Page 1

Instructions

Stainless Steel Air

Motor Conversion Kits

Conversion Kit 246450

For 1040 Pumps

Conversion Kit 246451

For 1590 Pumps

Conversion Kit 246452

For 2150 Pumps

309643B

Model 246450 Model 246522

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

Model 246451

Page 2

Installation

Installation

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of serious injury

from pressurized fluid, accidental spray from the gun

or splashing fluid, follow this procedure whenever you:

• Are instructed to relieve pressure

• Stop pumping

• Check, clean, or service any system equipment

• Install or clean fluid nozzles

1. Shut off the air to the pump

2. Open the dispensing valve, if used

3. Open the fluid drain valve to relieve all fluid pressure, having a container ready to catch the drainage

Installation Tools Required

• Torque wrench

• 10 mm socket wrench (1040)

• 13 mm socket wrench (1590 & 2150)

• 15 mm socket wrench (metal fluid section)

• adjustable wrench (plastic fluid section)

• 19 mm open end wrench

• O-ring pick

List of Parts in Kit

• Stainless steel air motor, with stainless steel air

covers

Small PTFE o-ring - used with center shaft, Qty 2

•

• Large PTFE o-ring - used with seats if applicable

Q

ty 4

,

Record Pump Information

Before you install the new stainless steel conversion kit,

record the information from the existing pump in the box

below. Refer to this information when you need to purchase repair kits or file a warranty claim.

PART NO. SERIES MADE IN

MAX

GPM-

/MIN

Plate No.

290-045

Rev. C

MAX FLUID & AIR PSI-barWEIGHT LB - kg

• Thread locking compound (blue) - tube

• Lithium-based Grease - tube

2 309643B

Page 3

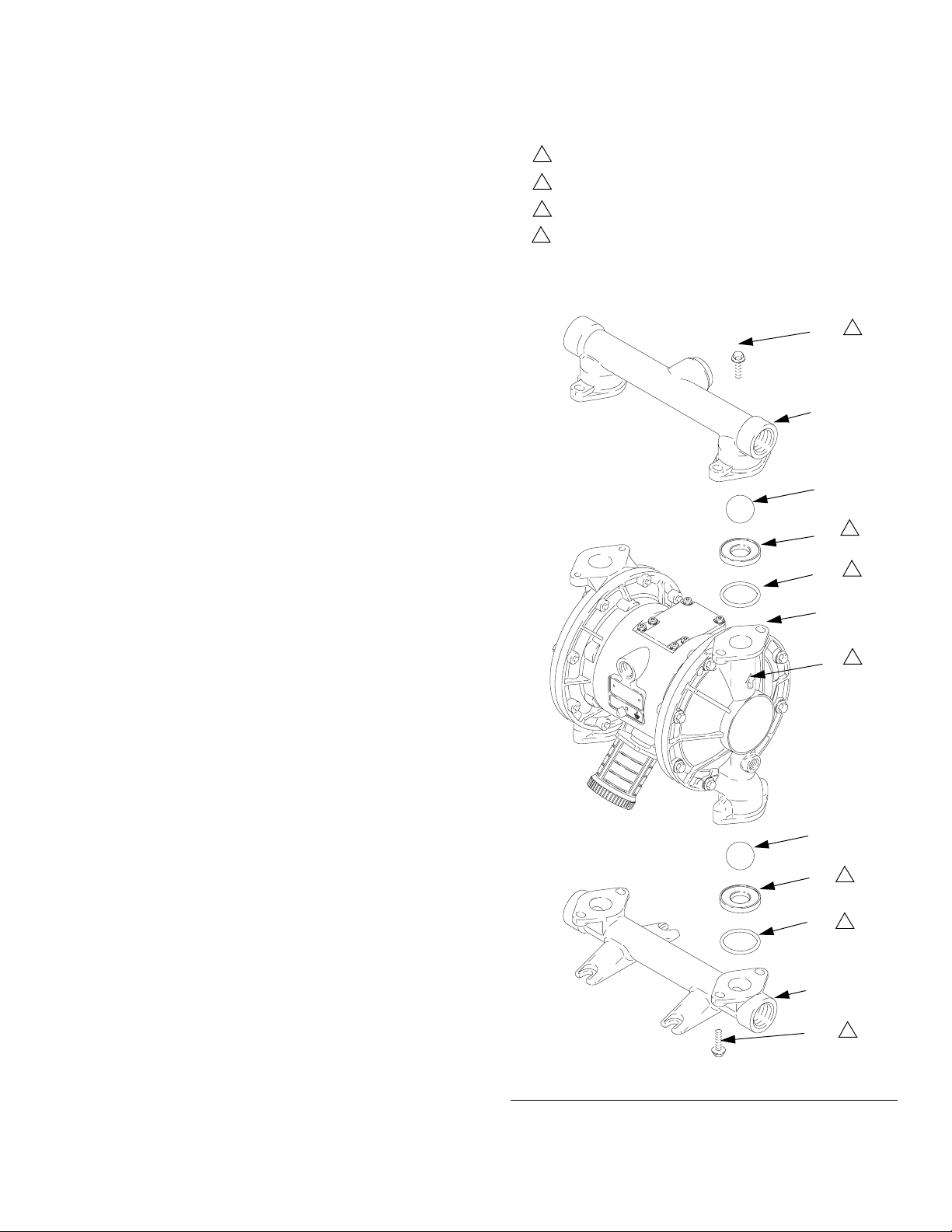

Metal Fluid Section Pumps

Disassembly of Inlet and Outlet Manifolds

1. Relieve the pressure, see page 2. Disconnect all

hoses.

2. Remove the pump from its mounting.

Installation

Apply medium-strength (blue) Loctite or equivalent to

1

the threads, and torque to 120-150 in-lb (14-17 N.m).

2

Arrow (A) must point toward outlet manifold (103).

3

Beveled seating surface must face the ball (301).

4

Not used on some models.

3. Remove the bolts (106) holding the outlet manifold

(103) to the fluid covers (101). See F

IG

. 1.

4. Remove the o-rings (202, not used on some models), seats (201), and balls (301) from manifold

(103).

5. Turn the pump over and remove the inlet manifold

(102). Remove the o-rings (202, not used on some

models), seats (201), and balls (301) from fluid covers (101).

1040 Model Shown

106

103

301

201

202

101

A

1

3

4

2

301

201

3

202

4

102

106

1

F

. 1

IG

309643B 3

Page 4

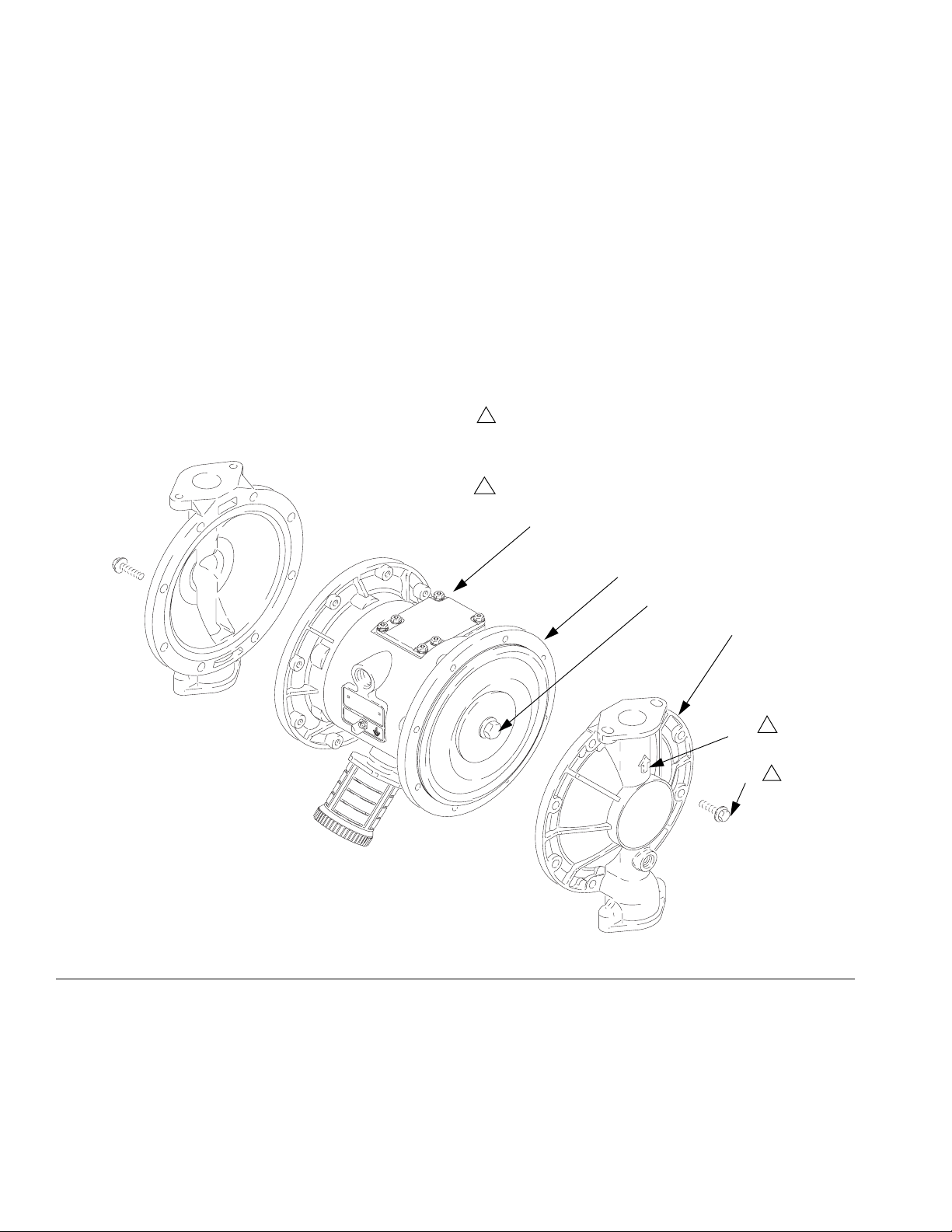

Installation

Disassembly of Fluid Covers

1. Remove the screws (106) holding the fluid covers

(101) to the air covers (23). Pull the fluid covers

(101) off the pump. See F

2. Loosen but do not remove the diaphragm shaft bolts

(107) on both ends.

IG

. 2.

3. Unscrew one bolt from diaphragm shaft (24) and

remove the o-ring (108), fluid side diaphragm plate

(105), PTFE diaphragm (403, used on PTFE mod-

els only), diaphragm (401), and air side diaphragm

plate (104). See F

IG

. 3

4. Pull the other diaphragm assembly and the diaphragm shaft (24) out of the center housing (1).

Hold the shaft flats with a open end wrench, and

remove the bolt (107) from the shaft. Disassemble

the remaining diaphragm assembly.

5. Clean and check all parts for wear or damage.

Replace parts as needed.

.

Apply medium-strength (blue) Loctite or equivalent to

1

the threads, and torque:

1040 models -120-150 in-lb (14-17 N.m.)

1590/2150 models - 190-220 in-lb (22-25 N.m.)

Arrow (A) must point toward air valve (B).

2

B

23

FIG. 2

107

101

A

106

2

1

4 309643B

Page 5

Installation

.

1

24

4

104

2

401

3

Cutaway View, with Diaphragms in Place

4

24

104

105

2

2

107

5

19

402

1

403

3

6

1

Cutaway View, with Diaphragms Removed

401

3

FIG. 3

403

3

6

105

2

108

107

5

1

24

4

1

Lips face out of housing (1).

2

Rounded side faces diaphragm (401).

3

Air Side must face center housing (1).

4

Grease.

5

Apply medium-strength (blue) Loctite® or

equivalent. Torque to 20-25 ft-lb (27-34 N.m)

at 100 rpm maximum.

6

Used on pumps with PTFE diaphragms

only.

309643B 5

Page 6

Installation

Reassembly of Fluid Covers

1. Install the diaphragm assembly on one end of the

shaft as follows:

a. Install new o-ring (108), provided with kit, on the

shaft bolt (107).

b. Install the fluid side diaphragm plate (105) on

the bolt so the rounded side faces the diaphragm (401).

c. On PTFE models only, install the PTFE dia-

phragm (403) with the side marked AIR SIDE

facing the center housing (1).

d. Install the diaphragm (401) on the bolt with the

side marked AIR SIDE facing the center housing (1).

e. Install the air side diaphragm plate (104) so the

rounded side faces the diaphragm (401). This

plate is used on all models, and is stamped with

its part number.

2. Grease the length and ends of diaphragm shaft

(24), and slide it through the new Stainless Steel

Plus housing (1).

3. Assemble the other diaphragm assembly to the

shaft as explained in step 1.

4. Hold one shaft bolt (107) with a wrench and torque

the other bolt to 20-25 ft-lb (27-34 N.m) at 100 rpm

maximum.

5. Align the fluid covers (101) and the center housing

(1) so the arrows (A) on the covers face the same

direction as the air valve (B). Apply

medium-strength (blue) Loctite or equivalent to the

threads of the screws (106). Secure the covers with

the screws handtight. See F

6. Torque the screws oppositely and evenly to:

1040 models -120-150 in-lb (14-17 N.m.)

1590/2150 models - 190-220 in-lb (22-25 N.m.)

IG

. 2.

Reassembly of the Inlet and Outlet

Manifolds

1. Reassemble in reverse order, following all notes in

IG

F

. 1.

f. Apply medium-strength (blue) Loctite or equiva-

lent to the bolt (107) threads. Screw the bolt into

the shaft (24) hand tight.

g. Inspect the wrench flats on the shaft (24) for

burrs that could damage the air motor seals

(402). Use a file to remove any burrs.

2. If o-rings (202) are used, replace with new ones to

assure the pump will seal properly. Be sure the ball

checks and manifolds are assembled exactly as

shown. The arrows (A) on the fluid covers(101)

must point toward the outlet manifold (103).

6 309643B

Page 7

Plastic Fluid Section Pumps

Disassembly of Inlet and Outlet Manifolds

1. Relieve the pressure, page 2. Disconnect all

hoses.

2. Remove the pump from its mounting.

3. Remove the bolts (106) holding the outlet manifold

(103) to the fluid covers (101). See F

4. Remove the o-rings (202, not used on some models), seats (201), and balls (301) from manifold

(103).

5. Turn the pump over and remove the inlet manifold

(102). Remove the o-rings (202, not used on some

models), seats (201), and balls (301) from fluid covers (101).

IG

. 4.

Installation

Torque to 80 to 90 in-lb (9 to 10 N.m)

1

Arrow (A) must point toward outlet manifold (103).

2

3

Not used on some models.

4

Beveled seating surface must face the ball (301).

106

1

103

301

201

202

301

201

202

4

A

4

3

3

2

101

102

112

1

F

. 4

IG

309643B 7

Page 8

Installation

Disassembly of Fluid Covers

1. Remove the screws (106) and (112) holding the fluid

covers (101) to the air covers (23). Pull the fluid covers (101) off the pump. See F

2. Unscrew one outer plate (105) from diaphragm

shaft (24), diaphragm (401), and air side diaphragm

plate (104). See F

112

1

IG

. 6.

IG

. 5.

3. Pull the other diaphragm assembly and the diaphragm shaft (24) out of the center housing (1).

Hold the shaft flats with a open end wrench, and

remove the other outer plate (105) from the shaft.

Disassemble the remaining diaphragm assembly.

4. Clean and check all parts for wear or damage.

Replace parts as needed.

You must torque the eight long screws (106) first,

1

then short screws (112). Torque the screws, (106)

first, then (112) oppositely and evenly to:

1040 models -100-150 in-lb (11-17 N.m.)

1590/2150 models - 190-220 in-lb (22-25 N.m.

Arrow (A) must point toward air valve (B).

2

B

23

113

101

A

106

2

1

F

. 5

IG

8 309643B

Page 9

Installation

19

402

1

105

2

403

3

1

24

4

104

2

401

3

6

1

24

4

104

2

401

3

403

6

3

5

105

1

24

4

Lips face out of housing (1).

1

Rounded side faces diaphragm (401).

2

Air Side must face center housing (1).

3

Grease.

4

5

Apply medium-strength (blue) Loctite® or

equivalent. Torque to 20-25 ft-lb (27-34 N.m)

at 100 rpm maximum.

6

Used on pumps with PTFE diaphragms

only.

. 6

F

IG

309643B 9

Page 10

Installation

Reassembly of Fluid Covers

1. Inspect the wrench flats on the shaft (24) for burrs

that could damage the air motor seals (402). Use a

file to remove any burrs.

2. Grease the length and ends of diaphragm shaft

(24), and slide it through the new Stainless Steel

Plus housing (1).

3. Assemble the inner diaphragm plates (104), dia-

phragms (401), PTFE diaphragms (403, if present),

and outer diaphragm plates (105) exactly as shown

in Fig. 6. These parts must be assembled correctly.

4. Apply medium-strength (blue Loctite or equivalent to

the threads of the fluid-side plate (105). Hold one of

the outer plates (105) with a wrench, and torque the

other outer plate to 20-25 ft-lb (27-34 N.m.) at 100

rpm maximum. Do not over-torque.

5. Align the fluid covers (101) and the center housing

(1) so the arrows (A) on the covers face the same

direction as the air valve (B). Apply

medium-strength (blue) Loctite or equivalent to the

threads of the screws (106) and (112). Place the

bolt caps (113) on the longer screws (106). Secure

the covers with the screws handtight. See F

6. Torque the screws, (106) first, then (112) oppositely

and evenly to:

1040 models -100-150 in-lb (11-17 N.m.)

1590/2150 models - 190-220 in-lb (22-25 N.m.)

IG

. 2.

Reassembly of the Inlet and Outlet

Manifolds

1. Reassemble in reverse order, following all notes in

IG

F

. 4.

2. If o-rings (202) are used, replace with new ones to

assure the pump will seal properly. Be sure the ball

checks and manifolds are assembled exactly as

shown. The arrows (A) on the fluid (101) must point

toward the outlet manifold (103).

10 309643B

Page 11

Installation

309643B 11

Page 12

Graco Standard Warranties

Graco Standard Husky Pump Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the date of

sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited warranty published

by Graco, Graco will, for a period of five years from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco's written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance

of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco's sole obligation and buyer's sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within six years of the date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection with

accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured by Graco (such

as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés à la suite

de ou en rapport, directement ou indirectement, avec les procedures concernées.

Extended Product Warranty

Graco warrants all Husky 205, 307, 515, 716, 1040, 1590, 2150, and 3275 air valve center sections to be free from defects in material and

workmanship for a period of fifteen years from date installed in service by the original purchaser. Normal wear of items such as packings or seals

are not considered to be defects in material and workmanship.

Five yearsGraco will provide parts and labor. Six to Fifteen yearsGraco will replace defective parts only.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1-800-367-4023 Toll Free; 612-623-6921; 612-378-3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Sales Offices: Minneapolis, Detroit

International Offices: Belgium Korea, Hong Kong, Japan

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

Printed in USA 309643A 10/2002

Loading...

Loading...