Page 1

®

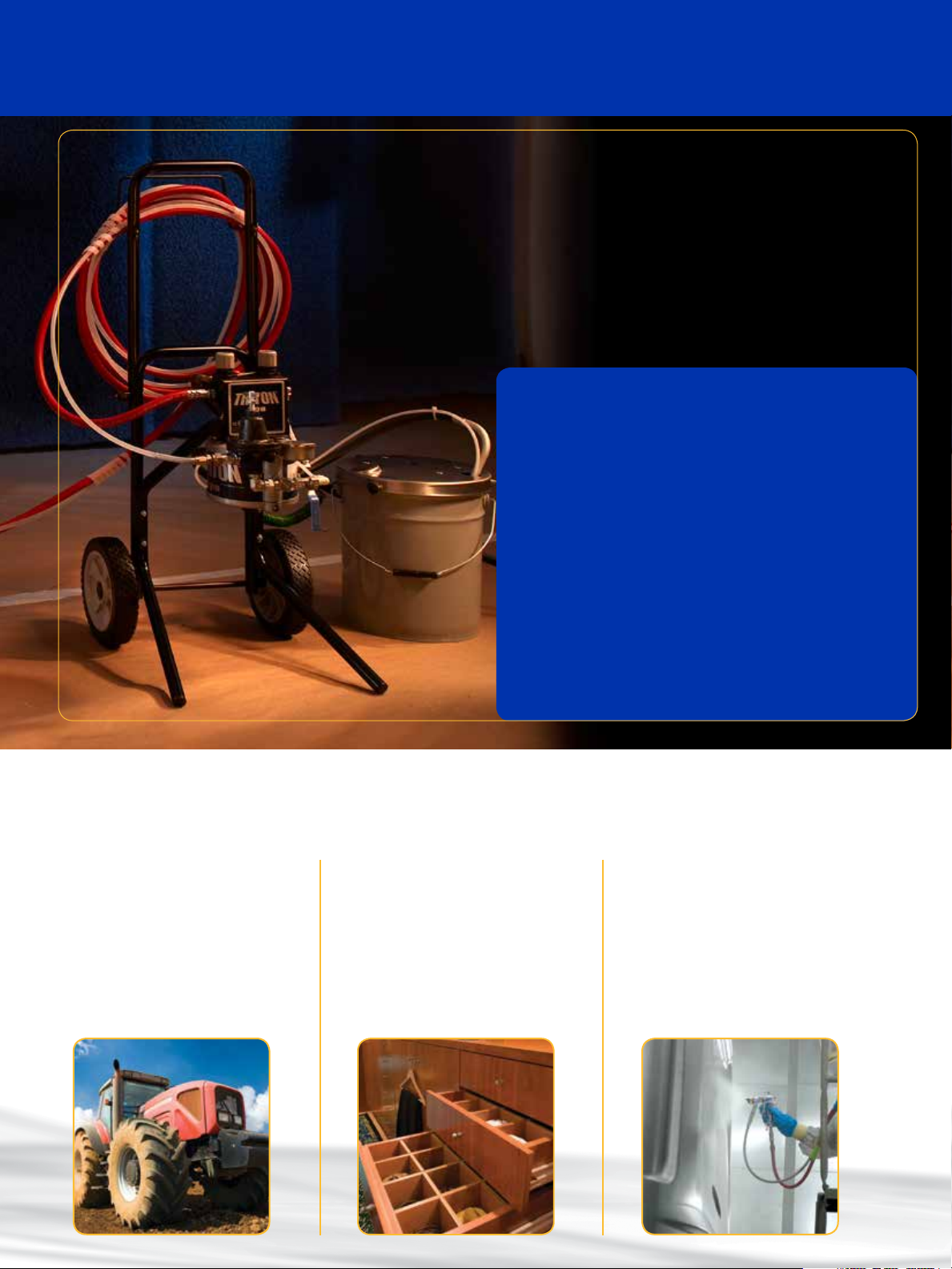

Triton

Affordable fine finish spray packages for wood and metal applications

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Diaphragm spray packages designed specifically for the finishing market

Triton is an air-operated diaphragm spray

package that applies a high quality, decorative

finish to wood and metal parts. Triton is a more

effective alternative to traditional pressure pots

and standard diaphragm pumps.

Features

HIGH QUALITY FINISH

Low pulsation output and smooth pump changeover deliver

a consistent spray pattern.

EASY-TO-USE

Quick color changes and fast material refills save

time and money.

RUGGED CONSTRUCTION

Stainless steel or aluminum pump handles

TRITON SPRAY PACKAGES

a wide variety of fluids.

Key Applications

Triton is designed for all types of metal and wood applications:

Applying primers, basecoats

and topcoats for:

• General Metal Fabrication

• Farm and Construction

• Truck and Bus

• Automotive Components

and Touch-up

Spraying stains, sealers,

lacquers and topcoats for:

• Wood Furniture and Cabinetry

• Wood Windows and Doors

• Customized Wood

Using a wide range

of technologies:

• Conventional

• HVLP

• Compliant

• Electrostatic Air Spray

Page 3

Best Spray Finishing Package in its Class!

Available with AirPro® Spray Guns and Pro Xp™ Electrostatic Spray Guns

Triton Packages

Available with general metal,

wood or waterborne AirPro

and Pro Xp guns.

AirPro or Pro Xp Spray Gun

Superior finish quality for

conventional, HVLP and

compliant or electrostatic

applications.

High-Flow Air Regulators

Supplies up to 35% extra air flow to

gun for superior atomization.

Durable Metal

Triton Pump

Provides low maintenance

and long life.

Flexible, Lightweight Air Hose

Reduces operator fatigue.

Easy-to-Use Circulation Valve

Saves material and time during

flushing, priming and color changes.

Low Pulsation

Triton Pump

Delivers a consistent spray pattern

and uniform film thickness.

Heavy-Duty Suction Performance

Sprays a wide variety of material viscosities.

Page 4

Upgrade Your Pumps!

Upgrade Your Standard Diaphragm Pumps to Triton

High-Performance Finishing

LONGER PUMP LIFE

• Rugged stainless steel or aluminum construction

requires less maintenance than a plastic pump

• Twice the output per stroke

• High output per stroke means less pump wear

EXTRA PUMPING POWER

• 30% more suction power than a standard

diaphragm pump to handle higher

viscosity materials

LOW PULSATION OUTPUT!

SUPERIOR FINISH QUALITY

• Consistent pattern and film on parts

• Constant flow to the spray gun

Triton pump provides 50% less pressure

pulsation than standard diaphragm pumps.

Note: Pump-to-pump comparison without fluid regulator

Upgrade Your Pressure Pots

and Cup Guns to Triton

Finishing Made Simple

• Refill and monitor material level

while spraying for easier operation

• Complete color changes in less than

3 minutes for reduced downtime

• Circulation valve saves time and

lowers solvent usage during

clean-up and color changes

Pro Xp Electrostatic Spray Gun Packages

Model No. 233747 with Pro Xp60 gun shown

Page 5

Ordering InformationUpgrade Your Pumps!

Triton

Package

Part No.

Pail

Mount

Stand

Mount

Cart

Mount

Wall

Mount

Fluid

Regulator*

Suction

Hose

Air Hose

25 ft (7.6 m)

Fluid Hose

25 ft (7.6 m)

Applicator

Part No. Applicator Description

Aluminum

Stainless

Steel

AirPro Wood Application Packages

• 289645 • 60 • • • 289110 AirPro HVLP Gun .040 in (1.0 mm) nozzle

• 289642 • 100 • • • 289110 AirPro HVLP Gun .040 in (1.0 mm) nozzle

• 289646 • 60 • • • 289111 AirPro Compliant Gun .040 in (1.0 mm) nozzle

• 289643 • 100 • • • 289111 AirPro Compliant Gun .040 in (1.0 mm) nozzle

• 289647 • • • • 289109 AirPro Conventional Gun .040 in (1.0 mm) nozzle

• 289644 • • • • 289109 AirPro Conventional Gun .040 in (1.0 mm) nozzle

• 289638 • 60 • • • 289110 AirPro HVLP Gun .040 in (1.0 mm) nozzle

• 289635 • 100 • • • 289110 AirPro HVLP Gun .040 in (1.0 mm) nozzle

• 289639 • 60 • • • 289111 AirPro Compliant Gun .040 in (1.0 mm) nozzle

• 289636 • 100 • • • 289111 AirPro Compliant Gun .040 in (1.0 mm) nozzle

• 289640 • • • • 289109 AirPro Conventional Gun .040 in (1.0 mm) nozzle

• 289637 • • • • 289109 AirPro Conventional Gun .040 in (1.0 mm) nozzle

• 289628 • 60 • • 289110 AirPro HVLP Gun .040 in (1.0 mm) nozzle

• 289625 • 100 • • 289110 AirPro HVLP Gun .040 in (1.0 mm) nozzle

• 289629 • 60 • • 289111 AirPro Compliant Gun .040 in (1.0 mm) nozzle

• 289626 • 100 • • 289111 AirPro Compliant Gun .040 in (1.0 mm) nozzle

• 289630 • • • 289109 AirPro Conventional Gun .040 in (1.0 mm) nozzle

• 289627 • • • 289109 AirPro Conventional Gun .040 in (1.0 mm) nozzle

AirPro General Metal Application Packages

• 233468 • • • • 288931 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 233469 • • • • 288931 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 233470 • 60 • • • 288938 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 233471 • 100 • • • 288938 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 234911 • 60 • • • 288945 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 234912 • 100 • • • 288945 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 233475 • • • • 288931 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 233476 • • • • 288931 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 233477 • 60 • • • 288938 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 233478 • 100 • • • 288938 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 234913 • 60 • • • 288945 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 234914 • 100 • • • 288945 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 233482 • • • • 288931 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 233483 • • • • 288931 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 233484 • 60 • • • 288938 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 233485 • 100 • • • 288938 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 234915 • 60 • • • 288945 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 234916 • 100 • • • 288945 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 233489 • • • 288931 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 233490 • • • 288931 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 233491 • 60 • • 288938 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 233492 • 100 • • 288938 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 234917 • 60 • • 288945 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 234918 • 100 • • 288945 AirPro Compliant Gun .055 in (1.4 mm) nozzle

*HVLP, Compliant, Pro Xp packages include fluid regulator:

– Aluminum packages use 60 psi (4 bar, 0.4 MPa) acetal fluid regulator.

– Stainless steel packages use 100 psi (7 bar, 0.7 MPa) stainless steel fluid regulator.

Page 6

Ordering Information

Stand Mount

Cart Mount

Wall Mount

Siphon tube and

pail ordered separately.

Pail Mount

Triton

Package

Part No.

Pail

Mount

Stand

Mount

Cart

Mount

Wall

Mount

Fluid

Regulator*

Suction

Hose

Air Hose

25 ft (7.6 m)

Fluid Hose

25 ft (7.6 m)

Applicator

Part No. Applicator Description

Aluminum

Stainless

Steel

AirPro Waterbourne Application Packages

• 289632 • 100 • • • 288969 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 289633 • 100 • • • 288972 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 289634 • • • • 288966 AirPro Conventional Gun .055 in (1.4 mm) nozzle

• 289622 • 100 • • 288969 AirPro HVLP Gun .055 in (1.4 mm) nozzle

• 289623 • 100 • • 288972 AirPro Compliant Gun .055 in (1.4 mm) nozzle

• 289624 • • • 288966 AirPro Conventional Gun .055 in (1.4 mm) nozzle

Pro Xp Electrostatic Gun Packages

• 233741 • 60 • • • L40T10 Pro Xp40 Electrostatic Gun .055 in (1.4 mm) nozzle

• 233742 • 60 • • • L60T10 Pro Xp60 Standard Electrostatic Gun .055 in (1.4 mm) nozzle

• 289648 • 60 • • • L85T10 Pro Xp85 Standard Electrostatic Gun .055 in (1.4 mm) nozzle

• 233743 • 60 • • • L40T10 Pro Xp40 Electrostatic Gun .055 in (1.4 mm) nozzle

• 233744 • 60 • • • L60T10 Pro Xp60 Standard Electrostatic Gun .055 in (1.4 mm) nozzle

• 289649 • 60 • • • L85T10 Pro Xp85 Standard Electrostatic Gun .055 in (1.4 mm) nozzle

• 233746 • 60 • • • L40T10 Pro Xp40 Electrostatic Gun .055 in (1.4 mm) nozzle

• 233747 • 60 • • • L60T10 Pro Xp60 Standard Electrostatic Gun .055 in (1.4 mm) nozzle

• 289641 • 60 • • • L85T10 Pro Xp85 Standard Electrostatic Gun .055 in (1.4 mm) nozzle

• 233748 • 60 • • L40T10 Pro Xp40 Electrostatic Gun .055 in (1.4 mm) nozzle

• 233749 • 60 • • L60T10 Pro Xp60 Standard Electrostatic Gun .055 in (1.4 mm) nozzle

• 289631 • 60 • • L85T10 Pro Xp85 Standard Electrostatic Gun .055 in (1.4 mm) nozzle

Bare Packages**

• 233466 • • None

• 233467 • • None

• 233473 • • None

• 233474 • • None

• 233480 • • None

• 233481 • • None

• 233487 • None

• 233488 • None

*HVLP, Compliant, Pro Xp packages include fluid regulator:

– Aluminum packages use 60 psi (4 bar, 0.4 MPa) acetal fluid regulator.

– Stainless steel packages use 100 psi (7 bar, 0.7 MPa) stainless steel fluid regulator.

**Bare packages do not include hose and gun.

Page 7

Ordering InformationOrdering Information

Ordering Information and Accessories

Bare Triton Pumps

233500 Triton Pump, Aluminum

233501 Triton Pump, Stainless Steel

Spray Guns

Refer to the following gun brochures for additional part numbers:

AirPro Air Spray brochure, form #339377

Pro Xp Electrostatic Gun brochure, form #345007

Accessory Air Bundled Hoses

For hose extensions or replacement (includes air and fluid hoses, bundled together).

233498 Air/Fluid Hose, 25 ft (7.6 m) Nickel Plated Steel Couplings, fits AirPro Spray guns

233499 Air/Fluid Hose, 25 ft (7.6 m) Stainless Steel Couplings, fits AirPro Spray guns

240425 Air/Fluid Hose, 25 ft (7.6 m), fits Pro Xp guns

Air and Fluid Hoses

For hose extensions or replacement (separate air and fluid hoses)

244448 Air Hose, 25 ft (7.6 m), fits AirPro Spray guns

210868 Air Hose, 50 ft (15.2 m), fits AirPro Spray guns

223070 Air Hose, 25 ft (7.6 m) Grounded, fits Pro Xp guns

244447 Fluid Hose, 25 ft (7.6 m) Nickel Plated Steel Couplings, fits AirPro Spray guns

235339 Fluid Hose, 25 ft (7.6 m) Stainless Steel Couplings, fits AirPro Spray guns

215637 Fluid Hose, 25 ft (7.6 m), fits Pro Xp guns

215638 Fluid Hose, 50 ft (15.2 m), fits Pro Xp guns

Suction Hoses

Order a suction hose (5 gal/18.9 l or 55 gal/200 l) for wall-mount applications.

245082 Aluminum, 4 ft (1.2 m), for 5 gal (18.9 l) pail

245083 Stainless Steel, 4 ft (1.2 m), for 5 gal (18.9 l) pail

245084 Aluminum, 6 ft (1.8 m), with acetal bung adapter for 55 gal (200 l) drum

245085 Stainless Steel, 6 ft (1.8 m), with acetal bung adapter for 55 gal (200 l) drum

Fluid Regulators

Use in HVLP applications and where required fluid pressure to spray gun

is less than 20 psi (1.4 bar, 0.14 MPa).

241976 Fluid Regulator, Acetal, 0-60 psi (0-4 bar, 0-0.4 MPa)

236450 Fluid Regulator, Acetal, 20-100 psi (1.4-7 bar, 0.14-0.7 MPa)

214706 Fluid Regulator, Stainless Steel, 5-100 psi (0.3-7 bar, 0.03-0.7 MPa)

Pump Outlet Fluid Filters

Filters attach to the outlet of the Triton pump.

114361 Fluid Filter, Nylon, 80 mesh, 3/8 npt(fbe), 150 psi (10 bar, 1 MPa)

223160 Fluid Filter, Stainless Steel, 60 mesh (250 micron), 3/8 npt(f) inlet x 1/4 npt(m)

outlet, 5000 psi (350 bar, 35 MPa)

Agitators

245081 SST Pail Agitator for Triton Packages

243340 SST Pail Cover with Agitator

Technical Specifications

Maximum fluid working pressure .................................................... 100 psi (0.7 MPa, 7 bar)

Maximum air input pressure ....................................................... 100 psi (0.7 MPa, 7 bar)

Maximum fluid flow (pump at 212 cpm).................................................... 8.5 gpm (32 lpm)

Pump displacement ............................................................ 5 oz/cycle (160 cc/cycle)

Air inlet fitting............................................................................. 1/4 npt(f)

Acetal fluid regulator outlet fitting ............................................................. 3/8 npt(m)

Stainless steel fluid regulator outlet fitting ..................................................... 3/8 npsm(m)

Pump inlet ............................................................................... 3/4 npt(f)

Pump outlet ...............................................................................3/8 npt(f)

Fluid outlet fitting ......................................................................... 3/8 npt(m)

Average Air Consumption

Conventional Compliant HVLP Electrostatic

Gun: 14.0 scfm Gun: 12.0 scfm Gun: 15.0 scfm Gun: 20.0 scfm

Pump: 1.5 scfm Pump: 1.5 scfm Pump: 1.5 scfm Pump: 1.5 scfm

Total: 15.5 scfm Total: 13.5 scfm Total: 16.5 scfm Total: 21.5 scfm

Sound data*

Sound pressure level at 40 psi (0.28 MPa, 2.8 bar) ................................................... 69 dBa

Sound power level at 40 psi (0.28 MPa, 2.8 bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 dBa

* Sound pressure measured one meter from unit. Sound power measured per ISO standard 3744. Sound data is for

Triton pump only, without spray gun. Refer to the spray gun instruction manual for gun sound data.

Weight

5 gal (18.9 l) pail package (Alum/SST)............................................. 22 lb (10 kg)/28 lb (12.7 kg)

Stand package (Alum/SST) .................................................... 20 lb (9.1 kg)/27 lb (12.3 kg)

Cart package (Alum/SST) .................................................... 30 lb (13.6 kg)/36 lb (16.4 kg)

Wall mount package (Alum/SST) ................................................ 19 lb (8.6 kg)/24 lb (10.9 kg)

Pump instruction and part manual ............................................................... 309303

Spray package instruction and parts manual ....................................................... 309304

Spray package operation manual................................................................ 309305

Agitator kit instruction manual .................................................................. 309306

Page 8

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd

Suite 17, 2 Enterprise Drive

Bundoora Victoria 3083

Australia

Tel: 61 3 9468 8500

Fax: 61 3 9468 8599

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Building 7

1029 Zhongshan Road South

Huangpu District

Shanghai, 200011

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 443, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-Si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Industrial Customer Service

800.328.0211

Fax 877.340.6427

Call today for product information or to request a demonstration.

877.84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2014 Graco Inc. 300541 Rev. K 05/14 All written and visual data contained in this document are based on the latest product information available at the time

of publication. Graco reserves the right to make changes at any time without notice. All other brand names or marks are used for identification purposes and

are trademarks of their respective owners.

Loading...

Loading...