Page 1

Instructions -- Parts List

R

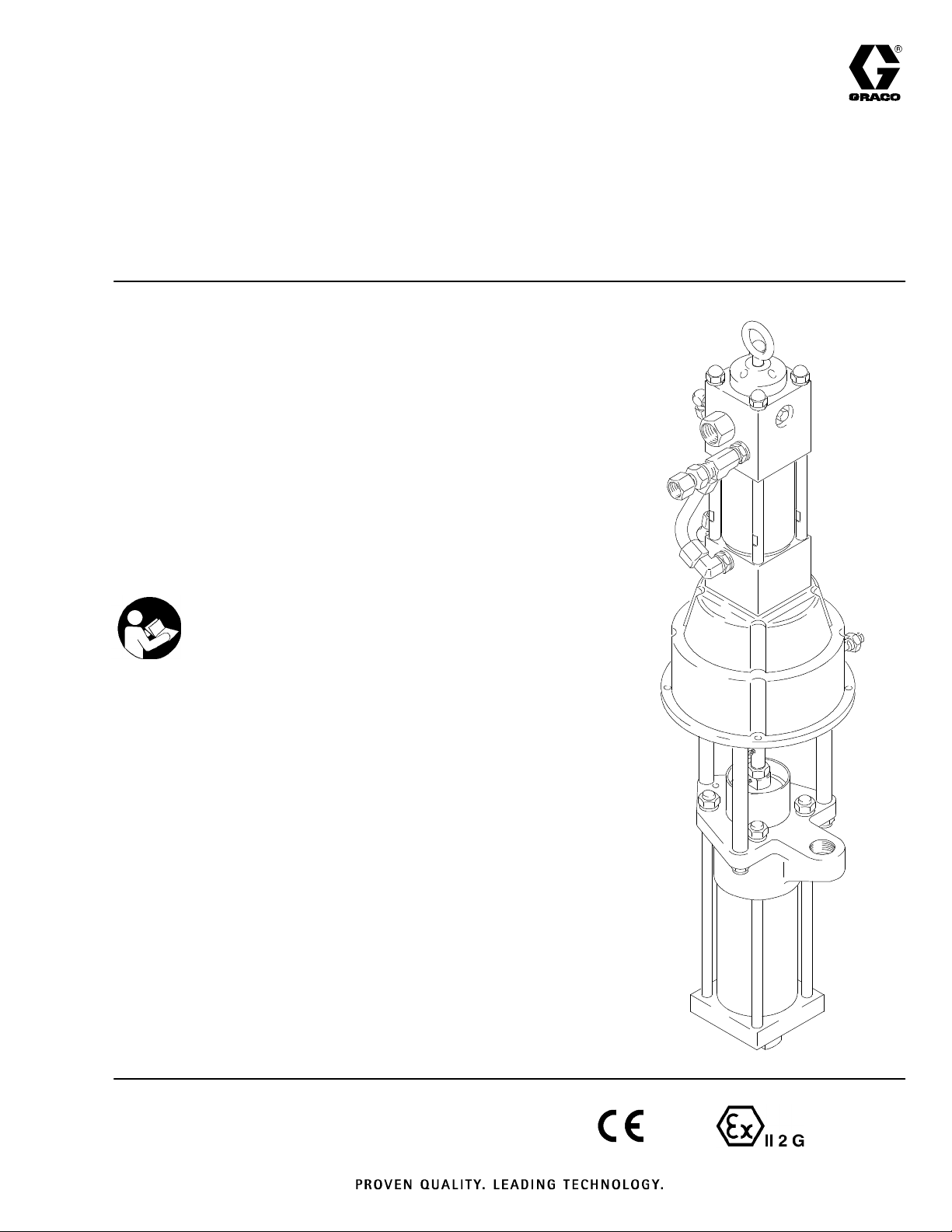

Viscount

Hydraulic powered, severe duty pump for use with solventborne

and waterborne paints and coatings.

1500 psi (10.3 MPa, 103 bar) Maximum Hydraulic Input Pressure

1000 psi (7 MPa, 69 bar) Maximum Pump Outlet Pressure

Model 210313, Series E

With Severe-Duty Displacement Pump*

* Severe-Duty displacement pumps have an abrasion

and corrosion-resistant displacement rod and cylinder.

Refer to the Technical Data section of the separate pump

manual for “Wetted Parts” information.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

II Pump

307160T

EN

Page 2

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

Dimensions 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting holes 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Charts 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 16. . . . . . . . . . . . . . . . . . . . . .

Graco Information 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure stated on the equipment or in the Technical Data

for your equipment. Do not exceed the maximum working pressure of the lowest rated component

in your system.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Handle hoses carefully. Do not pull on hoses to move equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 66_C (150_F) or below --40_C (--40_F).

D Wear hearing protection when operating this equipment.

D Do not move or lift pressurized equipment.

2 307160

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

Page 3

WARNING

INJECTION HAZARD

Spray from the gun/valve, leaks or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can

also cause serious injury.

D Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

D Do not point the gun/valve at anyone or at any part of the body.

D Do not put your hand or fingers over the spray tip/valve nozzle.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Do not “blow back” fluid; this is not an air spray system.

D Always have the tip guard and the trigger guard on the gun/valve when spraying/dispensing.

D Be sure the gun/valve trigger safety operates before spraying/dispensing.

D Lock the gun/valve trigger safety when you stop spraying/dispensing.

D Follow the Pressure Relief Procedure on page 8 if the spray tip clogs and before cleaning,

checking or servicing the equipment.

D Tighten all fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

D Keep clear of all moving parts when starting or operating the pump.

D Before checking or servicing the equipment, follow the Pressure Relief Procedure on page 8 to

prevent the equipment from starting unexpectedly.

3 307160

Page 4

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury.

D Ground the equipment and the object being sprayed. Refer to Grounding on page 5.

D If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing/dispensing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed/dispensed.

D Keep the spray/dispense area free of debris, including solvent, rags, and gasoline.

D Before operating this equipment, electrically disconnect all equipment in the spray/dispense area.

D Before operating this equipment, extinguish all open flames or pilot lights in the spray/dispense

area.

D Do not smoke in the spray/dispense area.

D Do not turn on or off any light switch in the spray/dispense area while spraying/dispensing or while

operating if fumes are present.

D Do not operate a gasoline engine in the spray/dispense area.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

4 307160

Page 5

Installation

General Information

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing.

NOTE: Always use Genuine Graco Parts and Accessories, available from your Graco distributor.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below. Also read

the section FIRE OR EXPLOSION HAZ-

ARD on page 4.

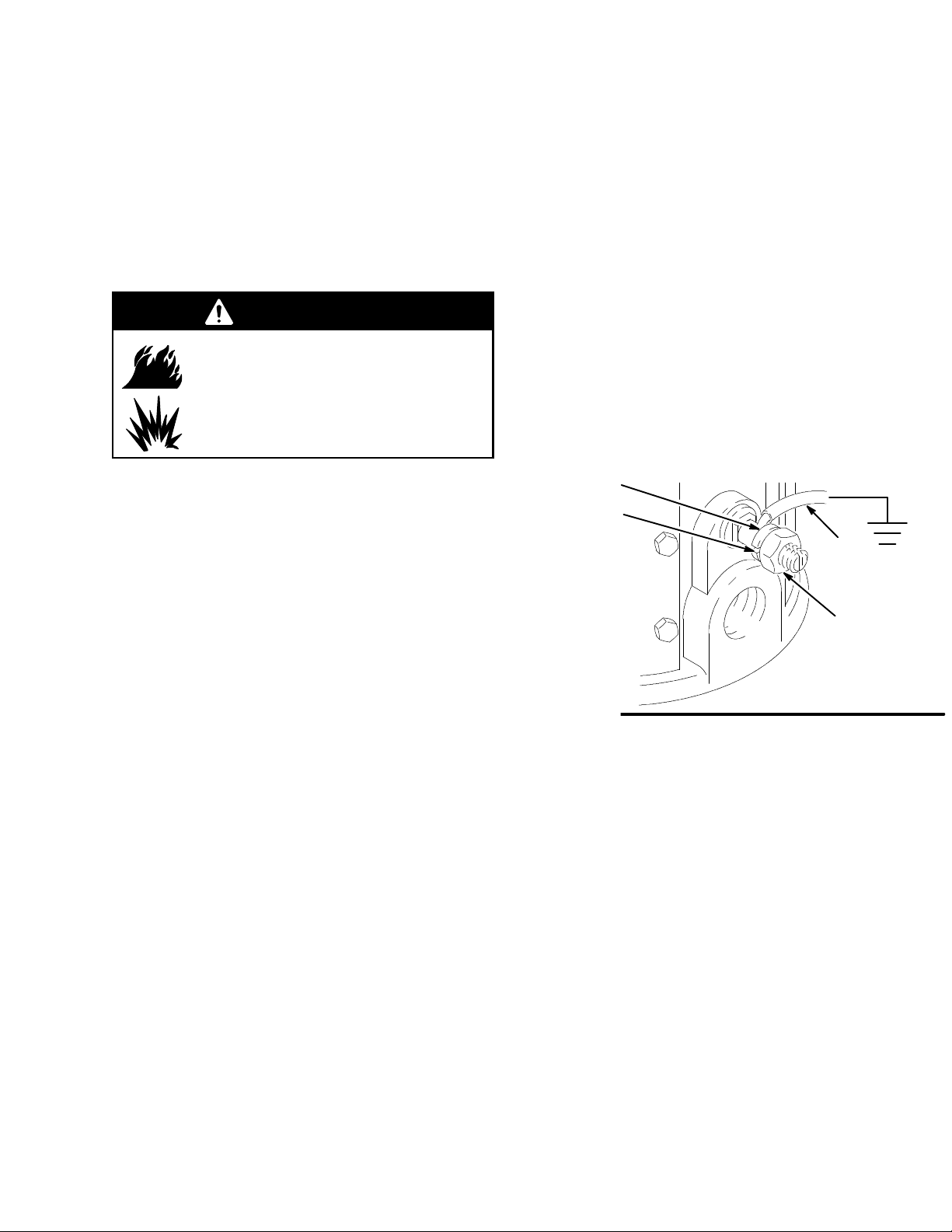

D Pump: Use a ground wire and clamp as shown in

Fig. 4. Loosen the grounding lug locknut (W) and

washer (X). Insert one end of a 12 ga (1.5 mm@)

minimum ground wire (Y) into the slot in lug (Z) and

tighten the locknut securely. Connect the other end

of the wire to a true earth ground. Order part number 237569 Grounding Clamp and Wire.

D Spray gun: Ground through connection to a prop-

erly grounded fluid hose and sprayer.

D Object being sprayed: Follow the local code.

D Fluid supply container: Follow the local code.

D Solvent pails used when flushing: Follow the local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the pail

on a nonconductive surface, such as paper or

cardboard, which interrupts the grounding continuity.

D To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the spray

gun firmly to the side of a grounded metal pail, then

trigger the gun.

Z

X

Y

D Fluid and hydraulic hoses: Use only grounded

hoses with a maximum of 500 ft (150 m) combined

hose length to ensure grounding continuity.

D Hydraulic Power Supply: Follow the manufacturer’s

recommendations.

W

06431

Fig. 4

5 307160

Page 6

Installation

CAUTION

CAUTION

Mount the pump to suit the type of installation planned.

Pump dimensions and mounting hole layout are shown

on page 14.

The hydraulic supply system must be kept clean at

all times to avoid damage to the motor and hydraulic

power supply. Blow out all hydraulic lines with air and

flush thoroughly with compatible solvent before

connecting the lines to the motor.

Always plug the hydraulic inlets, outlets, and lines

when disconnecting them for any reason, to avoid

introducing dirt and other contaminants into the system.

Filters

Be sure that your hydraulic power supply is equipped

with a suction filter to the hydraulic pump and a system

return line filter of 10 micron size.

Carefully follow the manufacturer’s recommendations

on reservoir and filter cleaning, and periodic changes

of hydraulic fluid. Use only Graco-approved hydraulic

oil.

D A pressure reducing valve (H), with a drain

line (K) running directly to the hydraulic return

line (D).

D An accumulator (J) to reduce the hammering

effect caused by the motor reversing direction.

D A shutoff valve (E) isolates the pump for service.

Do not exceed 10 gpm (37.8 liter/minute) volume to

avoid pump stalling.

Drip Pan

The hydraulic motor is equipped with a drip pan to

collect any leakage that might occur. connect a 1/4 in.

ID drain hose (Q) to the barbed hose fitting on the drip

pan.

Drain Valve

Install a high pressure fluid drain valve (B) near the

pump fluid outlet to relieve fluid pressure in the displacement pump and hose during shutdown.

Hydraulic Lines

Connect a 3/4 in. minimum ID hydraulic supply line (L)

to the 3.4 npt inlet of the hydraulic motor. See the

Typical Installation on page 7. Connect a 1 in. minimum ID return line (D) to the 1” npt return port on the

hydraulic motor.

On the hydraulic supply side (C), install the following

accessories shown in Fig. 5, using adapters as necessary.

D A shutoff valve (E) isolates the pump for service.

D A fluid pressure gauge (F) to monitor hydraulic oil

pressure to the motor and to avoid overpressurizing

the motor or displacement pump, and a pressure-

and temperature-compensated flow control

valve (G) to prevent the motor from running too

fast and possibly damaging itself.

WARNING

The fluid drain valve (B) is required in your system

to help reduce the risk of serious bodily injury,

including fluid injection and splashing in the eyes or

on the skin if you are adjusting or repairing any part

of the system. Triggering the gun to relieve pressure may not be sufficient.

Fluid Supply Lines

Connect a grounded fluid supply line to the 1--1/2” npt

fluid outlet on the displacement pump. Attach a fluid

supply line to the 2” npt pump fluid intake.

If you are pumping through a long hose, or if the fluid

being pumped is compressible, giving an accumulator

effect, install a check valve at the pump outlet. Be sure

that the check valve selected is capable of handling

the flow and pressure developed in your system.

6 307160

Page 7

Installation

JHFE

K

C

N

L

S

D

G

P

A

T

R

B

Q

0627A

M

Fig. 5

KEY

A

Fluid Hose to Gun

B

Fluid Drain Valve

C

Suction Hose

D

Hydraulic Return Line

E

Hydraulic Return Shutoff Valve

F

Pressure Gauge

G

Flow Control Valve

H

Pressure Reducing Valve

J

Accumulator

K

Drain Line (from pressure reducing valve)

L

Hydraulic Supply Line

M

Hydraulic Power Supply

N

Ground Wire

P

Wet-Cup

Q

Drain Line (from motor drip pan)

R

Check Valve

S

Hydraulic Supply Shutoff Valve

T

Return Line Filter

7 307160

Page 8

Operation

CAUTION

Pressure Relief Procedure

WARNING

INJECTION HAZARD

Fluid under high pressure can be injected through the skin and cause seri-

ous injury. To reduce the risk of an injury

from injection, splashing fluid, or moving parts, follow the Pressure Relief Procedure whenever you

D Are instructed to relieve the pressure

D Stop spraying/dispensing

D Check or service any of the system equipment

D Install or clean the spray tips/nozzles

1. Engage the safety latch.

2. Shut off the power supply to the hydraulic motor.

3. Disengage the gun safety latch.

4. Hold a metal part of the gun firmly to the side of a

grounded metal pail. Trigger to relieve pressure.

5. Open the fluid drain valve (required in your system) having a container ready to catch the drainage. Leave the drain valve open until you are

ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, very slowly loosen the

tip guard retaining nut or hose end coupling and relieve

pressure gradually, then loosen completely, then clear

the tip or hose.

When shutting down the hydraulic system, always

shut off the hydraulic supply line shutoff valve (S)

first, and then the return line shutoff valve (E). This

is to prevent overpressurizing the motor or its seals.

When starting the hydraulic system, open the return

line shutoff valve first.

Flushing the Pump

Flush the pump before using it for the first time to

remove the lightweight oil which is left in the pump

after factory testing to protect it from corrosion. Be

sure the solvent used is compatible with the fluid to be

sprayed, and with the wetted parts of the pump. Refer

to the Technical Data in the separate displacement

pump manual for the wetted parts. Flush until clean

solvent comes from the gun. In a circulating system,

flush long enough to clean the entire system.

8 307160

Page 9

Operation

CAUTION

WARNING

COMPONENT RUPTURE HAZARD

To reduce the risk of overpressurizing

your system, which could cause component rupture and serious injury, never

exceed the specified Maximum Hydraulic Input

Pressure to the pump (see the Technical Data on

page 15).

To prevent overpressurizing the hydraulic motor or

its seals, always shut off the supply line valve (S)

first, then shut off the return line valve (E).

NOTE: In a direct supply system, the pump starts and

stops automatically when the spray gun is opened and

closed. In a circulating system, the pump runs continuously, speeding up or slowing down as the spray gun is

opened or closed, until the hydraulic power supply is

turned off.

Never allow the hydraulic oil temperature to exceed

130_ F (54_ C). The pump seals will wear faster and

leaking may occur at higher temperatures.

Starting and Adjusting the Pump

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

NOTE: If the pump is not immersed in fluid, fill the

wet-cup (P) 1/3 full with Graco Throat Seal Liquid

(TSL) or a compatible solvent, to prevent fluid from

drying on the displacement rod and damaging the

pump packings. Refer to the Typical Installation on

page 7. Check the tightness of the packing nut/wetcup weekly. Before adjusting, relieve the pressure.

The nut should be tight enough to prevent leakage, but

no tighter.

Check the hydraulic fluid level, and add fluid as necessary to the fill lines, before each use. Turn on the

hydraulic power supply. Open the return line shutoff

valve (E). Slowly open the hydraulic supply shutoff

valve (S). Run the pump slowly until all air is pushed

out of the lines and fluid is flowing smoothly. Close the

spray gun; the pump will stall. Use the lowest pressure

possible to get the desired results. Higher pressures

will cause premature tip and pump wear.

WARNING

To reduce the risk of overpressurizing the system,

always follow these precautions:

Never exceed 1500 psi (10.3 MPa, 103 bar), or

10 gpm (37.8 liter/min) hydraulic input to the motor.

Never exceed 1000 psi (7 MPa, 69 bar) maximum

pump outlet pressure.

Check Valve Adjustment

The fluid piston and intake valve are factory set for

high-volume pumping of heavy, spray-viscosity fluids.

To adjust the check valves, refer to the operation

section in the separate displacement pump manual.

9 307160

Page 10

Maintenance

CAUTION

Carefully monitor your fluid supply. If your pump us

running too fast, or accelerates quickly, it is probably

out of fluid. Shut off the hydraulic power supply immediately to prevent damage to the pump. If the fluid

supply is empty, and air has entered the fluid lines, be

sure to prime the pump again before regular operation.

Flush the pump frequently enough to prevent the fluid

from drying or settling in the pump and hoses to prevent costly damage. Use a compatible solvent. Refer

to the Technical Data in the separate displacement

pump manual for a list of the wetted parts.

To help prevent corrosion of the pump, never leave

the pump filled with water or water-base fluids, or air

during non-use. After flushing, flush the pump again

with a compatible solvent, such as mineral spirits,

relieve the pressure, and leave a coating of solvent

in the pump and hoses..

Shutdown

If you are pumping water-base fluid, first flush with

water and then with a compatible solvent.

Corrosion Protection

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

Always stop the pump with the displacement rod in the

down position. This prevents fluid from drying on the

displacement rod and damaging the packings when

the pump is restarted. Relieve the pressure whenever

you shut off the pump.

10 307160

Page 11

Troubleshooting

Before servicing this equipment, always make sure to

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

Problem Cause Solution

Pump fails to operate Restricted lines or inadequate hydraulic

supply

Insufficient hydraulic pressure; closed

or clogged valves, etc.

Exhausted fluid supply Refill and reprime, or flush.*

Clogged fluid line, valves, etc. Clear.**

Damaged hydraulic motor Service the motor. See manual 307158

Dried fluid seizure of displacement rod. Clean. See Displacement pump manual

Pump operates, but the fluid

output is low on both strokes

Pump operates, but the output

is low on the downstroke

Pump operates, but the output

is low on the upstroke

Pump is operating erratically,

or speeds up suddenly

Restricted lines, or inadequate hydraulic supply

Insufficient hydraulic pressure; closed

or clogged valves, etc.

Exhausted fluid supply Refill and reprime or flush.*

Clogged fluid line, valves, etc. Clear.**

Piston check valve needs adjustment Adjust. See manual 308043.

Packing nut too tight Loosen.

Loose packing nut or worn throat packings.

The intake valve is stuck open or worn. Clear; service. See manual 308043.

The piston valve is stuck open, or the

packings are worn

Exhausted fluid supply Refill and reprime or flush.*

The intake valve is stuck open or worn Check; replace parts as needed. See

The piston valve is stuck open or the

packings are worn.

Excessive hydraulic fluid supply volume Lower volume.

Air entrained in fluid Purge all air; change fluid.

relieve the pressure.

NOTE: Check all possible problems and solutions

before disassembling the pump.

Clear lines. Increase hydraulic supply.

Open; clean.

308043. ALso, keep TSL in the pump

wet-cup and stop the pump at the bottom of its stroke during non-use.

Clear lines. Increase hydraulic supply.

Open; clean.

Tighten packing nut or replace packings

as needed, See manual 308043.

Clear; service. See manual 308043.

manual 308043.

Check; replace parts as needed. See

manual 308043.

* Stop the pump immediately if it is running too fast; check the fluid supply. If empty, refill and reprime the pump

being sure to eliminate all air from the system, or flush the pump and store it with an oil-based solvent, such as

mineral spirits, to prevent corrosion.

** Relieve the pressure, and then disconnect the fluid line. If the pump starts when the hydraulic power is re-

stored, line, etc. is clogged.

11 307160

Page 12

1

Torque to 40--50 ft-lb (54--68 NSm)

Service

NOTE: To service the displacement pump, refer to

manual 308043, supplied.

NOTE: To service the hydraulic motor, refer to manual

308158, supplied.

Disassembly (See Fig. 6)

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

1. Flush the pump with a compatible solvent, if pos-

11

2. Disconnect the hoses from the pump. Plug the

WARNING

sible. Stop the pump at the bottom of its stroke.

Relieve the pressure.

hydraulic lines to prevent contamination. Remove

the pump from its mounting and clamp it in a vise.

12

3. Remove the upper cotter pin (1). Unscrew the

coupling nut (7). Unscrew the three tie rod

locknuts (3), then unscrew the three tie rods (6)

from the hydraulic motor (11). Carefully pull the

8

7

1

9

4

1

5

6

T

3

1

displacement pump (12) away from the motor (11).

4. Remove the lower cotter pin (1). Loosen the

locknut (4). Unscrew the connecting rod (9) from

the displacement rod (T).

Reassembly (See Fig. 6)

1. Screw the three tie rods (6) into the motor (11).

Torque to 40--50 ft-lb (54--68 NSm).

2. Screw the connecting rod (9) into the displacement

rod (T). Install the cotter pin (1) and tighten the

locknut (4).

3. Guide the displacement pump (12) onto the tie

rods (6).

4. Install the locknuts (3) on the tie rods. Torque the

nuts to 40--50 ft--lb (54-68 NSm).

5. Tighten the coupling nut (7). Insert the upper cotter

pin (1) through the coupling (8)

Fig. 6

12 307160

6. Connect the hoses to the pump. Run the pump

slowly to be sure it runs smoothly and does not

bind. If necessary, adjust the displacement pump

tie rods and locknuts (see manual 308043), or the

tie rods (6) and locknuts (3) which attach the

motor, to eliminate binding.

06640

7. Reconnect the ground wire to the motor.

Page 13

Parts

11

Ref.

No. Part No. Description Qty.

1 100103 PIN, cotter; 1.5” (38.1 mm) long 2

3 101712 LOCKNUT; 5/8--11;

with nylon insert 3

4 101936 NUT, hex, jam; 3/4--10 1

5 158674 O-RING; nitrile rubber 1

6 167911 ROD, tie; 7” (177.8 mm) long,

shoulder-to-shoulder 3

7 168210 NUT, shouldered 1

8 168211 COUPLING, connecting rod 1

9 168212 ROD, connecting;

3.69” (93.7 mm) long 1

11 235345 HYDRAULIC MOTOR

See manual 307158 for parts 1

12 210208 DISPLACEMENT PUMP

See manual 308043 for parts 1

12

8

7

1

9

5

6

4

1

3

13 307160

06640

Page 14

1” npt

outlet

3/4 npt

inlet

Dimensions

Mounting Hole

Layout

gasket

161806

23.2”

(585 mm)

2” npt fluid inlet

(1220 mm)

1--1/2” npt

fluid outlet

06641

48.1”

4” (102 mm)

four 0.437” (11.1 mm)

holes on 10.5”

(267 mm) bolt circle

90_

45_

9.75”

(247.7 mm)

diameter

1.38”

(34.9 mm)

radius

06595

14 307160

Page 15

Technical Data

Maximum hydraulic input pressure 1500 psi (10.3 MPa, 103 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum pump outlet pressure 1000 psi (7.0 MPa, 69 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic fluid consumption 0.2 gal (0.76 liter) per cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Recommended Pump Speed 50 cycles/min; 15 gpm (56.8 liter/min). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts Displacement Pump: See manual 308043. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Performance Charts

Pump Pressure Developed

Hydraulic

Input Pressure

100 psi (0.7 MPa, 7 bar) 66 psi (0.45 MPa, 4.5 bar)

200 psi (1.4 MPa, 14 bar) 132 psi (0.9 MPa, 9 bar)

300 psi (2.1 MPa, 21 bar) 199 psi (1.4 MPa, 14 bar)

400 psi (2.8 MPa, 28 bar) 265 psi (1.8 MPa, 18 bar)

500 psi (3.4 MPa, 34 bar) 331 psi (2.3 MPa, 23 bar)

600 psi (4.1 MPa, 41 bar) 397 psi (2.7 MPa, 27 bar)

700 psi (4.8 MPa, 48 bar) 463 psi (3.2 MPa, 32 bar)

800 psi (5.5 MPa, 55 bar) 530 psi (3.6 MPa, 36 bar)

900 psi (6.2 MPa, 62 bar) 596 psi (4.0 MPa, 40 bar)

1000 psi (6.9 MPa, 69 bar) 662 psi (4.5 MPa, 45 bar)

1100 psi (7.6 MPa, 76 bar) 728 psi (5.0 MPa, 50 bar)

1200 psi (8.3 MPa, 83 bar) 794 psi (5.4 MPa, 54 bar)

1300 psi (9.0 MPa, 90 bar) 861 psi (5.9 MPa, 59 bar)

1400 psi (9.7 MPa, 97 bar) 927 psi (6.4 MPa, 64 bar)

1500 psi (10.3 MPa, 103 bar) 993 psi (6.8 MPa, 68 bar)

Pump Outlet

Pressure

Pump Output

Pump

Speed

(Cycles/min) gpm liter/min gpm liter/min

5 1.0 3.8 1.5 5.6

10 2.0 7.6 3.0 11.4

15 3.0 11.4 4.5 17.0

20 4.0 15.1 6.0 22.7

25 5.0 18.9 7.5 28.4

30 6.0 22.7 9.0 34.1

35 7.0 26.5 10.5 39.7

40 8.0 30.3 12.0 45.4

45 9.0 34.1 13.5 51.0

50 10.0 37.8 15.0 56.8

Hydraulic

Fluid Required

Pump

Output

15 307160

Page 16

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any partof the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non--Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages forlost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com. For patent information, see www.graco.com/

patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the distributor closest to you:

Phone: 612--623--6921 or Toll Free: 1--800--328--0211 Fax: 612--378--3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

16 307160

Original instructions. This manual contains English. MM 307160

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES SSSS P.O. BOX 1441 SSSS MINNEAPOLIS, MN 55440--1441 SSSS USA

Copyright 1975, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revised September 2014

Loading...

Loading...