Page 1

Instructions – Parts List

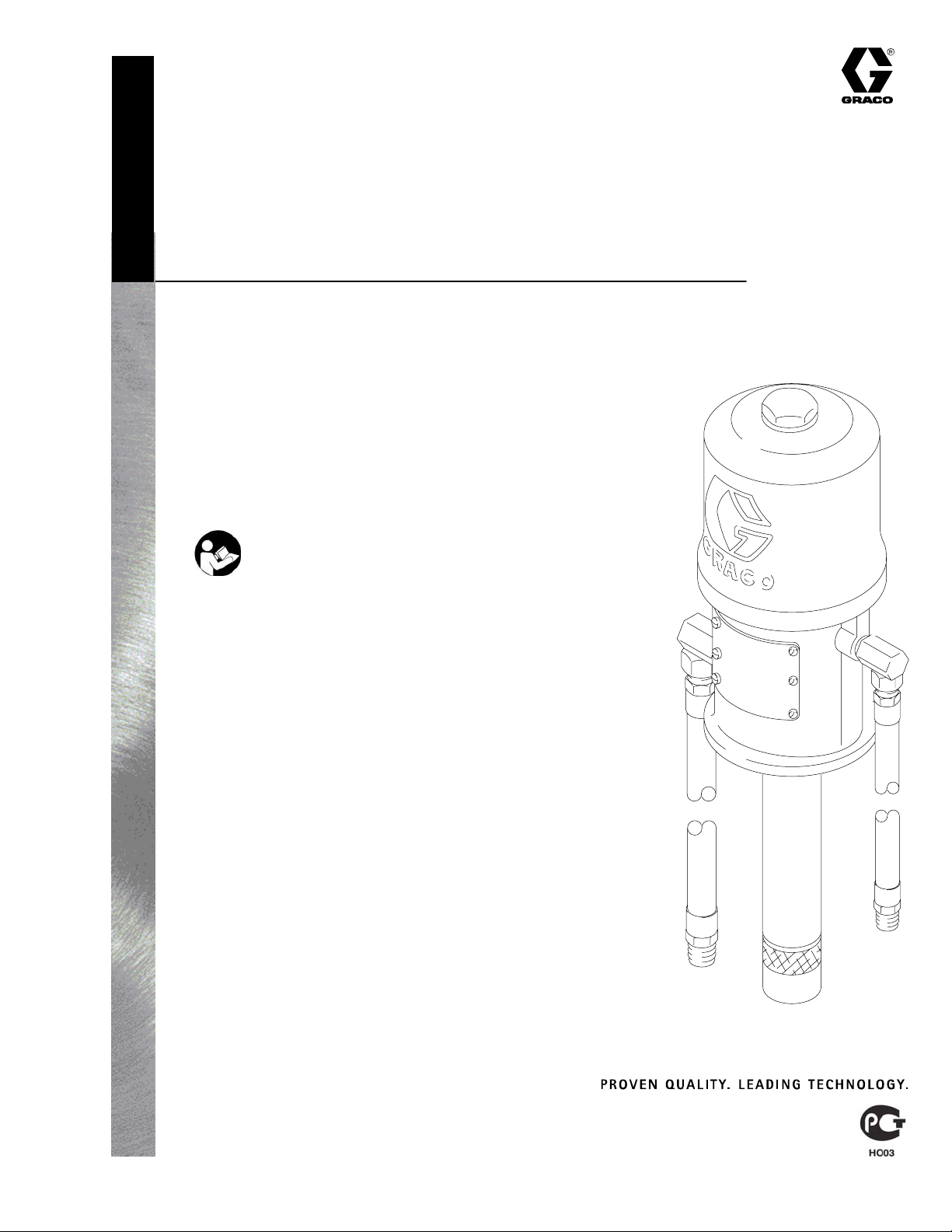

FIRE–BALL 300r and FIRE–BALL 425r

DRUM or TANK SUPPLY PUMPS

Used to pump petroleum and synthetic based oils.

5:1 Fire-Ball 300 Pump

Model 225852

900 psi (60 bar) Maximum Working Pressure

10:1 Fire–Ball 425 Pump

Model 225853

1800 psi (120 bar) Maximum Working Pressure

Important Safety Instructions.

Read all warnings and instructions in this manual.

Save these instructions.

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Lists 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 10. . . . . . . . . . . . . . . . . . . . . . . . . .

306520J

Model 225852 Fire–Ball 300 shown

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 1955, Graco Inc. is registered to I.S. EN ISO 9001

01494

Page 2

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNINGWARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Do not exceed the maximum working pressure stated on the equipment or in the Technical Data

for your equipment. Do not exceed the maximum working pressure of the lowest rated component in your system.

D Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warn-

ings.

D Handle hoses carefully. Do not pull on hoses to move equipment.

D All fluid hoses must have spring guards on both ends. The spring guards help protect the

hose from kinks or bends at or close to the coupling, which can result in hose rupture.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40_F).

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Use only dispensing valves that are designed to dispense motor oil. Do not modify any part of

the dispensing valve; doing so could cause a malfunction and result in serious bodily injury. Be

sure the dispensing valve has a maximum working pressure that meets or exceeds that of the

pump.

D The maximum fluid working pressure of these pumps, when operated at a maximum of 180 psi

(12.6 bar) air pressure is 900 psi (60 bar) on the 5:1 Fire-Ball 300 Pump, and it is 1800 psi

(120 bar) on the 10:1 Fire–Ball 425 Pump.

2 306520

Page 3

WARNINGWARNING

SKIN INJECTION HAZARD

Fluid from the dispensing valve, leaks, or ruptured components can inject fluid into your body and

cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on

the skin can also cause serious injury.

D Fluid injected into the skin may look like just a cut, but it is a serious injury. Get immediate

surgical treatment.

D Do not point the dispensing valve at anyone or at any part of the body.

D Do not put your hand or fingers over the end of the dispensing valve.

D Do not stop or deflect leaks with your hand, body, glove, or rag.

D Use only extensions and tips that are designed for use with your dispensing valve.

D Tighten all fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do

not repair high pressure couplings; you must replace the entire hose.

HAZARDOUS FLUIDS

Improper handling of hazardous fluids or inhaling toxic fumes can cause extremely serious injury or

death due to splashing in the eyes, ingestion, or bodily contamination.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state, and national guidelines.

D Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid

and solvent manufacturer.

3306520

Page 4

WARNINGWARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground the equipment. Refer to Grounding below.

D If there is any static sparking or you feel an electric shock while using this equipment, stop

dispensing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being dispensed.

D Do not smoke in the dispensing area.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

D Keep clear of all moving parts when starting or operating the pump.

D Before servicing the equipment, follow the Pressure Relief Procedure on page 8 to prevent the

equipment from starting unexpectedly.

United States Government safety standards have been adopted under the Occupational Safety and Health Act.

You should consult these standards–particularly General Standards, Part 1910, and Construction Standards, Part

1926.

Installation

Grounding

To reduce the risk of static sparking, ground the pump.

Check your local electrical code for detailed grounding

instructions for your area and type of equipment.

D Pump: Use ground wire and clamp as shown in

Fig. 1.

D Air and fluid hoses: Use only electrically conductive

hoses.

D Air compressor: Follow manufacturer’s

recommendations.

D Dispensing valve: Obtain grounding through

connection to a properly grounded fluid hose and

pump.

D To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

dispensing valve firmly to the side of a metal pail,

and then open the dispensing valve.

To ground the pump:

To ground the pump, use a ground wire and clamp as

shown below. Remove the ground screw (Z) and insert

through the eye of ring terminal at end of ground wire

(Y). Fasten the ground screw back onto the pump and

tighten securely. Connect the other end of the ground

wire to a true earth ground. See Fig. 1. To order a

ground wire and clamp, order Part No. 222011.

D Fluid supply container: Follow your local code.

D Object being lubricated: Follow your local code.

D Any pails used when flushing: Use only metal,

grounded pails when flushing. Make firm

metal-to-metal contact between a metal part of the

dispensing valve and the pail. Use the lowest

possible pressure.

4 306520

Fig. 1

Z

Y

TI1052

Page 5

Installation

The typical installation shown in Fig. 2 is only an installation guide; it is not an actual system design. Contact your

Graco distributor for assistance in designing a system to suit your needs.

A Maximum vertical lift, tank foot valve

to pump intake valve: 10 ft. (3 m)

B Suction line at pump: 9 in. (230 mm)

from wall

C Suction line at pump: 6 in. (150 mm)

above floor

D Vent pipe

D

C

E

B

A

E Pipe: 1.5 or 2 in. standard iron

F Horizontal suction line: 75 ft. (23 m)

maximum

G Stub assembly

H O.P.W. – Buckeye or equivalent

extractable suction

J Manhole cover

B

R

C

F

Q

K Fill cap

L 4 in. (102 mm) standard pipe

M Extractor fitting

N 4 in. (102 mm) from bottom of tank

P 1.5 in. foot valve

Q Swing joints

R Gate valve

J

K

H

L

G

M

E

Fig. 2

Permanent Supply and Suction Lines

D Install pumps as close to the tanks as practical.

D Use 1.5 or 2 in. (38 mm or 50 mm) standard iron

pipe and heavy malleable iron fittings. Ream the

ends of iron pipe and use thread sealant for an

airtight system.

D Use long sweeping bends for turns in piping; avoid

unnecessary turns.

D All tube ends must be clean and free of burrs.

Ream the ends of iron pipe.

D Minimize the use of fittings.

D Avoid using unions and other connections

underground and in hard to reach places.

D For underground tanks, blow out and clean all lines

before installing them. Start the connections at the

storage tank end.

P

N

01495

D Flush and test the lines under pressure before

covering or cementing in place.

D For installation dimensions for suction lines at the

pump end, see Fig. 3.

B

S

B

C

B 9 in. (230 mm),

Suction line at pump

C 6 in. (150 mm),

Suction line at pump

S 20 in. (510 mm),

Between suction lines

Fig. 3

C

01496

5306520

Page 6

Installation

Supply Lines From Pumps To Dispensing Units

Distance

Min. O.D. Min. Tube Wall Fittings Min. O.D. Min. Tube Wall Fittings Min. Size Fittings

< 25 ft. (7.6 m) 5/8 in. 0.035 in.

> 25 ft. (7.6 m) 7/8 in. 0.035 in.

> 75 ft. (23 m) Contact your Graco distributor

A Incoming supply line

B 3/4 in. npt line strainer

C Hose or pipe to metered unit

D Position outlet down

Annealed Steel Tube Annealed Copper Tube Standard Iron Pipe

(0.89)

(0.89)

B

C

D

Fig. 4

TO OUTLET

D

A

Flareless 5/8 in.

type K

Flareless 7/8 in.

type K

A

0.049 in.

(1.24 mm)

0.065 in.

(1.65 mm)

Flared 1/2 in. Heavy

malleable iron

Flared 3/4 in. Heavy

malleable iron

1. Use a Y-type line strainer in oil supply lines. Locate

as close to the meter inlets as practical and where

they are easily accessible. Mount the strainer body

horizontally with the clean-out plug pointed down.

See Fig. 4. Periodically, relieve the pressure, and

remove and clean the metal strainers.

To order a 3/4 in. npt(f) line strainer, order Part No.

101078.

To order a 1/2 in. npt(f) line strainer, order Part No.

110877.

WARNING

INJECTION HAZARD

To reduce the risk of serious injury

whenever you are instructed to relieve

pressure, always follow the Pressure

Relief Procedure on page 8.

B

C

A 3 in. (76 mm), Supply line to wall

B 20 in. (510 mm), Main fluid shutoff valves

C 24 in. (610 mm), Main air line to floor

D 20 in. (510 mm), Between suction lines

Fig. 5

01497

2. See Fig. 5 for installation dimensions for the

supply line. Space the line ends to be adjacent to

the pump location. For annealed steel or copper

tubing lines, use a straight male coupling elbow

and a shutoff valve. For iron pipe, a shutoff valve

may be used instead. The shutoff valve must close

off 1/2 in. npt(f) openings for the Fire-Ball 300

pump, and it must close off 3/4 in. npt(f) openings

for the Fire–Ball 425 pump.

Air Lines

Air lines

Pump to

main air

Compressor

to main air

Annealed Copper

Tube

O.D.

Type

L

1/2 or

3/8 in.

1/2 in. 0.035 in.

Minimum

Wall

Thickness

0.035 in.

(0.89 mm)

(0.89 mm)

Galvanized Pipe

Nominal

Size

1/2 in. or 3/8 in.

1/2 in. or 3/8 in.

6 306520

Page 7

Air and Fluid Line Accessories

CAUTION

Installation

D Install an air line lubricator for automatic air motor

lubrication.

Do not hang the air accessories directly on the air

inlet. Mount them on brackets. The fittings are not

strong enough to support the accessories and may

break.

D Use thread sealant on male threads except at

swivel connections.

D Install a bleed-type master air valve upstream from

the pump air regulator, but within easy reach of the

pump.

To order a 300 psi (21 bar) maximum working

pressure, 1/2 in. npt bleed-type master air valve,

order Part No. 107142.

WARNING

A bleed-type master air valve is required in the

system to help reduce the risk of serious bodily

injury, including fluid injection, splashing in the

eyes, and injury from moving parts when

adjusting or repairing the pump. This valve

relieves air trapped between the valve and the

pump to prevent the pump from cycling unexpectedly.

To order a 250 psi (17.5 bar) maximum working

pressure air line lubricator, order a Part No. below:

3/8 in. npt 214847

1/2 in. npt 214848

D Install an air regulator to control pump speed and

pressure.

To order a 300 psi (21 bar) maximum working

pressure regulator, order a Part No. below:

3/8 in. npt 109075

1/2 in. npt 104266

D Install an air line filter to remove harmful dirt and

contaminants from your compressed air supply.

To order a 250 psi (17.5 bar) maximum working

pressure air filter, order a Part No. below:

3/8 in. npt 106148

1/2 in. npt 214849

D Install a thermal relief kit on the dispensing valve

side of the pump to assist in relieving pressure in

the pump, hose, and dispensing valve due to heat

expansion.

D Install the pump end of the air supply lines about

24 in. (610 mm) above the floor.

D If you are installing several pumps, put tees in the

supply line immediately above and behind the pump

locations. See Fig. 5.

To order a thermal relief kit for the Fire-Ball 300

pump—900 psi (62 bar) maximum working

pressure—order Part No. 237893.

To order a thermal relief kit for the Fire–Ball 425

pump—1600 psi (110 bar) maximum working

pressure—order Part No. 248324.

7306520

Page 8

Operation

Pressure Relief Procedure

WARNING

INJECTION HAZARD

To reduce the risk of serious bodily

injury, including fluid injection, injury from

moving parts, or splashing in the eyes or

on the skin, always follow this procedure whenever

you shut off the pump, when checking or servicing

any part of the system, when installing or changing

dispensing devices, and whenever you stop dispensing.

1. Close the air regulator and disconnect the air

supply hose.

2. Close the pump’s bleed-type master air valve

(required in the system).

3. Open the dispensing valve until pressure is fully

relieved.

If you suspect that the dispensing valve is clogged, or

that pressure has not been fully relieved after following

the steps above, very slowly loosen the dispensing

valve coupler or hose end coupling to relieve pressure

gradually, then loosen completely.

Flushing

To reduce the risk of fluid injection injury, static

sparking, or splashing, relieve pressure, hold a metal

part of the dispensing valve firmly to the side of a

grounded metal pail and use the lowest possible fluid

pressure during flushing.

1. Before connecting the supply lines to the supply

tank, flush the pump and supply line with a

compatible solvent.

2. Connect the supply line to a solvent supply. Turn

on the main air, open the bleed-type master air

valve, and slowly open the pump air regulator until

the pump is cycling slowly. Use the lowest possible

pressure, and flush until the lines are thoroughly

cleaned. Shut off the pump, and relieve the

pressure.

WARNING

INJECTION HAZARD

To reduce the risk of serious injury

whenever you are instructed to relieve

pressure, always follow the Pressure

Relief Procedure above.

3. Disconnect the solvent supply, and connect the

supply lines to the tank.

4. Connect the fluid supply hose from the pump to

the dispensing valve.

Operating

WARNING

Never exceed 180 psi (12.6 bar) Maximum Air

Pressure to these pumps. Using higher air

pressure will cause the pump to overpressurize,

which may result in component rupture, fire, or

explosion and cause serious bodily injury.

1. Open the bleed-type master air valve.

2. Slowly open the pump air regulator until the pump

is running smoothly.

3. Open the dispensing valve, and allow the system

to prime. When the system is fully primed, the

pump starts and stops as the dispensing valve is

opened and closed.

CAUTION

Never allow the pump to run dry of the fluid

being pumped. A dry pump will quickly

accelerate to a high speed and possibly damage

itself. If the pump accelerates quickly, stop it

immediately, and check the fluid supply. If the

supply container is empty and air has been

pumped into the lines, prime the pump and lines

with fluid, or flush it and leave it filled with a

compatible solvent. Be sure to eliminate all air

from the fluid system.

4. Use the air regulator to control pump speed and

fluid pressure. Always use the lowest possible

pressure, which reduces pump wear.

5. When shutting off the system, and before checking

or servicing it, relieve the pressure.

WARNING

INJECTION HAZARD

To reduce the risk of serious injury

whenever you are instructed to relieve

pressure, always follow the Pressure

Relief Procedure at left.

8 306520

Page 9

13 or 18

11 or 16

Parts Drawing

4 or 6

12 or 17

10 or 15

Parts Lists

Model 225852

5:1 Fire-Ball 300 Pump, Includes items 6, 7, 10 to 13

Ref

No. Part No. Description Qty.

6 203876 5:1 FIRE-BALL 300 PUMP, stubby

See manual 306518 for parts. 1

7 222062 HOSE & FITTING KIT

See parts list to the right. 1

Model 225853

10:1 Fire–Ball 425 Pump, Includes items 4, 5, 15 to 18

Ref

No. Part No. Description Qty.

4 205626 10:1 FIRE-BALL 425 PUMP, stubby

See manual 308655 for parts. 1

5 222068 HOSE & FITTING KIT

See parts list to the right. 1

01498

Model 222062

Hose Kit for Fire-Ball 300 pump

Ref

No. Part No. Description Qty.

10 204560 AIR HOSE, 3/8” ID, cpld

3/8–14 npt (mbe), 18” (457 mm) 1

11 220598 FLUID HOSE, 1/2” ID, cpld

1/2–14 npt(mbe), 18” (457 mm) 1

12 155494 UNION, 90_, 3/8–14 npt(m) x

3/8 npsm(f) swivel 1

13 155470 UNION, 90_, 1/2–14 npt(m) x

1/2 npsm(f) swivel 1

Model 222068

Hose Kit for Fire–Ball 425 pump

Ref

No. Part No. Description Qty.

15 218093 AIR HOSE, 1/2” ID, cpld

1/2–14 npt (mbe), 18” (457 mm) 1

16 109108 FLUID HOSE, 3/4” ID, cpld

3/4–14 npt(mbe), 18” (457 mm) 1

17 155470 UNION, 90_, 1/2–14 npt(m) x

1/2 npsm(f) swivel 1

18 160327 UNION, 90_, 3/4–14 npt(m) x

3/4 npsm(f) swivel 1

9306520

Page 10

The Graco Warranty and Disclaimers

WARRANTY

Graco warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on the date

of sale to the original purchaser for use. As purchaser’s sole remedy for breach of this warranty, Graco will, for a period of twelve

months from the date of sale, repair or replace any part of the equipment proven defective. This warranty applies only when the

equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for, any malfunction, damage or wear caused by faulty installation,

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility with Graco

equipment of structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claim. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment

will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor and transportation.

DISCLAIMERS AND LIMITATIONS

The terms of this warranty constitute purchaser’s sole and exclusive remedy and are in lieu of any other warranties (express or

implied), including warranty of merchantability or warranty of fitness for a particular purpose, and of any non-contractual liabilities,

including product liabilities, based on negligence or strict liability. Every form of liability for direct, special, or consequential damages or

loss is expressly excluded and denied. In no case shall Graco’s liability exceed the amount of the purchase price. Any action for breach

of warranty must be brought within two (2) years of the date of sale.

EQUIPMENT NOT COVERED BY GRACO WARRANTY

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose, with respect to

accessories, equipment, materials, or components sold but not manufactured by Graco. These items sold, but not manufactured by

Graco (such as electric motor, switches, hose, etc.) are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–533–9655 Toll Free

612–623–6928

612–378–3590 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 306520

International Offices: Belgium, Korea, China, Japan

Graco Headquarters: Minneapolis

www.graco.com

306520 08/1955, Revised 01/2007

10 306520

Loading...

Loading...