Page 1

Instructions - Parts

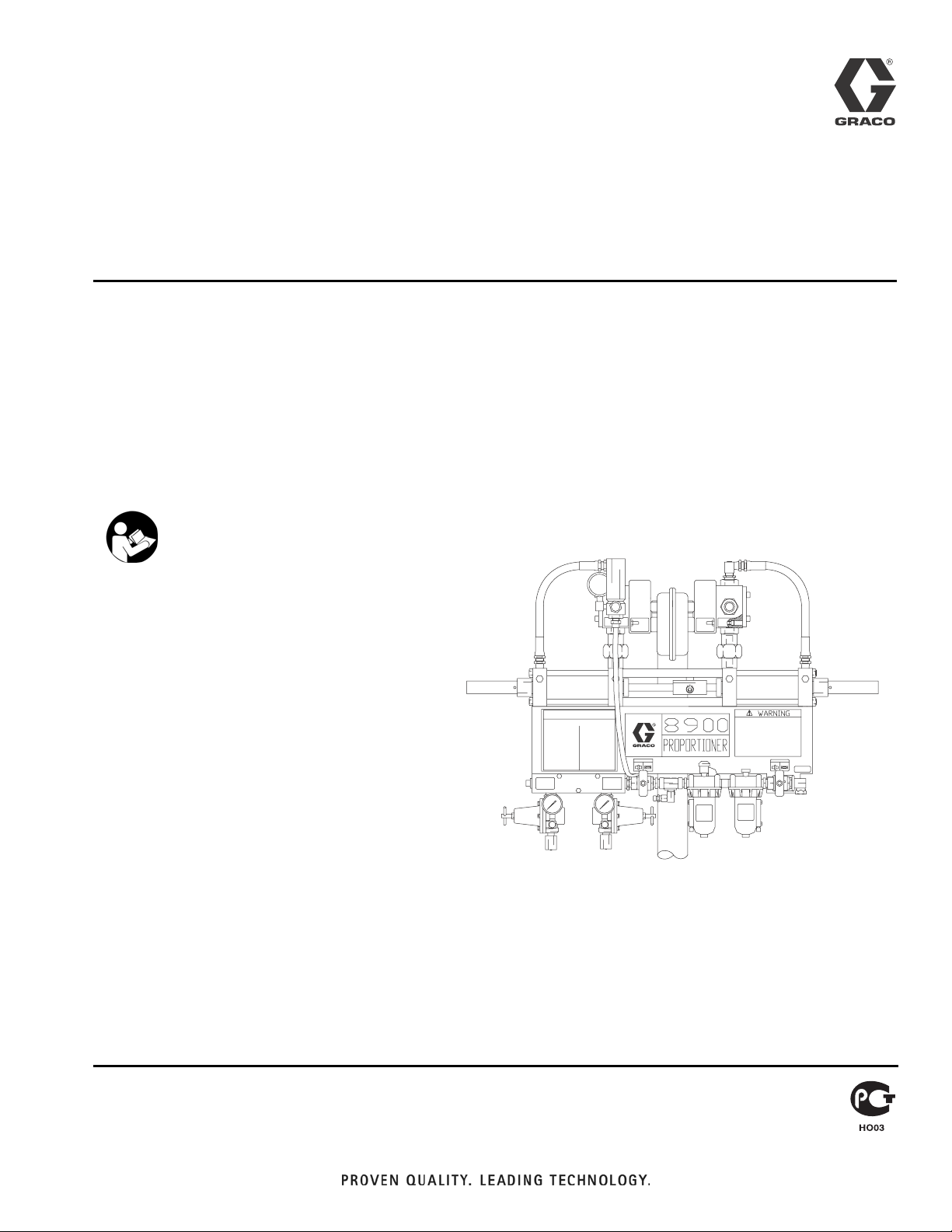

8900 Proportioner

309790ZAA

Configured product offering for dispensing fixed or variable ratio of two

fluids. For professional use only.

Not approved for use in European explosive atmosphere locations.

2000 psi (13.8 MPa, 138 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 8 for pump model numbers, ratios and

working pressures.

ENG

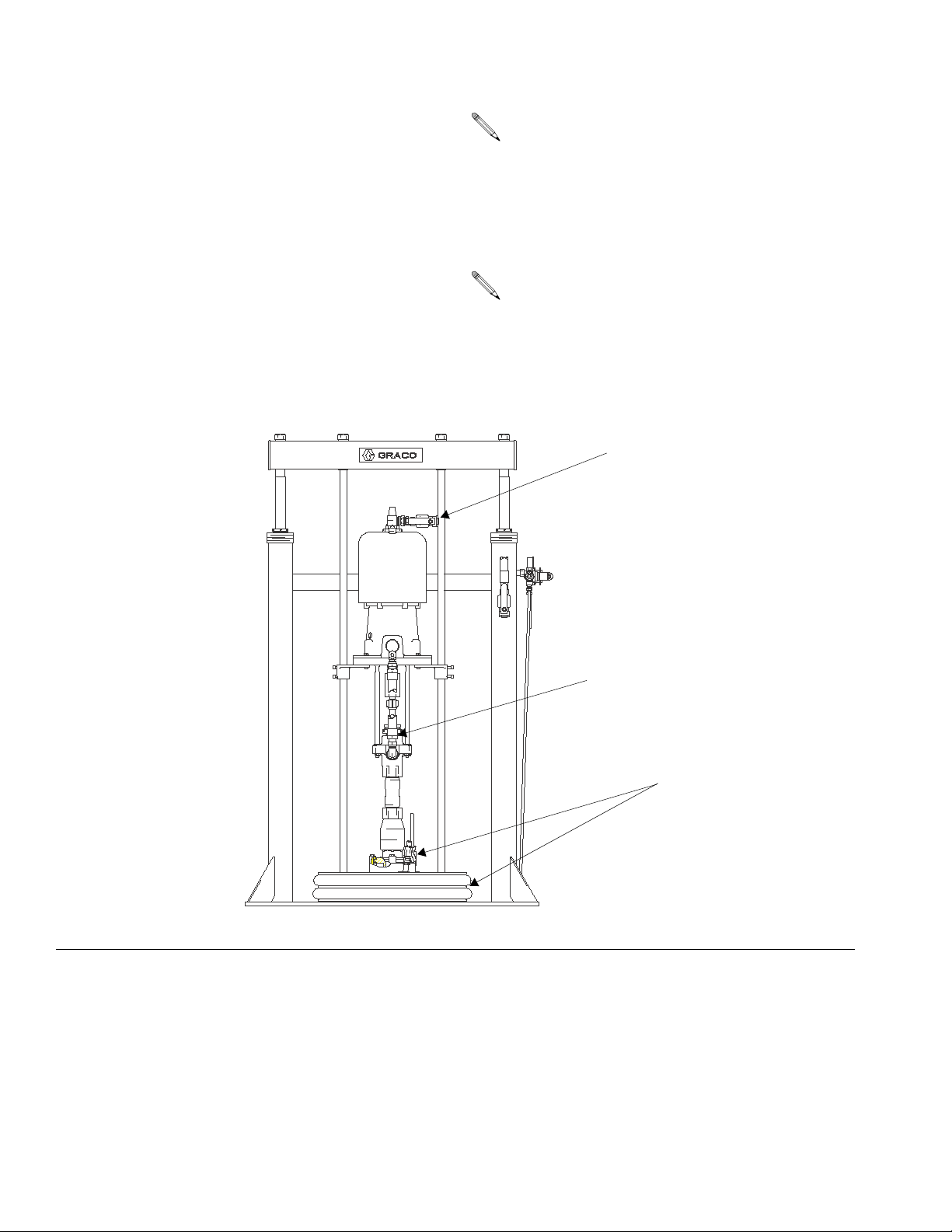

Fixed-ratio proportioner shown

TI2761A

Page 2

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . 6

Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Major Components . . . . . . . . . . . . . . . . . . . . . . . 6

Ratio Proportioning . . . . . . . . . . . . . . . . . . . . . . . 6

System Components and Operation Overview . . 6

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 10

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Set the Ratio (variable ratio models only) . . . . . 14

Output Charts/Ratio Settings . . . . . . . . . . . . . . 15

Before You Load Material . . . . . . . . . . . . . . . . . 18

Load Component A . . . . . . . . . . . . . . . . . . . . . . 19

Prime Pump A . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Load Component B . . . . . . . . . . . . . . . . . . . . . . 21

Prime with Component B . . . . . . . . . . . . . . . . . 24

Fill the 8900 Proportioner with Material . . . . . . 24

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Pressure Relief Procedure . . . . . . . . . . . . . . . . 27

Dispense Mixed Material . . . . . . . . . . . . . . . . . . 28

Changing Component A Drum . . . . . . . . . . . . . 30

Changing Component B Pail . . . . . . . . . . . . . . . 31

Filling Component B Pressure Tank . . . . . . . . . 32

Daily Procedures . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8900 Proportioner Operating Pressures . . . . . . 36

Air Supply Troubleshooting Chart . . . . . . . . . . . 37

Pump Troubleshooting Overview . . . . . . . . . . . 38

Troubleshooting Guide: Feed pumps . . . . . . . . 39

Troubleshooting Guide: 8900 Proportioner . . . . 40

Troubleshooting Guide: Manifold/Mixer . . . . . . . 41

Preventive Maintenance . . . . . . . . . . . . . . . . . . 42

Service and Repair . . . . . . . . . . . . . . . . . . . . . . . . 43

Repair the Cylinder (Fixed Ratio) . . . . . . . . . . . 43

Replace Air Valve . . . . . . . . . . . . . . . . . . . . . . . 45

Disassemble Fluid Valve . . . . . . . . . . . . . . . . . . . . 46

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8900 Proportioner, Fixed Ratio . . . . . . . . . . . . . 48

8900 Proportioner, Variable Ratio . . . . . . . . . . . 50

Cylinder Assemblies . . . . . . . . . . . . . . . . . . . . . 52

Limit Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Air Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-Way Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Pump Feed Module Selection for Component A or

Component B . . . . . . . . . . . . . . . . . . . . . . . 56

20:1 President on 5 Gallon Ram . . . . . . . . . . . . 56

34:1 Senator on 5 Gallon Ram . . . . . . . . . . . . . 58

23:1 Monark on 5 Gallon Ram . . . . . . . . . . . . . 60

20:1 President on 55 Gallon Ram . . . . . . . . . . . 62

34:1 Senator on 55 Gallon Ram . . . . . . . . . . . . 64

31:1 Bulldog on 55 Gallon Ram . . . . . . . . . . . . . 65

20:1 Senator on 55 Gallon Drum . . . . . . . . . . . . 66

9:1 DynaMite on 1 Gallon Can Ram . . . . . . . . . 67

10 Gallon Press Tank with 15:1 Booster . . . . . . 68

10:1 President 5 Gallon Pail Cover . . . . . . . . . . 69

Mix Kit Selection . . . . . . . . . . . . . . . . . . . . . . . . 70

Cartridge Fill Medium Viscosity Wide Ratio . . . 70

Cartridge Fill High Viscosity Wide Ratio . . . . . . 72

Brush Grade High Viscosity Wide Ratio . . . . . . 74

MD2 20 ft Automatic . . . . . . . . . . . . . . . . . . . . . 76

MD2 20 ft Hand Gun . . . . . . . . . . . . . . . . . . . . . 77

MD2 15 ft Hand Gun Wide Ratio Moisture Lock 78

High Volume Static Mix Manifold . . . . . . . . . . . . 79

High Volume Static Mix Kit with Pump Pilots . . . 80

Stanchion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Boom Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 82

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 86

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 86

2 309790ZAA

Page 3

309790ZAA 3

Page 4

Warnings

Warnings

Skin Injection Hazard

Spray from the gun, hose leaks, or ruptured components can inject fluid through skin and cause

extremely serious injury, including need for amputation. Fluid splashed in the eyes or on skin can cause

serious injury.

• Fluid injected into skin might look like just a cut, but it is a serious injury. Get immediate surgical

• Do not point the gun at anyone or any part of the body.

• Do not put hand or fingers over the spray tip/nozzle.

• Do not stop or deflect leaks with hand, body, glove or rag.

• Do not “blow back” fluid; this is not an air spray system.

• Always have tip guard and trigger guard on the gun when spraying.

• Check gun diffuser weekly. Refer to gun manual.

Warning

treatment.

• Check trigger safety operation before spraying. Lock trigger safety when you stop spraying.

• Follow the Pressure Relief Procedure, page 27, if the spray tip/nozzle clogs and before cleaning,

checking or servicing the equipment.

• Tighten fluid connections before operating equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do not repair

high pressure couplings; replace the entire hose.

• Fluid hoses must have spring guards on both ends to help protect them from rupture caused by kinks

or bends near the couplings.

Toxic Fluid Hazard

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on skin, swallowed, or inhaled.

• Know specific hazards of the fluid. Read fluid manufacturer’s warnings.

• Wear appropriate protective clothing, gloves, eyewear, and respirator.

4 309790ZAA

Page 5

Warnings

Warning

Equipment Misuse Hazard

Equipment misuse can cause equipment to rupture, malfunction, or start unexpectedly and cause serious

injury.

• This equipment is for professional use only.

• Read manuals, tags, and labels before operating equipment.

• Use equipment only for its intended purpose. If you are uncertain, call your Graco distributor.

• Do not alter or modify equipment. Use only genuine Graco parts and accessories.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed maximum working pressure of lowest rated system component.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data sec-

tion of all equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 180°F (82°C) or below -40°F (-40°C).

• Do not kink or overbend hoses or use hoses to pull equipment.

• Comply with all applicable local, state, and national fire, electrical, and other safety regulations.

• Do not use excessive drum separation air pressure as the drum could rupture. Make sure the drum is

not damaged and the ram plate is free to exit the drum before applying air pressure.

Fire and Explosion Hazard

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result

in fire or explosion and serious injury.

• Ground the equipment and object being sprayed. See Grounding, page 12.

• If you experience static sparking or electric shock, stop operation immediately. Identify and correct

the problem.

• Provide fresh air ventilation to avoid building up flammable fumes.

• Keep the spray area free of debris, including solvent, rags, and gasoline.

• Extinguish all sources of flames in the spray area, including pilot lights and cigarettes.

• Do not turn on or off any light switch or plug or unplug electrical equipment in the spray area while

operating or if fumes are present.

• Do not operate a gasoline engine in the spray area.

• Keep a fire extinguisher in the work area.

Moving Parts Hazard

Moving parts, such as priming piston and wiper plate, can pinch or amputate fingers. Keep clear of moving parts when starting or operating equipment and when equipment is pressurized.

• Keep hands and fingers away from the priming piston.

• Keep hands away from the ram wiper plate and pail lip.

• Before servicing, follow the Pressure Relief Procedure, page 27, to avoid equipment startup.

309790ZAA 5

Page 6

Theory of Operation

Theory of Operation

Use

The 8900 Proportioner is used with two component

materials where one or both components is high viscosity. This is typically found in the sealant and adhesive

industry, where special requirements for loading and

pumping necessitate the use of the 8900 proportioning

system.

Major Components

The major components of the 8900 Proportioner system

include the:

• Component A or major volume metering cylinder

• Component B or minor volume metering cylinder

• Component A or major volume feed supply

• Component B or minor volume feed supply

Ratio Proportioning

The A and B cylinders are positive displacement metering cylinders. Positive displacement cylinders displace a

defined volume of fluid for a given stroke length.

On fixed ratio units, the volumetric ratio is the ratio of the

area of the component A displacement cylinder to the

area of the component B displacement cylinder. At a 1:1

ratio, the displacement cylinders are the same size. On

higher ratio units the component A cylinder is usually the

larger of the two. The ratio of the components is the difference in effective area between the cylinders.

On variable ratio units, the component B cylinder has an

adjustable stroke length. The component A cylinder has

a fixed stroke length. By setting the stroke adjustment to

different points on the connecting linkage, you can

change the stroke length of the B cylinder, which

changes the mix ratio. You can calculate the material

mix ratio from the ratio of the cylinder displacement volume.

System Components and Operation Overview

Feed Systems - Feed Pumps

Load the Feed Pumps and Proportioner

The A and B feed pumps/cylinders must completely fill

(prime) on both strokes to ensure accurate material displacement.

With high viscosity materials, it is difficult for material to

flow into the pump. Individual feed pumps are used to

supply these materials under pressure to the 8900 Proportioner. When air is trapped in the feed system due to

improper loading, a condition called cavitation occurs.

If cavitation occurs, part of the downstroke will be used

to fill the vacuum before any material is actually displaced. Since the total stroke length is used to calculate

mix ratio, this may result in an off-ratio condition.

To prevent cavitation with higher viscosity materials,

both cylinders are pressure fed. The A pump is pressurized by a pneumatic ram supply unit applying a downward force on a 55-gallon plate fitted into the drum. A

shovel action pump fluid inlet further aids in pump priming. Component B is delivered to the B pump by pressure fed 5- or 55-gallon supply modules, depending on

the volumetric ratio of the material.

Pneumatic ram assisted feed pumps may not be

required for lower viscosity materials.

Feed Systems - Alternative Feed Supplies

Header or other feed systems may be used to supply A

and B materials to the 8900 Proportioner. Generally

these feed systems are provided by others and are not

addressed in this manual. This manual applies only to

the Graco Configured 8900 Proportioner system.

Note that the mix ratio of the 8900 Proportioner is

achieved by volumetric ratio of component A to component B and not by weight. These two ratios are often different depending on material properties.

6 309790ZAA

Page 7

Theory of Operation

Pump Fluids to the Mixer

Fluid is pumped through the proportioner to a mix chamber or to a 2-component dispense gun, where component A and component B are first introduced before

being mixed with a static mixer.

A fluid injector nozzle/check valve injects component B

into component A at the mix chamber. When enough

pressure builds up, the check valve opens and component B flows into the mix chamber. This means that during flow conditions with two positive displacement

cylinders linked together, the pressures at the mix point

are equal.

Any pressure differences noted on the gauges while

running, reflect differences in the pressure lost by each

fluid getting from the gauge to the mix point. These

pressure drops are caused by hoses and fittings in conjunction with material viscosity.

Mix the Fluids

Both components leave the mix chamber and enter a

static mixer where they are mixed to a homogeneous

blend. The mixer consists of a series of left and

right-hand spiral elements. This is true for both mix

chamber and 2-component mix gun.

Some 8900 Proportioners use a 2K disposable mixer

element dispense valve instead of the flow gun.

The 8900 Proportioner can be used in automatic

assembly lines with the addition of a logic interface.

When the components are pumped through the mixer,

they are progressively divided and recombined. Static

mixers used on the 8900 Proportioner system include

the tri-core mixer, flexible hose mixer, or disposable

mixer.

Ratio Checks

On the variable ratio model, a ratio check station option

verifies the volumetric mix ratio of the two components.

It is located at the outlet blocks. With all outbound fluid

valves closed, each component flows through individual

ball valves opened by a common handle into containers.

Volumetric mix ratio can be calculated from the weight of

each component or by direct measurement. Ratio

checks are performed with the back pressures set to

actual operating pressures to simulate the normal back

pressures created by the mix chamber and gun.

Dispense Valve

An extrusion flow gun is commonly used as the applica-

tion device. It has a final or clean up mixer installed in

the handle. Various extrusion nozzles are available for

caulking or sealing applications.

309790ZAA 7

Page 8

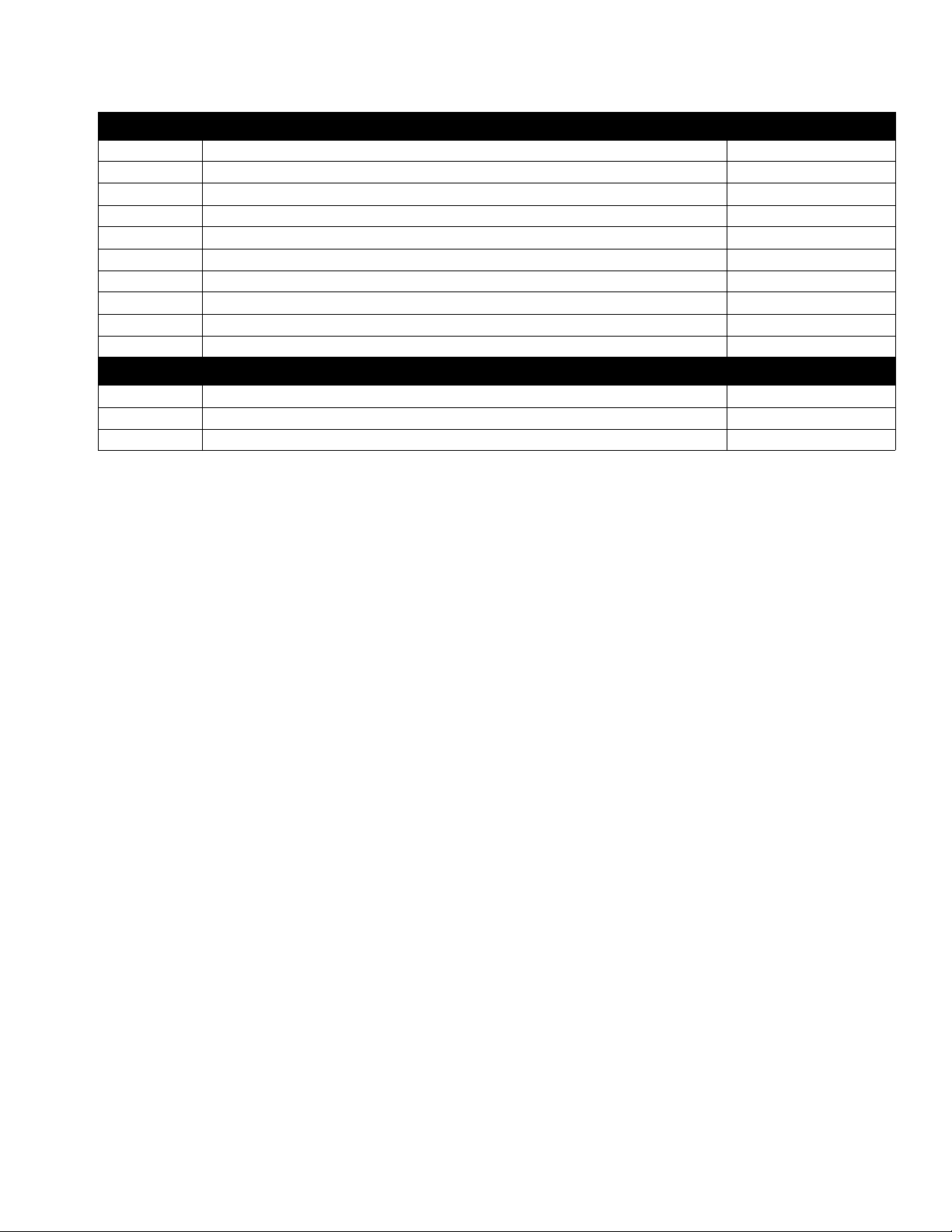

Models

Models

Refer to form 684041 for selection information.

Model Description

890-D Power Valved Passive Proportioner

Code A Proportioner Selection (“A” Cyl. / “B” Cyl.) Module Number

1 1:1 Fixed (1000/1000) 570371

2 2:1 Fixed (1000/500) 570372

3 2.5:1 Fixed (250/100) 570373

4 4:1 Fixed (1000/250) 570374

5 5:1 Fixed (500/100) 570375

6 10:1 Fixed (1000/100) 570376

7 9:1 Fixed (1000/111) 246557

A 1:1 to 4:1 Variable (500/500) 570377

B 2:1 to 8:1 Variable (500/250) 570378

D 5:1 to 20:1 Variable (500/100) 570380

Code B Pump Feed Module Selection for Component A Module Number

A 20:1 President on 5 Gallon Ram 965571

B 34:1 Senator on 5 Gallon Ram 965597

C 23:1 Monark on 5 Gallon Ram 570142

D 20:1 President on 55 Gallon Ram 570114

E 34:1 Senator on 55 Gallon Ram 965572

F 31:1 Bulldog on 55 Gallon Ram 570141

G 20:1 Senator on 55 Gallon Drum 570309

H 9:1 DynaMite 1 Gallon Can Ram 570249

J 10 Gallon Press Tank with 15:1 Booster 570037

K 10:1 President 5 Gallon Pail Cover 570264

NNone

Code C Pump Feed Module Selection for Component B Module Number

A 20:1 President on 5 Gallon Ram 965571

B 34:1 Senator on 5 Gallon Ram 965597

C 23:1 Monark on 5 Gallon Ram 570142

D 20:1 President on 55 Gallon Ram 570114

E 34:1 Senator on 55 Gallon Ram 965572

F 31:1 Bulldog on 55 Gallon Ram 570141

G 20:1 Senator on 55 Gallon Drum 570309

H 9:1 DynaMite 1 Gallon Can Ram 570249

J 10 Gallon Press Tank with 15:1 Booster 570037

K 10:1 President 5 Gallon Pail Cover 570264

NNone

8 309790ZAA

Page 9

Code D Mix Kit Selection Module Number

1 Cart Fill Medium Viscosity Wide Ratio 570248

2 Cart Fill High Viscosity Wide Ratio 570318

3 Brush Grade High Viscosity Wide Ratio 570358

4 MD2 20 ft Automatic Wide Ratio 24H258

5 MD2 20 ft Automatic Close Ratio 24H259

6 MD2 20 ft Hand Gun Wide Ratio 24H260

7 MD2 20 ft Hand Gun Close Ratio 24H261

8 MD2 15 ft Hand Gun Wide Ratio Moisture Lock 24H243

9 High Volume Static Mix Kit with Pump Pilots 570263

NNone

Code E Mounting Type Selection Module Number

1 Stanchion 570071

2 Boom Assembly 246589

N None (mount on 3 in. 55 gallon ram)

Models

309790ZAA 9

Page 10

Installation

Installation

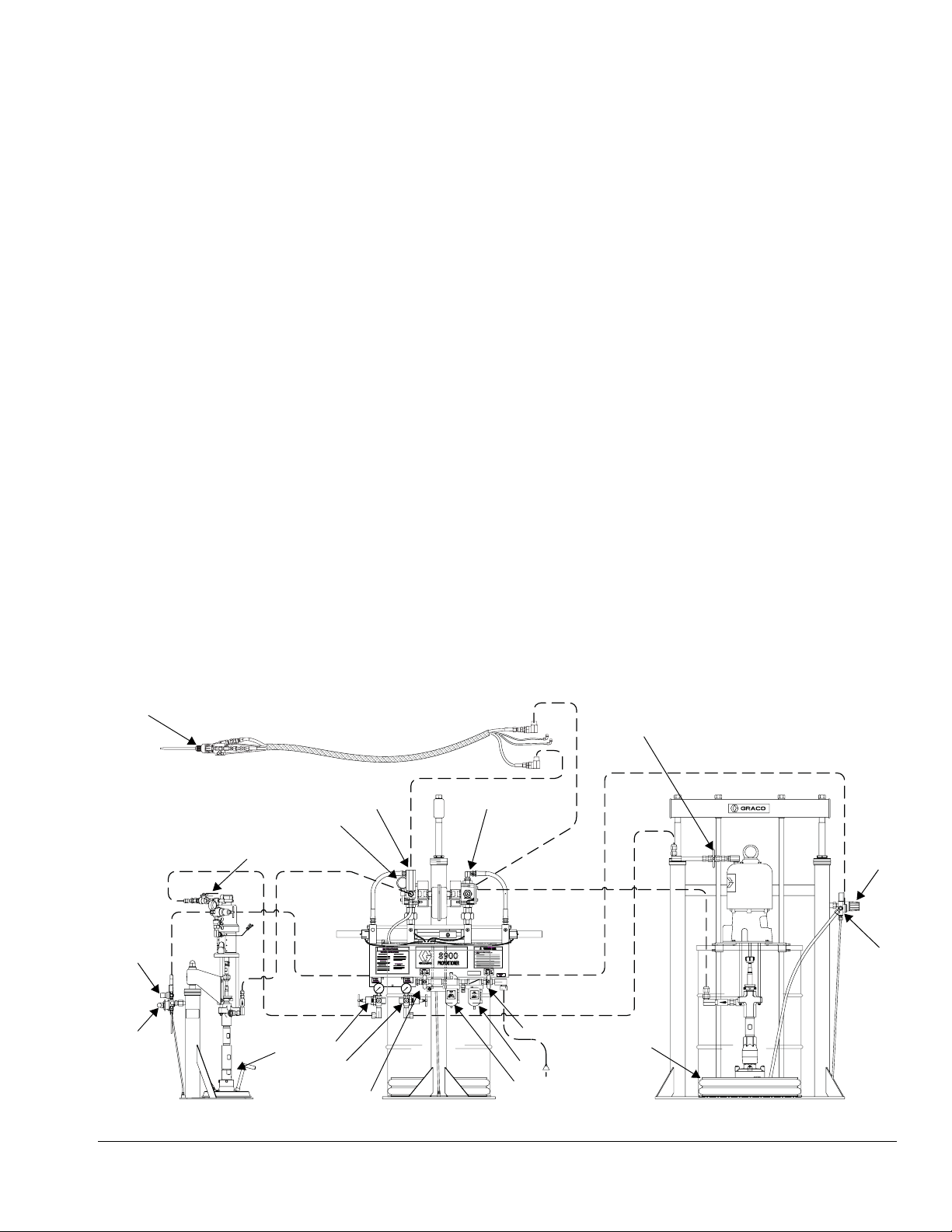

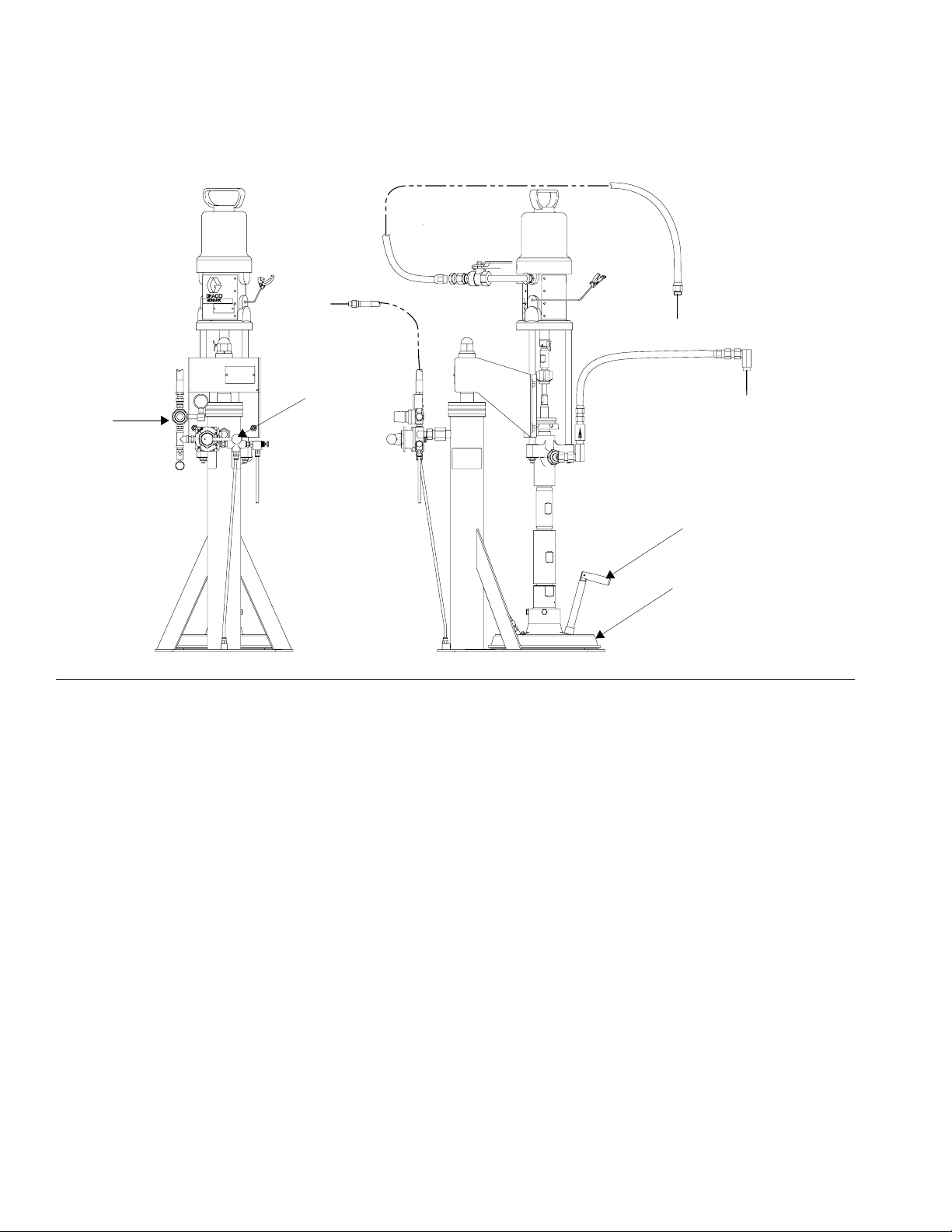

Typical Installation

Figures 1-3 are only guides for selecting and installing system components and accessories. Contact your

Graco distributor for assistance in designing a system to suit your needs.

Location

Position the feed modules so the pump and ram are

easily accessible. Ensure that there is sufficient overhead clearance when the ram is fully raised. Refer to

the ram manual for clearance dimensions.

Using the holes in the ram base as a guide, drill four

holes for 1/2 in. (13 mm) anchors.

Key:Figs. 1 and 2

A System Air Shutoff Valve (bleed-type)

B Main Air Filter

C Component B Ram Directional Valve

D Component B Ram Air Pressure Regulator

E Component B Air Supply Valve (bleed-type)

F Component B Air Supply Regulator

G Component A Air Supply Valve

H Component B Outlet Pressure Gauge

J Component B Feed Pressure Gauge

K Component A Feed Pressure Gauge

Q

J

(behind)

H

Check that the ram base is level in all directions. If

necessary, level the base using metal shims. Secure

the base to the floor using 1/2 in. (13 mm) anchors

that are long enough to prevent the ram from tipping.

L Component A and Component B Feed Pump Air

Motor Lubricator

M Component B Ram Plate with Vent Stick or Valve

N Component A Ram Plate with Drum Vent Valve

O Component A Pump Air Regulator

P Component A Ram Directional Valve

Q MD2 Gun with Disposable Mixers

R Component A Ram Air Pressure Regulator

S Accessory/Gun Air Supply Valve

G

K

(behind)

E

WARNINGWARNING

WARNINGWARNING

INSTRUCTIONS

INSTRUCTIONS

READ MANUAL BEFORE OPERATING

D

C

M

F

DISPENSE MIXED MATERIAL

ADJUST FLOW RATE

DRUM OR PAIL CHANGE

"B" PUMP

PRESSURE

ADJUSTMENT

R

BASE PURGE AND SHUT-DOWN

REFILLING PRESSURE POT

(IF EQUIPPED)

PUMPS

ONOFF

"A" PUMP

PRESSURE

ADJUSTMENT

O

8900

PROPORTIONER

WARNINGWARNING

High pressure device for professional use only.

Read instruction manual before operating. Observe all

warnings.

MAIN AIR

OFF ON

MAIN AIR

INLET

A

N

B

L

S

FIG. 1:

10 309790ZAA

R

P

ti16735a

Page 11

Installation

Supply header system supplied by others

(not covered in this manual).

Component B

Supply Header

Component B

Fluid Regulator

FIG. 2:

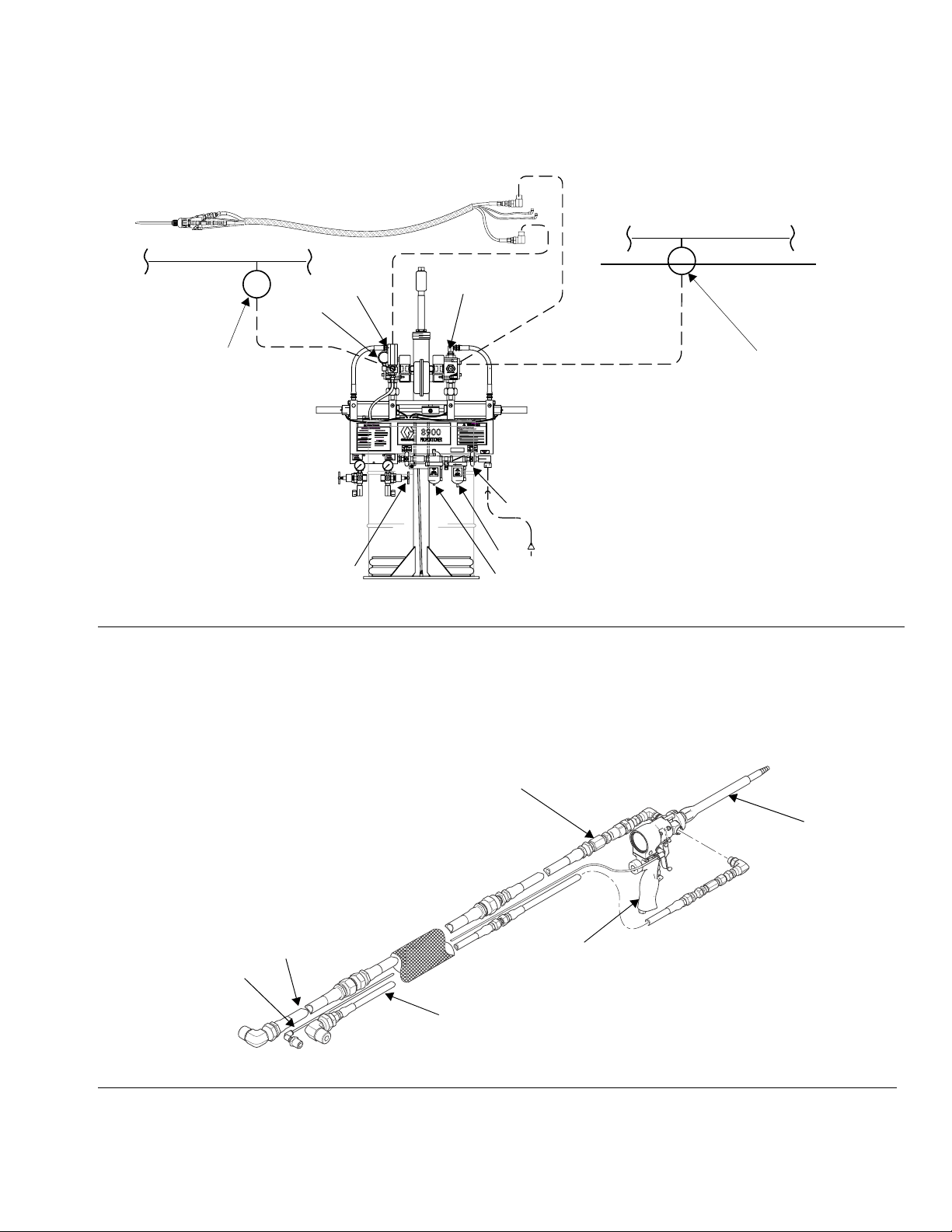

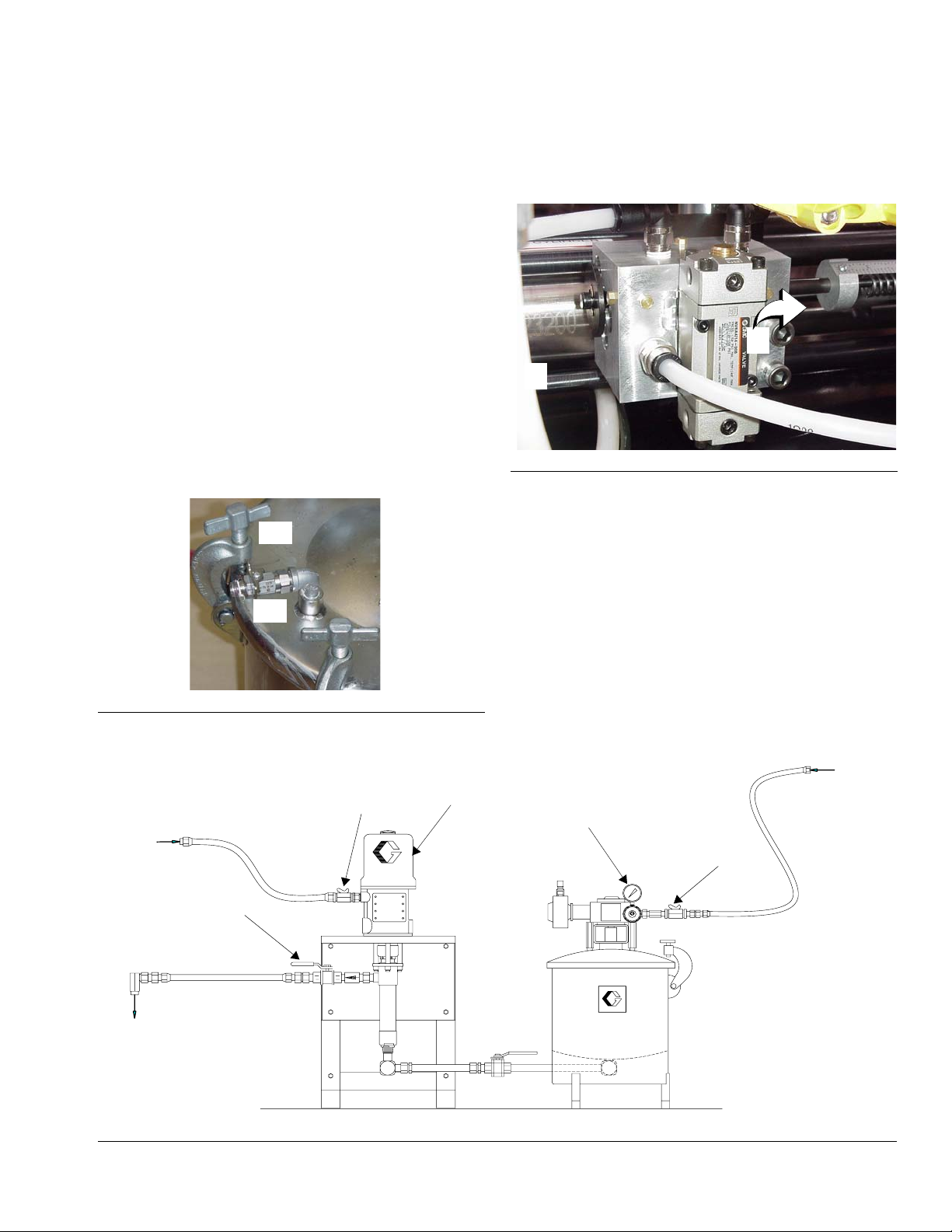

Key:FIG. 3

Q2K Gun

V Disposable Mixer Element

W Component B Injector Valve

H

J

(behind)

INSTRUCTIONS

INSTRUCTIONS

READ MANUAL BEFORE OPERATING

DISPENSE MIXED MATERIAL

ADJUST FLOW RATE

DRUM OR PAIL CHANGE

"B" PUMP

PRESSURE

ADJUSTMENT

S

K

(behind)

Component A

Supply Header

Component A

Fluid Regulator

WARNINGWARNING

WARNINGWARNING

8900

PROPORTIONER

WARNINGWARNING

High pressure device for professional use only.

Read instruction manual before operating. Observe all

warnings.

MAIN AIR

OFF ON

MAIN AIR

INLET

R

BASE PURGE AND SHUT-DOWN

REFILLING PRESSURE POT

(IF EQUIPPED)

PUMPS

ONOFF

"A" PUMP

PRESSURE

ADJUSTMENT

A

B

L

ti16759a

X Air Trigger Pilot

Y Component B Supply

Z Component A Supply

W

V

Y

Q

X

Z

ti16737a

FIG. 3

309790ZAA 11

Page 12

Installation

Ground

WARNING

The system must be properly grounded. Read warnings, page 5. Follow the instructions below.

Pump: use the ground wire and clamp (supplied). There

are two styles of ground connections on pump air

motors.

If you have the ground screw (a) shown in F

(King air motor only), order part no. 222011 ground wire,

ring terminal, and clamp assembly (b). To install

222011, remove the ground screw (a) and insert it

through the eye of ring terminal (c), then tighten ground

screw back into air motor as shown in F

IG. 4. Connect

the other end of the wire to a true earth ground.

b

a

c

IG. 4

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500

ft (150 m) combined hose

length to ensure grounding continuity. Check the electrical resistance of your air and fluid hoses. If the total

resistance to ground exceeds 29 megohms, replace the

hose immediately.

Air compressor: follow manufacturer’s recommendations.

Spray gun/dispense valve: ground through connection

to a properly grounded fluid hose and pump.

Fluid supply container: follow your local code.

Substrate: follow your local code.

Solvent pails used when flushing: follow your local

code. Use only conductive, metal pails, placed on a

grounded surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which

interrupts grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold a metal part of the gun/dis-

pense valve firmly to the side of a grounded metal pail,

then trigger the gun/valve.

IG. 4: Ground Screw (King air motors only)

F

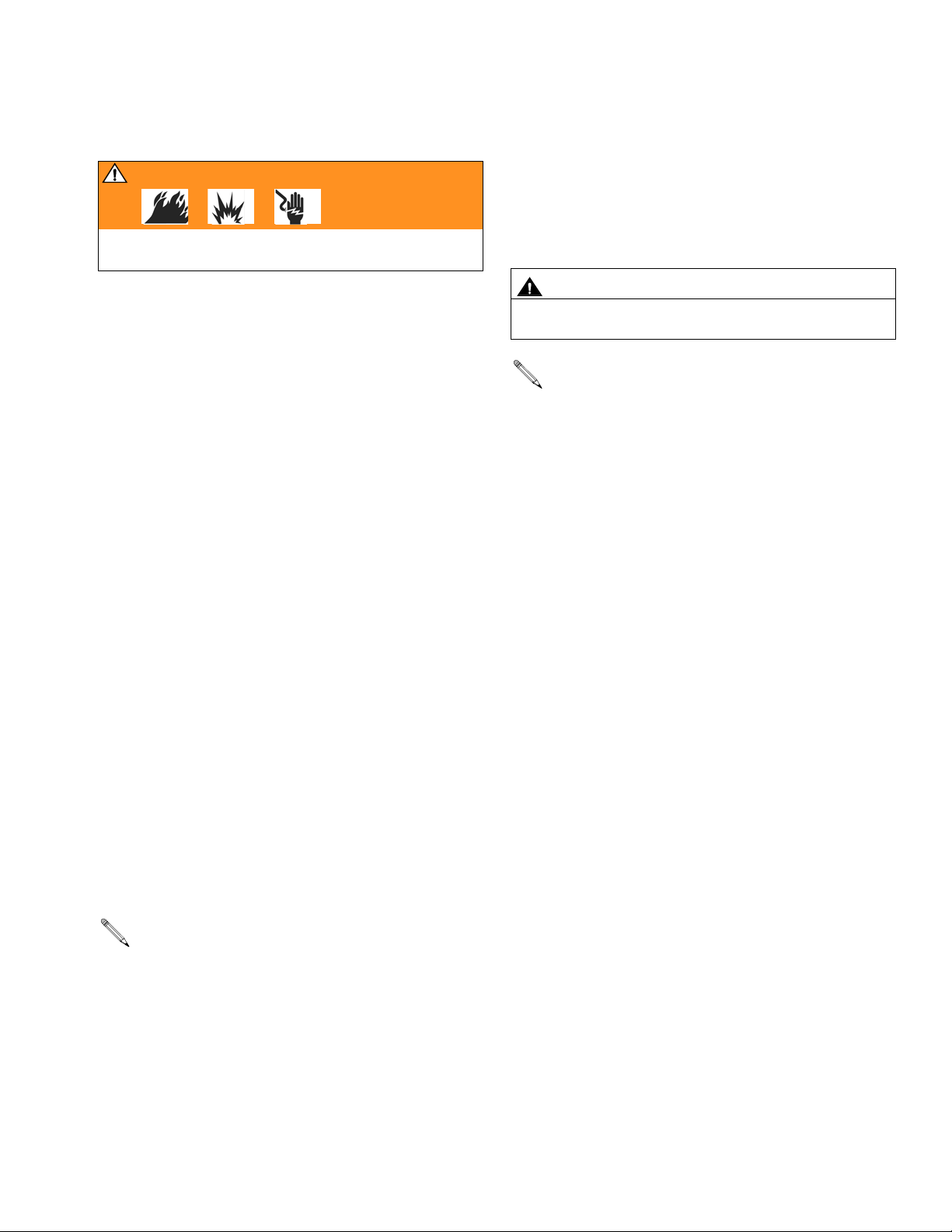

If you have the ground screw (d) shown in F

IG. 5,

loosen the grounding lug locknut (g) and washer (f).

Insert one end of the ground wire (e) into the slot in lug

(d) and tighten the locknut securely. Connect the other

end of the wire to a true earth ground. Order 237569

ground wire and clamp assembly.

e

g

f

d

IG. 5 Ground Screw

F

12 309790ZAA

Page 13

Installation

Flush

WARNING

Read warnings, pages 4-5. Follow Ground instructions, page 12.

• The equipment was tested with light, soluble oil.

Flush the system before loading material to avoid

contamination.

• Flush at the lowest pressure possible and check

connectors for leaks.

To flush the system:

1. On the ram-mounted component A supply units, you

must remove the drum ram plate to immerse the A

pump in a solvent pail. To remove the plate:

a. Disconnect the blow-off air line from the ram

plate.

b. Disconnect the tie rod nuts from the ram cross

beam.

2. Flush the system and all hoses by very slowly opening the motor control valves until 30 psi (207 kPa,

2.1 bar) is shown on the component A outlet pressure gauge.

Flush for 1-2 minutes, then close the motor control

valves.

CAUTION

To avoid damaging the pump, open the motor control

valves very slowly to prevent a pump runaway condition.

It is normal for the air valve to exhaust air when it is

partially open.

3. Check connectors for leaks and tighten them if necessary.

4. Remove the solvent pail(s) from the pump inlets.

5. Operate the pump(s) at low pressure to remove

excess solvent.

6. Reinstall the drum or pail ram plates.

c. Remove seal plates between the pump and

ram.

d. Loosen ram tie rods from plate and remove

plate.

e. If a pail ram is used with the component B sup-

ply, remove the pail plate by loosening the 2 set

screws.

f. Position the solvent pail so the pump inlet is in

the solvent.

Use solvent that is compatible with the equipment

wetted parts and the material you will dispense.

g. Support the ram(s) so that the pump inlet and

piston will not hit the base plate or pail bottom.

h. Make sure both component A and component B

outlet hoses are open.

309790ZAA 13

Page 14

Setup

Setup

WARNING

Read warnings, pages 4-5, before operating equipment.

Set the Ratio (variable ratio models only)

Adjust ratio

The ratio of this unit is produced partially by the difference in the area of the metering cylinders and partially

by the position of the adjustable fulcrum point in the Unibar linkage assembly. With the fulcrum point in the center, each meter cylinder strokes 3 in. (10.16 cm). In the

center position, the dispense ratio is the same as the

meter cylinder ratio.

The linkage is adjustable depending on the location of

the fulcrum point. The linkage must be adjusted for each

material application so the combined linkage and meter

cylinder ratio equals the desired material mix ratio by

volume. The ratio may be checked by weight, but the

machine meters by volume and that ratio must be known

before proceeding.

The initial linkage adjustment point can be calculated by

inserting known values into the formula on page 35. The

result is the distance in inches from the center of the fulcrum point to the center of the component B meter cylinder. For convenience, measure the distance between

the grease fitting on the top of the fulcrum and the center of the component B cylinder meter rod.

a

e

r

c

n

I

e

m

u

l

o

V

e

B

s

a

e

r

c

e

FIG. 6

Set Scale

Refer to the 8900 Proportioner Output Charts on the following pages to set the scale. Make final adjustments

after the material is loaded. See instructions on page 33

for detailed ratio check instructions.

e

s

14 309790ZAA

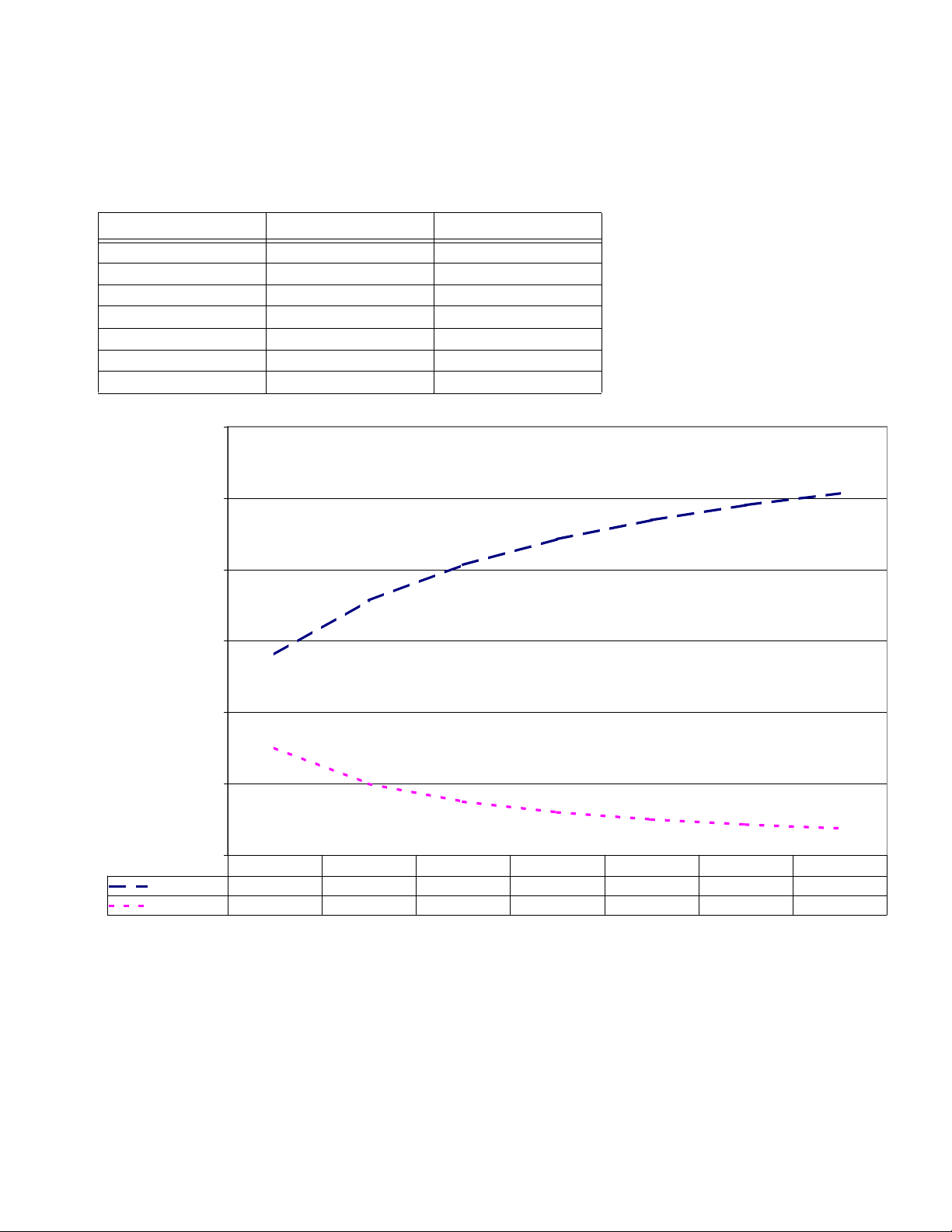

Page 15

Output Charts/Ratio Settings

g

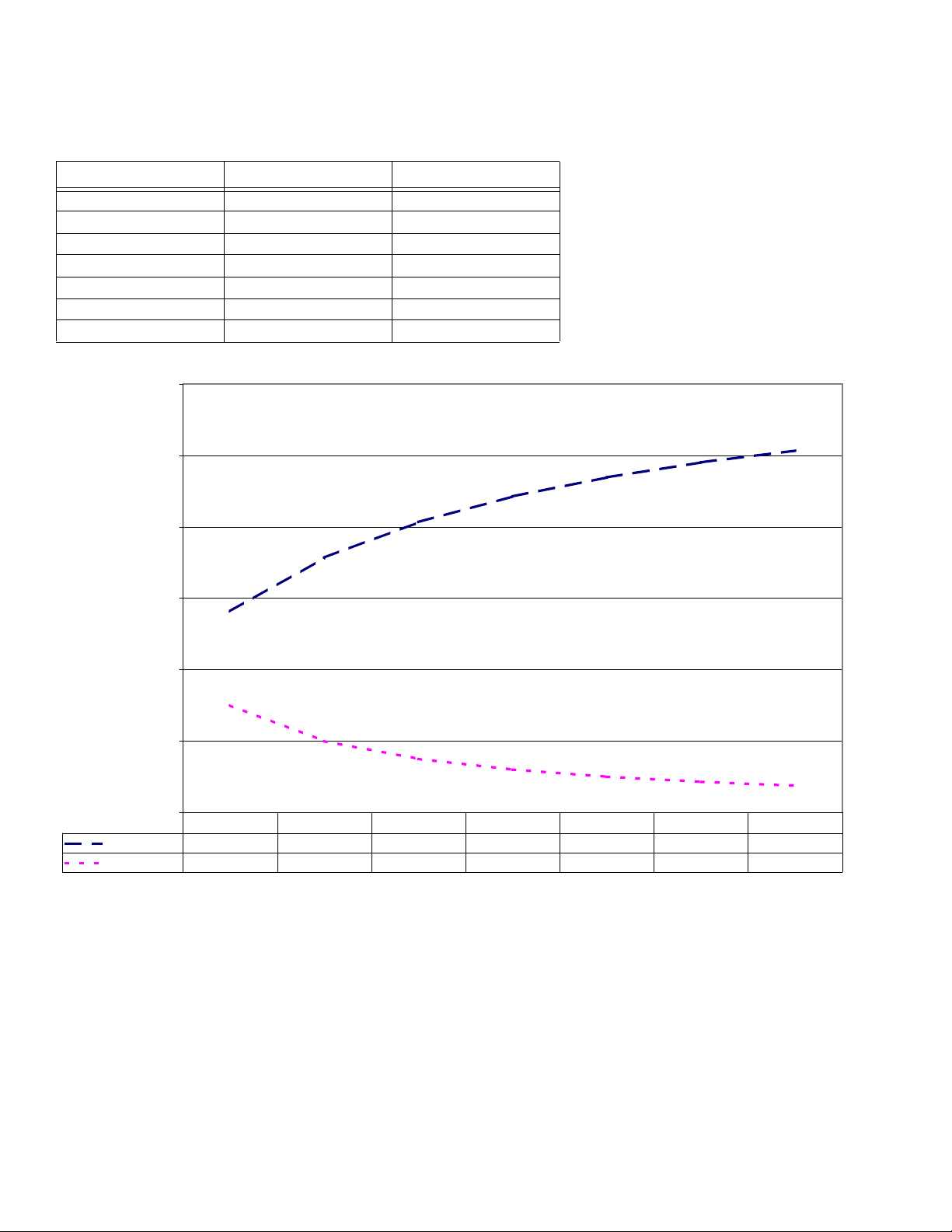

8900 Proportioner, 1:1 - 4:1 Variable Ratio

Mix Ratio by Volume Scale Setting Minor Stroke

1 5.63 3.00

1.5 7.13 2.00

2 8.13 1.50

2.5 8.85 1.20

3 9.38 1.00

3.5 9.80 0.86

4 10.13 0.75

12

10

Setup

Setting in Inches from Pivot or Minor Stroke

Mix Ratio by Volume

Scale Settin

Minor Stroke

8

6

4

2

0

1 1.5 2 2.5 3 3.5 4

5.63 7.13 8.13 8.85 9.38 9.80 10.13

3.00 2.00 1.50 1.20 1.00 0.86 0.75

309790ZAA 15

Page 16

Setup

g

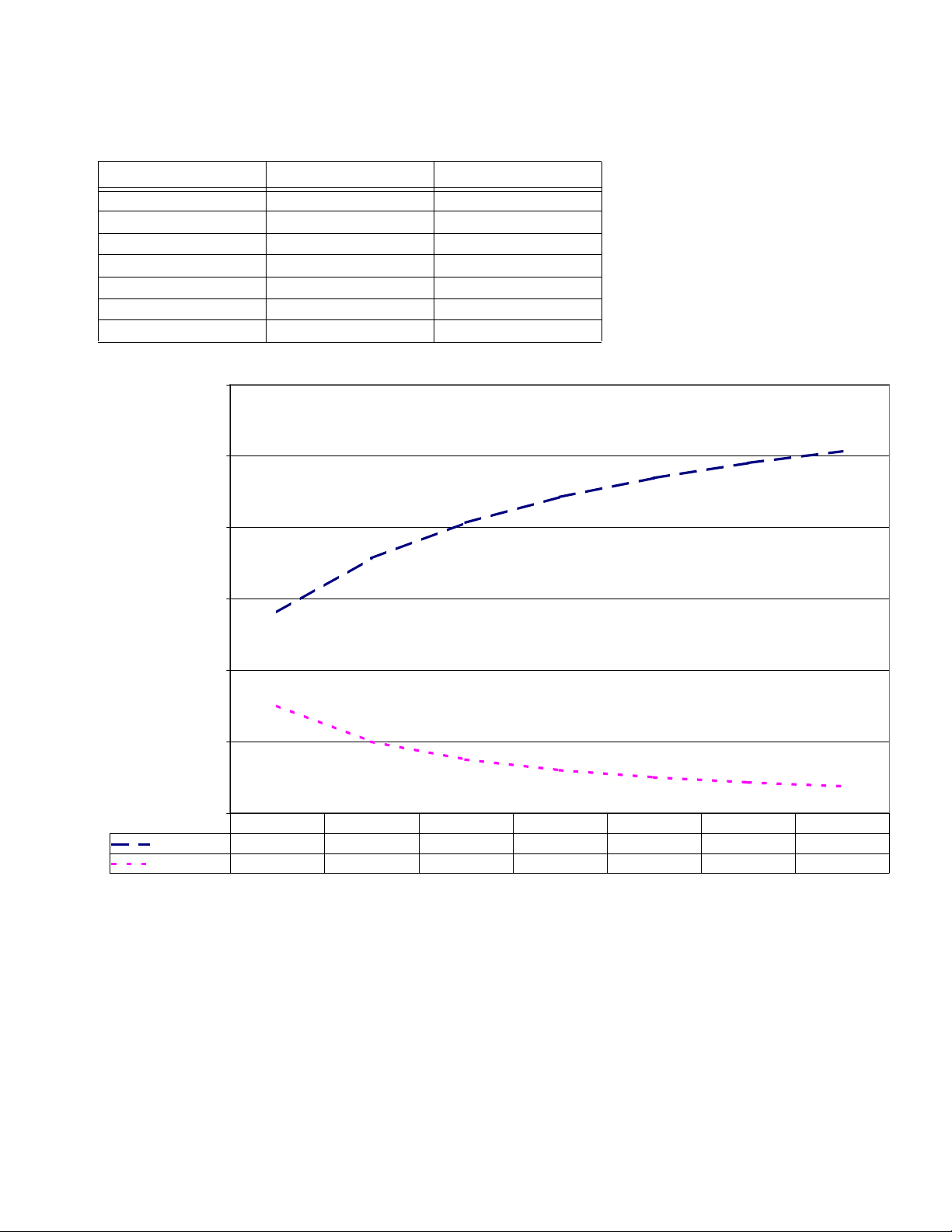

8900 Proportioner, 2:1 - 8:1 Variable Ratio

Mix Ratio by Volume Scale Setting Minor Stroke

2 5.63 3.00

3 7.13 2.00

4 8.13 1.50

5 8.85 1.20

6 9.38 1.00

7 9.80 0.86

8 10.13 0.75

12

10

Setting in Inches from Pivot or Minor Stroke

Mix Ratio by Volume

Scale Settin

Minor Stroke

8

6

4

2

0

2345678

5.63 7.13 8.13 8.85 9.38 9.80 10.13

3.00 2.00 1.50 1.20 1.00 0.86 0.75

16 309790ZAA

Page 17

8900 Proportioner, 5:1 - 20:1 Variable Ratio

g

Mix Ratio by Volume Scale Setting Minor Stroke

5 5.63 3.00

7 7.13 2.00

10 8.13 1.50

12 8.85 1.20

15 9.38 1.00

17 9.80 0.86

20 10.13 0.75

12

10

Setup

Setting in Inches from Pivot or Minor Stroke

Mix Ratio by Volume

Scale Settin

Minor Stroke

8

6

4

2

0

5 7 10 12 15 17 20

5.63 7.13 8.13 8.85 9.38 9.80 10.13

3.00 2.00 1.50 1.20 1.00 0.86 0.75

309790ZAA 17

Page 18

Setup

Before You Load Material

1. Check fluid and air lines and tighten if necessary.

2. Make sure there is a minimum overhead clearance

of 110 in. (279 cm) for 55 gallon supply.

3. Fill air line lubricator for the 8900 Proportioner module with SAE 10 W non-detergent oil (not included).

4. Fill the pump A and B wet cups 2/3 full with Graco

T.S.L. fluid (throat seal lubricant) or lubricant compatible with material being pumped.

ISO pump oil is used with moisture sensitive component B.

5. Close (turn fully counterclockwise) all air regulators.

6. Connect the 3/4 in. (19 mm) ID x 10 ft (3.05 m) air

hose (provided) to your air supply.

Do not use a restrictive quick-disconnect. The air

supply pressure must be consistently above the

pressure you set on the main air motor regulator.

G

F

Wet Cup

N

TI3263Ax

IG. 7

18 309790ZAA

Page 19

Load Component A

1. Make sure all air regulators on proportioner module

are fully closed.

Setup

2. Open the main air supply shutoff valve (A), F

3. Place the ram lever (P-F

IG. 10) in the UP position.

IG. 8.

CAUTION

As the ram rises, make sure hoses do not catch on any

components. If a hose catches, immediately stop the

ram (move lever to NEUTRAL position) and correct the

problem. Lower the ram if necessary to redirect hoses.

4. Slowly turn the ram air regulator (R) clockwise until

the ram begins rising.

N

W

FIG. 9

WARNING

When lowering the ram, keep hands and body away

from the ram plate and material drum. Read warnings,

page 5.

9. With hands away from the pail and wiper plate (N),

set the ram lever (P-F

IG. 10) to NEUTRAL (horizon-

tal position). Let the ram lower until the wiper plate

rests on the pail lip.

10. Lower the ram plate into the drum (move ram lever

to DOWN position).

O

F

IG. 8

5. When ram is fully raised, apply a thin coating of

lubricant to the ram plate drum seals.

6. Open the material container. Remove any packing

materials, and inspect for material contamination. If

the container has a plastic liner, pull it tightly over

the sides of the container, and secure the liner in

place with tape wrapped below the top drum rim.

7. Position the drum so it rests evenly between the

centering guides and is fully backed into the stops

located near the back of the ram base plate.

8. Open the drum vent valve (W), F

IG. 9.

CAUTION

Do not lower ram if a drum is not in place. Doing so can

damage drum centering guides.

A

R

Ram Separation

Air Button

FIG. 10

11. After the ram plate seals contact the drum, adjust

the ram air regulator (R) to about 30-50 psi

(207-345 kPa, 2.1-3.4 bar).

12. When the ram stops and material fills the bleed port

(or air stops bleeding out), close the drum vent valve

(W), F

IG. 9.

P

13. Supply unit is now ready to fill lines to proportioner.

309790ZAA 19

Page 20

Setup

Prime Pump A

1. Place a waste container under the pump bleed valve

located behind the displacement pump outlet, F

11. Using an adjustable wrench, open the bleed

valve counterclockwise 1/3-1/2 turn.

Bleed Valve

F

IG. 11

IG.

2. Slowly open the component A air motor shutoff

valve (G), F

IG. 7. Make sure the pump begins to

cycle and material flows from the bleed valve after

several cycles of the pump, F

IG. 11.

If the pump does not cycle, close the air shutoff

valve (G), adjust the air motor regulator (O-F

IG. 8)

up 5 psi (34 kPa, 0.3 bar) and repeat step 2.

Never adjust the regulator by more than 5 psi (34

kPa, 0.3 bar) increments.

3. Operate the pump until it moves smoothly in both

directions with no air popping or erratic movement,

then close the air motor shutoff valve (G).

4. Close the bleed valve, F

IG. 11.

20 309790ZAA

Page 21

Setup

Load Component B

Follow the procedure for the type of supply equipment

being used.

Pneumatic Pail Ram and Piston Pump

1. Close all air regulators and air valves.

2. Set the pail ram air regulator (D) to 40 psi (0.28

MPa, 2.8 bar), F

3. Push the ram directional lever (C) to the UP position

and let the ram rise to its full height.

4. When ram is fully raised, apply a thin coating of

lubricant to the ram plate drum seals.

5. Remove the component B pail cover. If the material

has separated, carefully stir it with a metal or plastic

rod until it is mixed. Do not use wood to stir as it can

splinter and contaminate the material. Do not mix air

into the material.

6. Set the pail on the ram base. Slide it back toward

the ram tube and supports and center it under the

wiper plate. To prevent air from being trapped under

the wiper plate, scoop fluid from the center of the

pail to the sides to make the surface concave.

IG. 12.

WARNING

When operating the pump or raising or lowering the

ram, keep hands away from the wiper plate, fluid container lip, and pump intake. Read warnings, page 5.

7. With hands away from the pail and wiper plate, set

the ram lever (C) to NEUTRAL (horizontal position).

Let the ram lower until the wiper plate rests on the

pail lip.

8. Ensure the pail is aligned with the wiper plate.

9. Push the ram directional lever (C) DOWN and

increase ram air pressure until plate completely

engages into the pail.

10. Slowly unscrew the vent stick until you hear air

escaping. When air is evacuated, set the ram lever

(C) to NEUTRAL and lower ram pressure to 20-30

psi (138-207 kPa, 1.4-2.1 bar).

11. Unscrew the vent stick and put the ram lever (M) in

the DOWN position, keeping the vent stick over the

vent port.

12. Slowly increase down pressure until material seeps

from vent port, the quickly refasten vent stick.

309790ZAA 21

Page 22

Setup

C

D

FIG. 12

M

Wiper Plate

TI3260B

22 309790ZAA

Page 23

Setup

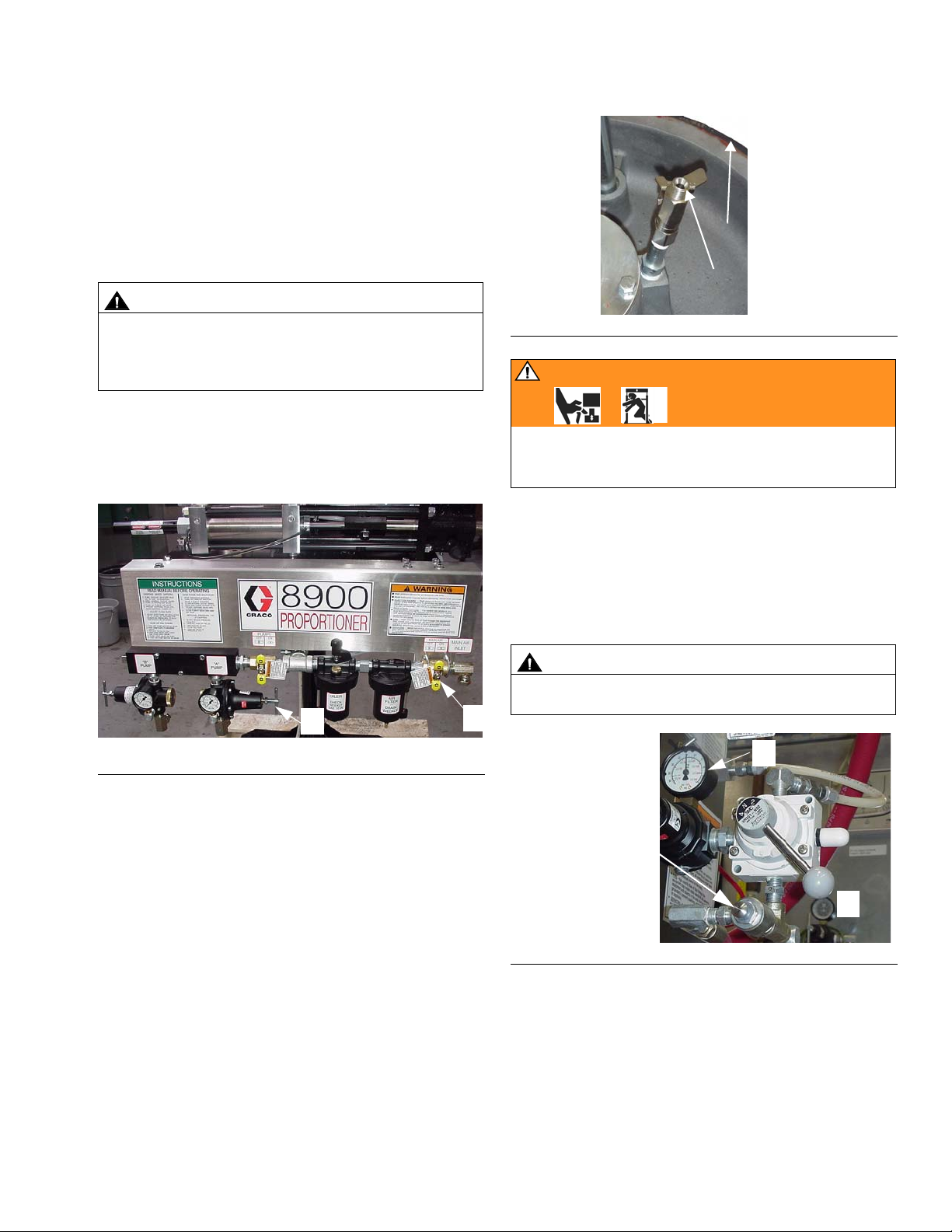

Pressure Tank with 15:1 Booster

1. Relieve tank pressure before opening.

2. Remove the pressure tank lid and any items

shipped inside the tank. Make sure the tank is

clean, or use the liner supplied.

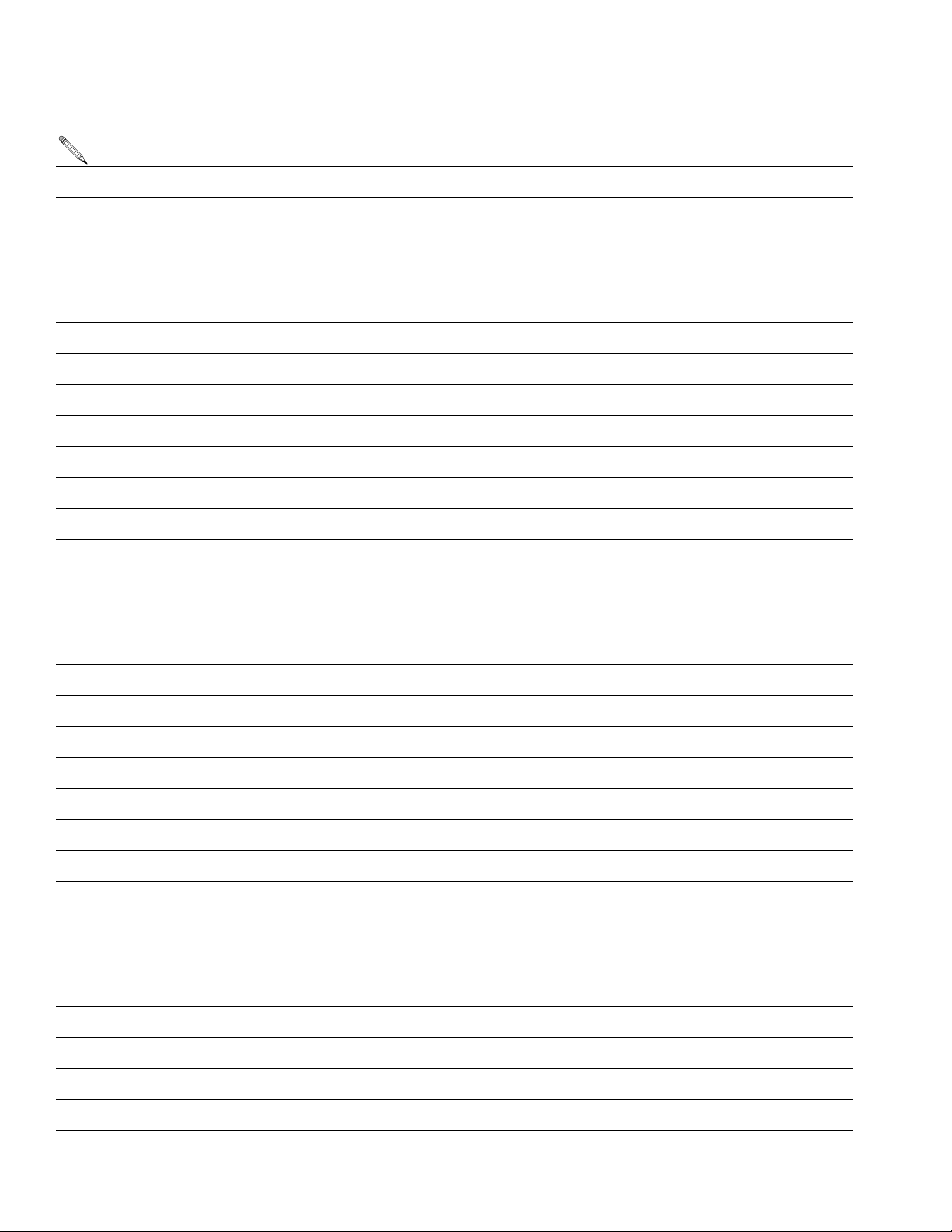

3. Be sure the desiccant air dryer is mounted in the

component B tank air supply of the proportioner air

control module. See F

4. Gently roll an unopened pail of component B on the

floor for several revolutions to mix it.

5. Open the pail outlet and carefully pour component B

into the tank.

6. Immediately close the tank by tightening the Thandles (GG) evenly, F

IG. 28, page 32.

IG. 13.

GG

HH

7. Pressurize the tank with dried air by opening the

component B air shutoff valve (S) and the pressure

tank air shutoff valve (T), Figures 14 and 15.

S

F

IG. 14

F

8. Set the component B tank air regulator (U) to

approximately 40 psi (276 kPa, 2.8 bar).

9. Check to ensure the air valve (E) to booster pump is

turned off and material supply ball valve (KK) is

closed.

10. Set feed pump regulator (F) on proportioner assembly to approximately 40 psi (276 kPa, 2.8 bar).

F

IG. 13

From component B pump air

regulator on proportioner

module.

KK

To component B

inlet on proportioner

11. The unit is ready to feed material to proportioner.

E

Pump

U

Booster

From air

manifold on

proportioner

module.

T

TI3259Ay

FIG. 15

309790ZAA 23

Page 24

Setup

Prime with Component B

1. Place a waste container under the pump bleed valve

located behind the displacement pump outlet, F

16. Using an adjustable wrench, open the bleed

valve counterclockwise 1/3-1/2 turn.

Bleed Valve

F

IG. 16

2. Slowly open the component B air motor shutoff

valve (E), F

IG. 15. Make sure the pump begins to

cycle and material flows from the bleed valve after

several cycles of the pump, F

IG. 16.

IG.

Fill the 8900 Proportioner with Material

1. Place a material waste container under dispense

gun (Q) and open gun. F

2. Open the main ball valve (A-F

tioner assembly. This air valve supplies air to the

proportioner control valving and to the feed pump

assemblies. All other air shut-off valves on the manifold and feed pump assemblies should be off.

3. Open the feed pump main air valve (S). This allows

the air supply to feed pump assemblies.

4. Adjust the component B supply pump air regulator

(F) to allow smooth pumping action. Continue until

component B flows from the dispense gun into the

waste container.

The minor or component B side of material is filled

first to minimize waste during initial startup.

5. Adjust the component A air regulator (O) to allow

smooth pumping action.

IG. 1, page 10.

IG. 17) on the propor-

If the pump does not cycle, close the air shutoff

valve (E), adjust the air motor regulator (F-F

IG.

17) up 5 psi (34 kPa, 0.3 bar) and repeat step 2.

Never adjust the regulator by more than 5 psi (34

kPa, 0.3 bar) increments.

3. Operate the pump until it moves smoothly in both

directions with no air popping or erratic movement,

then close the air motor shutoff valve (E), F

4. Close the bleed valve, F

IG. 16.

IG. 15.

6. Pump until component A and component B flow

from the gun into the waste container. When the

material is bubble-free, all air has been purged from

the system.

7. Turn off air supply valve (S).

8. Close dispense gun.

9. The 8900 Proportioner is now filled with components A and B and ready for operation.

OS A

IG. 17

F

F

24 309790ZAA

Page 25

MD2 Disposable Mixer Gun Models

Follow steps 10-12.

10. Fit the hose to the gun. Trigger the gun into a waste

container.

Setup

11. Open the component B feed air shutoff valve (E-F

15). Component B will feed through the metering

cylinder to the mix gun.

12. When bubble free material is dispensed, stop triggering the gun.

All Models

The system is now ready to dispense mixed

material.

CAUTION

The materials will cure after mixing. Purge the mixer,

hose, and gun with clean material before the material

begins to cure.

IG.

309790ZAA 25

Page 26

Setup

26 309790ZAA

Page 27

Operation

Operation

Pressure Relief Procedure

WARNING

Read warnings, page 4, and follow the Pressure

Relief Procedure whenever you:

• are instructed to relieve pressure

• stop dispensing

• check or service any of the equipment

• install or clean the nozzle.

1. Purge mixed material if necessary. See page 29.

2. Close the main air shutoff valve (A), F

IG. 18.

A

3. If a component B pressure tank is used, open its

vent (refer to page 23).

4. Hold a metal part of the gun firmly to the side of a

grounded metal pail, and trigger the gun to relieve

pressure.

5. For both component A and component B, open the

respective pump bleed valves, having a waste container ready to catch the drainage, F

F

IG. 19

6. Manually activate the limit valve (item 26 on page

48), to cause the 4-way valve to shift, fully relieving

pressure within the proportioner.

IG. 19.

Bleed Valve

F

IG. 18

7. If you suspect that the nozzle or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, very slowly loosen

the tip retaining nut or hose end coupling and relieve

pressure gradually, then loosen it completely, and

clear the nozzle or hose.

309790ZAA 27

Page 28

Operation

Dispense Mixed Material

CAUTION

Make sure the component B relief valve is operational

and free from blockage at all times. See manual

308547. If the relief valve fails, the overpressure rupture

disc opens and component B is diverted to a waste container mounted on the ram base plate.

8900 Proportioner with Static Mix Chamber

Kits

1. Load the material. See page 19.

2. On the variable ratio machine, set ratio (see page

14). On the fixed ratio machine, proceed to step 3.

3. Open the pump A and pump B air shutoff valve (S),

F

IG. 20.

4. Adjust the component A and component B air regulators (F and O) until both outbound gauges

(H and I) show the desired pressure, F

5. Trigger the gun to dispense mixed material.

IG. 20-21.

Adjust the Flow Rate

The dispensing flow rate for the system is controlled by

the material pressure of component A and component

B. The air pressure on pump A determines the flow rate

from the material outlet. Perform the steps on page

page 24 to set an initial flow rate. When the setup is

complete, adjust flow to the correct rate.

The diagram in F

meter cylinders in relation to the direction of rod movement. The material pressure gauges will represent

either inlet or outlet pressure, depending on the direction of the rod. Inlet and outlet pressures are critical to

establishing meter flow rates and balanced pressures.

IG. 22 shows the inlet and outlet of the

F

IG. 20

F

IG. 21

F

H

S

O

I

FIG. 22

Flow Rate Adjustment Example

A 20:1 fluid:air supply pump ratio with an air regulator

setting at 100 psi (.7 MPa, 7 bar). The pump generates

approximately 2000 psi (14 MPa, 140 bar). Fluid pressure, normal friction losses with mastic materials will

use 5-15% of the force, resulting in actual stall pressure

of 1700-1900 psi (13 MPa, 130 bar).

28 309790ZAA

Page 29

Operation

A/B Pump Relationship

As a rule of thumb, the pressures of the two components

should be adjusted to as close to equal as possible

under dynamic pressure. Adjust the A and B feed pressures to accomplish this. Differences on material viscosity, flow rates, hose diameter and length, dispense valve,

and mixer size cause this setting to vary from application to application.

1. Adjust the component A air regulator (O) for desired

flow rate, F

IG. 24.

2. Adjust the component B air regulator (F) to balance

the A and B regulators.

Solvent-flush Mixed Material (for units

using mix manifold gun kits)

1. Close the component A and component B valves on

the mix chamber assembly. See F

2. Ensure solvent valve is closed.

3. Set solvent flush pump air regulator to approximately 25 psi (172 kPa, 1.7 bar) and open the air

valve.

IG. 23.

8900 Proportioner with Disposable Mixer

Gun

1. Load the material. See page 19.

2. Set ratio. (For variable ratio models, see page 14).

3. Install the mixer on the gun.

4. Open the pump A and pump B air shutoff valve (S),

F

IG. 24.

S

F

FIG. 24

O

4. Open the solvent supply valve, ensuring that the dispense valve touches a grounded metal waste container and purge until solvent comes out clean.

5. Close solvent supply valve.

Component B Valve

TI3261A

Component A Valve Solvent Valve

F

IG. 23

5. Trigger the gun to dispense mixed material.

6. Adjust the component A air regulator (O) for the

desired flow rate.

7. Adjust the component B supply air regulator (F) so

that component B pressure is approximately equal

to the component A pressure.

8. When you have finished dispensing, remove and

dispose of the mixer, and install a red plastic cap

(part no. 551327).

309790ZAA 29

Page 30

Operation

Changing Component A Drum

When the ram plate is extended fully to the bottom of the

drum and the pump begins to cavitate, you need to

change the drum. It is recommended that you check and

refill the component B at the same time.

1. Close the air motor shutoff valve.

2. With the ram lever (PP) in the neutral position (F

25), adjust the ram regulator (R-F

F

IG. 25

IG. 26) to 0 psi.

3. Place the ram lever (PP) in the UP position, F

IG.

PP

IG. 26.

6. Continue to hold the drum separation air button

(PPP) just enough to keep the drum from rising with

the ram plate.

7. Follow the procedure to load material, pages 19-24.

You only need to lubricate the ram plate tire seals

the first time you load material.

R

PP

PPP

IG. 26

F

WARNING

Do not use excessive drum separation air pressure.

Make sure the drum is not damaged and the ram plate

is free to exit the drum. Read warnings, page 5.

4. Push and hold the ram separation air button (PPP).

5. Adjust the ram regulator (R) to approximately 10-15

psi (69-103 kPa, 0.7-1 bar) or until the ram plate

begins to rise.

30 309790ZAA

Page 31

Operation

Changing Component B Pail

If you are using a ram and pump to supply component

B, the procedure to change the pail is the same as

changing the Component A drum except that you use

the controls on the back of the pail ram.

Pressure Relief Procedure

(For component B tank models only.)

WARNING

PRESSURIZED EQUIPMENT HAZARD

The pressure tanks remain pressurized until pressure

is manually relieved. To reduce the risk of serious injury

from pressurized fluid or accidental spray from the gun,

always follow this procedure to relieve pressure in the

tank at the following times:

• Before you check or service any part of the spray

system

• Before you loosen or remove the pressure tank

cover or fill port.

• Whenever you stop spraying.

1. Shut off the air supply to the tank by closing the air

inlet valve. Refer to F

IG. 27.

2. Open the drain cock fitting by turning it counterclockwise.

3. Wait until there is no air escaping through the drain

cock fitting before removing the cover or opening the

fill port.

4. Leave the drain cock fitting open until you have reinstalled the cover or fill port.

FIG. 27

Air inlet valve

Fill port cap

Drain cock fitting

03089C

309790ZAA 31

Page 32

Operation

Filling Component B Pressure Tank

If you are using a pressure tank to supply component B,

check the tank level with a metal or plastic rod whenever

the Component A drum is changed. To add component

B to the tank, follow the procedure below.

1. Close the tank air supply shutoff valve, F

2. Relieve pressure in the tank (see page 27).

3. Open the fill port cap on top of cover.

CAUTION

Do not leave the pressure tank open. Component B will

crystallize if exposed to the moisture in the air.The tank

cover is normally removed only for tank cleaning.

1

Arrow points toward tank

IG. 28.

4. Gently roll an unopened pail of component B on the

floor for several revolutions to mix it.

5. Open the pail outlet and carefully pour the material

into the tank through a funnel.

6. Close the drain cock fitting and screw on the cap.

7. Make sure the silica-gel in the desiccant filter is

blue. If the gel is pink, replace it (part no. 106498) or

bake out the moisture.

The desiccant filter is an air dryer for moisturesensitive materials, it is not included with the package.

8. Pressurize the tank with dried air by opening the

component B air shutoff valve and the pressure tank

air shutoff valve.

IG. 28

F

Component B

air supply valve

1

Dry Air Line

Tank air shutoff valve

Desiccant

filter

ti3259ax

15:1 Component B pump

32 309790ZAA

Page 33

Operation

Adjust Ratio on Variable Ratio Machine

The ratio of this unit is determined partially by the difference in the area of the metering cylinders and partially

by the position of the adjustable fulcrum point in the Unibar linkage assembly. With the fulcrum in the center,

(next to stop at left of center), each meter cylinder

strokes 3 in. In this center position, the dispense ratio is

the same as the meter cylinder ratio. The ratio is adjustable from 1:1 to 20:1 depending on the location of the

fulcrum point and cylinder size. There are three

machines to accommodate these ratio ranges: 1:1-4:1,

2:1-8:1, and 5:1 to 20:1. The linkage must be adjusted

for each material application so that the combination

linkage and meter cylinder ratio equals the desired

material mix ratio by volume. The ratio is checked by

weight, but the machine meters by volume. Weight

ratios must be known before proceeding. If weight ratios

are not known, they can be calculated using the specific

gravity and known volumetric ratio of each component.

The initial linkage adjustment point can be calculated by

inserting known values into the following formula. The

resulting value is the distance in inches from the center

of the fulcrum point to the center of the component B

meter cylinder. Measure the distance from the grease

fitting on top of the fulcrum to the center of the component B cylinder meter rod. For reference, see the output

charts on pages 15 through 17.

Ratio Adjustment Calculation Example:

DR = Required mix ratio by desired volume (X:1)

PR = Selected cylinder ratio (1:1, 2:1, 5:1)

LR = Linkage ratio

LD = Linkage distance (component B cylinder center-

line to fulcrum center divided by LR+1)

DR

LR=

PR

Cylinder ratio 1:1-4:1 machine use PR = 1

Cylinder ratio 2:1-8:1 machine use PR = 2

Cylinder ratio 5:1-20:1 machine use PR = 5)

Verify the Ratio

1. Relieve pressure. See Pressure Relief Procedure

on page 27.

2. Remove gun and place a waste container under the

component A and component B hoses.

3. Open air valve to turn on unit.

4. Activate the unit and using a collection container of

known weight, collect a cup of component A and a

proportionate amount of component B.

5. Weigh each component carefully and subtract the

weight of the container.

6. Convert the manufacturer’s ratio to parts component

B per 100 parts Component A, by weight (2:1 =

100:50).

7. Divide component B weight by component A weight.

8. Multiply the result of step 7 by 100. The product is

the number of parts of component B the machine

dispenses per 100 parts of Component A.

9. Compare ratio obtained to ratio desired. Always

make several ratio checks to ensure accuracy at

final setup. Any air in the system will cause inaccurate ratio checks. If ratio checks are not consistent,

review setup procedure.

10. If the ratio is incorrect, loosen fulcrum screw (A) and

turn the ratio adjustment screw/nut (B) clockwise to

decrease and counterclockwise to increase the

amount of component B.

11. If the ratio is correct, tighten the fulcrum nut and

reattach hoses (7) to the dispensing gun.

Example:

• Desired volumetric mix ratio (DR) = 10:1

• Measured distance from grease fitting on top of the

fulcrum to the center of the component B cylinder

meter rod = 14.85 in.

DR

LR=

PR

measured distance

LD =

309790ZAA 33

10

5

LR + 1

=2:1

LD =

14.85 in.

2 + 1

or LD = 4.95 in.

Page 34

Operation

Daily Procedures

Daily Start-up Procedure

1. Perform daily maintenance operations, including:

a. Check oil level in main air lubricator.

b. Drain any water from filter in main air line.

c. Tighten pump packing nuts (daily the first week,

weekly thereafter).

d. Visually inspect system for leaks.

e. Grease zerk fittings.

2. Turn air pressure to the unit “ON”.

3. Check ratio on variable ratio models.

Steps 4 and 5 are applicable only to mix manifold

models.

4. Open the coupled ball valves (push up).

5. Ensure that the component A purge ball valve is

closed.

6. Place a material waste container under the gun outlet and open the dispense gun.

7. Dispense material until well mixed material is being

dispensed.

8. The system is now ready to operate.

After the system is purged, do not open the dispense gun until the next system operation.

Disposable Mixer System

1. Remove and discard the mixer.

2. Trigger gun to ensure the outlet is clear.

3. Turn off the main air valve.

4. Wiper off gun nose.

5. If material is moisture-sensitive or dries out, protect

the outlet with the night cap and ISO pump oil.

General Ratio Check Procedure

Checking the ratio allows the user to take samples of the

metered material to ensure the equipment is operating

properly.

The unit meters by volume but it is more convenient to check the ratio by weight. You must know

the ratio by weight or the specific gravity of the

materials to convert volumetric ratio to weight

ratio.

1. Remove the hoses from the dispense gun. Take a

material sample from the outlet of these hoses.

2. Open the air ball valves (push up) and collect a

large material sample (approximately 1 pint of component A) in separate containers of known weight.

Material flowing from each hose provides a sample

for ratio check. When sample is collected, turn off air

supply ball valve.

Daily Shut-down/Purge Procedures

Component A Purge

1. Close the coupled ball valves (push down).

2. Open the component A purge ball valve.

3. Hold the dispense gun over a material waste container.

4. Hold the dispense gun open until only component A

is evident.

5. Close the component A purge ball valve.

6. Close the main air valve located under the meter

base plate to remove air pressure from the meter.

34 309790ZAA

3. Weigh the component A and component B samples

and subtract the weight of the collection containers.

4. Convert the material manufacturer’s ratio to “parts

component B per 100 parts component A by

weight.” For example, a 2:1 ratio (component A:

component B) becomes 100:50.

5. Divide component B sample weight by component A

sample weight.

6. Multiply the result of previous step by 100. The

product is the parts component B dispensed by the

machine per 100 parts component A by weight.

7. Compare the weight ratio obtained to the desired

weight ratio. Repeat to obtain several successful

ratio checks.

8. Put new mix elements in the gun and reconnect the

hoses to the gun.

Page 35

9. Ration check is complete and the unit is ready for

operation

Ratio Check Example

Conversion Formula:

Parts by Volume (PBV) to Parts by Weight (PBW)

PBV component B

PBV component A

X

Specific gravity component B

Specific gravity component A

X = 100:Parts component B by weight

Ratio Check Example

component B sample weight LESS container weight

component A sample weight LESS container weight

PRODUCT = Parts component B per 100 parts component A

• Manufacture’s specified weight ratio = 4:1 or 100:25.

• Weight of component A in ratio check is 245 grams.

• Weight of component B in ratio check is 61.2 grams.

• 61.2 divided by 245 equals .2497 (61.2 / 245 = .2497).

X

X 100 = PRODUCT

100 =

Operation

X

Three ratio checks are recommended to ensure accuracy at final setup. The presence of any air (visible or not visible) in the material or system will cause inaccurate ratio checks. If the ratio check cannot be made with repetitive

accuracy, review air bleed procedures.

Some materials contain substantial amounts of entrained air due to manufacturing, transportation, system

setup, or drum change. Air must be removed by de-gassing, recirculation, or self removal over time, before

accurate metering can be accomplished.

309790ZAA 35

Page 36

Troubleshooting

Troubleshooting

8900 Proportioner Operating Pressures

There are four fluid pressure gauges on a typical 8900

Proportioner system. They are mounted on:

• Component A inlet block

• Component B inlet block

• Component A outlet block

• Component B outlet block

What the fluid gauges tell you

Inlet Gauge

The pump A and pump B inlet pressure gauge shows

whether there is sufficient material supply to reliably

feed each metering pump during its intake stroke.These

double- acting pumps dispense and load fluid on both

strokes.

The pump A and pump B supply air pressure should be

set high enough to maintain reliable pump feed pressures but no higher than necessary. If gauge pressure is

not consistently steady, increase fluid pressure.

The difference in the gauge reading between the

stall condition and running is the amount of dynamic

friction loss from the pump assembly, plus the

flow-induced pressure drop from the pump lower to

the pressure gauge.

Viscosity, temperature, flow rate, and gun setup can

affect the amount of gauge drop when the trigger is

pulled. On a typical manual gun system, the gauge

drops 100-400 psi (0.7-2.8 MPa, 7-28 bar).

Component B Pump Outlet Gauge

The component B pump gauge shows line pressure, but

the component B outlet pressure is generated primarily

as a reaction to component A pressure at the mix chamber.

For materials running at greater than 1:1 ratio, component B cannot open the check (injector) valve until its

pressure equals the component A pressure at the check

valve. Hoses and injector restriction are chosen to naturally balance the pressure drop while running and match

the component B pressure in the line when stalled.

Changeovers

Outlet Gauge

The pump A and pump B outlet gauge displays one of

two conditions, stalled and running.

• Stalled: With the pump air valve on and the gun

closed, the gauge will show full stall pressure. This

pressure is the fluid to air pressure ratio of the pump

assembly, times the air pressure from the main regulator, minus the friction loss of the motor and pump

assembly.

The fluid to air pressure ratio changes with different

motors, different supply pumps, and different ratio

settings.

• Running: When running, the gauge reads the

flow-induced pressure drop between the gauge and

the gun outlet. The motor power is used up by the

time the fluid exits the gun. The pressure drop is a

measure of friction loss caused by hoses, the 8900

Proportioner, fittings, mixers, and gun.

When the pumps change direction there is a momentary

change in gauges. In general, the gauges will drop

5-15%, then return. However, many factors affect the

actual fluctuation, such as pump selection, fluid characteristics, flow rate, temperature, and length of hoses.

Check valves near the pump outlets isolate the hoses to

let them serve as momentary surge chambers. This is

why flow from the gun is smooth during changeover.

Abnormal Readings

Since so many factors affect gauge readings, it is important to know what is normal. Note how your gauges read

when the machine is setup and running a good mix with

no soft spots. What are the stall pressures and what are

the running pressures for a given inbound air pressure?

How much drop is there on changeover?

If something goes wrong, a change on the gauges can

indicate what the problem is. Note those changes and

work through the troubleshooting guide, beginning on

page 39.

36 309790ZAA

Page 37

Air Supply Troubleshooting Chart

Problem Cause Solution

Troubleshooting

Abnormal pressure loss on air motor

pressure regulator gauge during both

changeovers.

Abnormal A and B pump outlet pressure loss during both changeovers.

Reduced flow rate. Undersized air compressor. Replace with properly sized air comOff-ratio material.

During normal operating conditions, the feed pump (A

and B) air motors are filled with air almost instantaneously on both changeovers.

However, if the feed pump air supply is restricted, it can

take significantly longer for air to fill the air motor. To

check for this, observe the gauge on the air motor pressure regulator during both changeovers:

• At the end of each stroke the air pressure will drop

abnormally as the air motor begins to fill.

• At the same time the A and B pump outlet pressures

will drop abnormally due to the feed pump’s respective air motor’s reduced pressure.

Air line restriction due to quick-disconnect pin fitting.

Air supply line ID to each feed pump

is too small.

Remove quick-disconnect from the

air line and replace it with bleed-type

air shutoff valve.

Replace with minimum 3/4 in. (19

mm) ID hose.

pressor.

• The decrease in the pump outlet pressures causes

the flow rate at the dispense gun to be reduced.

• Once the air motor has filled with air, all air pressures and flow rates will return to normal until the

end of the next stroke.

• The decreased pump outlet pressure may affect the

feed pumps’ checking action, and thus mix ratio,

resulting in the dispense of what appears to be

poorly mixed material.

• Changing air pressure changes the compression of

the component A hose and material. This causes an

off ratio condition until pressures stabilize. Equipment air supply pressure must always stay above

the motor regulator setpoint.

309790ZAA 37

Page 38

Troubleshooting

Pump Troubleshooting Overview

Pump Cavitation

Under normal operation, when the feed pump pressures

are balanced, component A and component B outlet

pressures are consistent.

Some up or down adjustments in feed pressures will be

necessary to keep the pumps’ outlet pressures balanced. This is due to viscosity differences in the two

materials, volumetric ratio, and required flow rate.

Because of the viscosity difference between the two

materials, most of the balancing effect comes from

adjusting the component A pressure. For ratios higher

than 1:1, the component B pressure should be set only

as high as necessary to avoid cavitation at the desired

flow rate. For 1:1 ratio there is equal balancing from

component A and component B pressure.

If either the A or B pump does not completely fill with

material on intake, the failing pump’s material output is

interrupted at the beginning of the next stroke. This is

referred to as cavitation.

Pump Failure to Seal

Under normal operation, the output of the component A

and component B pumps depends upon proper sealing

of their internal packings.

If packings fail to seal properly, the pump material output, and thus the output pressure, is reduced. Depending on the location of the failure, the pressure reduction

may occur on the pump upstroke, downstroke, or both

strokes.

Component B Pressure Relief Valve

The proportioner includes a spring-loaded, overpressure relief valve, which bypasses component B back to

the supply when pressures exceed 3400 psi (23 MPa,

234 bar).

Pump A cavitation is detected by observing the inlet

pressure gauges on pump A and pump B immediately

after changeover. When cavitation occurs, the proportioner pump outlet pressure gauge drops and the pump

A outlet pressure gauge shows an increase in pressure,

as described previously.

B pump cavitation is detected by observing the B pump

inlet pressure gauge immediately after pump top

changeover. When cavitation occurs, the B pump outlet

pressure gauge drops.

If the amount of cavitation is moderate, the pressure

gauges return to their normal readings at some point

during the downstroke of the failing pump.

During pump A cavitation, the pressure drop may cause

a noticeable reduction in flow rate at the dispense gun.

Additionally, the interruption in the pump A material output may cause component B-rich material to dispense,

which may appear as poorly mixed material.

During B pump cavitation, the interruption in the B pump

material output may cause component A- rich material

to dispense, which may appear as poorly mixed material.

38 309790ZAA

Page 39

Troubleshooting

Troubleshooting Guide: Feed pumps

Problem Cause Solution

Erratic feed pump speed. Pump cavitation. Bleed air from pump.

Pumping too fast. Turn down air pressure regulator.

Improper pump loading. Increase ram down pressure

Ram valve not in down position.

Pump lower not performing. Rebuild pump

Material leaking from top of pump Loose packing nut. Retighten.

Worn throat seals. Rebuild pump, replace seals.

Feed pump fails to cycle Air supply off. Check air valves/line pressure. Turn

on if required.

Air pressure too low. Increase air pressure on respective

feed pump air regulator.

Stalled air motor. Motor icing (warm up).

Check air filter and lubrication.

Ram fails to move up and down Lack of air pressure. Turn on or increase air supply pres-

sure to ram.

Ram failure. Check and rebuild.

Material leaking past follower plate

seal (small amount of leakage is normal)

Too much ram pressure. Reduce ram down pressure on ram

air pressure.

Worn wiper seals. Replace.

Dented container. Straighten or replace container.

309790ZAA 39

Page 40

Troubleshooting

Troubleshooting Guide: 8900 Proportioner

Problem Cause Solution

Inconsistent material mix Material inlet pressures are not set

correctly. Erratic feed pump.

Mix elements not assembled cor-

rectly or need to be replaced.

Cylinder cups are bypassing mate-

rial.

Material outlet hoses are not sized

correctly (pressures not balanced).

Material ball valves are bypassing. Rebuild/replace.

Insufficient air supply to material sup-

ply pumps.

Purge valve open (if applicable). Close during operation.

Meter pressures never change Broken material gauge(s). Replace.

Meter will not shift at the end of the

stroke.

Meter will not move Material inlet pressure not high

Material leaking from meter end caps Worn seals. Replace.

Meters not balanced Improper operation of supply pumps. Check for proper operation of mate-

Meter outlet pressure too high,

metering inaccurate, decreased flow

rate, non-uniform mix (streaking)

Incorrect ratio check and reduced

flow rate

Inaccurate metering Air in the material or trapped in the

Limit valve not working correctly. Rebuild/replace, see page 45.

No material inlet pressure. Verify.

No air supply to limit valve. Verify.

enough to drive meter.

4-way ball valve orientation incorrect. Check, fix.

Dispense valve closed. Open.

Blockage in material hose. Depressurize system and repair.

Blockage in meter assembly. Depressurize system and repair.

End caps loose. Hand tighten with wrench provided.

Inadequate material supply to

pumps.

Curing material in the mixer or block-

age of either mixer inlet port (check

valves/injector valves plugged).

Material may be bypassing rather

than flowing through the meter.

pumping and metering components.

Follow flow rate procedures and ram

feed pump troubleshooting guide.

Fix or replace.

Replace cylinder cups.

Call Graco Tech Service (800) 543-0339

Verify consistent air supply.

Verify low pressure on the gauges

before increasing.

rial supply pumps. Each should have

adequate material supply. Reasonably constant and balanced meter

inlet and outlet pressures indicate

proper pump function. If flow rate is

increased by increasing A pump

pressure, increase B pump pressure

proportionally to balance meter inlet

and outlet pressures.

Clear blockage.

Check for leakage in meter seals and

cups.

Bleed the air from the pump.

40 309790ZAA

Page 41

Troubleshooting

Troubleshooting Guide: Manifold/Mixer

Problem Cause Solution

Poor mix quality. Dirty mixer. Disassemble Tri-Core mixer, clean

housing and end caps, and replace

mix elements.

Inadequate mixing. Add mixer with more elements or

larger ID mixer.

Dirty mixer and gun. Replace flex mixer or clean Tri-Core

mixer and gun.

Tri-core mixer assembled improperly. Reassemble with scribe lines on end

caps aligned.

Fouled or plugged component B

injector.

Cavitation due to ram air control

valve not in DOWN position.

Cavitation due to low ram pressure. Increase to required operating

Reduced flow rate. Dirty mixer. Disassemble Tri-Core mixer, clean

Dirty mixer and gun. Replace flex mixer or clean Tri-core

Leaking component B shutoff valve. Repair or replace valve.

Poor purge quality. Leaking component B shutoff valve. Repair or replace valve. May require

Abnormally high B pump outlet pressures.

Abnormally high pump A outlet pressures.

Soft spots or color change relating to

changeovers.

Fouled or plugged component B

injector.

Feed pressure too high. Reduce feed pressure.

Restriction in gun or hose, plugged

check valve.

Pressures are out of balance. Adjust pressure settings on A and B

Clean or replace injector.

Place control valve in DOWN position.

pressure.

housing and end caps, and replace

mix elements.

mixer and gun.

solvent flush after valve replacement.

Clean or replace injector.

Clean out gun.

Inspect for cured material in check

valve.

supply pumps to balance outbound

ram pressure too low on feed pump.

309790ZAA 41

Page 42

Troubleshooting

Component B Injector

In most dispense systems, an injector is included in the

component B fluid line. This injector adds back pressure

to the system and provides the necessary pressure balance between component A and component B to

achieve the proper ratio and mix.

If the injector becomes fouled with mixed material, the

pressure indicated on the B pump outlet gauge will

increase and upset the pressure balance, resulting in

the dispense of poorly mixed material.

If the injector becomes completely plugged, only component A is dispensed from the gun and the B pump outlet

pressure will increase until the relief valve discharges.

If the injector valve sticks, it can react sluggishly causing

soft spots after valve triggering or changeover.

Keep the injector clean. Inspect the housing tip and needle end for dents or scratches. Lapping the needle to the

housing with automotive lapping compound will recondition the seat/needle. When reassembling the injector,

tighten the nut 2-2.5 turns after the slack is taken up.

It is good practice to have a clean injector on hand. A

fouled injector can then be replaced quickly, and thoroughly cleaned and held for future use.

Preventive Maintenance

1. Air supply: Oil level in main air line lubricator should

be checked daily and refilled when necessary with

SAE 10W non-detergent oil. Adjust to dispense 1

drop per minute during operation.

Main air line filter should be drained as required.

Excessive amounts of water in the system will

reduce machine performance.

2. Housekeeping: Spilled materials on any part of the

equipment should be cleaned up promptly. Your system is precision equipment and should be maintained as such. A light coating of petroleum jelly on

components will often prevent spilled material from

sticking to equipment.

3. Pumps: Pump packing should be tightened daily the

first week of operation and weekly thereafter.

4. When using Throat Seal Lubricant (TSL) or ISO oil,

the lubricant should be maintained at an adequate

level in the pump packing reservoir. These lubricants prevent material from sticking to pump rods,

extends packing life, and protects material from contamination from the atmosphere.

Use ISO oil when dispensing moisture-sensitive

materials.

Meter: Maintain TSL or ISO oil in reservoir if used;

grease zerk fitting. Clean up spills as soon as possible to prevent damage to the meter.

5. Mixer: With most materials, frequent use of equipment is all that is needed to prevent internal curing.

Some materials have a tendency to cure slowly on

the walls of the mixing chamber. Experience will dictate how often the mixer or mixer elements should

be thoroughly cleaned or replaced.

6. O-rings/Seals: O-rings and seals will be damaged if

soaked in solvents. When reusing, wipe with solvent

and dry immediately.

42 309790ZAA

Page 43

Service and Repair

Service and Repair

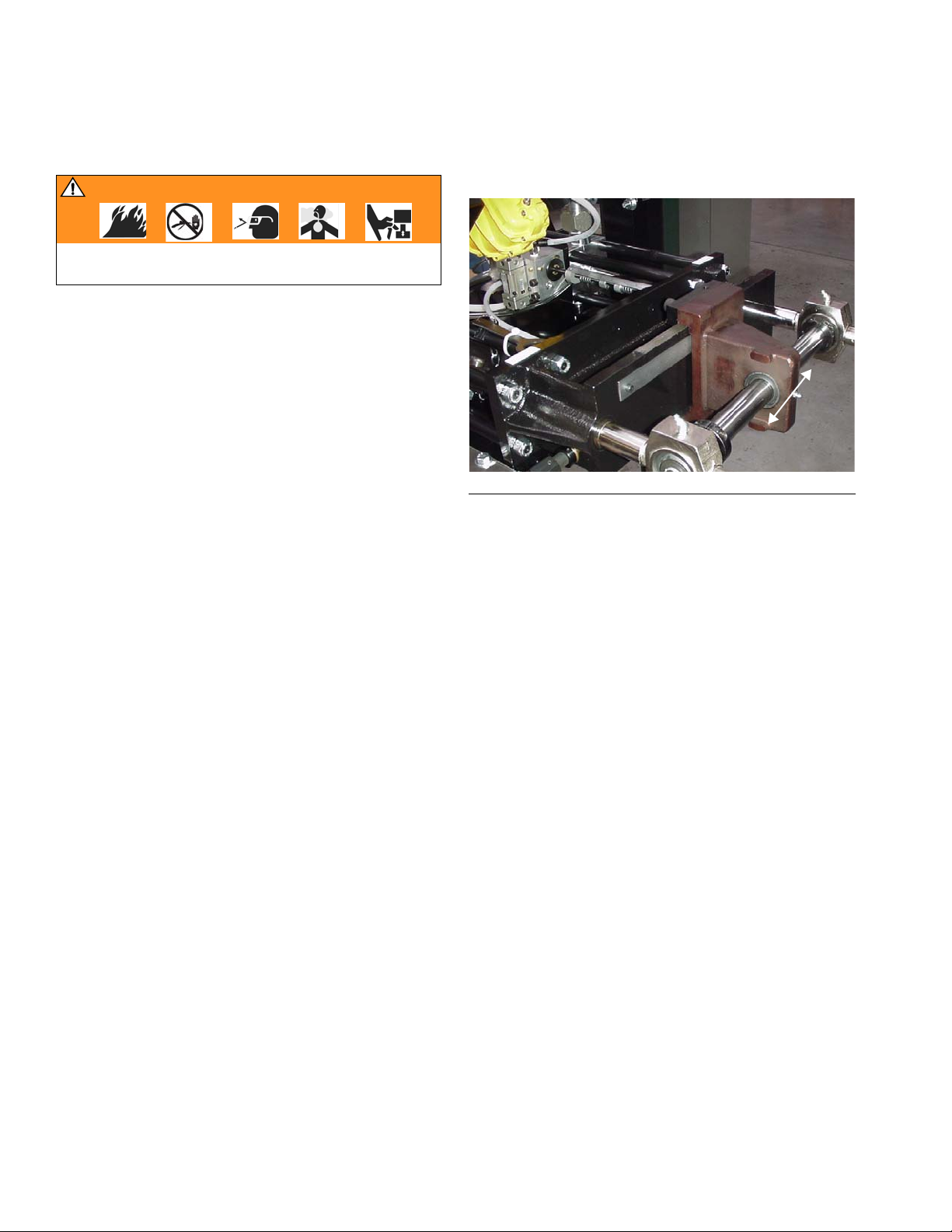

Repair the Cylinder (Fixed Ratio)

• Relieve pressure throughout the 8900 Proportioner assembly. Follow the pressure relief

procedure on page 31.

• Reference numbers shown in parentheses in

Service and Repair procedures refer to references in figures and parts lists.

17

30

116

30

113

F

IG. 29: Fixed Ratio 8900

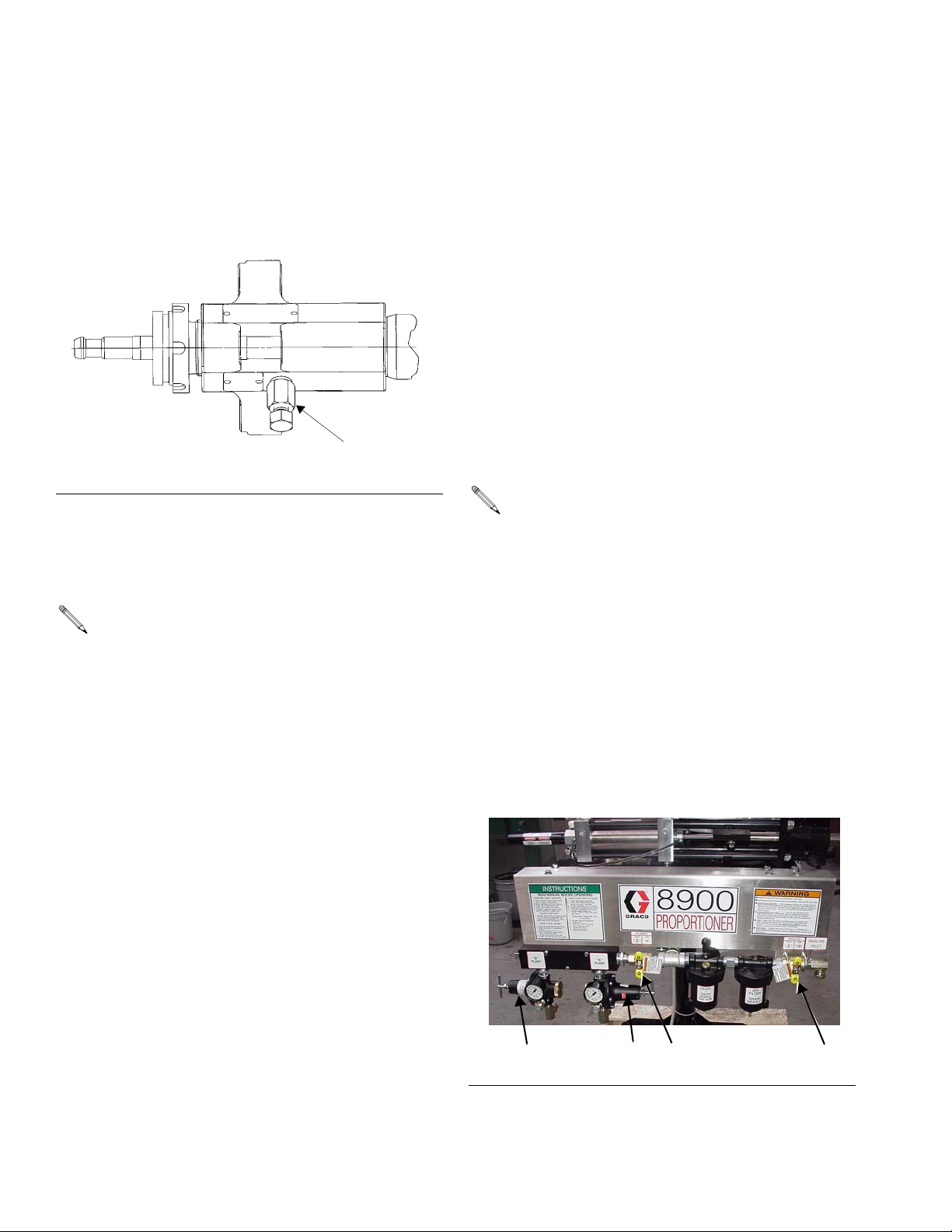

1. Disconnect hose (17) on cylinder end manifold, FIG.

29.

2. Remove guard tube (116).

10, 11

8. Remove packing nut (103) from opposite cylinder

end cap (106) and remove throat packings and

glands (110, 111, 112).

9. Remove piston assembly (106, 107) from rods (101,

102).

10. Replace V packings and glands on both ends with

new ones and reassemble in reverse order of disassembly.

11. Replace cylinder end o-rings (109) on each cylinder

end cap. Apply grease to each to help hold o-ring

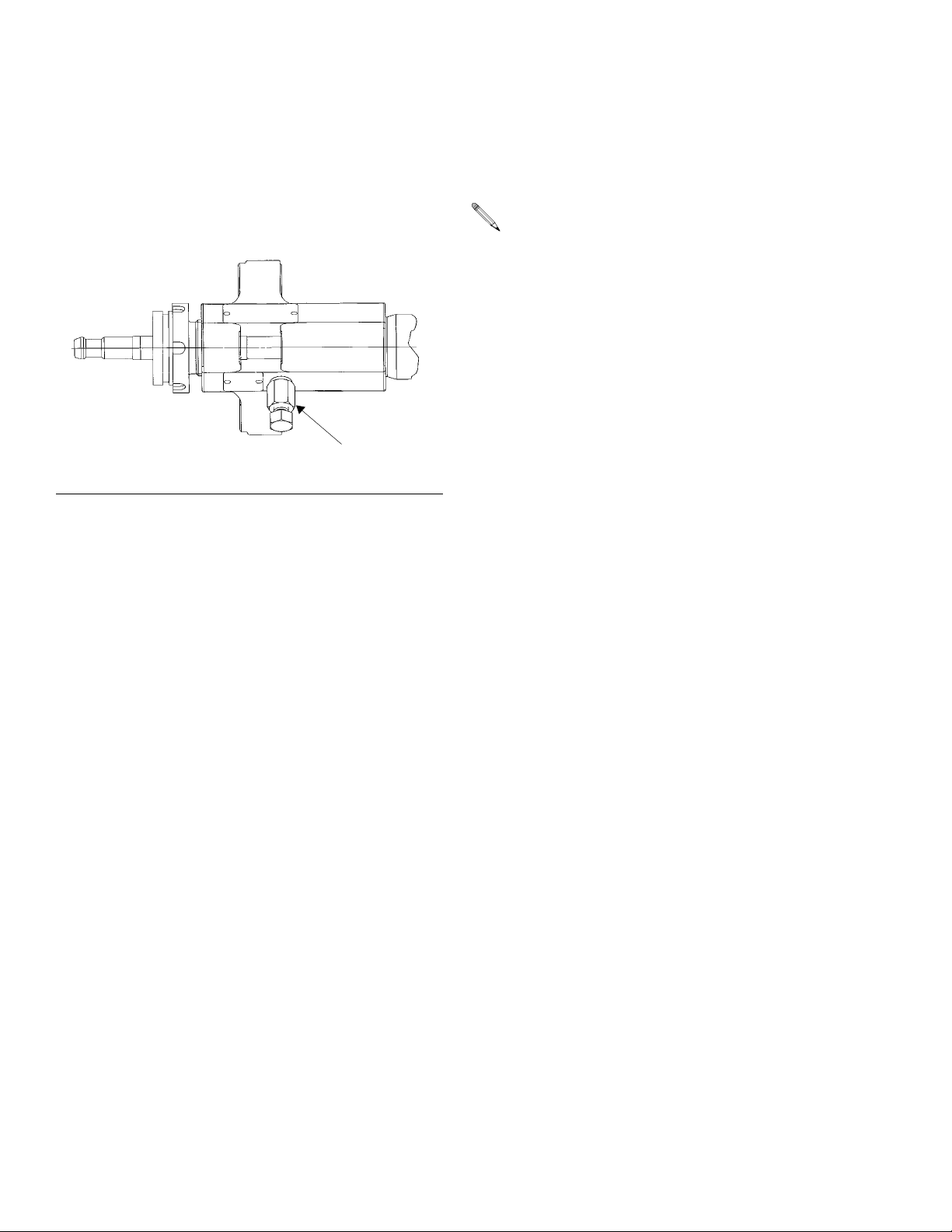

into end cap.