Page 1

Instructions–Parts List

Therm–O–FlowR

Automatic Dispense Valves

Air–operated dispense valves. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

310538M

EN

Model 918483 Shown

Page 2

Table of Contents

List of Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 48. . . . . . . . . . . . . . . . . . . . . .

Graco Information 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

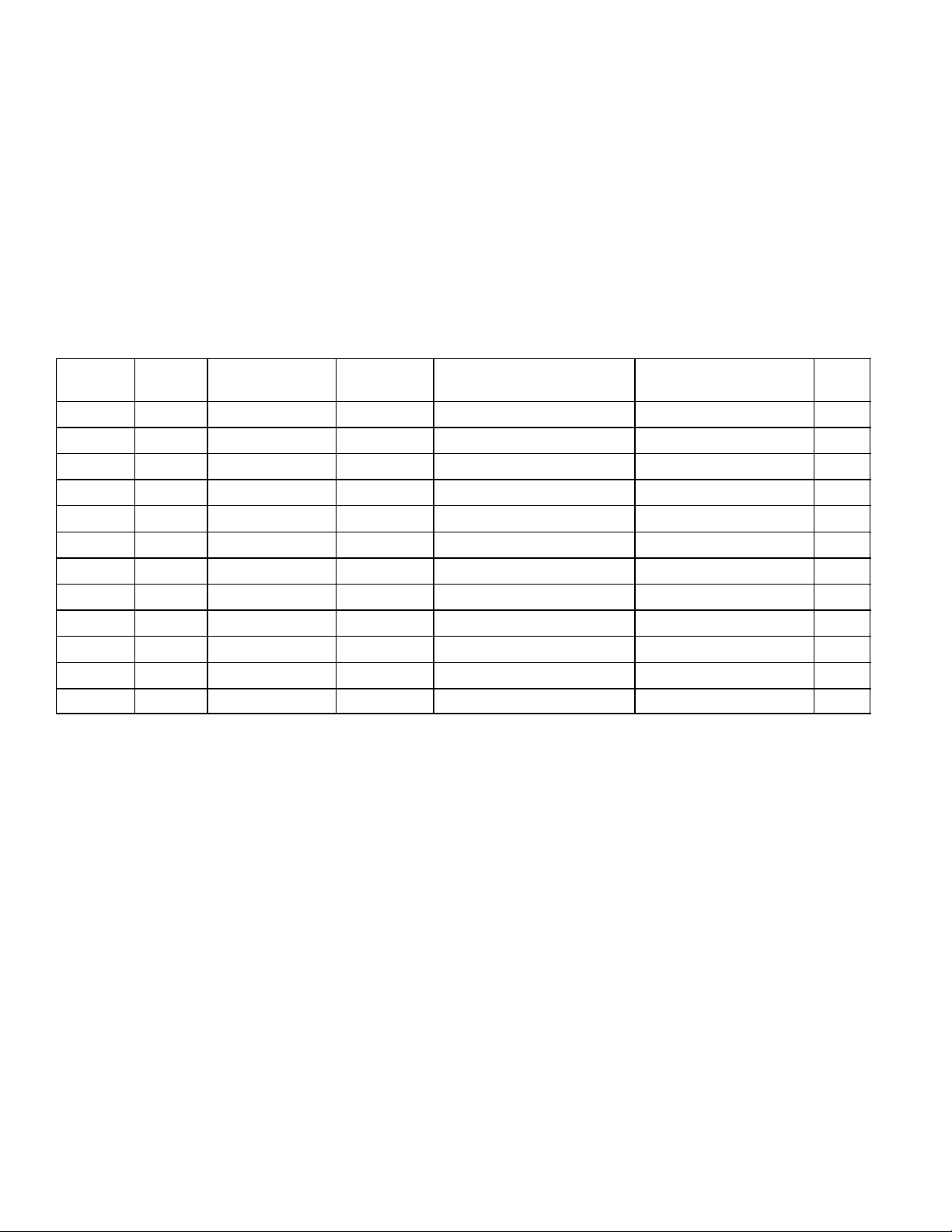

List of Models

Valve

Type

TOF 194485 Snuff Back 120 V / 6 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 20

TOF 918483 Snuff Back 120 V / 6 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 22

TOF 918639 Snuff Back 120 V / 6 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 26

TOF+ 243694 Base Seal 240 V / 8 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 28

TOF 200 297266 Snuff Back Swirl 240 V / 8 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 30

TOF+ 243695 Base Seal H.F. 240 V / 8 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 31

TOF+ 243696 Snuff Back 240 V / 8 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 33

TOF C27340 Base Seal Ambient 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 35

TOF C34068 Base Seal 120 V / 6 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 37

TOF C34079 Base Seal 120 V / 6 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 39

TOF C50592 Base Seal 120 V / 6 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 41

Part

No. Type

918512 Snuff Back Ambient 241 bar, 24 MPa (3500 psi) 10 bar, 1 MPa (150 psi) 24

Voltage /

No. of Pins

Maximum Fluid Working

Pressure

Maximum Air Input

Pressure

Parts

Page

2 310538

Page 3

Warnings

The following Warnings are for the safe setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure–specific risks.

Refer back to these Warnings. Additional product–specific warnings may be found throughout the body of this

manual where applicable.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and

INSTRUCTIONS

result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, warnings, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are uncertain, call your Graco distribu-

tor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check the equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum air working pressure of 1 MPa (10 bar, 150 psi) to the applicator.

D Do not exceed the maximum fluid working pressure of 24 MPa (241 bar, 3500 psi) to the

applicator or manifold.

D Never exceed the recommended working pressure or the maximum air inlet pressure stated on

your pump or in the Technical Data on page 47.

D Be sure that all spray/dispensing equipment and accessories are rated to withstand the maxi-

mum working pressure of the pump. Do not exceed the maximum working pressure of any

component or accessory used in the system.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces.

D Do not expose Graco standard hoses to temperatures above 180_F (82_C) or below –40_F

(–40_C). Do not expose Graco electrically heated hoses to temperatures above 400° F

(222° C) or below –40_F (–40_C).

D Do not expose Graco standard hoses to temperatures above 180_F (82_C) or below –40_F

(–40_C).

D Do not use the hoses to pull the equipment.

D Use only fluids and solvents that are compatible with the equipment wetted parts. See the

Technical Data sections of all the equipment manuals. Read the fluid manufacturer’s warnings.

D Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid

and solvent manufacturers.

D Wear hearing protection when operating this equipment.

D Comply with all applicable local, state and national fire, electrical and other safety regulations.

310538 3

Page 4

WARNING

HOT SURFACE AND FLUID HAZARD

Heated fluid can cause severe burns and can cause equipment surfaces to become very hot.

D Wear protective gloves and clothing when operating this equipment in a heated system.

D Do not touch the metal heat sink when the surface is hot.

D Allow the equipment to cool thoroughly before servicing.

Some heated systems are designed to dispense Polyurethane (PUR) heated materials. PUR

systems are supplied with ventilation hoods, and require proper ventilation and specially designed

system components.

SKIN INJECTION HAZARD

Spray from the applicator, hose leaks, or ruptured components can inject fluid into your body and

cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on

the skin can also cause serious injury.

D Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate

surgical treatment.

D Do not point the applicator at anyone or at any part of the body.

D Do not put hand or fingers over the front of the applicator.

D Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

D Follow the Pressure Relief Procedure on page 11 whenever you are instructed to: relieve

pressure; stop dispensing; clean, check, or service the equipment; or install or clean a tip or

nozzle.

D Tighten all the fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immedi-

ately. Permanently coupled hoses cannot be repaired; replace the entire hose.

D ALWAYS wear eye protection and protective clothing when installing, operating, or servicing this

dispensing equipment.

D Do not remove or modify any part of the applicator; this can cause a malfunction and result in

serious bodily injury.

D Use extreme caution when cleaning or changing tips. If the tip clogs while applying material,

ALWAYS follow the Pressure Relief Procedure on page 11, then remove the tip to clean it.

D NEVER wipe off build-up around the tip or air cap until pressure is fully relieved.

4 310538

Page 5

WARNING

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition

and result in fire or explosion and serious injury.

D Ground the equipment and the object being sprayed. The Automatic Dispense Valve is

grounded through proper connection of pin E inside the electrical control panel to truth earth

ground inside the electrical control panel. See Grounding on page 9.

D Ground the equipment and the object being sprayed, and all other electrically conductive

objects in the dispense area. Proper grounding dissipates static electricity generated in the

equipment. See Grounding on page 9.

D Do not use this equipment with flammable liquids.

D Keep the dispense area free of debris, including solvent, rags, and gasoline.

D If there is any static sparking or you feel an electric shock while using the equipment, stop dis-

pensing immediately. Do not use the equipment until you have identified and corrected the

problem.

D Make sure all electrical work is performed by a qualified electrician only.

D Have any checks, installation, or service to electrical equipment performed by a qualified electri-

cian only.

D Make sure all electrical equipment is installed and operated in compliance with applicable

codes.

D Make sure power is disconnected when servicing and repairing equipment.

D Before operating the equipment, extinguish all open flames or pilot lights in the dispense area.

D Do not smoke in the dispensing area.

D Keep liquids away from the electrical components

D Disconnect electrical power at the main switch before servicing the equipment.

D Never exceed maximum wattage of the supply unit.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled.

D Provide fresh air ventilation to avoid the buildup of vapors from the fluid being dispensed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all

local, state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid

and solvent manufacturer.

D Avoid exposure to heated material fumes.

310538 5

Page 6

Installation

Install the automatic applicator as follows:

D mount the automatic dispense valve

D attach dispense tip, nozzle, or swirl

D connect the air lines

D connect material hose

D connect the electrical cable

D make sure the automatic dispense valve is

grounded

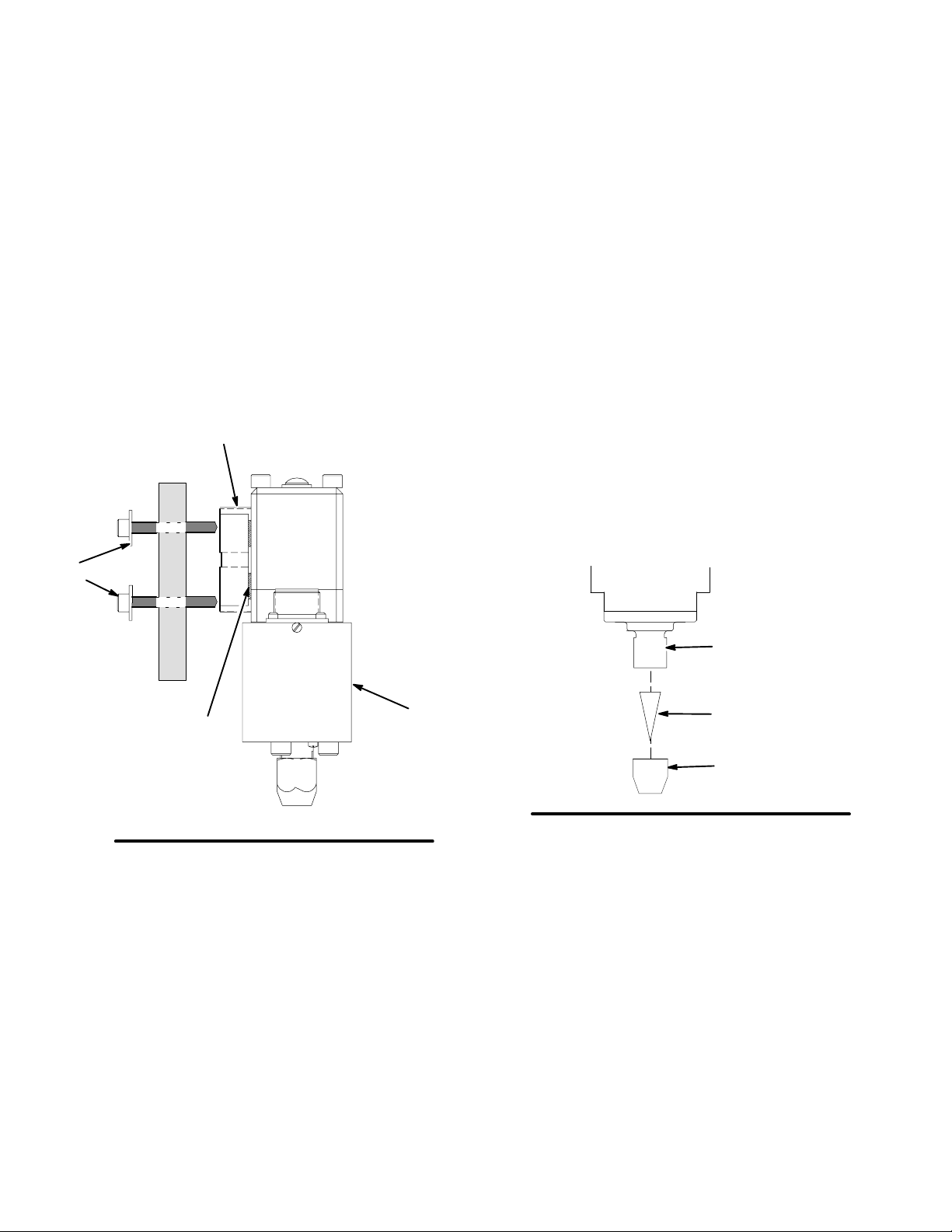

Mount the Automatic Dispense Valve

Mount the automatic dispense valve to the mounting

bracket on a stationary support or robotic arm (Fig. 1),

using two socket head screws (300) and two flat

washers (50). Be sure to position the insulation

block (280) and insulation tape (290) between the

dispense valve and the mounting bracket.

280

Attach Dispense Tip, Nozzle, or Swirl

Attach a dispense tip and a nozzle adapter, or a nozzle

adapter alone, to the automatic dispense valve.

Dispense Tip and Nozzle Adapter Attachment

Attach dispense tip (B) to the automatic dispense

valve.

1. Select a nozzle adapter (C) and a dispensing

tip (B).

2. Install the tip and then use the nozzle adapter (C)

to secure the tip to the seat adapter (D).

50

300

Fig. 1

290

D

A

Fig. 2

B

C

6 310538

Page 7

Installation

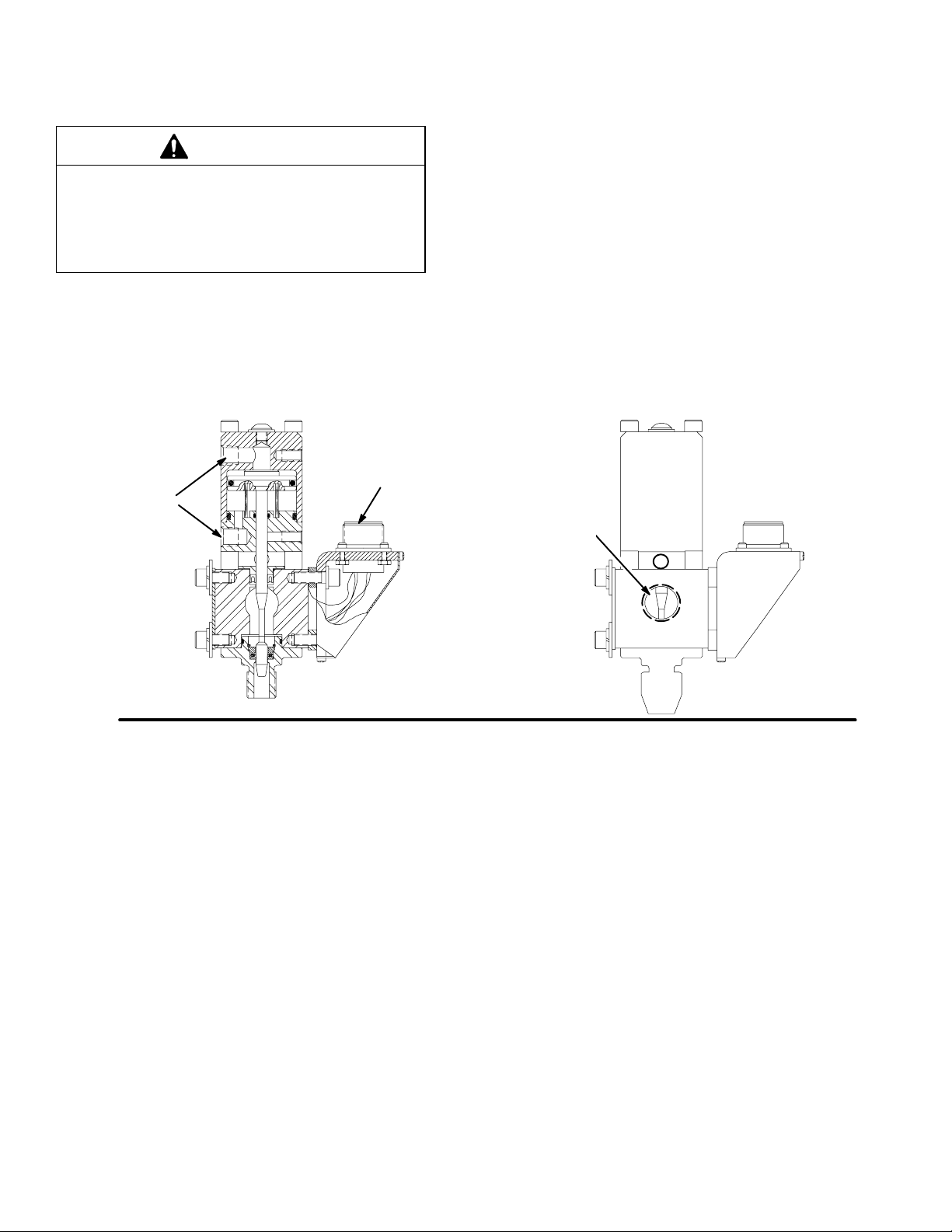

Nozzle Attachment

Attach a nozzle (C) to the automatic dispense valve.

1. Select a nozzle.

2. Install nozzle adapter (C) on the seat adapter (D).

3. Install nozzle in nozzle adapter (E).

D

C

E

Fig. 3

Swirl Nozzle Attachment

1. Install swirl adapter (C) on seat adapter (D).

2. Install swirl applicator head (E).

3. Install swirl nozzle (F).

D

C

E

F

Fig. 4

310538 7

Page 8

Installation

Connect Air Lines to Dispense Valve

CAUTION

Only use air fittings that are rated at a temperature

equal to or higher than the operating temperature of

your fluid dispensing system. Lower rated air fittings could melt and cause damage to the automatic dispense valve.

These valves are air to open and air to close with a

spring to bias them closed. Use a 4–way exhausting

solenoid to operate these valves.

Making sure to connect the appropriate air lines to the

appropriate ports (see Fig. 5), securely connect air

lines to dispense valve air ports (G).

1/8” npt

open

360

G

close

1/8” npt

Connect Material Hose to Dispense Valve

Securely connect the material hose to the dispense

valve material inlet port (A). See Fig. 5.

Connecting Electrical Cable to Dispense

Valve

Connect electrical cable plug from your Therm–O–

Flow or Therm–O–Flow Plus hose or control.

A

1/2” npt

Fig. 5

Snuff–Back Valve Shown

8 310538

Page 9

Installation

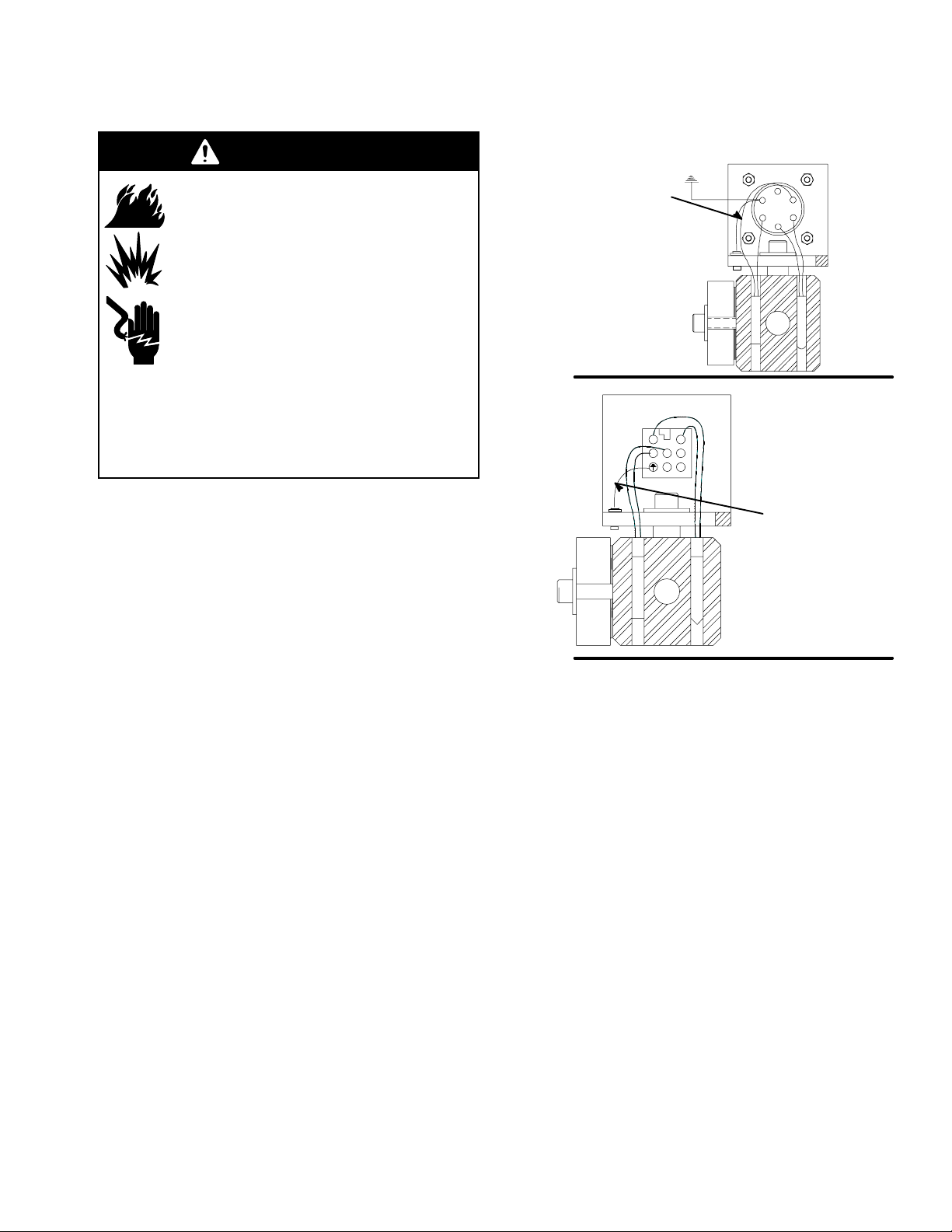

Grounding

WARNING

FIRE, EXPLOSION, AND ELECTRIC

SHOCK HAZARD

To reduce the risk of fire, explosion, or

electric shock:

D The power source conduit is not an ad-

equate ground for the system. The unit

must be grounded to either the building

ground or a true earth ground.

D A qualified electrician must complete

all grounding and wiring connections

and check the resistance.

D Refer to your local code for the requirements for

a “true earth ground” in your area.

D Also read and follow the warnings on page 5.

Ground the automatic dispense valve:

1. Connect the connector from a heated hose to the

receptacle on the dispense valve.

Ground lead

coming from pin

E is fastened to

the bracket.

D

C

E

B

F

A

Fig. 6

3

5412

67

Ground lead

coming from contact 8 to true

earth ground.

Fig. 7

TI0305

2. Connect the electrical cable to the electrical control

panel.

3. Verify that socket contact E on six pin models (see

Fig. 5) or contact eight on eight pin models (see

Fig. 7) , inside control panel receptacle, is connected to true earth ground.

310538 9

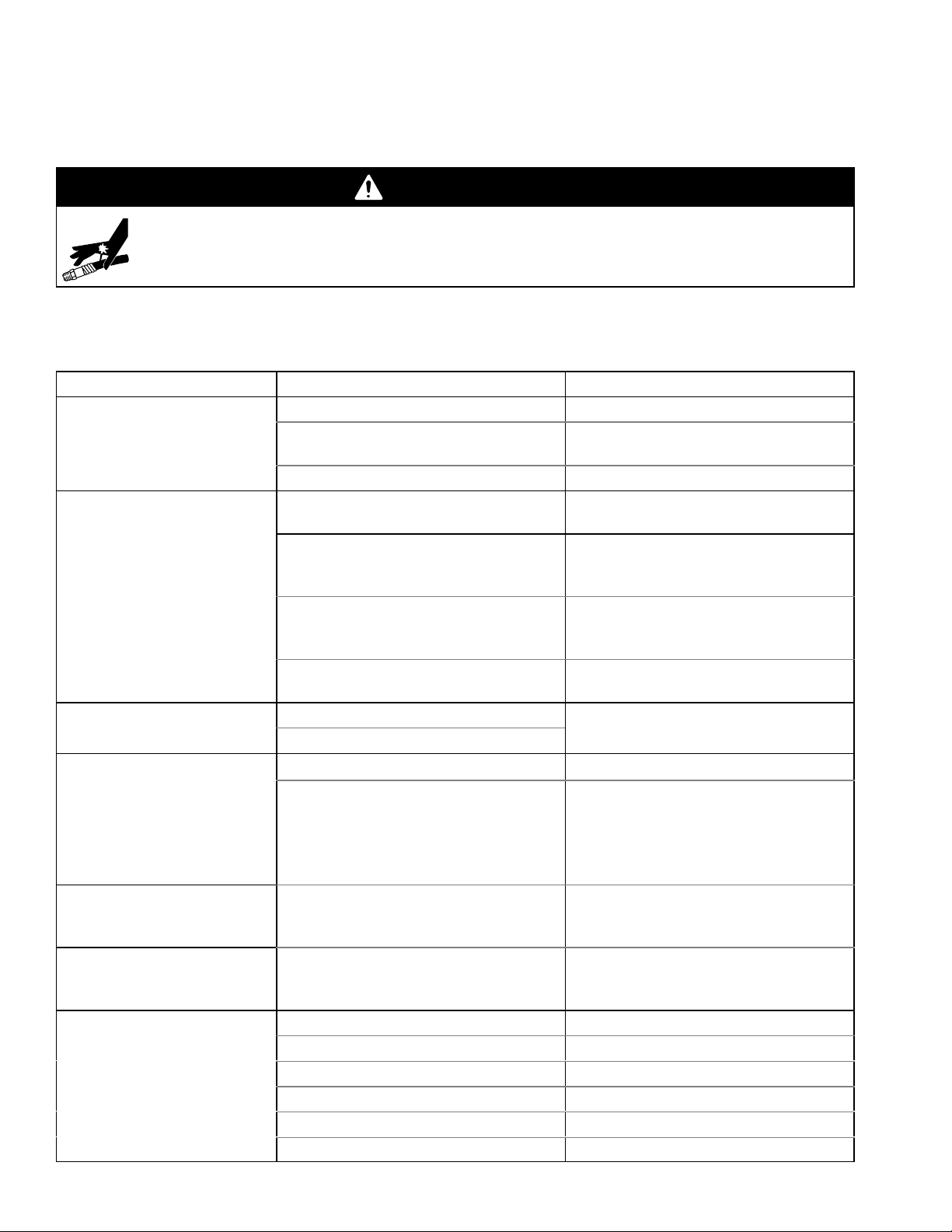

Page 10

Some solutions require disassembling the automatic dispense valve. Always relieve system pressure before per-

retaining ring (170)

forming these procedures.

See PARTS section for the parts that need to be serviced.

Problem Cause(s) Solution(s)

Air leaks from automatic dispense valve

Material leaks from front of

automatic dispense valve

Material leaks from automatic

dispense valve body

Automatic dispense valve

does not shut off

Automatic dispense valve

does not shut off

Automatic dispense valve

does not shut off

Automatic dispense valve

does not heat material

10 310538

Troubleshooting

WARNING

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow

the Pressure Relief Procedure (page 11).

Loose air connections Check air connections.

Worn o-rings Replace o-rings (90) and (100) in cylin-

der base.

Worn ring Replace ring (110) in cylinder base.

Seal, spacer or retaining ring is worn Replace rod seal (150), spacer (160),

and retaining ring (170).

Obstruction inside dispense valve Remove seat adapter (10). Check and

replace if necessary, rod seal (150),

spacer (160), and retaining ring (170).

Worn needle Check and replace needle (140), if

necessary.If replacing needle, you must

disassemble dispense valve.

Worn seat (Base seal models) Check and replace seat (10) if neces-

sary.

Seal not installed correctly Check seal (70) and replace if necesSeal is worn

Loose air connections Check air connections.

Worn needle-seal interface Check and replace, if necessary, needle

Worn spring-piston interface Disassemble dispense valve. Check

Spring broken or not installed correctly Disassemble dispense valve. Check

Loose heater wires Check and reconnect wire connections.

Loose sensor wires Check and reconnect wire connections.

Heater unit failed Replace heater. See page 17.

Sensor failed Replace sensor. See page 17.

Temperature controller failed Replace temperature controller.

No power to heating circuitry Apply power to heating circuitry.

sary.

(140), rod seal (150), spacer (160), and

.

If replacing needle, you must disas-

semble dispense valve

and replace, if necessary, needle (140),

and spring (370).

and replace, if necessary, needle (140),

and spring (370).

Page 11

Service

Pressure Relief Procedure

WARNING

HOT SURFACE AND FLUID HAZARD

The material and equipment will be

hot! To reduce risk of injury, wear eye

protection, gloves and protective clothing

when installing, operating, or servicing

this dispensing system.

SKIN INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected

through the skin and cause serious

injury. To reduce the risk of an injury

from injection, splashing fluid, or moving

parts, follow the Pressure Relief

Procedure whenever you:

D are instructed to relieve the pressure

D stop spraying/dispensing

D install or clean the nozzle

D check or service any of the system

equipment

This procedure describes how to relieve pressure from

the automatic dispense valve. See your supply unit or

system documentation for instructions on relieving

pressure for the entire dispensing system. Use this

procedure whenever you shut off the dispense valve

and before checking or adjusting any part of the

system, to reduce the risk of serious injury.

1. Shut off the material supply.

2. Shut off electrical power to the automatic dispense

valve.

3. Close all self bleeding air supply valves for supply

unit.

4. Have a container ready to catch the drainage, then

bleed off material pressure by actuating the dispense valve.

5. Shut off air supply to valve.

NOTE: If you suspect that the nozzle or hose is

completely clogged, or that pressure has not

been fully relieved after following the steps

above, very slowly loosen the tip guard,

retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Then

clear the tip/nozzle or hose.

PRESSURIZED FLUID HAZARD

High pressures can cause serious personal injury. Be sure to open the dis-

pense valve during system heat-up to

alleviate pressure which might occur in

the system due to material expansion.

310538 11

Page 12

Service

Prepare to Service Automatic

Dispense Valve

If the unit is hot, determine whether or not you can

service the unit after it has cooled down. Some materials, like polyurethanes, may cure permanently when

cooled and exposed to air, preventing you from disassembling the dispense valve. If you are working with

such a material, service the unit while the material is at

a temperature where the material is soft enough to

work with. If the material can be reheated at a later

time, you can service the unit after it has cooled,

reheating the material as necessary.

Perform this procedure before servicing the automatic

dispense valve.

1. Relieve the system pressure.

WARNING

To reduce the risk of serious injury, whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure (page 11).

2. Make sure material flow has been shut off.

3. Make sure system air has been shut off.

4. Remove power from the automatic dispense valve.

WARNING

HOT SURFACE AND FLUID HAZARD

The material and equipment will be

hot! To reduce risk of injury, wear eye

protection, gloves and protective clothing

when servicing this dispensing system

component.

5. If the material in the dispense valve can be reheated, wait for the dispense valve to cool thoroughly before servicing it.

If the material in the dispense valve cures permanently when cooled and/or exposed to air, service

the unit while the material is at a temperature

where the material is soft enough to work with.

12 310538

Page 13

Service

Service the Automatic Dispense Valve

Some dispense valve seals and o-rings can be replaced while the dispense valve is still mounted.

However, to replace the needle, you must remove the

automatic dispense valve from the mounting bracket

and disassemble it.

Prior to installation, lubricate all seals and o-rings with

115982 Graco thermal lubricant (3 oz. cartridge) or an

equivalent lubricant. Check with the material supplier

for a compatible lubricant.

50

300

A

Disconnect Automatic Dispense Valve from

Mounting Bracket

Remove the automatic dispense valve from its mounting bracket.

1. Perform the procedures in Prepare to Service

Automatic Dispense Valve on page 12.

WARNING

HOT SURFACE AND FLUID HAZARD

The material and equipment may be

hot! To reduce risk of injury, wear eye

protection, gloves and protective clothing

when servicing this dispensing system

component.

2. Disconnect the cable plug from receptacle on

dispense valve (H). See Fig. 8 on page 13.

3. Disconnect air lines from dispense valve air

ports (G).

Fig. 8

4. Disconnect material hose from material inlet

port (A).

5. Separate the dispense valve body from the temperature conditioning manifold if used:

Reconnect Automatic Dispense Valve to Mounting

G

Snuff–Back Valve Shown

H

Bracket

Reconnect the automatic dispense valve to its mounting bracket. See Fig. 8.

1. Reconnect air lines to dispense valve air ports (G).

2. Reconnect the electrical cable plug to the receptacle (H).

3. Reconnect the material hose to the dispense valve

material inlet port (A).

310538 13

Page 14

Service

Disassemble Automatic Dispense Valve

310

370

240

70

A

140

30

Fig. 9

To disassemble the automatic dispense valve:

1. Relieve automatic dispense valve pressure.

Snuff–Back Valve Shown

200

210

190

260

250

90

390

230

3. Remove the cable plug from the automatic dispense valve.

a. Remove the two screws (230) from the con-

nector cover. Then remove the connector

cover.

b. Remove the two socket head screws [Fig. 9,

Item (200)], two washers (210).The heater

cartridge (270) and

sensor (320) will come out of the dispense

valve body (Fig. 15).

4. Remove the four socket head screws (310) and

pull cylinder cap (260) and cylinder base (240)

from the dispense valve body (190). The needle

and piston remain with the cap and base.

5. Remove cap from base.

6. Remove needle from either the cap or the base

(depending on which piece it went with.) When the

needle is separated from the base, the closure

spring (370) falls out.

7. Using an o-ring pick, remove dispense valve body

seal (70).

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure (page 11).

2. Make sure you have removed the dispense valve

from its mounting.

14 310538

Page 15

Service

8. Disassemble adapter assembly (Fig. 10):

a. Unscrew nozzle adapter (C).

b. Remove three socket head screws (30 in

Fig. 9).

c. Remove seat adapter (10). Contains seat on

base seal valves.

d. Remove retaining ring (170) from adapter seat

(Fig. 10). Not on base seal guns.

e. Remove seal (150) and spacer (160) from

adapter seat (Fig. 10). Not on base seal guns.

f. Remove o-ring (20) from adapter seat.

70

20

160

150

C

170

Reassemble Automatic Dispense Valve

Prior to installation, lubricate all seals and o-rings with

115982 Graco high temperature grease (3 oz. cartridge), or an equivalent lubricant. Check with the

material supplier for a compatible lubricant.

To reassemble the automatic dispense valve:

1. Make sure all parts are free of solid material

residue.

2. Reassemble adapter assembly (Fig. 10):

a. Lubricate and replace o-ring (20).

b. Lubricate and replace seal (150) and spacer

(160). Make sure the seal energizer faces

toward the material pressure.

c. Replace retaining ring (170).

d. Replace seat retainer (10).

e. Insert and tighten three socket head screws

(30 in Fig. 9).

f. Screw on nozzle adapter (C).

Fig. 10

10

Snuff–Back Valve Shown

3. Lubricate then replace dispense valve body

seal (70). Make sure the seal energizer faces

toward the material pressure.

310538 15

Page 16

4. Reassemble cap and base (Fig. 11):

n

a. Lubricate o-ring (100) and ring (110).

b. Insert o-ring (100) into needle piston (140)

groove.

Service

c. Slide ring (110) on top of o-ring (100).

d. Lubricate, then replace o-rings (90) and (250).

Insert spring on base seal models (Fig. 12).

e. Insert needle assembly into cylinder cap (260).

f. Place spring (370) over shaft of needle/piston.

Seat spring in groove on piston face on snuff–

back models (Fig. 11).

g. Slide base (240), over the needle, into the

cylinder cap (260). Seat spring (370) in

groove on base.

310

260

250

90

Fig. 12

5. Reconnect the cable receptacle to the automatic

dispense valve. See Fig. 13.

a. Re-insert heater cartridge and sensor into their

appropriate holes.

b. Ensure the ground wire (380) is connected to

the bracket (330).

c. Connect the receptacle to the dispense valve

body. Then secure it with the two socket head

screws (200) and washers (210).

d. Reattach the receptacle cover . Then secure it

with the two screws (230).

Base Seal Valves

100

370

90

Fig. 11

16 310538

110

250140

240

Snuff–Back Valve Show

Fig. 13

390

200

210

230

Page 17

Service

n

Replace Heater Unit or Sensor

You can replace the automatic dispense valve heater

unit or sensor without removing the automatic dispense valve from its mounting bracket. You only have

to disconnect the cable connector from the automatic

dispense valve.

This procedure requires:

D soldering iron

D solder

D shrink wrap

D wire cutters

D heat sink compound, Graco part number C07664 or

equivalent. Check with the material supplier for a

compatible compound.

1. Perform the procedures in Preparing to Service

Automatic Dispense Valve on page 12.

2. Remove the cable receptacle from the automatic

dispense valve.

3. Remove old heater cartridge or sensor.

a. Locate the leads to the part you are replacing.

b. Remove the shrink wrap from the leads.

c. Unsolder the leads from the connector. Cut the

leads on 8 pin models, leaving enough to strip

and solder the leads.

4. Install new heater unit or sensor:

390

D

C

E

B

270

F

A

320

RTD Sensor

Heater

6 Pin 120 Volt

Shown

Fig. 15

a. Remove the two screws from the connector

cover [Fig. 9, Item (230)] and remove the

receptacle cover.

b. Remove the two socket head screws [Fig. 14,

Item (200)], two washers (210). The heater

cartridge (270) and sensor (320) will come out

of the dispense valve body.

200

210

Fig. 14

2

270

320

Fig. 16

8 Pin 240 Volt Show

a. Install the shrink wrap over the leads.

310538 17

Page 18

Service

b. Solder the leads to the appropriate connector

(Fig. 15) for 6 pin connector. For Therm–O–

Flow 8 pin assemblies, removal and replacement of the heaters and RTD require a pin

extraction tool, new pins, and a pin crimping

tool. These tools meet spec MIL–C–22520

[Ref. Daniels AF8 (crimp tool) or equivalent,

available at local electrical supply warehouse.

c. Coat heater or sensor with heat sink com-

pound.

d. Gently slide new heater or sensor into ap-

propriate hole.

e. Either shrink the shrink wrap, or use electrical

tape to electrically insulate the connection

between the leads and connector pins.

5. Reconnect the dispense valve to the receptacle

(Figs. 14):

a. Reattach the receptacle base to the dispense

valve body and secure it with the two socket

head screws [Fig. 14, Items (200) and washer

(210)].

b. Reattach the receptacle cover to the Amphe-

nol connector base and secure the cover with

the screws.

Inspection Frequency

Automatic Dispense Valve

Inspect automatic dispense valve at least once every

two weeks for leakage or other visible damage.

Check specifically for:

D material leaks

D air leaks

Hoses/Tubes

Inspect hoses/tubes at least once every two weeks for

leakage or other visible damage.

D material hose

D air hoses

Heater

Every two weeks, check heater for proper resistance.

Resistance should be approximately 96 ohms for the

120 volt valves or 288 ohms (+30/–40) for the 240 volt

valves. Replace heater if necessary.

Also inspect heater when performing regular maintenance procedures.

Sensor

Every two weeks, check sensor resistance. Resistance should be 108 ohms at 21° C (70° F). Replace

sensor if necessary.

Also inspect sensor when performing regular maintenance procedures.

18 310538

Page 19

Parts

Model 194485, Warm (2755F/1355C max) Automatic Dispense Valve with Snuff Back

120 130

260

370

250

100 110

50

40

30

90

80

70

60

20

10

310

300

50

Cyl. air ports

1/8 npt

SECTION A–A

A

Ref. Nozzle

Adapter

240

170

160

150

140

360

230

220

200 210

190

180

290

280

30

360

350

B

B

Material Inlet

Port 1/2 npt

5/8 – 18 external thread

A

310538 19

Page 20

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model 194485, Warm (2755F/1355C max) Automatic Dispense Valve with Snuff Back

Ref

No.

10

20*

30

Á

40

50

60

70*

80

90*

100*

110*

120

130*

140n

150*

160

170*

180

190

200

Á

210

Part No. Description Qty.

617479

722834

C19800

ÁÁ

100016

111591

C34044

551190

C34030

113944

103649

C32088

617495

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL, Polymite

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

SCREW, button head,

1

1

5

Á

2

4

1

1

4

1

1

1

1

1/4”–20 x 0.31

C20521

918471

C54172

617480

C20406

C34045

194527

112166

ÁÁ

C19197

SEAL, thread

NEEDLE, piston

SEAL, rod, 0.25 x 0.50 x 0.25

SPACER

RING, retaining, for 0.56 I.D.

SPACER

BODY, gun

SCREW, soc. hd. cap,

ББББББББ

1/4”–20 x 0.75

WASHER, flat, 3/16

1

1

1

1

1

2

1

2

Á

2

Ref

Part No. Description Qty.

No.

220

230

ÁÁ

240

250*

260

270n

ÁÁ

280

290

ÁÁ

300

C34040

C19269

ÁÁ

617537

103337

C34028

C31034

ÁÁ

C32099

C33037

ÁÁ

C19810

COVER

SCREW, fill. hd. machine,

ББББББББ

#4–40 x 0.25

BASE, cylinder

O–RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge 120V, 150W1

ББББББББ

BLOCK, mounting

TAPE, fiberglass,

ББББББББ

0.5” wide (229 mm)

SCREW, soc. hd. cap,

1

2

1

1

1

1

9”

2

1/4”–20 x 1

310

ÁÁ

320n

330

340

350

104594

ÁÁ

C32255

C34043

102794

C19270

SCREW, soc. hd. cap,

1/4”–20 x 3.25

ББББББББ

SENSOR, RTD

BRACKET

NUT, hex, #4–40

SCREW, fill. hd. machine,

4

1

1

4

4

#4–40 x 0.38

360

370*

380

390

400

460

510

C07329

617536

065345

101674

C07664

112144

157021

CONNECTOR, 6 pin

SPRING

WIRE, high temp, (127 mm)

TERMINAL, ring

COMPOUND, heat sink

SCREW

WASHER, lock

1

1

5”

1

A/R

1

1

* These parts are included in Repair Kit 194486, which

may be purchased separately.

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

20 310538

460

390

510

Ref.330

340

D

C

380

E

B

F

A

330

390

1

1

270

SECTION B–B

(Enlarged to show detail)

320

Notes

1

Coat with heat sink compound

(400) before installing.

Page 21

Parts

Model 918483, Therm-O-Flow Automatic Dispense Valve with Snuff Back

120 130

260

370

250

100 110

50

40

30

90

80

70

60

20

10

310

300

50

Cyl. air ports

1/8 npt

SECTION A–A

A

240

170

160

150

140

360

230

220

200 210

190

180

290

280

30

360

350

B

B

Material Inlet

Port 1/2 npt

5/8–18m Material Outlet

A

310538 21

Page 22

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model 918483, Therm-O-Flow Automatic Dispense Valve with Snuff Back

Ref

No.

10

20*

30

Á

40

50

60

70*

80

90*

100*

110*

120

130*

140n

150*

160

170*

180

190

200

210

Part No. Description Qty.

617479

722834

C19800

ÁÁ

100016

110755

C34044

617604

C34030

113944

103649

C32088

617495

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

SCREW, button head,

1

1

5

Á

2

4

1

1

4

1

1

1

1

1/4”–20 x 0.31

C20521

918471

617491

SEAL, thread

NEEDLE, piston

SEAL, rod hi temp,

1

1

1

0.25 x 0.50 x 0.25

617480

C20406

C34045

617605

112166

SPACER

RING, retaining, for 0.56 I.D.

SPACER

BODY

SCREW, soc. hd. cap,

1

1

2

1

2

1/4”–20 x 0.75

C19197

WASHER, flat, 3/16

2

Ref

Part No. Description Qty.

No.

220

230

ÁÁ

240

250*

260

270n

ÁÁ

280

290

ÁÁ

300

C34040

C19269

ÁÁ

617603

103337

C34028

C31034

ÁÁ

C32099

C33037

ÁÁ

C19810

COVER

SCREW, fill. hd. machine,

ББББББББ

#4–40 x 0.25

BASE, cylinder

O–RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge 120V, 150W1

ББББББББ

BLOCK, mounting

TAPE, fiberglass,

ББББББББ

0.5” wide (229 mm)

SCREW, soc. hd. cap,

1

2

1

1

1

1

9”

2

1/4”–20 x 1

310

ÁÁ

320n

330

340

350

104594

ÁÁ

C32255

C34043

102794

C19270

SCREW, soc. hd. cap,

1/4”–20 x 3.25

ББББББББ

SENSOR, RTD

BRACKET

NUT, hex, #4–40

SCREW, fill. hd. machine,

4

1

1

4

4

#4–40 x 0.38

360

370*

380

390

400

460

510

C07329

617536

065345

101674

C07664

112144

157021

CONNECTOR, 6 pin

SPRING

WIRE, high temp, (127 mm)

TERMINAL, ring

COMPOUND, heat sink

SCREW

WASHER, lock

1

1

5”

1

A/R

1

1

* These parts are included in Repair Kit 918520, which

may be purchased separately.

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

22 310538

460

390

510

Ref.330

340

D

C

380

E

B

F

A

330

390

1

1

270

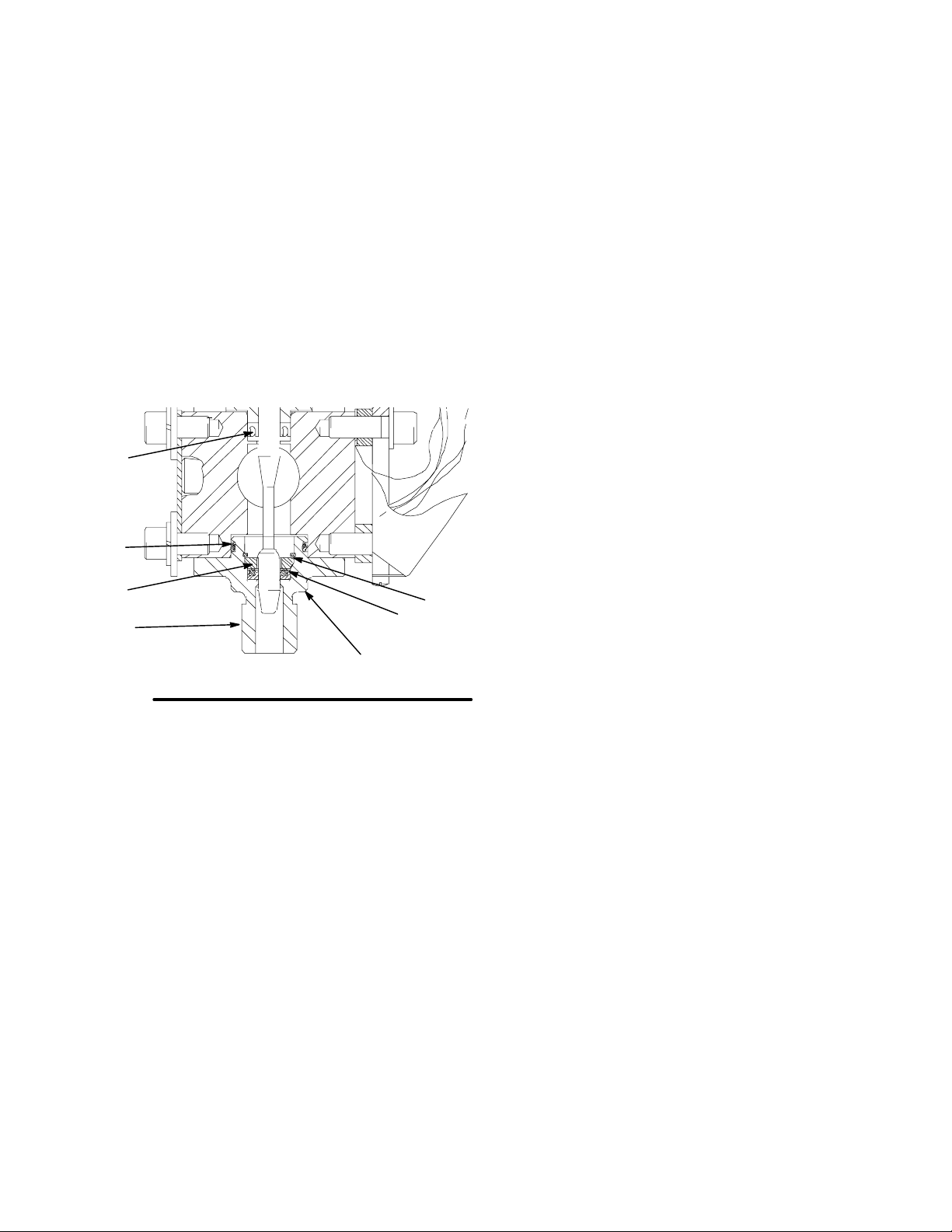

SECTION B–B

(Enlarged to show detail)

320

Notes

1

Coat with heat sink compound

(400) before installing.

Page 23

Parts

Model 918512, Ambient Therm-O-Flow Automatic Dispense Valve with Snuff Back

120 130

260

60

250

100 110

90

80

70

50

40

30

20

10

Cyl. air ports

1/8 npt

240

SECTION A–A

A

230

240

190

170

160

140

150

30

B

B

Material Inlet

Port 1/2 npt

1/8” npt female

material outlet

A

310538 23

Page 24

Parts

Á

Á

Á

Á

Model 918512, Therm-O-Flow Automatic Dispense Valve with Snuff Back

Ref

No.

10

20

30

Á

40

50

60

70

80

90

100

110

120

130

Part No. Description Qty.

617479

722834

C19800

ÁÁ

100016

110755

617536

C34032

C34030

113944

103649

C32088

112925

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

WASHER, lock, 1/4”

WASHER, flat, 1/4”

SPRING

SEAL

SPACER

O–RING, –123 fluoroelastomer

O–RING

O–RING

SCREW, button head, 1/4”–20 x

1

1

5

Á

2

4

1

1

4

1

1

1

1

0.31

C20521

SEAL, thread

1

Ref

Part No. Description Qty.

No.

140

150n

160

170

190

200

210

220

230

240

617491

918471

617480

111209

194527

617537

103337

C34028

C32089

104594

SEAL, outlet

NEEDLE assembly

SPACER

RING, retaining, for 0.56 I.D.

BODY

BASE, cylinder

O–RING, –010 fluoroelastomer

CAP, cylinder

RETAINER

SCREW, cap

1

1

1

1

1

1

1

1

1

4

n Keep these spare parts on hand to reduce down time.

24 310538

Page 25

Parts

Model 918639, Therm-O-Flow Automatic Dispense Valve with Snuff Back

120 130

260

370

250

100 110

50

40

30

90

80

70

60

20

10

310

300

50

Cyl. air ports

1/8 npt

SECTION A–A

A

150

140

240

170

160

360

230

220

200 210

190

180

290

280

30

360

350

B

B

Material Inlet

Port 1/2 npt

#8 37° sae (3/4–16)

material outlet

A

310538 25

Page 26

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model 918639, Therm-O-Flow Automatic Dispense Valve with Snuff Back

Ref

No.

10

20*

30

Á

40

50

60

70*

80

90*

100*

110*

120

130*

140n

150*

160

170*

180

190

200

210

Part No. Description Qty.

617690

722834

C19800

ÁÁ

100016

110755

C34044

617604

C34030

113944

103649

C32088

617495

ADAPTER, nozzle/valve

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

SCREW, button head,

1

1

5

Á

2

4

1

1

4

1

1

1

1

1/4”–20 x 0.31

C20521

918471

617491

SEAL, thread

NEEDLE, piston

SEAL, rod hi temp,

1

1

1

0.25 x 0.50 x 0.25

617480

C20406

C34045

617605

112166

SPACER

RING, retaining, for 0.56 I.D.

SPACER

BODY

SCREW, soc. hd. cap,

1

1

2

1

2

1/4”–20 x 0.75

C19197

WASHER, flat, 3/16

2

Ref

Part No. Description Qty.

No.

220

230

ÁÁ

240

250*

260

270n

ÁÁ

280

290

ÁÁ

300

C34040

C19269

ÁÁ

617603

103337

C34028

C31034

ÁÁ

C32099

C33037

ÁÁ

C19810

COVER

SCREW, fill. hd. machine,

ББББББББ

#4–40 x 0.25

BASE, cylinder

O–RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge 120V, 150W1

ББББББББ

BLOCK, mounting

TAPE, fiberglass,

ББББББББ

0.5” wide (229 mm)

SCREW, soc. hd. cap,

1

2

1

1

1

1

9”

2

1/4”–20 x 1

310

ÁÁ

320n

330

340

350

104594

ÁÁ

C32255

C34043

102794

C19270

SCREW, soc. hd. cap,

1/4”–20 x 3.25

ББББББББ

SENSOR, RTD

BRACKET

NUT, hex, #4–40

SCREW, fill. hd. machine,

4

1

1

4

4

#4–40 x 0.38

360

370*

380

390

400

460

510

C07329

617536

065345

101674

C07664

112144

157021

CONNECTOR, 6 pin

SPRING

WIRE, high temp, (127 mm)

TERMINAL, ring

COMPOUND, heat sink

SCREW

WASHER, lock

1

1

5”

1

A/R

1

1

* These parts are included in Repair Kit 918520, which

may be purchased separately.

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

26 310538

460

390

510

Ref.330

340

D

C

E

B

F

380

1

270

A

SECTION B–B

(Enlarged to show detail)

330

320

1

Notes

1

Coat with heat sink compound

(400) before installing.

Page 27

Parts

Model 243694, Therm-O-Flow Automatic Dispense Valve

120, 130

100,110

50, 40, 30

80

90

70

60

Cyl. air ports

1/8 npt

140

125

260

370

TI0304

250

20

360

430

240

230

220

200 210

190

180

140

310

300

50

280

10

290

30

Section A–A

410

A

420

410

TI11204a

360

350

B

B

Material Inlet

Port 1/2 npt

1/8” npt female

material outlet

A

310538 27

Page 28

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model 243694, Therm-O-Flow Automatic Dispense Valve

Ref

No.

10

20*

30

Á

40

50

60

70*

80

90*

100*

110*

120

125

130*

140n

180

190

200

Á

210

220

230

Á

Part No. Description Qty

.

C32083

103610

C19800

ÁÁ

100016

110755

C34044

C34032

C34030

113944

103649

C32088

112248

C19359

C20521

C32082

C34045

C32097

112166

ÁÁ

C19197

C34040

C19269

ÁÁ

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL, graphite/PTFE

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

NUT, hex

SCREW, set

SEAL, thread

NEEDLE, assembly

SPACER

BODY

SCREW, soc. hd. cap,

1/4”–20 x 0.75

ББББББББ

WASHER, flat, 3/16

COVER

SCREW, fill. hd. machine,

#4–40 x 0.25

ББББББББ

1

1

5

Á

2

4

1

1

4

1

1

1

1

1

1

1

2

1

2

Á

2

1

2

Á

Ref

No.

240

250*

260

270n

Part No. Description Qty

.

C32085

103337

C34028

116011

BASE, cylinder

O-RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge

1

1

1

1

230 V, 200 W

280

290

ÁÁ

300

C32099

C33037

ÁÁ

C19810

BLOCK, mounting

TAPE, fiberglass,

0.5” wide (229 mm)

ББББББББ

SCREW, soc. hd. cap,

1

9”

2

1/4”–20 x 1

310

104594

SCREW, soc. hd. cap,

4

1/4”–20 x 3.25

320n

330

350

C32255

C34043

C19949

SENSOR, RTD

BRACKET

SCREW, panhd. machine,

1

1

2

#4–40 x 0.5

360

370

380

390

410

420

430

440

460

510

520

115861

C34041

065345

101674

C32090

C32089

115860

115862

112144

157021

116640

HOUSING, 8 pin

SPRING

WIRE, high temp, (127 mm)

TERMINAL, ring

SEAT

NUT, retainer

INSERT, male

CONNECTOR, male, crimp

SCREW, PH 8–32 X 1/4

WASHER, lock

CONNECTOR

1

1

5”

1

1

1

1

1

1

1

4

* These parts are included in Repair Kit C27342, which

may be purchased separately.

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

БББББББББББББББ

Ref. 330

28 310538

510

390

460

1

270, 520

1

320, 520

2

Notes

1

Coat with heat sink compound

(400) before installing.

SECTION B–B

380, 440

(Enlarged to show detail)

Page 29

Parts

Model 297266, Automatic Hot Melt Swirl Dispense Valve

A

310

300, 50

290

360

350

30

280

B

B

Material Inlet

Port 1/2 npt

360

430

A

230

220

380

200, 210

370

125

120, 130

260

250

90

240

80

50, 40, 30

70

60

410

140

TI11205a

190

180

10

410

Section A–A

20

140

480

490

500

310538 29

Page 30

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model 297266, Automatic Hot Melt Swirl Dispense Valve

Ref

No.

10

20*

30

Á

40

50

60

70*

80

90*

100*

110*

120

125

130*

140n

180

190

200

Á

210

220

230

Á

Part No. Description Qty.

C32083

103610

C19800

ÁÁ

100016

110755

C34044

C34032

C34030

113944

103649

C32088

112248

C19359

C20521

C32082

C34045

C32097

112166

ÁÁ

C19197

C34040

C19269

ÁÁ

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

ББББББББ

1/4”–20 x 0.5

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL, graphite/PTFE

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

NUT, hex

SCREW, set

SEAL, thread

NEEDLE, assembly

SPACER

BODY

SCREW, soc. hd. cap,

ББББББББ

1/4”–20 x 0.75

WASHER, flat, 3/16

COVER

SCREW, fill. hd. machine,

#4–40 x 0.25

ББББББББ

1

1

5

Á

2

4

1

1

4

1

1

1

1

1

1

1

2

1

2

Á

2

1

2

Á

Ref

Part No. Description Qty.

No.

240

250*

260

270n

ÁÁ

280

290

ÁÁ

300

C32085

103337

C34028

116011

ÁÁ

C32099

C33037

ÁÁ

C19810

BASE, cylinder

O-RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge

230 V, 200 W

ББББББББ

BLOCK, mounting

TAPE, fiberglass,

ББББББББ

0.5” wide (229 mm)

SCREW, soc. hd. cap,

1

1

1

1

1

9”

2

1/4”–20 x 1

310

ÁÁ

320n

330

350

ÁÁ

360

370

380

390

410

430

440

460

480

490

500

510

520

104594

ÁÁ

C32255

C34043

C19949

ÁÁ

115861

C34041

065345

101674

C32090

115860

115862

112144

15H098

118072

117950

157021

116640

SCREW, soc. hd. cap,

1/4”–20 x 3.25

ББББББББ

SENSOR, RTD

BRACKET

SCREW, panhd. machine,

#4–40 x 0.5

ББББББББ

HOUSING, 8 pin

SPRING

WIRE, high temp, (127 mm)

TERMINAL, ring

SEAT

INSERT, male

CONNECTOR, male, crimp

SCREW, PH 8–32 X 1/4

ADAPTER, swirl

HEAD. applicator, swirl

NOZZLE, swirl, 0.30

WASHER, lock

CONNECTOR

4

1

1

2

1

1

5”

1

1

1

1

1

1

1

1

1

4

* These parts are included in Repair Kit C27342, which

БББББББББББББББ

may be purchased separately.

n Keep these spare parts on hand to reduce down time.

БББББББББББББББ

1

320, 520

SENSOR RTD

30 310538

380, 440

SECTION B–B (Enlarged to show detail)

270, 520

1

HEATER

200W @ 240 VOLTS

Notes

1

Coat with heat sink compound

before installing.

Ref. 330

510

390

460

Page 31

Parts

Model 243695, Therm-O-Flow Automatic Dispense Valve

120 130

100,110

90

60

80

70

20210, 40, 30

Close

Cyl. air ports

1/8 npt

10

Open

410

SECTION A–A

125

140

TI0432

Ref. 1/2” npt(m) outlet

260

370

250

360

430

240

230

220

200 210

190

180

140

310

300

210

290

280

30

A

410

TI11206a

360

350

B

B

Material Inlet

Port 1/2 npt

1/2” npt male

material outlet

A

310538 31

Page 32

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model 243695, Therm-O-Flow Automatic Dispense Valve

Ref

No.

10

20*

30

Á

40

50

60

70*

80

90*

100*

110*

120

125

130*

140n

150

160

170

180

190

200

Á

210

Part No. Description Qty

.

C51762

722834

C19800

ÁÁ

100016

C34044

C34032

C34030

113944

103649

C32088

112248

C19359

C20521

C32082

C34045

C32097

112166

ÁÁ

C19197

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

WASHER, lock, 1/4”

PLATE, blank–off

SEAL

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

NUT, hex

SCREW, set

SEAL, thread

NEEDLE, piston

SPACER

BODY

SCREW, soc. hd. cap,

ББББББББ

1/4”–20 x 0.75

WASHER, flat, 3/16

1

1

5

Á

2

1

1

4

1

1

1

1

1

1

1

2

1

2

Á

6

Ref

No.

220

230

ÁÁ

240

250*

260

270n

ÁÁ

280

290

ÁÁ

300

Part No. Description Qty

.

C34040

C19269

ÁÁ

C32085

103337

C34028

116011

ÁÁ

C32099

C33037

ÁÁ

C19810

COVER

SCREW, fill. hd. machine,

ББББББББ

#4–40 x 0.25

BASE, cylinder

O–RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge

230 V, 200 W

ББББББББ

BLOCK, mounting

TAPE, fiberglass,

ББББББББ

0.5” wide (229 mm)

SCREW, soc. hd. cap,

1

2

1

1

1

1

1

9”

2

1/4”–20 x 1

310

ÁÁ

320n

330

350

ÁÁ

360

370

380

390

410

430

440

460

510

520

104594

ÁÁ

C32255

C34043

C19949

ÁÁ

115861

C34041

065345

101674

C51774

115860

115862

112144

157021

116640

SCREW, soc. hd. cap,

1/4”–20 x 3.25

ББББББББ

SENSOR, RTD

BRACKET

SCREW, pan hd. machine,

#4–40 x 0.5

ББББББББ

HOUSING, conn.

SPRING

WIRE, high temp, (127 mm)

TERMINAL, ring

SEAT

INSERT, male

CONNECTOR, male

SCREW

WASHER, lock

CONNECTOR

4

1

1

2

1

1

5”

1

1

1

1

1

1

4

* These parts are included in Repair Kit C50594, which

may be purchased separately.

БББББББББББББББ

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

Ref. 330

32 310538

510

390

460

1

270, 520

1

320, 520

2

SECTION B–B

Notes

1

Coat with heat sink compound

(400) before installing.

380, 440

(Enlarged to show detail)

Page 33

Parts

Model 243696, Therm-O-Flow Automatic Dispense Valve with Snuff Back

120 130

260

370

250

240

100 110

50

40

30

90

70

60

80

20

10

310

300

50

Cyl. air ports

1/8 npt

SECTION A–A

A

410

170

160

150

140

420

360

230

220

200 210

190

180

TI0433

290

280

30

360

350

B

B

Material Inlet

Port 1/2 npt

1/8” npt male

material outlet

A

310538 33

Page 34

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model 243696, Therm-O-Flow Automatic Dispense Valve with Snuff Back

Ref

No.

10

20*

30

40

50

60

70*

80

90*

100*

110*

120

Á

130*

140n

150*

Á

160

170*

180

190

200

210

Part No. Description Qty.

617479

722834

C19800

100016

110755

C34044

617604

C34030

113944

103649

C32088

617495

ÁÁ

C20521

918471

617491

ÁÁ

617480

C20406

C34045

617605

112166

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL, PTFE, .25 x .44

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

SCREW, button head,

ББББББББ

1/4”–20 x 0.31

SEAL, thread

NEEDLE, piston

SEAL, rod hi temp,

ББББББББ

0.25 x 0.50 x 0.25

SPACER

RING, retaining, for 0.56 I.D.

SPACER

BODY

SCREW, soc. hd. cap,

1

1

5

2

4

1

1

4

1

1

1

1

Á

1

1

1

Á

1

1

2

1

2

1/4”–20 x 0.75

C19197

WASHER, flat, 3/16

2

Ref

Part No. Description Qty.

No.

220

230

C34040

C19269

COVER

SCREW, fill. hd. machine,

1

2

#4–40 x 0.25

240

250*

260

270n

617603

103337

C34028

116011

BASE, cylinder

O–RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge

1

1

1

1

230 V, 200 W

280

290

C32099

C33037

BLOCK, mounting

TAPE, fiberglass,

1

9”

0.5” wide (229 mm)

300

ÁÁ

310

C19810

ÁÁ

104594

SCREW, soc. hd. cap,

1/4”–20 x 1

ББББББББ

SCREW, soc. hd. cap,

2

4

1/4”–20 x 3.25

320n

330

340

350

ÁÁ

360

C32255

C34043

112144

C19949

ÁÁ

115860

SENSOR, RTD

BRACKET

SCREW

SCREW, pan hd. machine,

ББББББББ

#4–40 x 0.5

INSERT, male

1

1

1

2

1

1

370*

390

400

410

420

430

510

520

617536

065345

101674

C32089

115861

115862

157021

116640

SPRING

WIRE, high temp, (127 mm)

TERMINAL, ring

NUT, nozzle

HOUSING, connector

CONNECTOR, male

WASHER, lock

CONNECTOR

1

5”

1

1

1

1

1

4

* These parts are included in Repair Kit 918520, which

may be purchased separately.

БББББББББББББББ

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

34 310538

Ref. 330

510

390

460

1

270, 520

1

320, 520

1

2

SECTION B–B

Notes

Coat with heat sink compound

(400) before installing.

380, 440

(Enlarged to show detail)

Page 35

Parts

Model C27340, Ambient Therm-O-Flow Automatic Dispense Valve, Double Acting

120 130 250

100 110

90

80

70

20

10

Cyl. air ports

1/8 npt

230

280

220

60

150

210

240

190

SECTION A–A

150

270

A

280

30

TI11207a

B

B

Material Inlet

Port 1/2 npt

1/8” npt female

material outlet

A

310538 35

Page 36

Parts

Á

Á

Á

Á

Model C27340, Ambient Therm-O-Flow Automatic Dispense Valve, Double Acting

Ref

No.

10

20

30

Á

60

70

80

90

100

110

120

130

Part No. Description Qty.

C32083

103610

C19800

ÁÁ

C34041

C34032

C34030

113944

103649

C32088

C19359

112248

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

SPRING

SEAL

SPACER

O–RING, –123 fluoroelastomer

O–RING

GLIDE RING

SCREW, set, 1/4–20 x 1.5 in.

NUT, hex, 1/4–20

1

1

3

Á

1

1

4

1

1

1

1

1

Ref

Part No. Description Qty.

No.

150n

190

210

220

230

240

250

270

280

C32082

C32097

103337

C34028

C32089

C32085

C20521

C32090

104594

NEEDLE assembly

BODY

O–RING, –010 fluoroelastomer

CAP, cylinder

RETAINER

BASE, cylinder

SEAL, thread

SEAT

SCREW, soc. hd.

1

1

1

1

1

1

1

1

4

n Keep these spare parts on hand to reduce down time.

36 310538

Page 37

Parts

Model C34068, Warm Automatic Dispense Valve, Double Acting

100,110

50, 40, 30

90

80

70

60

120

130

Cyl. air ports

1/8 npt

140

125

260

370

250

240

20

180

360

230

220

200, 210

190

140

310

300

50

280

10

290

30

B

410

Section A–A

A

420

TI0304

B

Material Inlet

Port 1/2 npt

410

TI11208a

360

350

1/8” npt female

material outlet

310538 37

Page 38

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model C34068, Warm (2755F/1355C max) Automatic Dispense Valve with Snuff Back

Ref

No.

10

20*

30

Á

40

50

60

70*

80

90*

100*

110*

120

125

130*

140n

180

190

200

Á

210

220

230

Á

Part No. Description Qty.

C32083

103610

C19800

ÁÁ

100016

110755

C34044

C34032

C34030

113944

103649

C32088

112248

C19359

C20521

C32082

C34045

C32097

112166

ÁÁ

C19197

C34040

C19269

ÁÁ

ADAPTER, seat

O–RING, –018 fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL, graphite/PTFE

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

NUT, hex

SCREW, set

SEAL, thread

NEEDLE, assembly

SPACER

BODY

SCREW, soc. hd. cap,

1/4”–20 x 0.75

ББББББББ

WASHER, flat, 3/16

COVER

SCREW, fill. hd. machine,

#4–40 x 0.25

ББББББББ

1

1

5

Á

2

4

1

1

4

1

1

1

1

1

1

1

2

1

2

Á

2

1

2

Á

Ref

Part No. Description Qty.

No.

240

250*

260

270n

C32085

103337

C34028

C31034

BASE, cylinder

O-RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge

1

1

1

1

120 V, 150 W

280

290

ÁÁ

300

C32099

C33037

ÁÁ

C19810

BLOCK, mounting

TAPE, fiberglass,

0.5” wide (229 mm)

ББББББББ

SCREW, soc. hd. cap,

1

9”

2

1/4”–20 x 1

310

104594

SCREW, soc. hd. cap,

4

1/4”–20 x 3.25

320n

330

340

350

C32255

C34043

102794

C19270

SENSOR, RTD

BRACKET

NUT, hex, #4–40

SCREW, fill. hd. machine,

1

1

4

4

#4–40 x 0.38

360

370

380

390

400

ÁÁ

410

420

460

510

C07329

C34041

065345

101674

073019

ÁÁ

C32090

C32089

112144

157021

CONNECTOR, 6 pin

SPRING

WIRE, high temp (127 mm)

TERMINAL, ring

COMPOUND, heatsink (not

shown)

ББББББББ

SEAT

NUT, retainer

SCREW

WASHER, lock

1

1

5”

1

A/R

1

1

1

1

* These parts are included in Repair Kit C27342, which

may be purchased separately.

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

38 310538

460

390

510

Ref.330

340

D

C

E

B

F

380

1

270

A

SECTION B–B

(Enlarged to show detail)

330

320

1

Notes

1

Coat with heat sink compound

(400) before installing.

Page 39

Parts

Model C34079, Therm–O–Flow Automatic Dispense Valve, Double Acting

125

120

130

260

370

250

100,110

90

80

70

60

50, 40, 30

Cyl. air ports

1/8 npt

310

10

410

Section A–A

A

140

Ref. 1/2” npt(m) outlet

20

240

180

TI0304

360

230

220

50, 200

190

140

300, 50

280

290

30

410

TI11209a

360

350

B

B

Material Inlet

Port 1/2 npt

1/8” npt female

material outlet

310538 39

Page 40

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model C34079, Therm–O–Flow Automatic Dispense Valve, Double Acting

Ref

No.

10

20*

30

Á

40

50

60

70*

80

90*

100*

110*

120

125

130*

140n

180

190

200

Á

220

230

Á

Part No. Description Qty.

C51762

722834

C19800

ÁÁ

100016

C19197

C34044

C34032

C34030

113944

103649

C32088

112248

C19359

C20521

C32082

C34045

C32097

112166

ÁÁ

C34040

C19269

ÁÁ

ADAPTER, seat

O–RING, fluoroelastomer

SCREW, soc. hd. cap,

1/4”–20 x 0.5

ББББББББ

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL, graphite/PTFE

SPACER

O–RING, –125 fluoroelastomer

O–RING, –123 fluoroelastomer

RING

NUT, hex

SCREW, set

SEAL, thread

NEEDLE, assembly

SPACER

BODY

SCREW, soc. hd. cap,

1/4”–20 x 0.75

ББББББББ

COVER

SCREW, fill. hd. machine,

ББББББББ

#4–40 x 0.25

1

1

5

Á

2

6

1

1

4

1

1

1

1

1

1

1

2

1

2

Á

1

2

Á

Ref

Part No. Description Qty.

No.

240

250*

260

270n

C32085

103337

C34028

C31034

BASE, cylinder

O-RING, –010 fluoroelastomer

CAP, cylinder

HEATER, cartridge

1

1

1

1

120 V, 150 W

280

290

ÁÁ

300

C32099

C33037

ÁÁ

C19810

BLOCK, mounting

TAPE, fiberglass,

0.5” wide (229 mm)

ББББББББ

SCREW, soc. hd. cap,

1

9”

2

1/4”–20 x 1

310

104594

SCREW, soc. hd. cap,

4

1/4”–20 x 3.25

320n

330

340

350

360

370

380

390

400

ÁÁ

410

460

510

C32255

C34043

102794

113970

C07329

C34041

065345

101674

073019

ÁÁ

C51774

112144

157021

SENSOR, RTD

BRACKET

NUT, hex, #4–40

SCREW, machine, #4–40

CONNECTOR, 6 pin

SPRING

WIRE, high temp (127 mm)

TERMINAL, ring

COMPOUND, heatsink (not

ББББББББ

shown)

SEAT

SCREW

WASHER, lock

1

1

4

4

1

1

5”

1

A/R

1

1

1

* These parts are included in Repair Kit C34080, which

may be purchased separately.

БББББББББББББББ

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

40 310538

460

390

510

Ref.330

340

D

C

E

B

380

1

270

F

A

SECTION B–B

(Enlarged to show detail)

330

320

1

Notes

1

Coat with heat sink compound

(400) before installing.

Page 41

Parts

Model C50592, Therm–O–Flow Automatic Dispense Valve, Double Acting

100,110

90

80

70

60

50, 40, 30

20

10

215

15

Ref. 1/4” npt(f) outlet

120

130

Cyl. air ports

1/8 npt

225, 235

125

260

370

250

240

140

360

230

220

50, 200

190

140

180

455

40

195

295

A

TI0869

TI11210a

Section A–A

A

310

300, 50

290

280

30

360

350

B

B

Material Inlet

Port 1/2 npt

TI0869

1/4” npt female

material outlet

A

310538 41

Page 42

Parts

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model C50592, Therm–O–Flow Automatic Dispense Valve, Double Acting

Ref

No.

10

15

20*

30

40

50

60

70*

80

90*

100*

110*

120

125

130*

140n

180

190

195

200

215*

220

225

230

Á

235

Part No. Description Qty.

C50881

C50582

722834

C19800

ADAPTER, nozzle manifold

MANIFOLD, nozzle

O–RING, fluoroelastomer

SCREW, soc. hd. cap,

1

1

1

2

1/4”–20 x 0.5

100016

C19197

C34044

C34032

C34030

113944

103649

C32088

112248

C19359

C20521

C50583

C34045

C32097

100333

112166

WASHER, lock, 1/4”

WASHER, flat, 1/4”

PLATE, blank–off

SEAL, graphite,PTFE

SPACER

O–RING, –125, fluoroelastomer

O–RING, –123, fluoroelastomer

RING, piston

NUT, hex

SCREW, set

SEAL, thread

NEEDLE, assembly

SPACER

BODY

SCREW, cap, hex. hd.

SCREW, soc. hd. cap,

5

6

1

1

4

1

1

1

1

1

1

1

2

1

3

2

1/4”–20 x 0.75

109576

C34040

112788

C19269

ÁÁ

100079

O–RING, fluoroelastomer

COVER

SCREW, soc. hd. cap,

SCREW, fill. hd. machine,

ББББББББ

#4–40 x 0.25

WASHER, lock, spring

1

1

4

2

Á

4

Ref

Part No. Description Qty.

No.

240

250*

260

270n

C32085

103337

C34028

C31034

BASE, cylinder

O-RING, –010, fluoroelastomer

CAP, cylinder

HEATER, cartridge

1

1

1

1

120 V, 150 W

280

290

ÁÁ

295

300

ÁÁ

310

C32099

C33037

ÁÁ

C38014

C19810

ÁÁ

104594

BLOCK, mounting

TAPE, fiberglass,

0.5” wide (229 mm)

ББББББББ

PLUG, o–ring boss

SCREW, soc. hd. cap,

ББББББББ

1/4”–20 x 1

SCREW, soc. hd. cap,

1

11”

1

2

4

1/4”–20 x 3.25

320n

330

340

350

360

370

380

390

400

ÁÁ

460

510

C32255

C34043

102794

113970

C07329

C34041

065345

101674

073019

ÁÁ

112144

157021

SENSOR, temperature

BRACKET

NUT, hex, #4–40

SCREW, machine, #4–40

CONNECTOR, 6 pin

SPRING

WIRE, lead, motor

TERMINAL, ring

COMPOUND, heatsink (not

shown)

ББББББББ

SCREW

WASHER, lock

1

1

4

4

1

1

5”

1

A/R

1

1

* These parts are included in Repair Kit C50594, which

may be purchased separately.

БББББББББББББББ

БББББББББББББББ

n Keep these spare parts on hand to reduce down time.

42 310538

460

390

510

Ref.330

380

1

270

D

C

E

B

F

A

SECTION B–B

340

330

390

320

(Enlarged to show detail)

1

Notes

1

Coat with heat sink compound

(400) before installing.

Page 43

Accessories

p

Use Only Genuine Graco Parts and Accessories

Description Part No.

LOW PRESSURE HEATED HOSES

14 MPa (138 bar, 2000 psi)

Heated hoses for use with Therm-O-Flow® 5 and Therm-O-Flow 55 supply units.

Contact your Graco Service Representative for more information.

HIGH PRESSURE HEATED HOSES

28 MPa (275 bar, 4000 psi)

Heated hoses for use with Therm-O-Flow 5 and Therm-O-Flow 55 supply units.

Contact your Graco Service Representative for more information.

HOSE FITTINGS