Page 1

Repair and Parts

RTX 1500 Electric Texture Sprayer

U.S. Patent No. D580,517S

Europe Patent No. 1511575

- For Water-Based Materials Only -

(Consult your Material Supplier for Warnings and Application Requirements)

Models: Page 2

Maximum Working Air Pressure: 45 psi (3.1 bar)

Maximum Working Fluid Pressure: 100 psi (6.9 bar)

Read all warnings and instructions.

310645K

NOTICE

Use RTX 1500 non-bleeder texture gun 248091. All

other guns will damage sprayer.

ti4305a

Graco Inc. P.O. Box 1441 Minneapolis, MN

55440-1441

www.graco.com

Copyright 2004

Page 2

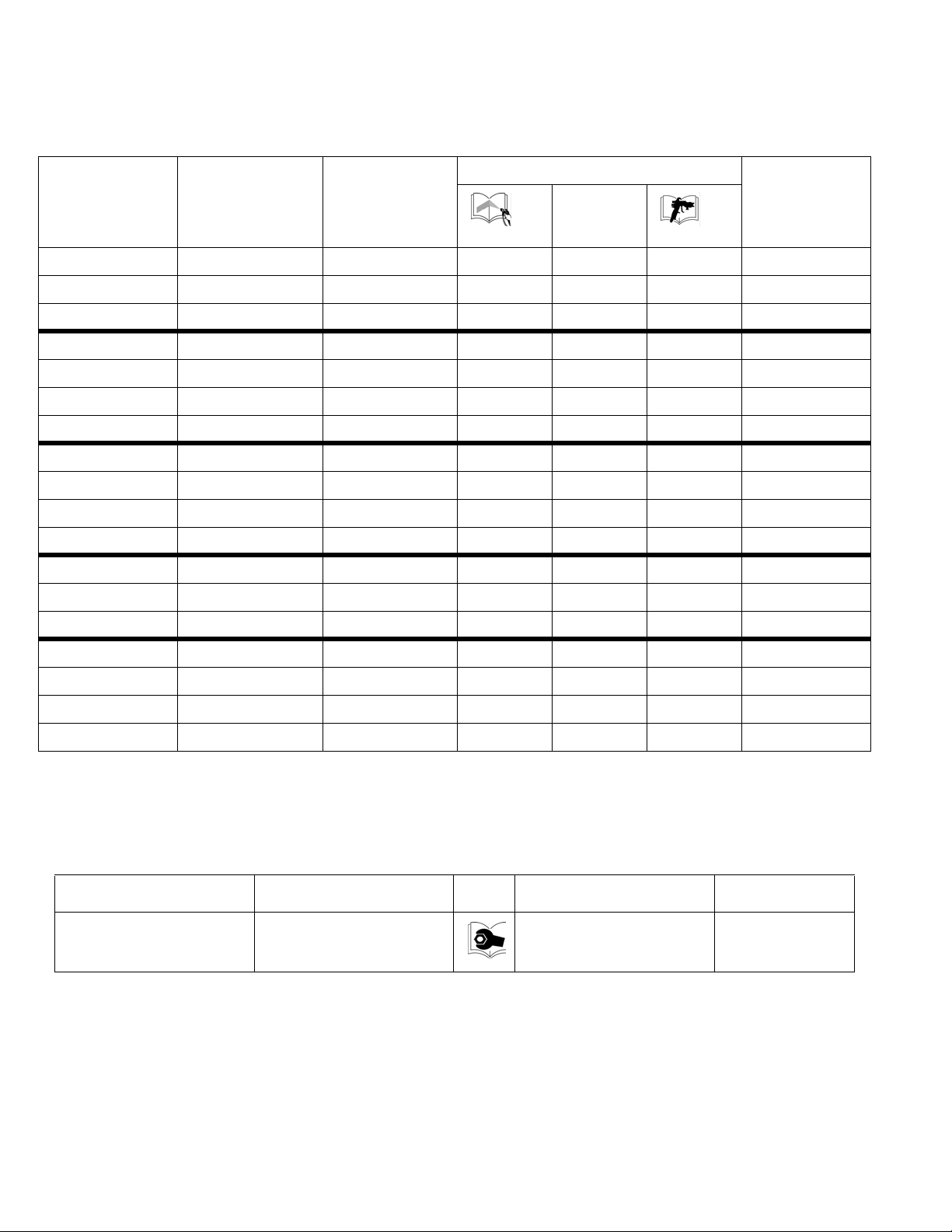

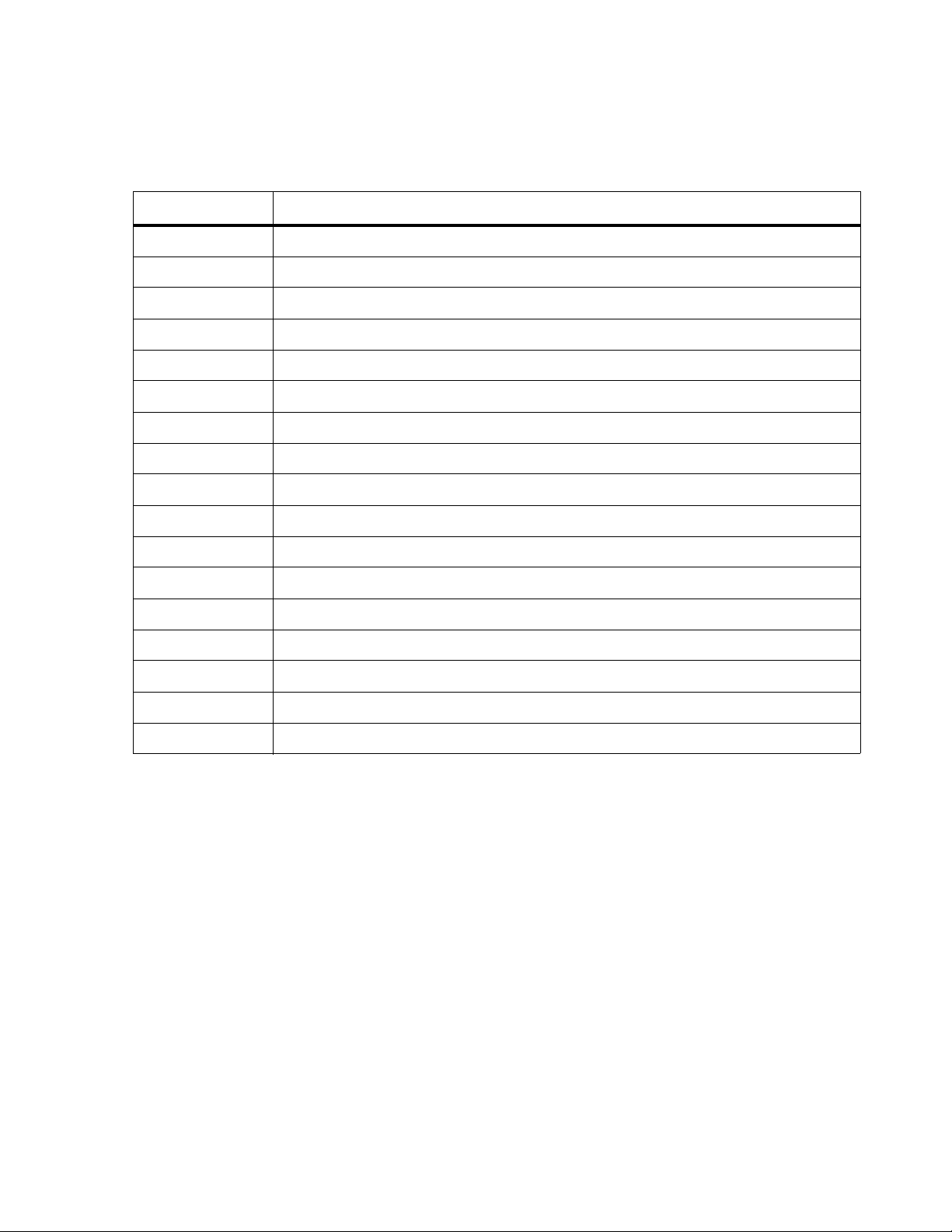

Models

Models

Manual

Model Electric

Requirements

248201 120V, 60 Hz, 15 A N. America 310624 310694 310616 English

248370 / 248315 230V. 50 Hz, 10 A Europe 310624 310616 French

248370 230V. 50 Hz, 10 A Europe 310624 Dutch

248370 230V. 50 Hz, 10 A Europe 310625 310616 Spanish

248370 / 248315 230V. 50 Hz, 10 A Europe 310625 Italian

248370 230V. 50 Hz, 10 A Europe 310625 Portuguese

248370 / 248315 230V. 50 Hz, 10 A Europe 310625 German

248315 230V. 50 Hz, 10 A Europe 310697 Swiss

248315 230V. 50 Hz, 10 A Europe 310697 Danish

248370 230V. 50 Hz, 10 A Europe 310697 Norwegian

248370 230V. 50 Hz, 10 A Europe 310697 Swedish

248370 230V. 50 Hz, 10 A Europe 310698 Polish

248370 230V. 50 Hz, 10 A Europe 310698 Russian

248370 230V. 50 Hz, 10 A Europe 310698 Greek

Country

Operation

287328*

Gun

Languages

248315 230V. 50 Hz, 10 A Asia 310699 Chinese

248315 230V. 50 Hz, 10 A Asia 310699 Japanese

248315 230V. 50 Hz, 10 A Asia 310699 Korean

248315 230V. 50 Hz, 10 A Australia 310699 310694 310616 English

*Auxiliary Air Hookup Kit

RELATED MANUALS

Model Country Manual Languages

ALL ALL

310645 English

2 310645K

Page 3

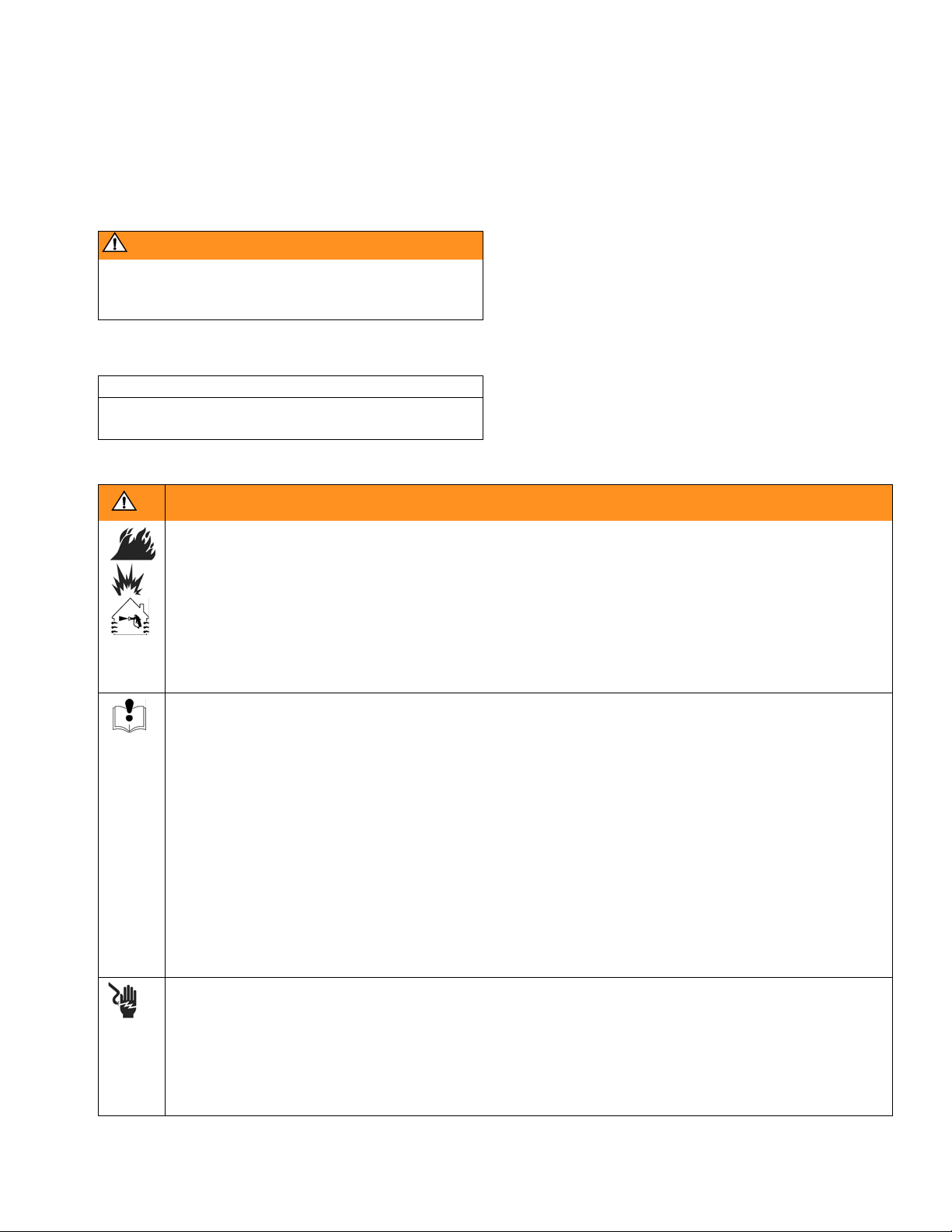

Warnings

The following are general Warnings related to the safe setup, use, maintenance and repair of this

equipment. Additional, more specific warnings may be found throughout the text of this manual where

applicable.

Warning

WARNING

This symbol alerts you to the possibility of serious injury or death if you do not follow the

instructions.

Caution

CAUTION

Alerts you to the possibility of damage or destruction

of equipment if you do not follow the instructions.

Warnings

Fire and Explosion Hazard

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Keep work area free of debris, including solvent, rags, and gasoline.

• Ground equipment in the work area. See Grounding instructions.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

Equipment Misuse Hazard

Equipment misuse can cause death or serious injury.

• Do not exceed maximum working pressure or temperature rating of lowest rated system compo-

nent. See Technical Data, in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify this equipment.

• Use the equipment only for its intended purpose. Call your Graco distributor for information.

• For professional use only.

• Route hoses away from traffic areas, sharp edges, moving parts and hot surfaces.

• Do not use hoses to pull equipment.‘

•

• Comply with all applicable safety regulations.

Electric Shock Hazard

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

310645K 3

Page 4

Warnings

WARNINGS

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

Cleaning Solvent Hazard with Plastic Parts

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many

solvents can degrade plastic parts to the point where they could fail. Such failure could cause serious

injury or property damage. See Technical Data on page 34 of this instruction manual and in all other

equipment manuals. Read fluid and solvent manufacturer’s warnings.

Moving Parts Hazard

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

Personal Protective Equipment

Wear appropriate protective equipment when operating, servicing or when in the operating area of this

equipment to help protect yourself from serious injury, including eye injury, inhalation of toxic fumes,

burns and hearing loss. This equipment includes, but is not limited to:

• protective eye wear

• clothing and respirator as recommended by fluid and solvent manufacturer

• hearing protection

•gloves

CAUTION

Water or material remaining in unit when temperatures are below freezing can damage pump and/or delay startup.

To insure water and material are completely drained out of unit:

• remove hose from material outlet,

• tip sprayer forward 45° to allow material (water) to flow out of pump inlet.

Before adding material or starting unit in cold weather, circulate warm water through pump.

4 310645K

Page 5

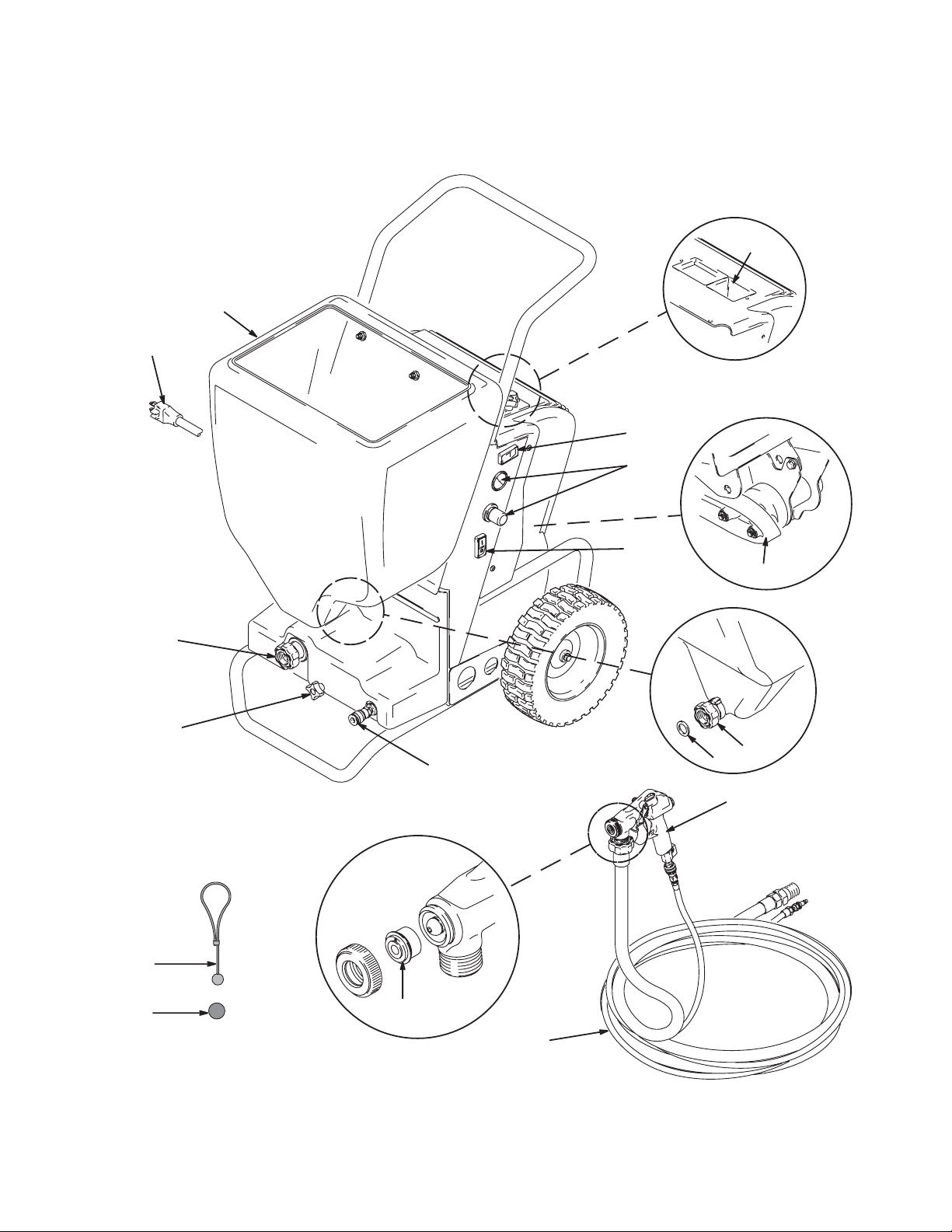

Component Identification

Component Identification

B

C

R

P

K

A

E

F

ti4500a

S

D

H

U

W

M

V

310645K 5

L

T

Page 6

Component Identification

Component Identification

ITEM

A Main Power Switch

B Nozzle Storage

C Hopper

D Hopper Connect/Disconnect

E Graco RotoFlex™ HD Pump

F Material Outlet

H Air Outlet

K Fluid Flow Regulator and Pressure Gauge

L Gun Nozzle (5 sizes)

M Gun (see manual 310616)*

PPrime Switch

RPower Cord

S Pump Access Screw

T Hose - 25-ft.

COMPONENT

U Material Thickness Gauge

V Cleaning Ball

W Spare Hose Gaskets

6 310645K

Page 7

Preparation

Preparation

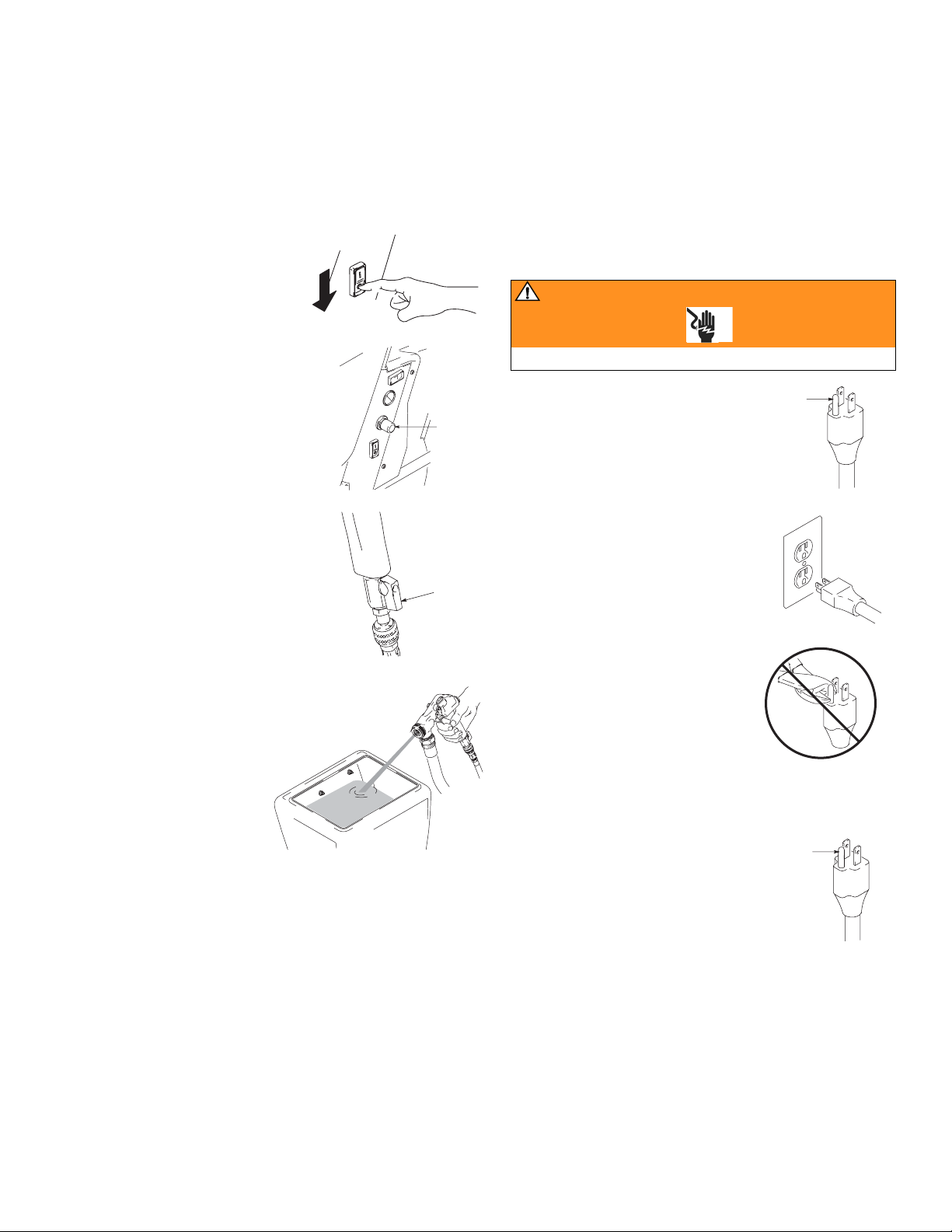

Pressure Relief Procedure

1 Turn Main Power Switch

(A) OFF.

2 Turn fluid flow regulator

(K) all the way down to

reduce pressure.

3 Open gun air valve (aa).

ti4303a

Grounding and Electric Requirements

The sprayer must be grounded. Grounding reduces the

risk of electrical shock by providing an escape wire for

the electrical current.

WARNING

Read warnings, page 3.

• The sprayer cord includes a

grounding wire with an appro-

K

priate grounding prong.

• The plug must be plugged into

an outlet that is properly

installed and grounded in

accordance with all local codes

A

and ordinances.

Ground

ti4295a

ti4296a

4 Trigger gun, spraying

material back into

hopper (C).

ti4000a

ti4294a

• Do not modify plug! If it will not

fit in outlet, have grounded outlet installed by a qualified electrician.

• Sprayer model electric requirements are provided on page 2.

Extension Cords

• Only use an extension cord with

an undamaged 3-prong plug.

• For up to 100 ft (30.48 m) cord,

use 3-wire, 12 AWG (2.5 mm

2

)

minimum.

ti4297a

Ground

ti4295a

310645K 7

Page 8

Preparation

Auxiliary Air Compressor

• Use Auxiliary Air Hookup Kit 287328 when additional

atomization air is necessary.

CAUTION

Attaching auxiliary air to sprayer without using the

Auxiliary Air Hookup Kit will damage sprayer.

Generators

7500 W (7.5 KW) minimum.

Tips for Using Generators

• Before running sprayer, make sure it is at room temperature. This will reduce startup current.

• Run generator at full throttle.

Hose Lengths

• The system comes with a twin line hose set consisting of a 1 in. ID x 25 ft (25 mm x 7.6 m) material hose

and a 3/8 in. ID air hose. Additional hose sections can

be added. Total final length of hose used should not

exceed 100 feet in length.

CAUTION

Sprayer air hose fitting can get hot! Allow sprayer to

cool down 5 minutes before removing air hose.

8 310645K

Page 9

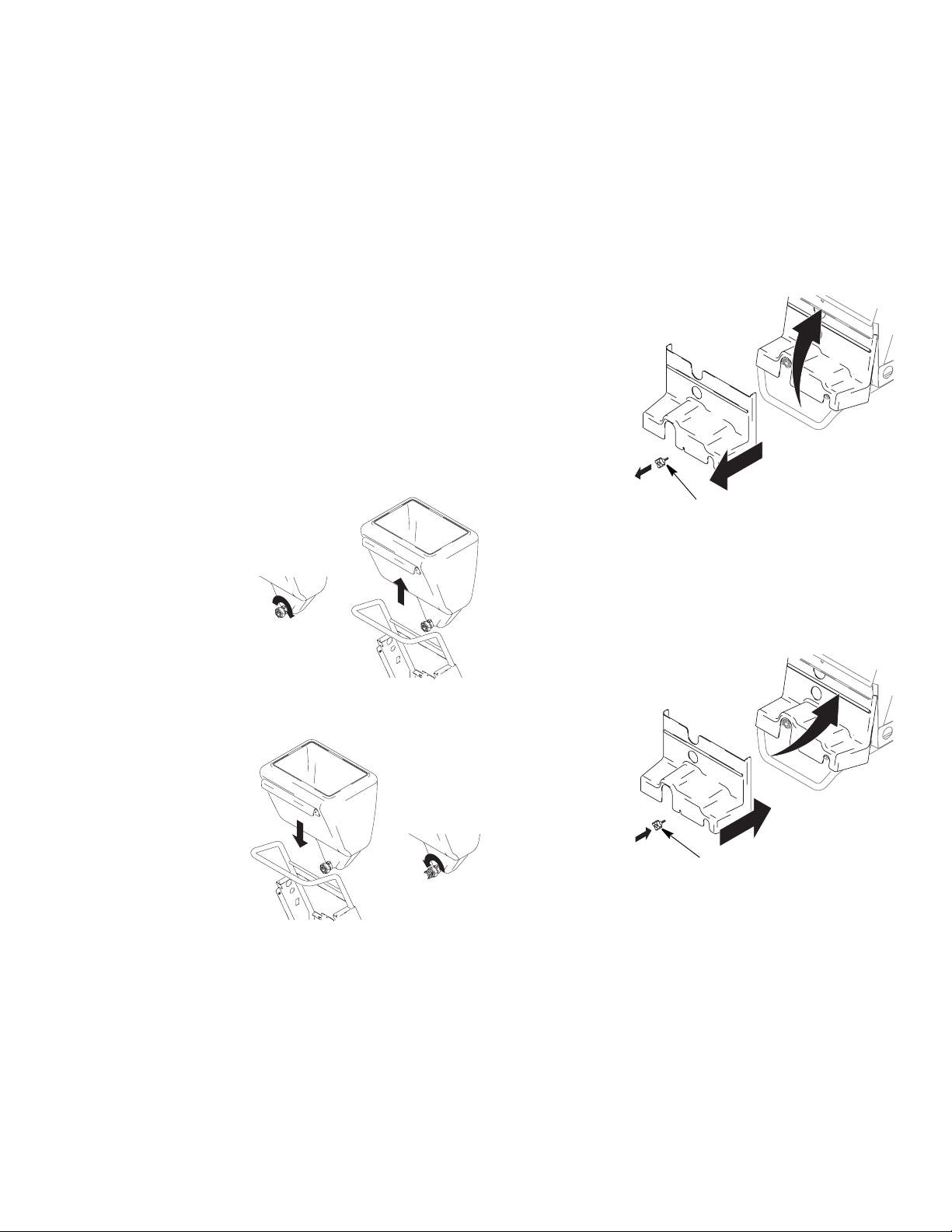

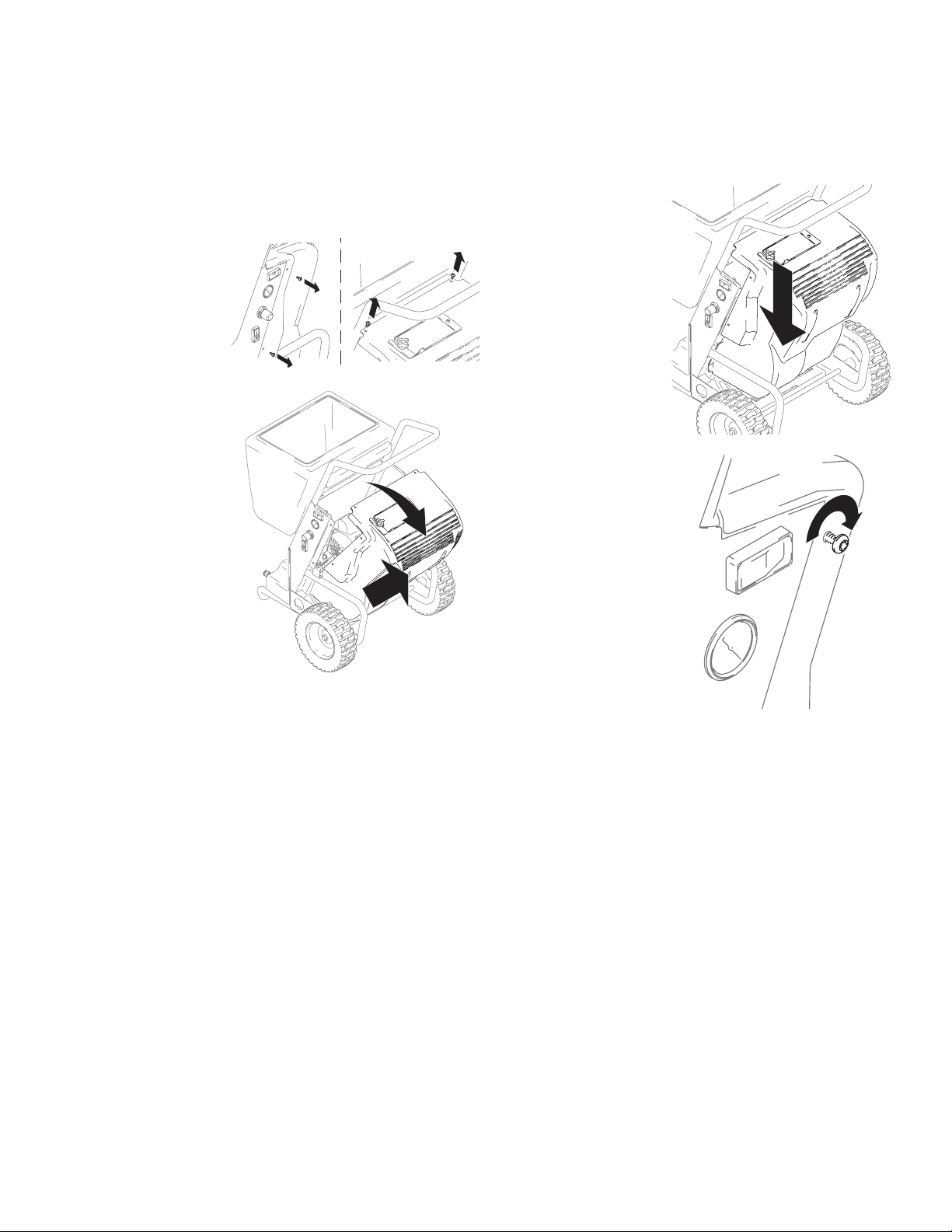

Removing and Replacing Hopper, Front and Back Covers

Removing and Replacing Hopper, Front and Back Covers

Before performing any service on sprayer

always:

• Read all warnings, page 3.

• Read operating instructions manual, page 2.

• Relieve Pressure, page 7.

• Turn main power switch (A) OFF.

• Unplug sprayer from outlet.

• Remove air and material hoses.

• Clean sprayer. See Operation Manual 310624 or

310625.

Hopper

Removing Hopper

1 To remove hopper

loosen fitting.

Fittings are

hand-tightened

and should not

require tools to

loosen.

Front Cover

Removing Cover

1 Remove hopper.

2 Unscrew and

remove knob

(S).

3 Place you

hand under

front, bottom

edge of

cover.

(3a) Lift

cover up,

(3b) then pull

bottom

toward you

and out to remove cover.

Replacing Cover

3a

ti4408a

3b

S

2 Lift hopper straight

up, off frame.

Replacing Hopper

1 To replace

hopper, position

drain over fitting

as far as it will

go, making sure

identification label

faces out.

2 Hand tighten fit-

ting.

1 Place your

ti4503a

hand under

front, bottom

edge of cover.

(1a) Position

top edge of

cover under

1a

ti4411a

top metal lip

on sprayer

frame.

1b

(1b) Then

push up on

S

cover so lower

plastic edge

ti4504a

of cover has room to clear front metal frame and slide

cover into place. To position cover correctly, it will go

in at an angle.

2 Replace knob (S). Hand tighten fitting.

3 Replace hopper.

310645K 9

Page 10

Removing and Replacing Hopper, Front and Back Covers

Back Cover

To access the motor and all other components, it is

necessary to remove the hopper, front and back covers.

Removing Cover

1 Completely

remove 6

screws (2 on top

and each side)

from cover.

ti4430a

2 Lift cover up and

then tilt it back

and off sprayer

frame.

Replacing Cover

1 To reposition cover

on sprayer frame,

tip the cover back,

toward you and

slide it down, into

place in the base of

the frame. Then

push the top back

into place. Align

screw holes in side

and top of cover

with holes in frame.

ti4432a

2 Replace and

tighten screws.

ti4431a

ti4433a

10 310645K

Page 11

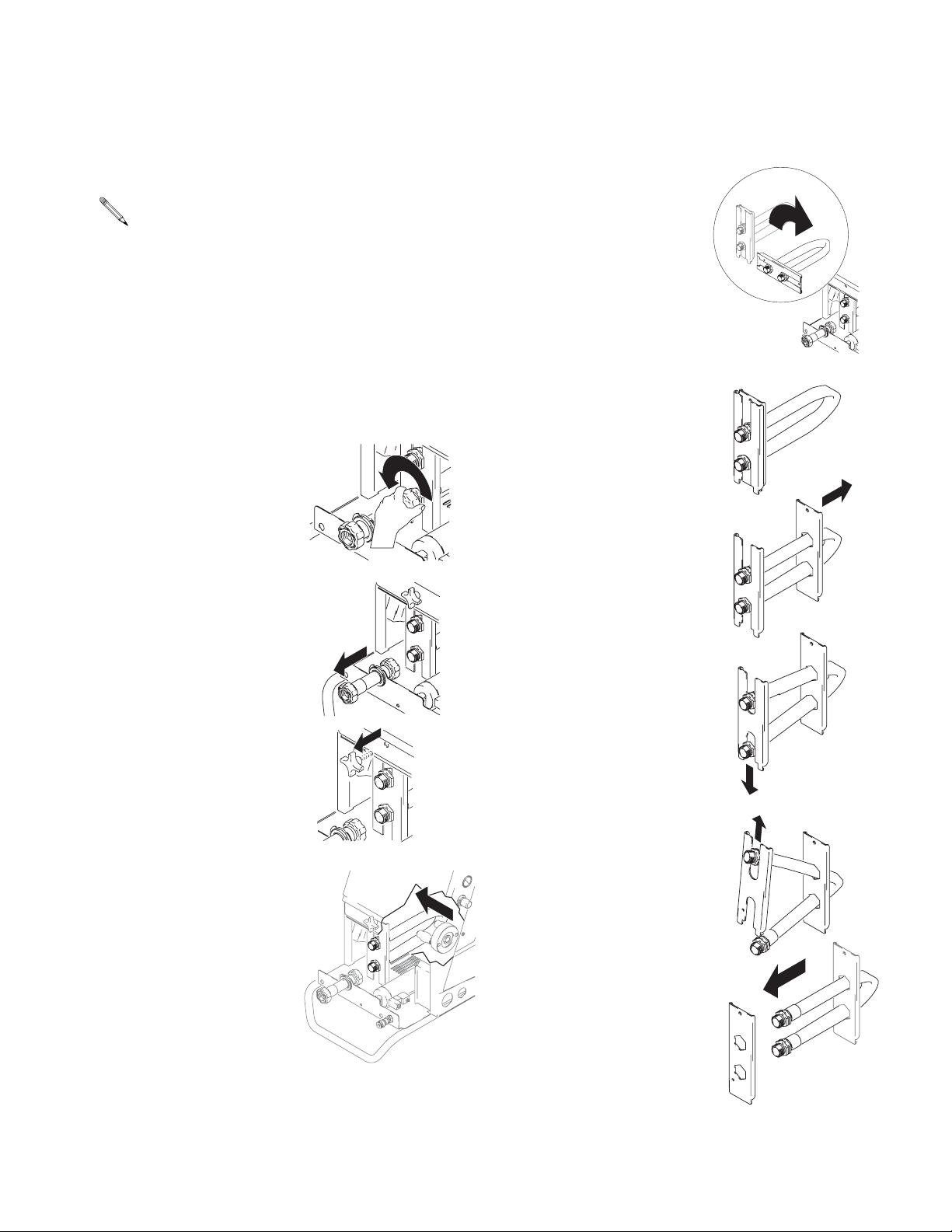

RotoFlex™ HD Pump

RotoFlex™ HD Pump

Use RotoFlex HD Pump Replacement Kit 287314.

IMPORTANT

• After replacing RotoFlex HD Pump hose, always

follow Hose Break-In Procedure, page 13,

before operating sprayer.

Disassembly

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove hopper and front cover, page 9.

1 Loosen and remove hose

extension.

ti4377a

4 Rotate pump assembly

sideways. Pull entire

assembly out of front of

sprayer frame.

ti4376a

.

5 Separate the inner and

outer hose brackets.

2 Loosen and remove knob.

3 Slide RotoFlex HD hose

off rollers.

ti4374a

ti4378a

ti4519a

6 Slide hose ends out of

slots in outer hose

bracket.

• Slide out of short slot

first.

7 Pull hose out of inner

hose bracket.

ti4379a

8 Discard pump hose.

310645K 11

Page 12

RotoFlex™ HD Pump

Reassembly

1 Bend and kink new

pump hose from kit in

the middle as shown,

making sure dots on

hose fittings face each

other.

2 Insert hose ends

through holes in inner

hose bracket, keeping

dots on fittings facing

each other and kinked

portion of hose horizontal to the underside of

bracket.

3 Slide hose ends into

outer hose bracket,

making sure dots on fittings face each other

and alignment holes are

together.

• Slide into long slot

first.

4 Slide plates together, inserting inner plate in outer

plate, matching alignment holes.

DOTS

5 Replace bracket

assembly in housing

making sure the

mounting screw hole,

located in the top center of the inner plate,

faces up.

ti3127a

ti4383a

6 Slide pump hose

around rollers. Make

sure the rollers are

horizontally parallel to

each other.

ti4520a

alignment

holes

7 Slide feet on the bot-

tom of hose bracket,

into the slot on the bottom of sprayer.

ti4429a

8 Replace knob. Hand

tighten.

9 Reattach hose extension.

10 Replace front cover and

hopper. See Removing

and Replacing Hopper,

ti4381a

Front and Back Cover,

page 9.

ti4386a

12 310645K

Page 13

RotoFlex™ HD Pump

Hose Break-In Procedure

1 Make sure fluid flow regulator

(K) is turned all the way down.

2 Pour approxi-

mately 1 gallon hot

water in sprayer

hopper to lubricate the pump.

WATER

ti4303a

3 Turn power switch (A) on.

4 Hold in prime switch (P).

K

5 Turn fluid flow regulator

(K) up to full pressure.

ti4301a

ti4653a

P

ti4364a

K

ti4655a

6 Run sprayer dry for 1 to 1-1/2 minutes.

310645K 13

Page 14

Compressor and Motor Repair

Compressor and Motor Repair

For 120 V sprayer use Compressor and Motor

Replacement Kit, 287315.

For 230 V sprayer use Compressor and Motor

Replacement Kit, 287344.

Kits include motor/compressor and mounting hardware.

Disassembly

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove hopper, front and back covers, page 9.

Remove hose extension and RotoFlex HD Pump

assembly from frame, page 11.

1 Remove two screws and

access cover on the left

side of the motor.

4 Loosen 4 bolts (2 each

side) to loosen tension on

belt.

ti4388b

5 Slide belt off motor pully.

ti4459a

6 Disconnect air line from

compressor to cooler and

remove.

2 Remove ground nut and

disconnect green ground

wire.

3 Disconnect black and white

wires to motor.

ti4457a

ti4460a

7 Remove 3 screws on

right side of cover and

remove cover.

ti4458a

ti4479a

ti4405a

ti4478a

14 310645K

Page 15

Compressor and Motor Repair

8 Loosen 2 shoulder bolts

about 2-3 turns. Do not

remove them.

9 Remove single shoulder

bolt on other side of

motor completely.

10 Slide out motor

assembly.

ti4425a

ti4463a

Reassembly

1 Using two new shoulder

bolts and rubber mounts

included in your kit, insert

bolts into openings until

they start to snug up on

rubber mounts.

ti4465a

2 Slide new motor into

sprayer frame, aligning

motor frame opening

under bolts. Tighten bolts.

ti4468a

3 Replace shoulder bolt

on left side with new

bolt from your kit.

Tighten bolt.

ti4462a

11 Completely remove

old shoulder bolts and

rubber mounts.

ti4464a

12 Thoroughly clean inside housing to remove dust and

debris.

ti4424a

4 Replace end cover.

Replace and tighten 3

screws.

ti4484a

ti4485a

5 Reattach air line to cooler

and compressor. Tighten

fitting.

ti4516a

310645K 15

Page 16

Compressor and Motor Repair

6 Slide belt over pulleys and set tension. See Replacing

Belt, page 19.

7 Reattach black and white

wires to motor.

Wires are not polarity

sensitive.

ti4412a

8 Replace reattach green

ground wire and grounding

nut.

9 Replace cover plate and

screws.

10 Replace RotoFlex HD

Pump and hose extension, page 12.

11 Replace front and back

covers and hopper. See

Removing and Replacing

Hopper, Front and Back

Cover, page 9.

ti4470a

ti4471a

16 310645K

Page 17

Compressor Rebuild Kit

Compressor Rebuild Kit

To replace piston, seals and sleeve.

For 120 V sprayer use Compressor Rebuild Kit 287330.

For 230 V sprayer use Compressor Rebuild Kit 287331.

Disassembly

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove back cover, page 9.

1 Disconnect air line to

motor.

ti4460a

2 Remove 3 screws in

side of motor cover.

Remove cover.

4 Remove 3/8 in. bolt

holding piston to

motor shaft.

ti4707a

5 Loosen 4 bolts on top

of motor housing.

ti4708a

6 Remove bolts and

housing from motor.

ti4479a

3 Remove fan bolt from

center of fan and

remove fan from housing.

ti4478a

7 Remove piston rod

from motor.

8 Using parts in kit

replace piston, seals

ti4709a

and sleeve.

ti4710a

ti4706a

310645K 17

Page 18

Compressor Rebuild Kit

Reassembly

1 Insert new piston rod from

kit in motor housing.

2 Replace and tighten

piston bolt.

3 Replace top motor

hosing and 4 bolts.

4 Tighten bolts.

ti4700a

ti4701a

5 Replace motor fan

and center fan bolt.

6 Tighten bolt.

ti4704a

7 Replace motor

cover and screws.

ti4485a

8 Reconnect air line

from motor to

cooler.

9 Replace back cover.

See Removing and

Replacing Hopper,

Front and Back

Cover, page 9.

ti4703a

18 310645K

Page 19

Removing and Replacing Belt

Removing and Replacing Belt

Use Belt Replacement Kits 118845.

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove hopper, front and back covers, page 9.

Remove hose extension and RotoFlex HD Pump

assembly from frame, page 11.

Removing Belt

1 Loosen 4 bolts (2 each

side) to loosen tension on

belt.

2 Loosen 2 bolts (1 each

side) holding down support rod.

Replacing Belt

1 Using new belt from Kit,

position new belt around

pulleys making sure the

teeth in the belt are

properly engaged with

teeth on pulleys.

2 Replace support rod.

Tighten 2 bolts (1 each

side) to secure supporting rod.

ti4388b

3 Insert crow bar under

assembly as shown and

raise motor assembly

until desired belt tension is achieved.

ti4392a

ti4393a

3 Using a screw driver for

leverage, lift up on motor

support rod on one side

of motor and ease it out of

the holding bracket far

enough to remove old

belt. Discard old belt.

At the same time, slide in

the new belt.

ti4459a

ti4388a

ti4469a

4 While holding motor

assembly in place with

crow bar. Spin pulley to

assure proper belt

engagement. Adjust

motor assembly position

as necessary.

ti4391a

ti4472a

310645K 19

Page 20

A correctly tensioned belt will feel very tight. To

measure correct tension, apply 4-5 lbs pressure

at belt midpoint with thumb. Belt should have

approximately 1/8 in. (3.175 mm) deflection.

Removing and Replacing Belt

5 Tighten all 4 bolts.

ti4394a

6 Turn belt one more

time with your hand to

make sure teeth are

properly engaged and

tension is correct.

ti4477a

A loose belt will not last long. If in doubt, tighten

more.

7 Replace RotoFlex HD

Pump and hose extension, page 12.

8 Replace back and front

ti4473a

covers and hopper.

See Removing and

Replacing Hopper, Front and Back Cover, page 9.

20 310645K

Page 21

Roller Replacement

Roller Replacement

Use Roller Replacement Kit 287321.

Kit includes 2 rollers, 4 nylon washer, and 2 retaining

rings.

Disassembly

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove hopper, front and back covers, page 9.

Remove hose extension and RotoFlex HD Pump

assembly from frame, page 11.

1 Remove snap ring.

ti4396a

2 Remove roller assembly

from rotor pins (a).

3 Clean rotor pins (a) and

check for damage. If pins

are worn or damaged,

replace rotor assembly,

(Rotor Assembly

Replacement, page 22).

ti4397a

a

Reassembly

1 Replace roller assembly.

ti4398a

2 Reinstall snap ring.

ti4399a

3 Replace RotoFlex HD Pump and hose extension,

page 12.

4 Replace back and front covers and hopper. See

Removing and Replacing Hopper, Front and Back

Cover, page 9.

310645K 21

Page 22

Rotor Assembly Replacement

Rotor Assembly Replacement

Use Pump Assembly Replacement Kit 287255.

Disassembly

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove hopper, front and back covers, page 9.

Remove hose extension and RotoFlex HD Pump

assembly from frame, page 11.

1 To prevent rotor assembly

from moving, insert a long

screw driver or pry bar in the

pulley.

2 Remove large bolt and

washer in center of rotor

assembly.

3 Pull rotor assembly off shaft.

ti4711a

Reassembly

1 Put new rotor assembly from kit on shaft.

2 Insert a wrench in the

pulley to prevent it from

moving.

ti4714a

3 Replace bolt. Torque to

40 ft. lb.

ti4714a

ti4712a

4 Replace RotoFlex HD Pump and hose extension,

page 12.

5 Replace back and front covers and hopper. See

Removing and Replacing Hopper, Front and Back

Cover, page 9.

22 310645K

Page 23

Air Cylinder and Solenoid Valve

Air Cylinder and Solenoid Valve

Use Cylinder Replacement Kit, 287323.

For 120 V sprayer use Solenoid Replacement Kit

287324.

For 230V sprayer use Solenoid Replacement Kit

287351.

Disassembly

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove hopper, front and back covers, page 9.

Remove hose extension and RotoFlex HD Pump

assembly from frame, page 11.

1 Remove hose from quick

release fitting by using your

fingers on one hand to push

in on ring while at the same

time, using the other hand,

gently pull the hose out of the

fitting.

2 Remove electric wire ter-

minal connections.

ti4406a

4 Gently push cylinder forward,

relieving tension on pin. Pull

out pin.

ti4409a

If replacing solenoid valve only, it can be done at

this time.

a Using an adjustable wrench, rotate entire solenoid

valve assembly counter clockwise from cylinder.

b Replace solenoid valve and continue with step 4 of

reassembly.

5 Lift cylinder up and pull it

back.

6 Remove dampening

grommet.

ti4518a

7 Using a 15/16 in. wrench,

loosen nut, located inside

sprayer frame at the end of

the air cylinder.

ti4415a

3 Remove cotter key located

on the end of the cylinder pin,

by using a pliers to straighten

the ends and pull it out of the

hole.

ti4416a

8 Using a 15/16 in. wrench,

loosen nut on the other

side of the sprayer frame.

9 Pull cylinder out of sprayer

frame.

If replacing cylinder only,

remove solenoid valve (see

a and b above) and reinstall on new cylinder.

ti4453a

ti4414a

310645K 23

Page 24

Air Cylinder and Solenoid Valve

Reassembly

1 Insert crowned backing

nut on shaft of cylinder.

2 Using new cylinder

from kit, position cylinder in sprayer frame,

inserting end of cylinder through pump

bracket mounting hole.

3 Install locking nut flush to end of shaft.

4 Install dampening grommet.

5 Align hole in end of air cylin-

der and replace pin.

ti4421a

ti4410a

6 Replace cotter pin

through hole in pin,

bending ends to secure.

7 Reattach electric wire

terminals. Terminals are

not polarity sensitive and

ti4417a

can be connected to

either post.

8 Gently push hose in

quick release fitting.

ti4407a

9 Replace RotoFlex HD Pump and hose extension,

page 12.

ti4456a

ti4455a

10 Replace front cover and hopper. See Removing and

Replacing Hopper, Front and Back Cover, page 9.

24 310645K

Page 25

Relief Valve and Flow Sensor Manifold

Relief Valve and Flow Sensor Manifold

For 120 V sprayer use Relief Valve Replacement Kit

287325.

For 230 V sprayer use Relief Valve Replacement Kit

287350.

Disassembly

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove hopper, front and back covers, page 9.

1 Remove air line to

regulator.

2 Remove air line from

cooler to manifold.

3 Disconnect wires to Relief Valve. Pay attention to their

location to insure they are reattached correctly.

4 Remove 2 nuts securing

Relief Valve to sprayer.

ti4423a

Reassembly

1 Position new relief valve from Kit in back of sprayer.

2 Replace and tighten screws.

3 Reattach wires to Relief Valve.

4 Reattach air line from cooler to manifold.

5 Reattach air line to regulator.Replace RotoFlex HD

Pump and hose extension, page 12.

6 Replace front cover and hopper. See Removing and

Replacing Hopper, Front and Back Cover, page 9.

5 Remove Relief Valve

from sprayer frame.

ti4418a

ti4419a

310645K 25

Page 26

Air Flow Sensor Replacement

Air Flow Sensor Replacement

For 120 V sprayer use Sensor Replacement Kit 287326.

For 230 V sprayer use Sensor Replacement Kit 287345.

If you are just replacing the sensor, you do not

have to remove the motor first.

Disassembly

First read and follow instructions in the Before

performing any service on sprayer section, page 9.

Then remove hopper, front and back covers, page 9.

Remove hose extension and RotoFlex HD Pump

assembly from frame, page 11.

1 Disconnect all

wire connections.

ti4481a

2 Rotate coun-

ter-clockwise to

remove sensor

from manifold.

ti4480a

Reassembly

1 Rotate new sensor

from kit clockwise, all

the way into opening

in Relief Valve

housing. Lightly

tighten nut.

ti4486a

2 Reconnect all wires.

WHITE WIRE

ti4482a

3 Replace RotoFlex HD

Pump and hose extension, page 12.

4 Replace back and front

covers and hopper. See

Removing and Replacing Hopper, Front and

Back Cover, page 9.

ti4487a

ti4488a

WHITE WIRE

26 310645K

Page 27

Pressure Relief, page 7

Problem Cause Solution

Sprayer won’t run or stops intermittently

Pump won’t pump material or low

output

Soft start won’t work/pump, always

loaded

Troubleshooting

Troubleshooting

Power switch not on Turn switch on.

No power at wall outlet Check outlet by plugging in another

appliance. If appliance does not

work, try another outlet.

Wrong size generator Use a 7500 watt or larger generator.

Refer to Generator Requirements,

page 8.

Temperature too cold Allow unit to warm up.

Too many items on same circuit Unplug other items from circuit.

Internal thermal switch tripped Self-resetting. Allow unit to cool down

15 minutes and restart. Usually

occurs when wrong size extension

cord is used.

Extension cord too long or wrong

gauge

Breaker tripped Reset breaker.

Air lock Open air valve on gun.

Mix too thick Add water to thin material. Use Mate-

Loose fittings Check and retighten all fittings.

Plugged gun Relieve Pressure, page 7. Remove

RotoFlex HD Pump worn out Replace hose.

Pump cold or material frozen in pump Move pump to warm room and allow

Sensor is bad Replace, page 26

Check air system for leaks Remove shroud and examine for air

Loose wire Remove shroud and examine wiring

No air pressure Rebuild compressor

Sensor is bad Change sensor, page 26

Air leak due to bad seal keeps valve

open

Normal soft start system delay Release trigger for 10-15 seconds.

Switch is not operating properly Replace switch

Damaged solenoid valve on cylinder Check gun supply, hose and sprayer

AIr leak

Use a 12 gage extension cord or

remove extension cord. Refer to

Grounding and Electric Require-

ments, page 7.

rial Thickness Gauge.

gun from hose. Clean gun.

it to warm up or run hot water through

sprayer.

leaks

Replace seal

Retry.

for leaks

310645K 27

Page 28

Troubleshooting

Problem Cause Solution

Material runs out of bottom of sprayer RotoFlex HD Pump worn out Replace hose.

Loose fittings Check and retighten all fittings.

No air from compressor Gun air valve closed Open gun air valve.

Gun needle plugged Clean needle and retry.

Lines not connected Check all quick disconnect connec-

tions to gun and hoses.

Damaged hose Replace hose.

Worn compressor Service compressor. Contact a quali-

fied Graco Service Center.

Speed of application too slow Material too thick Thin material.

Nozzle too small Change nozzles to a larger size. See

Operation Manual, Recommended

Nozzle Selection Chart, page 20.

Speed of application too slow (cont.) Flow control set too low Increase flow control setting

Plugged or dirty gun Relieve Pressure, page 7. Clean

gun.

Kinked hose Unkink hose.

Gun fluid flow adjustment set too low Increase flow adjustment with flow

adjustment nut.

Intermittent flow/sputtering or air in

material

Air quick disconnect does not stay

connected.

Gun will not shut off Worn nozzle or needle. Relieve Pressure, page 7. Replace

Fluid leaking at Flow Adjustment Nut Damaged seal. Relieve Pressure, page 7. Replace

Needle adjustment won’t adjust Dirty threads Clean threads

Hopper connection not tight Check gasket. TIghten connection.

Debris in system Clean

Dirty or corroded fitting Clean thoroughly. Soak in oil. Apply a

few drops of light oil.

worn parts.

Debris in needle passage Relieve Pressure, page 7. Clean.

seal.

Nozzle not on gun Put nozzle on gun

Flow nut set to maximum adjustment Turn flow nut adjustment the other

way

28 310645K

Page 29

Air Cylinder

Air Diagram

Air Diagram

Air Compressor

Guage

Regulator

One Way Valve

Air Cylinder

Air Cooler

One Way Valve

Air Flow Control

Wiring Diagram

Air Compressor

Gun

ti4369a

39

51

32

Prime

Switch

50

Power

Switch

Air Flow

Control

150/151

Green

White

Black

50

8

50

ti4370d

310645K 29

Page 30

Parts

102

49A

49C

Parts

19

34

1D

49B

1A

1C

42

52

49

31

53

57

36

45

22

38

9

63

21

40

1B

88

9

43

33

52

38A

1

1E

ti4371b

73

38B

101

55

62

37

41

13

62

88

63

4

56

67

30 310645K

Page 31

Parts List

Item

No. Part No. Description Qty

1 287315 KIT, compressor replacement

(includes 1A and 1B-1E),

120V sprayers

287330 KIT, compressor rebuild,

120V sprayers

287344 KIT, compressor replacement

(includes 1A, and 1B-1D),

230V sprayers

287331 KIT, compressor rebuild,

230V sprayers

1A 119872 SCREW, shoulder 3

1B 118886 GROMMET, isolator 2

1C 118889 GROMMET, isolator 1

1D 119381 COVER, terminal 1

1E 121479 CAPACITOR, start 1

4 118845 BELT 1

9 117728 FITTING, compression, union 2

13 15D156 PULLEY, rotor 1

16 118888 HOSE, air (includes 1/4 in. tubing

and one-way valve)

19 15D862 NUT, hand 1

21 118876 TUBE, air, aluminum 1

22 117637 NUT, compression 1

31 112395 SCREW, cap 4

32 15D633 WIRE, jumper 1

33 103473 STRAP, tie, wire 2

34 15B815 COOLER 1

36 101242 RING, retaining, ext. 2

37 287255 ROTOR, pump, assbly

(includes 38, 38A, 38B)

38 287321 KIT, roller replacement

(includes 38A, 38B and two rollers)

38A 113983 RING, retaining, ext 2

38B 117726 WASHER, nylon 4

Item

No. Part No. Description Qty

39 15D628 CONDUCTOR, ground 1

40 103785 RIVET 2

1

41 287327 KIT, repair, shaft, bracket, pump

assbly.

42 287256 BRACKET, compressor 1

43 118869 TUBE 1

45 15D610 SHAFT, motor, mount 1

49 287346 SHIELD, rear, assbly

(includes 19, 49A, 49B, 49C)

49A 15D561 COVER, tool tray 1

49B▲ 15D939 LABEL, warning, English, French,

Spanish

287336 KIT, label, warning, all languages

except those included in 15D939

49C▲ 15D940 LABEL, identification

51 15D634 WIRE, jumper 1

52 116937 BEARING, flanged, bronze 2

53 117630 SCREW, torx, tri lob 8

54 116666 TUBE, air 1

55 287304 HOSE SET, twin line, 1 in. x 25-ft 1

1

56 15C090 GAUGE, thickness, fluid 1

57 183401 KEY, parallel 2

58 116720 COUPLER, air, quick disconnect 1

62 108851 WASHER, plain 2

63 106276 SCREW, cap, hex head 2

67 113397 BALL, sponge, 30 mm 2

73 112785 SCREW, flanged, hex head 2

74 115498 SCREW, mach, slot, hex, wash hd 1

82 118887 HOSE, air (includes 1/4 in. tubing

1

88 118866 WASHER, flat 1

101 248091 GUN, non-bleeder 1

2

102 122104 VALVE PLATE, compressor 1

▲ Replacement Danger and Warning labels, tags and

cards are available at no cost.

and one-way valve)

Parts List

1

1

1

310645K 31

Page 32

18

Parts

Parts

24

90

25

26

93

29

27

81

66

154

91

A

30

92

12

17

6

3

7

10

70

71

35

ti4372C

55

93

19

28

153

151

23

14

58

83

20

59

60

77

8

72

5B

89

5A

5

15

A

150a

150b 150c152a 152c 152d152b 152e

32 310645K

Page 33

Parts List

Parts List

Item

No. Part No. Description Qty

3 118844 REGULATOR, air, 1/8 in. NPT 1

5 287323 KIT, cylinder, replacement,

(includes 5A, 5B, 89)

5A 15D576 SPACER, crowned 1

5B 118871 NUT, lock, 1/2-20 1

6 117720 GAUGE, pressure 1

7 115244 NUT, regulator 1

8▲ 186620 LABEL, ground, symbol 1

10 117693 SWITCH, power 1

12 119064 SWITCH, power 1

14 15D559 VALVE, assembly, 120V (includes

sensor) sprayer

287350 VALVE, assembly, 230V (includes

sensor) sprayer

15 15D560 VALVE, cylinder, 120V sprayer 1

287351 VALVE, cylinder, 230V sprayer 1

16 118888 HOSE, air (includes 1/4 in. tubing

and one-way valve)

17 15C968 TUBE, air 1

18 287347 HOPPER, texture (includes

bracket)

19 15D862 NUT, hand 1

20 287326 KIT, sensor only, 120V 1

287345 KIT, sensor only, 230V

23 287348 SHIELD, front (includes 28) 1

24 108471 KNOB, pronged 1

25 15D589 BRACKET, hose, outer 1

26 15D588 BRACKET, hose, inner 1

27 287314 KIT, RotoFlex HD Pump 1

28▲ 189286 LABEL, warning 1

29 118885 HOSE, coupled (includes grommet) 1

30 287254 FRAME, texture, blue 1

32 15D633 WIRE, jumper 1

35 116478 WHEEL, pneumatic 2

49B▲ 15D939 LABEL, warning, English, French,

Spanish

287336 KIT, label, warning, all languages

except those included in 15D939

49C▲ 15D940 LABEL, identification

Item

No. Part No. Description Qty

51 15D634 WIRE, jumper 1

54 116666 TUBE, air 1

1

55 287304 HOSE SET, twin line, 1 in. x 25-ft 1

58 116720 COUPLER, air, quick disconnect 1

59 104641 FITTING, bulkhead 1

60 116658 FITTING, tube, male, 1/4 NPT 1

66 116171 BUSHING, strain relief 1

70 116411 SPRING, compression 2

71 116477 WASHER, flat, nylon 2

72 116342 CAP, end 2

74 115498 SCREW, mach, slot, hex, wash hd 1

1

77 102040 NUT, lock, hex 2

81▲ 198492 LABEL, warning 2

82 118887 HOSE, air (includes 1/4 in. tubing

and one-way valve)

83▲ 15D089 LABEL, warning, hot surface 1

89 801012 GROMMET 1

1

90▲ 15D951 LABEL, identification 1

91▲ 15D953 LABEL, identification 1

92▲ 15D952 LABEL, identification 1

1

93 118872 GASKET 4

150 CORD, power

150a 15D630 Americas/Canada, 120V, 60 Hz 1

150b 15E056 Europe/Asia, 230V, 50 Hz

(hardwired, rubber cord)

150c 15E061 United Kingdom, 110V, 60, Hz 1

151 15D902 CORD, power, Europe/Austra-

lia/China, 230V, 50 Hz (requires

cordset adapter, 152, following)

152 ADAPTER, cordset, (for 15D902),

152a 242001 Europe 1

152c 242002 Italy 1

152d 242003 Denmark 1

152d 242004 Switzerland 1

152e 242005 Australia/China 1

153 195551 RETAINER, (for 15D902) 1

154 15F966 BAFFLE, hopper 1

1

1

1

310645K 33

Page 34

Technical Data

Technical Data

Maximum working fluid pressure 100 psi (6.9 bar)

Maximum working air pressure 45 psi (3.1 bar)

Material pressure operating range 0-100 psi (0 to 6.9 bar)

Compressor

Ty pe Oilless

Air delivery 6.5 CFM @ 40 psi (184.1 lpm @ 2.8 bar)

Motor

120V, 60 Hz 15A

230V, 50 Hz 10A

Hopper capacity 15 US gallons (57 liters)

Maximum delivery with texture material 2.0 gpm (7.57 lpm)

Dimensions

Length 27 in. (685.8 mm) with handles

Width 26 in. (660.4 mm)

Height 40 in. (1016 mm)

Weight

With hoses and gun 147 lb (66.68 kg)

Without hoses and gun 131 lb (59.47 kg)

Wetted parts PVC, Buna-N, anodized aluminum, powder coat

aluminum, brass, polyethylene, SST, UHMW

Sound data

Sound pressure level* 85.8 db(A)

Sound power level# 100.1 db(A)

Generator (minimum size requirement) 7500W (7.5 kW)

Maximum external working air pressure (must use

External Air Hookup Kit 287328 ONLY)

120 psi (8.3 bar)

*Measured while spraying at 1 m.

#Measured per ISO-3744

34 310645K

Page 35

Warranty

Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

POUR LES CLIENTS DE GRACO PARLANT FRANCAIS

Les parties reconnaissent avoir convenu que la rédaction du présent document ainsi que de tous les documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procédures concernées, sera en anglais.

PARA LOS CLIENTES DE GRACO QUE HABLAN ESPAÑOL

Las partes reconocen haber convenido que el presente documento, así como todos los documentos, notificaciones y procedimientos judiciales

emprendidos, presentados o establecidos que tengan que ver con estas garantías directa o indirectamente, estarán redactados en inglés.

PER I CLIENTI GRACO ITALIANI

Le controparti riconoscono di aver richiesto che il presente documento, e tutti gli altri documenti, avvisi e informazioni di natura legale sottoscritti,

conferiti o istituiti direttamente o indirettamente, siano redatti in lingua inglese.

PARA CLIENTES PORTUGUESES DA GRACO

As partes confirmam que solicitaram que o presente documento, assim como todos os demais documentos, notas e processos legais inseridos,

atribuídos ou instituídos de acordo com o mesmo ou relacionados directa ou indirectamente com este documento, fossem redigidos em inglês.

VOOR GRACO-KLANTEN IN NEDERLAND

De partijen zijn zich ervan bewust dat zij hebben geëist dat het onderhavige document, evenals alle documenten, berichtgevingen en wettelijke

procedures die worden aangegaan, overhandigd of in gang gezet hetzij als gevolg van hetzij rechtstreeks hetzij indirect in relatie tot het

onderhavige worden opgesteld in de Engelse taal.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty Program”.

310645K 35

Page 36

Warranty

TO PLACE AN ORDER, contact your Graco distributor, or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

MM 310645

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

3/2004 Rev. 08/2009

36 310645K

Loading...

Loading...