Page 1

PRODISPENSE

™

PROVEN QUALITY. LEADING TECHNOLOGY.

Accurately and quickly dispenses preset

amounts of oil, grease and water

FINISHING

Page 2

Compatible Fluids

Radiator Fluid

Crankcase Oil

Grease

Inks

Lacquers

Power Steering Fluid

Brake Fluid

Transmission Fluid

Windshield Wash

Hydraulic Fluids

Key Applications

Construction Equipment

Farm Equipment

Lawn and Garden

Furniture Manufacturing

Engine Manufacturing: Truck & Bus,

Motorcycle, Lift Truck/Forklifts

Graco’s ProDispense is a

COST-EFFECTIVE and USER-FRIENDLY

electronic system that dispenses preset

amounts of fluids. The ProDispense system

allows durable goods manufacturers to

QUICKLY and ACCURATELY fill cavities

with oil, grease or water in assembly line

environments where accurate dispensing is

essential. ProDispense can deliver up to three

different fluids at multiple dispense points,

and accurately measure flow.

Fast and Accurate Dispensing

PART NO. 244561

• 250 Recipes

• Reporting capability tracks volume and usage

• Return on investment assures that

ProDispense quickly pays for itself

• EasyKey™ pad provides simple operation

and data entry

• Manual or automatic dispense

• User-friendly FloSync™ Controller menu

navigation

Page 3

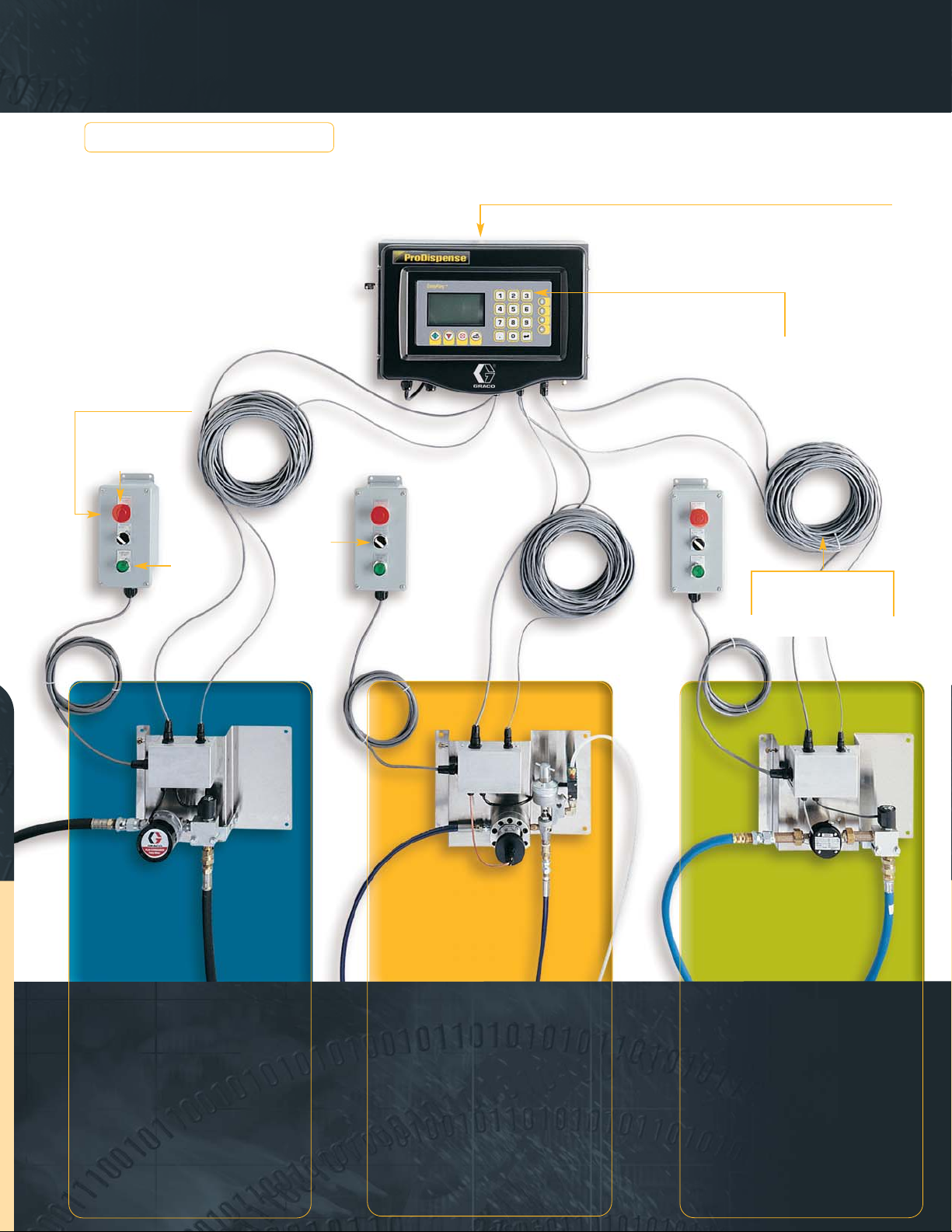

ProDispense System Components

Stop

Start

Manual/

Automatic

Dispense

Remote Operator

Station

50 extra feet of cable allows

the controller to be in a room

separate from the fluid panels

Easy Installation

Installation is easy and integrates

seamlessly with other Graco pumps.

FloSync™ Controller

Provides user-friendly menu navigation and data input.

EasyKey™ pad

Large keys and universal icons

allows for easy data entry.

Flow rate .25-4 gpm (.95-15 lpm)

Viscosity range 10 wt oil - #2 grease

Accuracy ± 1/2 % on dispenses

over one gallon

Resolution 4.73 cc/pulse

Working pressure 1500 psi

Porting sizes

Inlet 1/2" npt(f)

Outlet 1/2" npt(f)

OIL

Flow rate .2-1 gpm (.76-3.8 lpm)

Viscosity range 20 – 5000 cps

Accuracy ± 3% on dispenses

over 12 cc

Resolution .119 cc/pulse

Working pressure 3000 psi

Porting sizes

Inlet 1/4" npt(f)

Outlet 3/8" npt(m)

Air inlet 1/4" npt (f)

GREASE

Flow rate .25-4 gpm (.95-15 lpm)

Viscosity range 1 – 20 cps

Accuracy ± 3% on dispenses

over one gallon

Resolution 25 cc/pulse

Working pressure 250 psi

Porting sizes (inlet) 1/2" npt(m)

(outlet) 1/2" npt(m)

WATER, ANTIFREEZE

Page 4

Set up and operate the system in four easy steps!

Easy Recipe Set-up

Easy Fluid Set-up

1

2

3

4

Monitor Dispenses

Dispense Total Summary

Easy Recipe Set-up

• Delivers up to three different fluids at

multiple dispense points simultaneously

• Dispense quantities as low as 1 oz (30 cc)

• 250 different recipes to choose from

1

Easy Fluid Set-up

• Recipe set-up options are available in

standard or metric units

• Multiple panel options provide the ability

to dispense virtually any material

2

Monitor Dispenses

Accurately measure and select dispense

quantities three ways:

• Manual

• Preset recipe

• Bar code system

3

Dispense Total Summary

• On screen reporting or printed reports

are available to track daily usages

4

Fluid1 Fluid2 Fluid3

Target Amount 001.50 003.75 025.00

Gal Qt oz

System Fluids Recipes Meters

FLUID SETUP

Units of Measure:

1=cc 2=oz 3=Qt 1 2 3

4=Ltr 5=Gal

Tolerance (%) 4 5 3

Timeout Value (min) 10 20 10

K-factor (cc/pulse) 04.730 00.119 25.000

System Fluids Recipes Meters

RECIPE 1 SETUP

Type in 0 for target amount if fluid

is not used for this recipe.

Fluid1 Fluid2 Fluid3

FLUID DISPENSE ID# 1234

Fluid 1 Fluid 2 Fluid 3

Idle Disp'ng Idle

Target 001.50 gal 003.75 qt 025.00 oz

Actual 001.50 gal 003.75 qt 025.00 oz

Tolerance % 4 5 3

Deviation % 0 0 0

Run Totals Alarms

Fluid Totals

Fluid # Resettable Grand

1 000100.0 gal 001000.0 gal

2 002000.0 gal 020000.0 gal

3 030000.0 gal 300000.0 gal

Last Reset

Date: 27/03/01

Time: 15:20

Press ENTER and CLEAR to reset totals.

Run Totals Alarms

Page 5

ProDispense pays for itself!

Tank Capacity

Time to Fill Tank

Worker Compensation

Cycles Per Day

Total Labor Cost

Working Days Per Year

Annual Cost

X

=

X

X

=

Additional Benefits

• Improved quality as a result of increased dispense accuracy.

• Less rework and warranty claims.

X

=

X

X

=

X

=

X

X

=

X

=

X

X

=

4 gal

10 min

$50/hr or

85¢/min

$50/hr or

85¢/min

10

10

4 gal

$85

250 250

$21,250

1 min

$8.50

$2,125

Typical Savings with

ProDispense: $19,125

Manual Fill ProDispense Manual Fill ProDispense

Typical Scenario Typical Scenario Calculator Calculator

Return-on-Investment

Use this exclusive return-on-investment analysis tool to see exactly how much your manufacturing process

currently costs you, where there is waste, and best of all, how quickly a Graco ProDispense pays for itself.

=

–

Your Savings with

ProDispense: $

=

–

Page 6

Ordering Information

244561 ProDispense FloSync™Controller

Choose one to three fluid panels.

Order feed equipment separately.

Standard Fluid Panels

244599 Oil Fluid Panel

244600 Water Fluid Panel

244601 Grease Fluid Panel

Special Fluid Panels

246839 Helical Meter Panel

For high viscosity materials

246837 G3000HR Meter Panel

For small dispenses

246838 No Meter

For unique applications where special fluid

monitoring is required. Meter must be ordered

separately.

Accessories

239873 Printer Kit

Includes 113774 printer and 25 ft.

(7.6 m) 192491 power cable

514037 Printer Paper

456

123

789

.0

EasyKey

TM

ProDispense Typical Installation

Air-Operated

Double-Diaphragm Pump

Remote Operator

Station

55 Gallon

(200 Liter) Drum

Flo-Sync™ Controller

with EasyKey™ Pad

Dispense

Nozzle

Fire-Ball®

Pump

Pump

Note: Feed pumps and dispense assemblies provided by distributors.

Page 7

Technical Specifications

Power Requirements

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85-265 VAC .25 amp maximum

50 or 60 Hz

Materials

Number of fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 fluids

Totalizers

Last dispense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . All 3 materials

Resettable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . All 3 materials

Grand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . All 3 materials

Recipes

Quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Dimensions (controller only)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.5 lb. (5.67 kg)

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 in. (30.5 cm)

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.2 in. (56.4 cm)

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 in. (25.4 cm)

Display size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.40 in. (6.1 m) x 4.40 in. (11.1 m), 128 x 240 pixels

Fluid Stations

Cable lengths (for all fluid panels)

Meter signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 ft. (15.24 m)

Solenoid signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 ft. (15.24 m)

Remote operator station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 ft. (3.05 m)

Oil

Flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.25-4 gpm (.95-15 lpm)

Viscosity range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 wt oil - #2 grease

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .± 1/2 % on dispenses over one gallon

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.73 cc/pulse

Working pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1500 psi

Porting sizes (inlet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2" npt(f)

(outlet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2" npt(f)

Grease

Flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.2-1 gpm (.76-3.8 lpm)

Viscosity range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 – 5000 cps

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .± 3% on dispenses over 12 cc

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.119 cc/pulse

Working pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3000 psi

Porting sizes (inlet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4" npt(f)

(outlet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/8" npt(m)

Air inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4" npt (f)

Water, Antifreeze

Flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.25-4 gpm (.95-15 lpm)

Viscosity range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 – 20 cps

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .± 3% on dispenses over one gallon

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 cc/pulse

Working pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250 psi

Porting sizes (inlet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2" npt(m)

(outlet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2" npt(m)

Approvals

ETLul

ETLc

CE

Page 8

ABOUT GRACO

PROVEN QUALITY. LEADING TECHNOLOGY.

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used in vehicle

lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology which set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

©2001-2003 Graco Inc. 300543 Rev. C 12/03 Printed in U.S.A.

All other brand names or marks are used for identification purposes and are trademarks of their respective owners.

Sales/Distribution/Service North America

Industrial Customer Service

800-328-0211

FAX 877-340-6427

Industrial Product Information/Demonstration

1-877-84GRACO (1-877-844-7226)

FAX 612-378-3597

Graco Inc. is registered to I.S. EN ISO 9001

GRACO HEADQUARTERS

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88-11th Avenue N.E.

Minneapolis, MN 55413

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel 612 623-6000

Fax 612 623-6777

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein - Oude Bunders

Slakweidestraat 31

3630 Maasmechelen, Belgium

Tel 32 89 770 700

Fax 32 89 770 777

ASIA PACIFIC

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel 81 45 593 7300

Fax 81 45 593 7301

CHINA

Graco Hong Kong Ltd.

Representative Office

Room 118 1st Floor

No. 2 Xin Yuan Building

No. 509 Cao Bao Road

Shanghai, P.R.China 200233

Tel 86 21 649 50088

Fax 86 21 649 50077

KOREA

Graco Korea Inc.

Choheung Bank Bldg, 4th Floor

#1599, Gwanyang-Dong, Dongan-Ku

Anyang-Si, Gyunggi-Do, Korea

431-060

Tel 82 31 476 9400

Fax 82 31 476 9801

GRACO INC.

P.O. Box 1441

Minneapolis, MN 55440-1441

PRODISPENSE

™

Call today for product information or to request a demonstration.

1. 87 7. 8 4 G R A C O (1-877-844-7226) or visit us at www.graco.com.

Loading...

Loading...