Page 1

Instructions-Parts List

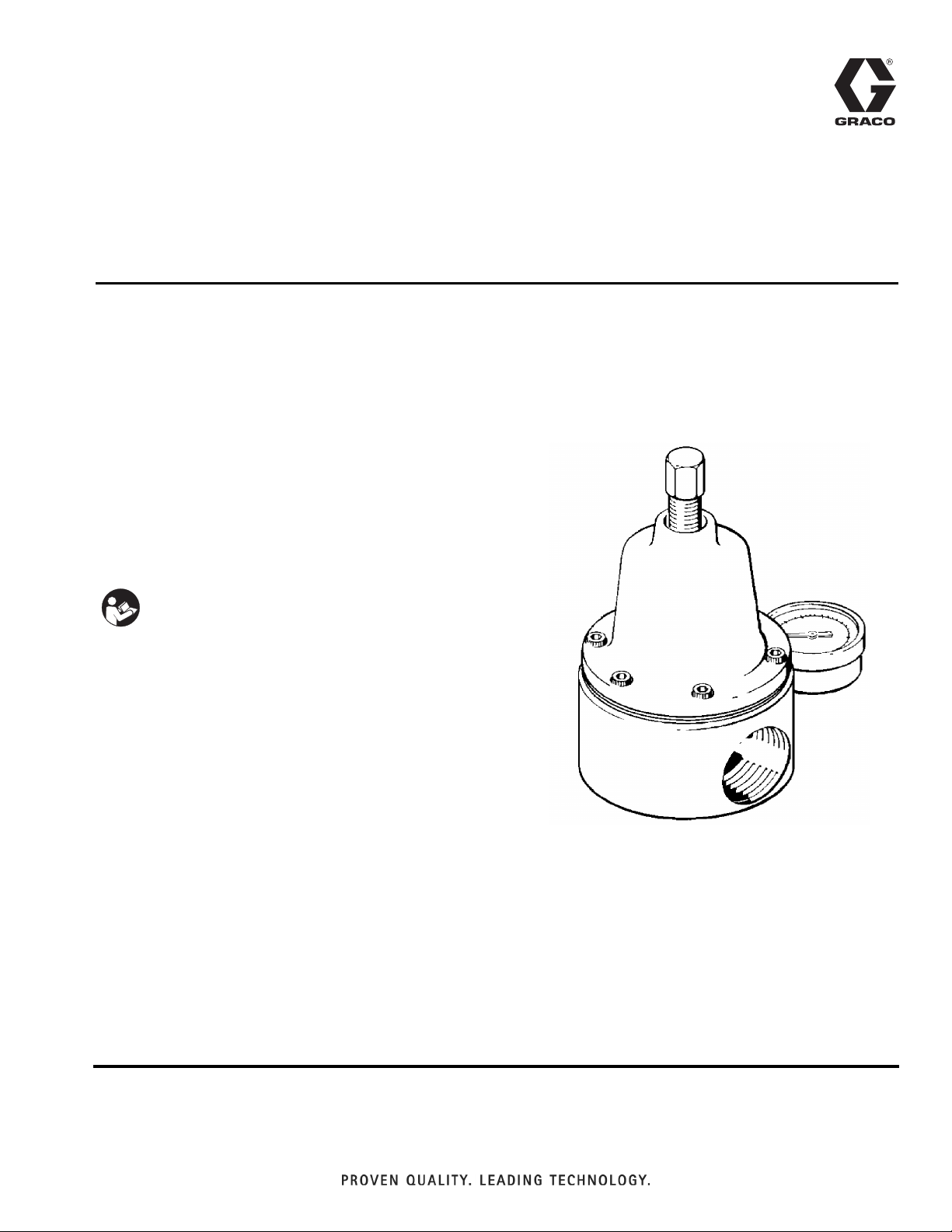

STAINLESS STEEL, WATERBASE COMPATIBLE

307107N

Back Pressure Valve

Used in circulating systems to provide regulated back pressure to the spray gun(s) and to

maintain proper circulating pressure throughout the system. For professional use only.

Model 208997, Series E

Stainless Steel Back Pressure Valve

300 psi (2.1 MPa, 21 bar) Maximum Inlet Pressure

200 psi (1.4 MPa, 14 bar) Maximum Regulated Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . 9

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Page 2

WARNING

WARNINGWARNINGWARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

• This equipment is for professional use only.

• Read all instruction manuals, tags, and labels before operating the equipment.

• Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

• Do not alter or modify this equipment.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed the maximum inlet pressure of the lowest rated system component. The maximum

inlet pressure of this equipment is 300 psi (2.1 MPa, 21 bar).

• Follow the Pressure Relief Procedure on page 4 if the spray tip clogs and before cleaning, checking

or servicing the equipment.

• Do not stop or deflect leaks with your hand, body, glove or rag.

• Be sure all equipment safety devices are operating properly before each use.

• Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

• Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

• Wear hearing protection when operating this equipment.

• Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 307107N

Page 3

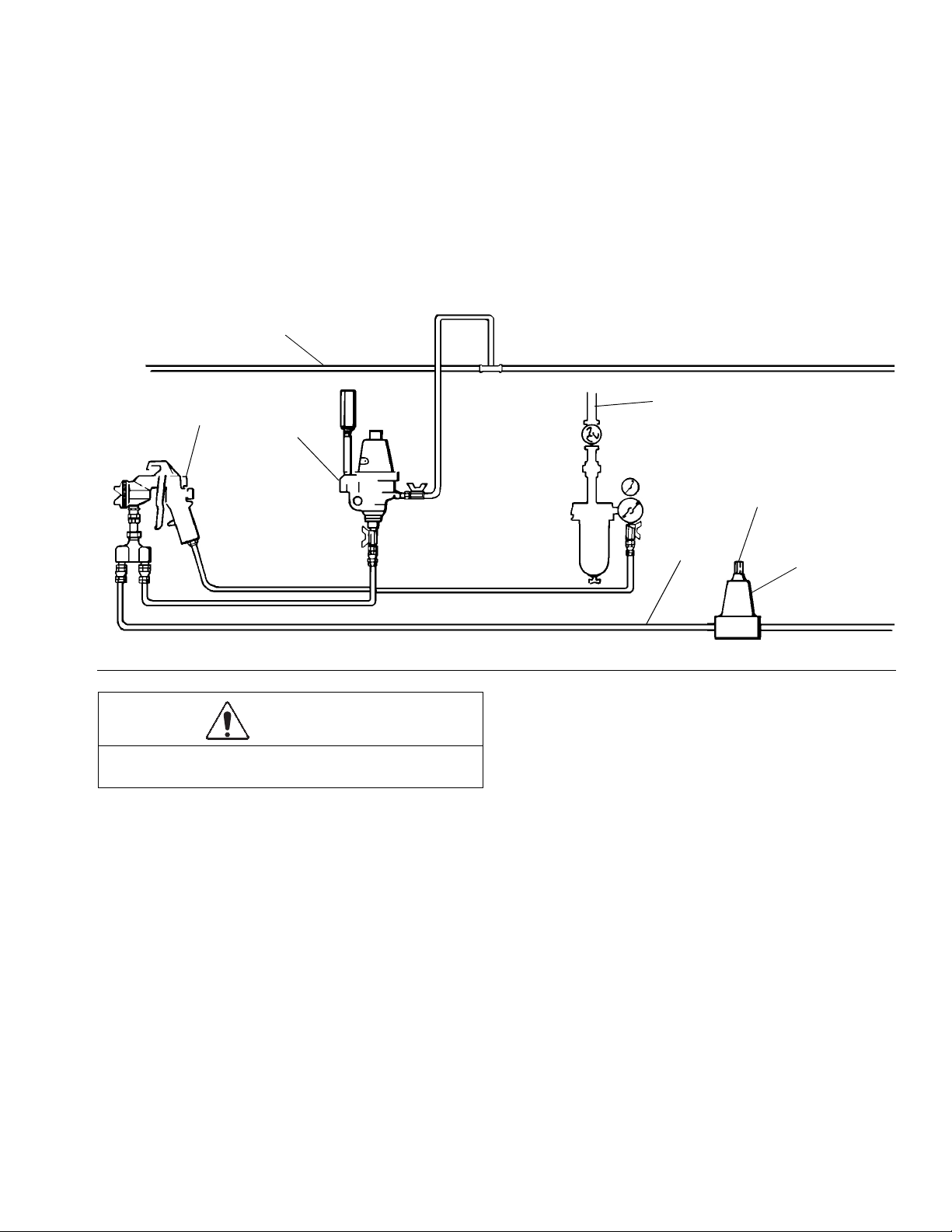

Installation

KEY

A Fluid supply line E Adjusting screw

B Air spray gun F Back pressure valve

C Fluid pressure regulator G Fluid return line

D Air supply line

A

Operation

B

C

FIG. 1

CAUTION

Handle the back pressure valve with care to avoid damaging the diaphragm.

Installing the Back Pressure Valve

Install the back pressure valve in the spray gun return

line. See Fig. 1.

D

E

G

F

8719A

Connect the line to the 1-1/4 in. npt(f) inlet and outlet.

Make sure the flow direction agrees with the IN and

OUT markings on the valve body.

The back pressure valve is adjustable to control the fluid

pressures in a circulating system from 5 to 200 psi

(0.035 to 1.4 MPa, 0.35 to 14 bar).

If more than one spray station is used, install the back

pressure valve in the fluid supply line after the last station. This will help maintain proper circulating pressures

in the system.

Operation

NOTE: The back pressure valve controls pressure

ahead of its intake.

Turn the adjusting screw

and

counterclockwise

307107N 3

clockwise

to decrease pressure.

to increase pressure

Adjust the pump pressure and back pressure valve for

the best spraying combination and for proper circulation

of fluid.

Flush the back pressure valve with a compatible solvent

whenever the rest of the system or unit is being flushed.

Open the back pressure valve before flushing by turning

the screw

counterclockwise

.

Page 4

Operation

Service

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

The system pressure must be manually relieved to

prevent the system from starting or spraying

accidentally. To reduce the risk of an injury from

accidental spray from the gun, splashing fluid, or

moving parts, follow the Pressure Relief Procedure

whenever you

• Are instructed to relieve the pressure

• Stop spraying

• Check or service any of the system equipment

• Install or clean the spray nozzle

1. Shut off the pump.

2. Open the dispensing valve, if used.

3. Open the fluid drain valve to relieve all fluid pressure, having a container ready to catch the drainage.

8. Install the diaphragm parts onto the valve housing

(15). Torque the retaining nut (20) to 10 to 12 ft-lb

(13.5 to 16 N-m).

9. Carefully inspect the seat (10) for damage, wear, or

dirt. These things could cause the regulated pressure to creep. Replace the seat if necessary.

10. Replace the seat gasket (14) when replacing the

seat (10). Torque the seat to 15 to 20 ft-lb (21 to 27

N-m).

11. To remove or install the gauge (8), use the wrench

on the square portion of the gauge stud only.

CAUTION

Use thread sealer sparely on the gauge’s male threads

when installing it to avoid plugging the gauge.

12. Lubricate both sides of the spring plate (7) and

spring (5) with lithium-base grease.

13. Lubricate the adjusting screw threads.

14. Assemble the remaining parts.

Service Procedure

NOTE: Regular cleaning and inspection of the valve,

based upon the degree and kind of service, is essential.

1. Shut off the pump and open the back pressure valve

by turning the adjusting screw (13)

wise

until no spring pressure is felt. Relieve all air

and fluid pressures in the system.

2. Remove the back pressure valve from the fluid line.

3. Disassemble the valve and clean it with a suitable

solvent. See the parts drawing, page 5.

4. Carefully inspect the diaphragm (12) for cracks or

other damage. Replace if necessary.

5. Check for chips or dirt that could puncture the membrane or diaphragm before assembling the valve.

6. Check if the gasket (17) needs to be replaced.

7. Lubricate the threads of the diaphragm retainer

(11).

counterclock-

15. Tighten the regulator cap screws (1) finger-tight,

then torque them to 120 to 130 in-lb (13.6 to 14.7

N-m) in a criss-cross pattern. See the TOP VIEW in

the parts drawing.

16. Install the back pressure valve back in the fluid line.

4 307107N

Page 5

Parts

Operation

See TOP VIEW

13

7

1

Torque to 10–12 ft-lb

2

(13.5–16 N-m)

19

1

1

PTFE side down Lubricate threads

3 7

Torque to 15–20 ft-lb

4

(21–27 N-m)

Apply anaerobic pipe

5

sealant to threads

Apply lithium-base

6

grease

TOP VIEW

6

7

6

5

Torque screws (1) to 120–130 in-lb

20

22

2

16

12

Model 208997, Series E

Stainless Steel Back Pressure Valve

Includes items 1 to 22

Ref.

3

No. Part No. Description Qty.

1 101682

(13.6–14.7 N-m) in order shown

SCREW, soc hd cap;

1/4–20 x 5/8

18

3 111697 PLUG, sq hd pipe; 1/4 npt 1

5 104144 SPRING, compression 1

7 160033 PLATE, spring 1

17

8✓ 187873

GAUGE, 0 to 200 psi

(0 to 1.4 MPa, 0 to 14 bar)

10✓ 188006 SEAT, stainless steel 1

11

7

11 188512

RETAINER, diaphragm,

stainless steel

12✓ 172193 DIAPHRAGM 1

5

8

4

10

13 186872 SCREW, adjusting 1

14✓ 171117 GASKET, acetal copolymer 1

15 187878 HOUSING 1

14

16 164864 PLATE, diaphragm 1

17✓ 171912 GASKET, cellulose fibre 1

18✓ 171913 GASKET, cellulose fibre 1

19 209027 CAP 1

5

3

15

20 101926 NUT, retaining 1

22 157277 O-RING, Thiokol

5

3

1

2

4

6

ti24721a

6

1

1

®

✓

Keep these spare parts on hand to reduce down

time.

8718A

307107N 5

Page 6

Operation

Dimensions

4 in. (102 mm)

diameter

7.25 in.

(184 mm)

1-1/4 npt(f) inlet

and outlet

8717A

6 307107N

Page 7

Technical Data

Stainless Steel, Waterbase Compatible Back Pressure Valve

US Metric

Maximum inlet pressure 300 psi 1.4 MPa, 14 bar

Regulated pressure range 5-200 psi 0.035-1.4 MPa, 0.35-14 bar

Inlet and Outlet size

Gauge port size

Wetted parts 304 & 316 stainless steel, celcon

Diaphragm: nylon fabric base, with impregnated buna-N, and

material side is PTFE coated.

Weight 8.5 lb. 3.9 kg

Notes

Canadian Registration Number (CRN):

Alberta – 0C4155.2

Ontario – 0C4784.5

Thiokol ® is a registered trademark of the Thiokol Chemical Corporation.

1-1/4 in. npt(f)

1/4 in. npt(f)

Operation

307107N 7

Page 8

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissen

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

t avoir convenu que la

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 1974, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions.

This manual contains English. MM 307107

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision N, October 2014

Loading...

Loading...