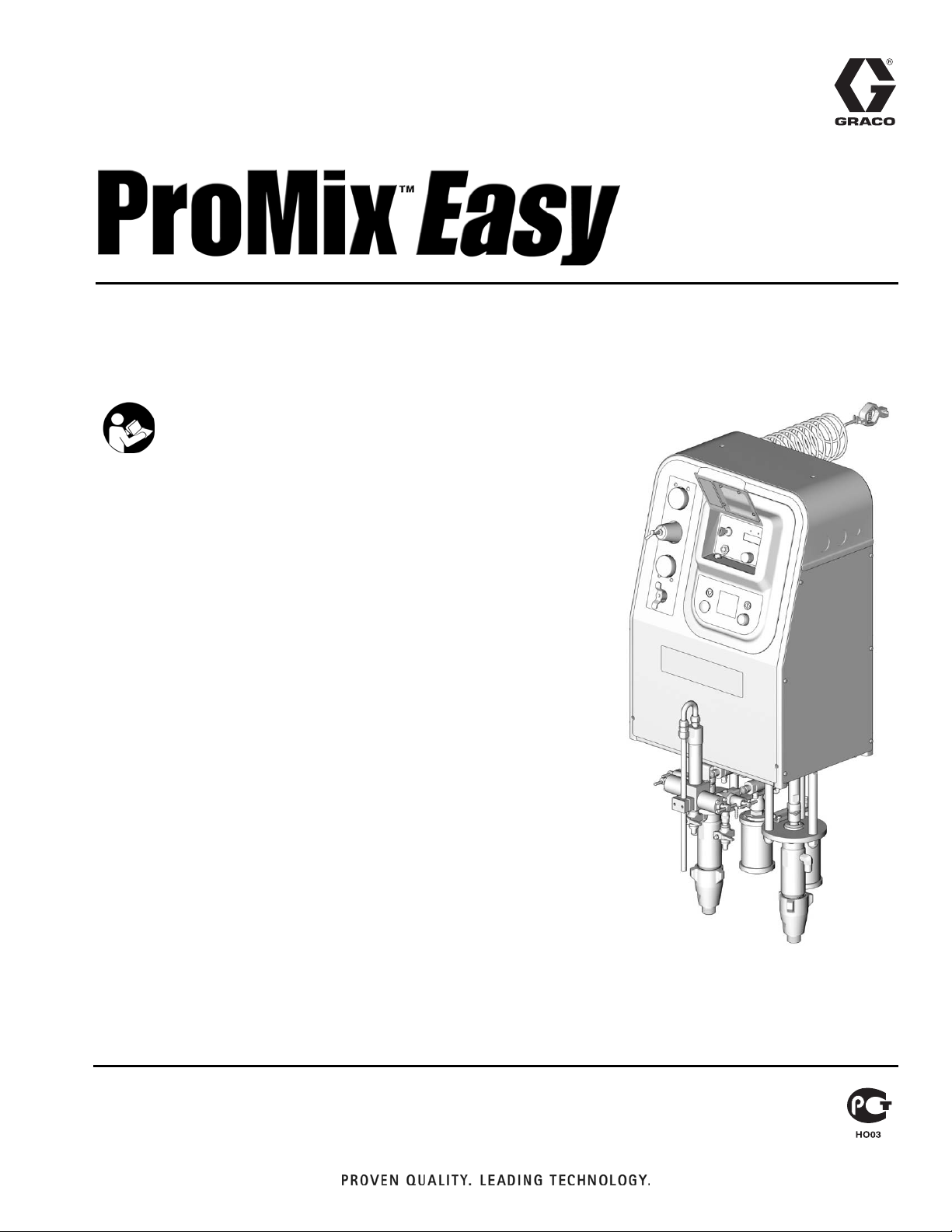

Page 1

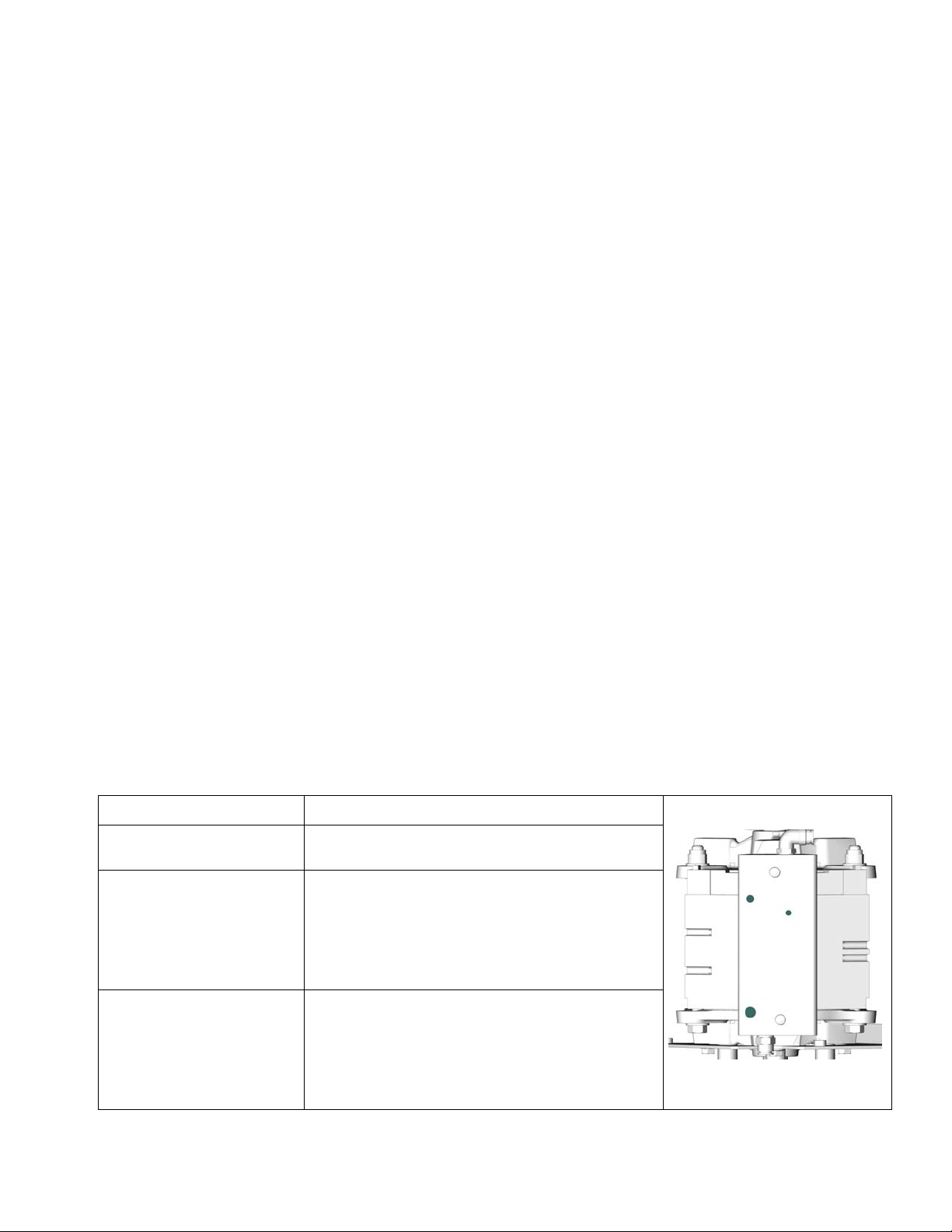

Repair - Parts

Self-contained, single color, electronic plural component paint proportioner.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 3 for model information, including maximum working pressure and approvals.

309909H

ENG

TI4909a

Page 2

Manual Conventions

Contents

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2

ProMix Easy Models . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 7

Fluid Manifold to Gun . . . . . . . . . . . . . . . . . . . . . 7

Pump to Fluid Manifold . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Preventive Maintenance Schedule . . . . . . . . . . . 9

Mix Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dispense Valve . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Turbine Alternator . . . . . . . . . . . . . . . . . . . . . . . . 9

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pump Test/Meter Calibration . . . . . . . . . . . . . . . . 9

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Icing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replacing Air Filter Element . . . . . . . . . . . . . . . 15

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pneumatic Control . . . . . . . . . . . . . . . . . . . . . . 19

Dispense Valve/Mix Manifold Assembly . . . . . . 21

Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . 21

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . 22

248349 Main Control Board Schematic . . . . . . . . 23

246899 Pump Solenoid Expansion Board

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Part No. 234596 Series A, Pump-based,

Cart-mounted Air Spray Unit . . . . . . . . . . . . 24

Pump and Meter-based, Wall-mounted

Air Spray Units . . . . . . . . . . . . . . . . . . . . . . 27

Pump-based, Wall-mounted Air Spray Units . . . 30

Meter-based, Wall-mounted High Pressure

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pump-based, Wall-mounted High Pressure

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Pump and Meter-based, Wall-mounted High

Pressure Units . . . . . . . . . . . . . . . . . . . . . . 40

Tube Connections, Low Pressure Pumps . . . . . 44

Tube Connections, High Pressure Pumps . . . . . 45

Tube Connections, Meters . . . . . . . . . . . . . . . . . 46

Pneumatic Schematic . . . . . . . . . . . . . . . . . . . . 47

248270 Intrinsically Safe Pneumatic Control . . . 48

248316 Non-intrinsically Safe

Pneumatic Control . . . . . . . . . . . . . . . . . . . 50

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 52

287230 Pump Air Control . . . . . . . . . . . . . . . . . 53

287231 Meter Air Control . . . . . . . . . . . . . . . . . 53

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 56

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 56

Manual Conventions

WARNING

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage or

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

Warnings included in instructions generally have a

symbol indicating the hazard. Follow the instructions

and read the hazard section on warning pages 5 to 6

for additional information.

2 309909H

destruction of equipment.

Note

A note indicates additional helpful information.

CAUTION

Page 3

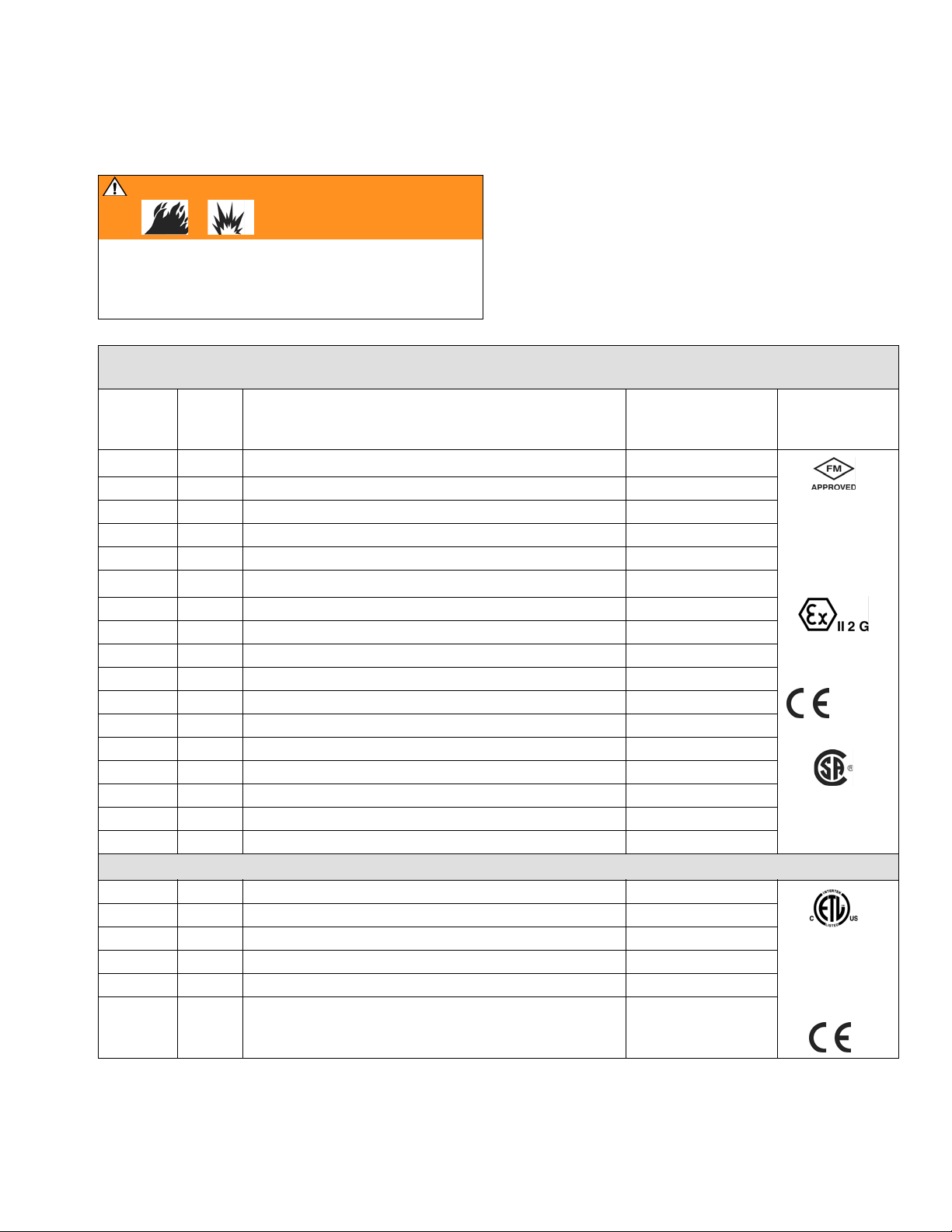

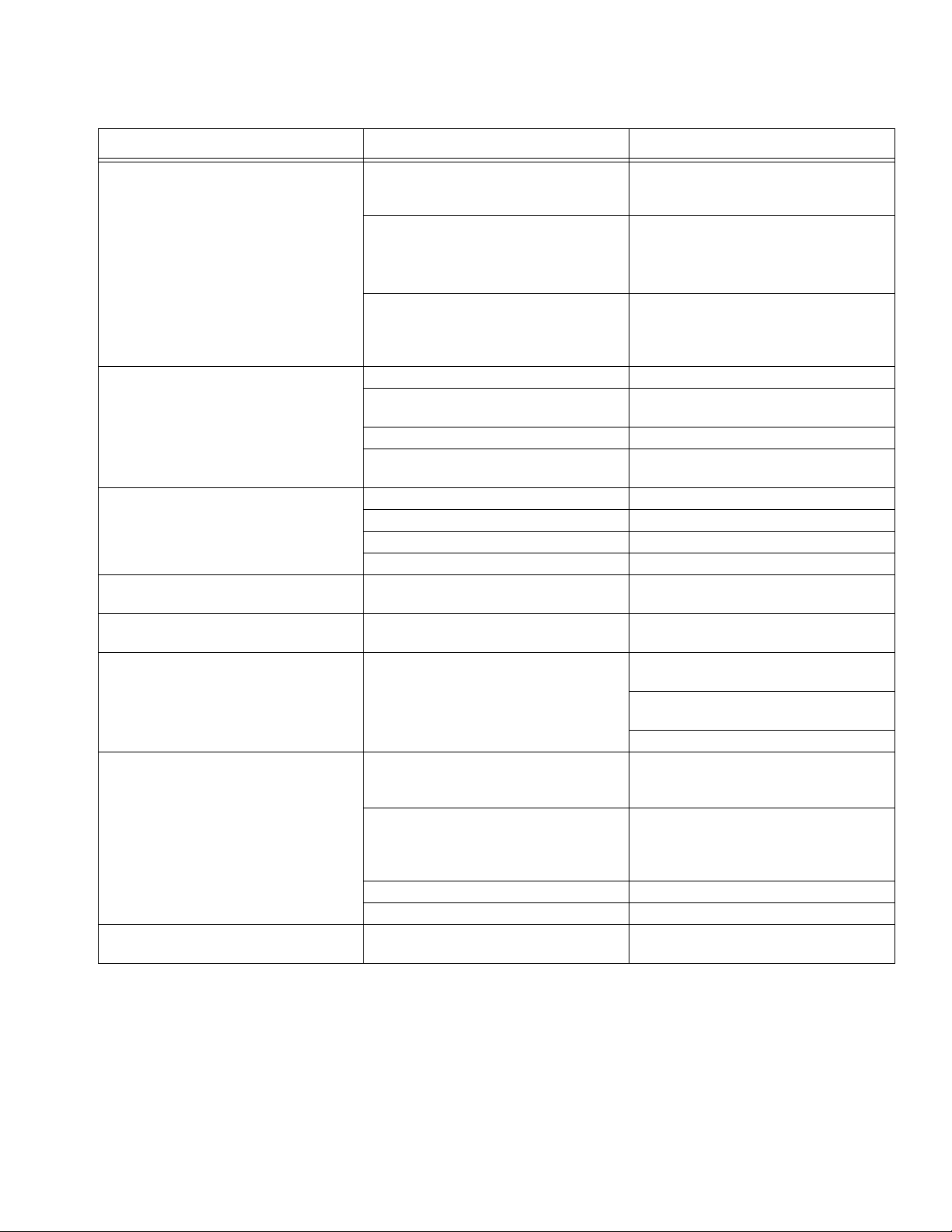

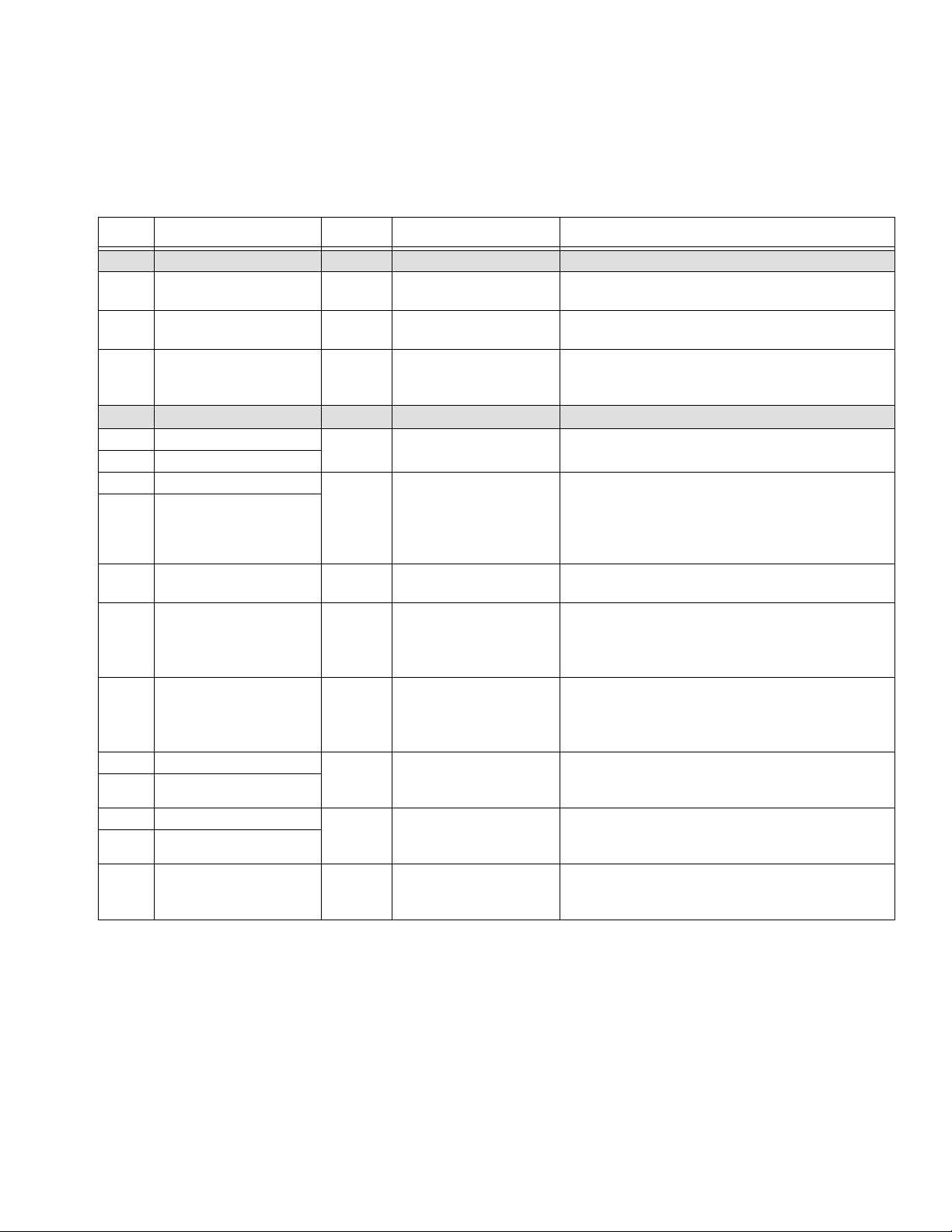

ProMix Easy Models

WARNING

Do not install equipment approved only for non-hazardous location in a hazardous area. Substitution of

components may impair intrinsic safety and cause personal injury. Read page 5.

Approved for Hazardous Location

Class I, Div 1, Group D (North America); Class I, Zones 1 and 2 (Europe)

ProMix Easy Models

ProMix

Easy

Part No. Series Description

234596 A

234597 A

234598 A

234599 A

234601 A

234602 A

234603 A

234604 A

234605 A

234606 A

234608 A

234609 A

234611 A

234612 A

234613 A

234618 A

234619 A

Cart mount, UltraMix

Wall mount, UltraMix cst* Pump/G3000 Meter

Wall mount, UltraMix sst** Pump/G3000 Meter

Wall mount, UltraMix cst* Pumps

Wall mount, UltraMix sst** Pumps

Wall mount, HydraMix

Wall mount, HydraMix 500 sst** Pump/G3000 Meter

Wall mount, HydraMix 600 cst* Pump/G3000 Meter

Wall mount, HydraMix 600 sst** Pump/G3000 Meter

Wall mount, HydraMix 500 cst* Pumps

Wall mount, HydraMix 500 sst** Pumps

Wall mount, HydraMix 600 cst* Pumps

Wall mount, HydraMix 600 sst** Pumps

Wall mount, HydraMix 700 cst* Pumps

Wall mount, HydraMix 700 sst** Pumps

Wall mount, G3000 Meter, cst* mix manifold

Wall mount, G3000 Meter, sst** mix manifold

™

cst* Pumps, hose and gun

™

500 cst* Pump/G3000 Meter

Approved for Non-hazardous Location

234600 A

234825 A

234607 A

234826 A

234610 A

234827 A

Wall mount, UltraMix cst* Pumps

Wall mount, UltraMix sst** Pumps

Wall mount, HydraMix 500 cst* Pumps

Wall mount, HydraMix 500 sst** Pumps

Wall mount, HydraMix 600 cst* Pumps

Wall mount, HydraMix 600 sst** Pumps

Maximum Working

Pressure

psi (MPa, bar) Approvals

250 (1.7, 17)

250 (1.7, 17)

250 (1.7, 17)

250 (1.7, 17)

250 (1.7, 17)

Conforms to

FM std 3600 & 3610

for use in

Class I Div 1

Group D T3

Hazardous Locations

2400 (16, 166)

2400 (16, 166)

3400 (23, 234)

3400 (23, 234)

ISSeP 04 ATEX 020X

EEx ia p IIA T3

2400 (16, 166)

2400 (16, 166)

3400 (23, 234)

3400 (23, 234)

4700 (32, 324)

4700 (32, 324)

4000 (28, 280)

CAN/CSA

22.2 No. 157-92

& No. 1010.1-92

4000 (28, 280)

250 (1.7, 17)

250 (1.7, 17)

2400 (16, 166)

2400 (16, 166)

3400 (23, 234)

3400 (23, 234)

9902471

Conforms to

UL61010A-1

Certified to

CAN/CSA

22.2 No. 1010.1-92

0359

* cst=carbon steel. ** sst=stainless steel.

309909H 3

Page 4

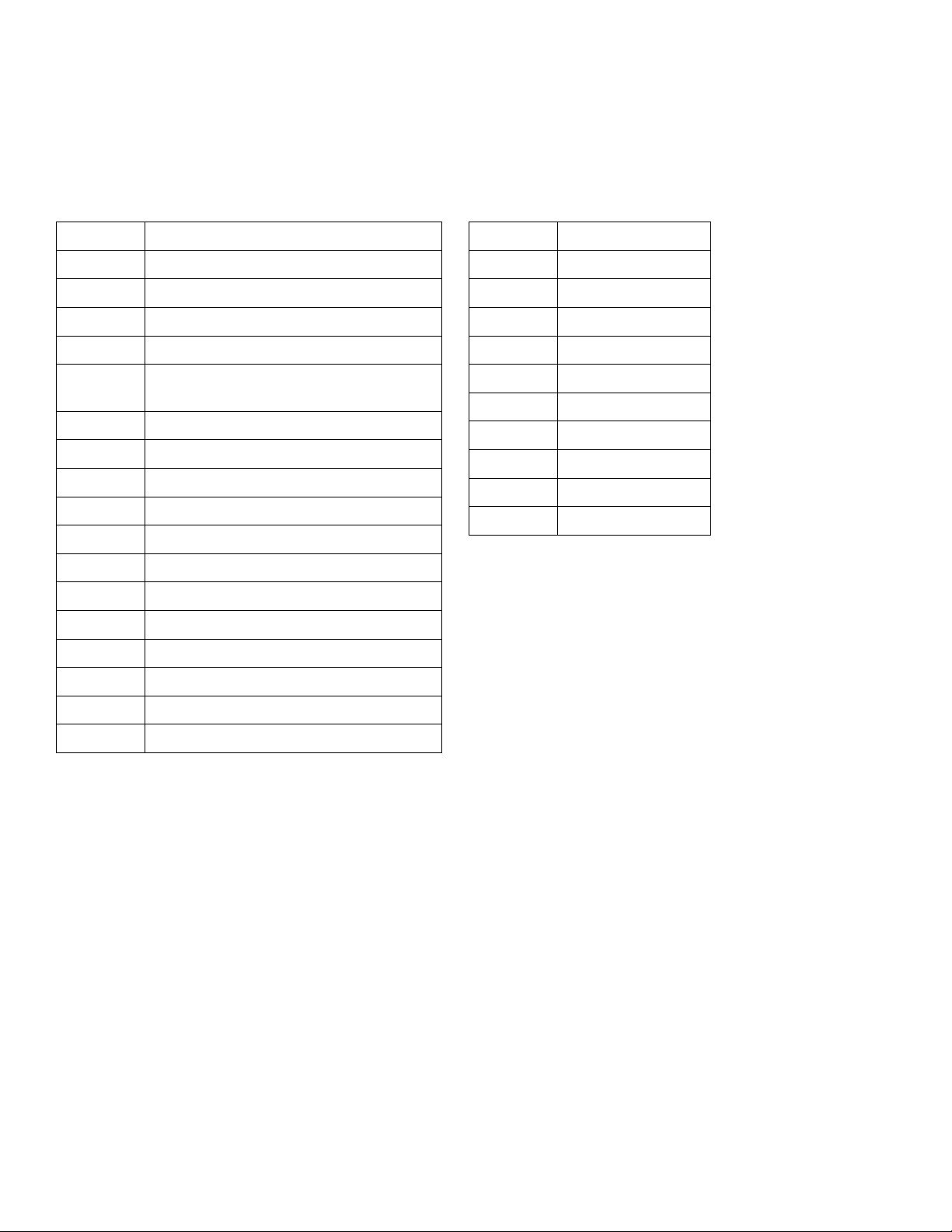

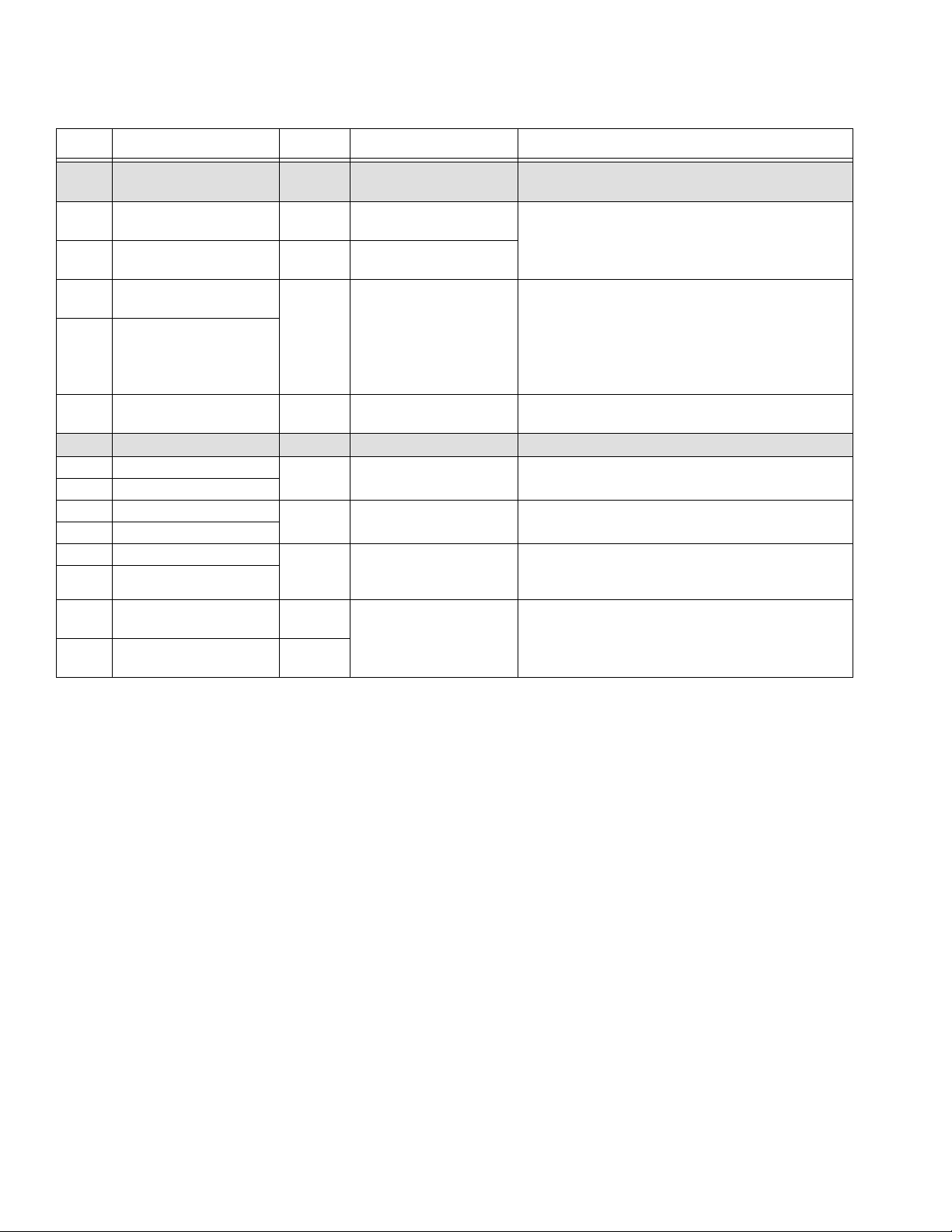

Related Manuals

Related Manuals

Component Manuals in English This manual available in the following languages:

Manual Description

309908 ProMix Easy Operation

309909 ProMix Easy Repair-Parts

310654 Fluid Mix Manifold

310655 Dispense Valve

310662 UltraMix and HydraMix Displacement

Pumps

310671 UltraMix Pumps

310672 HydraMix Pumps

310673 Circulation Kits

310674 Stand and Caster Kits

310675 AC Power Supply

310676 Remote Manifold Kit

310677 Heater Installation Kit

310678 TSL Pump Kits

309192 ISO Supply Kit

309623 Data Download Kits

Manual Language

309909 English

310680 French

310682 Spanish

310684 German

310686 Italian

310688 Chinese

310690 Japanese

310769 Dutch

310771 Finnish

310773 Swedish

308778 G3000 Flowmeter

308034 Turbine Alternator Repair Kit

4 309909H

Page 5

Warnings

Warnings

The following general warnings are related to the safe setup, use, grounding, maintenance, and repair of this equipment. Additional more specific warnings may be found throughout the text of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground equipment and conductive objects in work area. See Setup instructions in ProMix Easy

Operation manual 309908.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like

just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

309909H 5

Page 6

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kind or overbend hoses or use hoses to pull equipment.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

6 309909H

Page 7

Pressure Relief Procedure

Pressure Relief Procedure

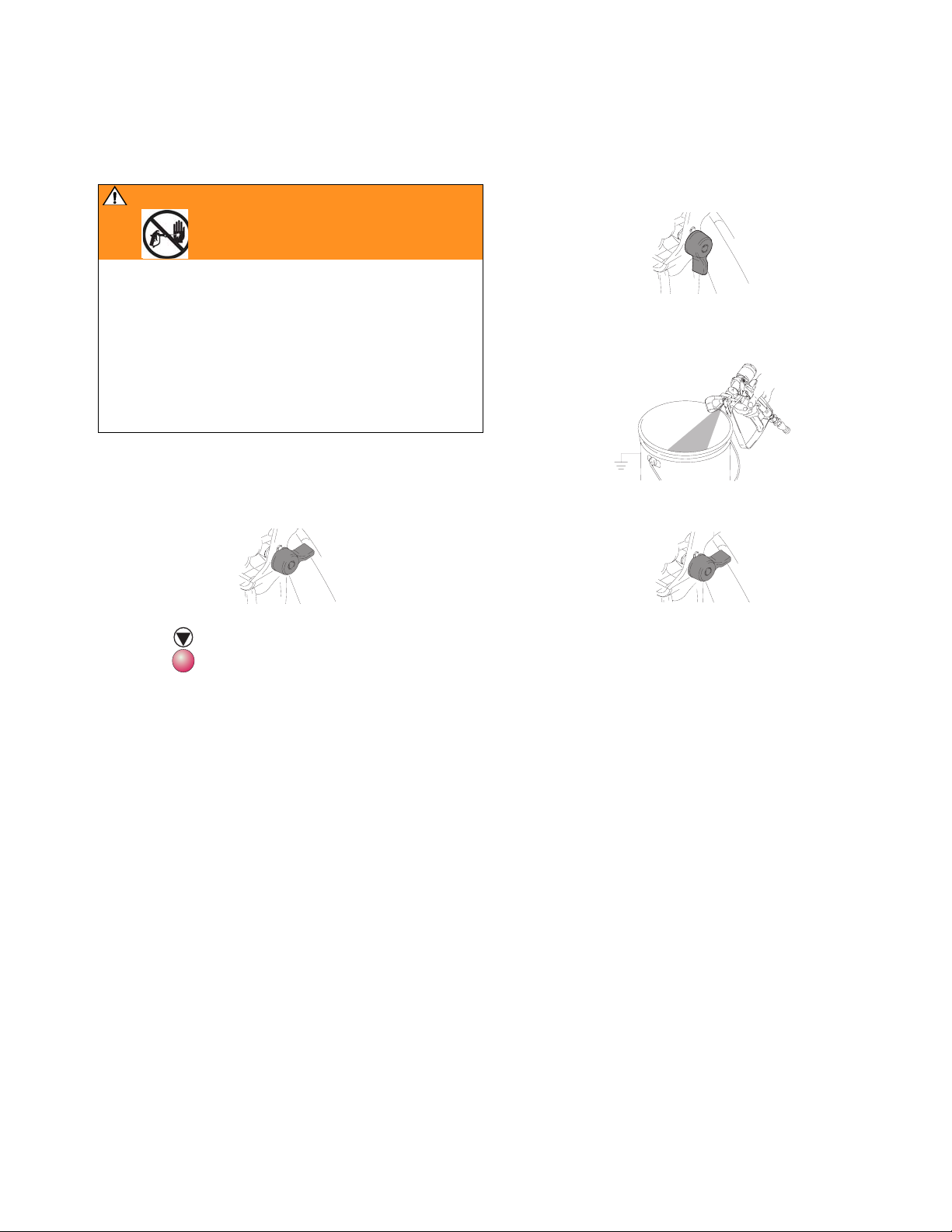

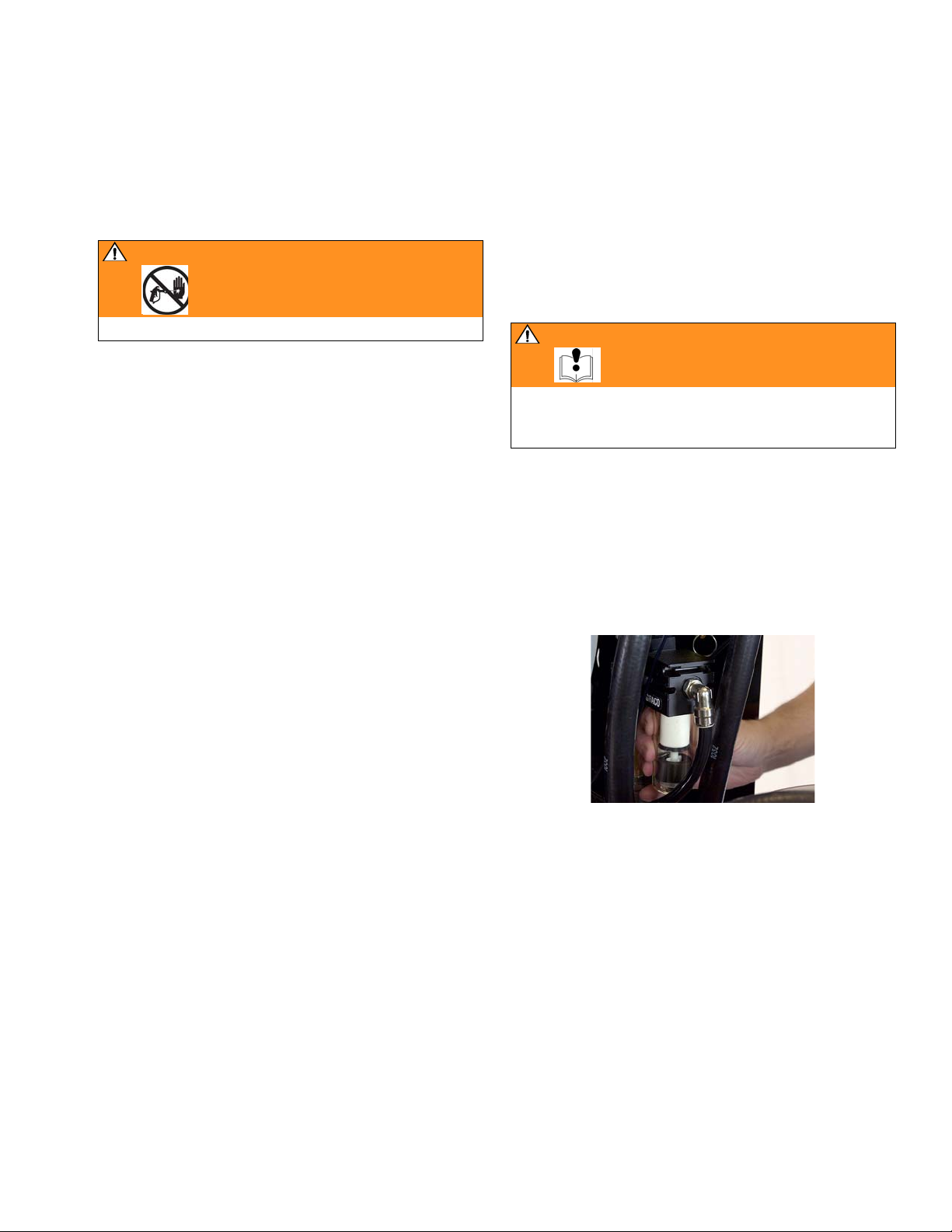

WARNING

Relieve pressure from fluid manifold to gun whenever

you stop spraying and before servicing gun or removing spray tip.

In addition, relieve pressure from pump to fluid manifold at end of day and before cleaning, checking, or

servicing pump, manifold, or fluid line accessories or

transporting equipment.

Read warnings, page 5.

Fluid Manifold to Gun

1. Engage trigger lock.

3. Disengage trigger lock.

4. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve pressure.

5. Engage trigger lock.

2. Press .

309909H 7

Page 8

Pressure Relief Procedure

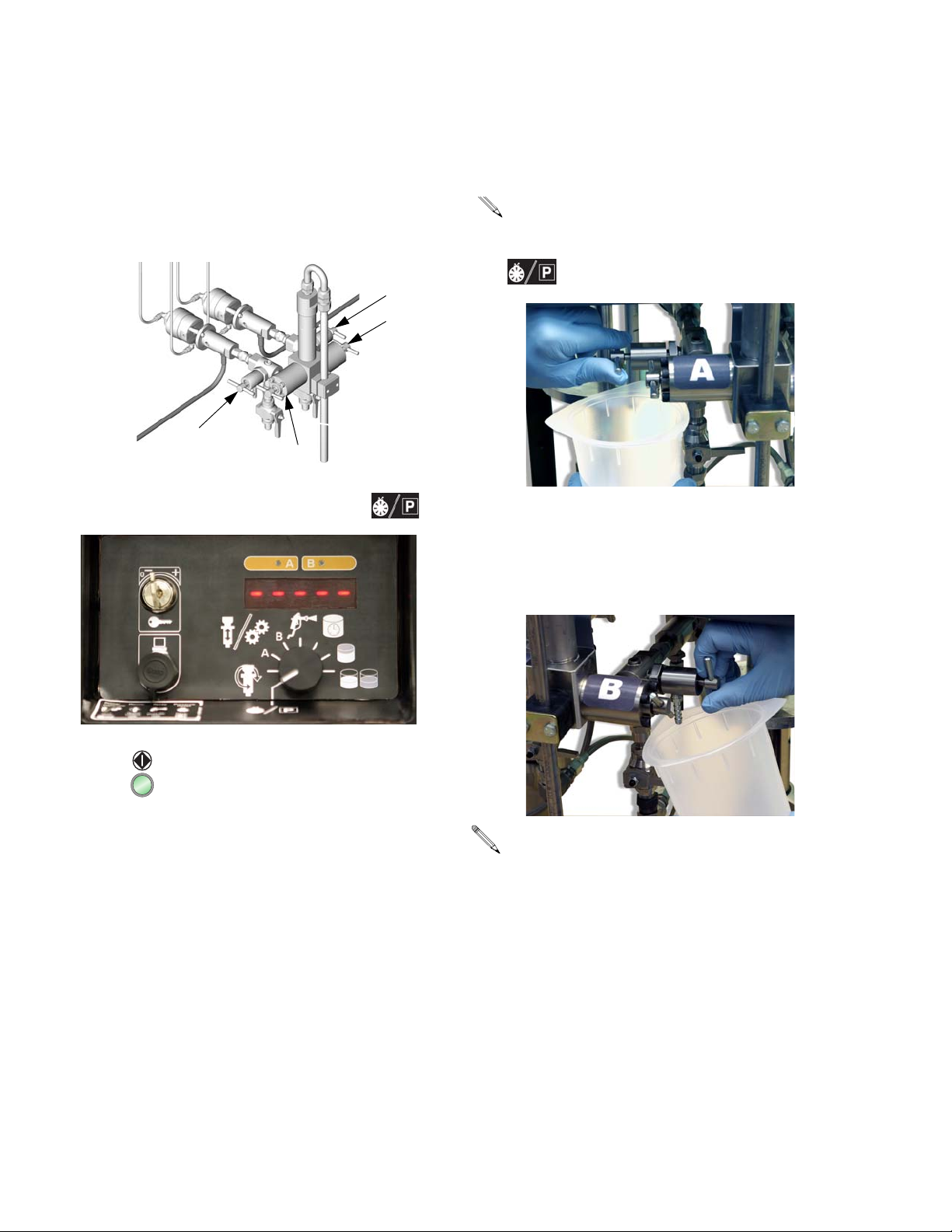

Pump to Fluid Manifold

1. Close shutoff valves G

2. Place waste container under sampling valves H

B

and H

.

A

H

3. Turn function knob to pressure relief/park .

A

and GB.

A

B

H

B

G

A

G

TI4699a

5. Open sampling valve A slowly to bleed off pressure.

Indicator A will stay on for 5 sec after Pump A

reaches Park position, then go off.

Pump air supply pressure must be sufficient to

cause pumps to stroke to bottom-most position

when function knob to is set to pressure relief/park

.

6. Indicator B comes on and Pump B pressurizes.

7. Open sampling valve B slowly to bleed off pressure.

Indicator B will stay on for 5 sec after Pump B

reaches Park position, then go off.

4. Press . Indicator A comes on, and Pump A pres-

surizes.

If both pumps are not parked after 1 min, Alarm

26 will sound.

8. Close sampling valves A and B before restarting

system.

8 309909H

Page 9

Maintenance

Maintenance

Preventive Maintenance Schedule

Establish a preventive maintenance schedule, based on

the pump’s repair history.

Mix Manifold

See mix manifold manual 310654.

Dispense Valve

See dispense valve manual 310655.

Pump

See applicable pump manual 310671, 310672, or

310662.

Turbine Alternator

Replace bearings every 2000 hours. See page 19.

Air Filters

Check daily. Drain and clean as necessary. See page

15.

Pump Test/Meter Calibration

See ProMix Easy Operation manual. If pumps/meters

fail test, see Troubleshooting, page 10.

Wet Cup

Check pump and dispense valve wet-cups daily. Keep

filled with Graco Throat Seal Liquid (TSL), Part No.

206995.

Storage

Before storing the pump, always flush it, see ProMix

Easy Operation manual. Relieve the pressure, page 7.

Icing

If you experience icing at the pump air manifold:

• Reduce pump input air pressure below 80 psi (0.56

MPa, 5.6 bar), if required spray pressure allows.

• Reduce moisture in compressed air supply, or use

heated air.

If icing persists, see table below.

Problem Solution

Pump slows on both up

and down stroke.

Pump slows on down

stroke.

Pump slows on up stroke. Turn U port bleed screw 90° (1/4 turn) counter-

309909H 9

Turn D port bleed screw 60° (1/6 turn) counterclockwise, to bleed 1 cfm air to melt ice.

Turn D port bleed screw 60° (1/6 turn) counterclockwise, to bleed 1 cfm air to melt ice. If icing

continues, turn screw to 90° (1/4 turn) to increase

air flow to 2 cfm. If necessary, increase air flow to

3 cfm by turning screw to 270° (3/4 turn). Do not

exceed 3 cfm (3/4 turn maximum).

clockwise, to bleed 1 cfm air to melt ice. If icing

continues, turn screw to 120° (1/3 turn) to

increase air flow to 2 cfm. If necessary, increase

air flow to 3 cfm by turning screw to 180° (1/2

turn). Do not exceed 3 cfm (1/2 turn maximum).

U

D

TI5294a

Page 10

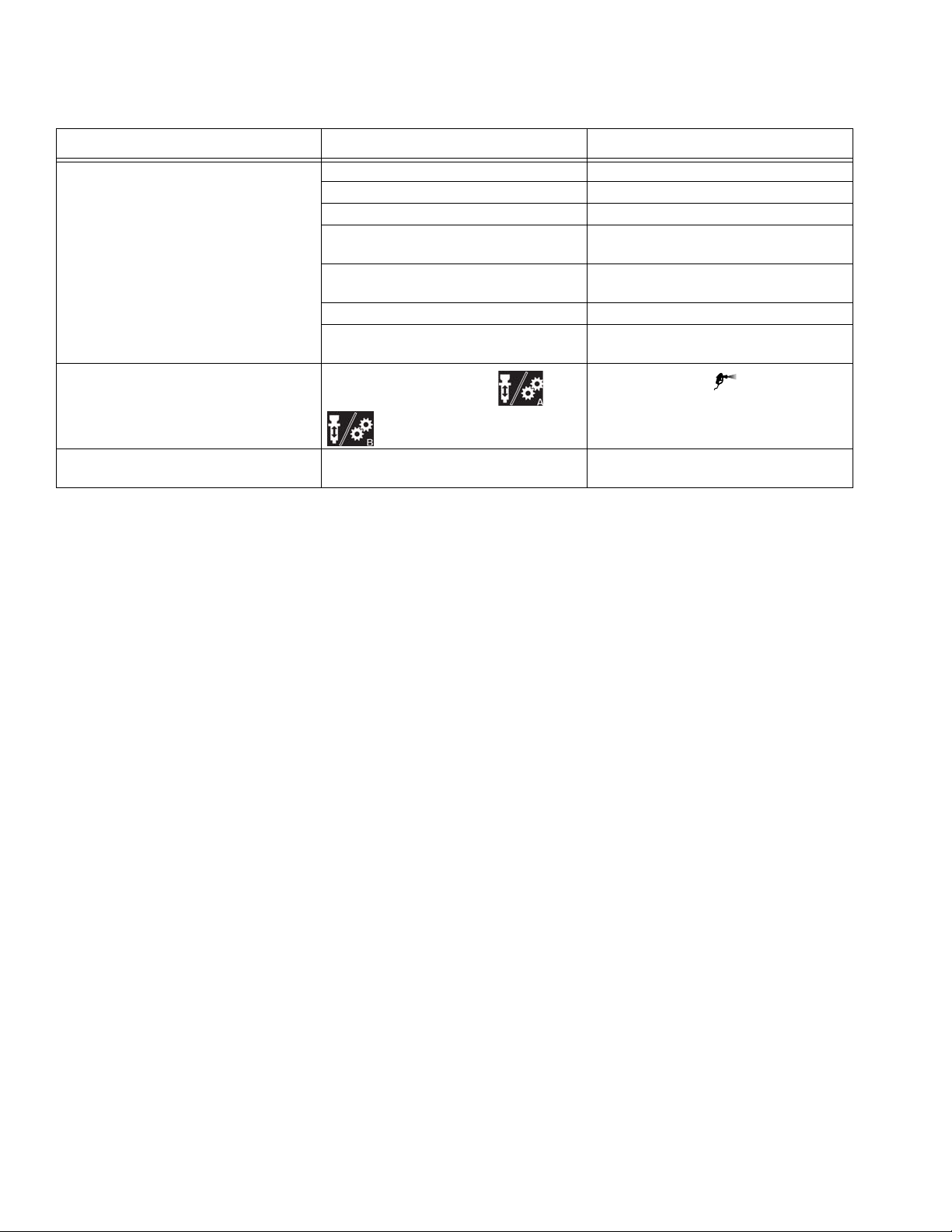

Troubleshooting

Troubleshooting

WARNING

If an alarm code displays, see page 13.

Read warnings, page 5-6.

Problem Cause Solution

Display not lit.

No electric power.

Pumps do not run. Air pressure to pumps too low. Increase pressure to 50 psi (0.35 MPa,

Pump test volume is not correct. Air pressure to pumps too low Increase pressure to 50 psi (0.35 MPa,

Air valve not turned on. Turn on main air valve to system.

Air supply pressure too low. Increase pressure to 60 psi (0.42 MPa,

4.2 bar) or greater.

Air supply filters plugged. Clean filter bowls; replace filter elements.

Page 15.

Turbine air regulator set too low. Adjust to proper setting.

Turbine alternator failure. Repair or replace turbine. Page 19.

Power supply not connected to main

board.

Main board not connected to display

board.

Display board failure. Replace display board. Page 18.

Power not connected to unit (non-IS units

only).

Solenoid valve stuck. Actuate solenoid manually, if it does not

Dispense valve(s) not opening. Service or replace valve(s). See 310655.

Sensors not functioning properly. Check position of sensors. See ProMix

Pump cavitating excessively. Check for air in lines caused by loose fit-

Check power connections to main board.

See Electrical Schematic, page 22.

Check electrical connections between

display and main board. See Electrical

Schematic, page 22, and 248349 Main

Control Board Schematic, page 23.

Ensure that power cord is plugged in.

Check that cord is connected properly;

see ProMix Easy Operation manual.

3.5 bar).

operate, replace solenoid. Page 20.

3.5 bar).

Easy Operation manual, and applicable

pump manual.

Check board calibration and recalibrate if

necessary. See ProMix Easy Operation

manual.

Replace sensors. See pump manual

310671 or 310672.

ting or use of agitator.

Material too viscous. Use heater.

10 309909H

Page 11

Troubleshooting

Problem Cause Solution

Paint does not cure consistently. Ratio not set correctly. Check that correct ratio is set and set by

volume. See ProMix Easy Operation

manual.

Material not mixing correctly. Test pump. Page 9.

Make sure mixer is clean; flush as

needed. See ProMix Easy Operation

manual.

Pump not operating correctly. Observe whether pumps are loading and

checking correctly, if not, clean and repair

pump. See displacement pump manual

310662.

Poor spray pattern. Fluid pressure too low. Increase pump pressure.

Spray tip dirty or worn. Relieve pressure. Clean or replace tip.

Follow gun manual instructions.

Fluid A or B filters plugged. Clean filters.

Mixer or hoses partially plugged or too

restrictive.

System runs erratically. Air filter(s) clogged. Replace elements. Clean. Replace element(s). See page 15.

Air supply hoses undersized. Replace hoses with appropriate size.

Air compressor undersized. Use larger air compressor.

Air supply pressure tank undersized. Use larger pressure tank.

Air supply relief valve opens. Turbine air regulator set too high. Lower setting to 23-25 psi (172-241 kPa,

Turbine alternator makes high-pitched

whining noise.

Display shows 88888 or unit reboots

unexpectedly.

ProMix Easy does not start when start

button is pressed.

Dispense valves leaking. Loose or worn packings. Tighten packing nut. If leak continues,

Turbine bearings worn. (Setting turbine

air regulator too high, wears bearings.)

Turbine is not supplying enough power to

board.

Faulty start switch or wire harness. Check start switch and wiring harness

Faulty stop switch or wiring harness. Check stop switch and wiring harness

Bad I/O port on display board. Replace board. Page 18.

Bad I/O port on main board. Replace board. Page 17.

Inspect parts for cured material. Clean or

replace, or use larger hoses and mixer.

1.7-2.4 bar).

Replace bearings. Page 19.

Increase turbine regulator setting to

23-25 psi (172-241 kPa, 1.7-2.4 bar).

Check turbine and electrical control

exhaust air for restrictions.

Replace turbine bearings. Page 19.

continuity; switch is normally open circuit.

See Electrical Schematic, page 22.

continuity; stop switch is normally closed

circuit. See Electrical Schematic, page

22.

replace packings. See 310655.

309909H 11

Page 12

Troubleshooting

Problem Cause Solution

Flow rate too low. Inadequate air supply. Use larger CFM compressor.

Air pressure to pumps too low. Increase pressure.

Fluid A or B filters plugged. Clean filters.

Spray tip too small. Relieve pressure. Install larger tip. Follow

gun manual instructions.

Mixer or hoses partially plugged or too

restrictive.

Insufficient dispense valve travel. Increase travel. See 310655.

Shutoff valves are not fully open. Ensure that shutoff valves are fully open

Inspect parts for cured material. Clean or

replace, or use larger hoses and mixer.

and sampling valves are closed.

Pump stops after 12 cycles.

Pump cycle rate slows and eventually

stops.

Knob is set to Run pump A

or B

Turn knob to spray

rial.

independently.

Icing at pump air manifold. See Icing, page 9.

if spraying mate-

12 309909H

Page 13

Alarms

* Indicates error where audible alarm sounds once briefly. ** Indicates error where audible alarm sound pulses.

Code Alarm Active Problem Cause

Startup Errors

01 Sensor Error A* Always No signal from pump A

sensor

02 Sensor Error B* Always No signal from pump B

sensor

03 Communication Error* Always Loss of communication

between main and display boards

Operating Errors

04 not used

05 not used

06 Pump Error A** Spray

07 Pump Error B**

08 Sensor Code Error Always Sensor values reverted to

09 Metering Error A** Spray A dose too great Dispense valve A leak

Te st

Batch

Pump does not stall after

top change over

Pump cavitating excessively

default

Loose cable, failed sensor or cable, failed magnet

assembly

Loose cable, failed sensor or cable, failed magnet

assembly

Loose cable, failed board

Intake valve leak

Air in lines caused by loose fitting or use of agitator

Empty fluid supply

Sensor value data corrupt; board needs replacement

and /or recalibration

Empty B fluid supply

Alarms

Clogged flow meter

10 Metering Error B** Spray B dose too great Dispense valve B leak

Empty A fluid supply

Clogged flow meter

11 Sensor Reading Low A* Spray

12 Sensor Reading Low B*

13 Sensor Reading High A* Spray

14 Sensor Reading High B*

21 Pot Life Error Spray

Te st

Batch

Te st

Batch

first, then

Always

Pump stroke travels

beyond sensor range at

top change over

Pump stroke travels

beyond sensor range at

bottom change over

Pot life timer timed out Not enough material sprayed after last reset

Sensor or bracket loose

Sensor magnet dirty

Sensor or bracket loose

Sensor magnet dirty

309909H 13

Page 14

Alarms

Code Alarm Active Problem Cause

Operating Errors

(continued)

22 High Ratio (units with

meter[s] only)

23 Low Ratio (units with

meter[s] only)

24 Dose Timeout A (units

with meter[s] only)

25 Dose Timeout B (units

with meter[s] only)

26 Park Timeout

(pump-based units only)

Testing Error

15 Piston packing/ball A* Test Pump does not com16 Piston packing/ball B*

17 Inlet Ball A* Test Pump does not com18 Inlet Ball B*

19 Dispense Valve A* Test Pump does not com20 Dispense Valve B*

27 Pump Calibration

Timeout A

28 Pump Calibration

Timeout B

Spray Mix ratio higher than

Tar g et + Tole r anc e

Spray Mix ratio lower than

Target - Tolerance

Spray Air flow switch indicates

more than 40 sec of air

flow without dose completing

Park Pumps not at bottom of

stroke

pletely stall in up stroke

pletely stall in downstroke

pletely stall in both up

and down strokes

Run A Pump doesn’t run

through calibration.

Run B

Flow rate too high

Slow actuation of dispense valve A or B

Clogged flow meter

Air flow switch stuck open.

Atomizing air leak downstream of air flow switch.

Clogged flow meter.

Gun triggered without fluid (dusting parts)

Sampling valves closed, or gun not triggered.

Piston packing or ball check failure

Intake valve ball check failure

Throat packing or dispense valve failure

Sampling valves closed.

14 309909H

Page 15

Repair

Repair

Flush before repairing equipment, if possible. See ProMix Easy Operation manual.

WARNING

Read warnings, page 5.

Follow Pressure Relief Procedure, page 7, if service

time may exceed pot life time, before servicing fluid

components, and before transporting equipment to a

service area.

Replacing Air Filter Element

There are 2 air filters on the unit: the 5 micron air manifold filter (7) and 40 micron pump air filter (9). Check filters daily and replace element as needed. Order

15D909 5 micron filter and 15D890 40 micron filter.

WARNING

Removing the bowl of a pressurized air filter could

cause serious injury. Do not service air filter until air

line is depressurized.

1. Close main air shutoff valve on air supply line and

on unit.

2. Remove left side plate (21).

3. Unlock filter bowl guard and remove.

4. Unscrew filter bowl.

5. Remove and replace element.

6. Screw filter bowl on securely.

7. Reassemble.

309909H 15

Page 16

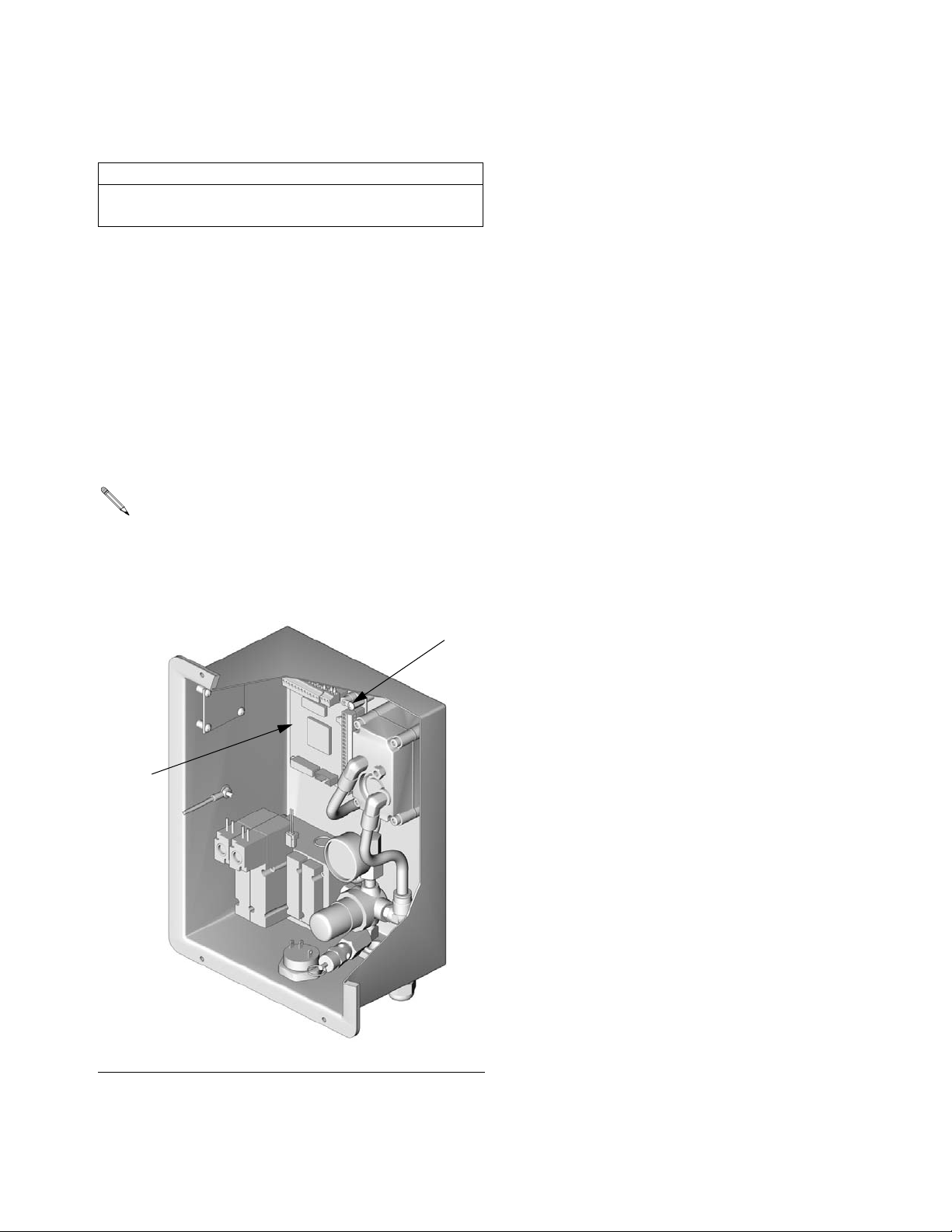

Repair

User Interface

Removal

1. Close main air shutoff valve on air supply line and

on unit.

2. Remove side panels (21).

3. Remove fasteners (45). Gently pull user interface

(11) away from pneumatic control (10).

21

10

315

45

Software Upgrades

CAUTION

To avoid damaging circuit board, wear a grounding

strap.

1. Remove User Interface cover. See above.

2. Use a chip remover (D) to remove software chip (C).

F

IG. 2.

C

D

F

IG. 2

11

TI4901a

F

IG. 1

4. To completely remove user interface (11), disconnect ground wire (315), and wires (416 and 406)

from main control board (301). See Electrical

Schematic, page 22.

3. Install new chip (beveled corner down).

4. Reassemble.

5. Recalibrate main circuit board. See ProMix Easy

Operation Manual.

16 309909H

Page 17

Replacing Main Circuit Board

CAUTION

To avoid damaging circuit board, wear a grounding

strap.

1. Remove User Interface cover. See page 16.

2. Disconnect all wire connectors from board (301).

F

IG. 3.

3. Remove four screws (302) and replace board (301).

4. Reassemble. Refer to Electrical Schematic, page

22.

5. Recalibrate system. See ProMix Easy Operation

Manual.

NOTE: If the main control board is replaced on

units that use a flow meter, the flow meter calibration data must be set using a PC and a Data

Download Kit (Graco P/N 248403 for hazardous

locations or Graco P/N 248404 for non-hazardous

locations).

Repair

F

320

301

TI4561a

IG. 3

309909H 17

Page 18

Repair

Replacing Display Circuit Board

CAUTION

To avoid damaging circuit board, wear a grounding

strap.

1. Remove User Interface cover. See page 16.

2. Disconnect wires from display board (410). F

404

413 418

407

N

3. Remove two screws (411).

4. Loosen setscrew (419) from knob (405) and remove

knob assembly. Remove jam nut (N).

5. Remove and replace display board (410).

6. Reassemble. Refer to Electrical Schematic, page

22.

IG. 4.

410

411

406

405

419

FIG. 4

403

401

TI4755a TI4756a

406

416

407

403

416

18 309909H

Page 19

Repair

Pneumatic Control

Alternator Repair

Turbine Alternator Repair Kit 223688 is available to

replace turbine bearings.

1. Remove User Interface cover. See page 16.

P

306r

301

310

304

• Lightly lubricate turbine o-ring before installing turbine in housing.

• Connect alternator red wire to + side and

black wire to – side of main circuit board.

• Connect turbine to 3-pin connector on main

circuit board.

305

310

F

IG. 6

304

304d

313

TI4561a

F

IG. 5

2. Disconnect power supply wires (P). F

IG. 5.

3. Disconnect two air lines (310) from alternator (304).

F

IG. 6.

4. Remove top nut (305) and loosen bottom nut. Slide

alternator up and off bottom nut.

5. Remove four screws (304d) to separate alternator

housings. F

IG. 7.

6. Disconnect turbine (304e) from board (A). Follow

instructions in turbine kit manual 308034 to remove

and repair turbine.

7. Replace gasket (304a) if damaged. Place between

housings before securing with screws (304d).

1

304d

1

Torque to 20 in-lbs (2 N•m)

IG. 7

F

A

304a

304e

8. Reassemble. Refer to Electrical Schematic, page

22.

309909H 19

Page 20

Repair

Replacing Solenoids

Follow this procedure to replace a single solenoid.

1. Remove User Interface cover. See page 16.

2. Disconnect two solenoid wires (V) from main board.

F

IG. 8.

3. Disconnect dispense valve pilot lines (A1, A2, B1,

B2). F

IG. 8.

4. Remove two screws (S).

5. Remove and replace solenoid (306b).

From left to right, solenoid functions are as follows:

• Component A

• Component B

6. Reassemble. Solenoid wires are polarized (red +,

black –). Refer to Electrical Schematic, page 22.

Replacing Alternator Regulator

1. Remove User Interface cover. See page 16.

3. Disconnect supply and exhaust air lines (310). F

IG.

5, page 19.

4. Disconnect solenoid wires 12 position Phoenix connector (306r) from main board.

5. Remove solenoid module (306) with regulator

(306e). F

IG. 8.

6. Unscrew and replace regulator (306e).

7. Reassemble. Refer to Electrical Schematic, page

22.

Make sure gaskets (306j, 306k) are in place when

reinstalling solenoid module.

8. Set regulator to 24 psi (160 kPa, 1.6 bar).

Replacing Alarm

1. Remove User Interface cover. See page 16.

2. Disconnect alarm wires from main board.

3. Unscrew alarm (313) and replace. F

IG. 5, page 19.

2. Remove two screws (309) from the back of the control box.

Dispense Valve

Pilot Lines

A1 (off), clear tube

1

Set regulator pressure to 24 psi (160 kPa, 16 bar).

2

Safety relief valve (306t) is required on all IS units.

A2 (on), black tube

B1 (off), green tube

B2 (on), red tube

B1

A1

B2

A2

306k

306j

TI4699a

F

IG. 8

4. Reassemble. Refer to Electrical Schematic, page

22.

310

306e

V

AB

306t

B2

A2

A1

S

B1

306b

TI4558a

1

2

20 309909H

Page 21

Repair

Dispense Valve/Mix Manifold Assembly

WARNING

Read warnings, page 5.

See the Parts drawing for your model.

1. Follow Pressure Relief Procedure, page 7.

2. Label all air and fluid lines, and disconnect from fittings on manifold assembly.

3. Remove fasteners.

4. Remove mix manifold (2).

5. To repair mix manifold, see manual 310654. To

repair dispense valves, see manual 310655.

6. Reassemble.

Pump Assembly

WARNING

Read warnings, page 5.

See the Parts drawing for your model.

1. Follow Pressure Relief Procedure, page 7.

2. Remove side plates (21).

3. Remove wire harnesses from sensor and solenoids.

Refer to Electrical Schematic, page 22.

4. Disconnect fluid inlet and outlet lines from pump

lower. Disconnect air supply from pump.

5. Label all tubing and disconnect from fittings on

pump assembly.

6. Remove mounting hardware and slide pump out of

frame.

7. Repair as instructed in pump manuals 310671,

310672, or 310662.

8. Reassemble.

309909H 21

Page 22

Electrical Schematic

Electrical Schematic

AIR INPUT

3

1

2

COM PORT PIN LOCATIONS

FRONT SIDE VIEW

(OPPOSITE SIDE OF SOLDER CUPS)

TX

GND

RX

FRONT PANEL

COM PORT

RS232

CONNECTOR

1

2

4

START

3

3

15A851

START/STOP

SWITCH ASSY

STOP

GND

A

LIGHT

B

KEY SWITCH ASSY

15A852

2

GND

1

2

1

1

2

KEY SWITCH

MOM.

8

1

+-

7

2

27

POWER SUPPLY ASSEMBLY 245223

POWER

POWER

SUPPLY

SUPPLY

BARRIER

WHITE

3

245706

BROWN

GREEN

BLACK

4

53412

12345

RED

BLACK

GREEN

3

152

J3

1

2

3

6

RED

MOTOR B DOWN

MOTOR A DOWN

MOTOR B UP

MOTOR A UP

-

+

+

-

-

+

-

125

P4

246899

+

RED

BLACK

RED

RED

RED

RED

15D794

BLACK

BLACK

BLACK

BLACK

6

3

7

8

4

ALARM COM

ALARM +

WHITE

COMM PORT ASSY

15A850

ALARM ASSY 15A849

6378412

5

G

S

P

BOARD

239790

SOLENOID

BOARD

1

2

J2

DISPLAY BOARD

J1

METER A

243678

OPT. SOLENOID, RECIRC. 552180

FLUID

VALVES

1

5

4

2

6

2

3

431

5

6

4

1

3

"B"

SENSOR

243678

"A"

SENSOR

METER B

526

234628

AIR FLOW SWITCH

11

119159

1

26

1

2

GREEN

WHITE_W/GRN

3

3

ORANGE

WHITE_W/ORANGE

4

5

458117

CABLE # 15D607 (X2)

BLUE

WHITE_W/BLUE

8

9

6

9

6

GREEN

WHITE_W/ORANGE

WHITE_W/GRN

10714

11

12

10

12

ORANGE

RED

BLACK

WHITE

WHITE

SIGNAL A

COM

12VDC

SIGNAL B

123456788

J8

123

4

ORANGE

567

BLUE

WHITE_W/BLUE

BLACK

WHITE

CABLE # 15A854 (MAIN TO DISPLAY)

RED

SHIELD

1

526

3

4

16

17

13

1234567

18

15

J2

1234567

18

15

16

17

13

14

1

J1

12345

6

CABLE # 114213

+

- SOLENOID VALVE A

+

- SOLENOID VALVE B

+

-

SHIELD

1

15VDC

1

RED

BLACK

COM

3

2

12VDC

RED

RED

RED

BLACK

5

6

3

BLACK

RED

ORANGE

RED

BLACK

BLACK

BLACK

BLACK

12VDC

1

10

72811412

12

9

JUMPER (15V)

J4

1

9

10

11712

Under operating conditions, voltage

at J6 will be approximately 12 Vdc.

1

J6

123

J5

1234568

248349

MAIN CONTROL

BOARD

22 309909H

Page 23

248349 Main Control Board Schematic

248349 Main Control Board Schematic

Pin 1 Pin 1

J5

D12 D6 D13 D5 D10

U4

J6

F1

J4

Pin 1

D2

J2

J1

J8

Pin 1 Pin 1 Pin 1

TI11316a

248349 Main Control Board LEDs

LED Description

D2 In normal operation D2 flashes on and off in 1

second intervals. If D2 is off (not flashing),

software is not booting; check for power to

the board or a short circuit.

D5 On: Dispense valve B is on (open).

Off: Dispense valve B is off (closed).

D6 Active only on units with recirculation option.

On: Recirculation solenoid is on.

Off: Recirculation solenoid is off.

D10 On: Dispense valve A is on (open).

Off: Dispense valve A is off (closed).

D12 On: Remote alarm output on.

Off: Remote alarm output off.

D13 D13 is always off. Output powers the 246899

Expansion Board, turning the board on and

off.

246899 Pump Solenoid Expansion Board Schematic

246899 Pump Solenoid Expansion Board LEDs

LED Description

D1 D2 D3 D4

1

P4

Pin 1

Pin 1

J1

P3

P2

P1

TI11229a

D1 On: Pump B is on the downstroke.

D2 On: Pump B is on the upstroke.

D3 On: Pump A is on the downstroke.

D4 On: Pump A is on the upstroke.

S

G

P

309909H 23

Page 24

Parts

Parts

Part No. 234596 Series A, Pump-based, Cart-mounted Air Spray Unit

11

21, 28

22

103

104

102

41

20

38

72

79

39

10

45

51

71

71

21

22

85

22

100

30

73

84

101 (Ref)

24 309909H

101

101 (Ref)

98

81

TI4769a

Page 25

Part No. 234596 Series A, Pump-based, Cart-mounted Air Spray Unit, continued

Parts

12

49

48

63

75

67

65

76

82

74

47

40

47

25

37

9

32

33

16 17

17

16

15

5

15

3

1

65 (Ref)

39

46

15

4

24

7

8

45

31

6

32

33

24 (Ref)

23

Pump Solenoid

Cable Connections

2 1

45

17

16

78

1

Downstroke solenoid is on the outside.

2

Upstroke solenoid is on the inside.

TI11228a

14

44

2

63

78 (Ref)

TI4770a

309909H 25

Page 26

Parts

Part No. 234596 Series A, Pump-based, Cart-mounted Air Spray Unit, continued

Ref.

No. Part No. Description Qty.

1 15D771 FRAME, wall mount

2 234593 MIX MANIFOLD; see 310654

3 287230 CONTROL, air; see page 53

4 109544 ELBOW, pipe; 3/8 npt (mbe)

5 116756 ELBOW, street, 45°; 3/8 npt (m x f)

6 155665 UNION, adapter; 3/8 npsm(f) x

3/8 npt(m)

7 117629 FILTER, air; 5 micron

8 114316 ELBOW; 3/8 npt(m) x

3/8 in. (10 mm) OD tube fitting

9 15D795 FILTER, air; 40 micron

10 248270 PNEUMATIC CONTROL,

intrinsically safe; see page 54

11 234620 USER INTERFACE; see page 52

12 248570 PUMP, UltraMix; see 310671

14 15D873 BRACKET, support, fluid manifold

15 C38211 ELBOW; 1/2 npt(m) x

3/8 in. (10 mm) OD tube

16 C19038 WASHER, lock; 1/4

17 112925 SCREW, cap, button hd;

1/4-20 x 3/8 in. (10 mm)

20 103196 SCREW, machine, phillips;

8-32 x 7/16 in. (11 mm)

21 15D767 PLATE, side

22 119291 SCREW, self-tapping

23 113802 SCREW, hex hd, flanged;

3/8-16 x 5/8 in. (16 mm)

24 220598 HOSE, air; nitrile; 1/2 in. (13 mm)

ID; 1/2 npt (mbe); 18 in. (457 mm);

see also pages 44 and 47

25 C19024 ELBOW, swivel; 1/2 npt(m) x

1/2 npsm(f)

26 15D607 CABLE, sensor; see Electrical

Schematic, page 22

27 15D794 HARNESS, connector; see Electri-

cal Schematic, page 22

28▲ 290331 LABEL, warning

30 15D775 CART

31 101765 GROMMET

32 100451 COUPLING; 1/8 npt (fbe)

33 115671 CONNECTOR; 1/8 npt(m) x

1/4 in. (6 mm) OD tube

37 244524 GROUND WIRE

38 113279 PLUG, tube fitting;

5/32 in. (4 mm) OD tube

39 113505 NUT, keps, hex hd; 10-24

40 551787 SCREW, cap, button hd;

10-32 x 3/8 in. (10 mm)

41 111218 CAP

44 114104 SCREW, machine; 1/4-20 x

1-1/2 in. (38 mm)

45 115942 NUT, hex, flange hd; 1/4-20

20

Ref.

No. Part No. Description Qty.

46 113319 FITTING, air; 1/4 npt(m) x

1

1

47 115841 ELBOW; 1/4 npt(m) x

1

1

48 114158 FITTING, Y-adapter;

1

1

49 115743 ADAPTER; 3/8 in (10 mm) tube x

1

51 116780 SCREW, hex hd flanged;

1

56 598095 TUBE; nylon; 5/32 in. (4 mm) OD;

1

1

57 054753 TUBE; nylon; 5/32 in. (4 mm) OD;

1

58 054754 TUBE; nylon; 5/32 in. (4 mm) OD;

2

1

59 054757 TUBE; nylon; 5/32 in. (4 mm) OD;

3

60 590385 TUBE; polyethylene; 3/8 in. (10 mm)

5

5

63 162453 NIPPLE; 1/4 npsm x 1/4 npt

65 104641 FITTING, bulkhead

4

67 100840 ELBOW, street; 1/4 npt (m x f)

70 054123 TUBE; nylon; 1/4 in. (6 mm) OD;

2

71 112958 NUT, hex, flange hd; 3/8-16

8

72 116935 SCREW, cap; 3/8-16 x 3 in. (76 mm)

73 198720 WHEEL

1

74 116513 REGULATOR, air

75 108190 GAUGE, pressure, air

76 116514 NUT, regulator

1

78 206966 HOSE, fluid; 1/4 npsm (fbe); PTFE;

2

79 195889 BUSHING, strain relief

2

81 113436 RING, retaining

82 160701 ELBOW, street; 1/8 npt (m x f)

1

84 15E106 BUSHING, wheel

1

85 15D986 PLATE, rear

2

98 154628 WASHER

2

100 239561 GUN, spray, HVLP; see 308741

2

101 233498 HOSE ASSEMBLY; 3/8 npsm (f)

1

2

102 162485 NIPPLE; 3/8 npt x 3/8 npsm

103 155495 ELBOW, swivel; 3/8 npt(m) x

2

4

104 214706 REGULATOR, pressure, fluid;

2

1

▲ Replacement Danger and Warning labels, tags, and cards

7

are available at no cost.

3/8 in. (10 mm) OD tube

3/8 in. (10 mm) OD tube

1/4 in. (6 mm) OD tube

1/4 in. (6 mm) tube

3/8-16 x 1-3/4 in. (44 mm)

clear; see pages 44 and 47

black; see pages 44 and 47

red; see pages 44 and 47

green; see pages 44 and 47

OD; see pages 44 and 47

see pages 44 and 47

1/4 in. (6 mm) ID; 18 in. (457 mm);

see also pages 44 and 47

nylon fluid hose; 1/4 npsm(f) air

hose; 25 ft (7.6 m)

1/4 npsm(f)

see 307212

1

2

2

2

2

2 ft

2 ft

2 ft

2 ft

9 ft

3

1

1

4.2

ft

4

2

2

1

1

1

2

2

2

1

2

1

2

1

1

1

1

1

26 309909H

Page 27

Pump and Meter-based, Wall-mounted Air Spray Units

Part No. 234597 Series A, UltraMix carbon steel pump and G3000 Meter

Part No. 234598 Series A, UltraMix stainless steel pump and G3000 Meter

10

39

11

Parts

21, 28

22

20

38

79

45

22

21

TI4901b

309909H 27

Page 28

Parts

Pump and Meter-based, Wall-mounted Air Spray Units, continued

46

37

67

63

65

65 (Ref)

1

39

16 17

3

13

17169

53

80

88

47

49

40

25

32

33

15

5

4

48

24

8

45

31

6

7

32

33

23

87

89

86

91

17

90

45

16

83

63

78 (Ref)

14

44

2

24 (Ref)

Pump Solenoid

Cable Connections

12

78

21

1

Downstroke solenoid is on the outside.

2

Upstroke solenoid is on the inside.

TI4902a

TI11262a

28 309909H

Page 29

Pump and Meter-based, Wall-mounted Air Spray Units, continued

See page 27 for model numbers and descriptions.

Ref.

No. Part No. Description Qty.

1 15D771 FRAME, wall mount

2 234593 MIX MANIFOLD; cst; carbon steel

models only; see 310654

234451 MIX MANIFOLD; sst; stainless steel

models only; see 310654

3 287230 CONTROL, air; see page 53

4 109544 ELBOW, pipe; 3/8 npt (mbe)

5 116756 ELBOW, street, 45°; 3/8 npt (mxf)

6 155665 UNION, adapter; 3/8 npsm(f) x

3/8 npt(m)

7 117629 FILTER, air; 5 micron

8 114316 ELBOW; 3/8 npt(m) x 3/8 in.

(10 mm) OD tube fitting

9 15D795 FILTER, air; 40 micron

10 248270 PNEUMATIC CONTROL,

intrinsically safe; see page 48

11 234620 USER INTERFACE; see page 52

12 248570 PUMP, UltraMix, cst; carbon steel

models only; see 310671

248571 PUMP, UltraMix, sst; stainless steel

models only; see 310671

13 100361 PLUG, pipe; 1/2 npt

14 15D873 BRACKET, support, fluid manifold

15 C38211 ELBOW; 1/2 npt(m) x

3/8 in. (10 mm) OD tube fitting

16 C19038 WASHER, lock; 1/4

17 112925 SCREW, cap, button hd;

1/4-20 x 3/8 in. (10 mm)

20 103196 SCREW, machine, phillips;

8-32 x 7/16 in. (11 mm)

21 15D767 PLATE, side

22 119291 SCREW, self-tapping

23 113802 SCREW, hex hd, flanged;

3/8-16 x 5/8 in. (16 mm)

24 220598 HOSE, air; nitrile; 1/2 in. (13 mm)

ID; 1/2 npt (mbe); 18 in. (457 mm);

see also pages 44, 46, and 47

25 C19024 ELBOW, swivel; 1/2 npt(m) x

1/2 npsm(f)

26 15D607 CABLE, sensor; see Electrical

Schematic, page 22

27 15D794 HARNESS, connector; see Electri-

cal Schematic, page 22

28▲ 290331 LABEL, warning

31 101765 GROMMET

32 100451 COUPLING; 1/8 npt (fbe)

33 115671 CONNECTOR; 1/8 npt(m) x

1/4 in. (6 mm) OD tube

37 244524 GROUND WIRE

Ref.

No. Part No. Description Qty.

38 113279 PLUG, tube fitting;

1

1

39 113505 NUT, keps, hex hd; 10-24

40 551787 SCREW, cap, button hd;

1

1

44 114104 SCREW, machine; 1/4-20 x

1

45 115942 NUT, hex, flange hd; 1/4-20

1

46 113319 FITTING, air; 1/4 npt(m) x

1

47 115841 ELBOW; 1/4 npt(m) x

1

1

48 114158 FITTING, Y-adapter;

1

49 115743 ADAPTER; 3/8 in (10 mm) tube x

1

53 111763 ELBOW; 1/4 npt (mbe)

1

56 598095 TUBE; nylon; 5/32 in. (4 mm) OD;

1

57 054753 TUBE; nylon; 5/32 in. (4 mm) OD;

1

58 054754 TUBE; nylon; 5/32 in. (4 mm) OD;

1

1

59 054757 TUBE; nylon; 5/32 in. (4 mm) OD;

2

60 590385 TUBE; polyethylene; 3/8 in. (10 mm)

5

5

63 162453 NIPPLE; 1/4 npsm x 1/4 npt

65 104641 FITTING, bulkhead

4

67 100840 ELBOW, street; 1/4 npt (m x f)

70 054123 TUBE; nylon; 1/4 in. (6 mm) OD;

2

12

78 206966 HOSE, fluid; 1/4 npsm (fbe); PTFE;

4

1

79 195889 BUSHING, strain relief

80 100206 BUSHING; 1/2 npt(m) x 1/4 npt(f)

83 501867 CHECK VALVE

1

86 114339 UNION, swivel; 1/4 npsm(f) x

2

87 15D957 HARNESS, wire

88 119159 SWITCH, air flow

2

89 166846 ADAPTER; 1/4 npsm x

1

90 239716 METER, G3000; see 308778

2

91 195283 SHIELD, ESD, G3000

2

2

▲ Replacement Danger and Warning labels, tags, and cards

1

are available at no cost.

5/32 in. (4 mm) OD tube

10-32 x 3/8 in. (10 mm)

1-1/2 in. (38 mm)

3/8 in. (10 mm) OD tube

3/8 in. (10 mm) OD tube

1/4 in. (6 mm) OD tube

1/4 in. (6 mm) tube

clear; see pages 44, 46, and 47

black; see pages 44, 46, and 47

red; see pages 44, 46, and 47

green; see pages 44, 46, and 47

OD; see pages 44, 46, and 47

see pages 44, 46, and 47

1/4 in. (6 mm) ID; 18 in. (457 mm);

see also pages 44 and 47

1/4 npt(m)

1/4 npt (mbe)

Parts

2

2

4

1

7

1

1

1

1

1

2 ft

2 ft

2 ft

2 ft

4.7

ft

2

1

1

4.2

ft

1

1

1

1

1

1

1

1

1

1

309909H 29

Page 30

Parts

Pump-based, Wall-mounted Air Spray Units

Part No. 234599 Series A, carbon steel, intrinsically safe

Part No. 234600 Series A, carbon steel, non-intrinsically safe

Part No. 234601 Series A, stainless steel, intrinsically safe

Part No. 234825 Series A, stainless steel, non-intrinsically safe

10

39

11

21, 28

22

20

38

79

45

22

21

TI4904b

30 309909H

Page 31

Pump-based, Wall-mounted Air Spray Units, continued

1

Parts

37

12

49

48

40

39

17

45

16

24

25

45

23

14

44

4

31

9

32

33

24 (Ref)

1716

17

16

15

5

15

3

13

7

8

6

32

33

78

2

Pump Solenoid

Cable Connections

2 1

63

78 (Ref)

TI4905a

1

Downstroke solenoid is on the outside.

2

Upstroke solenoid is on the inside.

TI11228a

309909H 31

Page 32

Parts

Pump-based, Wall-mounted Air Spray Units, continued

See page 30 for model numbers and descriptions.

Ref.

No. Part No. Description Qty.

1 15D771 FRAME, wall mount

2 234593 MIX MANIFOLD; cst; carbon steel

models only; see 310654

234451 MIX MANIFOLD; sst; stainless steel

models only; see 310654

3 287230 CONTROL, air; see page 53

4 109544 ELBOW, pipe; 3/8 npt (mbe); intrin-

sically safe models only

114316 ELBOW; 3/8 npt(m) x 3/8 in.

(10 mm) OD tube fitting; non-intrin-

sically safe models only

5 116756 ELBOW, street, 45°; 3/8 npt (mxf);

intrinsically safe models only

6 155665 UNION, adapter; 3/8 npsm(f) x

3/8 npt(m); intrinsically safe models

only

7 117629 FILTER, air; 5 micron; intrinsically

safe models only

8 114316 ELBOW; 3/8 npt(m) x 3/8 in.

(10 mm) OD tube fitting;

intrinsically safe models only

9 15D795 FILTER, air; 40 micron

10 248270 PNEUMATIC CONTROL;

intrinsically safe models only;

see page 48

248316 PNEUMATIC CONTROL; non-intrin-

sically safe models only; see page

50

11 234620 USER INTERFACE; see page 52

12 248570 PUMP, UltraMix, cst; carbon steel

models only; see 310671

248571 PUMP, UltraMix, sst; stainless steel

models only; see 310671

13 100361 PLUG, pipe; 1/2 npt

14 15D873 BRACKET, support, fluid manifold

15 C38211 ELBOW; 1/2 npt(m) x

3/8 in. (10 mm) OD tube fitting

16 C19038 WASHER, lock; 1/4

17 112925 SCREW, cap, button hd;

1/4-20 x 3/8 in. (10 mm)

20 103196 SCREW, machine, phillips;

8-32 x 7/16 in. (11 mm)

21 15D767 PLATE, side

22 119291 SCREW, self-tapping

23 113802 SCREW, hex hd, flanged;

3/8-16 x 5/8 in. (16 mm)

24 220598 HOSE, air; nitrile; 1/2 in. (13 mm)

ID; 1/2 npt (mbe); 18 in. (457 mm);

see also pages 44 and 47

25 C19024 ELBOW, swivel; 1/2 npt(m) x

1/2 npsm(f)

Ref.

No. Part No. Description Qty.

26 15D607 CABLE, sensor; see Electrical

1

1

27 15D794 HARNESS, connector; see Electri-

1

28▲ 290331 LABEL, warning

31 101765 GROMMET

1

32 100451 COUPLING; 1/8 npt (fbe);

1

1

33 115671 CONNECTOR; 1/8 npt(m) x

1

1

1

37 244524 GROUND WIRE

38 113279 PLUG, tube fitting;

1

39 113505 NUT, keps, hex hd; 10-24

40 551787 SCREW, cap, button hd;

1

1

44 114104 SCREW, machine; 1/4-20 x

45 115942 NUT, hex, flange hd; 1/4-20

1

48 114158 FITTING, Y-adapter;

49 115743 ADAPTER; 3/8 in (10 mm) tube x

1

2

56 598095 TUBE; nylon; 5/32 in. (4 mm) OD;

2

57 054753 TUBE; nylon; 5/32 in. (4 mm) OD;

1

58 054754 TUBE; nylon; 5/32 in. (4 mm) OD;

1

2

59 054757 TUBE; nylon; 5/32 in. (4 mm) OD;

5

60 590385 TUBE; polyethylene; 3/8 in. (10 mm)

5

63 162453 NIPPLE; 1/4 npsm x 1/4 npt

4

70 054123 TUBE; nylon; 1/4 in. (6 mm) OD;

2

78 206966 HOSE, fluid; 1/4 npsm (fbe); PTFE;

12

8

79 195889 BUSHING, strain relief

1

▲ Replacement Danger and Warning labels, tags, and cards

1

100451 COUPLING; 1/8 npt (fbe);

115671 CONNECTOR; 1/8 npt(m) x

are available at no cost.

Schematic, page 22

cal Schematic, page 22

intrinsically safe models only

non-intrinsically safe models only

1/4 in. (6 mm) OD tube;

intrinsically safe models only

1/4 in. (6 mm) OD tube; non-intrinsically safe models only

5/32 in. (4 mm) OD tube

10-32 x 3/8 in. (10 mm)

1-1/2 in. (38 mm)

1/4 in. (6 mm) OD tube

1/4 in. (6 mm) tube

clear; see pages 44 and 47

black; see pages 44 and 47

red; see pages 44 and 47

green; see pages 44 and 47

OD; see pages 44 and 47

see pages 44 and 47

1/4 in. (6 mm) ID; 18 in. (457 mm);

see also pages 44 and 47

2

2

1

2

2

1

2

1

1

2

2

4

1

7

2

2

2 ft

2 ft

2 ft

2 ft

6.7

ft

2

4.2

ft

2

2

32 309909H

Page 33

Meter-based, Wall-mounted High Pressure Units

Part No. 234618 Series A, carbon steel

Part No. 234619 Series A, stainless steel

10

39

11

Parts

21, 28

22

20

38

45

22

21

TI4917a

309909H 33

Page 34

Parts

Meter-based, Wall-mounted High Pressure Units, continued

67

63

65

46

37

65 (Ref)

1

40

39

25

16

17

9

5

32

33

1716

3

80

53

88

47

4

24

45

31

6

8

1

7

32

33

17

45

16

14

24 (Ref)

44

87

89

86

91

90

83

2

1

Wires to circuit board; see Electrical Schematic, page 22.

TI4918a

34 309909H

Page 35

Meter-based, Wall-mounted High Pressure Units, continued

See page 33 for model numbers and descriptions.

Ref.

No. Part No. Description Qty.

1 15D771 FRAME, wall mount

2 234593 MANIFOLD, mix (234618); cst;

see 310654

234451 MANIFOLD, mix (234619); sst;

see 310654

3 287231 CONTROL, air; see page 53

4 109544 ELBOW, pipe; 3/8 npt (mbe)

5 116756 ELBOW, street, 45°; 3/8 npt (m x f)

6 155665 UNION, adapter; 3/8 npsm(f) x

3/8 npt(m)

7 117629 FILTER, air; 5 micron

8 114316 ELBOW; 3/8 npt(m) x

3/8 in. (10 mm) OD tube

9 15D795 FILTER, air; 40 micron

10 248270 PNEUMATIC CONTROL,

intrinsically safe; see page 54

11 234620 USER INTERFACE; see page 52

14 15D873 BRACKET, support, fluid manifold

16 C19038 WASHER, lock; 1/4

17 112925 SCREW, cap; 1/4-20 x

3/8 in. (10 mm)

20 103196 SCREW, machine, phillips;

8-32 x 7/16 in. (11 mm)

21 15D767 PLATE, side

22 119291 SCREW, self-tapping

24 220598 HOSE, air; nitrile; 1/2 in. (13 mm) ID;

1/2 npt (mbe); 18 in. (457 mm); see

also pages 46 and 47

25 C19024 ELBOW, swivel; 1/2 npt(m) x

1/2 npsm(f)

28▲ 290331 LABEL, warning

31 101765 GROMMET

32 100451 COUPLING; 1/8 npt (fbe)

33 115671 CONNECTOR; 1/8 npt(m) x

1/4 in. (6 mm) OD tube

37 244524 GROUND WIRE

38 113279 PLUG, tube fitting;

5/32 in. (4 mm) OD tube

39 113505 NUT, keps, hex hd; 10-24

40 551787 SCREW, cap, button hd;

10-32 x 3/8 in. (10 mm)

44 114104 SCREW, machine; 1/4-20 x

1-1/2 in. (38 mm)

45 115942 NUT, hex, flange hd; 1/4-20

46 113319 FITTING, air; 1/4 npt(m) x

3/8 in. (10 mm) OD tube

47 115841 ELBOW; 1/4 npt(m) x

3/8 in. (10 mm) OD tube

53 111763 ELBOW; 1/4 npt (mbe)

Ref.

No. Part No. Description Qty.

56 598095 TUBE; nylon; 5/32 in. (4 mm) OD;

1

1

57 054753 TUBE; nylon; 5/32 in. (4 mm) OD;

1

58 054754 TUBE; nylon; 5/32 in. (4 mm) OD; red;

1

59 054757 TUBE; nylon; 5/32 in. (4 mm) OD;

1

1

60 590385 TUBE; polyethylene; 3/8 in. (10 mm)

1

63 162453 NIPPLE; 1/4 npsm x 1/4 npt

1

65 104641 FITTING, bulkhead

1

67 100840 ELBOW, street; 1/4 npt (m x f)

70 054123 TUBE; nylon; 1/4 in. (6 mm) OD; see

1

1

80 100206 BUSHING; 1/2 npt(m) x 1/4 npt(f)

83 501867 CHECK VALVE

1

86 114339 UNION, swivel; 1/4 npsm(f) x

1

5

87 15D957 HARNESS, wire

5

88 119159 SWITCH, air flow

89 166846 ADAPTER; 1/4 npsm x

4

90 239716 METER, G3000; see 308778

2

12

91 195283 SHIELD, ESD, G3000

1

▲ Replacement Danger and Warning labels, tags, and cards

are available at no cost.

1

1

2

2

2

1

2

2

4

1

7

1

1

1

clear; see pages 46 and 47

black; see pages 46 and 47

see pages 46 and 47

green; see pages 46 and 47

OD; see pages 46 and 47

pages 46 and 47

1/4 npt(m)

1/4 npt (mbe)

Parts

2 ft

2 ft

2 ft

2 ft

3.5

ft

1

1

1

4 ft

1

2

2

1

1

2

2

2

309909H 35

Page 36

Parts

Pump-based, Wall-mounted High Pressure Units

Part No. 234606 Series A, HydraMix 500 carbon steel, intrinsically safe

Part No. 234607 Series A, HydraMix 500 carbon steel, non-intrinsically safe

Part No. 234609 Series A, HydraMix 600 carbon steel, intrinsically safe

Part No. 234610 Series A, HydraMix 600 carbon steel, non-intrinsically safe

Part No. 234612 Series A, HydraMix 700 carbon steel, intrinsically safe

Part No. 234608 Series A, HydraMix 500 stainless steel, intrinsically safe

Part No. 234826 Series A, HydraMix 500 stainless steel, non-intrinsically safe

Part No. 234611 Series A, HydraMix 600 stainless steel, intrinsically safe

Part No. 234827 Series A, HydraMix 600 stainless steel, non-intrinsically safe

Part No. 234613 Series A, HydraMix 700 stainless steel, intrinsically safe

10

39

11

21, 28

22

45

22

20

38

79

21

TI4910b

36 309909H

Page 37

Pump-based, Wall-mounted High Pressure Units, continued

Parts

40

17

39

1

45

16

24

25

45

2

14

44

37

16 17

9

32

33

16

15

5

15

3

96

94

95

17

13

4

7

12

31

6

93

23

24 (Ref)

8

32

68

69

34

33

15

34

50

35

Detail of B Side

Muffler

50

36

TI4911b

Pump Solenoid

Cable Connections

2 1

1

Downstroke solenoid connection.

2

Upstroke solenoid connection.

TI5294a

309909H 37

Page 38

Parts

Pump-based, Wall-mounted High Pressure Units, continued

See page 36 for model numbers and descriptions.

Ref.

No. Part No. Description Qty.

1 15D771 FRAME, wall mount

2 234593 MIX MANIFOLD; cst; carbon steel

models only; see 310654

234451 MIX MANIFOLD; sst; stainless steel

models only; see 310654

3 287230 CONTROL, air; see page 53

4 109544 ELBOW, pipe; 3/8 npt (mbe); intrin-

sically safe models only

114316 ELBOW; 3/8 npt(m) x 3/8 in.

(10 mm) OD tube fitting; non-intrin-

sically safe models only

5 116756 ELBOW, street, 45°; 3/8 npt (mxf);

intrinsically safe models only

6 155665 UNION, adapter; 3/8 npsm(f) x

3/8 npt(m); intrinsically safe models

only

7 117629 FILTER, air; 5 micron; intrinsically

safe models only

8 114316 ELBOW; 3/8 npt(m) x

3/8 in. (10 mm) OD tube fitting;

intrinsically safe models only

9 15D795 FILTER, air; 40 micron

10 248270 PNEUMATIC CONTROL;

intrinsically safe models only;

see page 48

248316 PNEUMATIC CONTROL; non-intrin-

sically safe models only; see page

50

11 234620 USER INTERFACE; see page 52

12 248572 PUMP, HydraMix 500, cst; 234606

and 234607; see 310672

248573 PUMP, HydraMix 500, sst; 234608

and 234826; see 310672

248574 PUMP, HydraMix 600, cst; 234609

and 234610; see 310672

248575 PUMP, HydraMix 600, sst; 234611

and 234827; see 310672

248576 PUMP, HydraMix 700, cst; 234612;

see 310672

248577 PUMP, HydraMix 700, sst; 234613;

see 310672

13 100361 PLUG, pipe; 1/2 npt

14 15D873 BRACKET, support, fluid manifold

15 114110 ELBOW; 1/2 npt(m) x

1/2 in. (13 mm) OD tube fitting

16 C19038 WASHER, lock; 1/4

17 112925 SCREW, cap, button hd;

1/4-20 x 3/8 in. (10 mm)

20 103196 SCREW, machine, phillips;

8-32 x 7/16 in. (11 mm)

21 15D767 PLATE, side

Ref.

No. Part No. Description Qty.

22 119291 SCREW, self-tapping

1

23 113802 SCREW, hex hd, flanged;

1

24 220598 HOSE, air; nitrile; 1/2 in. (13 mm)

1

1

25 C19024 ELBOW, swivel; 1/2 npt(m) x

1

26 15D607 CABLE, sensor; see Electrical

1

27 15D794 HARNESS, connector; see Electri-

1

28▲ 290331 LABEL, warning

1

31 101765 GROMMET

32 100451 COUPLING; 1/8 npt (fbe); intrinsi-

1

1

33 115671 CONNECTOR; 1/8 npt(m) x

1

1

34 15D966 BRACKET, muffler

1

35 15E020 FITTING, compression; cst;

1

2

2

36 15E018 ELBOW, compression; cst;

2

2

37 244524 GROUND WIRE

2

38 113279 PLUG, tube fitting;

2

39 113505 NUT, keps, hex hd; 10-24

1

40 551787 SCREW, cap, button hd;

1

42 15D998 TUBE, fluid, A component; see

3

43 15D999 TUBE, fluid, B component; see

5

5

44 114104 SCREW, machine; 1/4-20 x

4

45 115942 NUT, hex, flange hd; 1/4-20

2

100451 COUPLING; 1/8 npt (fbe);

115671 CONNECTOR; 1/8 npt(m) x

15E021 FITTING, compression; sst;

15E019 ELBOW, compression; sst;

12

8

3/8-16 x 5/8 in. (16 mm)

1

ID; 1/2 npt (mbe); 18 in. (457 mm);

see also pages 45 and 47

1

1/2 npsm(f)

2

Schematic, page 22

2

cal Schematic, page 22

1

2

2

cally safe models only

1

non-intrinsically safe models only

2

1/4 in. (6 mm) OD tube;

intrinsically safe models only

1

1/4 in. (6 mm) OD tube; non-intrinsically safe models only

2

2

carbon steel models only;

1/4 npt(m) x 1/2 in. (13 mm) tube

2

stainless steel models only;

1/4 npt(m) x 1/2 in. (13 mm) tube

2

carbon steel models only;

3/8 npt(m) x 1/2 in. (13 mm) tube

2

stainless steel models only;

3/8 npt(m) x 1/2 in. (13 mm) tube

1

2

5/32 in. (4 mm) OD tube

2

4

10-32 x 3/8 in. (10 mm)

1

pages 45 and 47

1

pages 45 and 47

1

1-1/2 in. (38 mm)

7

38 309909H

Page 39

Parts

Ref.

No. Part No. Description Qty.

50 102656 MUFFLER

56 598095 TUBE; nylon; 5/32 in. (4 mm) OD;

clear; see pages 45 and 47

57 054753 TUBE; nylon; 5/32 in. (4 mm) OD;

black; see pages 45 and 47

58 054754 TUBE; nylon; 5/32 in. (4 mm) OD;

red; see pages 45 and 47

59 054757 TUBE; nylon; 5/32 in. (4 mm) OD;

green; see pages 45 and 47

60 590385 TUBE; polyethylene; 3/8 in. (10 mm)

OD; see pages 45 and 47

61 061134 TUBE; nylon; 1/2 in. (13 mm) OD;

see pages 45 and 47

68 114129 FITTING; 3/8 npt(m) x

1/2 in. (13 mm) OD tube fitting

2 ft

2 ft

2 ft

2 ft

0.7

5.2

Ref.

No. Part No. Description Qty.

2

69 100081 BUSHING, pipe; 1/2 npt(m) x

3/8 npt(f)

70 054123 TUBE; nylon; 1/4 in. (6 mm) OD;

see pages 45 and 47

79 195889 BUSHING, strain relief

93 113796 SCREW, hex hd, flange; 1/4-20 x

3/4 in. (19 mm)

94 15A818 COVER, sensor; non-intrinsically

safe carbon steel models only

95 C20272 O-RING; non-intrinsically safe car-

ft

96 15E383 BUSHING, strain relief;

ft

1

▲ Replacement Danger and Warning labels, tags, and cards

are available at no cost.

bon steel models only

non-intrinsically safe carbon steel

models only

1

4 ft

2

4

2

2

2

309909H 39

Page 40

Parts

Pump and Meter-based, Wall-mounted High Pressure Units

Part No. 234602 Series A, HydraMix 500 carbon steel pump and G3000 Meter

Part No. 234603 Series A, HydraMix 500 stainless steel pump and G3000 Meter

Part No. 234604 Series A, HydraMix 600 carbon steel pump and G3000 Meter

Part No. 234605 Series A, HydraMix 600 stainless steel pump and G3000 Meter

10

39

11

21, 28

22

20

38

79

45

22

21

TI4907b

40 309909H

Page 41

Pump and Meter-based, Wall-mounted High Pressure Units, continued

Parts

67

63

1

65

65 (Ref)

40

17 16

45

39

46

24

25

4

45

14

44

37

31

9

32

33

5

23

24 (Ref)

16

15

16 17

3

17

13

80

53

88

47

7

12

6

93

8

68

69

32

34

33

89

86

87

91

90

83

35

2

50

36

TI4908a

Pump Solenoid

Cable Connections

2 1

1

Downstroke solenoid connection.

2

Upstroke solenoid connection.

TI5294a

309909H 41

Page 42

Parts

Pump and Meter-based, Wall-mounted High Pressure Units, continued

See page 40 for model numbers and descriptions.

Ref.

No. Part No. Description Qty.

1 15D771 FRAME, wall mount

2 234593 MIX MANIFOLD; cst; carbon steel

models only; see 310654

234451 MIX MANIFOLD; sst; stainless steel

models only; see 310654

3 287230 CONTROL, air; see page 53

4 109544 ELBOW, pipe; 3/8 npt (mbe)

5 116756 ELBOW, street, 45°; 3/8 npt (mxf)

6 155665 UNION, adapter; 3/8 npsm(f) x

3/8 npt(m)

7 117629 FILTER, air; 5 micron

8 114316 ELBOW; 3/8 npt(m) x

3/8 in. (10 mm) OD tube fitting

9 15D795 FILTER, air; 40 micron

10 248270 PNEUMATIC CONTROL,

intrinsically safe; see page 48

11 234620 USER INTERFACE; see page 52

12 248572 PUMP, HydraMix 500, cst; 234602;

see 310672

248573 PUMP, HydraMix 500, sst; 234603;

see 310672

248574 PUMP, HydraMix 600, cst; 234604;

see 310672

248575 PUMP, HydraMix 600, sst; 234605;

see 310672

13 100361 PLUG, pipe; 1/2 npt

14 15D873 BRACKET, support, fluid manifold

15 114110 ELBOW; 1/2 npt(m) x

1/2 in. (13 mm) OD tube fitting

16 C19038 WASHER, lock; 1/4

17 112925 SCREW, cap, button hd;

1/4-20 x 3/8 in. (10 mm)

20 103196 SCREW, machine, phillips;

8-32 x 7/16 in. (11 mm)

21 15D767 PLATE, side

22 119291 SCREW, self-tapping

23 113802 SCREW, hex hd, flanged;

3/8-16 x 5/8 in. (16 mm)

24 220598 HOSE, air; nitrile; 1/2 in. (13 mm)

ID; 1/2 npt (mbe); 18 in. (457 mm);

see also pages 45, 46, and 47

25 C19024 ELBOW, swivel; 1/2 npt(m) x

1/2 npsm(f)

26 15D607 CABLE, sensor; see Electrical

Schematic, page 22

27 15D794 HARNESS, connector; see Electri-

cal Schematic, page 22

28▲ 290331 LABEL, warning

31 101765 GROMMET

32 100451 COUPLING; 1/8 npt (fbe)

Ref.

No. Part No. Description Qty.

33 115671 CONNECTOR; 1/8 npt(m) x

1

1/4 in. (6 mm) OD tube

carbon steel models only;

1/4 npt(m) x 1/2 in. (13 mm) tube

stainless steel models only;

1/4 npt(m) x 1/2 in. (13 mm) tube

carbon steel models only;

3/8 npt(m) x 1/2 in. (13 mm) tube

stainless steel models only;

3/8 npt(m) x 1/2 in. (13 mm) tube

5/32 in. (4 mm) OD tube

10-32 x 3/8 in. (10 mm)

pages 45 and 47

1-1/2 in. (38 mm)

3/8 in. (10 mm) OD tube

3/8 in. (10 mm) OD tube

clear; see pages 45, 46, and 47

black; see pages 45, 46, and 47

red; see pages 45, 46, and 47

green; see pages 45, 46, and 47

OD; see pages 45, 46, and 47

see pages 45, 46, and 47

1/2 in. (13 mm) OD tube fitting

3/8 npt(f)

12

1

34 15D966 BRACKET, muffler

35 15E020 FITTING, compression; cst;

1

1

1

1

1

36 15E018 ELBOW, compression; cst;

1

1

1

1

37 244524 GROUND WIRE

38 113279 PLUG, tube fitting;

1

1

39 113505 NUT, keps, hex hd; 10-24

40 551787 SCREW, cap, button hd;

1

42 15D998 TUBE, fluid, A component; see

1

44 114104 SCREW, machine; 1/4-20 x

1

45 115942 NUT, hex, flange hd; 1/4-20

1

46 113319 FITTING, air; 1/4 npt(m) x

1

1

47 115841 ELBOW; 1/4 npt(m) x

5

50 102656 MUFFLER

5

53 111763 ELBOW; 1/4 npt (mbe)

56 598095 TUBE; nylon; 5/32 in. (4 mm) OD;

4

57 054753 TUBE; nylon; 5/32 in. (4 mm) OD;

2

58 054754 TUBE; nylon; 5/32 in. (4 mm) OD;

4

59 054757 TUBE; nylon; 5/32 in. (4 mm) OD;

1

60 590385 TUBE; polyethylene; 3/8 in. (10 mm)

1

61 061134 TUBE; nylon; 1/2 in. (13 mm) OD;

1

63 162453 NIPPLE; 1/4 npsm x 1/4 npt

65 104641 FITTING, bulkhead

1

67 100840 ELBOW, street; 1/4 npt (m x f)

68 114129 FITTING; 3/8 npt(m) x

1

2

69 100081 BUSHING, pipe; 1/2 npt(m) x

2

15E021 FITTING, compression; sst;

15E019 ELBOW, compression; sst;

2

1

1

1

1

1

1

2

2

4

1

1

7

1

1

1

1

2 ft

2 ft

2 ft

2 ft

4.6

ft

1 ft

1

1

1

1

1

42 309909H

Page 43

Ref.

No. Part No. Description Qty.

70 054123 TUBE; nylon; 1/4 in. (6 mm) OD;

see pages 45, 46, and 47

79 195889 BUSHING, strain relief

80 100206 BUSHING; 1/2 npt(m) x 1/4 npt(f)

83 501867 CHECK VALVE

86 114339 UNION, swivel; 1/4 npsm(f) x

1/4 npt(m)

87 15D957 HARNESS, wire

88 119159 SWITCH, air flow

89 166846 ADAPTER; 1/4 npsm x

1/4 npt (mbe)

90 239716 METER, G3000; see 308778

91 195283 SHIELD, ESD, G3000

▲ Replacement Danger and Warning labels, tags, and cards

are available at no cost.

3.5

Parts

ft

1

1

1

1

1

1

1

1

1

309909H 43

Page 44

Parts

Tube Connections, Low Pressure Pumps

Find the keys on the drawing to ensure proper connections.

Ref.

Key Description

A1 Dispense Valve A OFF 56 24 (610)

A2 Dispense Valve A ON 57 24 (610)

B1 Dispense Valve B OFF 59 24 (610)

B2 Dispense Valve B ON 58 24 (610)

C1 Air to Pneumatic Control (10) 60 8 (203)

D1 Air Filter (9) Drain Tube 70 24 (610)

D2 Air Filter (7) Drain Tube 70 18 (457)

G1 Gun Air Regulator (74) Input 60 31 (787)

No.

Length,

in. (mm)

Ref.

Length,

Key Description

G2 Gun Air Regulator (74) Output 60 30 (762)

L1 Fluid Line, Pump A to Dispense Valve A 78 18 (457)

L2 Fluid Line, Pump B to Dispense Valve B 78 18 (457)

M1 Air Filter (9) to Air Control (3) 24 18 (457)

P1 Pump A Input Air 60 17 (432)

P2 Pump B Input Air 60 21 (533)

S1 Pump A Solenoid Inputs (2 tubes) 70 2 (51)

S2 Pump B Solenoid Inputs (2 tubes) 70 2 (51)

No.

in. (mm)

G1

P2

L2

G2

M1

D1

P2

C1

C1

D1 D2

A2B2

P1

G1

M1

D2

P1

A SideB Side

S1S2

L1

A1

B1

B1 A1

L2

44 309909H

A2B2

L1

TI5278a

Page 45

Tube Connections, High Pressure Pumps

Find the keys on the drawing to ensure proper connections.

Ref.

Key Description

A1 Dispense Valve A OFF 56 24 (610)

A2 Dispense Valve A ON 57 24 (610)

B1 Dispense Valve B OFF 59 24 (610)

B2 Dispense Valve B ON 58 24 (610)

C1 Air to Pneumatic Control (10) 60 8 (203)

D1 Air Filter (9) Drain Tube 70 24 (610)

D2 Air Filter (7) Drain Tube 70 18 (457)

E1 Pump A Exhaust 61 8 (203)

E2 Pump B Exhaust 61 12 (305)

No.

Length,

in. (mm)

Ref.

Length,

Key Description

L1 Fluid Line, Pump A to Dispense Valve A 42 molded

L2 Fluid Line, Pump B to Dispense Valve B 43 molded

M1 Air Filter (9) to Air Control (3) 24 18 (457)

P1 Pump A Input Air 61 18 (457)

P2 Pump B Input Air 61 24 (610)

No.

in. (mm)

tube

tube

P1P2

Parts

L2

M1

B1

D1

C1

A1

C1

D1 D2

A2B2

M1

D2

P1P2

A SideB Side

E1E2

L1

B1 A1

L2

A2B2

309909H 45

L1

TI5279a

Page 46

Parts

Tube Connections, Meters

Find the keys on the drawing to ensure proper connections. This page shows a unit with meters on both sides. If your

model is a pump/meter combination unit, also refer to pages 44 and 45 for additional connections.

Ref.

Ref.

Key Description

A1 Dispense Valve A OFF 56 24 (610)

A2 Dispense Valve A ON 57 24 (610)

B1 Dispense Valve B OFF 59 24 (610)

B2 Dispense Valve B ON 58 24 (610)

C1 Air to Pneumatic Control (10) 60 8 (203)

No.

Length,

in. (mm)

G1

Key Description

D1 Air Filter (9) Drain Tube 70 24 (610)

D2 Air Filter (7) Drain Tube 70 18 (457)

G1 Gun Air Flow Switch (88) to Gun Air Line 60 30 (762)

M1 Air Filter (9) to Air Control (3) 24 18 (457)

No.

Length,

in. (mm)

B Side

M1

B1

D1

A1

C1

A2B2

C1

P2

D1

G1

M1

D2

D2