Page 1

Process Equipment

Pumping Solutions for Process Industries

Page 2

Ordering Information

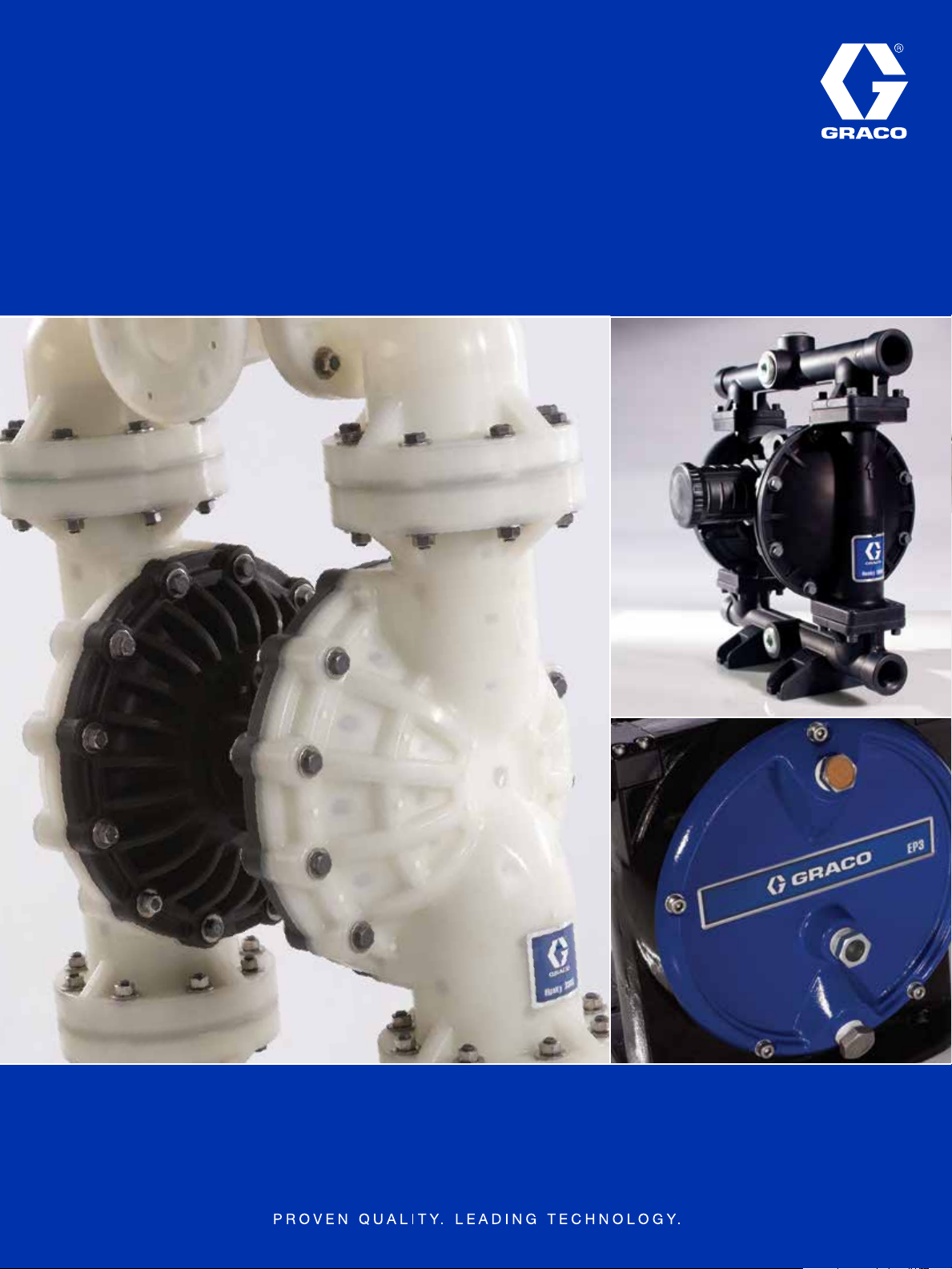

Husky Air-Operated Double Diaphragm Pumps

™

Husky

Pumping Technology

Our Husky air-operated double

diaphragm pumps are loaded with

features to help you get the job

done right, every time, and are built

to save you money.

Rugged construction

Resists corrosion for reliable performance and long life

Heavy-duty design - Offers long life, increased

productivity and lower overall cost of ownership

Flow rates up to 300 gpm (1135 lpm)

Lube-free for cleaner operation

DataTrak

pump runaway and track material usage

™

available to prevent

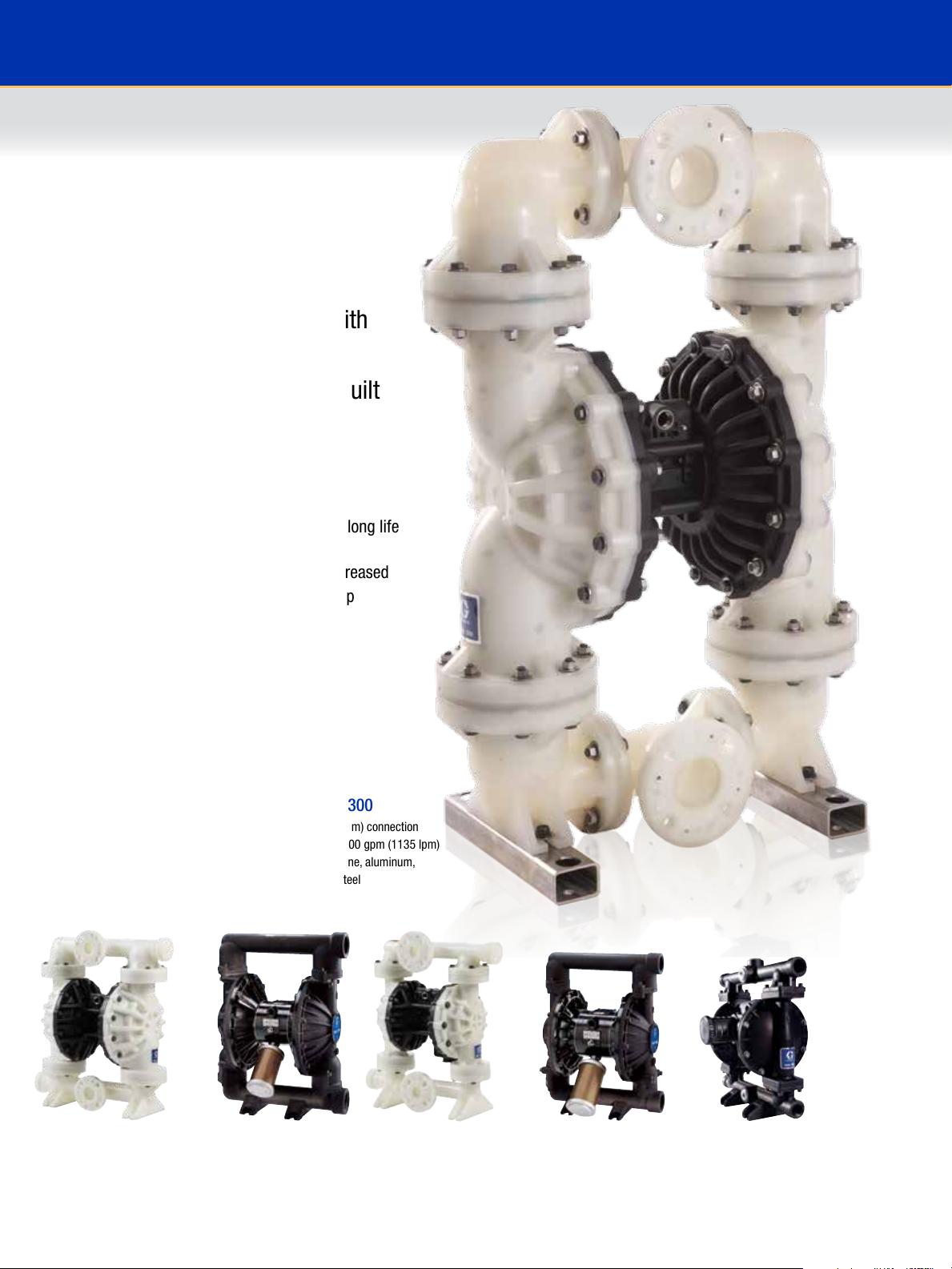

Husky 3300

3 in (76.2 mm) connection

Max flow: 300 gpm (1135 lpm)

Polypropylene, aluminum,

stainless steel

Husky 2200

2 in (50.8 mm) connection

Max flow: 200 gpm (757 lpm)

Polypropylene, PVDF

2

Husky 2150

2 in (50.8 mm) connection

Max flow: 150 gpm (568 lpm)

Polypropylene, PVDF, aluminum,

stainless steel, iron

Husky 15120

1-1/2 in (38.1 mm) connection

Max flow: 120 gpm (454 lpm)

Polypropylene, PVDF

Husky 1590

1-1/2 in (38.1 mm) connection

Max flow: 90 gpm (340 lpm)

Polypropylene, PVDF, aluminum,

stainless steel

Husky 1050

1 in (25.4 mm) connection

Max flow: 50 gpm (189 lpm)

Aluminum, polypropylene, PVDF,

conductive polypropylene, hastelloy,

stainless steel

Page 3

The Husky Advantage

Loaded with Options

Ordering Information

Choose from a wide selection

of materials to handle numerous

applications, including corrosive

and abrasive fluid transfer.

Key Fluids

• Paints, stains, coatings, inks

and dyes

• Chemicals

• Acids

• Corrosive and abrasive fluids

• Lubricants

• Ceramic glazes

• Sludge, slurry and

Balls

Seats

Diaphragms

waste fluid

• Soaps, detergents

and solvents

Husky 1050HP

1 in (25.4 mm) connection

Max flow: 50 gpm (189 lpm)

Aluminum and stainless steel

Available materials of construction and accessories may vary depending on pump model.

Husky 716

3/4 in (19.1 mm) connection

Max flow: 16 gpm (61 lpm)

Aluminum, stainless steel

Husky 515

1/2 in (12.7 mm) connection

Max flow: 15 gpm (57 lpm)

Polypropylene, acetal, PVDF

Husky 307

3/8 in (9.4 mm) connection

Max flow: 7 gpm (26 lpm)

Polypropylene, acetal

Husky 205

1/4 in (6.3 mm) connection

Max flow: 5 gpm (19 lpm)

Polypropylene, acetal, PVDF

3

Page 4

Hose Pumps

EP Series

Peristaltic Hose Pumps

Graco’s positive displacement hose pumps rotate a

full 360-degrees. Because they use a single roller to

compress the hose once per revolution, your hoses last

longer so you have less maintenance and downtime.

Efficient Pumping Action

One hose compression per revolution extends hose life

Low Maintenance

Quick replacement of hose

Removable Cover - Easier access to internal parts,

making maintenance fast and simple

Integral Drive Train - Pump speeds as low as 1 rpm

Hose Clamp Assembly

One-piece “quick change” assembly for easy service

EP2

Max flow: 0.8 gpm (3.0 lpm)

Ideal for chemical metering

4

applications

EP3

Max flow: 2.4 gpm (9.0 lpm)

Typically used for chemical

metering and sanitary applications

EP4

Max flow: 19.5 gpm (73.8 lpm)

Ideal for abrasive material

transfer applications

Page 5

Hoses Built to Handle

Choose from 4 different hose materials to meet

your specific application requirements

the Toughest Jobs

Ink Pumps

Long-Lasting piston pumps

with sealed wet cup.

Prolonged seal life with enclosed,

dual seal wet cup

Only the interior of the hose is in contact with

the fluid being pumped, making it easy to

sterilize and clean the inside pumping surfaces.

The gentle pumping action is ideal for shear

sensitive materials and fragile cell cultures.

Innovative Hose Design

Graco’s 360-degree hose pump is designed to put 40%

less stress on the hose compared to conventional shoe

pumps running at the same flow rate. The hoses are highly

engineered for long life and durability and are available in

a wide variety of configurations for the most demanding

applications and materials.

Runaway control

MaxLife

Handles the most difficult inks

®

seal for longer life

with optional DataTrak

Hydraulic or pneumatic motors

OUTER LAYER

REINFORCED LAYERS

Stripe Color /

Hose Materials

Natural Rubber (NR) None / Black 160ºF (71ºC)

Nitrile Rubber (NBR) Yellow / Black 220ºF (104ºC)

Ethylene propylene (EPDM) Blue / Black 250ºF (121ºC)

Chlorosulfonated

polyethylene (CSM)

Inside Color

Orange / Black 250ºF (121ºC)

INNER LAYER

Max. Fluid

Temperature

Priming Piston Ink Pump

Enclosed, dual seal

wet cup for longer

seal life. Runaway

control with optional

DataTrak

™

Hydraulic Ink Pump

Up to 3 times

more efficient than

pneumatic pumps

Typical applications:

- Letterpress inks

- Lithographic inks

5

Page 6

High Pressure Cleaning

®

Hydra-Clean

On-Demand High Pressure Cleaning

Graco Hydra-Clean heavy-duty pressure washers are perfect for use in a variety

of in-plant cleaning applications and can be used with hot or cold water,

detergents or strong chemical solutions up to 200ºF (93ºC).

Wall-mount and cart-mount options

Air or hydraulic powered units

300 Series Stainless Steel Lower

Compatible with many extreme chemicals and ideal

for use with open-head drums

Supports multiple guns

Five different spray tips – Standard

Optional hose reel – Easy hose storage

6

Page 7

Husky

Transfer Pumps

Easily pump from 55 gallon drum with flow rates up to

16 gpm (61 lpm). Available in aluminum, carbon steel,

stainless steel and polypropylene.

Suction tube immersed inside the drum

Quick-priming and immediate flow of product

Fluid viscosities up to 5,000 cps

and solids up to 0.09 in (2.29 mm)

Ordering Information

Transfer Pumps

Air tight seal for moisture-sensitive fluids

Bung adapter fits into any 2 in (50.8 mm) bung opening

Fast-Flo® 1:1

Transfer Pumps

Deliver a smooth, reliable flow. Drum length and stubby

models are available in either carbon steel or stainless

steel materials of construction. Ideal for a variety of

non-corrosive and corrosive materials.

Flow rates up to 5 gpm

Immersed inlet for faster priming of heavier fluids

Air-powered for high reliability and low cost

Disc check options for lower viscosity fluids

7

Page 8

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9468 8500

Fax: 61 3 9468 8599

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Building 7

1029 Zhongshan Road South

Huangpu District

Shanghai 200011

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 443, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Customer Service

800-328-0211

Fax 877-340-6427

Call today for product information or to request a demonstration.

877-84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2014 Graco Inc. 300570 Rev. I 12/14 All written and visual data contained in this document are based on the latest product information available at the time

of publication. Graco reserves the right to make changes at any time without notice. All other brand names or marks are used for identification purposes and

are trademarks of their respective owners.

Loading...

Loading...