Page 1

Instructions – Parts List

50:1 FIRE–BALLR, 120–LB DRUM SIZE

Topper Units

Grease dispense unit with pneumatic pump elevator for easy drum replacement.

Model No. 222073

Important Safety instructions

Read all warnings and instructions in this manual.

Save these instructions.

306523K

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 1996, Graco Inc. is registered to I.S. EN ISO 9001

06381B

Page 2

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

Sound Data 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Change Summary 8. . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 8. . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Handle hoses carefully. Do not pull on hoses to move equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 66_C (150_F) or below –40_C (–40_F).

D Do not move or lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 306523

Page 3

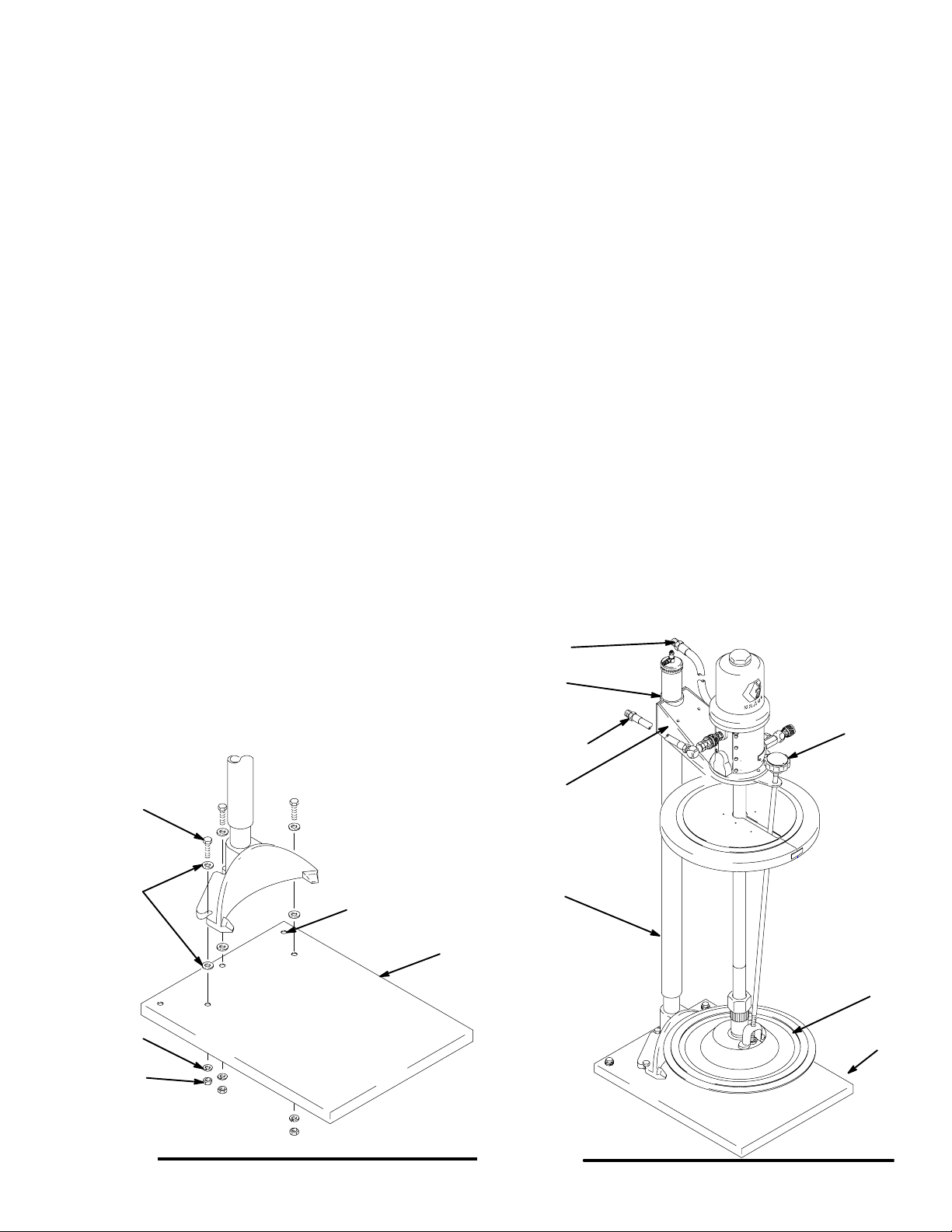

Installation

B

Note: Choose a location with sufficient overhead

clearance, and adequate clearance for plumbing when

unit is being raised or lowered.

Note: Numbers and letters in parenthesis refer to

callouts in the Figures and Parts Drawing.

Assemble the Elevator to the Base

(See Fig. 1)

Note: All necessary nuts, screws, and washers are

provided with Base Assy. 204740.

1. Set three flat washers (B) in place over the mounting holes in the base.

2. Position the elevator on the washers (B).

Assemble the Pump to the Elevator

(See Fig. 2)

1. Remove the elevator clamp (34) from the elevator

bracket (33).

2. Center the pump and inductor plate (8) on the

base (H), straddling the elevator tube (F).

3. Tighten the screws (19) securing the clamp (34) to

the bracket (33). See the Parts Drawing on

page 6.

4. Place the unit in the desired location, and use

metal shims to to level the base, if necessary.

5. Anchor the unit to the floor using the mounting

holes (G) in the base. See Fig 1.

Connect the Hoses

1. Connect the 1/4 npt(m) end of the fluid hose (27)

between the outlet of the pump and the permanent

supply line.

3. Place three flat washers (B) over the holes in the

elevator base casting.

4. Fasten securely with three screws (A),

lockwashers (C) and nuts (D).

A

B

G

E

2. Connect the 3/8 npt(m) end of the air hose (5) to

the permanent supply.

27

34

37

5

33

F

8

C

D

Fig. 1

H

06384

Fig. 2

06381

3306523

Page 4

Operation

WARNING

To reduce the risk of serious injury, always disconnect air and relieve pressure in lines before attempting any service.

1. Open the vent inductor plate (8) by turning the

knob (37) counterclockwise. See Fig. 2.

Changing the Drums

1. Disconnect the air line coupler (4) from the

pump.

2. Open the inductor plate vent, and connect the

coupler to the elevator to raise the unit.

Note: For steps 2–8, see the parts drawing on

page 6.

2. With the air supply turned on, connect the airline

coupler (4) to the fitting on top of the elevator

tube. Elevator speed may be regulated by turning

the adjusting screw clockwise to decrease, and

counterclockwise to increase elevator speed.

3. Center an opened drum of material under the

inductor plate (8) so that the drum bottom touches

the elevator base casting. The top surface of the

material should be made concave by scooping

material from the center to the sides of the container.

4. Disconnect the air line coupler (4) and guide the

inductor plate (8) into the drum. Press down on the

pump and rock or jiggle it back and forth to seat

the inductor plate and get rid of any trapped air,

and continue action until material appears at the

vent opening. Slide the plastic cover (9) down onto

the drum.

5. Close the inductor plate vent, and open the bleeder valve (25*) by turning the thumbscrew counterclockwise.

6. Start the pump by connecting the air line

coupler (4) to the pump inlet fitting.

Note: If the empty drum rises with the unit, pull the

front of the drum down and forward to break it loose

from the inductor plate.

3. Remove the empty drum from the base, and install

a full drum as explained at left.

Removing the Pump for Service

Unscrew the locking nut (40) (taking note of the

number of turns). Disconnect hoses and pump from

the mounting and remove.

When attaching the pump, turn the locking

nut (40) the same number of turns as when disassembling, or a slight distance further. Check for 1/8”

(3 mm) clearance. See Fig. 3.

Note: For pump and elevator operation,

troubleshooting, and service instructions, see the

separate manuals.

23

40

7. Let the pump run until material appears at the

bleeder valve.

8. Disconnect the air line coupler (4) and close the

bleeder valve. The unit is now ready for operation.

Note: When supplied with sufficient air pressure, the

pump is remotely controlled at the dispensing valve.

The pump starts and stops as the dispensing valve is

opened or closed.

Note: For overnight or holiday shutdown, disconnect

the air line coupler (4) and relieve the pressure in the

lines.

4 306523

8

1/8” (3 mm)

06383

Fig. 3

Page 5

Notes

5306523

Page 6

Model 222073, Topper Unit

5

Parts

27

6

41

4

42

25*

30

38

32

19

1

16

40

23

*31

12

19

34

33

21

3e

37

18

17

21

9

39

22

8

7

6 306523

15

11

13

14

36*

*29

06382B

Page 7

Model 222073, Topper Unit

Parts List

Ref.

No. Part No. Description Qty.

1 204121 ELEVATOR, 120 lb

see manual 306522 for parts 1

2 222074 SUPPORT, pump

includes items 4,5,7–42 1

4 114558 COUPLER, female, air line,

quick disconnect 1

5 203320 . HOSE, air; cpld 3/8 npt (mbe)

3/8” ID; 6’ (1.8 m) long 1

6 239887 50:1 FIREBALL PUMP

see manual 308883 for parts 1

7 204194 VENT JACK SCREW and LEG 1

8 204195 PLATE, inductor 1

9 204739 COVER, drum; plastic 1

10 204740 BASE, mounting

includes items 11–15 1

11 . BASE, bare 1

12 100004 . SCREW, hex hd cap;

3/8–16 x 1–1/4 3

13 100133 . LOCKWASHER, spring; 3/8” 3

14 100307 . NUT, hex; 3/8–16 3

15 100731 . WASHER, steel; 3/8” 6

16 100015 NUT, hex; 1/4–20 1

17 100016 LOCKWASHER, spring; 1/4” 2

Ref.

No. Part No. Description Qty.

18 100021 SCREW, hex hd cap;

1/4–20 x 1” 1

19 100022 SCREW, hex hd cap;

1/4–20 x 3/4” 6

21 100677 NUT, sq hd mach; 1/4–20 6

22 101537 PIN, roll; 1/8” dia; 1/2” long 1

23 101644 SLEEVE, coupling 1

24 102472 RIVET, blind: 1/8” dia 4

25* 205528 VALVE, bleeder 1

27* 109150 HOSE, fluid; cpld 1/4 npt(mbe)

1/4” ID; 6’ (1.9 m) long 1

29* 155463 O-RING, nitrile rubber 1

30 155494 UNION 90_, swivel;

3/8 npt(m) x 3/8 npt (f) 1

31* 158776 O-RING, nitrile rubber 1

32 156971 ADAPTER; 1/4 npt(m) 1

33 160853 BRACKET, elevator 1

34 160854 CLAMP, elevator bracket 1

35 160858 PLATE, instruction 1

36* 160861 WIPER, drum 1

37 160865 HANDLE, vent 1

38 160878 UNION 90_, swivel; 1/4 npt(f);

1/8 npt hole tapped in body 1

39 161028 ROD, vent jack screw 1

40 161107 NUT, sleeve locking 1

41 169971 FITTING, air line; 3/8 npt(m) 1

42 150287 COUPLING,

1/4 npt(m) x (3/8 npt(f) 1

* Recommended “tool box” spare parts. Keep these spare

parts on hand to reduce down time

Sound Data

See the pump instruction manual for technical data including wetted parts, port sizes, maximum air consumption,

maximum delivery, and so on. Sound data for the air motors of the pumps on these units is follows:

Tested at 100 psi (0.7 MPa, 7 bar) at 40 cycles per minute

Sound Pressure Level, measured at 1 meter from unit 77.9 dB(A)

Sound Power Level, tested in accordance with ISO 9614–2 85.6 dB(A)

7306523

Page 8

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Phone Numbers

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–533–9655 Toll Free

612–623–6928

612–378–3590 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

8 306523

This manual contains English. MM 306523

Graco Headquarters: Minneapolis

International Offices: Belgium, Korea, China, Japan

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

306523K

10/1995 Rev. 11/2006

Loading...

Loading...