Page 1

Process Equipment Catalog

Pumping Solutions for Process Industries

Page 2

Table of Contents

Process Equipment Buyer’s Guide

Contents

Air-Operated Double Diaphragm Pumps Model Overview ........................... 2

Pump Selection Key for Husky AODD Pumps .............................................. 4

Husky™ 205 Plastic Pumps ........................................................................ 9

Husky 307 Plastic Pumps ........................................................................ 11

Husky 515 Plastic Pumps ........................................................................ 14

Husky 716 Metal Pumps .......................................................................... 17

Husky 1050 Plastic Pumps ...................................................................... 20

Husky 1050 Metal Pumps ........................................................................ 23

Husky 1050HP Metal Pumps .................................................................... 27

Husky 1590 Plastic Pumps ...................................................................... 31

Husky 1590 Metal Pumps ........................................................................ 35

Husky 15120 Plastic Pumps .................................................................... 39

Husky 2150 Plastic Pumps ...................................................................... 43

Husky 2150 Metal Pumps ........................................................................ 47

Husky 2200 Plastic Pumps ...................................................................... 51

Husky 3300 Plastic Pumps ...................................................................... 55

Husky 3300 Metal Pumps ........................................................................ 58

Husky Transfer Pump Packages ............................................................... 62

Husky Pump Accessories ......................................................................... 66

EP Series Hose Pumps ............................................................................. 71

Hydra-Clean® ........................................................................................... 75

CycleFlo™ and CycleFlo II ......................................................................... 78

Fast-Flo® 1:1 ........................................................................................... 80

Piston Pumps for Ink Applications ............................................................ 81

Surge Suppressors .................................................................................. 85

PROCESS EQUIPMENT CATALOG

1

Page 3

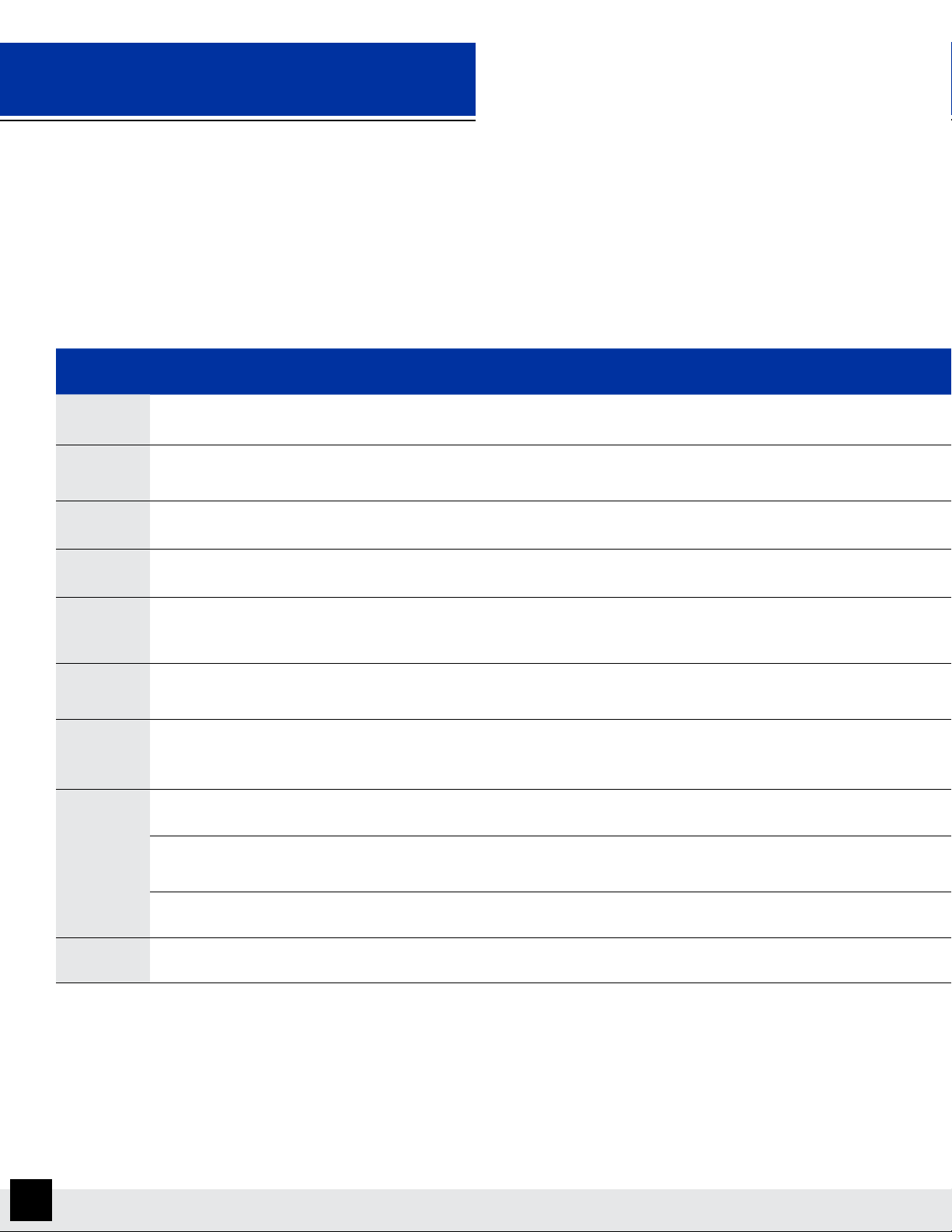

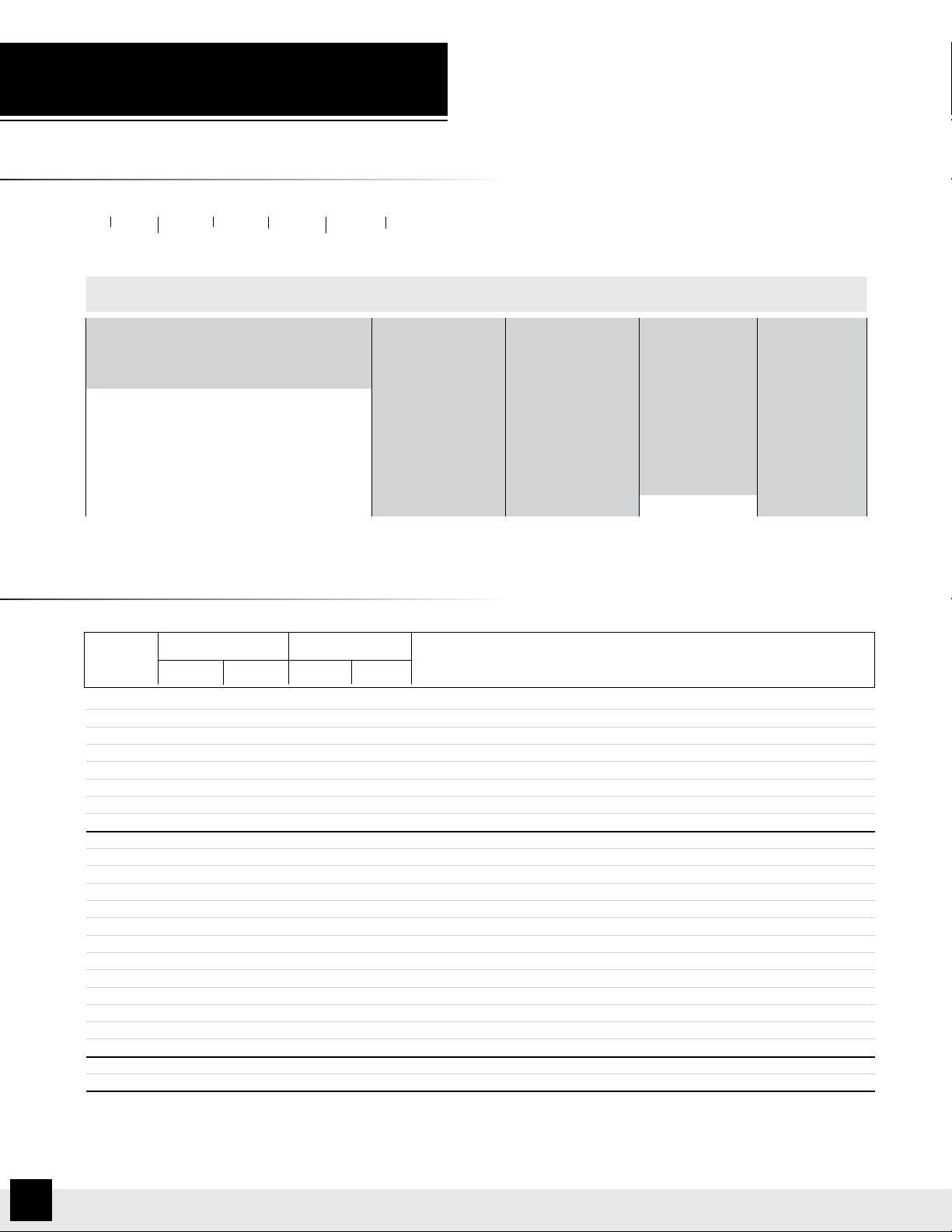

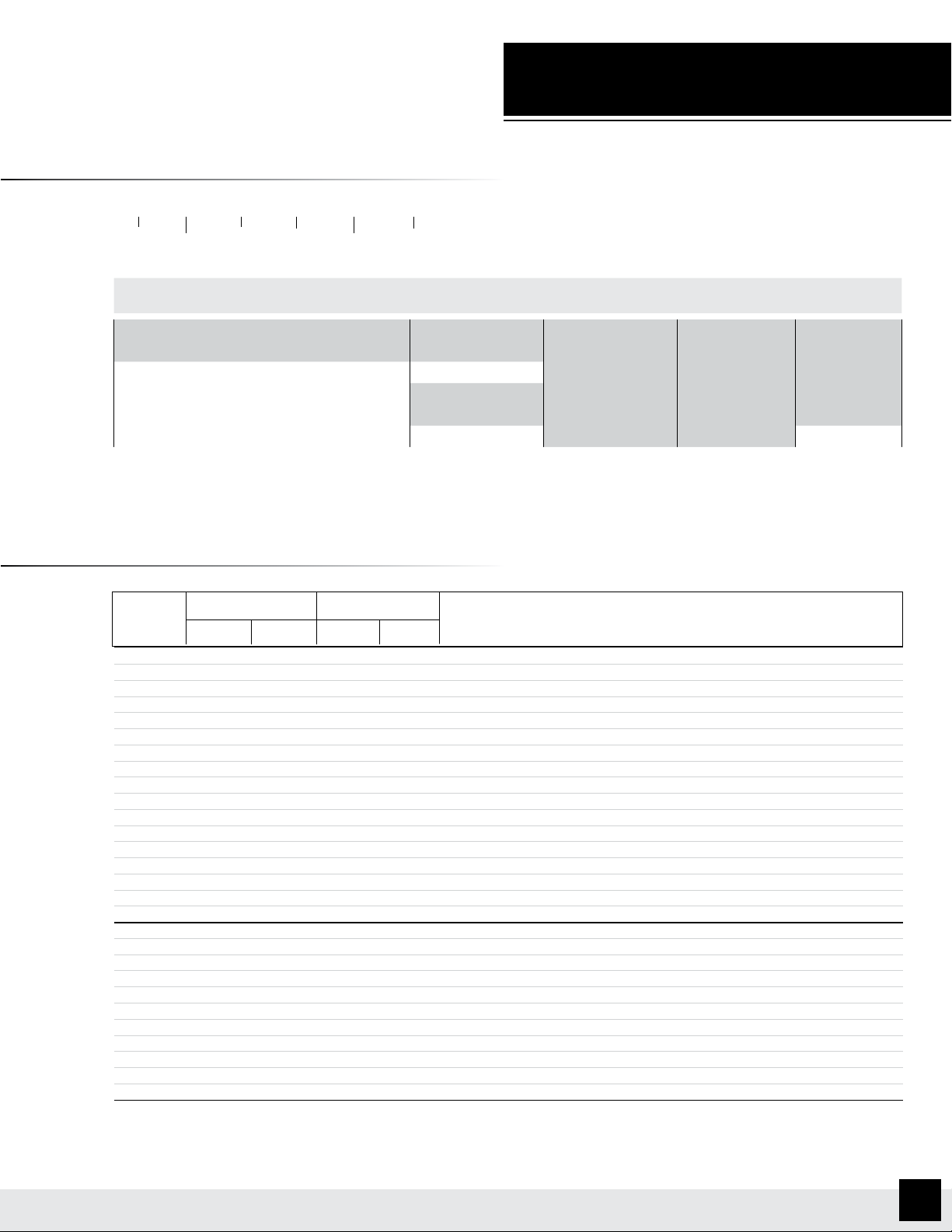

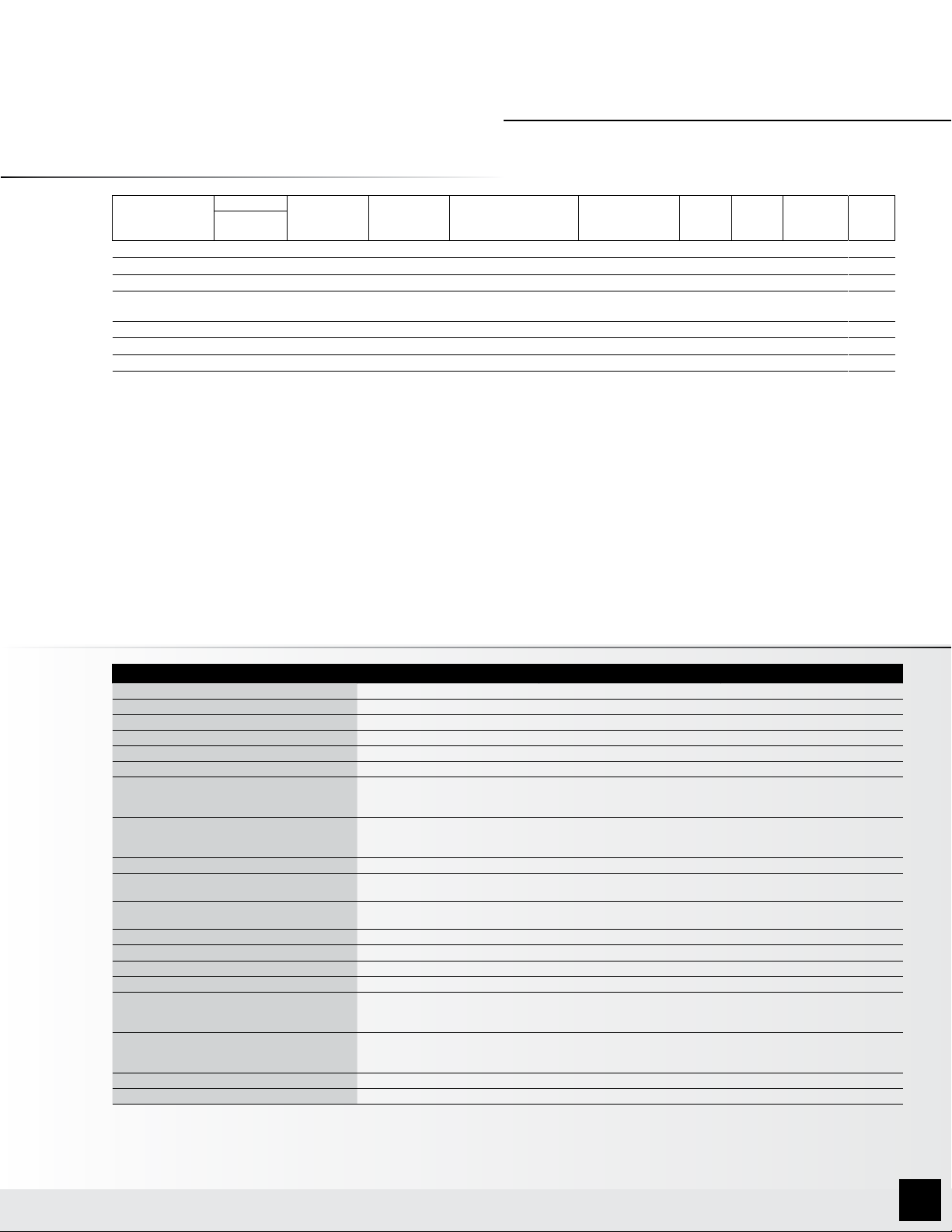

Air-Operated Double Diaphragm Pumps

Model Overview

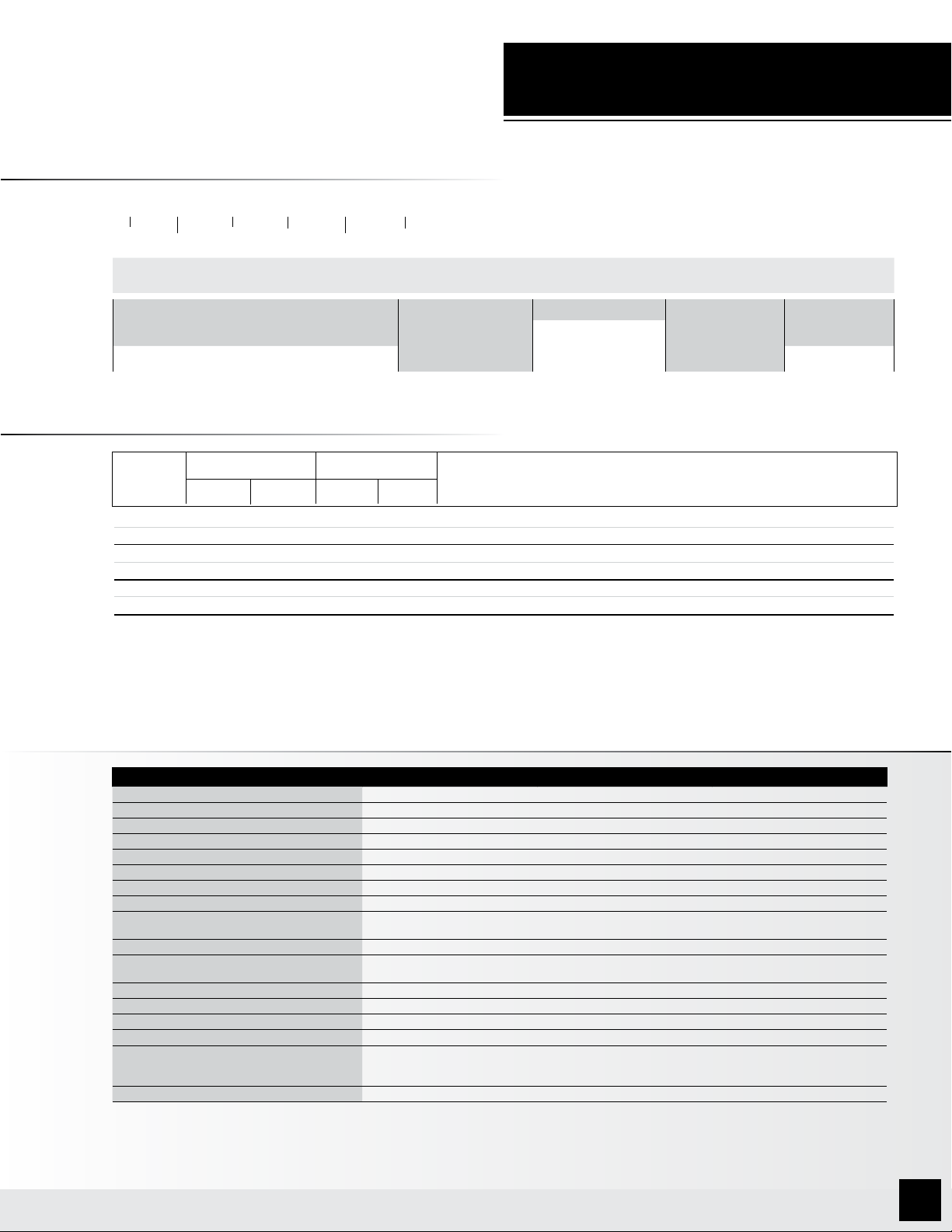

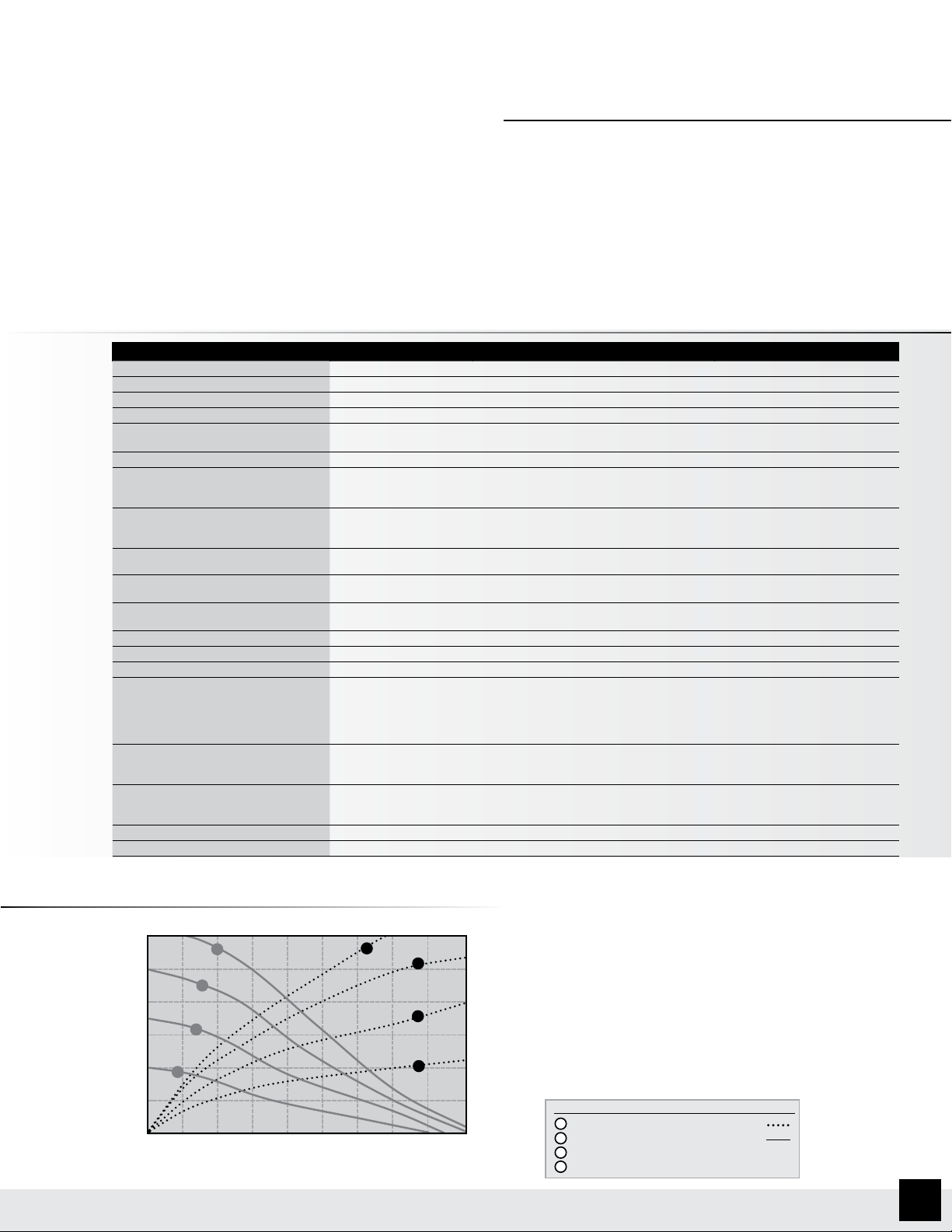

Model Husky™ 205

Plastic

Connection

Size

Thread Type NPT or BSP NPT or BSP NPT or BSP NPT or BSP ANSI/DIN Flange NPT or BSP NPT or BSP ANSI Flange NPT or BSP DIN/ANSI ANSI Flange NPT or BSP DIN/ANSI DIN/ANSI NPT and BSP

Air Valve Standard and

Maximum

Flow Rate

Maximum

Discharge

Pressure

Materials of

Construction

Available

Center Section

Available

Pump Weight 2.0 lb (0.9 kg)

1/4 in

(6.3 mm)

Remote

5 gpm

(19 lpm)

100 psi

(7 bar, 0.7 MPa)

Polypropylene,

PVDF, Acetal

Polypropylene Polypropylene Polypropylene Polypropylene Polypropylene,

Polypropylene

Husky 307

Plastic

3/8 in

(9.4 mm)

Standard Standard and

7 gpm

(26 lpm)

100 psi

(7 bar, 0.7 MPa)

Polypropylene,

Acetal

4.75 lb (2.2 kg)

Polypropylene

Husky 515

Plastic

1/2 in

(12.7 mm)

Remote

15 gpm

(57 lpm)

100 psi

(7 bar, 0.7 MPa)

Polypropylene,

PVDF, Acetal

6.5 lb (2.9 kg)

Polypropylene

Husky 716

Metal

3/4 in

(19.1 mm)

Standard and

Remote

16 gpm

(61 lpm)

100 psi

(7 bar, 0.7 MPa)

Aluminum,

316 SST

8.5 lb (3.9 kg)

Aluminum

Husky 1050

Plastic

1 in

(25.4 mm)

Standard, Smart

and Remote

50 gpm

(189 lpm)

125 psi

(8.6 bar. 0.9 MPa)

Polypropylene,

Conductive Poly,

PVDF

Conductive Poly

18 lb (8.2 kg)

Polypropylene

Husky 1050

Metal

1 in

(25.4 mm)

Standard, Smart

and Remote

50 gpm

(189 lpm)

125 psi

(8.6 bar, 0.9 MPa)

Aluminum,

316 SST,

Hastelloy

Coated Aluminum,

Polypropylene,

Conductive Poly

23 lb (10.4 kg)

Aluminum

Husky

1050HP

1 in

(25.4 mm)

Standard Standard and

50 gpm

(189 lpm)

125 psi

(8.6 bar, 0.9 MPa)

Aluminum,

316 SST

Aluminum Coated Aluminum,

48 lb (21.8 kg)

Aluminum

2.5 lb (1.1 kg)

Acetal

2.8 lb (1.3 kg)

PVDF

Maximum

Solids

2

PROCESS EQUIPMENT CATALOG

0.06 in

(1.5 mm)

5.2 lb (2.4 kg)

Acetal

0.063 in

(1.6 mm)

7.8 lb (3.5 kg)

Acetal

8.5 lb (3.9 kg)

PVDF

0.094 in

(2.5 mm)

18 lb (8.2 kg)

SST

0.094 in

(2.5 mm)

26 lb (11.8 kg)

PVDF

0.125 in

(3.2 mm)

36.3 - 41 lb

(16.5-18.6 kg)

SST

41 lb (18.6 kg)

Hastelloy

0.125 in

(3.2 mm)

60 lb (27.2 kg)

SST

0.125 in

(3.2 mm)

Page 4

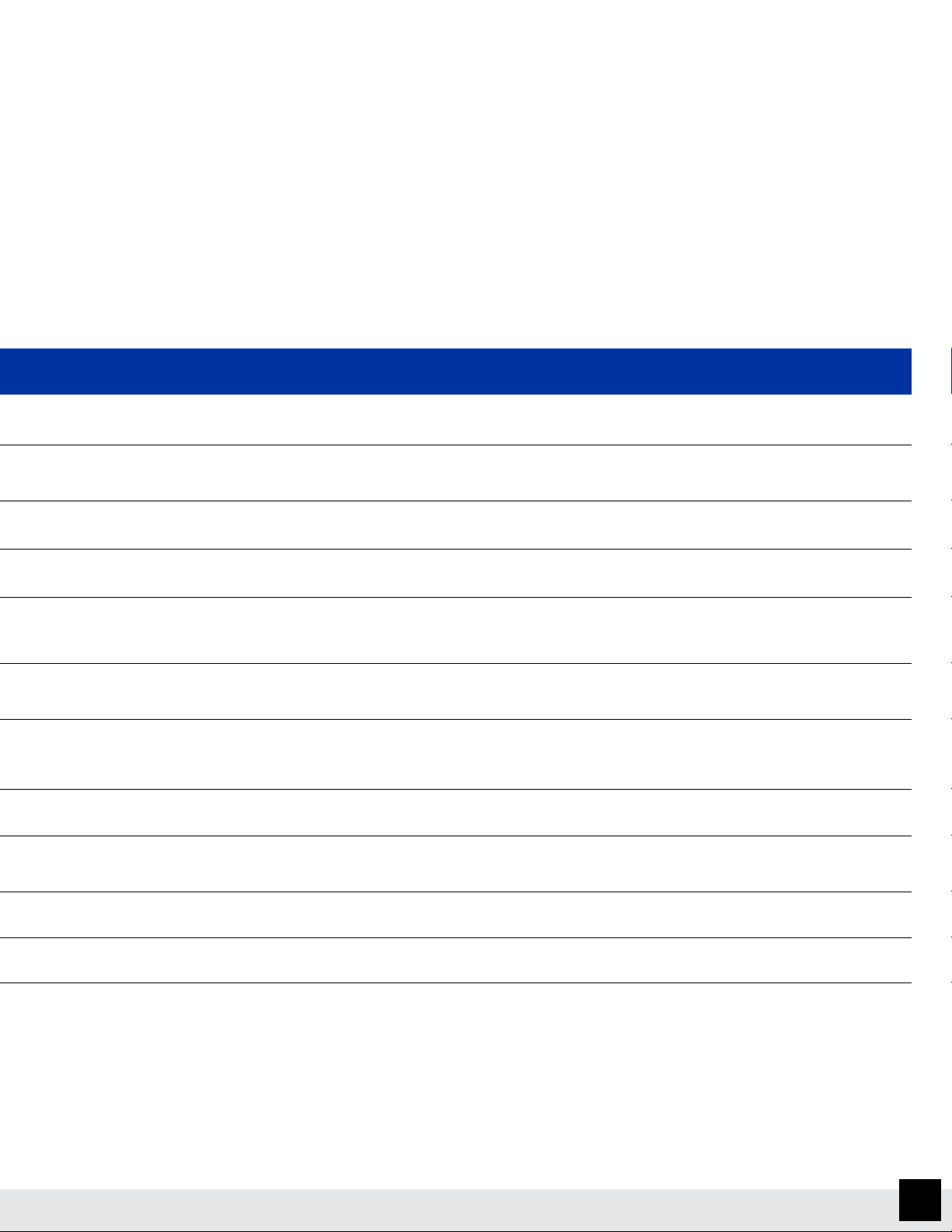

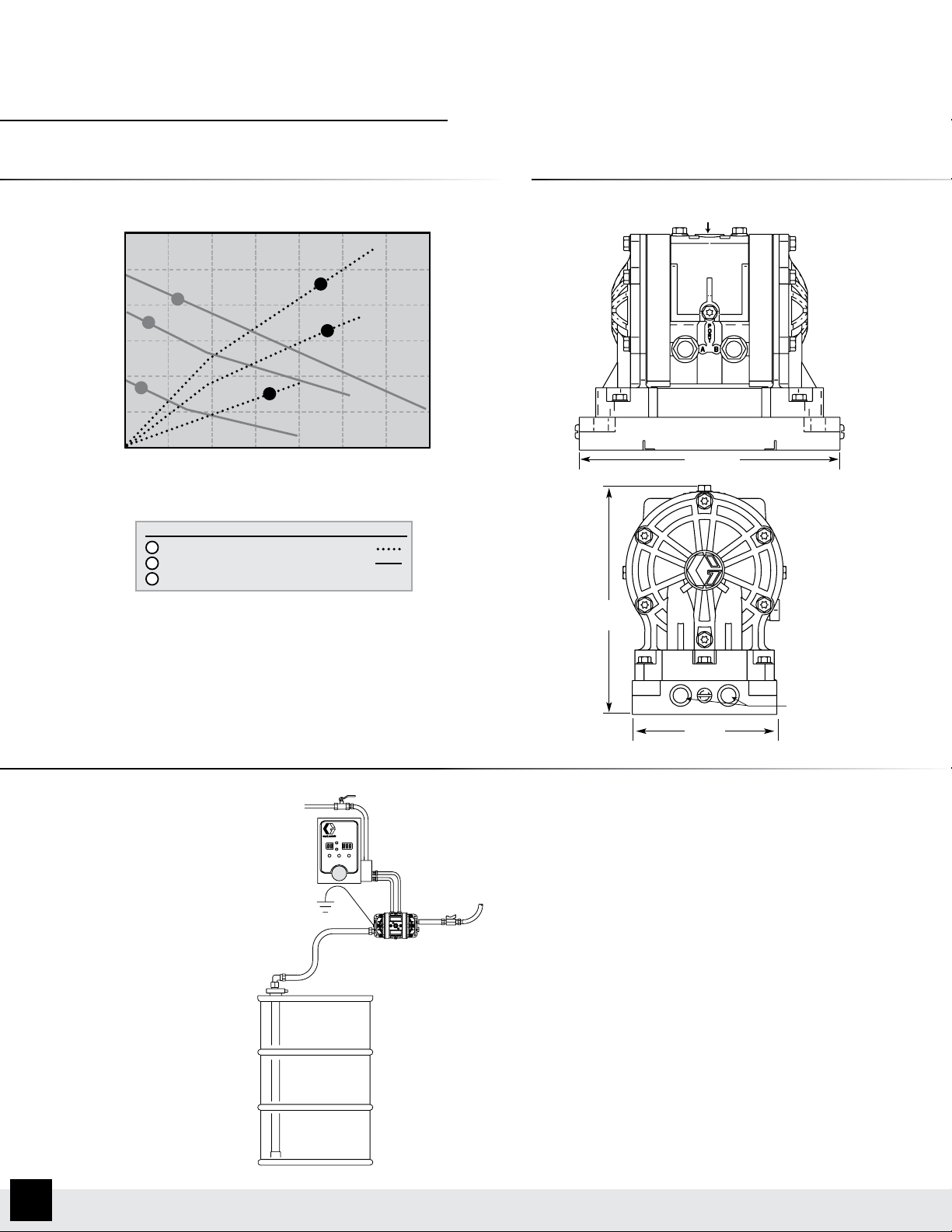

Husky 1590

Plastic

1-1/2 in

(38.1 mm)

Remote

Husky 1590

Metal

1-1/2 in

(38.1 mm)

Standard and

Remote

Husky 15120

Plastic

1-1/2 in

(38.1 mm)

Standard

Husky 2150

Plastic

2 in

(50.8 mm)

Standard and

Remote

Husky 2150

Metal

2 in

(50.8 mm)

Standard and

Remote

Husky 2200

Plastic

2 in

(50.8 mm)

Standard

Husky 3300

Plastic

3 in

(76.2 mm)

Standard Standard

Husky 3300

Metal

3 in

(76.2 mm)

DIN/ANSI

(AL only)

100 gpm

(379 lpm)

120 psi

(8.3 bar, 0.8 MPa)

Polypropylene,

PVDF

316 SST

35 lb (16 kg)

Polypropylene

49 lb (22 kg)

PVDF

0.188 in

(4.8 mm)

100 gpm

(379 lpm)

120 psi

(8.3 bar, 0.8 MPa)

Aluminum,

316 SST

Coated Aluminum,

316 SST

33.5 lb (15.2 kg)

Aluminum

86 lb (40 kg) SST

0.188 in

(4.8 mm)

120 gpm

(454 lpm)

125 psi

(8.6 bar, 0.9 MPa)

Polypropylene,

PVDF

Polypropylene Coated Aluminum,

57 lb (25.9 kg)

Polypropylene

74 lb (33.6 kg)

PVDF

0.25 in

(6.3 mm)

150 gpm

(568 lpm)

120 psi

(8.3 bar, 0.8 MPa)

Polypropylene,

PVDF

316 SST

49 lb (22 kg)

Polypropylene

68 lb (31 kg)

PVDF

0.25 in

(6.3 mm)

150 gpm

(568 lpm)

120 psi

(8.3 bar, 0.8 MPa)

Aluminum,

316 SST,

Ductile Iron

Coated Aluminum,

316 SST

58 lb (26.3 kg)

Aluminum

111 lb (50.3 kg)

SST

130 lb (59 kg)

Ductile Iron

0.25 in

(6.3 mm)

200 gpm

(757 lpm)

125 psi

(8.6 bar, 0.9 MPa)

Polypropylene,

PVDF

Polypropylene Polypropylene Aluminum,

80 lb (36.3 kg)

Polypropylene

106 lb (48.1 kg)

PVDF

0.375 in

(9.5 mm)

280 gpm

(1,059 lpm)**

100 psi

(7 bar, 0.7 MPa)

Polypropylene Aluminum,

200 lb (90.7 kg)

Polypropylene

0.5 in

(12.7 mm)

300 gpm

(1,135 lpm)**

125 psi

(8.6 bar, 0.9 MPa)

with AL center

316 SST

Polypropylene*

(*SST pump only)

150 lb (68 kg)

Aluminum

255 lb (115.6 kg)

SST

0.5 in

(12.7 mm)

**Maximum flow rate using standard diaphragm at 125 psi (8.6 bar).

PROCESS EQUIPMENT CATALOG

3

Page 5

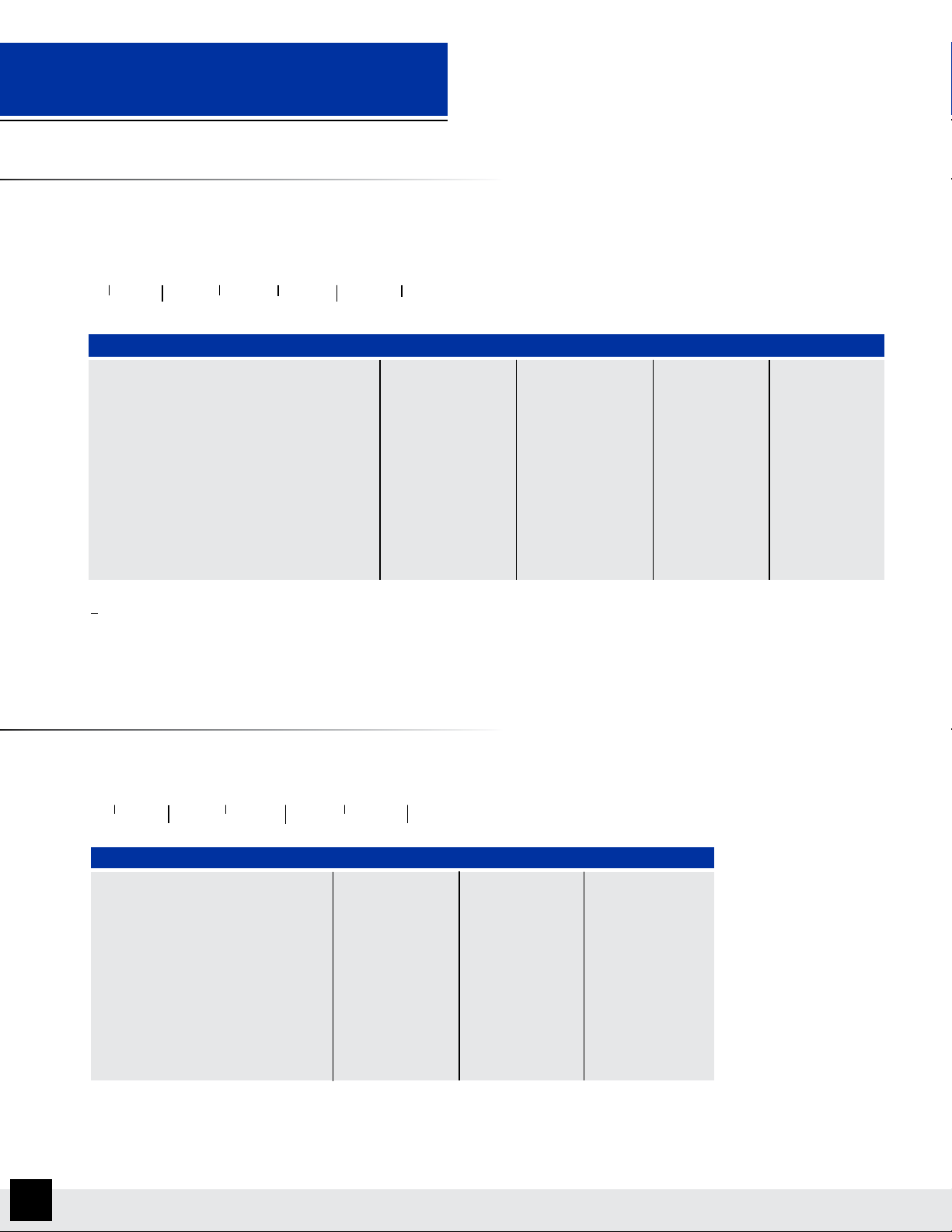

Pump Selection Key

Husky AODD Pumps

Diaphragm Pump Designation Key

For Husky 205, 307, 515, 716, 1590 and 2150 Pumps

Part numbers are located on ID tag on center section of all Husky diaphragm pumps.

D X X X X X

Diaphragm

Pump

Pump Size

Wetted

Parts

PUMP SIZE (air motor type and material) WETTED PARTS SEATS BALLS/CHECKS DIAPHRAGM

1 = 1/4” (6.35 mm) Standard: Polypropylene center section

2 = 1/4” (6.35 mm) Remote: Polypropylene center section

3 = 3/8” (9.52 mm) Standard: Polypropylene center section

5 = 1/2” (12.7 mm) Standard: Polypropylene center section

4 = 1/2” (12.7 mm) Remote: Polypropylene center section

5 = 3/4” (19.05 mm) Standard: Polypropylene center section

4 = 3/4” (19.05 mm) Remote: Polypropylene center section

B = 1-1/2” (38.1 mm) Standard: aluminum center section

C = 1-1/2” (38.1 mm) Remote: aluminum center section

T = 1-1/2” (38.1 mm) Standard: stainless steel center section

U = 1-1/2” (38.1 mm) Remote: stainless steel center section

F = 2” (50.8 mm) Standard: aluminum center section

G = 2” (50.8 mm) Remote: aluminum center section

V = 2” (50.8 mm) Standard: stainless steel center section

Seats

Balls/

Checks

Diaphragms

1 = Acetal (npt)

2 = Polypropylene (npt)

3 = Aluminum (npt)

4 = Stainless Steel (npt)

5 = PVDF (npt)

6 = Ductile Iron (npt)

A = Acetal * (bsp)

B = Polypropylene * (bsp)

C = Aluminum (bsp)

D = Stainless Steel (bsp)

E = PVDF (bsp)

F = Ductile Iron (bsp)

G = 2 bsp Alum Extended

H = 2 npt Alum Extended

2 = Acetal

3 = Stainless Steel

4 = Hardened SST

5 = TPE

6 = Santoprene

7 = Buna N

8 = Fluoroelastomer

9 = Polypropylene

A = PVDF

B = SST with FKM seal

C = Santoprene with

FKM seal

G = Geolast

1 = PTFE

2 = Acetal

3 = Stainless Steel

4 = Hardened SST

5 = TPE

6 = Santoprene

7 = Buna N

8 = Fluoroelastomer

9 = Polypropylene

A = PVDF

G = Geolast

1 = PTFE

5 = TPE

6 = Santoprene

7 = Buna N

8 = Fluoroelastomer

G = Geolast

* = BSP plastic in 1/2” (12.7mm) pumps

>1” Plastic pumps flange connections

Note: Above matrix is possible combinations. All combination may not be available. See specific pump listings for available combinations.

Diaphragm Pump Kit Designation Key

When selecting a kit, use the same code numbers as for the pumps regarding pump size, seat, ball/checks and diaphragm.

D O X X X X

Diaphragm

Pump

Kit

PUMP SIZE SEATS BALLS/CHECKS DIAPHRAGM

1 = 1/4 in (6.35 mm)

3 = 3/8 in (9.52 mm)

5 = 1/2 in (12.7 mm) and 3/4 in (19.05 mm)

B = 1-1/2 in (38.1 mm) metal pump

C = 1-1/2 in (38.1 mm) plastic pump

F = 2 in (50.8 mm) metal pump

G = 2 in (50.8 mm) plastic pump

Pump

Size

Seats

Balls/

Checks

Diaphragms

0 = No seat

2 = Acetal

3 = Stainless Steel

4 = Hardened SST

5 = TPE

6 = Santoprene

7 = Buna N

8 = Fluoroelastomer

9 = Polypropylene

A = PVDF

B = SST with FKM seal

C = Santoprene with

FKM seal

= Geolast

G

1 = PTFE

2 = Acetal

3 = Stainless Steel

4 = Hardened SST

5 = TPE

6 = Santoprene

7 = Buna

8 = Fluoroelastomer

9 = Polypropylene

A = PVDF

G = Geolast

0 = No Balls/Checks

1 = PTFE

5 = TPE

6 = Santoprene

7 = Buna

8 = Fluoroelastomer

G = Geolast

0 = No Diaphragm

4

PROCESS EQUIPMENT CATALOG

Page 6

Pump Selection Key

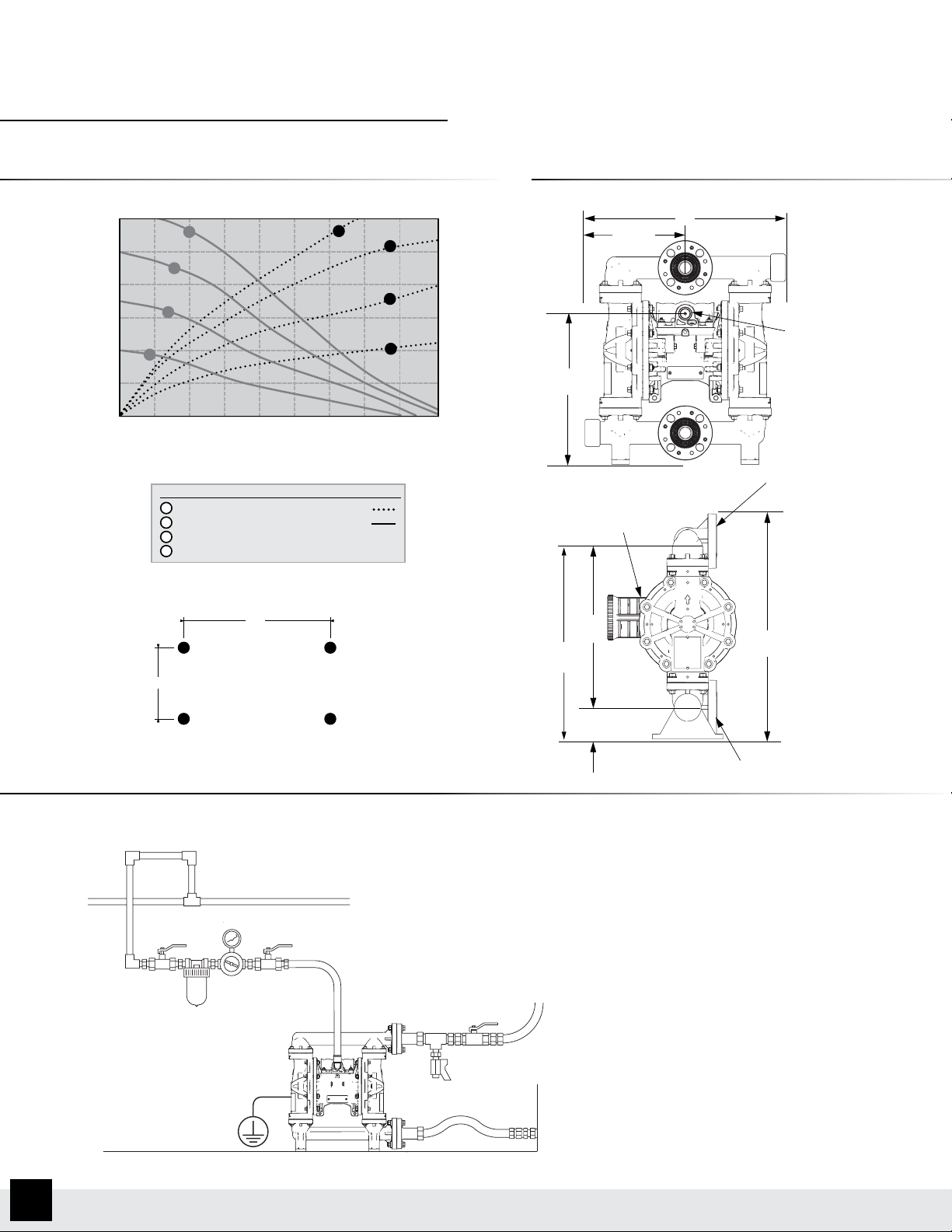

Husky Selector Tool

For Husky 1050, 1590, 15120, 2150, 2200 and 3300 Pumps

Find the Right Pump for your Application

To order a Husky 1050, 1590, 15120, 2150, 2200 or 3300, use the online selector tool at www.graco.com/process or contact your distributor.

From the homepage at www.graco.com/process click on “Online Husky Selector Tool”

Example of Product Selector Tool on www.graco.com/process.

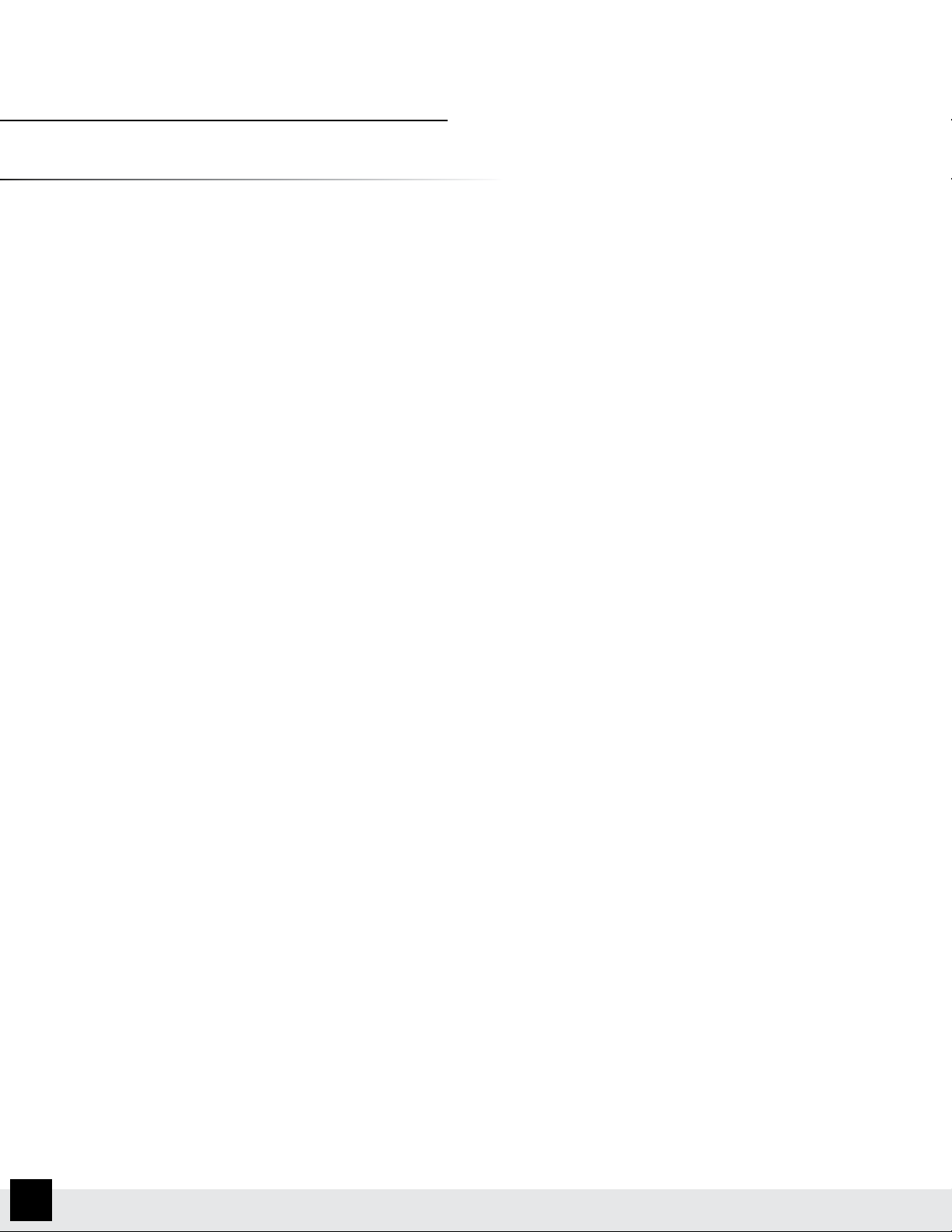

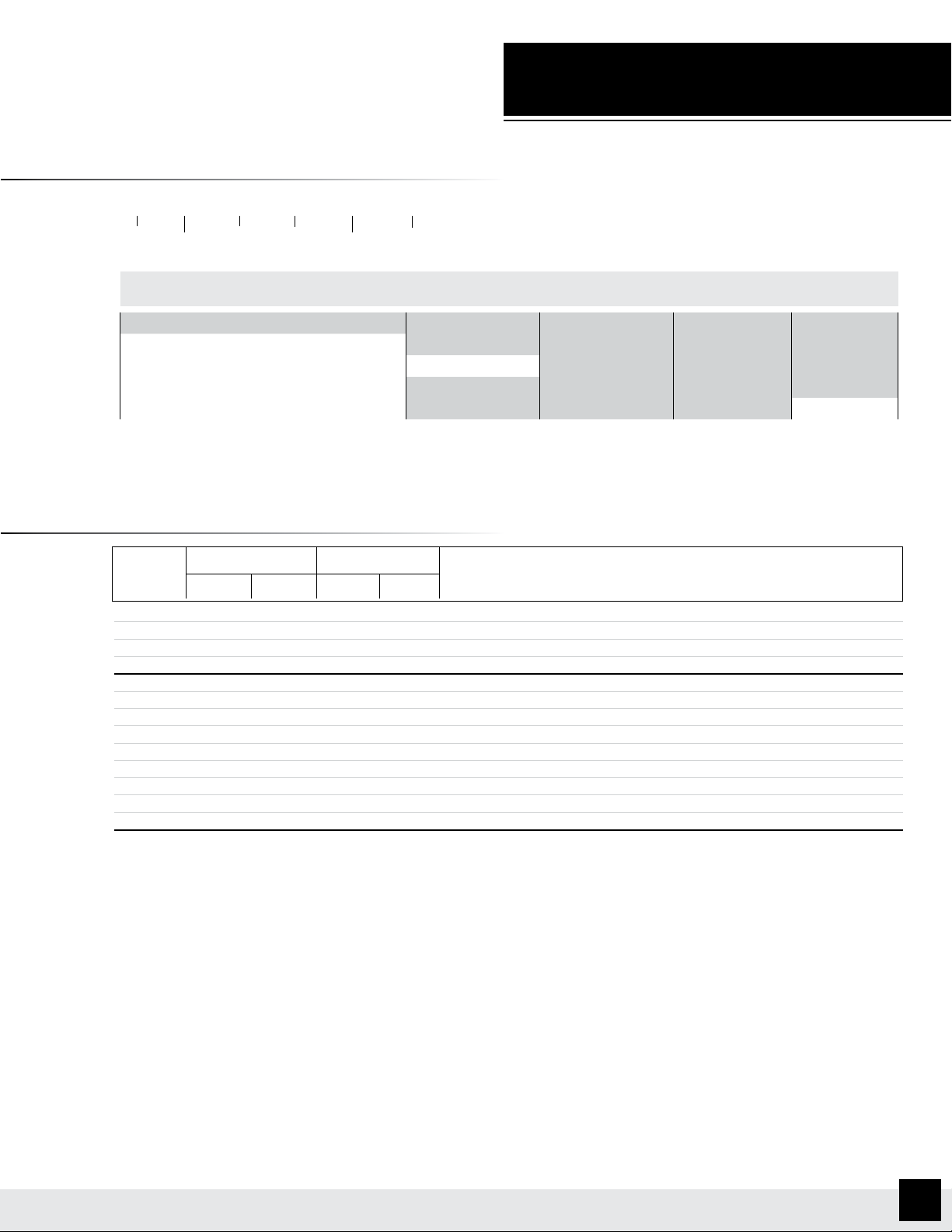

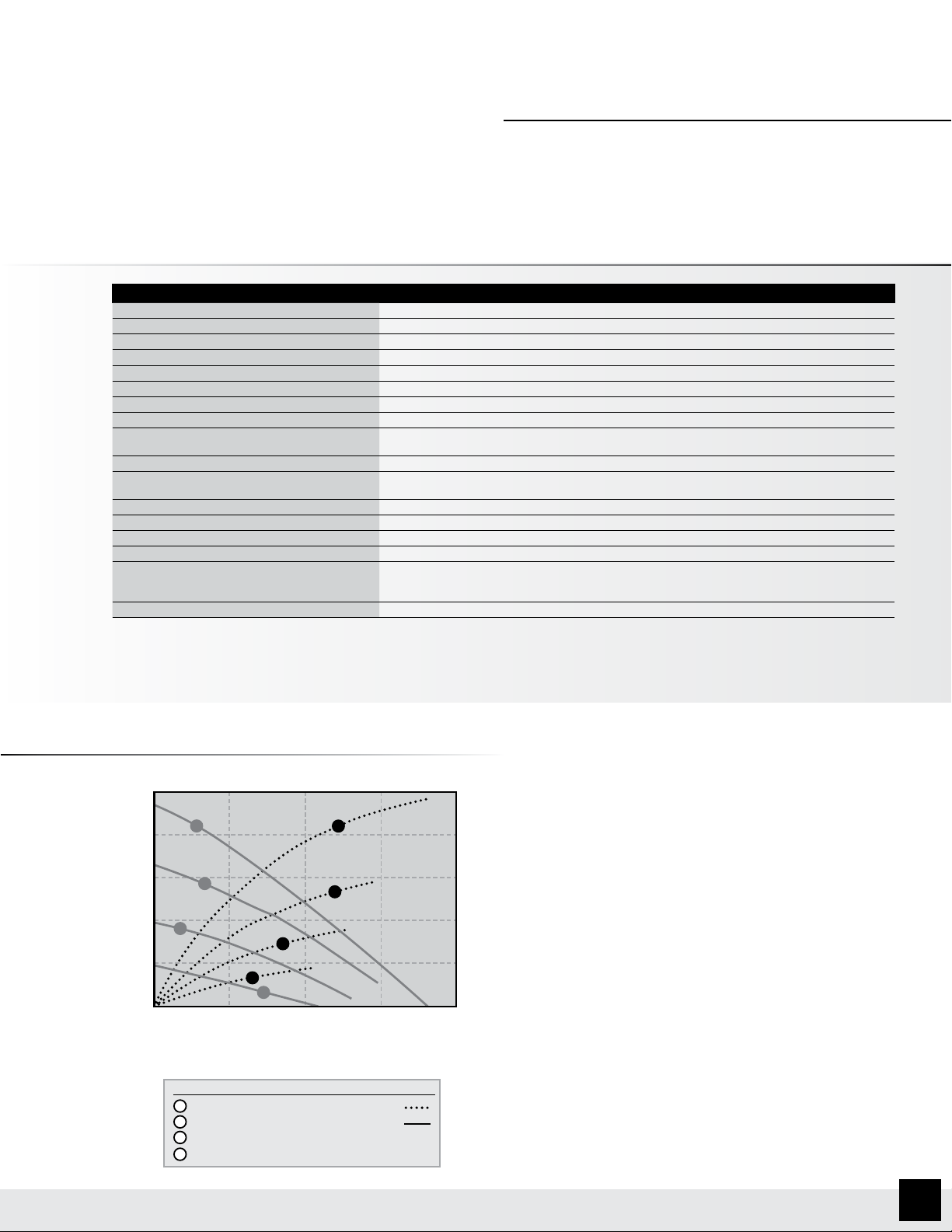

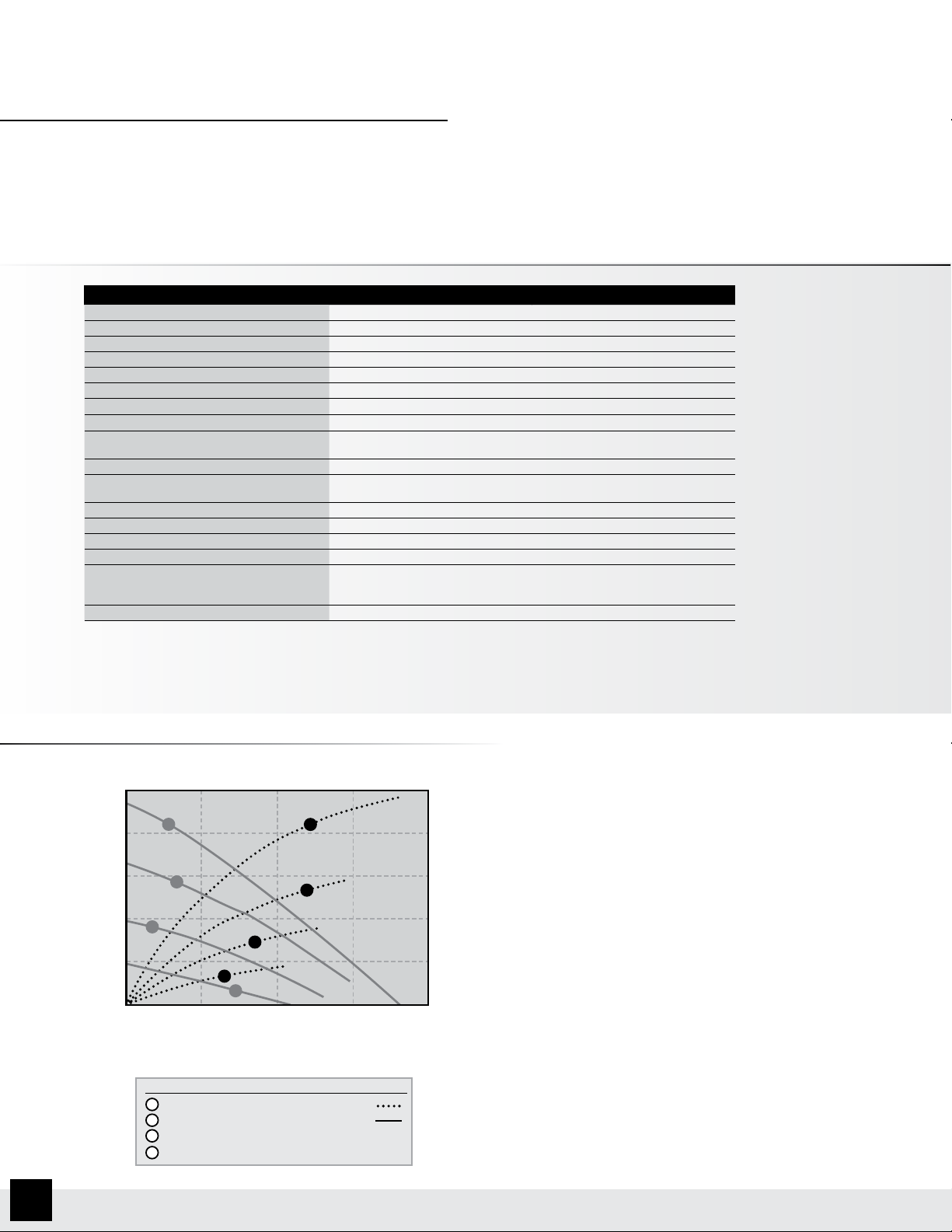

Maximum Diaphragm Operating Temperature

NOTICE:

Temperature limits are based on mechanical stress only. Certain chemicals will further limit the fluid temperature range. Stay within the temperature

range of the most-restricted wetted component. Operating at a fluid temperature that is too high or too low for the components of your pump may

cause equipment damage.

180 ºF

150 ºF

32 ºF

275 ºF

225 ºF

180 ºF

Acetal Pumps

Acetal

Buna

FKM Fluoro

Geolast

Polychloroprene

Polypropylene

PTFE Overmold

PTFE Check

PVDF

Santoprene

Diaphragm/Ball/Seat Material

Aluminum, Hastelloy, or Stainless Steel Pumps

TPE

150 ºF

100 ºF

50 ºF

250 ºF

200 ºF

150 ºF

100 ºF

150 ºF

32 ºF

225 ºF

180 ºF

Acetal

Buna

Polypropylene or

Conductive Poly Pumps

FKM Fluoro

Geolast

Polychloroprene

Polypropylene

PTFE Overmold

PTFE Check

Diaphragm/Ball/Seat Material

PVDF Pumps

PVDF

Santoprene

TPE

150 ºF

100 ºF

50 ºF

200 ºF

150 ºF

Acetal

Buna

FKM Fluoro

Geolast

Polychloroprene

Polypropylene

PTFE Overmold

PTFE Check

PVDF

32 ºF

10 ºF

-40 ºF

Santoprene

Diaphragm/Ball/Seat Material

The maximum temperature listed is based on the ATEX standard for T4 temperature classification. If you are operating in a non-explosive environment,

FKM fluoroelastomer’s maximum fluid temperature in aluminum or stainless steel pumps is 320°F (160°C).

Actual pump performance may be affected by prolonged usage at temperature.

TPE

50 ºF

0 ºF

-50 ºF

32 ºF

10 ºF

Acetal

Buna

FKM Fluoro

Geolast

Polychloroprene

Diaphragm/Ball/Seat Material

Polypropylene

PROCESS EQUIPMENT CATALOG

PTFE Overmold

PTFE Check

PVDF

Santoprene

TPE

100 ºF

50 ºF

0 ºF

5

Page 7

Pump Selection Key

Fluid Section Materials

Aluminum Medium corrosion and abrasion resistance.

Polypropylene Wide chemical compatibility.

Conductive

Polypropylene Wide chemical compatibility.

Not for use with halogenated hydrocarbons.

General purpose.

General purpose. Groundable.

Stainless Steel High level of corrosion and abrasion resistance.

(316 Grade)

Acetal

Wide range of solvent resistance.

Withstands extreme fatigue. Good level of abrasion

resistance. Groundable for use with flammables.

Not for use with acids or bases.

Ductile Iron High abrasion resistance.

Hastelloy Good resistance to aggressive chemicals

in corrosive environments.

high temperature fluids.

Compatible with

PVDF Strong chemical resistance to acids and bases.

Fluid section materials vary depending on pump model

6

PROCESS EQUIPMENT CATALOG

Good abrasion resistance. High temperature resistance.

Page 8

Pump Selection Key

Diaphragm Materials

Diaphragm Material* Description

PTFE/EPDM Two Piece Widest chemical compatibility, extreme corrosion resistance,

PTFE/EPDM Overmolded Same as above. Overmolded design improves wear, durability and cleanability.

Thermoplastic Polyester

Elastomer (TPE)

Santoprene Good abrasion and chemical resistance. OK for use with some solvents (e. g. MEK, Acetone), caustic

Buna Good for petroleum-based fluids, water, oils, hydrocarbons

Fluoroelastomer (FKM) High heat resistance. Good resistance to aggressive chemicals including acids and some solvents (e.g.

Geolast Good abrasion resistance. Approximately same chemical compatibility as Buna.

Polychloroprene

Overmolded (CR)

EPDM, used with 3A pump

(Ethylene Propylene Diene

M-class rubber)

very low frictional coefficient, non-adhesive, high heat resistance.

Longer life than above.

Good low temp properties. Good abrasion resistance.

Often substituted for Buna.

solutions, dilute acids, and alcohols. Often substituted for EPDM or EPR.

and MILD chemicals (e.g. mineral spirits).

xylene and mineral spirits). Good resistance to steam as well as animal, vegetable, and petroleum oils.

Resists unleaded fuels.

High resilience. Good with whiskey, wine, beer and natural gas. One source calls an "all purpose

Polymer ". About 30% higher abrasion resistance than Buna.

High heat resistance. Good resistance to gas permeability and to steam. OK with caustic solutions,

dilute acids, ketones and alcohols. Recommended for use with CIP Sanitizing Agent OXONIA.

*Available materials of construction varies depending on pump model

PROCESS EQUIPMENT CATALOG

7

Page 9

Pump Selection Key

Ball Check Materials

Ball Check Material Description

Thermoplastic Polyester

Elastomer (TPE)

Stainless Steel High level of corrosion and abrasion resistance. Passivated 316 grade.

Santoprene Good abrasion and chemical resistance. OK for use with some solvents, (e.g. MEK, acetone) caustic

Geolast Good abrasion resistance. Approximately same chemical compatibility as Buna.

Buna Good for petroleum-based fluids, water, oils, hydrocarbons and MILD chemicals (e.g. mineral spirits).

Fluoroelastomer

(FKM)

PTFE Widest chemical compatibility, extreme corrosion resistance, very low frictional coefficient,

Polychloroprene

(CR)

Polychloroprene

(CR) Weighted

Acetal Wide range of solvent resistant and withstands extreme fatigue. Good level of abrasion resistance. Not

Good low temperature properties. Good abrasion resistance.

solutions, dilute acids and alcohols. Often substituted for EPDM or EPR.

Not for use with strong solvents or chemicals (e.g. acetone, MEK, ozone, chrlorinated hydrocarbons and

nitro hydrocarbons).

High heat resistance. Good resistance to aggressive chemicals including acids and some solvents (e.g.

Xyleneand mineral spirits). Good resistance to steam as well as animal, vegetable and petroleum oils. Resists

unleaded fuels. Not for use with ketones, low molecular weight ester and nitro containing compounds.

non-adhesive, high heat resistance. Poor abrasion resistance.

High resilience. Good with whiskey, wine, beer and natural gas. Good with animal and vegetable

oil, moderate chemicals, fats and greases. Not for use with strong oxidizing acids, esters, ketones,

chlorinated aromatic and nitro hydrocarbons.

High resilience. Good with whiskey, wine, beer and natural gas. Good with animal and vegetable

oil, moderate chemicals, fats and greases. Not for use with strong oxidizing acids, esters, ketones,

chlorinated aromatic and nitro hydrocarbons

for use with acids or bases.

Seat Materials

Seat Material Description

Polypropylene Wide chemical compatibility. General purpose.

Thermoplastic Polyester

Elastomer (TPE)

Stainless Steel High level of corrosion and abrasion resistance. Passivated 316 grade.

Santoprene Good abrasion and chemical resistance. OK for use with some solvents, (e.g. MEK, acetone) caustic

Geolast Good abrasion resistance. Approximately same chemical compatibility as Buna.

Buna Good for petroleum-based fluids, water, oils, hydrocarbons and MILD chemicals (e.g. mineral spirits).

Fluoroelastomer (FKM) High heat resistance. Good resistance to aggressive chemicals including acids and some solvents

Aluminum Medium corrosion and abrasion resistance. Not for use with halogenated hydrocarbons.

Acetal Wide range of solvent resistant and withstands extreme fatigue. Good level of abrasion resistance.

PVDF Strong chemical resistance: Acids and bases. Good abrasion resistance. High temperature resistance.

8

PROCESS EQUIPMENT CATALOG

Good low temp properties. Good abrasion resistance.

solutions, dilute acids, and alcohols. Often substituted for EPDM or EPR.

Not for sue with strong solvents or chemicals (e. g. acetone, MEK, ozone, chrlorinated hydrocarbons,

and nitro hydrocarbons).

(e. g. Xylene and mineral spirits). Good resistance to steam as well as animal, vegetable and

petroleum oils. Resists unleaded fuels. Not for use with ketones, low molecular weight ester and

nitro containing compounds.

Not for use with acids or bases.

Page 10

Husky 205 Plastic Pumps

Air-Operated Double Diaphragm

Ordering Information

D X X X X X

Diaphragm

Pump

Pump

Size

PUMP SIZE

1 = 1/4” (6.35 mm) Standard: polypropylene center section 1 = Acetal (npt) 0 = No Seats 2 = Acetal 1 = PTFE

2 = 1/4” (6.35 mm) Remote: polypropylene center section 2 = Poly (npt) 9 = Polypropylene 6 = Santoprene

Wetted

Parts

(air motor type and material)

Popular Models

Part Number Part Number

(NPT Ported) (BSP Ported)

Material Air Valve Air Valve Air Valve Air Valve Check Valves Diaphragms Kit Air Kit Control**

Acetal D11021 D21021 D11021 D21021 Acetal PTFE D01021 238853 246946

PVDF D150A1 D250A1 D150A1 D250A1 PVDF PTFE D010A1 238853 246946

Polypropylene D12091 D22091 D12091 D22091 Polypropylene PTFE D01091 238853 246946

* Requires Cycleflo or external valve control

** Air control includes air regulator and filter with gauge

Standard Remote* Standard Remote* Materials for Materials for Fluid Air

D11026 D21026 D11026 D21026 Acetal Santoprene D01026 238853 246946

D150A6 D250A6 D150A6 D250A6 PVDF Santoprene D010A6 238853 246946

D12096 D22096 D12096 D22096 Polypropylene Santoprene D01096 238853 246946

Seats

Balls/

Checks

Diaphragms

WETTED PARTS SEATS CHECK VALVES DIAPHRAGM

5 = PVDF (npt) A = PVDF

Technical Specifications

Husky 205 Plastic Pumps Acetal Polypropylene PVDF

Maximum fluid working pressure 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa)

Maximum free flow delivery* 5.0 gpm (18.9 lpm) 5.0 gpm (18.9 lpm) 5.0 gpm (18.9 lpm)

Maximum pump speed 250 cpm 250 cpm 250 cpm

Displacement per cycle** 0.012 gallon (0.045 liter) 0.012 gallon (0.045 liter) 0.012 gallon (0.045 liter)

Maximum suction lift (D12096) 10 ft (3 m) dry 10 ft (3 m) dry 10 ft (3 m) dry

Maximum size pumpable solids 0.06 in (1.5 mm) 0.06 in (1.5 mm) 0.06 in (1.5 mm)

Maximum ambient operating temperature*** 180°F (82°C) 150°F (66°C) 180°F (82°C)

Maximum diaphragm operating temperature*** Refer to page 5 Refer to page 5 Refer to page 5

Typical sound level at 70 psi

(4.9 bar, 0.49 MPa) air @ 125 cpm

Maximum air consumption 9.0 scfm (0.252 m3/min) 9.0 scfm (0.252 m3/min) 9.0 scfm (0.252 m3/min)

Air pressure operating range 20 to 100 psi

Air inlet size 1/4 npt(f) 1/4 npt(f) 1/4 npt(f)

Air exhaust port size 1/4 npt(f) 1/4 npt(f) 1/4 npt(f)

Fluid inlet & outlet size**** 1/4 npt(f) 1/4 npt(f) 1/4 npt(f)

Weight 2.5 lb (1.1 kg) 2.0 lb (0.9 kg) 2.8 lb (1.3 kg)

Wetted parts

(in addition to ball, seat and diaphragm

materials– which may vary by pump)

Instruction manual

** Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type

*** Actual pump performance may be affected by prolonged usage at temperature

**** Hybrid thread allows for either 1/4 npt or 1/4 bspt fitting

70 dBa 70 dBa 70 dBa

(1.4 to 7 bar, 0.14 to 0.7 MPa)

Acetal with Stainless Steel fibers,

PTFE, Acetal, Santoprene

308652 308652

20 to 100 psi

(1.4 to 7 bar, 0.14 to 0.7 MPa)

Glass-filled Polypropylene,

Santoprene, PTFE, Polypropylene

20 to 100 psi

(1.4 to 7 bar, 0.14 to 0.7 MPa)

PVDF, PTFE, Santoprene

308652

Wall bracket

standard

with pump

PROCESS EQUIPMENT CATALOG

9

Page 11

Husky 205 Plastic Pumps

FLUID OUTLET PRESSURE psi (bar, MPa)

AIR CONSUMPTION scfm (m

/min)

Husky 205 Performance

(145 mm)

Fluid Inlet/Outlet

Performance Charts

120

(8, 0.8)

100

(7, 0.7)

(5.5, 0.55)

(4.1, 0.41)

(2.8, 0.28)

(1.4, 0.14)

gpm

(lpm)

80

60

40

20

0

0

A

B

C

0.5

(1.9)

AIR PRESSURE LEGEND

A

= at 100 psi (7 bar, 0.7 MPa) Air Consumption

= at 70 psi (4.8 bar, 0.48 MPa) Fluid Pressure

B

= at 40 psi (2.8 bar, 0.28 MPa)

C

1

(3.8)

(Pump tested in water with inlet submerged

C

1.5

(3.8)2(7.6)

FLUID FLOW

A

B

2.5

(9.5)3(11.4)

3.5

(13.3)

6

(0.17)

5

(0.14)

4

(0.11)

3

(0.085)

2

(0.057)

1

(0.028)

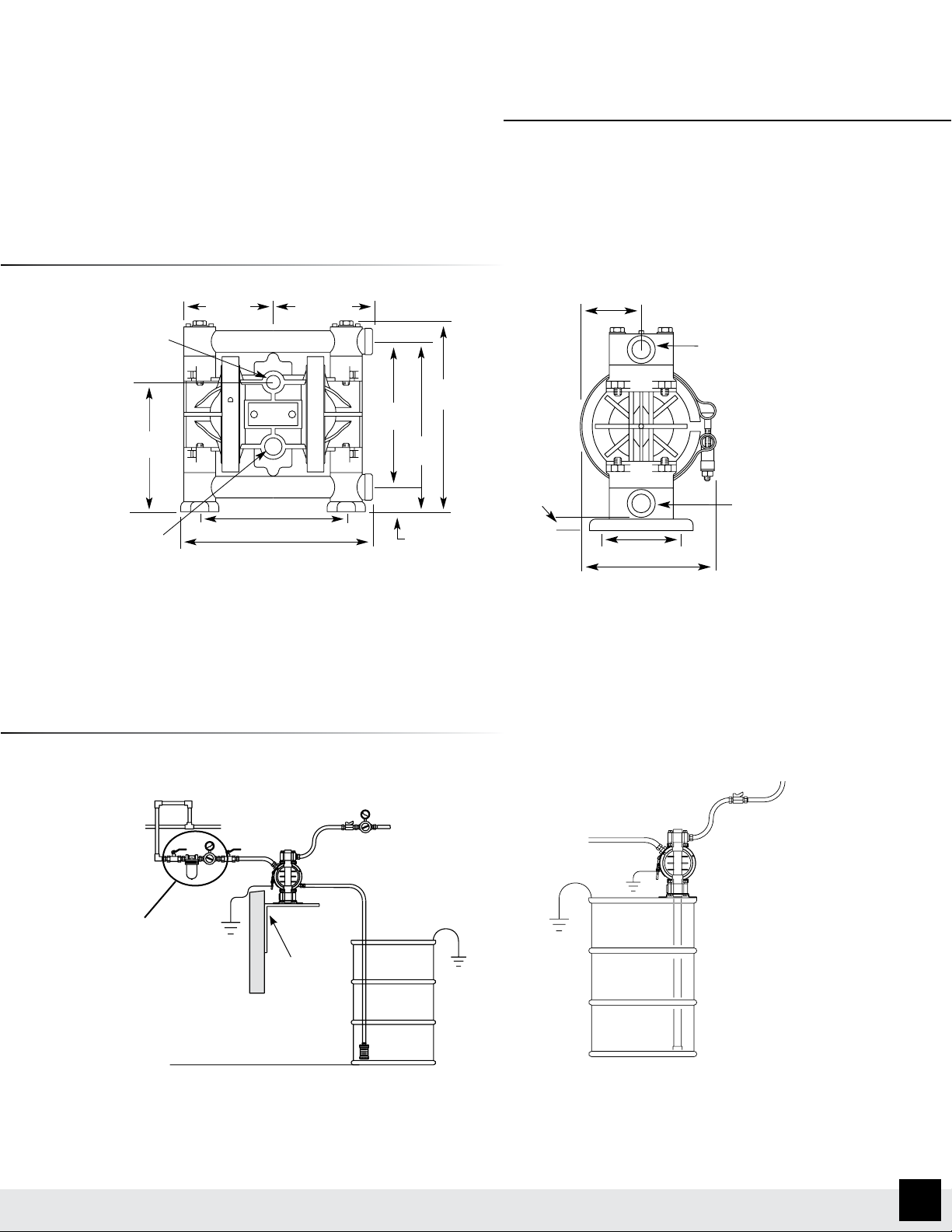

Dimensions

Air Inlet

1/4 in npt(f)

3

6.8 in (173 mm)

6 in

Typical System Drawings

Husky 205 Wall-Mount

(shown with CycleFlo controller)

3.7 in

(94 mm)

1/4 in npt/bsp

10

PROCESS EQUIPMENT CATALOG

Page 12

Ordering Information

D X X X X X

Diaphragm

Pump

Pump

Size

Wetted

Parts

Seats

Balls/

Checks

Husky 307 Plastic Pumps

Air-Operated Double Diaphragm

Diaphragms

PUMP SIZE

3 = 3/8” (9.52 mm) Standard: polypropylene center section 1 = Acetal (npt) 2 = Acetal 1 = PTFE 1 = PTFE

(air motor type and material)

WETTED PARTS SEATS BALLS DIAPHRAGM

2 = Poly (npt) 3 = Stainless Steel 3 = SST 5 = TPE

9 = Polypropylene 5 = TPE 6 = Santoprene

A = Acetal (bsp) 6 = Santoprene 7 = Buna N

B = Poly (bsp) 7 = Buna N

Popular Models

Part Number Part Number

(NPT Ported) (BSP Ported)

Material Air Valve Air Valve Air Valve Air Valve Seats Balls Diaphragms Kit Air Kit Control*

Acetal D31211 NA D3A211 NA Acetal PTFE PTFE D03211 239952 246946

Polypropylene D32211 NA D3B211 NA Acetal PTFE PTFE D03211 239952 246946

* Air control includes air regulator and filter with gauge (see drawing on page 13)

Standard Remote Standard Remote Materials for Materials for Materials for Fluid Air

D31255 NA D3A255 NA Acetal TPE TPE D03255 239952 246946

D31277 NA D3A277 NA Acetal Buna Buna D03277 239952 246946

D31311 NA D3A311 NA Stainless Steel PTFE PTFE D03311 239952 246946

D32255 NA D3B255 NA Acetal TPE TPE D03255 239952 246946

D32277 NA D3B277 NA Acetal Buna Buna D03277 239952 246946

D32311 NA D3B311 NA Stainless Steel PTFE PTFE D03311 239952 246946

D32366 NA D3B366 NA Stainless Steel Santoprene Santoprene D03366 239952 246946

D32911 NA D3B911 NA Polypropylene PTFE PTFE D03911 239952 246946

D32955 NA D3B955 NA Polypropylene TPE TPE D03955 239952 246946

D32966 NA D3B966 NA Polypropylene Santoprene Santoprene D03966 239952 246946

D32977 NA D3B977 NA Polypropylene Buna Buna D03977 239952 246946

PROCESS EQUIPMENT CATALOG

11

Page 13

Husky 307 Plastic Pumps

FLUID OUTLET PRESSURE psi (bar, MPa)

AIR CONSUMPTION scfm (m

/min

Husky 307 Performance

Technical Specifications

Husky 307 Plastic Pumps Acetal Polypropylene

Maximum fluid working pressure 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa)

Maximum free flow delivery* 7.0 gpm (26.5 lpm) 7.0 gpm (26.5 lpm)

Maximum pump speed 330 cpm 330 cpm

Displacement per cycle** 0.02 gallon (0.076 liter) 0.02 gallon (0.076 liter)

Maximum suction lift (D31255) 12 ft (3.7 m) dry 12 ft (3.7 m) dry

Maximum size pumpable solids 0.06 in (1.5 mm) 0.06 in (1.5 mm)

Maximum ambient operating temperature*** 180°F (65.5°C) 150°F (65.5°C)

Maximum diaphragm operating temperature*** Refer to page 5 Refer to page 5

Typical sound level at 50 psi

(3.5 bar, 0.35 MPa) air @ 50 cpm

Maximum air consumption 6 scfm (0.17 m3/min) 6 scfm (0.17 m3/min)

Air pressure operating range 20 to 100 psi

Air inlet size 1/4 npt(f) or bspt(f) 1/4 npt(f) or bspt(f)

Fluid inlet & outlet size**** 3/8 npt(f) 3/8 npt(f)

Weight 5.2 lb (2.4 kg) 4.75 lb (2.2 kg)

Wetted parts (in addition to ball, seat and

diaphragm materials–which may vary by pump)

Instruction manual

*Flow rates are with muffler and do not vary based on diaphragm material

**Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type

***Actual pump performance may be affected by prolonged usage at temperature

75 dBa 75 dBa

20 to 100 psi

(1.4 to 8.4 bar, 0.14 to 0.84 MPa)

Acetal with Stainless

(1.4 to 8.4 bar, 0.14 to 0.84 MPa)

Polypropylene, PTFE

Steel fibers, PTFE

308553 308553

Performance Chart

120

(8.4, 0.84)

100

(7, 0.7)

(5.5, 0.55)

(4.1, 0.41)

(2.8, 0.28)

(1.4, 0.14)

gpm

(lpm)

A

80

B

60

40

C

20

0

1

0

(3.8)

AIR PRESSURE LEGEND

A

= at 100 psi (7 bar, 0.7 MPa) Air Consumption

= at 70 psi (4.8 bar, 0.48 MPa) Fluid Pressure

B

= at 40 psi (2.8 bar, 0.28 MPa)

C

= at 20 psi (1.4 bar, 0.14 MPa)

D

D

D

2

(7.6)3(11.4)4(15.2)5(19.0)6(22.7)

(Pump tested in water with inlet submerged

FLUID FLOW

A

B

C

(26.5)

6

(0.17)

5

(0.14)

3

4

(0.11)

3

(0.085)

2

(0.057)

1

(0.028)

8

7

(30.0)

12

PROCESS EQUIPMENT CATALOG

Page 14

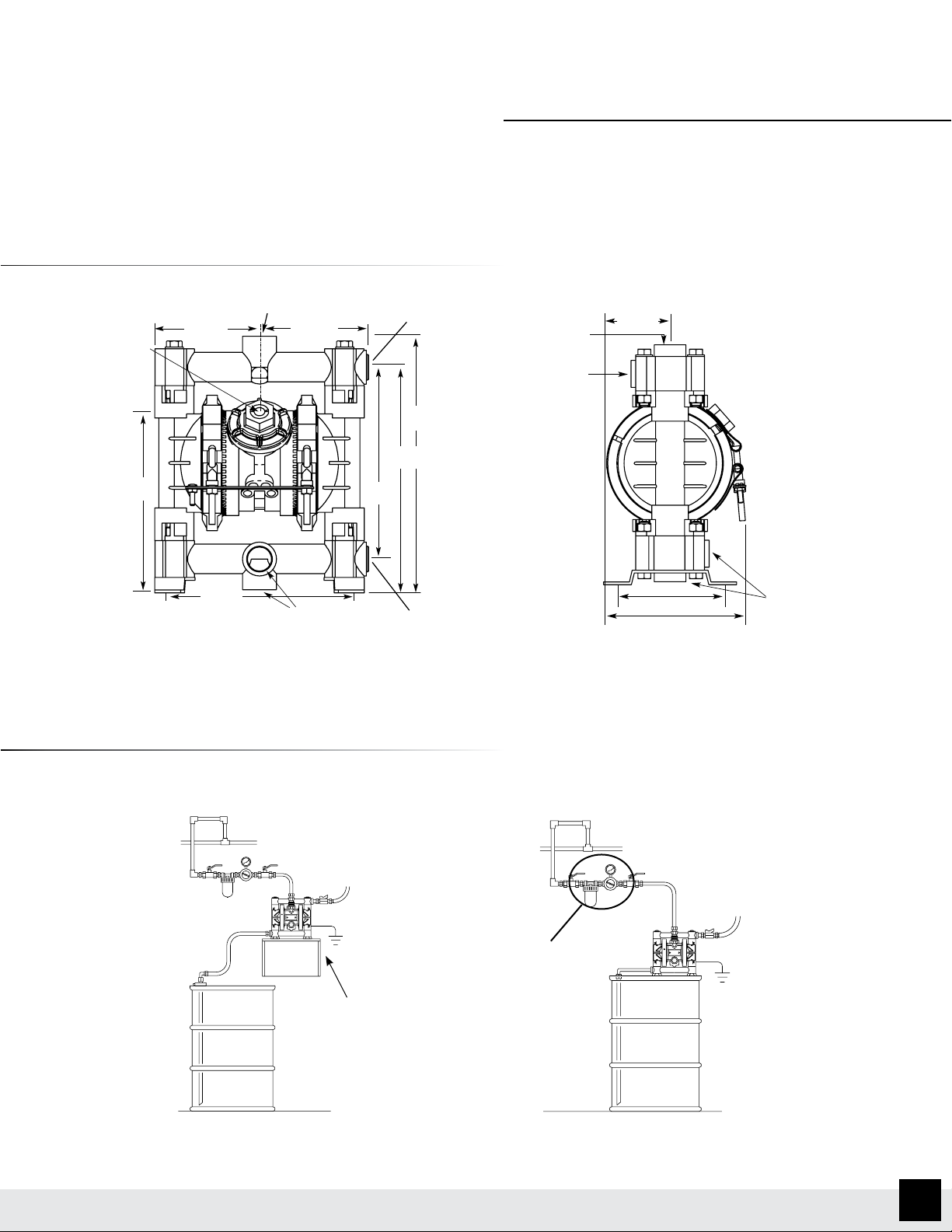

Dimensions

(muffler included)

Husky 307 Plastic Pumps

3.14 in

(80 mm)

1/4 npt(f)

Air Inlet

6.05 in

(153.55 mm)

3/8 npt(f)

Air Exhaust

6.3 in (160 mm)

8.12 in (206.5 mm)

Typical System Drawings

4.98 in

(126.5 mm)

6.18 in

(157 mm)

(206.5 mm)

7.24 in

(184 mm)

1.06 in

(2.7 mm)

8.13 in

2.53 in

(64.5 mm)

0.66 in

(17 mm)

Fluid Outlet:

3/8 npt(f)

Fluid Inlet:

3/8 npt(f)

3.5 in (89 mm)

5.3 in (134.5 mm)

Husky 307 Wall-Mount with Siphon Feed

Air Control Kit

Wall Mount

Bracket

PN 224835

Husky 307 Drum-Mount with Siphon Feed

PROCESS EQUIPMENT CATALOG

13

Page 15

Husky 515 Plastic Pumps

Air-Operated Double Diaphragm

Ordering Information

D X X X X X

Diaphragm

Pump

Pump

Size

Wetted

Parts

Seats

Balls/

Checks

Diaphragms

PUMP SIZE

5 = 1/2” center (12.7 mm) or 3/4” ends (19.05)

4 =

* = BSP plastic in 1/2” (12.7 mm) pumps

(air motor type and material)

Standard: polypropylene center section

1/2” center (12.7 mm) or 3/4” ends (19.05)

Remote: polypropylene center section

WETTED PARTS SEATS BALLS DIAPHRAGM

1 = Acetal (npt) 2 = Acetal 1 = PTFE 1 = PTFE

2 = Poly (npt) 3 = Stainless Steel 3 = Stainless Steel 5 = TPE

5 = PVDF (npt) 9 = Polypropylene 5 = TPE 6 = Santoprene

A = Acetal * (bsp) A = PVDF 6 = Santoprene 7 = Buna N

B = Poly * (bsp) D = Urethane Duckbill 7 = Buna N 8 = Fluoroelastomer

E = PVDF (bsp) 8 = Fluoroelastomer

0 = Duckbill

Popular Models

Part Number Part Number

(NPT Ported) (BSP Ported)

Material Air Valve Air Valve Air Valve Air Valve Seats Balls Diaphragms Kit Air Kit Control**

Acetal D51211 D41211 D5A211 D4A211 Acetal PTFE PTFE D05211 241657 246946

Polypropylene D52211 D42211 D5B211 D4B211 Acetal PTFE PTFE D05211 241657 246946

PVDF D55A11 D45A11 D5EA11 D4EA11 PVDF PTFE PTFE D05A11 241657 246946

*Required Cycleflo or external valve control

** Air control includes air regulator and filter with gauge (see drawing on page 16)

Standard Remote* Standard Remote* Materials for Materials for Materials for Fluid Air

D51255 D41255 D5A255 D4A255 Acetal TPE TPE D05255 241657 246946

D51277 D41277 D5A277 D4A277 Acetal Buna Buna D05277 241657 246946

D51311 D41311 D5A311 D4A311 Stainless Steel PTFE PTFE D05311 241657 246946

D51331 D41331 D5A331 D4A331 Stainless Steel Stainless Steel PTFE D05331 241657 246946

D51D05 D41D05 D5AD05 D4AD05 Duckbill TPE D05D05 241657 246946

D51D06 D41D06 D5AD06 D4AD06 Duckbill Santoprene D05D06 241657 246946

D51D07 D41D07 D5AD07 D4AD07 Duckbill Buna D05D07 241657 246946

D52277 D42277 D5B277 D4B277 Acetal Buna Buna D05277 241657 246946

D52311 D42311 D5B311 D4B311 Stainless Steel PTFE PTFE D05311 241657 246946

D52331 D42331 D5B331 D4B331 Stainless Steel Stainless Steel PTFE D05331 241657 246946

D52336 D42336 D5B336 D4B336 Stainless Steel Stainless Steel Santoprene D05336 241657 246946

D52911 D42911 D5B911 D4B911 Polypropylene PTFE PTFE D05911 241657 246946

D52955 D42955 D5B955 D4B955 Polypropylene TPE TPE D05955 241657 246946

D52966 D42966 D5B966 D4B966 Polypropylene Santoprene Santoprene D05966 241657 246946

D52977 D42977 D5B977 D4B977 Polypropylene Buna Buna D05977 241657 246946

D52988 D42988 D5B988 D4B988 Polypropylene Fluoroelastomer Fluoroelastomer D05988 241657 246946

D52D05 D42D05 D5BD05 D4BD05 Duckbill TPE D05D05 241657 246946

D52D06 D42D06 D5BD06 D4BD06 Duckbill Santoprene D05D06 241657 246946

D52D07 D42D07 D5BD07 D4BD07 Duckbill Buna D05D07 241657 246946

D55A88 D45A88 D5EA88 D4EA88 PVDF Fluoroelastomer Fluoroelastomer D05A88 241657 246946

14

PROCESS EQUIPMENT CATALOG

Page 16

Husky 515 Plastic Pumps

FLUID OUTLET PRESSURE psi (bar, MPa)

AIR CONSUMPTION scfm (m

/min)

Husky 515 Performance

Technical Specifications

Husky 515 Plastic Pumps Acetal Polypropylene PVDF

Maximum fluid working pressure 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa)

Maximum free flow delivery* 15 gpm (57 lpm) 15 gpm (57 lpm) 15 gpm (57 lpm)

Maximum pump speed 400 cpm 400 cpm 400 cpm

Displacement per cycle** 0.04 gallon (0.15 liter) 0.04 gallon (0.15 liter) 0.04 gallon (0.15 liter)

Maximum suction lift *** 15 ft (4.5 m) dry 15 ft (4.5 m) dry 15 ft (4.5 m) dry

Maximum size pumpable solids 0.09 in (2.5 mm) 0.09 in (2.5 mm) 0.09 in (2.5 mm)

Maximum ambient operating temperature† 180°F (82°C) 150°F (66°C) 180°F (82°C)

Maximum diaphragm operating temperature† Refer to page 5 Refer to page 5 Refer to page 5

Typical sound level at 70 psi

(4.9 bar, 0.49 MPa) air @ 125 cpm

Maximum air consumption 28 scfm (0.672 m3/min) 28 scfm (0.672 m3/min) 28 scfm (0.672 m3/min)

Air pressure operating range 30 to 100 psi

Air inlet size 1/4 npt(f) 1/4 npt(f) 1/4 npt(f)

Air exhaust port size 3/8 npt(f) 3/8 npt(f) 3/8 npt(f)

Fluid inlet & outlet size**** 1/2 npt(f) or bspt(f) 1/2 npt(f) or bspt(f) 1/2 npt(f) or bspt(f)

Weight 7.8 lb (3.5 kg) 6.5 lb (2.9 kg) 8.5 lb (3.9 kg)

Wetted parts

(in addition to ball, seat and diaphragm materials–

which may vary by pump)

Instruction manual

* Flow rates are with muffler and do not vary based on diaphragm material.

** Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type

*** Duckbill suction lift 11 ft (3.3 m)

**** Hybrid thread allows for either 1/4 npt or 1/4 bspt fitting

† Actual pump performance may be affected by prolonged usage at temperature.

74 dBa 74 dBa 74 dBa

(2.1 to 7 bar, 0.21 to 0.7 MPa)

30 to 100 psi

(2.1 to 7 bar, 0.21 to 0.7 MPa)

30 to 100 psi

(2.1 to 7 bar, 0.21 to 0.7 MPa)

Groundable Acetal, PTFE, SST Polypropylene, PTFE, SST PVDF, PTFE

308981 308981 308981

Performance Charts

16

(60.56)

30

(0.84)

24

(0.67)

18

(0.50)

12

(0.37)

6

(0.17)

3

100

(7, 0.7)

80

(5.5, 0.55)

60

(4.1, 0.41)

40

(2.8, 0.28)

20

(1.4, 0.14)

0

gpm

(lpm)

A

B

C

0

AIR PRESSURE LEGEND

A

B

C

D

4

(15.2)

(Pump tested in water with inlet submerged

= at 100 psi (7 bar, 0.7 MPa) Air Consumption

= at 70 psi (4.8 bar, 0.48 MPa) Fluid Pressure

= at 40 psi (2.8 bar, 0.28 MPa)

= at 20 psi (1.4 bar, 0.14 MPa)

C

D

D

FLUID FLOW

(30)

A

B

8

12

(45.42)

PROCESS EQUIPMENT CATALOG

15

Page 17

Husky 515 Plastic Pumps

1/2 npt(f) or bspt(f)

3/4 npt(f)

Dimensions

1/4 npt(f)

Air Inlet

7.75 in

(196.9 mm)

1/2 npt(f) or bspt(f) Fluid Inlet

4.7 in

(119 mm)

6.12 in

(155.4 mm)

Fluid Outlet

5.01 in

(127 mm)

3/4 npt(f) or bspt(f) Fluid Inlet

(252.5 mm)

8.56 in

(217.4 mm)

9.94 in

10.63 in

(270 mm)

3/4 npt(f)

Outlet

Inlet

Typical System Drawings

Husky 515 Wall-Mount with Drum Feed

Wall Mount

Bracket

PN 224835

Husky 515 Drum-Mount with Siphon Feed

Air Control Kit

16

PROCESS EQUIPMENT CATALOG

Page 18

Ordering Information

D X X X X X

Diaphragm

Pump

Pump

Size

Wetted

Parts

Seats

Balls/

Checks

Husky 716 Metal Pumps

Air-Operated Double Diaphragm

Diaphragms

PUMP SIZE

5 = 3/4” (19.05 mm) Standard: polypropylene center section 3 = Aluminum (npt) 2 = Acetal 1 = PTFE 1 = PTFE

4 = 3/4” (19.05 mm) Remote: polypropylene center section 4 = Stainless Steel (npt) 3 = Stainless Steel 3 = Stainless Steel 5 = TPE

(air motor type and material)

WETTED PARTS SEATS BALLS DIAPHRAGM

9 = Polypropylene 5 = TPE 6 = Santoprene

C = Aluminum (bsp) A = PVDF 6 = Santoprene 7 = Buna N

D = Stainless Steel (bsp) D = Duckbill 7 = Buna N 8 = Fluoroelastomer

8 = Fluoroelastomer

Popular Models

Part Number Part Number

(NPT Ported) (BSP Ported)

Material Air Valve Air Valve Air Valve Air Valve Seats Balls Diaphragms Kit Air Kit Control**

Aluminum D53211 D43211 D5C211 D4C211 Acetal PTFE PTFE D05211 241657 246946

Stainless Steel D54211 D44211 D5D211 D4D211 Acetal PTFE PTFE D05211 241657 246946

* Requires CycleFlo or external valve control

** Air control includes air regulator and filter with gauge (see drawing on page 19)

Standard Remote* Standard Remote* Materials for Materials for Materials for Fluid Air

D53255 D43255 D5C255 D4C255 Acetal TPE TPE D05255 241657 246946

D53277 D43277 D5C277 D4C277 Acetal Buna Buna D05277 241657 246946

D53288 D43288 D5C288 D4C288 Acetal Fluoroelastomer Fluoroelastomer D05288 241657 246946

D53311 D43311 D5C311 D4C311 Stainless Steel PTFE PTFE D05311 241657 246946

D53331 D43331 D5C331 D4C331 Stainless Steel Stainless Steel PTFE D05331 241657 246946

D53355 D43355 D5C355 D4C355 Stainless Steel TPE TPE D05355 241657 246946

D53366 D43366 D5C366 D4C366 Stainless Steel Santoprene Santoprene D05366 241657 246946

D53377 D43377 D5C377 D4C377 Stainless Steel Buna Buna D05377 241657 246946

D53388 D43388 D5C388 D4C388 Stainless Steel Fluoroelastomer Fluoroelastomer D05388 241657 246946

D53911 D43911 D5C911 D4C911 Polypropylene PTFE PTFE D05911 241657 246946

D53955 D43955 D5C955 D4C955 Polypropylene TPE TPE D05955 241657 246946

D53966 D43966 D5C966 D4C966 Polypropylene Santoprene Santoprene D05966 241657 246946

D53977 D43977 D5C977 D4C977 Polypropylene Buna Buna D05977 241657 246946

D53D05 D43D05 D5CD05 D4CD05 Duckbill TPE D05D05 241657 246946

D53D06 D43D06 D5CD06 D4CD06 Duckbill Santoprene D05D06 241657 246946

D53D07 D43D07 D5CD07 D4CD07 Duckbill Buna D05D07 241657 246946

D54311 D44311 D5D311 D4D311 Stainless Steel PTFE PTFE D05311 241657 246946

D54331 D44331 D5D331 D4D331 Stainless Steel Stainless Steel PTFE D05331 241657 246946

D54335 D44335 D5D335 D4D335 Stainless Steel Stainless Steel TPE D05335 241657 246946

D54336 D44336 D5D336 D4D336 Stainless Steel Stainless Steel Santoprene D05336 241657 246946

D54355 D44355 D5D355 D4D355 Stainless Steel TPE TPE D05355 241657 246946

D54366 D44366 D5D366 D4D366 Stainless Steel Santoprene Santoprene D05366 241657 246946

D54377 D44377 D5D377 D4D377 Stainless Steel Buna Buna D05377 241657 246946

D54388 D44388 D5D388 D4D388 Stainless Steel Fluoroelastomer Fluoroelastomer D05388 241657 246946

D54911 D44911 D5D911 D4D911 Polypropylene PTFE PTFE D05911 241657 246946

D54966 D44966 D5D966 D4D966 Polypropylene Santoprene Santoprene D05966 241657 246946

PROCESS EQUIPMENT CATALOG

17

Page 19

Husky 716 Metal Pumps

FLUID OUTLET PRESSURE psi (bar, MPa)

AIR CONSUMPTION scfm (m

/min)

Husky 716 Performance

Technical Specifications

Husky 716 Metal Pumps Aluminum Stainless Steel

Maximum fluid working pressure 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa)

Maximum free flow delivery* 16 gpm (61 lpm) 16 gpm (61 lpm)

Maximum pump speed 400 cpm 400 cpm

Displacement per cycle** 0.04 gallon (0.15 liter) 0.04 gallon (0.15 liter)

Maximum suction lift 15 ft (4.5 m) dry 15 ft (4.5 m) dry

Maximum size pumpable solids 0.09 in (2.5 mm) 0.09 in (2.5 mm)

Maximum ambient operating temperature***

Maximum diaphragm operating temperature*** Refer to page 5 Refer to page 5

Typical sound level at 70 psi air

(4.9 bar, 0.49 MPa) air @ 200 cpm

Maximum air consumption 28 scfm (0.672 m3/min) 28 scfm (0.672 m3/min)

Air pressure operating range 30 to 100 psi

Air inlet size 1/4 npt(f) 1/4 npt(f)

Air exhaust port size 3/8 npt(f) 3/8 npt(f)

Fluid inlet & outlet size 3/4 npt(f) or bspt(f) 3/4 npt(f) or bspt(f)

Weight 8.5 lb (3.9 kg) 18 lb (8.2 kg)

Wetted parts (in addition to ball, seat and

diaphragm materials–which may vary by pump)

Instruction manual

*Flow rates are with muffler and do not vary based on diaphragm material

**Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type

***Actual pump performance may be affected by prolonged usage at temperature

180ºF (82ºC) 180ºF (82ºC)

74 dBa 74 dBa

(2.1 to 7 bar, 0.21 to 0.7 MPa)

Aluminum, Stainless Steel, PTFE,

Buna-N, Santroprene, Zinc-Plated Steel

308981 308981

30 to 100 psi

(2.1 to 7 bar, 0.21 to 0.7 MPa)

Acetal, Polypropylene, Stainless Steel,

Polyester, Santoprene, Fluoroelastomer,

Nickel-Plated Brass, Epoxy-Coated Steel

Performance Charts

16

(60.56)

30

(0.84)

24

(0.67)

18

(0.50)

12

(0.37)

6

(0.17)

3

100

(7, 0.7)

80

(5.5, 0.55)

60

(4.1, 0.41)

40

(2.8, 0.28)

20

(1.4, 0.14)

0

gpm

(lpm)

A

B

C

0

AIR PRESSURE LEGEND

A

B

C

D

4

(15.2)

(Pump tested in water with inlet submerged

= at 100 psi (7 bar, 0.7 MPa) Air Consumption

= at 70 psi (4.8 bar, 0.48 MPa) Fluid Pressure

= at 40 psi (2.8 bar, 0.28 MPa)

= at 20 psi (1.4 bar, 0.14 MPa)

C

D

D

FLUID FLOW

(30)

A

B

8

12

(45.42)

18

PROCESS EQUIPMENT CATALOG

Page 20

Dimensions

Husky 716 Metal Pumps

3/4 npt(f) or bspt(f) Fluid Outlet

3/4 npt(f) or bspt(f) Fluid Inlets

1/4 npt(f)

Air Inlet

7.37 in

(187.2 mm)

4.25 in

(108 mm)

(168.1 mm)

6.62 in

Typical System Drawings

4.44 in

(112.8 mm)

(233.2 mm)

7.8 in

(198.1 mm)

9.18 in

3/4 npt(f)

Outlet

10.43 in

(264.9 mm)

3/4 npt(f)

Inlet

3/4 npt(f)

or bsp(f)

Fluid Outlets

2.76 in

(62.5 mm)

4.29 in (109 mm)

6.04 in (153.4 mm)

3/4 npt(f)

or bsp(f)

Fluid Inlets

Husky 716 Wall-Mount with Drum Feed

Wall Mount

Bracket

PN 224835

Husky 716 Drum-Mount with Siphon Feed

Air Control Kit

PROCESS EQUIPMENT CATALOG

19

Page 21

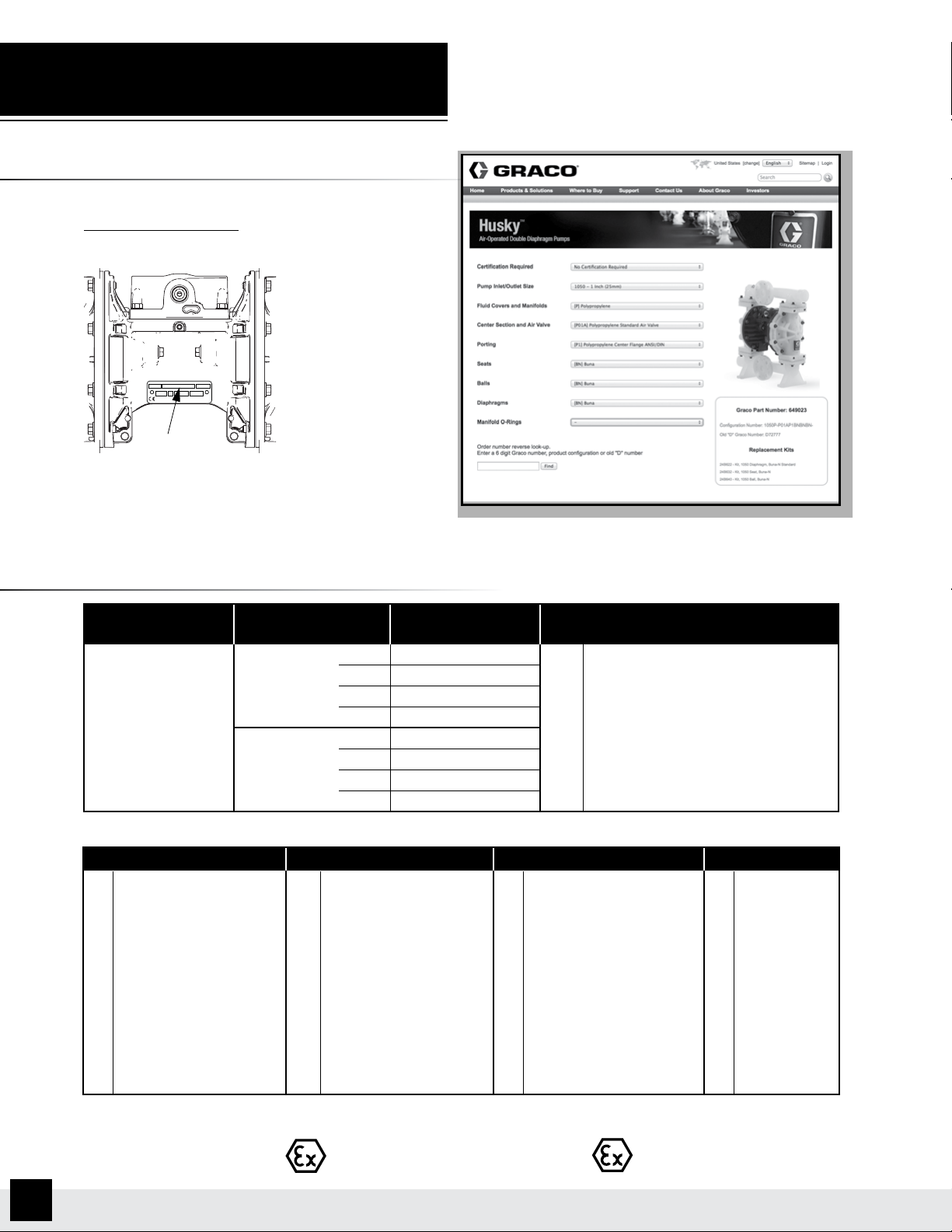

Husky 1050 Plastic Pumps

II 2 G c IIC T4

II 2 G

Air-Operated Double Diaphragm

Husky 1050 Selector Tool

To order a Husky 1050, use the online selector tool at

www.graco.com/process or contact your distributor.

CONFIGURATION NO..ON LAIRES.ON TRAP

SERIESDATE CODE

MADE IN

MAX WPR PSI-bar

Pump ID

NOTE: Options for seats, check balls, diaphragms, and seals

vary for the 1050A, 1050C, 1050F, 1050H, 1050P, and 1050S

pump models.

Example of Product Selector Tool on www.graco.com/process.

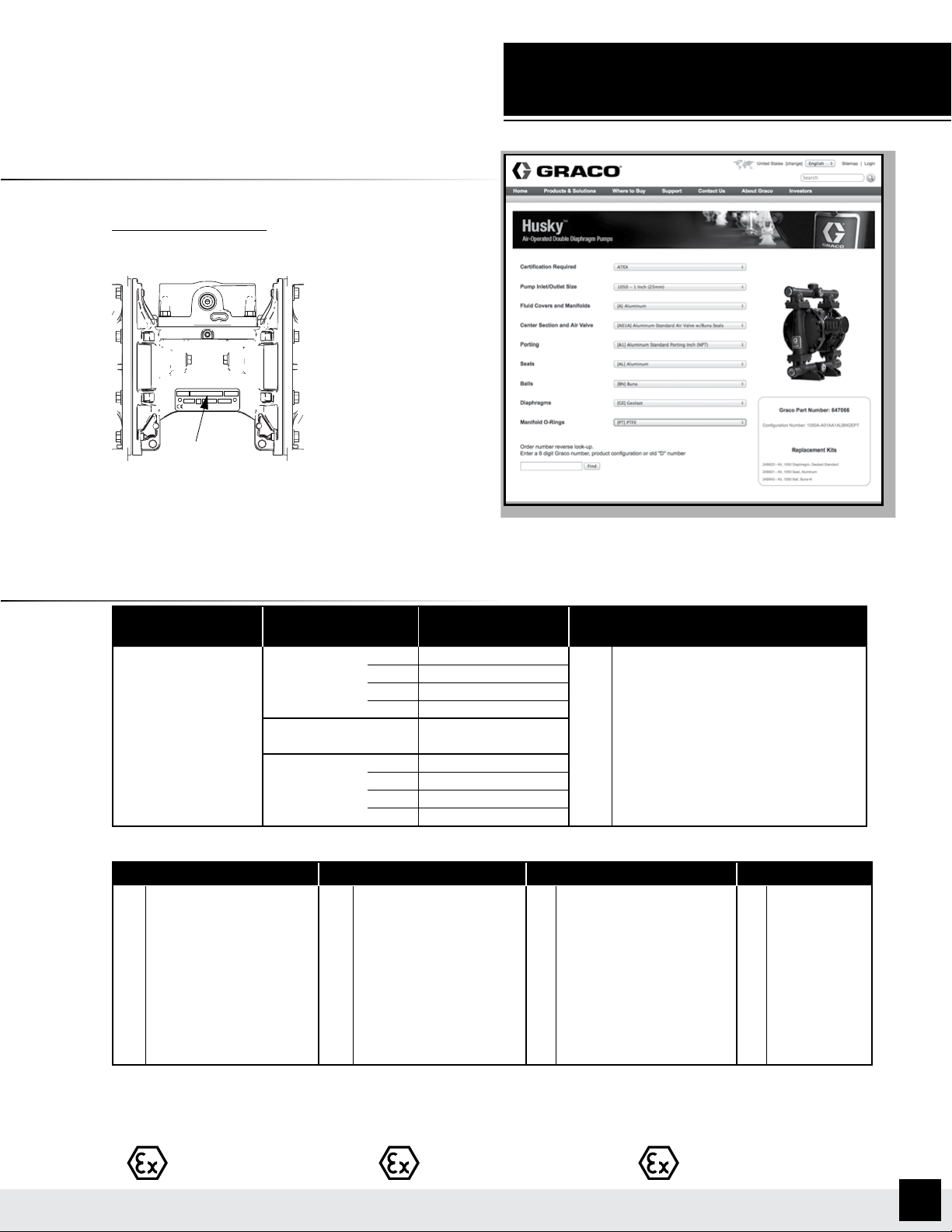

Pump Configuration Options

Pump

(1 inch ports, 50 gpm)

C ★

Conductive

Polypropylene 1050

P

Polypropylene 1050

F

PVDF 1050

★, ‡, or ✖: See ATEX Certifications below.

Check Valve Seats Check Valve Balls Diaphragm Manifold O-Rings

AC Acetal AC Acetal BN Buna-N — None

FK FKM Fluoroelastomer BN Buna-N CO Polychloroprene Overmolded PT PTFE

PP Polypropylene FK FKM Fluoroelastomer FK FKM Fluoroelastomer

PV PVDF PT PTFE PO PTFE/EPDM Overmolded

SP Santoprene® SP Santoprene PT PTFE/EPDM Two-Piece

SS 316 Stainless Steel SS 316 Stainless Steel SP Santoprene

BN Buna-N TP TPE TP TPE

AL Aluminum GE Geolast GE Geolast

GE Geolast CR Polychloroprene

TP TPE CW Polychloroprene w/SST Core

Center Section and

Air Valve Material Air Valve/Monitoring Fluid Covers and Manifolds

Conductive

Polypropylene

Polypropylene

C01A Standard

C01B Pulse Count ✖

C01C DataTrak ✖

C01D Remote

P01A Standard

P01B Pulse Count ✖

P01C DataTrak ✖

P01D Remote

C1 Conductive polypropylene, center flange

C2 Conductive polypropylene, end flange

P1 Polypropylene, center flange

P2 Polypropylene, end flange

F1 PVDF, center flange

F2 PVDF, end flange

20

PROCESS EQUIPMENT CATALOG

ATEX Certifications

★ All Conductive Polypropylene 1050

pumps are certified:

✖ DataTrak and Pulse

Count are certified:

EEx ia IIA T3

Nemko

06ATEX1124

Page 22

Husky 1050 Plastic Pumps

Popular Models

Part Number

Material

Polypropylene 649001 Polypropylene Santoprene Santoprene 24B773 24B635 24B646 24B628

Conductive

Polypropylene

PVDF 649392 316 SST PTFE PTFE/EPDM 2 Piece 24B773 24B637 24B645 24B627

Standard

Air Valve

649006 Polypropylene PTFE PTFE/EPDM 2 Piece 24B773 24B635 24B645 24B627

649034 Polypropylene PTFE PTFE/EPDM 2 Piece 24B773 24B635 24B645 24B627

649218 Acetal PTFE PTFE/EPDM 2 Piece 24B775 24B630 24B645 24B627

649211 316 SST PTFE PTFE/EPDM 2 Piece 24B775 24B637 24B645 24B627

649398 PVDF PTFE PTFE/EPDM 2 Piece 24B773 24C721 24B645 24B627

Materials for

Seats

Materials for

Balls Materials for Diaphragms

Air Valve

Replacement Kit Seat Kit Ball Kit

Diaphragm

Kit

Flange

Center

Center

End

End

End

End

End

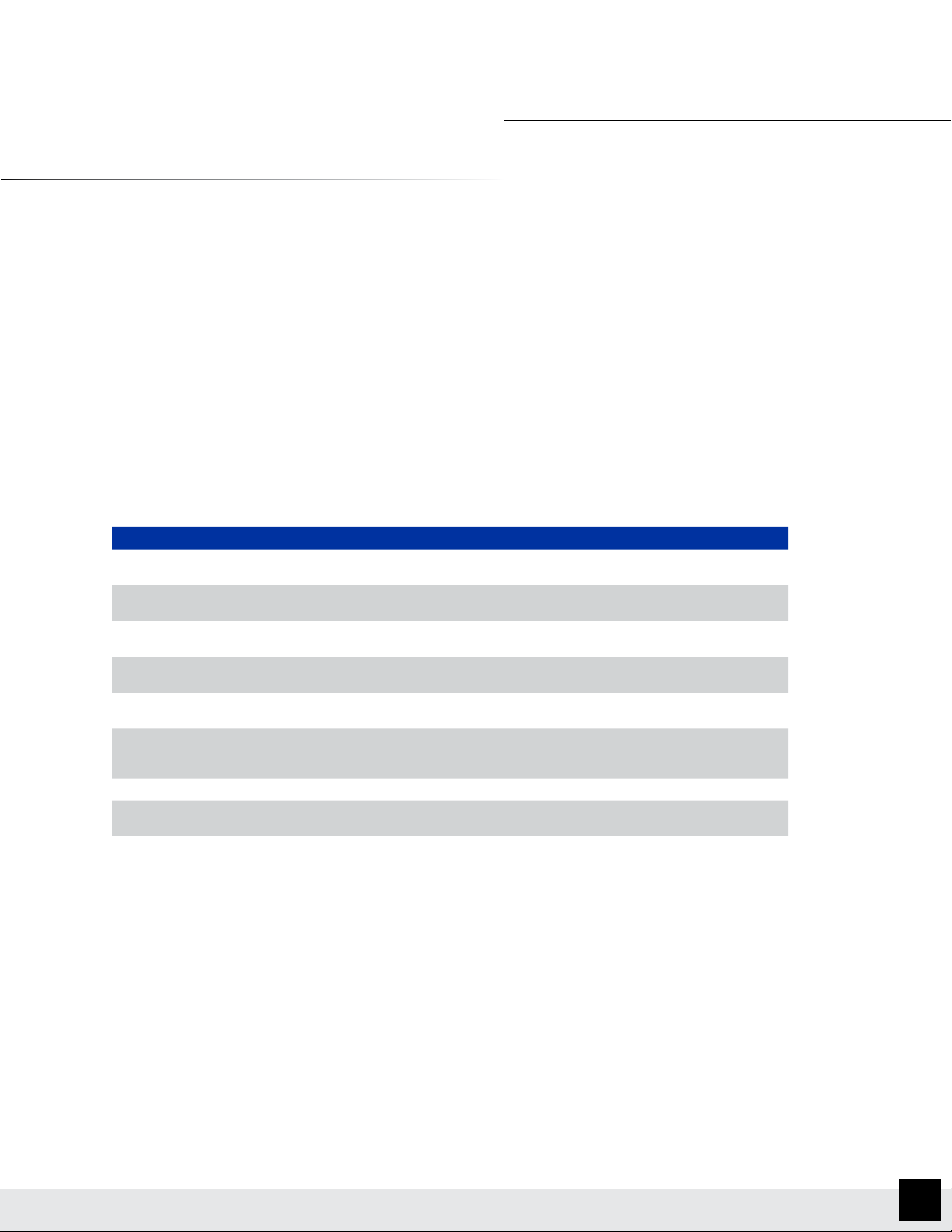

Technical Specifications

Husky 1050 Plastic Pumps Conductive Polypropylene Polypropylene PVDF

Maximum fluid working pressure 125 psi (8.6 bar, 0.86 MPa) 125 psi (8.6 bar, 0.86 MPa) 125 psi (8.6 bar, 0.86 MPa)

Maximum free flow delivery 50 gpm (189 lpm) 50 gpm (189 lpm) 50 gpm (189 lpm)

Maximum pump speed 280 cpm 280 cpm 280 cpm

Displacement per cycle 0.17 gal (0.64 liters) 0.17 gal (0.64 liters) 0.17 gal (0.64 liters)

Maximum suction lift 16 ft (4.9 m) dry, 29 ft (8.8 m) wet 16 ft (4.9 m) dry, 29 ft (8.8 m) wet 16 ft (4.9 m) dry, 29 ft (8.8 m) wet

Maximum size pumpable solids 1/8 in (3.2 mm) 1/8 in (3.2 mm) 1/8 in (3.2 mm)

Sound Power*

at 70 psi (4.8 bar, 0.48 MPa) and 50 cpm

at 100 psi (7.0 bar, 0.7 MPa) and full flow

Sound Pressure**

at 70 psi (4.8 bar, 0.48 MPa) and 50 cpm

at 100 psi (7.0 bar, 0.7 MPa) and full flow

Maximum air consumption 67 scfm 67 scfm 67 scfm

Air consumption at 70 psi (4.8 bar, 0.48 MPa),

20 gpm (76 lpm)

Air pressure operating range 20-125 psi (1.4-8.6 bar,

Air inlet size 1/2 npt(f) 1/2 npt(f) 1/2 npt(f)

Fluid inlet size 1 in raised face ANSI/DIN flange 1 in raised face ANSI/DIN flange 1 in raised face ANSI/DIN flange

Fluid outlet size 1 in raised face ANSI/DIN flange 1 in raised face ANSI/DIN flange 1 in raised face ANSI/DIN flange

Weight 18 lb (8.2 kg) 18 lb (8.2 kg) 26 lb (11.8 kg)

Wetted parts polypropylene and material(s)

Non-wetted Parts

Center

Bolts

Instruction manual

Repair/parts manual

* Sound power measured per ISO-9614-2.

** Sound pressure was tested 3.28 ft (1 m) from equipment.

78 dBa

90 dBa

84 dBa

96 dBa

25 scfm 25 scfm 25 scfm

0.14-0.86 MPa)

chosen for seat, ball, and

diaphragm options

polypropylene

stainless steel

312877 312877 312877

313435 313435 313435

78 dBa

90 dBa

84 dBa

96 dBa

20-125 psi (1.4-8.6 bar,

0.14-0.86 MPa)

polypropylene and material(s)

chosen for seat, ball, and

diaphragm options

polypropylene

stainless steel

78 dBa

90 dBa

84 dBa

96 dBa

20-125 psi (1.4-8.6 bar,

0.14-0.86 MPa)

PVDF and material(s) chosen for

seat, ball, and diaphragm options

polypropylene

stainless steel

PROCESS EQUIPMENT CATALOG

21

Page 23

Husky 1050 Plastic Pumps

FLUID OUTLET PRESSURE psi (bar, MPa)

AIR CONSUMPTION scfm (m

/min)

Husky 1050 Performance

Polypropylene (1050P) and Conductive Polypropylene (1050C)

12.0 in.

(305 mm)

8.0 in.

(203 mm)

1/2 npt(f)

air inlet

Center Flange: 16.0 in. (406 mm)

End Flange: 15.2 in. (386 mm)

10.3"

5.0"

Performance Charts

120

(8.3, 0.83)

100

100

(7, 0.7)

(7, 0.7)

(5.5, 0.55)

(4.1, 0.41)

(2.8, 0.28)

(1.4, 0.14)

gpm

(lpm)

80

60

40

20

0

0

A

B

C

D

5

10

(19)

(38)15(57)20(76)25(95)30(114)

(Pump tested in water with inlet submerged)

AIR PRESSURE LEGEND

A

= at 125 psi (8.3 bar, 0.83 MPa) Air Consumption

= at 100 psi (7 bar, 0.7 MPa) Fluid Pressure

B

= at 70 psi (4.8 bar, 0.48 MPa)

C

= at 40 psi (2.8 bar, 0.28 MPa)

D

Mounting Pattern

FLUID FLOW gpm (lpm)

Dimensions

Center Flange: 16.0 in. (406 mm)

60

A

35

(133)

B

C

D

40

(152)45(152)

(1.68)

50

(1.4)

40

(1.12)

30

(0.84)

20

(0.56)

10

(0.28)

3

12.0 in.

(305 mm)

13.2 in.

(335 mm)

15.7 in.

(399 mm)

End Flange: 15.2 in. (386 mm)

8.0 in.

(203 mm)

3/4 npt(f)

air exhaust port

1 in. ANSI/DIN

flange

17.8 in.

(452 mm)

1/2 npt(f)

air inlet

Typical System Drawings

Husky 1050 Floor-Mount

2.5 in.

(63.5 mm)

1 in. ANSI/DIN flange

22

PROCESS EQUIPMENT CATALOG

Page 24

II 2 G

II 2 G c IIC T4

II 2 G c IIC T4

Husky 1050 Selector Tool

To order a Husky 1050, use the online selector tool at

www.graco.com/process or contact your distributor.

CONFIGURATION NO..ON LAIRES.ON TRAP

SERIESDATE CODE

MADE IN

MAX WPR PSI-bar

Pump ID

NOTE: Options for seats, check balls, diaphragms, and seals

vary for the 1050A, 1050C, 1050F, 1050H, 1050P, and 1050S

pump models.

Husky 1050 Metal Pumps

Air-Operated Double Diaphragm

Example of Product Selector Tool on www.graco.com/process.

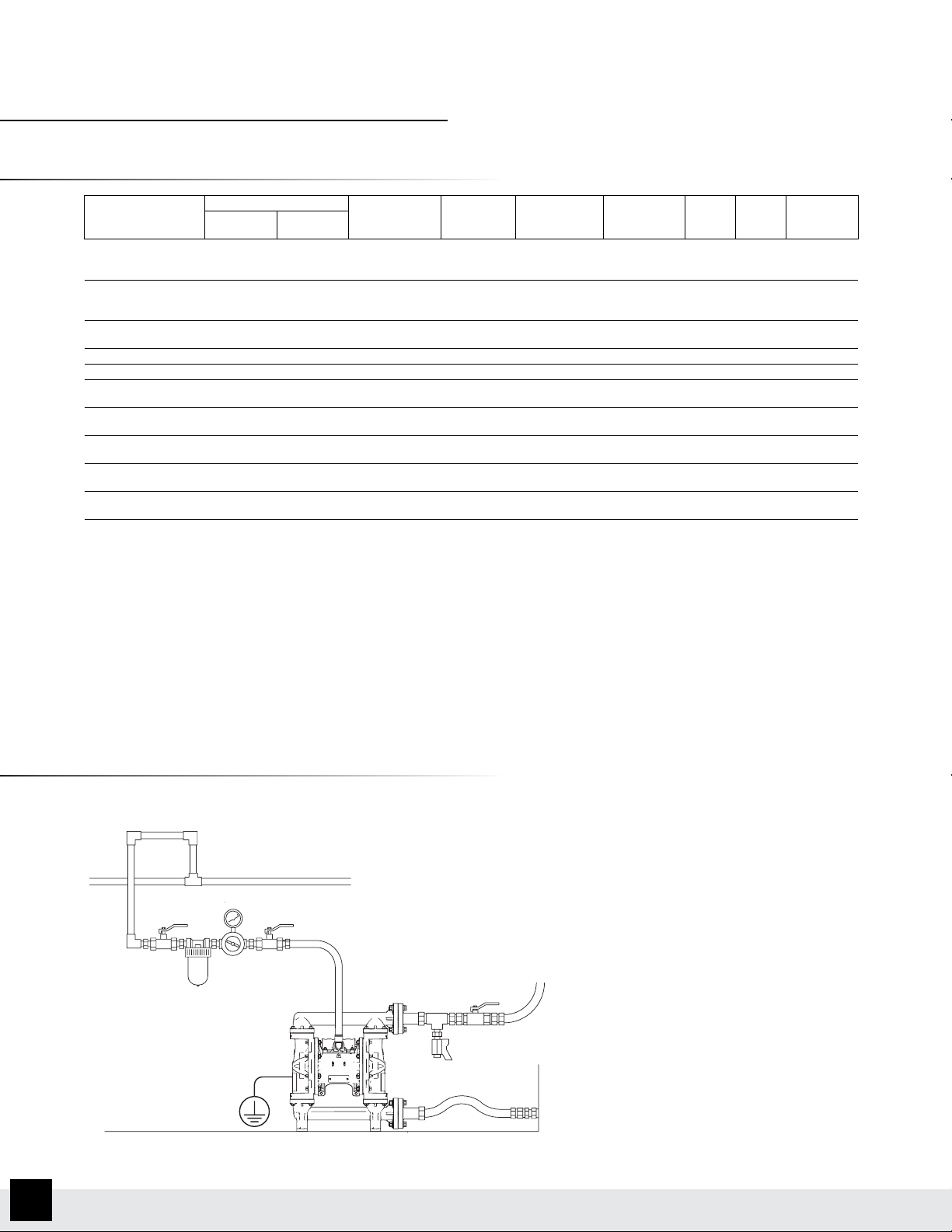

Pump Configuration Options

Pump

(1 inch ports, 50 gpm)

A ★

Aluminum 1050

S ‡

Stainless Steel 1050

H

Hastelloy 1050

★, ‡, or ✖: See ATEX Certifications below.

Check Valve Seats Check Valve Balls Diaphragm Manifold O-Rings

AC Acetal AC Acetal BN Buna-N — None

AL Aluminum BN Buna-N CO Polychloroprene Overmolded PT PTFE

BN Buna-N CR Polychloroprene Standard FK FKM Fluoroelastomer

FK FKM Fluoroelastomer CW Polychloroprene Weighted GE Geolast

GE Geolast® FK FKM Fluoroelastomer PO PTFE/EPDM Overmolded

PP Polypropylene GE Geolast PT PTFE/EPDM Two-Piece

SP Santoprene® PT PTFE SP Santoprene

SS 316 Stainless Steel SP Santoprene TP TPE

TP TPE SS 316 Stainless Steel

Center Section and

Air Valve Material Air Valve/Monitoring Fluid Covers and Manifolds

Aluminum

Conductive

Polypropylene

Polypropylene

TP TPE

A01 Standard

A01B Pulse Count ✖

A01C DataTrak ✖

A01D Remote

C01A Standard

P01A Standard

P01B Pulse Count ✖

P01C DataTrak ✖

P01D Remote

A1 Aluminum, standard ports, inch

A2 Aluminum, standard ports, metric

S1 Stainless steel, standard ports, inch

S2 Stainless steel, standard ports, metric

H1 Hastelloy, standard ports, inch

H2 Hastelloy, standard ports, metric

ATEX Certifications

★

All Aluminum 1050 pumps are certified: ‡ Stainless Steel pumps with aluminum or

conductive polypropylene centers are certified:

✖ DataTrak and Pulse Count are certified:

EEx ia IIA T3

Nemko

06ATEX1124

PROCESS EQUIPMENT CATALOG

23

Page 25

Husky 1050 Metal Pumps

Popular Models

Part Number

Material

Aluminum 647666 647502

Stainless Steel 651009 651125 316 SST PTFE

Hastelloy 651440 FKM PTFE

Standard

Air Valve

647016

(UL Certified)

647075 647561 Acetal PTFE

647040 647526 Geolast Geolast Geolast 24B766 24B633 24B641 24B623

647035 647521 Santoprene Santoprene Santoprene 24B766 24B636 24B646 24B628

647028 647514 316 SST PTFE

647004 647490 Polypropylene PTFE

647018 647504 316 SST 316 SST

Remote

Air Valve

Materials for

Seats

Thermoplastic

Polyester

Elastomer

Thermoplastic

Polyester

Elastomer

Materials for

Balls

Acetal

Acetal

Materials for

Diaphragms

Thermoplastic

Polyester

Elastomer

Thermoplastic

Polyester

Elastomer

PTFE/EPDM

2 Piece

PTFE/EPDM

2 Piece

PTFE/EPDM

2 Piece

PTFE/EPDM

2 Piece

PTFE/EPDM

2 Piece

PTFE/EPDM

2 Piece

Air Valve

Replacement

Kit Seat Kit Ball Kit

24B766 24B634 24B639 24B624

24B766 24B634 24B639 24B624

24B766 24B630 24B645 24B627

24B766 24B637 24B645 24B627

24B766 24B635 24B645 24B627

24B766 24B637 24B647 24B627

24B766 24B637 24B645 24B627

24B773 24B638 24B645 24B627

Diaphragm

Kit

24

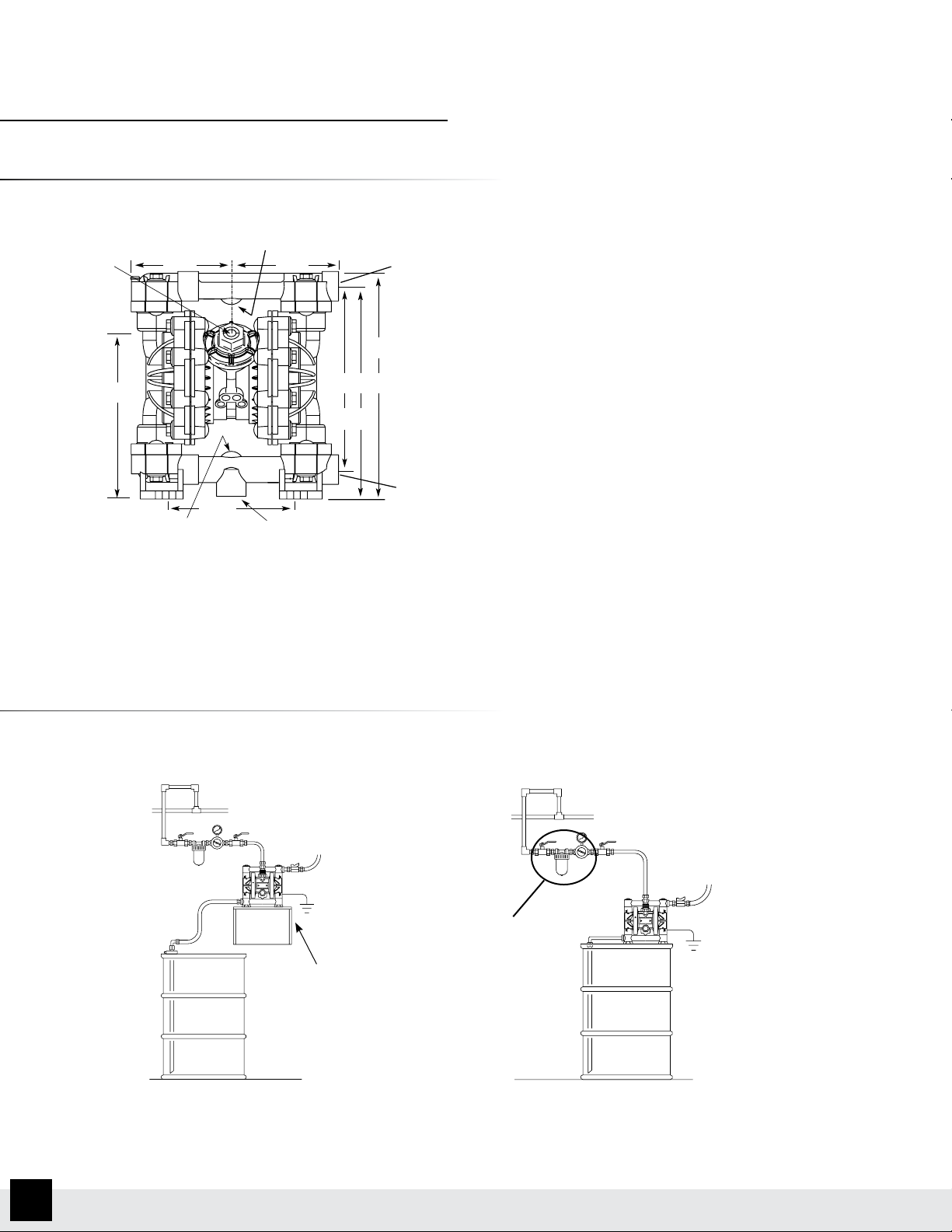

Typical System Drawings

Husky 1050 Floor-Mount

PROCESS EQUIPMENT CATALOG

Page 26

FLUID OUTLET PRESSURE psi (bar, MPa)

AIR CONSUMPTION scfm (m

/min)

Husky 1050 Performance

FLUID FLOW gpm (lpm)

(Pump tested in water with inlet submerged)

AIR CONSUMPTION scfm (m

3

/min)

5

(19)

10

(0.28)

30

(0.84)

20

(0.56)

40

(1.12)

50

(1.4)

60

(1.68)

10

(38)15(57)20(76)25(95)30(114)

40

(152)45(152)

35

(133)

Husky 1050 Performance

A

B

D

C

A

B

C

D

(8.3, 0.83)

(5.5, 0.55)

(4.1, 0.41)

(2.8, 0.28)

(1.4, 0.14)

Husky 1050 Metal Pumps

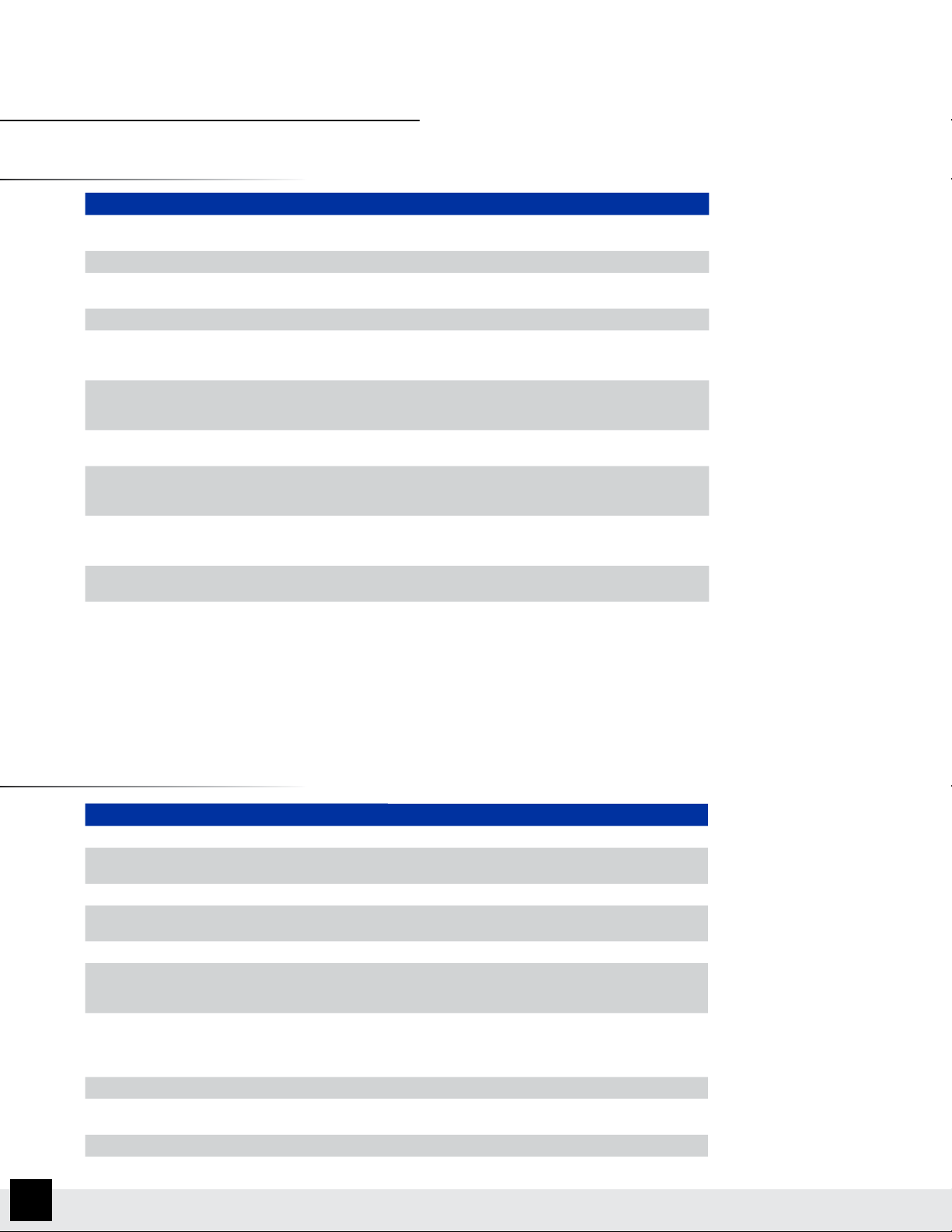

Technical Specifications

Husky 1050 Metal Pumps Aluminum Stainless Steel Hastelloy

Maximum fluid working pressure 125 psi (8.6 bar, 0.86 MPa) 125 psi (8.6 bar, 0.86 MPa) 125 psi (8.6 bar, 0.86 MPa)

Maximum free flow delivery 50 gpm (189 lpm) 50 gpm (189 lpm) 50 gpm (189 lpm)

Maximum pump speed 280 cpm 280 cpm 280 cpm

Displacement per cycle 0.17 gal (0.64 liters) 0.17 gal (0.64 liters) 0.17 gal (0.64 liters)

Maximum suction lift 16 ft (4.9 m) dry,

29 ft (8.8 m) wet

Maximum size pumpable solids 1/8 in (3.2 mm) 1/8 in (3.2 mm) 1/8 in (3.2 mm)

Sound Power*

at 70 psi (4.8 bar, 0.48 MPa) and 50 cpm

at 100 psi (7.0 bar, 0.7 MPa) and full flow

78 dBa

90 dBa

Sound Pressure**

at 70 psi (4.8 bar, 0.48 MPa) and 50 cpm

at 100 psi (7.0 bar, 0.7 MPa) and full flow

84 dBa

96 dBa

Maximum air consumption 67 scfm 67 scfm 67 scfm

Air consumption at 70 psi (4.8 bar,

25 scfm 25 scfm 25 scfm

0.48 MPa),20 gpm (76 lpm)

Air pressure operating range 20-125 psi (1.4-8.6 bar,

0.14-0.86 MPa)

Air inlet size 1/2 npt(f) 1/2 npt(f) 1/2 npt(f)

Fluid inlet size 1 in npt(f) or 1 in bspt 1 in npt(f) or 1 in bspt 1 in npt(f) or 1 in bspt

Fluid outlet size 1 in npt(f) or 1 in bspt 1 in npt(f) or 1 in bspt 1 in npt(f) or 1 in bspt

Weight 23 lb (10.5 kg) with conductive

Wetted parts aluminum and material(s)

chosen for seat, ball, and

diaphragm options

Non-wetted Parts

Center

Bolts

Instruction manual

Repair/parts manual

* Sound power measured per ISO-9614-2. ** Sound pressure was tested 3.28 ft (1 m) from equipment.

Performance Charts

120

100

100

(7, 0.7)

(7, 0.7)

80

60

40

20

0

0

gpm

(lpm)

C

D

5

(19)

A

B

10

(38)15(57)20(76)25(95)30(114)

(Pump tested in water with inlet submerged)

FLUID FLOW gpm (lpm)

aluminum

coated carbon steel

312877 312877 312877

313435 313435 313435

A

35

(133)

B

C

D

40

(152)45(152)

16 ft (4.9 m) dry,

29 ft (8.8 m) wet

78 dBa

90 dBa

84 dBa

96 dBa

20-125 psi (1.4-8.6 bar,

0.14-0.86 MPa)

polypropylene center 36.3 lb (16.5 kg)

with polypropylene center 37.3 lb (16.9 kg)

with aluminum center 41.4 lb (18.8 kg)

stainless steel and material(s) chosen for seat,

ball, and diaphragm options

polypropylene

stainless steel

60

(1.68)

50

(1.4)

3

40

(1.12)

30

(0.84)

20

(0.56)

10

(0.28)

aluminum

stainless steel

AIR PRESSURE LEGEND

A

= at 125 psi (8.3 bar, 0.83 MPa) Air Consumption

= at 100 psi (7 bar, 0.7 MPa) Fluid Pressure

B

= at 70 psi (4.8 bar, 0.48 MPa)

C

= at 40 psi (2.8 bar, 0.28 MPa)

D

PROCESS EQUIPMENT CATALOG

16 ft (4.9 m) dry,

29 ft (8.8 m) wet

78 dBa

90 dBa

84 dBa

96 dBa

20-125 psi (1.4-8.6 bar,

0.14-0.86 MPa)

41 lb (18.6 kg)

hastelloy, stainless steel and

material(s) chosen for seat, ball, and

diaphragm options

polypropylene

stainless steel

25

Page 27

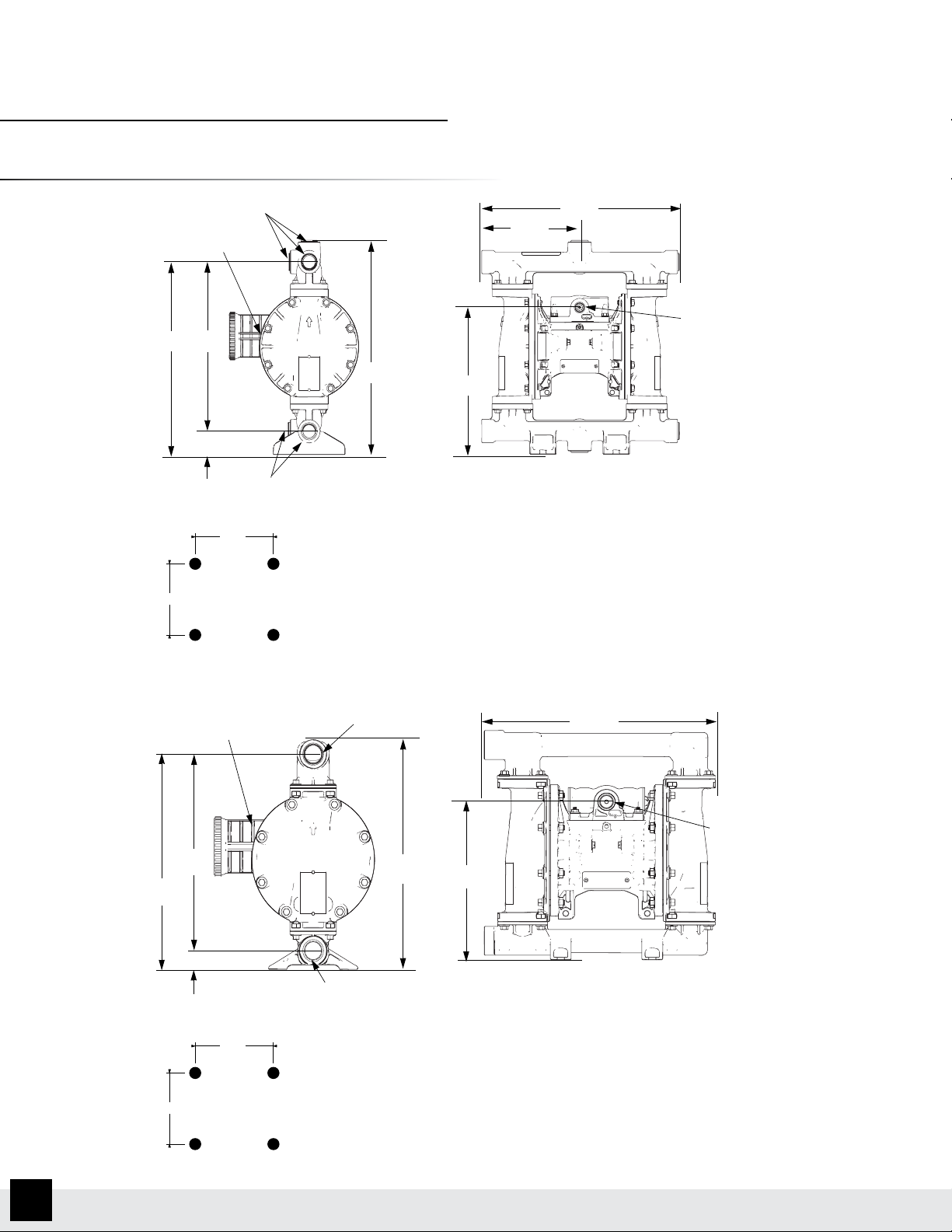

Husky 1050 Metal Pumps

Aluminum (1050A)

Stainless Steel (1050S)

5.5"

5.0"

5.5"

5.0"

Dimensions

Aluminum

1 in. npt(f) or 1 in. bspt

fluid outlet ports (4)

3/4 npt(f) air exhaust port

14.4 in.

12.7 in.

(366 mm)

(323 mm)

1.8 in.

(46 mm)

Mounting Pattern

15.9 in.

(404 mm)

1 in. npt(f) or 1 in. bspt fluid inlet ports (4)

10.9 in.

(277 mm)

7.3 in.

(185 mm)

14.7 in.

(373 mm)

1/2 npt(f)

air inlet

Stainless Steel and Hastelloy

3/4 npt(f) air exhaust port

11.8 in.

(300 mm)

12.9 in.

(328 mm)

1.1 in. (28 mm)

Mounting Pattern

1 in. npt(f) or 1 in. bspt fluid outlet ports (4)

13.7 in.

(348 mm)

1 in. npt(f) or 1 in. bspt fluid inlet ports (4)

9.5 in.

(241 mm)

13.9 in.

(353 mm)

1/2 npt(f)

air inlet

26

PROCESS EQUIPMENT CATALOG

Page 28

Husky 1050HP Metal Pumps

HIgh Pressure Air-Operated Diaphragm

Pump Configuration Options

Pump Center Section and Air Valve Material Air Valve Manifolds

1050HP

Aluminum

Aluminum A01A Standard A1

A2

S1

S2

Check Valve Seats Check Valve Balls Diaphragm Material Manifold O-Rings

SS 316 Stainless Steel SP Santoprene SP Santoprene PT PTFE

Popular Models

Part No. Seat Ball Fluid Diaphragm Center Diaphragm Fluid Covers Fluid Manifold Porting

24W756 Stainless Steel Santoprene Santoprene Santoprene Stainless Steel Aluminum

24W757 Stainless Steel Santoprene Santoprene Santoprene Stainless Steel Aluminum

24W758 Stainless Steel Santoprene Santoprene Santoprene Stainless Steel Stainless Steel

24W759 Stainless Steel Santoprene Santoprene Santoprene Stainless Steel Stainless Steel

24W762 Santoprene Santoprene Santoprene Santoprene Stainless Steel Aluminum

24W763 Santoprene Santoprene Santoprene Santoprene Stainless Steel Aluminum

24W764 Geolast Geolast Buna Santoprene Stainless Steel Aluminum

24W765 Geolast Geolast Buna Santoprene Stainless Steel Aluminum

24W766 Stainless Steel Weighted Neoprene Buna Santoprene Stainless Steel Aluminum

24W767 Stainless Steel Weighted Neoprene Buna Santoprene Stainless Steel Aluminum

24W768 Stainless Steel Weighted Neoprene Neoprene Overmold Santoprene Stainless Steel Aluminum

24W769 Stainless Steel Weighted Neoprene Neoprene Overmold Santoprene Stainless Steel Aluminum

24X388 Stainless Steel Stainless Steel 2-piece PTFE/Santoprene Santoprene Stainless Steel Stainless Steel

24X389 Stainless Steel Stainless Steel 2-piece PTFE/Santoprene Santoprene Stainless Steel Stainless Steel

Aluminum, Standard Ports, NPT

Aluminum, Standard Ports, BSP

Stainless Steel, Standard Ports, NPT

Stainless Steel, Standard Ports, BSP

NPT

BSPT

NPT

BSPT

NPT

BSPT

NPT

BSPT

NPT

BSPT

NPT

BSPT

NPT

BSPT

PROCESS EQUIPMENT CATALOG

27

Page 29

Husky 1050HP Metal Pumps

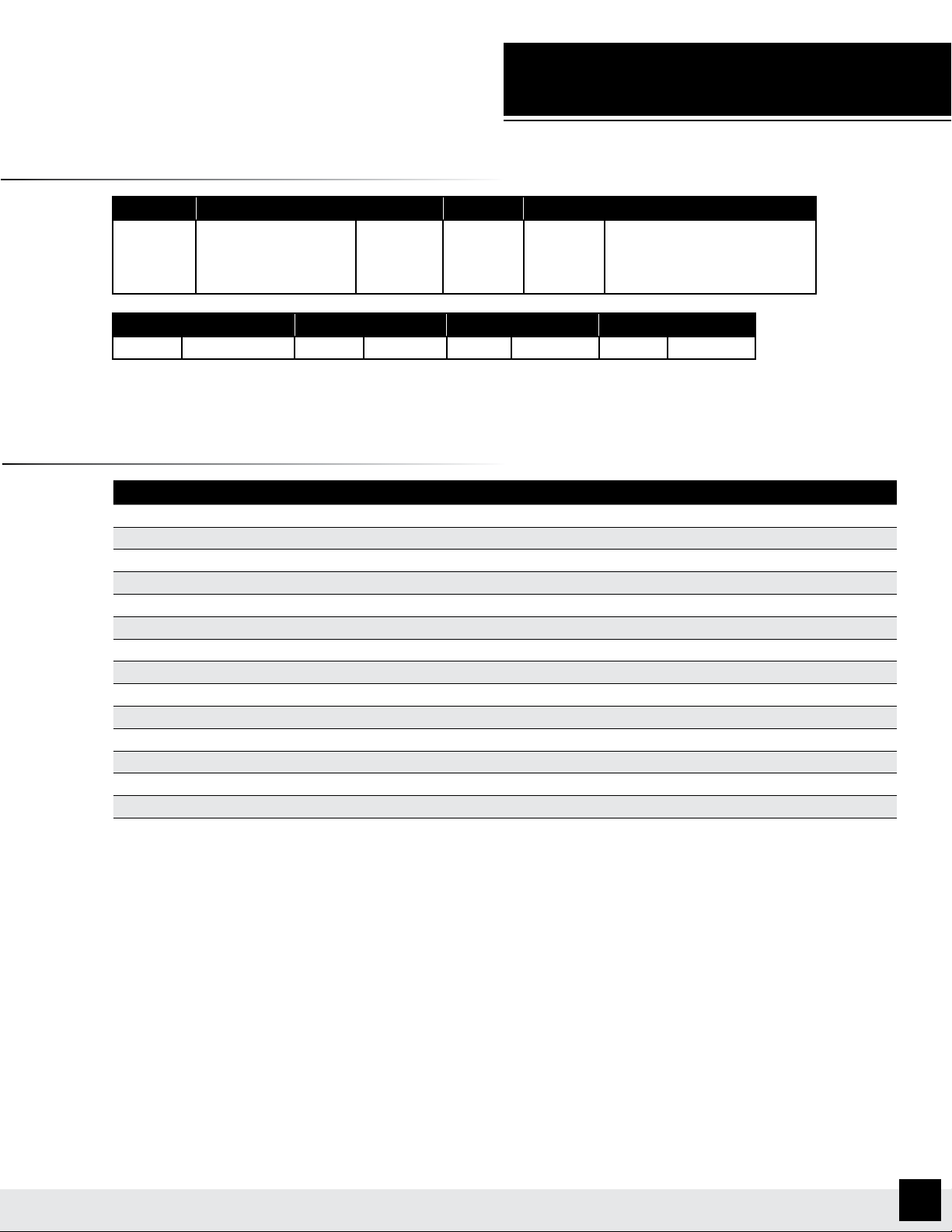

Technical Specifications

Maximum fluid working pressure .................................................................... 250 psi (14 bar, 1.4 MPa)

Air pressure operating range ............................................................ 20-125 psi (1.4-6.9 bar, 0.14-0.69 MPa)

Fluid displacement per cycle

Low Pressure Setting................................................................................0.17 gal (0.64 l)

High Pressure Setting ...............................................................................0.20 gal (0.76 l)

Air consumption at 70 psi (4.8 bar), 20 gpm (76 lpm)

Low Pressure Setting............................................................................26 scfm (0.7 m3/min)

High Pressure Setting ..........................................................................51 scfm (1.4 m3/min)

Maximum values with water as media under submerged inlet conditions at ambient temperature:

Maximum air consumption

Low Pressure Setting .........................................................................59 scfm (1.7 m3/min)

High Pressure Setting .........................................................................95 scfm (2.7 m3/min)

Maximum free-flow delivery

Low Pressure Setting ........................................................................... 50 gpm (189 lpm)

High Pressure Setting ........................................................................... 46 gpm (174 lpm)

Maximum pump speed

Low Pressure Setting .................................................................................. 280 cpm

High Pressure Setting .................................................................................. 225 cpm

Maximum suction lift*

Dry ................................................................................................16 ft (4.9 m)

Wet ...............................................................................................29 ft (8.8 m)

Maximum size pumpable solids .............................................................................1/8 in (3.2 mm)

Recommended cycle rate for continuous use ....................................................93–140 cpm (in Low or High setting)

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4 npt(f)

Fluid inlet size.........................................................................................1 in npt(f) or bspt

Fluid outlet size........................................................................................1 in npt(f) or bspt

Weight

Aluminum manifolds .................................................................................48 lb (21.8 kg)

SST manifolds......................................................................................60 lb (27.2 kg)

Wetted parts.................................. aluminum or stainless steel plus the material(s) chosen for seat, ball, and diaphragm options

Non-wetted external parts ...................................................................aluminum, coated carbon steel, sst

*Varies based on ball/seat selection and wear, operating speed, material properties, and other variables

28

PROCESS EQUIPMENT CATALOG

Page 30

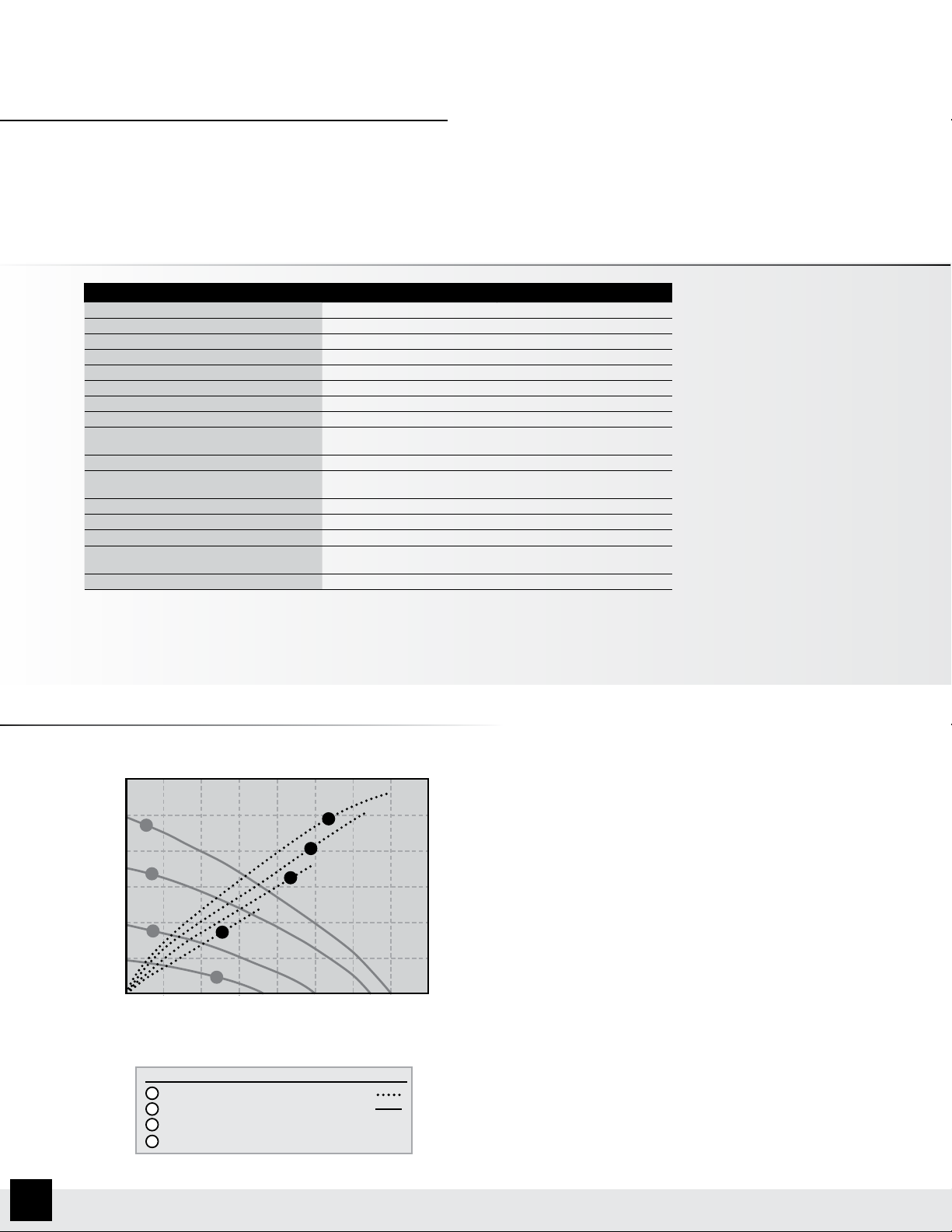

Performance Charts

AIR CONSUMPTION

Low Pressure Setting

56 112 168 224 280

A

B

C

D

E

10

(38)

FLUID OUTLET PRESSURE psi (bar, MPa)

(8.6, 0.86)

100

(7, 0.7)

(5.2, 0.52)

(3.4, 0.34)

(1.7, 0.17)

gpm

(lpm)

125

75

50

25

0

0

Husky 1050HP Performance

Approx. Cycles per Minute

A

C

E

20

(76)

(Pump tested in water with inlet submerged)

FLUID FLOW

30

(114)

Husky 1050HP Metal Pumps

100

(2.8)

80

(2.3)

/min)

3

scfm (m

60

50

(189)

(1.7)

40

(1.1)

20

(0.6)

B

D

40

(151)

AIR PRESSURE LEGEND

A

B

C

D

High Pressure Setting

250

(17, 1.7)

A

200

(13, 1.3)

B

150

(10, 1.0)

C

100

(7, 0.7)

D

50

FLUID OUTLET PRESSURE psi (bar, MPa)

(3.4, 0.34)

gpm

(lpm)

E

0

0

= at 125 psi (8.3 bar, 0.83 MPa) Air Consumption

= at 100 psi (7 bar, 0.7 MPa) Fluid Pressure

= at 70 psi (4.8 bar, 0.48 MPa)

= at 40 psi (2.8 bar, 0.28 MPa)

Husky 1050HP Performance

Approx. Cycles per Minute

50 100 150 200 250

A

B

C

D

E

(38)

10

20

(76)

(Pump tested in water with inlet submerged)

FLUID FLOW

(114)

30

40

(151)

50

(189)

125

(3.5)

100

(2.8)

75

(2.1)

50

(1.4)

25

(0.7)

/min)

3

AIR CONSUMPTION scfm (m

AIR PRESSURE LEGEND

A

= at 125 psi (8.3 bar, 0.83 MPa) Air Consumption

= at 100 psi (7 bar, 0.7 MPa) Fluid Pressure

B

= at 70 psi (4.8 bar, 0.48 MPa)

C

= at 40 psi (2.8 bar, 0.28 MPa)

D

PROCESS EQUIPMENT CATALOG

29

Page 31

Husky 1050HP Metal Pumps

Dimensions

A

C

B

E

1 in npt(f) or bspt

Fluid Outlet

Key Aluminum SST

A 12.7 in (323 mm) 11.8 in (300 mm)

B 14.4 in (366 mm) 12.9 in (328 mm)

C 15.3 in (389 mm) 13.7 in (348 mm)

D 10.9 in (277 mm) 9.5 in (241 mm)

E 1.8 in (46 mm) 1.1 in (28 mm)

F 10.8 in (274 mm) 10.7 in (272 mm)

G 21.5 in (546 mm) 20.6 in (523 mm)

All dimensions are approximate

3/4 npt(f)

Air Inlet

1 in npt(f) or bspt

Fluid Outlet

1 in npt(f) or bspt

Fluid Inlet

15.6 in

(396 mm)

9.4 in

(239 mm)

6.2 in

(157 mm)

D

1 in npt(f) or bspt

F

G

12.3 in

(312.4 mm)

3/4 npt(f)

Air Exhaust Port

Fluid Inlet

5.0 in

(127 mm)

30

PROCESS EQUIPMENT CATALOG

Page 32

Husky 1590 Selector Tool

To order a Husky 1590, use the online selector tool at

www.graco.com/process or contact your distributor.

CONFIGURATION NO..ON LAIRES.ON TRAP

SERIESDATE CODE

MADE IN

MAX WPR PSI-bar

Pump ID

NOTE: Check the identification plate (ID) for the Configuration

Number of your pump. Use the following matrix to

define the components of your pump.

Husky 1590 Plastic Pumps

Air-Operated Double Diaphragm

Example of Product Selector Tool on www.graco.com/process.

Pump Configuration Options

Pump

(1.5 inch ports,

90 gpm)

P

Polypropylene 1590

F

PVDF 1590

Check Valve Seats Check Valve Balls Diaphragm Manifold O-Rings

BN Buna-N AC Acetal BN Buna-N — None

FK Fluoroelastomer BN Buna-N FK Fluoroelastomer PT PTFE

GE Geolast FK Fluoroelastomer GE Geolast

PP Polypropylene GE Geolast PT PTFE/EPDM Two-Piece

PV PVDF PT PTFE PT PTFE/EPDM Two-Piece

SA 17-4 Stainless Steel SD 440C Stainless Steel SP Santoprene

SP Santoprene SP Santoprene TP TPE

SS 316 Stainless Steel TP TPE

TP TPE

Center Section and

Air Valve Material Air Valve/Monitoring Fluid Covers and Manifolds

Aluminum

Stainless Steel

A01A Standard w/Buna Seals

A01D Remote w/ Buna Seals

S01A Standard

S01D Remote

F1 PVDF, center Flange

P1 Polypropylene, center flange

PROCESS EQUIPMENT CATALOG

31

Page 33

Husky 1590 Plastic Pumps

Ordering Information

D X X X X X

Diaphragm

Pump

Pump

Size

Wetted

Parts

Seats

Balls/

Checks

Diaphragms

PUMP SIZE

B = 1-1/2” (38.1 mm) Standard: aluminum center section 2 = Poly (flange) 3 = Stainless Steel 1 = PTFE 1 = PTFE

C = 1-1/2” (38.1 mm) Remote: aluminum center section 5 = PVDF (flange) 4 = Hardened SST 2 = Acetal 5 = TPE

T = 1-1/2” (38.1 mm) Standard: stainless steel center section 5 = TPE 4 = Hardened SST 6 = Santoprene

U = 1-1/2” (38.1 mm) Remote: stainless steel center section 6 = Santoprene 5 = TPE 7 = Buna N

(air motor type and material)

WETTED PARTS SEATS BALLS DIAPHRAGM

7 = Buna N 6 = Santoprene 8 = Fluoroelastomer

8 = Fluoroelastomer 7 = Buna N G = Geolast

9 = Polypropylene 8 = Fluoroelastomer

A = PVDF G = Geolast

G = Geolast

Popular Models

Part Number Part Number

(ANSI-Flange) (BSP Ported)

Material Air Valve Air Valve Air Valve Air Valve Seats Balls Diaphragms Kit Air Kit Control**

Standard Pumps with Aluminum Center Section

Polypropylene DB2311 Stainless Steel PTFE PTFE D0C311 236273 246947

*Requires CycleFlo or external valve control

** Air control includes air regulator and filter with gauge

Standard Remote* Standard Remote* Materials for Materials for Materials for Fluid Air

DB2377 DC2377 Stainless Steel Buna Buna D0C377 236273 246947

DB2777 DC2777 Buna Buna Buna D0C777 236273 246947

DB2888 DC2888 Fluoroelastomer Fluoroelastomer Fluoroelastomer D0C888 236273 246947

DB2911 DC2911 Polypropylene PTFE PTFE D0C911 236273 246947

DB2955 Polypropylene TPE TPE D0C955 236273 246947

DB2966 Polypropylene Santoprene Santoprene D0C966 236273 246947

DB2977 Polypropylene Buna Buna D0C977 236273 246947

DB2988 Polypropylene Fluoroelastomer Fluoroelastomer D0C988 236273 246947

DB29GG DC29GG Polypropylene Geolast Geolast D0C9GG 236273 246947

32

PROCESS EQUIPMENT CATALOG

Page 34

Husky 1590 Plastic Pumps

Technical Specifications

Husky 1590 Plastic Pumps Polypropylene PVDF

Maximum fluid working pressure 120 psi (8.4 bar, 0.84 MPa) 120 psi (8.4 bar, 0.84 MPa)

Maximum free flow delivery* 100 gpm (378.5 lpm) 100 gpm (378.5 lpm)

Maximum pump speed 200 cpm 200 cpm

Displacement per cycle** 0.5 gallon (1.96 liter) 0.5 gallon (1.96 liter)

Maximum suction lift (DB2366) 20 ft (6.1 m) dry 20 ft (6.1 m) dry

Maximum size pumpable solids 0.19 in (4.8 mm) 0.19 in (4.8 mm)

Maximum operating temperature*** 150°F (65.5°C) 150°F (65.5°C)

Maximum diaphragm operating temperature***

PTFE

Santoprene

Buna-N

TPE

Fluoroelastomer

Geolast

Typical sound level at 70 psi

(4.9 bar, 0.49 MPa) air @ 125 cpm

Maximum air consumption 125 scfm (3.5 m3/min.) 125 scfm (3.5 m3/min.)

Air pressure operating range 20 to 120 psi

Air inlet size 1/2 npt(f) 1/2 npt(f)

Fluid inlet & outlet size**** 1-1/2 in (38.1 mm) ANSI-flange 1-1/2 in (38.1 mm) ANSI-flange

Weight 35 lb (16 kg) 49 lb (22 kg)

Weight with stainless steel center section 48.3 lb (21.9 kg) 62.3 lb (28.2 kg)

Instruction manual

* Flow rates are with muffler and do not vary based on diaphragm material

** Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type

*** Actual pump performance may be affected by prolonged usage at temperature

220°F (104.4°C)

180°F (82.2°C)

180°F (82.2°C)

150°F (65.5°C)

250°F (121.1°C)

150°F (65.5°C)

77 dBa 77 dBa

(1.4 to 8.4 bar, 0.14 to 0.84 MPa)

308549 308549

220°F (104.4°C)

180°F (82.2°C)

180°F (82.2°C)

150°F (65.5°C)

250°F (121.1°C)

150°F (65.5°C)

20 to 120 psi

(1.4 to 8.4 bar, 0.14 to 0.84 MPa)

PROCESS EQUIPMENT CATALOG

33

Page 35

Husky 1590 Plastic Pumps

(76 mm)

Performance Charts

120

(8.4, 0.84)

100

100

(7, 0.7)

FLUID OUTLET PRESSURE psi (bar, MPa)

(7, 0.7)

(5.5, 0.55)

(4.1, 0.41)

(2.8, 0.28)

(1.4, 0.14)

gpm

(lpm)

B

80

60

40

D

20

0

0

20

(76)

AIR PRESSURE LEGEND

A

= at 120 psi (8.4 bar, 0.84 MPa) Air Consumption

= at 100 psi (7 bar, 0.7 MPa) Fluid Pressure

B

= at 70 psi (4.8 bar, 0.48 MPa)

C

= at 40 psi (2.8 bar, 0.28 MPa)

D

Husky 1590 Performance

A

B

C

D

40

(152)

(Pump tested in water with inlet submerged

(227)80(303)

FLUID FLOW

C

60

Dimensions

7.55 in

100

(2.80)

A

100

(379)

120

(454)

85

(2.38)

70

(1.96)

55

(1.54)

40

(1.12)

25

(0.70)

/min)

3

AIR CONSUMPTION scfm (m

11.99 in

(304.5 mm)

3/4 npt(f)

Air Exhaust

(muffler included)

(191.77 mm)

6.0 in (152.5 mm)

17.55 in (445.5 mm)

1/2 npt(f)

Air Inlet

10 in

(254 mm)

Outlet Port ID:

1.75 in (44.5 mm)

Flange Diameter:

5.5 in (140 mm)

Eight Slots:

0.73 in (18.5 mm)

16.25 in

(412.5 mm)

(552.5 mm)

19.25 in