Page 1

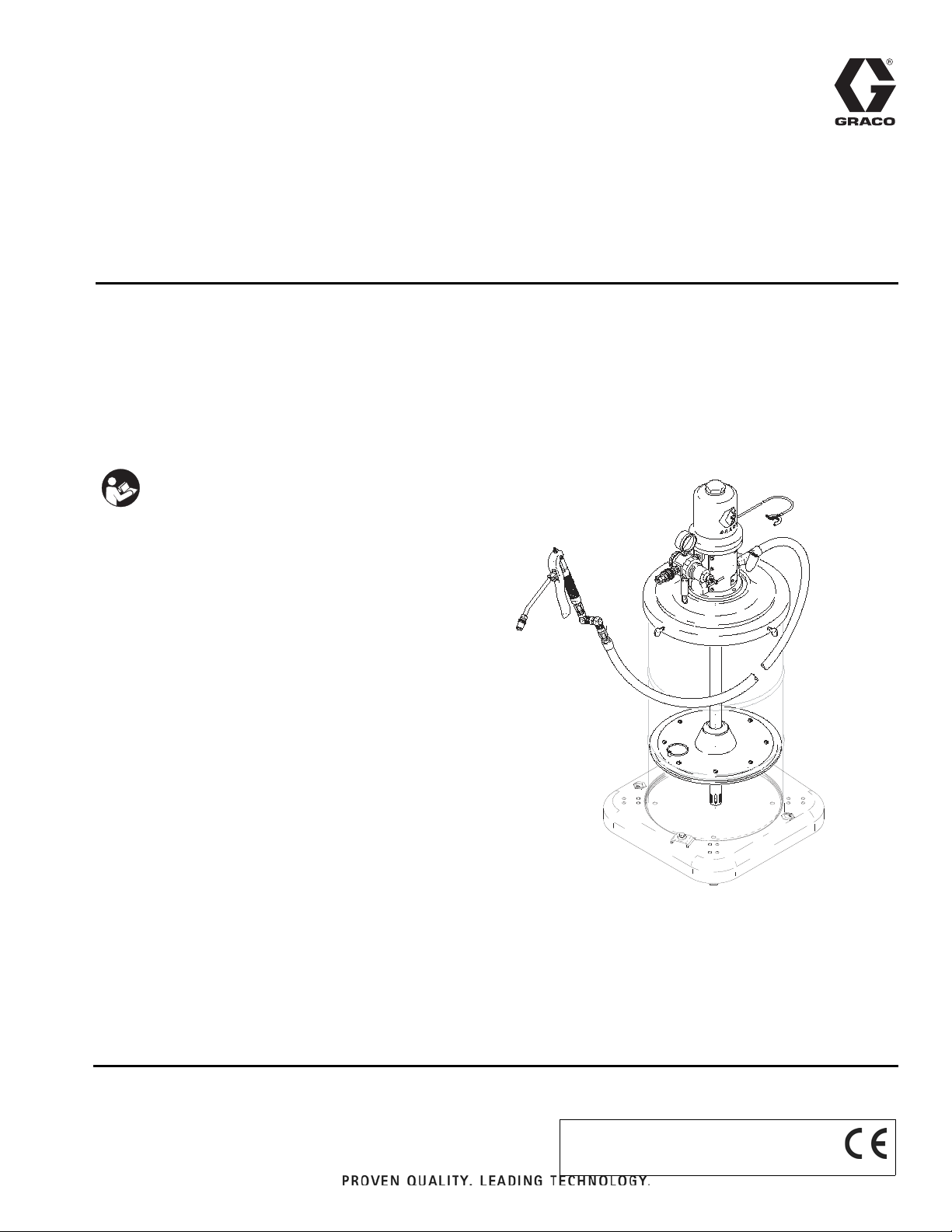

Instructions - Parts List

Model 253388 shown

Mini Fire-Ball® 225,

50:1 Grease Pump Packages

Portable units for dispensing heavy grease.

See page 2 for model numbers.

5000 psi (34 MPa, 345 bar) Maximum Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

309967C

EN

Page 2

Models

Models

Model No. Size

246910 35-50 lb

(16-23 kg)

253384† 35-50 lb

(16-23 kg)

253362 35-50 lb

(16-23 kg)

246911 35-50 lb

(16-23 kg)

253385† 35-50 lb

(16-23 kg)

246913 35-50 lb

(16-23 kg)

253386† 35-50 lb

(16-23 kg)

246914 120 lb

(55 kg)

253387† 120 lb

(55 kg)

246915 120 lb

(55 kg)

253388† 120 lb

55 kg)

246916 120 lb

(55 kg)

253389† 120 lb

(55 kg)

246917 400 lb

(180 kg)

253390† 400 lb

(180 kg)

Dispense Kit

236058

Hose/Fitting

Kit 222072

Follow

Base Type Cover

222059 24F901

222059 220653

222059 24F901

24R350

204574

2-wheel

truck

2-wheel

truck

portable 24R350 24F902

portable 204574 220654

2-wheel

truck

2-wheel

truck

24R350

204574

24R350 24F902

204574 220654

24R350 24F902

204574 220654

200326 24F903

200326 223845

Plate

CE Kit

Handle Pail

240979

† These models are CE certified.

2 309967C

Page 3

Warnings

Warnings

The following general warnings are for the setup, use, grounding, maintenance, and repair of this equipment. Additional, more specific warnings may be found throughout the body of this manual where applicable. Symbols appear-

ing in the body of the manual refer to these general warnings. When these symbols appear throughout the manual,

refer back to these pages for a description of the specific hazard.

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine Graco

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop dispensing and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

309967C 3

Page 4

Operation/Service

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and

gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

WARNING

• Read SDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

• Gloves

• Hearing protection

Operation/Service

Refer to pump manual 309966 (supplied) for operating and service instructions.

4 309967C

Page 5

Installation

Z

Y

ti1052

Installation

General Information

NOTE: Reference numbers and letters in parenthe-

ses in the text refer to the callouts in the figures and

parts drawing.

NOTE: Always use genuine Graco parts and

accessories, available from your Graco distributor.

Air Line Accessories

See page 6 for recommended air accessories and

installation.

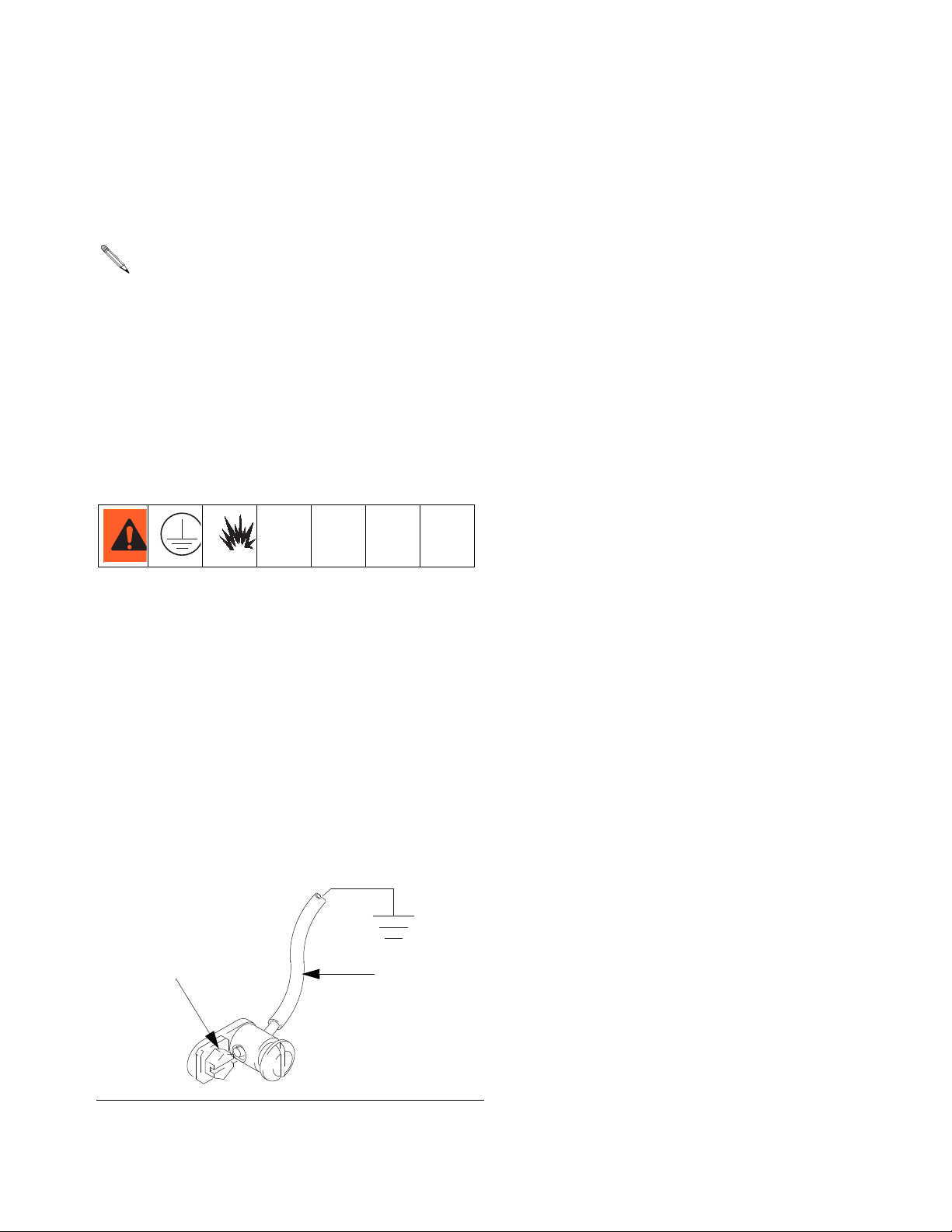

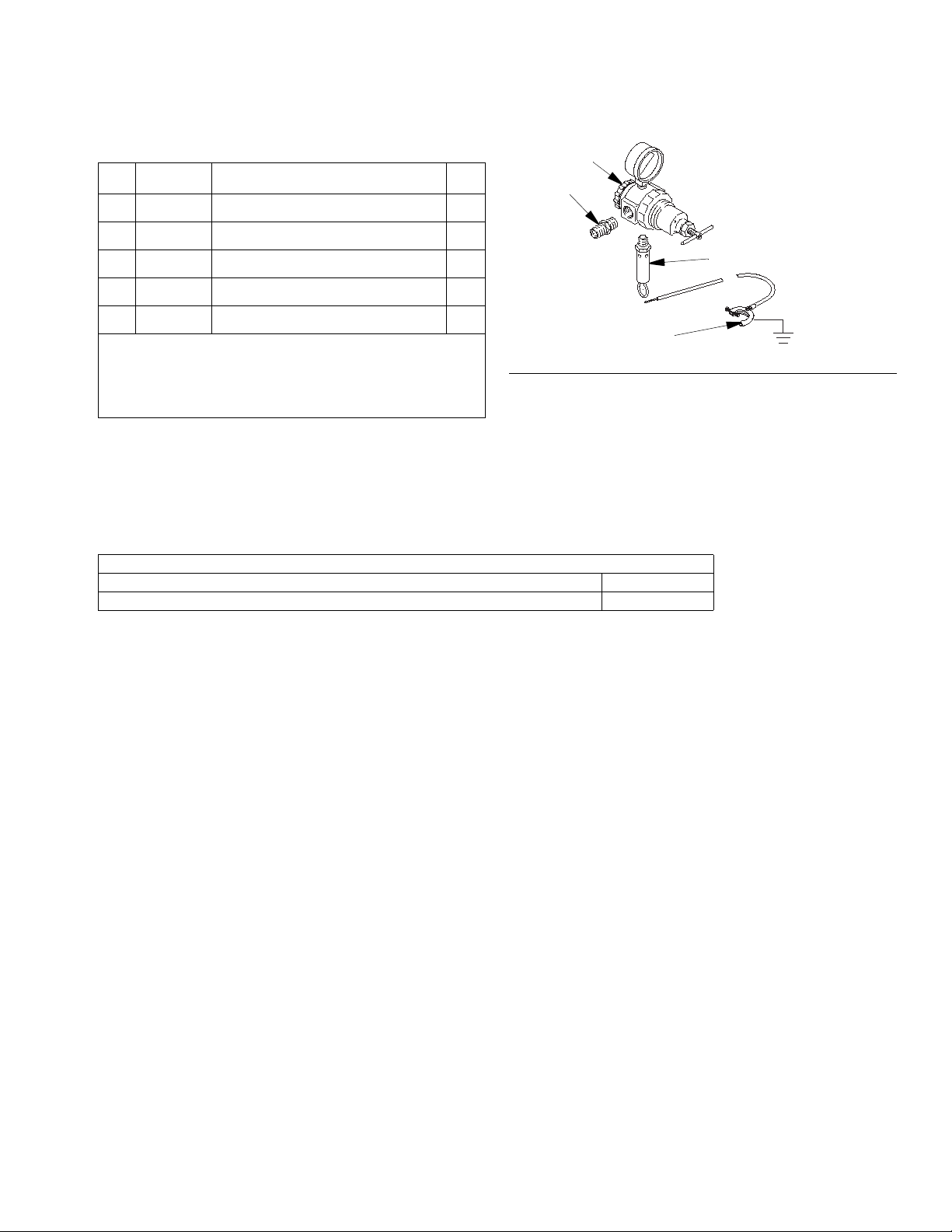

Grounding

Air compressor: follow manufacturer’s recommenda-

tions.

Dispense valve: ground through connection to a properly grounded fluid hose and pump.

Fluid supply container: follow local code.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

To reduce the risk of static sparking, ground the pump

and all other components used or located in the

dispensing area. Check your local electrical code for

detailed instructions for your area and type of

equipment.

Ground this equipment:

Pump: remove the ground screw (Z) and insert through

the eye of the ring terminal at end of ground wire (Y).

Fasten the ground screw back onto the pump and

tighten securely. Connect the other end of the ground

wire to a true earth ground. See F

ground wire and clamp, order Part No. 222011.

IG. 1. To order a

FIG. 1

Air and fluid hoses: use only grounded hoses.

309967C 5

Page 6

Installation

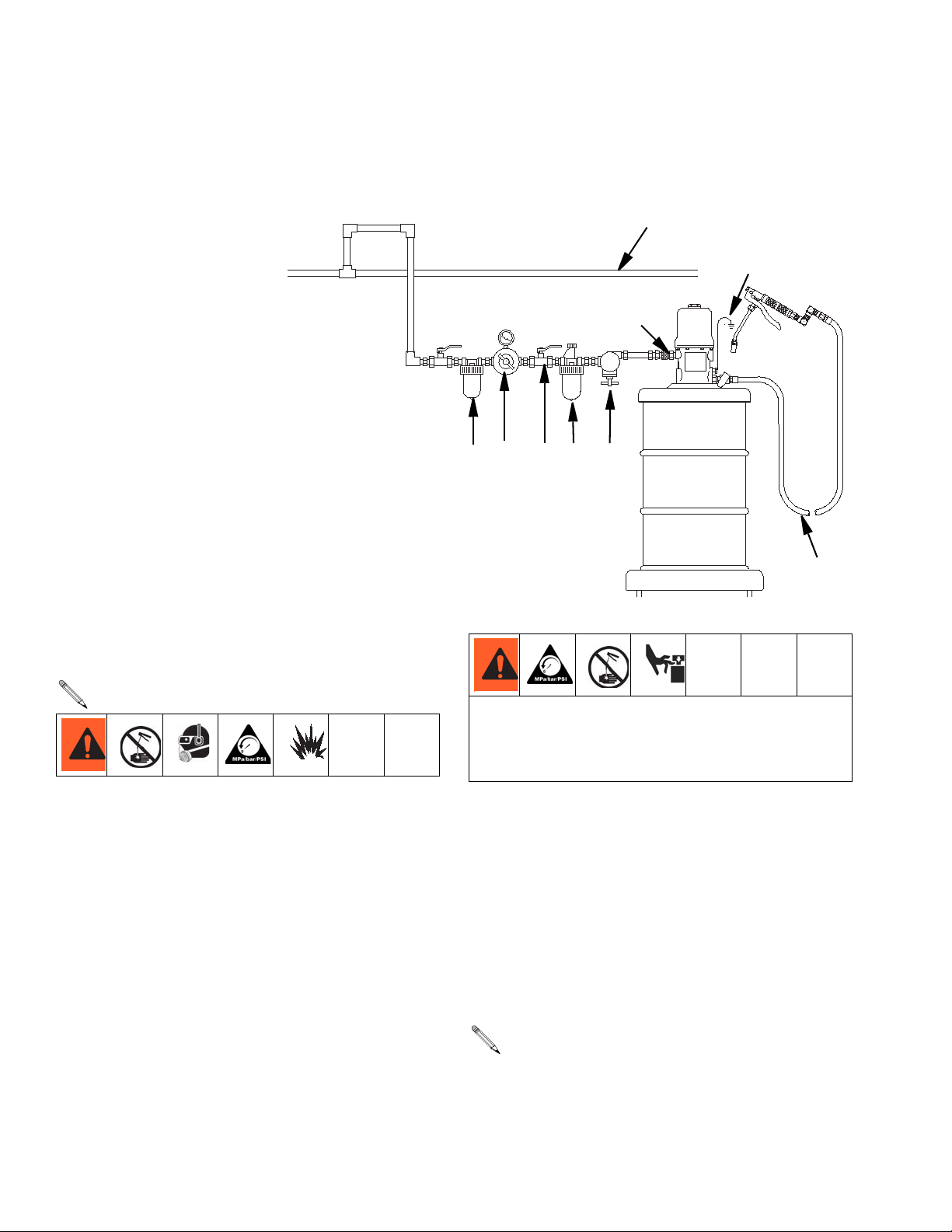

Key:

A Fluid dispense line

B Pump ground wire (required)

C Air regulator

D Main air supply line

EAir filter

F Pump lubricator

G Pump runaway valve

H Bleed-type master air valve (required)

J Quick-disconnect couple and nipple

K Air regulator (9b) with safety valve (9c) and gauge (not shown)

Included with models 253384 through 253390

A

C

D

F

G

H

J

E

01519

B

Typical Installation

The installation shown below is only a guide for selecting and installing system components and accessories. Contact your Graco distributor for assistance in designing a system to suit your particular needs.

Air Line and Accessories

NOTE: Install air line accessories in the order

shown in the Typical Installation illustration.

• Install a pump runaway valve (G) to shut off the air

to the pump if the pump accelerates beyond the preadjusted setting. A pump that runs too fast can be

seriously damaged.

• Install an air line lubricator (F) for automatic air

motor lubrication.

• Install a bleed-type master air valve (H) to relieve air

trapped between the valve and the motor when the

valve is closed.

6 309967C

Trapped air can cause the air motor to cycle

unexpectedly, causing serious injury if you are

adjusting or repairing the pump. Be sure to follow the

Pressure Relief Procedure on page 11.

• Install the air regulator (C) to control pump speed

and pressure.

• On the main air supply line from the compressor,

install an air line filter (E) to remove harmful dirt and

contaminants fro the compressed air supply.

• For models 253384 through 253390, install the provided air regulator/safety valve (K) at the pump air

inlet with the nipple (9a, also included).

Avoid hanging air accessories directly on the pump

air inlet. The fittings are not strong enough to support the accessories and may cause one or more to

break. If accessories must be installed directly on

the pump, provide a bracket on which to mount

them.

Page 7

Installation

9b

2c, 2d

4f

5

4a

2b

2a

Model 253384 shown

01517

4b

Models 246910, 253362, and 253384 (FIG. 2)

1. Remove the cover from the pail, and scoop the

lubricant from the center to the sides of the pail to

make its surface concave.

2. Center the follow plate (5) in the pail opening. Press

the plate firmly downward and rotate it over the

lubricant surface to eliminate air pockets and prevent channeling.

3. Insert the pump through the cover (4a) and slide the

cover up far enough to let the pump pass easily

through the follow plate grommet. The pump stop

plate(4b) will secure the pump in place.

4. Place the cover (4a) on the pail, and tighten the

thumbscrews (4f).

5. Assemble the gun (2b) and hose (2a), and connect

the hose to the pump fluid outlet.

6. Connect the nipple (2d) to the pump air inlet or air

regulator (9b) inlet, whichever is applicable. Connect the quick–disconnect coupler (2c) to the air

supply hose.

F

IG. 2

309967C 7

Page 8

Installation

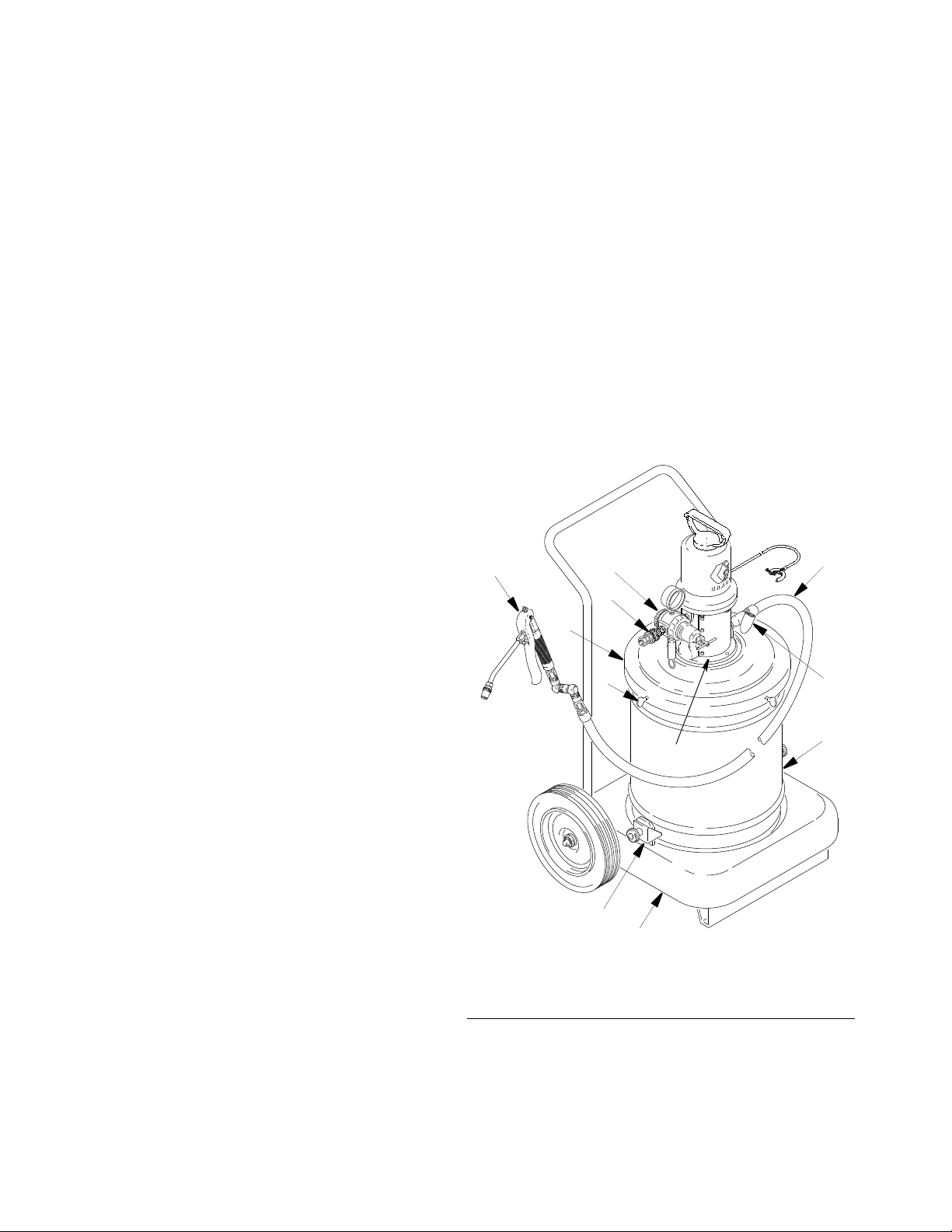

Model 253386 shown

01514

2a

4

A

7c, 7d

10

6

2c

9b

2b

2d

7

11

Models 246911, 246913, 253385 and 253386

(FIG. 3)

1. Remove the fluid outlet adapter included with the

pump, and screw the holster (6) into the pump outlet

using thread sealant.

2. Models 246913 and 253386: Assemble the truck (7)

as shown in the parts drawing on page 13. Secure

the truck pail (10) to the truck base with the pointed

clamps (7d) and thumbnuts (7c).

3. Remove the cover from the pail of lubricant. Place

the pail of lubricant into the truck pail.

4. Secure the cover (4) on the pail with the three

thumbscrews (A).

5. Install shim (11) on top of drum. Align holes in shim

with holes in cover (4).

6. Insert the pump riser tube through the top of the

shim (11) and cover (4). Lower the pump until it

rests on the shim and cover.

7. Assemble the gun (2b) and hose (2a), and connect

the hose to the pump fluid outlet.

8. Connect the nipple (2d) to the pump air inlet or air

regulator (9b) inlet, whichever is applicable. Connect the quick-disconnect coupler (2c) to the air

supply hose.

8 309967C

FIG. 3

Page 9

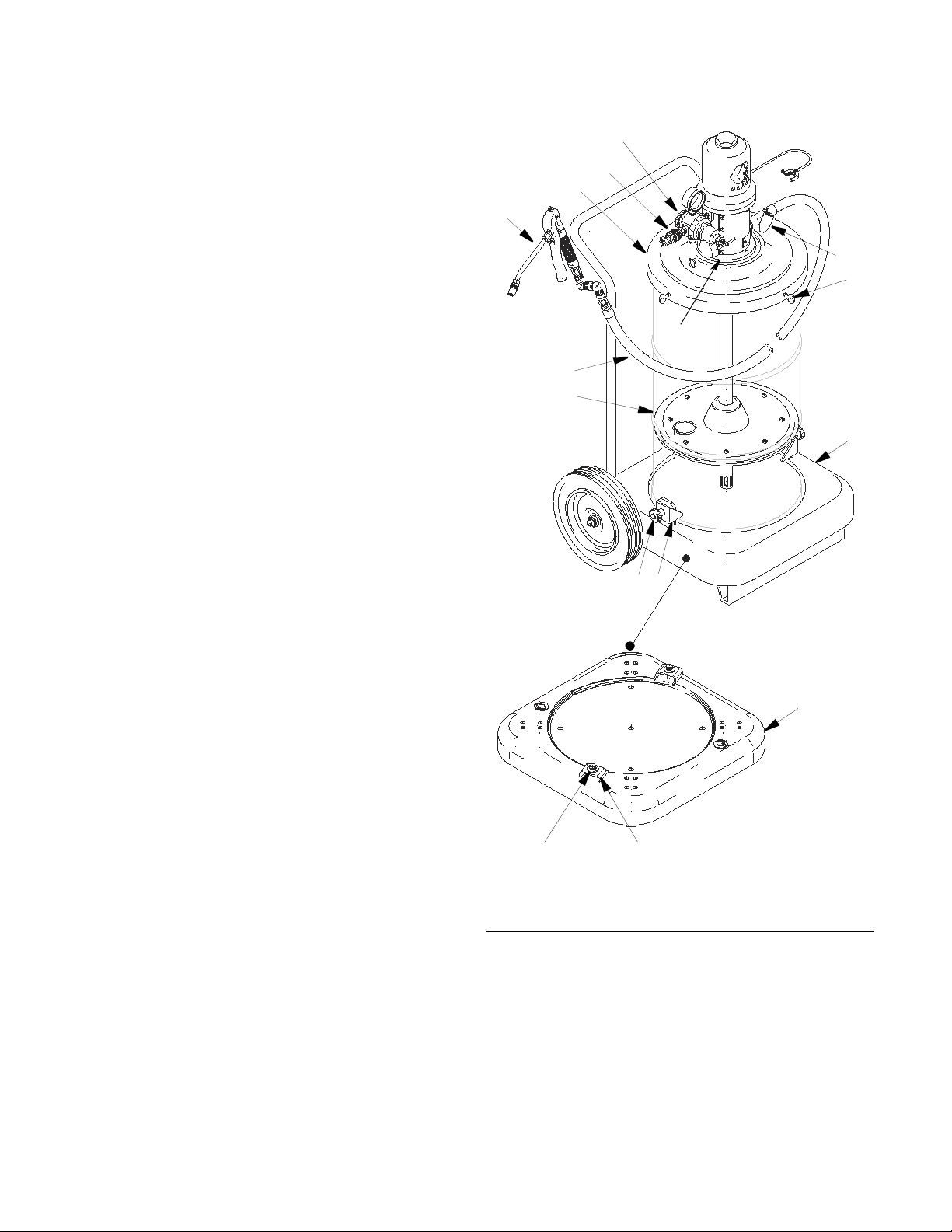

Models 246914, 246917, 253387 and 253390

Model 253390 shown

3a

5

4

9b

3c

11

8729

Model 253387

5

A

4

9b

3a

3c

11

(FIG. 5 and FIG. 4)

1. Remove the cover from the pail, and scoop the

lubricant from the center to the sides of the pail to

make its surface concave.

2. Center the follow plate (5) in the pail opening. Press

the follow plate firmly downward and rotate it over

the lubricant surface to eliminate air pockets and

prevent channeling.

3. Place the cover (4) on the pail and tighten the

thumbscrews (A).

4. Install shim (11) on top of cover. Insert the pump

riser tube through the top of the shim (11) and cover

(4). Lower the pump until it rests on the shim and

cover.

5. Connect the swivel adapter to the pump fluid outlet.

Connect fluid hose (3c) to the swivel adapter. Connect a suitable dispense valve.

Installation

6. Connect the swivel adapter to the pump air inlet or

air regulator (9b), whichever is applicable. Connect

the air hose (3a) to the swivel. Connect the air hose

to the air accessories.

FIG. 5

FIG. 4

309967C 9

Page 10

Model 253389 shown

246916

4

5

8d

7d7c

A

2b

2a

6

7

06790

8b

2c, 2d

9b

8

11

Installation

Models 246915, 246916, 253388 and 253389

(FIG. 6)

1. For Models 246915 and 253388: Assemble the por-

table base (8) as shown in the parts drawing on

page 15

For Models 246916 and 253389: Assemble the

truck (7) as shown in the parts drawing on page 15.

2. Remove the fluid outlet adapter included with the

pump, and screw the holster (6) into the pump outlet, using thread sealant.

3. Place an open 120–lb drum of grease on the mounting base or truck, and secure it with hold-down

clamps (7d or 8d).

For Models 246915 and 253388: Use pointed end of

clamps (8d) for steel drums only. Position the clamp

above the drum bead. Tighten bolts (8b). Reverse

clamps (8d) to use the flat end for fiber drums.

For Models 246916 and 253389: Use pointed end of

clamps (7d) for steel drums only. Position the clamp

above the drum bead. Tighten the thumbnuts (7c).

4. Press the follow plate (5) down firmly onto the

grease, and rotate it to eliminate air pockets and

reduce channeling. Insert the pump through the

cover (4). Slide the cover up far enough to let the

pump pass easily through the follow plate grommet.

5. Secure the cover on the drum with the thumbscrews

(A).

6. Place shim (11) on top of cover. Install pump. Insert

the pump riser tube through the top of the shim (11)

and cover (4). Lower the pump until it rests on the

shim and cover.

7. Assemble the gun (2b) and hose (2a), and connect

the hose to the pump fluid outlet.

8. Connect the nipple (2d) to the pump air inlet or air

regulator (9b) inlet, whichever is applicable. Con-

FIG. 6

nect the quick–disconnect coupler (2c) to the air

supply hose.

10 309967C

Page 11

Operation

Operation

Pressure Relief Procedure

1. Shut off the air to the pump.

2. Bleed off the air pressure by closing the air regulator

(self–relieving type), or closing the bleed–type master air valve installed upstream of the air regulator,

or disconnecting the air supply hose at the

quick–disconnect.

3. Hold a metal part of the gun or valve firmly to the

side of a grounded metal waster container and trigger to relieve fluid pressure.

Start–up: Single or Multiple Pump Systems

1. Close the air regulators and bleed–type master air

valves to all but one pump.

2. Open the master air valve from the compressor.

NOTE: A pump runaway valve can be installed on

the air line to automatically shut off the pump if it

starts to run too fast.

NOTE: Never allow the pump to run dry of the fluid

being pumped. A dry pump will quickly accelerate

to a high speed, possibly damaging itself. If the

pump accelerates quickly or is running too fast,

stop it immediately and check the fluid supply. If the

supply container is empty and air has been

pumped into the lines, prime the pump and lines

with fluid, or flush it and leave it filled with a compatible solvent. Be sure to eliminate all air from the

fluid system

The maximum working pressure of each pump in your

system may not be the same. To reduce the risk of

over–pressurizing any part of your system, be sure you

know the maximum working pressure rating of each

pump and its connected components. Never exceed

the maximum working pressure of the lowest rated

component connected to a particular pump.

3. For the pump which is connected, trigger the dispensing valve into a grounded metal waste container, making firm metal–to–metal contact between

the container and valve. Open the bleed–type master air valve, and open the pump air regulator slowly

until the pump is running. When the pump is primed

and all air has been pushed out of the lines, release

the trigger.

4. If you have more than one pump, repeat this procedure for each pump.

NOTE: When the pump is primed, and with sufficient air supplied, the pump starts when the dispensing valve is opened and shuts off when it is

closed.

5. Set the air pressure to each pump at the lowest

pressure needed to get the desired results.

To determine the fluid output pressure using the air

regulator reading, multiply the ratio of the pump by the

air pressure shown on the regulator gauge. For example:

50:(1) ratio x 100 psi air = 5000 psi fluid output

50:(1) ratio x 0.7 MPa air = 35 MPa fluid output

50:(1) ratio x 7 bar air = 350 bar fluid output

Limit the air to the pump so that no air line or fluid line

component or accessory is overpressurized.

6. Read and follow the instructions supplied with each

component in the system.

7. When shutting off the system, always follow the

Pressure Relief Procedure.

309967C 11

Page 12

Parts

1

4d

2

9

4a

4b

4e

4h

4g

5

4f

4c

Parts

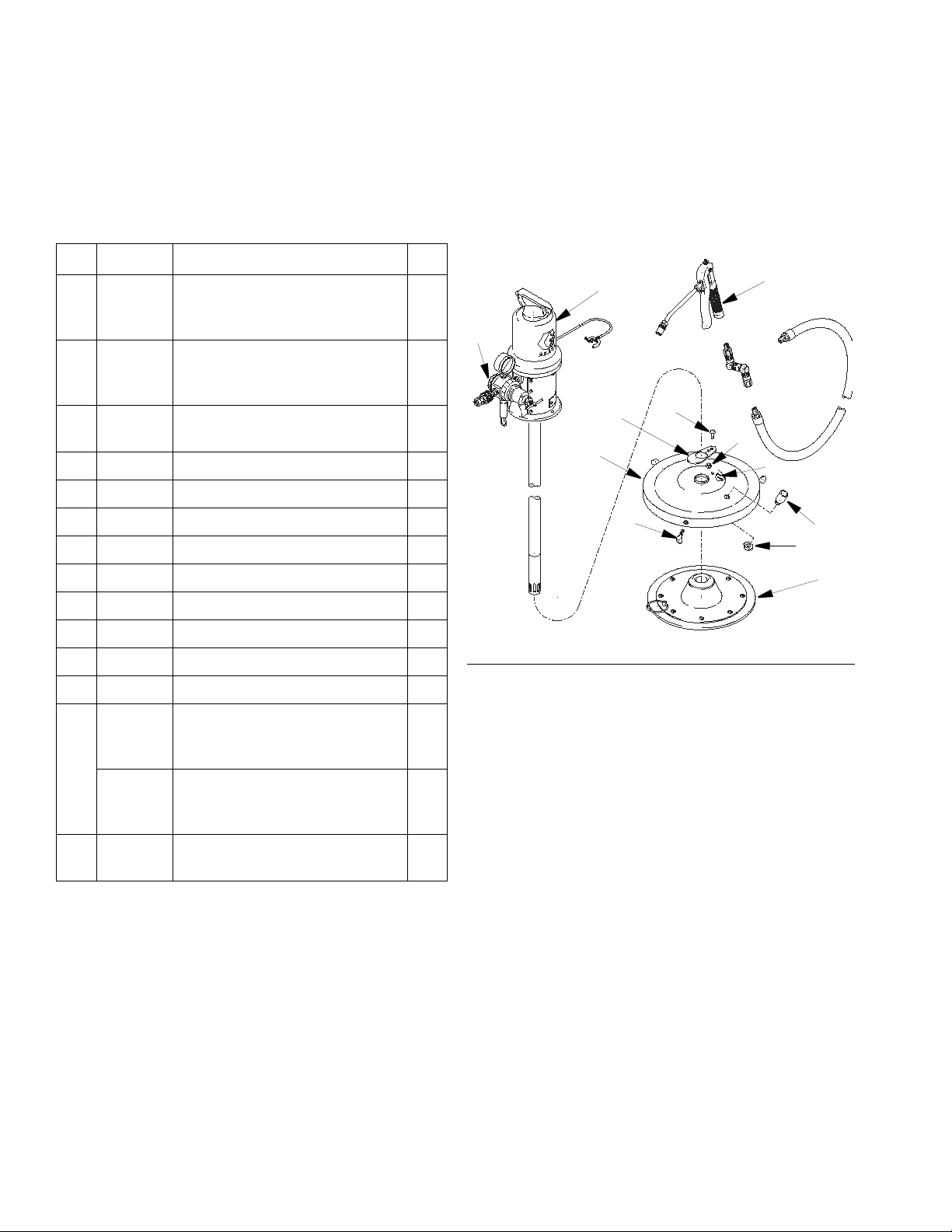

Models: 246910, 253362, 253384

35-50 lb (16-23 kg) pail size

Ref. Part Description Qty

.

1 246909 PUMP, Mini Fire-Ball 225 50:1

(with handle)

See manual 309966 for parts.

253361 PUMP, Mini Fire-Ball 225 50:1

(without handle) Model 253362

See manual 309966 for parts.

2 236058 DISPENSE KIT; 12 ft (3.7 m)

hose; See parts list on page 17.

4 222059 COVER; includes items 4a-4h

4a 207617 • COVER, pail

4b 168102 • PLATE, stop, pump

4c 158048 • BUMPER, button, rubber

4d 159608 • RIVET

4e 150868 • HOLDER, gun

4f 100220 • SCREW, thumb

4g 100025 • NUT, 1/4 npsm thd

4h 100579 • PIN, cotter; 1/8” x 1”

5 220653 FOLLOW PLATE, model

253384. See manual 306345

for parts.

24F901 FOLLOW PLATE, models

246910, 253362

See manual 306345 for parts.

9 240979 CE Kit for 253384

See parts on page 19.

1

1

1

1

1

1

1

1

3

FIG. 7: Model 253384 shown

1

1

1

1

1

12 309967C

Page 13

Parts

1

6

2

10

4

9

11

10

1

6

2

4

9

7

11

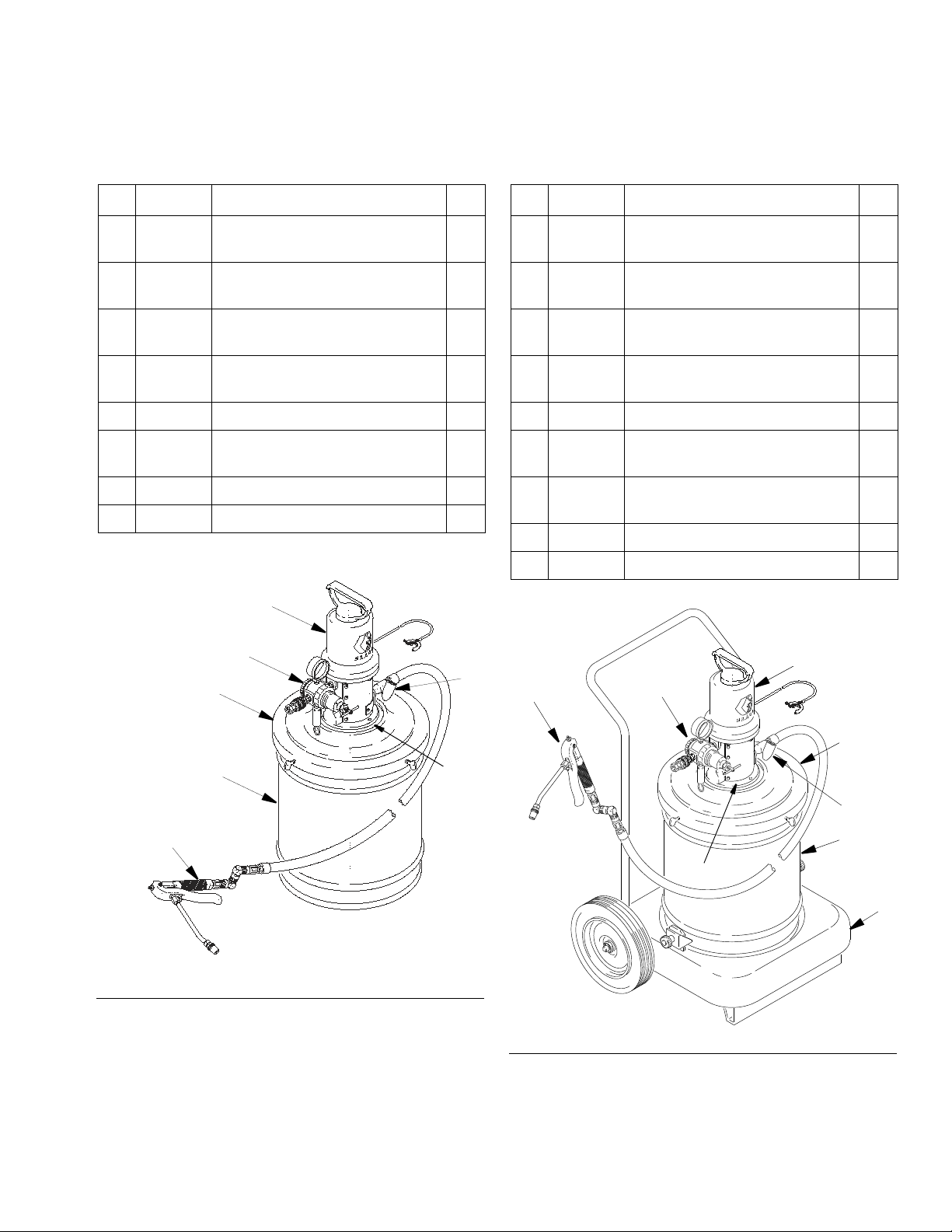

Models: 246911, 253385

35-50 lb (16-23 kg) pail size

Ref Part Description Qty

1 246909 PUMP, Mini Fire-Ball 225 50:1

See manual 309966 for parts.

2 236058 DISPENSE KIT; 12 ft (3.7 m)

hose; See parts list on page 17.

4 204574 COVER, model 253385.

See manual 306345 for parts.

24R350 COVER, model 245911.

See manual 306345 for parts.

6 203976 HOLSTER

9 240979 CE Kit for 253385

See parts on page 19.

10 204134 PAIL

11 176270 SHIM

Models: 246913, 253386

35-50 lb (16-23 kg) pail size

Ref Part Description Qty

1

1

1

1

1

1

1

1

1 246909 PUMP, Mini Fire-Ball 225 50:1

See manual 309966 for parts.

2 236058 DISPENSE KIT; 12 ft (3.7 m)

hose; See parts list on page 17.

4 204574 COVER, model 253386.

See manual 306345 for parts.

24R350 COVER, model 246913.

See manual 306345 for parts.

6 203976 HOLSTER

7 203650 TRUCK, 2-wheel;

See parts list on page 18.

9 240979 CE Kit for 253386

See parts on page 19.

10 204134 PAIL

11 176270 SHIM

1

1

1

1

1

1

1

1

1

FIG. 8: Model 253385 shown

FIG. 9: Model 253386 shown

309967C 13

Page 14

Parts

3

9

1

4

5

11

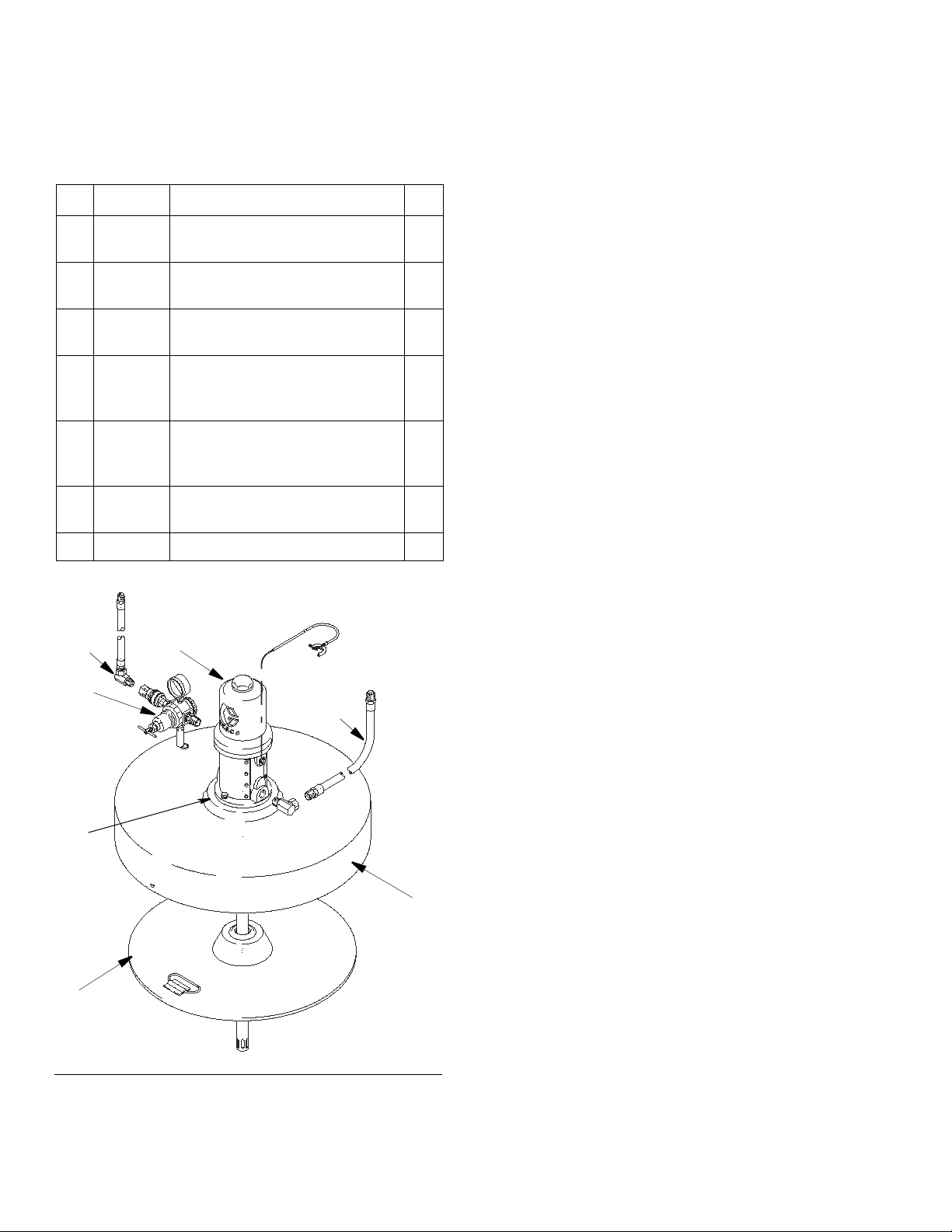

Models: 246914, 253387

120 lb (55 kg) drum size

Ref Part Description Qty

1 246780 PUMP, Mini Fire-Ball 225 50:1

See manual 309966 for parts.

3 222072 Hose and Fitting Kit; 6 ft (1.8 m)

hose; See parts list on page 17.

4 204574 COVER, model 253387.

See manual 306345 for parts.

24R350 COVER, model 246914. See

manual 306345 for parts.

5 220654 FOLLOW PLATE, model

253387. See manual 306345

for parts.

24F902 FOLLOW PLATE, model

246914. See manual 306345

for parts.

9 240979 CE Kit for 253387

See parts on page 19.

11 176270 SHIM

1

1

1

1

1

1

1

1

FIG. 10: Model 253387 shown

14 309967C

Page 15

Parts

2

4

1

9

5

8

6

11

1

4

5

6

2

7

9

11

Models: 246915, 253388

120 lb (55 kg) drum size

Ref Part Description Qty

1 246780 PUMP, Mini Fire-Ball 225 50:1

See manual 309966 for parts.

2 236058 DISPENSE KIT; 12 ft (3.7 m)

hose; See parts list on page 17.

4 204574 COVER, model 253388.

See manual 306345 for parts.

24R350 COVER, model 246915.

See manual 306345 for parts.

5 220654 FOLLOW PLATE, model

253388. See manual 306345

for parts.

24F902 FOLLOW PLATE, model

246915. See manual 306345

for parts.

6 203976 HOLSTER

8 203622 PORTABLE BASE;

See parts list on page 18.

9 240979 CE Kit for 235388

See parts on page 19.

11 176270 SHIM

Models: 246916, 253389

120 lb (55 kg) drum size

Ref Part Description Qty

1

1

1

1

1

1

1

1

1

1

1 246780 PUMP, Mini Fire-Ball 225 50:1

See manual 309966 for parts.

2 236058 DISPENSE KIT; 12 ft (3.7 m)

hose; See parts list on page 17.

4 204574 COVER, model 253389.

See manual 306345 for parts.

24R350 COVER, model 246916.

See manual 306345 for parts.

5 220654 FOLLOW PLATE, model

253389. See manual 306345

for parts.

24F902 FOLLOW PLATE, model

246916. See manual 306345

for parts.

6 203976 HOLSTER

7 203650 TRUCK, 2-wheel;

See parts list on page 18.

9 240979 CE Kit for 235389

See parts on page 19.

11 176270 SHIM

1

1

1

1

1

1

1

1

1

1

FIG. 11: Model 253388 shown

309967C 15

FIG. 12: Model 253389 shown

Page 16

Parts

5

1

4

9

3

3

11

Models: 246917, 253390

400 lb (180 kg) drum size

Ref Part Description Qty

1 246781 PUMP, Mini Fire-Ball 225 50:1

See manual 309966 for parts.

3 222072 Hose and Fitting Kit; 6 ft (1.8 m)

hose; See parts list on page 17.

4 200326 COVER

See manual 306345 for parts.

5 223845 FOLLOW PLATE, model

253390. See manual 306345

for parts.

24F903 FOLLOW PLATE, model

246917. See manual 306345

for parts.

9 240979 CE Kit for 253389

See parts on page 19.

11 176270 SHIM

1

1

1

1

1

1

1

FIG. 13: Model 253390 shown

16 309967C

Page 17

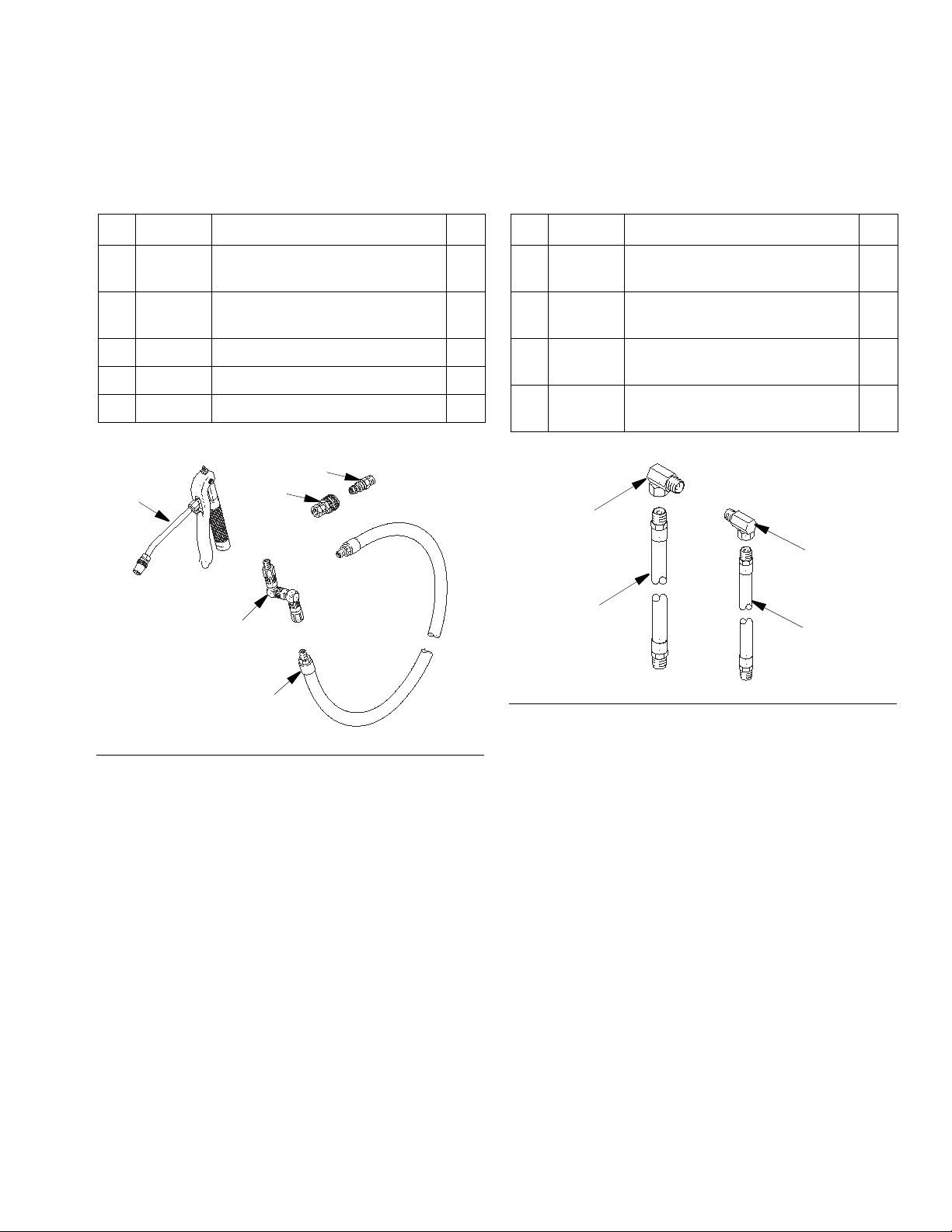

Components and Kits

2c

2a

2d

2b

2e

3d

3c

3b

3a

Ref No. 2: Dispense Kit 236058 Ref No. 3: Hose and Fitting Kit 222072

Parts

Ref Part Description Qty

2a 109151 HOSE; 1/4 npt(mbe) x 12 ft (3.7

m)

2b 242056 VALVE, grease dispense

See manual 309032

2c 114558 COUPLER, quick-disconnect

2d 169971 NIPPLE, quick-disconnect

2e 202577 Z-SWIVEL

Ref Part Description Qty

1

3a 203320 HOSE; air, buna-N; 3/8

npt(mbe) x 6 ft (1.8 m)

1

3b 155494 UNION, 90°; 3/8 npt(m) x 3/8

npsm(f) swivel

1

1

1

3c 109150 HOSE; fluid, buna-N; 1/4

npt(mbe) x 6 ft (1.8 m)

3d 155541 UNION, 90°; 1/4 npt(m) x 1/4

npsm(f) swivel

1

1

1

1

FIG. 15

FIG. 14

309967C 17

Page 18

Parts

7h

7d

7c

7f

7e

7b

7a

8b

8c

8e

8d

8a

8f

8g

Ref No. 7: Truck 203650 Ref No. 8: Portable Base 203622

Ref Part Description Qty

7a 203651 BASE, truck; bare

7b 101251 WHEEL

7c 159912 NUT, thumb, 5/16-18

7d 159913 CLAMP, hold down;

(for steel drums only)

7e 154636 WASHER, 5/8”, 16 GA

7f 100609 SCREW, machine, panhead;

1/4-20 x 0.375”

7g 101242 RING, retaining

7h 159924 HANDLE, truck

Ref Part Description Qty

1

2

2

2

8a 191750 BASE, drum

8b 102547 BOLT, hex head; 5/16”-18 x

1.5”

8c 100214 WASHER, lock

8d 191747 BRACKET

4

2

8e 100132 WASHER, flat

8f 113660 RIVET

8g 113646 CASTER; polyurethane

2

1

1

2

2

2

2

16

4

FIG. 16

FIG. 17

18 309967C

Page 19

Ref No.9: CE Kit 240979

9c

9d

9a

9b

Ref Part Description Qty

Sound Data

9a 156849 NIPPLE

9b 109075 REGULATOR, air, with gauge

9c 103347 VALVE, safety

9d 222011 CLAMP, grounding

9e † CE Label (not shown)

† Attention: To comply with CE directives, the CE

identification label must be affixed to the back of the

cart or to the top of the drum cover. Permanently mark

the date of assembly on the label.

1

1

1

1

1

FIG. 18

Sound Data

See the pump instruction manual for technical data including wetted parts, port sizes, maximum air consumption,

maximum delivery, and so on. Sound data for the air motors of the pumps on these portable units is as follows:

Tested at 140 psi (1.0 MPa, 10 bar) at 100 cycles per minute

Sound Pressure Level, measured at 1 meter from unit 77.8 dB(A)

Sound Power Level, tested in accordance with ISO 9614-2 85.6 dB(A)

309967C 19

Page 20

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2007, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 309678

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

revised January 2015

Loading...

Loading...