Page 1

Instructions

Pump Wet-cup Flush

Kits

309911C

COMPLETE KITS CONVERT ELECTRIC REACTOR™ TO WET-CUP FLUSH

DESIGN

Kits include reservoir, pump wet-cup, tubes, and fittings

Part No. 248061, for Reactor Models E-20 and E-XP1

Part No. 248062, for Reactor Model E-XP2

Part No. 248063, for Reactor Model E-30

EN

RESERVOIR KIT MODIFIES ELECTRIC REACTOR TO USE WET-CUP FLUSH

DESIGN

Kit includes reservoir, tubes, and fittings (pump not included)

Part No. 246928

TI3765a-2

Page 2

Flush Pump Before Installing Kit

Flush Pump Before

Installing Kit

WAR NING

Read warnings in Reactor operation manual. Flush

equipment only in a well-ventilated area. Do not spray

flammable fluids. Do not turn on heaters while flushing

with flammable solvents.

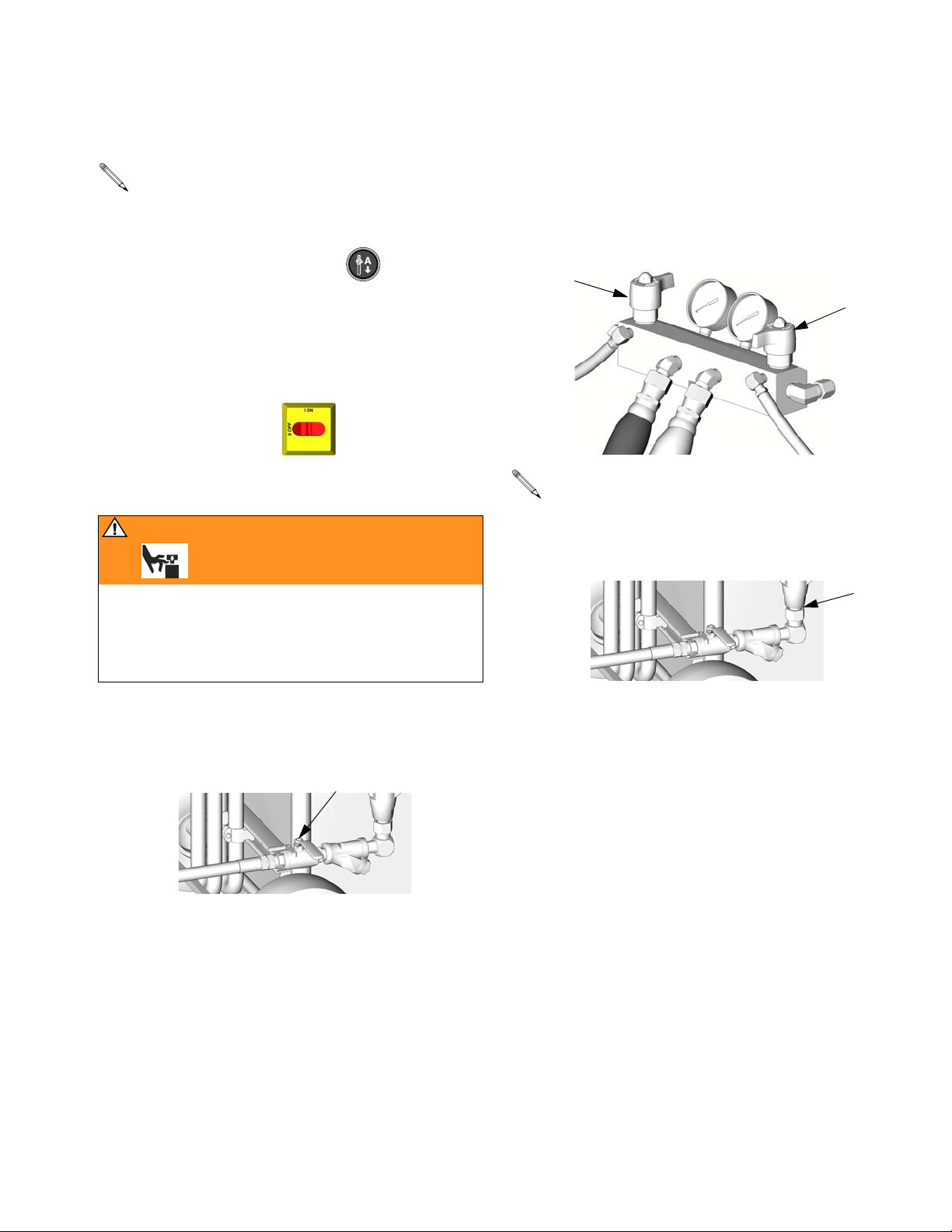

See FIG. 1. Flush component A (ISO) side from pump A

inlet (C) to PRESSURE RELIEF/SPRAY valve (SA) on

Reactor fluid manifold. See Reactor operation manual

for details.

SA

Tools Required

• 12 in. adjustable wrench

• 1/4 in. open end wrench

• 7/16 in. open end wrench

• 13/16 in. open end wrench

• 7/8 in. open end wrench

• non-sparking hammer

• channel locks

• dropcloth and rags

• vise with soft jaws

• thread sealant

F

C

TI2602a

IG. 1

2 309911C

Page 3

Disassembly

Disassembly

Numbers and letters in parentheses refer to the figures and the parts list and drawing on page 9.

1. If pumps are not parked, press . Trigger gun

until pumps stop. After fluid pressure drops below

700 psi (4.9 MPa, 49 bar), motor will run until pumps

are at bottom of strokes, then shut off. Pump rod

pins will be showing.

2. Turn main power OFF . Disconnect power

supply.

WAR NING

Pump rod and connecting rod move during operation.

Moving parts can cause serious injury such as pinching or amputation. Keep hands and fingers away from

connecting rod during operation. Read warnings in

Reactor operation manual.

4. Turn both PRESSURE RELIEF/SPRAY valves (SA,

SB) to PRESSURE RELIEF. Route fluid to waste

containers or supply tanks. Ensure gauges drop to

0. Refer to Reactor operation manual.

SA

SB

TI2481a

Use dropcloth or rags to protect Reactor and surrounding area from spills.

5. Disconnect swivel elbow from pump A fluid inlet (C).

C

TI4174a

3. Shut off both feed pumps. Close both fluid inlet ball

valves (B).

B

TI4174a

309911C 3

Page 4

Disassembly

6. See F

IG. 2. Disconnect outlet tube (D) from pump A

outlet and from heater inlet.

7. Push retaining wire clip (S) up. Push pin (P) out.

Loosen star-shaped locknut (G) by hitting firmly with

a non-sparking hammer. Unscrew pump from bearing housing (H).

P

S

H

F

IG. 2

D

TI2602a

G

4 309911C

Page 5

Installation

Installation

1. Place pump in vise with soft jaws. Remove brass

packing nut assembly.

TI4093a

2. Install new wet-cup assembly (10). Screw it all the

way down, so external o-ring (R) seats on top of

pump housing. Wrap base of wet-cup with a rag and

tighten securely with channel locks.

10

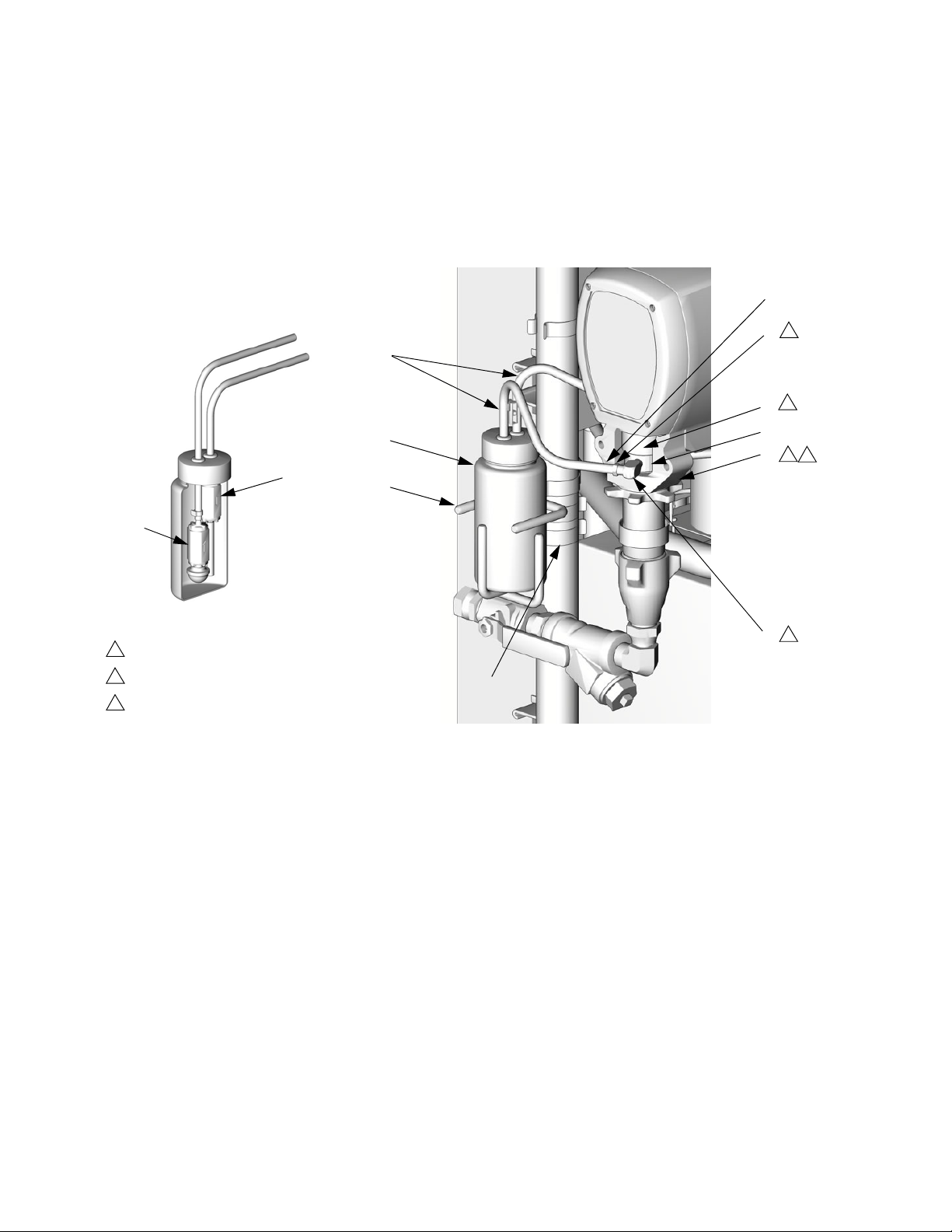

4. Wet-cup (10) has four 1/8 npt ports. Two will be

obstructed by bearing housing (H) when pump is

installed. Note or mark these ports. Remove pump.

Apply thread sealant and install plugs (3) in the two

obstructed ports. Torque plugs to 10-15 ft-lb (14-20

N•m). Do not overtighten.

3

10

R

G

3

H

TI4331a

D

R

TI4094a

3. Screw pump (A) into bearing housing (H) until top

threads are level with bearing face (N). Rotate pump

to align pump outlet fitting to outlet tube (D).

D

A

H

N

TI4171a

5. Ensure star-shaped locknut (G) is screwed on pump

with flat side up. Carefully twist and extend the rod

(R) 2 in. (51 mm) above the wet-cup assembly (10).

6. Start threading pump (A) into bearing housing (H).

Place finger guard (9) over rod when it is accessible

through window of bearing housing (H). When pin

holes align, insert pin. Pull retaining wire clip down.

10

A

H

N

TI4171a

Finger guard is not used on Model E-30.

7. Seat finger guard on wet-cup (10). Continue threading pump into bearing housing (H) until top threads

are +/- 1/16 in. (2 mm) of bearing face (N).

309911C 5

Page 6

Installation

8. Apply thread sealant and screw barbed fitting (2)

into motor side of wet-cup (10). Torque to 10-15 ft-lb

(14-20 N•m). Do not overtighten.

9. Apply thread sealant and screw elbow (8) into

remaining wet-cup port. Torque to 10-15 ft-lb (14-20

N•m). Do not overtighten.

10. Apply thread sealant and screw barbed fitting (2)

into elbow (8). Torque to 10-15 ft-lb (14-20 N•m). Do

not overtighten.

11. Connect component A outlet tube (D) loosely at

pump and at heater. Line up tube, then tighten fittings securely.

12. Tighten star-shaped locknut (G) by hitting firmly with

a non-sparking hammer.

13. Position holder (4) on Reactor frame upright and

secure with two spring clips (5).

14. Fill reservoir (1) 3/4 full with TSL (6). Place in holder

(4).

15. Apply thin film of TSL to barbed fittings (2). Using

two hands, support tubing (1a) while pushing it

straight onto barbed fittings (2). Do not let tubing

kink or buckle. Secure each tube with a wire tie (7)

between two barbs.

16. Connect swivel elbow (C) to pump fluid inlet.

17. Purge Air and Prime Flush Kit, page 7.

1a

1

Torque to 10-15 ft-lb (14-20 N•m). Do not overtighten.

2

Apply thin film of TSL to barbs.

Top View of Wet-Cup

1a

5

1

4

9

10

2

1

2

8

1

3

1

D

2

2

1

G

C

3

1

1a

TI4331aTI4173a

F

IG. 3

6 309911C

Page 7

Purge Air and Prime Flush Kit

Purge Air and Prime Flush Kit

1. Open fluid inlet ball valves (B).

B

TI4173a

2. Turn on feed pumps.

3. Secure bleed lines (L) in grounded, sealed waste

containers.

4. Slowly turn both PRESSURE RELIEF/SPRAY

valves (SA, SB) to SPRAY.

SA

5. Run motor in jog mode.

6. Each time pump A rod reaches bottom of stroke,

check that some TSL is pumped from reservoir (1),

through wet-cup (10), and back to reservoir.

1

10

TI4173a

7. When system is fully loaded, check that reservoir is

3/4 full of TSL. Be sure all air is purged from pumps,

lines, and heaters through PRESSURE

RELIEF/SPRAY valves (SA, SB). Trapped air can

cause mix problems at gun.

8. Return Reactor to service.

SB

L

L

TI2482a

309911C 7

Page 8

Maintenance

Maintenance

Changing the TSL

Part No. 206995 Throat Seal Liquid (TSL) carries isocyanate from the pump rod into the reservoir. After some

time the TSL will thicken and darken, and must be

replaced. Thick, dirty TSL will not pump through the

lines and will harden in the pump wet-cup.

How long TSL lasts depends on which chemicals are

used, how much is used, what pressure, and condition

of the pump seal and rod. Check the condition of the

TSL every week, minimum, and change when needed.

To change TSL:

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, see Reactor operation manual.

3. Remove reservoir cap. Empty reservoir (1). Clean

any residue.

5. Fill reservoir 3/4 full with TSL (6).

6. Run pump. Each time pump A rod reaches bottom of

stroke, check that some TSL is pumped from reservoir (1), through wet-cup (10), and back to reservoir.

1

10

TI4173a

Converting to a New Component

A (ISO) Pump

4. Clean screen (V) of inlet check valve (1c). If check

valves are not sealing and dirty TSL is getting into

the wet-cup, replace the check valves (1b, 1c).

1b

1c

V

TI4170a

Part No. 246928 includes reservoir, tubing, and fittings

necessary to modify the Reactor to use the wet-cup

flush design. Order the pump separately, see below.

Refer to displacement pump manual 309577 for further

information.

Reactor Model Order Pump No.

E-20, E-XP1 246830

E-XP2 246831

E-30 246832

8 309911C

Page 9

Parts

248061 Complete Kit, Models E-20 and E-XP1; includes items 1-10

248062 Complete Kit, Model E-XP2; includes items 1-10

248063 Complete Kit, Model E-30; includes items 1-8, 10

246928 Reservoir Kit, All Models; includes items 1-8

Parts

Detail of Check Valves

1a

1

1b

4

1c

TI4170a

1

Torque to 10-15 ft-lb (14-20 N•m).

2

Out of view.

3

Not used on Model E-30.

Ref.

No. Part No. Description Qty

1 246995 ASSEMBLY, reservoir; includes 1a-1c 1

1a 054826 . TUBE; PTFE; 1/4 in. (6 mm) ID;

1b 118433 . VALVE, check, outlet 1

1c 118432 . VALVE, check, inlet 1

2 116746 FITTING, barbed 2

3 C19263 PLUG, pipe; 1/8 npt 2

4 15C568 HOLDER, reservoir 1

5 186494 CLIP, spring 2

6 206995 THROAT SEAL LIQUID; 1 qt (1 liter) 1

7 103473 WIRE TIE 2

2 ft (0.6 m)

7

2

1

3

9

10

3

1

2

8

1

5

Ref.

No. Part No. Description Qty

8 191892 ELBOW; 1/8 npt (m x f) 1

9 15C587 GUARD, finger; E-20 and E-XP1; used

2

15C588 GUARD, finger; E-XP2; used on Kit

10 246962 KIT, wet-cup conversion; E-20 and

246963 KIT, wet-cup conversion; E-XP2; used

246964 KIT, wet-cup conversion; E-30; used in

on Kit 248061

248062

E-XP1; used in Kit 248061; see 309577

for parts

in Kit 248062; see 309577 for parts

Kit 248063; see 309577 for parts

TI3765a-2

1

1

1

1

1

309911C 9

Page 10

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material

and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance

of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1-800-367-4023 Toll Free

612-623-6921

612-378-3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2003, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 309911

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision C, January 2014

Loading...

Loading...