main Base Assembly (page 2 of 2) . . . . . . . . . . 16

Main Base Assembly Parts List . . . . . . . . . . . . . 16

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 18

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 18

CAUTION

CAUTION: a potentially hazardous situation which, if

not avoided, may result in property damage or

destruction of equipment.

Note

Additional helpful information.

2 310664D

Page 3

Warnings

Warnings

The following are general Warnings related to the safe setup, use, maintenance and repair of this equipment. Additional, more specific warnings may be found throughout the text of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground equipment and conductive objects in work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

310664D 3

Page 4

Warnings

WARNING

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide can cause death. Do not operate in an enclosed area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

4 310664D

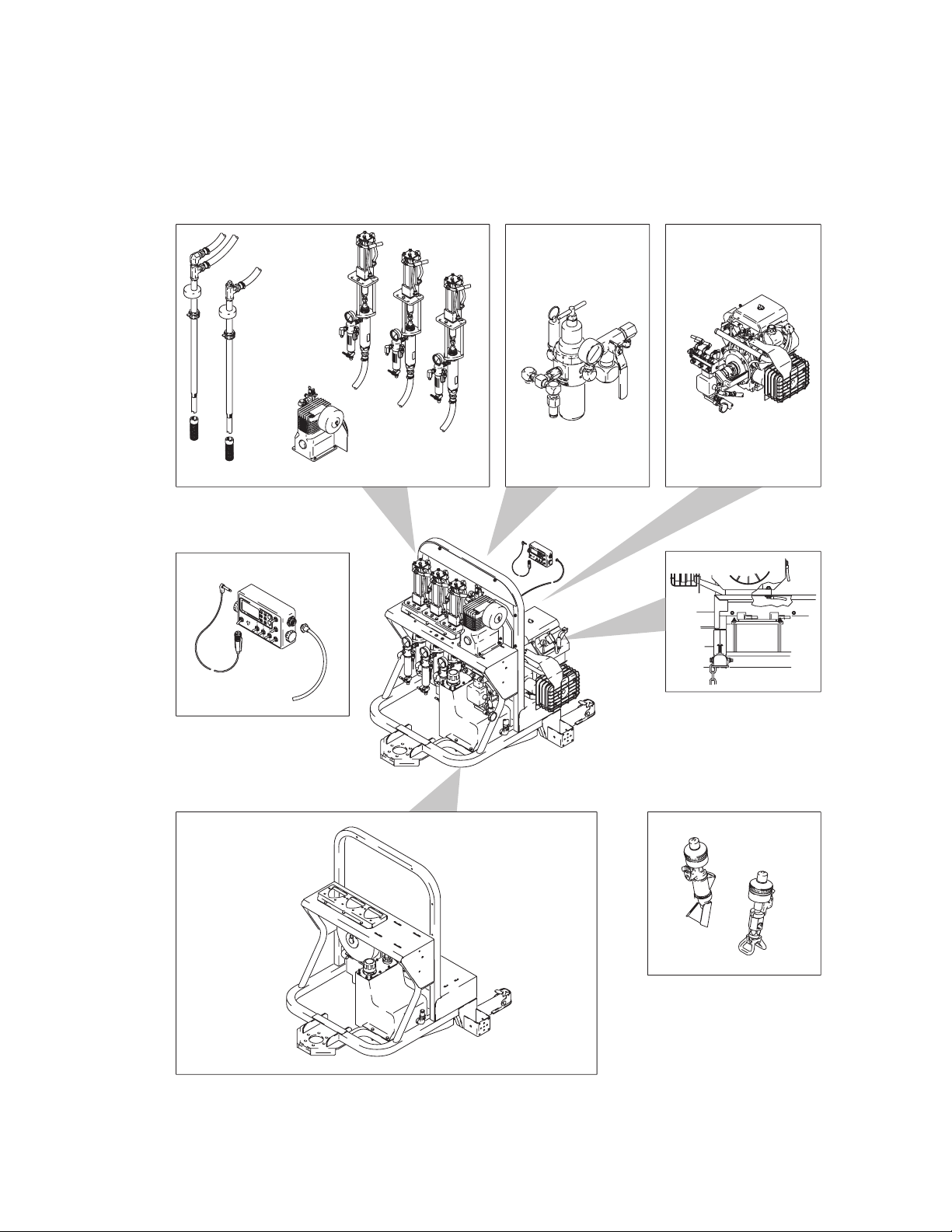

Page 5

Parts

RoadLazer Line Striper Kit Components

Parts

Programmable

Skipline Controller

(manual 308616)

Pump System

page 6

ti4742a

Regulator

page 8

Engine

System

page 10

Battery System

page 12

Guns

page 6

Pallet Base

page 14 and 16

310664D 5

Page 6

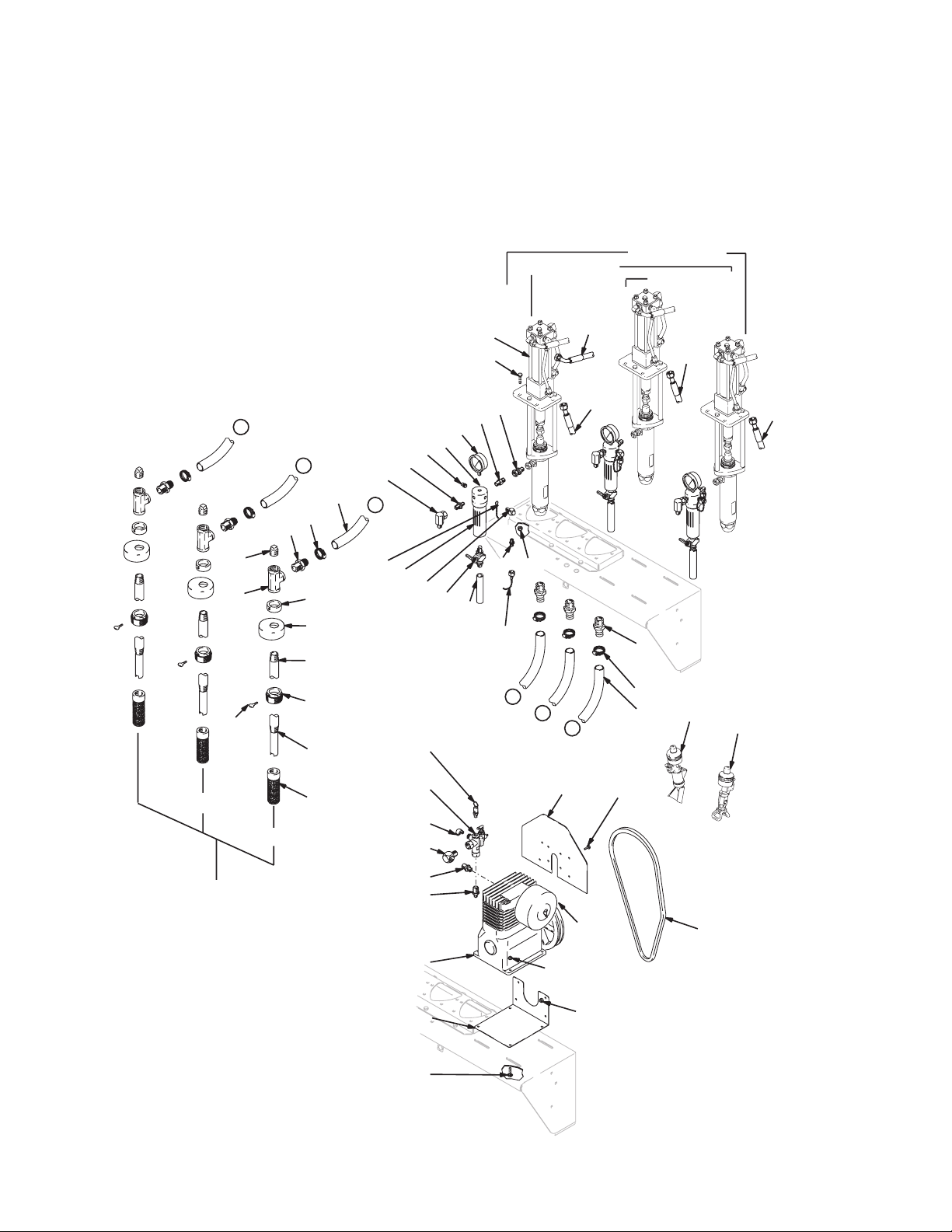

Parts

Pump System

Parts

54

49

50

2-Pump System

45

29

74

91

87

117

192

86

90

14

93

A

A

174

173

93

88

C

87

89

42

46

B

48

47

141

55

51

53

51

72

64,119

B

C

3-Pump System

1-Pump System

64,120

46

47

200

48

64,121

201

2-Pump System

40

52

147

1-Pump System

41

39

149

21

153

22

23

79

94

23

Ti4744a

152

18

6 310664D

Page 7

Pump System Parts List

Parts

Ref.

No. Part No. Description Qty.

14 101566 NUT, lock 22

18 113300 BELT, vee 1

21 112796 COMPRESSOR, air 1

22 107129 BOLT, round head 4

23 111040 NUT, lock, insert, nylock, 5/16 in. 8

29 100004 SCREW, cap, hex hd 14

39 159239 FITTING, nipple, pipe, rdcg 1

40 112795 REGULATOR, unloader 1

41 158683 FITTING, elbow, 90° 1

42 113286 VALVE, safety 1

45 238349 PUMP, paint, line striper 3

46 113607 FITTING, barb, 1 in. 6

47 101818 CLAMP, hose 8

48 191627 HOSE, suction 3

49 113606 FITTING, tee 3

50 113561 PLUG, pipe 3

51 191624 TUBE, suction 3

52 191635 STRAINER, inlet 3

53 176684 ADAPTER, bung 3

54 100220 SCREW, thumb 3

55 191641 CAP, splash 3

64 191645 HOSE, coupled, 24 in. (61 cm) 3

72 191647 HOSE, coupled, 27 in. (68.5 cm) 3

Ref.

No. Part No. Description Qty.

74 235208 FITTING, union, swivel 3

79 191688 GUARD, belt, comp 1

86 166469 NIPPLE, pipe, hex 3

87 238782 FILTER, fluid, sst 3

88 501684 VALVE, check 3

89 166866 ELBOW, street 3

90 166846 FITTING, adapter 3

91 238967 VALVE, ball, heavy duty 3

93 220285 CAP 3

94 113687 FILTER, intake 1

117 102814 GAUGE, pressure, fluid 3

119 054163 TUBE, polyolefin, shrink

120 054747 TUBE, polyolefin, shrink, blue

121 054748 TUBE, polyolefin, shrink, green

REF

REF

REF

141 113797 COLLAR, screw, set

147 100286 ELBOW, street

149 162449 FITTING, nipple, reducing

152 109468 SCREW, cap, hex hd

153 239022 BRACKET, comp, painted

173 112026 ELBOW, street

174 111697 PLUG, pipe

192 191731 EXTENSION, pipe, pump

200 238329 GUN, spray, bead (manual 308612)

201 238332 GUN, spray, auto (manual 308613)

3

1

1

4

1

3

3

3

3

3

310664D 7

Page 8

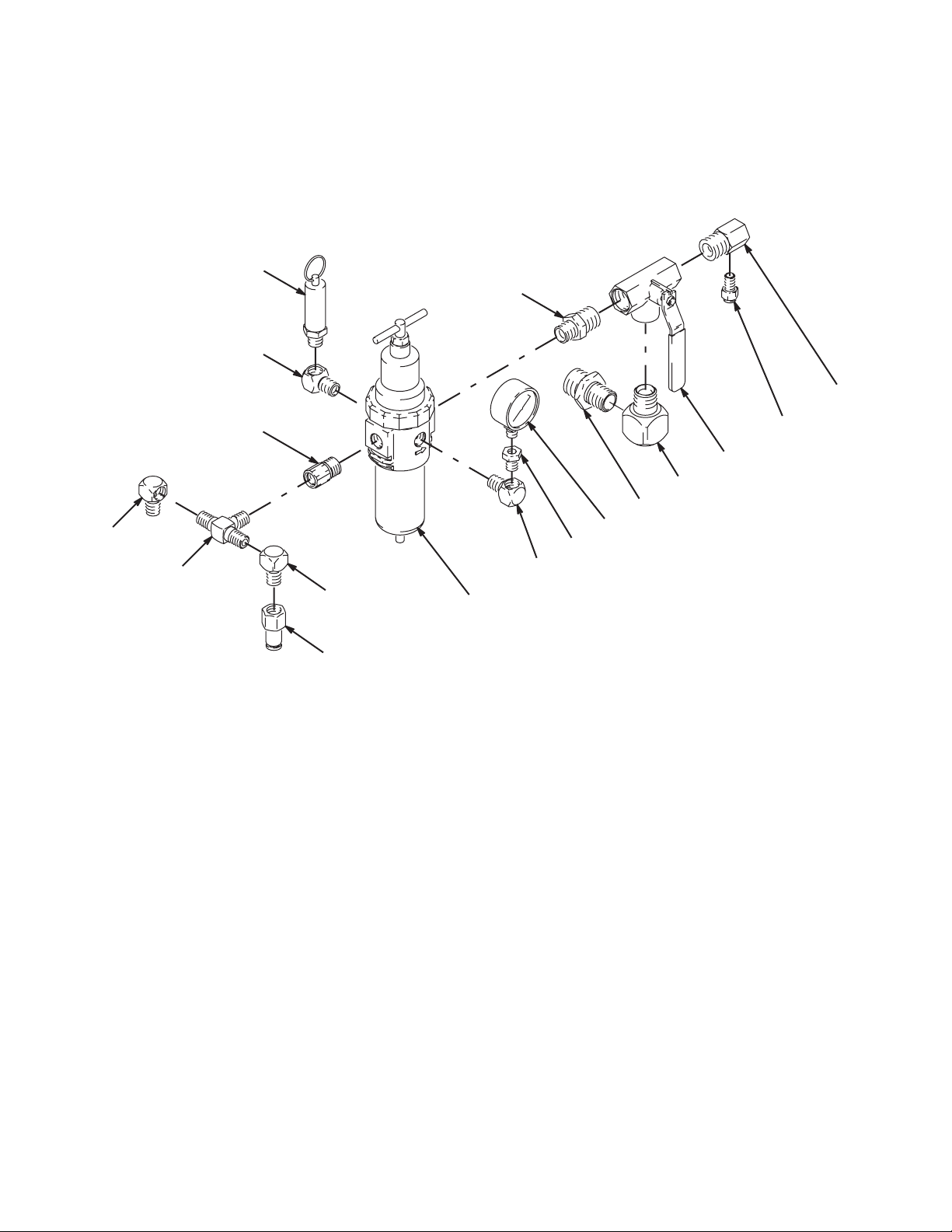

Parts

Regulator

Parts

2

4

3

6

17

3

15

3

ti4743a

14

Regulator Parts List

Ref.

No. Part No. Description Qty.

1 113291 REGULATOR, air 1

2 108124 VALVE, safety 1

3 100840 ELBOW, street, 1/4-18 npt 4

4 159239 NIPPLE, reducing, 1/2 in. npt x 3/8

in. npt, 1-5/8 in. (41 mm) long

5 113292 VALVE, ball, 3-way 1

6 166999 ELBOW, 90° street, reducing

1/4 in. npt (f) x 1/2 in. npt (m)

7 113319 FITTING, air, 3/8 OD x 1/4-18 npt 1

REF

5

10

9

13

12

3

1

Ref.

No. Part No. Description Qty.

9 157191 NIPPLE, reducing 3/4 in. npt x

1/2 npt, 1-7/8 in. (46 mm) long

10 158683 FITTING, elbow, 90°, 1/2-14 npt(f) x

1/2-14 npt(m)

12 100030 BUSHING 1

13 104655 GAUGE, pressure, air 1

14 112790 CONNECTOR, tube, 1/4-18 npt 1

1

15 113548 TEE, 1/4-18 npt 1

17 159841 ADAPTER, 1/4-18 npt(f) x

3/8-18 npt(m)

18 070408 SEALANT, pipe, sst (not shown) 1

7

1

1

1

8 310664D

Page 9

Notes

Notes

310664D 9

Page 10

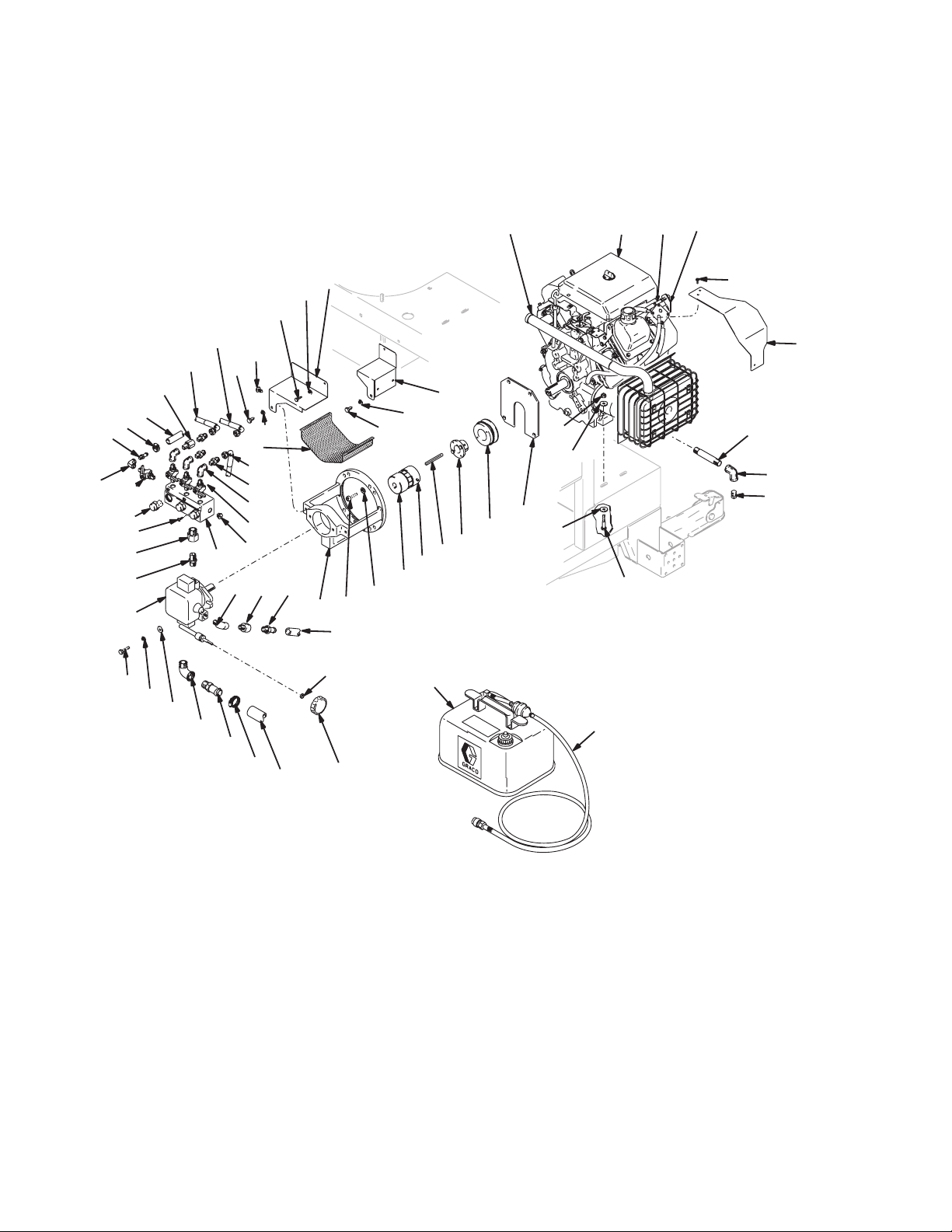

Parts

Engine System

Parts

133

66

68

65

61

155

57

56

32

29

69

31

160

64,119

30

64,120

58

99

85

100

75

84

31

83

64,121

60

130

65

59

47

36

63

1(Ref)

77

112

78

30

85

16

17

19

150

6676

28

26

435 (REF)

33

34

15

27

96

14

20

82

20

1

25

96a

ti4745a

98

154

118

123

129

130

1(Ref)

10 310664D

Page 11

Engine System Parts List

Parts

Ref.

No. Part No. Description Qty.

1 113287 ENGINE, Kohler, 18 hp 1

14 101566 LOCKNUT, nylon, 3/8-16

REF

15 106063 COUPLING, flexible 1

16 113295 SHEAVE, 1 groove, ‘B’ 1

17 801376 BUSHING, H-1.125 1

19 605358 KEY, sprocket 1

20 100132 WASHER, flat 11

26 191620 SUPPORT, pump 1

27 100052 WASHER, lock 4

28 107143 CAPSCREW, soc hd, grade 5,

7/16-14 unc-3a; 1.25 in. (31 mm)

long

29 100004 CAPSCREW, hex hd, grade 5,

REF

7/16-14 unc-2a; 1.25 in. (31 mm)

long

30 100023 WASHER, flat 2

31 100133 WASHER, lock, 3/8 in. 4

32 191253 PUMP, vane 1

33 100187 NUT, grade 5, 5/16-24 1

34 219099 KNOB, pump 1

36 100022 CAPSCREW, hex hd, grade 5,

1/4-20 unc-2a; 3/4 in. (19 mm) long

41 158683 ELBOW, 90°, 1/2-14 npt(f) x

REF

1/2-14 npt (m)

56 158491 NIPPLE, 1/2 in. npt x 1/2 npt,

1-5/8 in. (41 mm) long

57 113613 ADAPTER, female pipe, 1/2-14

npt(f) x 1-1/16-12 unf-2a

58 192045 MANIFOLD, valve 1

59 104813 PLUG, pipe; 3/8-18 npt 1

60 110311 NIPPLE, straight; 3/8-18 npt(f) x

3/4-16 unf

61 113703 REGULATOR, hydraulic flow 3

63 191648 HOSE, 1 in. ID 1

64 191645 HOSE, coupled, 29.5 in. (75 cm)

REF

Ref.

No. Part No. Description Qty.

65 210658 VALVE, ball REF

66 107050 INSERT, hose, beaded 2

68 102473 CLAMP, hose 2

69 191649 HOSE, 0.63 in. ID, 15 in. (38 cm) 1

75 107032 ELBOW, 90°, 3/8-18 npt 1

76 156022 ADAPTER, 3/8 in. npt x 1/2 in. npt,

1-1/2 in. (38 mm) long

77 191686 GUARD, top, left 1

78 191687 GUARD, top, right 1

80 191686 GUARD, top, left 1

4

81 191687 GUARD, top right 1

82 191695 GUARD, motor, front 1

83 191696 GUARD, belt, lower 1

84 113609 BUMPER, nylon 4

85 100575 CAPSCREW, hex hd, grade 5,

3/8-16 unc-2a, 5/8 in. (16 mm) long

96 238681 TANK, fuel 1

96a 113371 HOSE, fuel line 1

98 113372 COUPLING, fuel line 1

99 100549 ELBOW, street pipe, 90° 1

100 107049 INSERT, hose, beaded 1

4

101 113681 SPRING, compression (not shown) 1

112 100015 NUT, hex, grade 5, 1/4-20 unc-2b 2

118 112179 SCREW, mch, grade 5, M5 x 12 2

123 191863 GUARD, hose 1

129 100195 NIPPLE, pipe, 3/8-18 npt 1

1

130 165472 ELBOW, pipe, 90°, 3/8 npt(f) 1

133 107053 ELBOW, street, 3/8-18 npt(f) x

1

1/2-14 npt(f)

150 100421 SCREW,set grade 5, 5/16-18

unc-3a, 0.375 in. (10 mm) long

154 192228 BRACKET, fuel coupler 1

3

155 111445 SCREW, drive 3

160 150286 ADAPTER, 3/8 in. 1

435 238346 HOSE, 0.63 in. ID, 19 in. (48 cm) 1

1

2

1

2

310664D 11

Page 12

Parts

Battery System

Parts

13

14

20

25

10

9

6

4

5

8

7

36

67

112

12

36

12

112

12

11

10(Ref)

9(Ref)

ti4749a

Regulator Parts List

Ref.

No. Part No. Description Qty.

4 115753 BATTERY, 33 AH, sealed 1

5 107072 CABLE, electric, negative 1

6 107073 CABLE, electric, positive 1

7 801958 PROTECTOR, terminal, red

8 801959 PROTECTOR, terminal, black 1

9 803525 BOLT, battery 2

10 107069 CLAMP, battery 1

11 100527 WASHER, wrought 2

12 310664D

Ref.

No. Part No. Description Qty.

12 100016 WASHER, lock 4

13 102040 NUT, lock, hex 5

14 101566 NUT, lock 22

20 100132 WASHER, flat 11

1

25 111803 SCREW, cap, hex hd 5

36 100022 SCREW. cap, hex hd 5

67 801972 PAD, battery 1

112 100015 NUT, hex mscr 2

Page 13

Notes

Notes

310664D 13

Page 14

Parts

Main Base Assembly (page 1 of 2)

Parts

125

408

438

409

412

406

410

407

14

14

145

95

2

107

25

24

20

80

128

81

170

410

431

436

434

431

436

435

436

104

409

428

184

183

412

402

411

ti4746a

14 310664D

Page 15

Main Base Assembly Parts List

(page 1 of 2)

Parts

Ref.

No. Part No. Description Qty.

2 248422 Base RoadLazer Palletized 1

14 101566 LOCKNUT, nylon, 3/8-16

20 100132 WASHER, flat 11

24 113619 IDLER, vee, pulley 1

25 111803 CAPSCREW, hex hd, grade 5,

3/8-16 unc-2a, 2 in. (51 mm) long

80 191690 GUARD, belt, front 1

81 191697 GUARD, belt, side 1

95 100531 CAPSCREW, hex hd, grade 5,

3/8-16 unc-2a, 2.5 in. (63.5 mm)

long

104 115501 SENSOR, proximity 1

107 107257 SCREW, thd forming, hex, washer

hd, grade 5, 1/4-20 unc-3a, 0.50 in.

(13 mm) long

125 191855 PLATE, logo 1

128 111583 PAD, vibration, motor 4

145 187797 SPACER, duct 2

170 114040 CAP, connector, weathertight 1

183 113603 CAP, hub 1

184 191965 RING, rubber 1

22

Ref.

No. Part No. Description Qty.

400 248422 MAIN BASE ASSEMBLY (includes

40 to 459). Also page 16.

401 238337 BASE, main 1

405 100731 WASHER 6

406 100469 CAPSCREW, hex hd, grade 5,

5

407 191248 BASE. pump mount 1

408 113597 COOLER, air 1

408a 240798 KIT, motor and fan replacement 1

5

409 100424 SCREW 4

410 801020 NUT, lock, hex, grade 5, 1/2-13

411 100454 CAPSCREW, hex hd, grade 5,

2

412 101566 LOCKNUT, grade 5 20

428 113667 BUSHING, nylon 1

431 107050 INSERT, hose, beaded 4

434 191650 HOSE, 0.63 in. ID, 14 in. (36 cm) 1

435 191651 HOSE, 0.63 in. ID, 19 in. (48 cm) 1

436 102473 CLAMP, hose 4

438 109570 WASHER, plain 4

3/8-16 unc-2a, 3/4 in. (19 mm) long

unc-2b

3/8-16 unc-2a, 7/8 in. (22 mm) long

5

4

4

310664D 15

Page 16

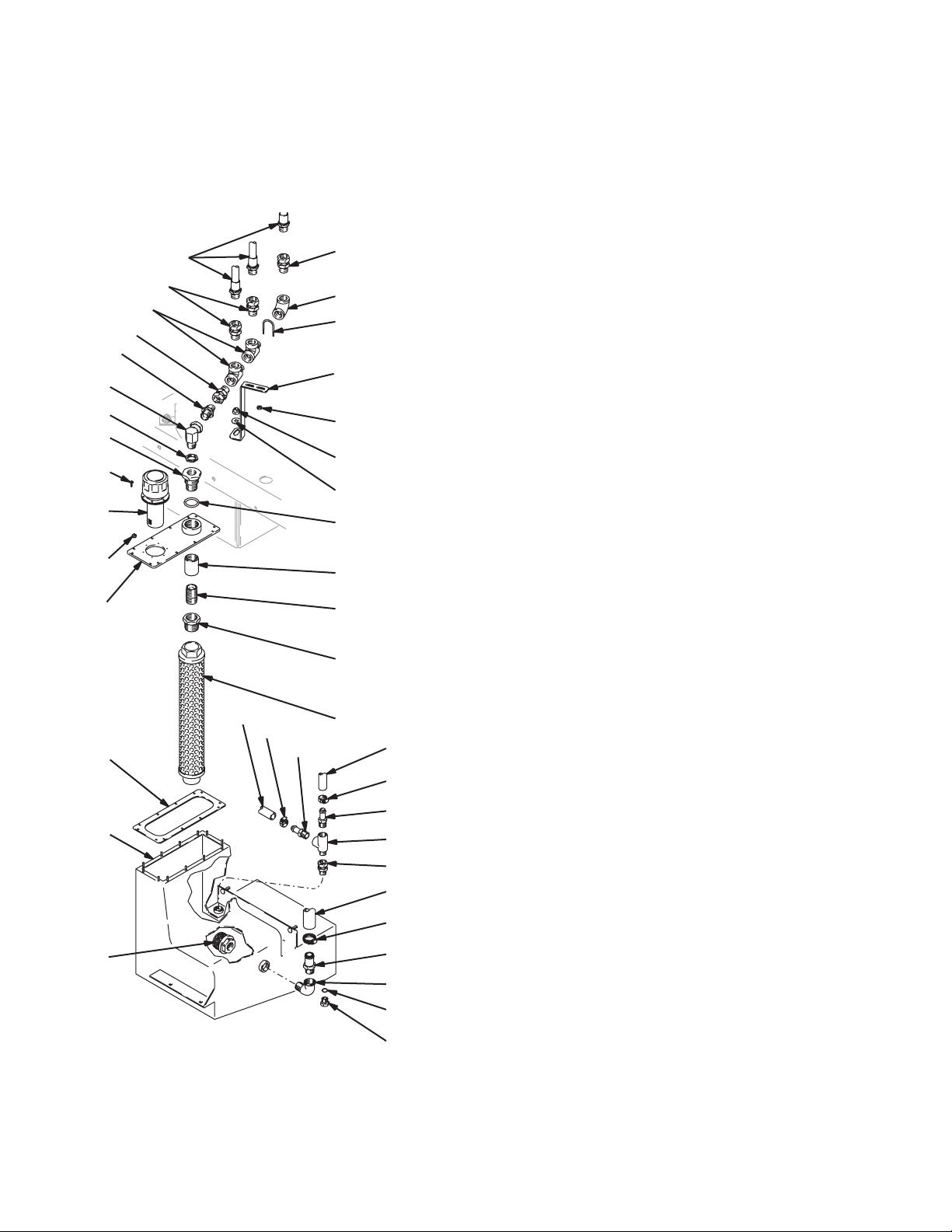

Parts

0

9

7

Main Base Assembly (page 2 of 2) Main Base Assembly Parts List

(page 2 of 2)

Ref.

No. Part No. Description Qty.

24 113619 PULLEY, idler, vee 1

43 109570 WASHER, plain 1

44 801020 NUT, lock, hex, grade 5, 1/2-13

unc-2b

47 101818 CLAMP, hose 1

62 157785 UNION, swivel; 3/4 npt(m) x 3/4

npsm(f) carbon steel

63 191648 HOSE, 1 in. ID, 9 in. (X mm) long 1

68 102473 CLAMP, hose 1

69 191649 HOSE, 0.63 in. ID, 12 in. (X mm)

long

70 160032 NIPPLE, 3/4-14 npt(f) 1

71 111337 TEE, street, 3/4-14 npt(f) 2

72 191647 HOSE, coupled, 27 in. 1

73 113671 ELBOW, 3/4-14 npt(f) 1

108 191656 BRACKET, manifold 1

109 106285 U-BOLT, grade 5, 2 x 1/4-20 unc-2a 1

400 248422 MAIN BASE ASSEMBLY (includes

items 401 to 438).

402 238787 RESERVOIR, hydraulic 1

404 102040 NUT, lock, hex, grade 5, 1/4-20

unc-3b

413 191634 GASKET, reservoir 1

414 238818 COVER, reservoir 1

415 107074 BREATHER 1

416 178794 FILTER, fluid 1

417 500054 BUSHING, hex hd, 1-11.5 npt(f) x

1-1/4-11.5 npt(m)

418 100485 NIPPLE, pipe 1

419 100474 COUPLING, pipe 1

420 107067 PACKING, o-ring 1

421 178750 FITTING, return, 1-11.5 npt(m) x

3/4-14 npt(f)

422 105429 NUT, seal, grade 5 1

423 160327 UNION, angle adapter, 3/4-14

npsm x 3/4-14 npt(f)

424 106114 STRAINER, inlet 1

426 104444 PACKING, o-ring 1

427 104126 PLUG, boss 1

429 100549 ELBOW, street, pipe, 90° 1

430 107049 INSERT, hose, beaded 1

431 107050 INSERT, hose, beaded

432 101353 NIPPLE, pipe 1

433 103475 TEE, pipe, 1/2-14 npt(f) 1

434 191650 HOSE, 0.63 in. ID, 14 in. (36 cm)

436 102473 CLAMP, hose

423

422

421

415

415

404

414

413

402

24

70

62

71

62

72

434

436

ti4747a

431

62

73

109

108

109

44

43

420

419

418

417

416

69

68

431

433

432

63

47

43

42

426

42

Parts

1

3

1

12

1

1

1

REF

REF

REF

16 310664D

Page 17

Technical Data

Technical Data

Maximum Working Pressure

Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 psi (138 bar)

Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500 psi (103 bar)

Glass bead system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 psi (5 bar)

Maximum Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 gpm/pump @ 2000 psi (138 bar)

Operating Pressure of Air-actuated Trigger

Minimum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 psi (3 bar)

Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 psi (12 bar)

Sound Levels*

Sound power level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99.4 dB(A)

Sound pressure level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81.5 dB(A)

Weight (empty / full)

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4 npt(f) air inlets

Hydraulic Oil Reservoir Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 gallons (45 liters)

Glass Bead Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 lb (136 kg)

Wetted Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . tungsten carbide, 303, 316 & 415 series stainless steel;

*Sound levels measured at 3.1 ft (1 m) under maximum operating conditions per ISO3744.

®

Kohler

is a registered trademark of the Kohler Co.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Kohler

PTFE, acetal homopolymer, leather

®

18 HP

310664D 17

Page 18

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2004, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

18 310664D

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 310664

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised 08/2011

Loading...

Loading...