Page 1

Instructions - Parts List

™

CleanLine

For petroleum-based oils, synthetic oils and anti-freeze* mixtures.

Not for use in explosive atmospheres.

*CleanLine 1800 filters must be used for anti-freeze mixtures,

CleanLine 900 filters are not compatible with anti-freeze.

Model 248418 Wall Mount CleanLine 900 Filter Assembly

900 psi (6.2 Mpa 62 bar) Maximum Working Pressure

Model 248421 Pump Mount CleanLine 900 Filter Assembly

900 psi (6.2 Mpa 62 bar) Maximum Working Pressure

Model 248417 Wall Mount CleanLine 1800 Filter Assembly

1800 psi (12.4 Mpa 124 bar) Maximum Working Pressure

Model 248419 Pump Mount CleanLine 1800 Filter Assembly

1800 psi (12.4 Mpa 124 bar) Maximum Working Pressure

Filter

310652K

ENG

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Model 248421 shown

TI6278B

Page 2

Warnings

Warnings

The following warnings include general safety information for this equipment. More specific warnings are included in

the text where applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Seek immediate surgical

treatment.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure in this manual, when you replace the filter.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Comply with all applicable safety regulations.

2 310652K

Page 3

Installation

Installation

The CleanLine Filter™ is installed upstream from the dispense equipment. It can be pump or wall-mounted.

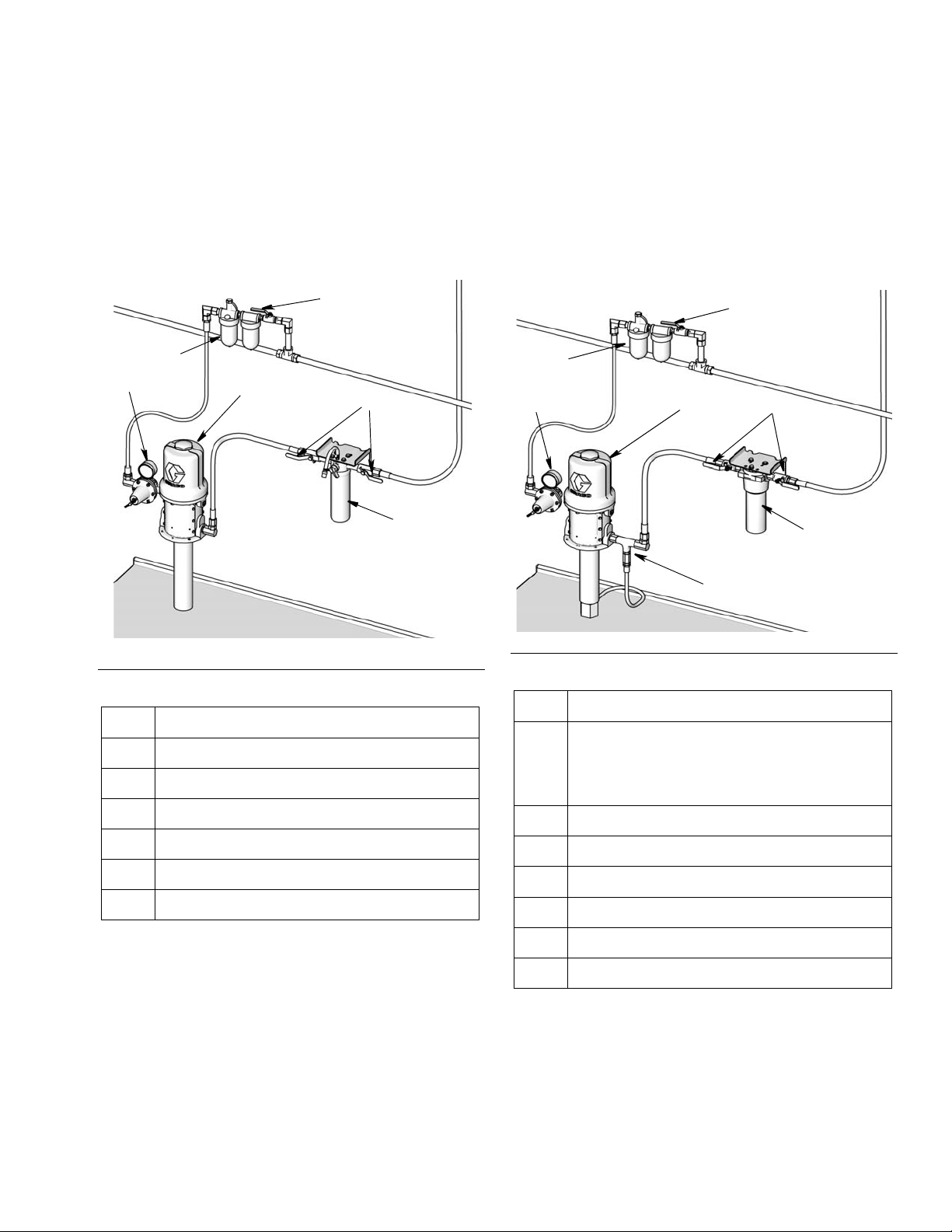

Wall Mount Clean Line 900 Installation Wall Mount Clean Line 1800 Installation

K

J

F

FIG. 1

KEY DESCRIPTION, See F

E Fluid shut-off valves (two)

F Air Regulator

G CleanLine Filter System

HPump * †

J Filter and Lubricator Assembly

K Master Bleed Air Valve (ball valve)

* Do not use diaphragm pumps in a Matrix system.

† Special pump packages are required for anti-

freeze. See instruction manual 310650.

H

E

G

ti10680a

IG. 2.

K

J

F

FIG. 2

KEY DESCRIPTION, See F

Thermal Pressure Relief Kit must be

D

installed downstream from the pump. The

Thermal Pressure Relief Kit will vary based

on the pump selected. See manual 308403.

E Fluid shut-off valves (two)

F Air Regulator

G CleanLine Filter System

H Pump * †

J Filter and Lubricator Assembly

K Master Bleed Air Valve (ball valve)

* Do not use diaphragm pumps in a Matrix system.

† Special pump packages are required for anti-

freeze. See instruction manual 310650.

H

D

E

G

IG. 2.

ti5127

310652K 3

Page 4

Installation

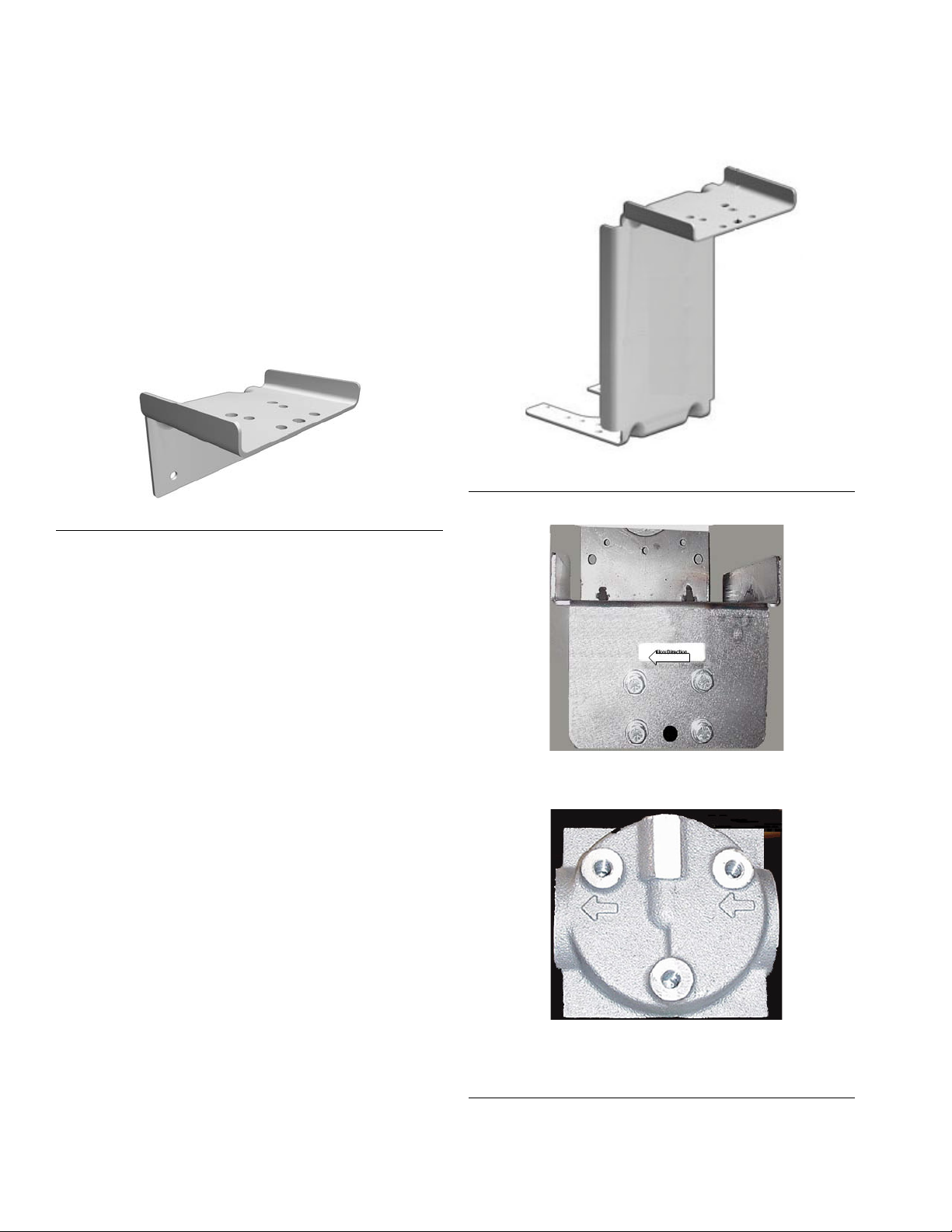

Wall-mount

1. Fasten the wall-mount bracket (part no. 249568) to

the wall using screws long enough to provide secure

support. See F

2. Observe the flow-direction arrows on the top of the

filter assembly. See F

bly correctly and secure the assembly to the bracket

using four screws (10) for models 248418 and

248421 or three screws (107) for models 248417

and 248419.

F

IG. 3

IG. 3.

IG. 5. Position the filter assem-

Part No. 249568

Wall Mount

F

Part No. 249565

Pump Mount

IG. 4

Pump-mount

1. Attach the pump-mount bracket (part no. 249565) to

the base of the pump. See F

attachment will vary by pump. The Fire-Ball 425 6:1

and 425 10:1 pumps use machine screws to mount

the bracket into pre-tapped holes tn the pump base.

The 425 3:1 is not compatible with the pump mount

bracket. The Fire-Ball 225 and 300 series pump

bases are not tapped. You will need to use the

machine screws and lock-nuts provided with bracket

kit 249565.

2. Observe the flow-direction arrows on the top of the

filter assembly. See F

IG. 5. Position the filter assem-

bly correctly and secure the assembly to the bracket

using four screws (10) for models 248418 and

248421 or three screws (107) for models 248417

and 248419.

CleanLine 900

1. Install barbed fitting (9) and pressure relief tube (12)

as shown in F

IG. 6. Apply thread sealant to threads

of barbed fitting (9).

IG. 4. The method of

CleanLine 900 Filter

Models 248418 and 248421

2. Route the tube (12) back to bulk tank or to used oil

container.

F

IG. 5

4 310652K

CleanLine 1800 Filter

Models 248417 and 248419

Page 5

Operation

Operation

Relieve Pressure

WAR NING

Follow Relieve Pressure procedure before replacing

CleanLine Filter cartridge. Read warnings on page 2.

CleanLine 900 Filter (models 248418 and 248421)

1. Turn off air supply to pump.

2. Close upstream and downstream ball valves (6).

See F

IG. 6.

3. Turn drain valve (4) slowly to relieve filter pressure.

System will release oil through pressure relief tube

(12). Be sure tube is installed correctly. Drain valve

(4) springs back to closed position.

Pressure Relief

1

Tube

Barbed Fitting

Apply

thread

sealant

Flush System

Flush the system before installing meters and for ongoing operation for all service fluids. Follow this procedure

for each dispense location in the system, starting at the

location farthest from the pump.

WARNING

Follow Relieve Pressure procedure before replacing

CleanLine Filter cartridge. Read warnings on page 2.

1. To determine the necessary flush time in minutes:

a. Measure the approximate length of the fluid line

from the filter outlet to the dispense end of the

hose. Be sure to include the entire length of

hose coiled in the hose reel.

b. Determine the largest inside diameter (I.D.) of

pipe or hose in the system.

c. On the following table, select the line length and

the larger I.D. of pipe or hose to determine flush

time.

Flush Time (minutes)

Combined

length of

pipe and

hose (feet)

50-100 ¹/

Drain Valve

100-200 ¹/

200-300 111¹/

TI5171C

1

Not to be routed to Matrix tank level monitor.

F

IG. 6

CleanLine 1800 Filter (models 248417 and 248419)

1. Turn off air supply to pump.

2. Close upstream ball valve (101).

3. Trigger the dispense valve.

4. Close downstream ball valve (101) to ensure oil

does not run out.

310652K 5

300-400 11¹/

400-500 122¹/

500-750 1¹/

750-1000 23¹/

2. Install all system components including the Graco

CleanLine Filter system. Do not install dispense

equipment until initial flush is complete.

3. Close the fluid shut-off valve.

Largest inside diameter of pipe or

hose (inches)

.5 .625 .75 1.0 1.5

¹/

²

²

1124

2¹/

²

¹/

²

²

²

²

²

23¹/²8

3¹/

56¹/²20

12

36

²

410

²

6¹/

²

15

²

Page 6

Operation

4. Ensure the main fluid outlet valve at the pump is

closed.

5. Place dispense end of hose into a waste oil container. Secure the hose so it will not come out during

flushing.

6. Slowly open the main fluid outlet valve at the pump.

At the same time, gradually increase the air pressure to the pump until there is good flow through the

hose.

7. Dispense fluid continuously at 2 gpm or more for the

length of time determined by the table information.

In an existing fluid line, the flushed oil can be

returned to the bulk tank and reused. In a newly

installed line, the flushed oil should be not be

reused.

8. Repeat this procedure for each dispense location

and each service fluid in the system.

9. After service fluids have been flushed install

meter(s).

10. The system is now ready for use.

4. Unscrew the filter (5).

5. Apply oil to the new filter seal.

6. Tighten new filter 1/10 turn after filter contacts base.

7. Open both ball valves (6).

8. Turn system pressure back on.

Replacing the filter cartridge allows air into the system. Spitting will occur during dispense until air is

purged from the system.

CleanLine 1800 Filter (models 248417 and 248419)

1. Relieve pressure (see Relieve Pressure on page 5).

2. Close both ball valves (101).

3. Place a waste oil container below the filter to catch

the oil in the housing (104) and filter cartridge (103).

4. Unscrew the housing (104).

5. Pull the filter cartridge (103) straight down.

It is all right to flush with mineral spirits, kerosene

and other petroleum-based fluids with the CleanLine Filter installed.

CleanLine Filter Cartridge Replacement

WAR NING

Follow Relieve Pressure procedure before replacing

CleanLine Filter cartridge. Read warnings on page 2.

The CleanLine Filter cartridge should be replaced at

least once a year or any time you notice a reduced flow

rate or other signs of degraded performance. To replace

the CleanLine Filter, perform the following steps:

CleanLine 900 Filter (models 248418 and 248421)

1. Relieve pressure (see Relieve Pressure on page 5).

6. Apply grease to the o-ring inside the replacement

cartridge (103).

7. Firmly push the replacement cartridge (103) straight

up, onto the nipple inside the manifold (102).

8. Replace the housing (104) and torque to 15 ft. lbs.

9. Open both ball valves (101).

10. Turn system pressure back on.

Replacing the filter cartridge allows air into the system. Spitting will occur during dispense until air is

purged from the system.

2. Close both ball valves (6).

3. Place a waste container below the filter to catch the

oil in the filter.

6 310652K

Page 7

Operation

310652K 7

Page 8

Parts for CleanLine 900 Filter

Parts for CleanLine 900 Filter

Model 248418 Wall Mount CleanLine Filter Assembly

Model 248421 Pump Mount CleanLine Filter Assembly

2

1314

12

3

17★

◆16

6

To dispense

system

4

7

1

Torque to 130-150 in-lb.

2

Apply sealant.

3

Route tube to used oil container or

to bulk oil tank, not to TLM port.

14

2

9

10

11

8

18a◆

6

3

1

2

2

1

8

18b★

5

From pump

TI5170E

Ref. Part Description Qty.

1 15E281 MANIFOLD, filter 1

2 234842 VALVE, drain 1

3 287389 BASE, valve 1

4 187625 HANDLE, valve, drain 1

5 15D702 FILTER, spin-on 1

6 119388 VALVE, ball, 3/4 2

7 111600 PIN, grooved 1

8 15H103 NIPPLE, pipe 2

9 114287 FITTING, barbed, 1/4 ID tube,

1/8 npt

10 111801 SCREW, cap, hex head 4

11 15E328 LABEL, product ID filter 1

12 15E327 TUBE, pressure relief 1

13 119529 FITTING, barbed, 1/4 ID tube,

3/8 npt

14 119454 CLAMP, worm drive 2

15 110110 SEALANT, pipe (not shown)

8 310652K

Ref. Part Description Qty.

16◆ 249568 BRACKET, wall mount for 248418

Includes label (11)

17★ 249565 KIT, pump mount bracket for

248421 (includes pump mounting

hardware and label (11)

18au 111010 HOSE, 3/4” x 10’, coupled 3/4 npt

(mbe) for wall mount model 248418

18bH 109105 HOSE, 3/4” x 6’, coupled 3/4 npt

1

19* 113344 FITTING, swivel (connects Fire-Ball

20* 157785 FITTING, swivel (connects Fire-Ball

1

u Model 248418

H Model 248421

* Not shown

(mbe) for pump mount model 248421

300 fluid out to hose (18)

424 fluid out to hose (18)

1

1

1

1

1

Page 9

Parts for CleanLine 1800 Filter

Model 248417 Wall Mount CleanLine Filter Assembly

Model 248419 Pump Mount CleanLine Filter Assembly

To dispense

system

101

Torque to 15 ft-lb.

1

106

105

102

107

112

110

106

105

Parts for CleanLine 1800 Filter

109◆

101

111a◆

111b★

1

Ref.

No. Part No. Description Qty.

101 119388 VALVE, ball 2

102 119189 MANIFOLD, filter 1

103 119278 ELEMENT, filter 1

104 119279 HOUSING, filter 1

105 15H103 NIPPLE, pipe 2

106 119200 FITTING, adapter, SAE12-3/4

npt(f)

107 113802 SCREW, hex head, flanged 3

108 110110 SEALANT, pipe (not shown)

109◆ 249568 BRACKET, wall mount for 248418

Includes label (112)

110★ 249565 KIT, pump mount bracket for

248421(includes pump mounting

hardware and label (112)

103

A CleanLine Filter must be used when you

use a Matrix fluid management system to

dispense oil or anti-freeze. For anti-freeze

mixtures, use the CleanLine 1800 wall

mount unit (248417), CleanLine 900 Filters

are not compatible with anti-freeze.

From pump

Ref.

No. Part No. Description Qty.

111a◆ 111010 HOSE, 3/4” x 10” coupled 3/4 npt

(mbe) on wall mount for model

248417

111b★ 109105 HOSE, 3/4” x 6’, coupled 3/4 npt

(mbe) on tank mount model

2

112 15E328 LABEL 1

113* 113344 FITTING, swivel (connects

114* 157785 FITTING, swivel (connects

1

1

◆ Model 248417

★ Model 248419

* Not shown

248419

Fire-Ball 300 fluid out to hose (18)

Fire-Ball 424 fluid out to hose (18)

TI6276B

1

1

1

1

310652K 9

Page 10

Technical Data

Technical Data

Maximum Working Pressure

CleanLine 900 Filter (models 248418 and 248421) 900 psi (6.2 MPa, 62 bar)

CleanLine 1800 Filter (models 248417 and 248419) 1800 psi (12.4 MPa, 124 bar)

Outlet 3/4 x 14 npt

Filtration Efficiency

CleanLine 900 Filter (models 248418 and 248421)

CleanLine 1800 Filter (models 248417 and 248419)

ß

= 1000 (ISO 16889)

14

= 1000 (ISO 16889)

ß

10

Wetted parts

CleanLine 900 Filter (models 248418 and 248421)

CleanLine 1800 Filter (models 248417 and 248419)

zinc plated steel, filter media

aluminum, filter media

Weight (dry) 7 lbs. (3.18 Kg.)

1

For particle sizes 14 micron and larger, filtration is 99.9% efficient.

2

For particle sizes 10 micron and larger, filtration is 99.9% efficient.

3

The filter media is compatible with petroleum-based fluids and most phosphate esters, water/oil emulsions, and

high water content fluids.

1

2

3

3

Flow Characteristics

Flow measurements were made with 32cSt [150 SSU] hydraulic oil at 100°F (37.7°C), fluid specific gravity of 0.9.

Corrections:

Pressure Drop vs. Flow

3.5

3

2.5

2

1.5

1

Pressure Drop (psi)

0.5

0

0 5 10 15 20 25

Flow (gpm)

To correct filter element pressure drops for

various viscosities and specific gravities, use

one of the following formulae:

ΔPm = ΔPe x (SSU/150) x S.G./0.9)

or

ΔPm = ΔPe x (cSt/32) x S.G./0.9)

or

ΔPm = ΔPe x (cP/29)

Calculation Definitions:

ΔPe = Element pressure drop from curve

ΔPm = Corrected element pressure drop

S.G. = New specific gravity

SSU = New SSU viscosity

(Saybolt Seconds Universal)

cSt = New cSt viscosity (centistokes)

cP = New cP viscosity (centipoise)

10 310652K

Page 11

Dimensions

Dimensions

12.25”

Part No. 249565

13”

7”

2.25”

.75”

Part No. 249568

4”

5.5”

7”

.375”

2.25”

2”

Part No. 249568

mounting hole positions

4”

6”6”

310652K 11

Page 12

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 310652

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2004, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 03/2010

Loading...

Loading...