Page 1

Instructions - Parts List

Manuel d’instructions – Liste des pièces

Instrucciones – Lista de piezas

™

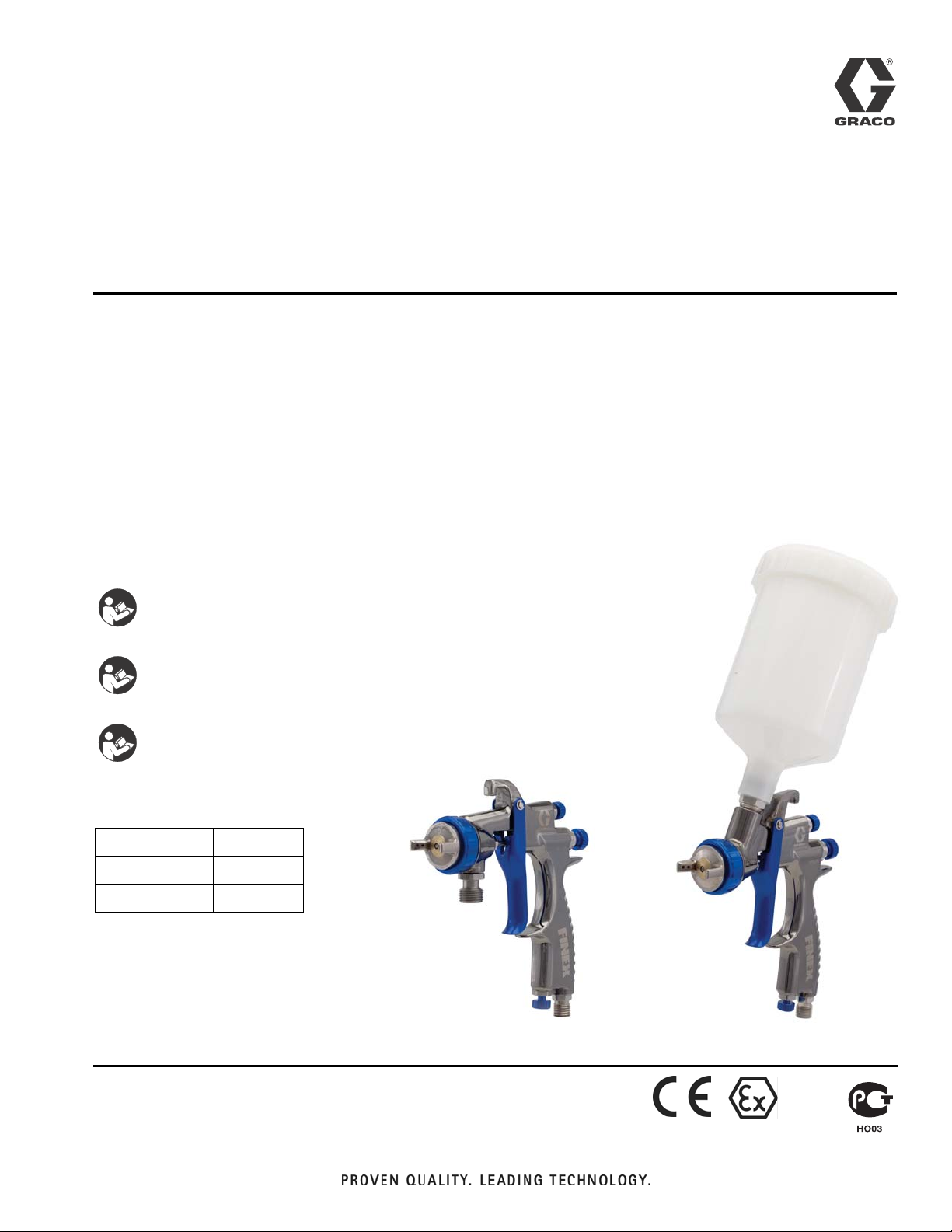

Finex

Gun

™

Pistolet Finex

™

Pistola Finex

For the spray application of paints and coatings.

Pour la pulvérisation de peintures et de revêtements.

Para la aplicación mediante pulverización de pinturas y revestimientos.

Includes Mini-HVLP, HVLP, and Conventional Styles with Pressure and Gravity Feeds.

See page 2 for list of models.

Comprend les styles Mini-HVLP, HVLP et Conventional à alimentation par pression ou par gravité.

Voir page 13 pour la liste des modèles.

Incluye Mini-HVLP, HVLP, y Estilos convencionales con alimentación a presión y por gravedad.

Consulte la página 24 para ver una lista de modelos.

100 psi (0.7 MPa, 7 bar) Maximum Working Fluid and Air Pressure

Pressions maximales de service et pneumatique : 100 psi (0,7 MPa, 7 bars)

Presión máxima de funcionamiento de aire y de fluido de 100 psi (0,7 MPa, 7 bar)

312388K

ENG FRA SPA

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Instructions de sécurité importantes

Lire toutes les mises en garde et instructions

de ce manuel. Sauvegarder ces instructions.

Instrucciones importantes de seguridad

Lea todas las advertencias e instrucciones

de este manual. Guarde las instrucciones.

English

Français

Español

page 2

page 13

página 25

Alimentation sous pression

Alimentación a presión

Gravity FeedPressure Feed

Alimentación por gravedad

Alimentation par gravité

II 2 G

Page 2

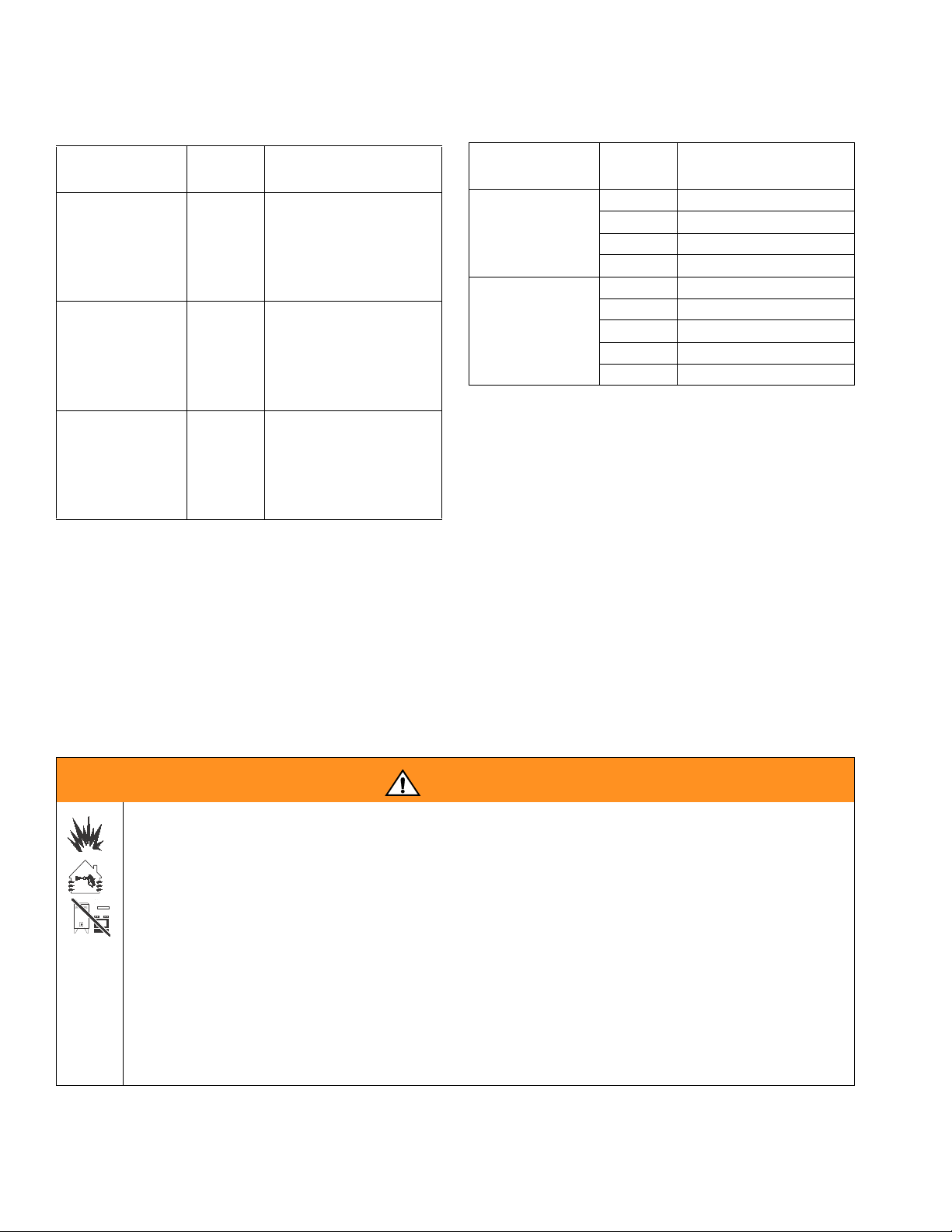

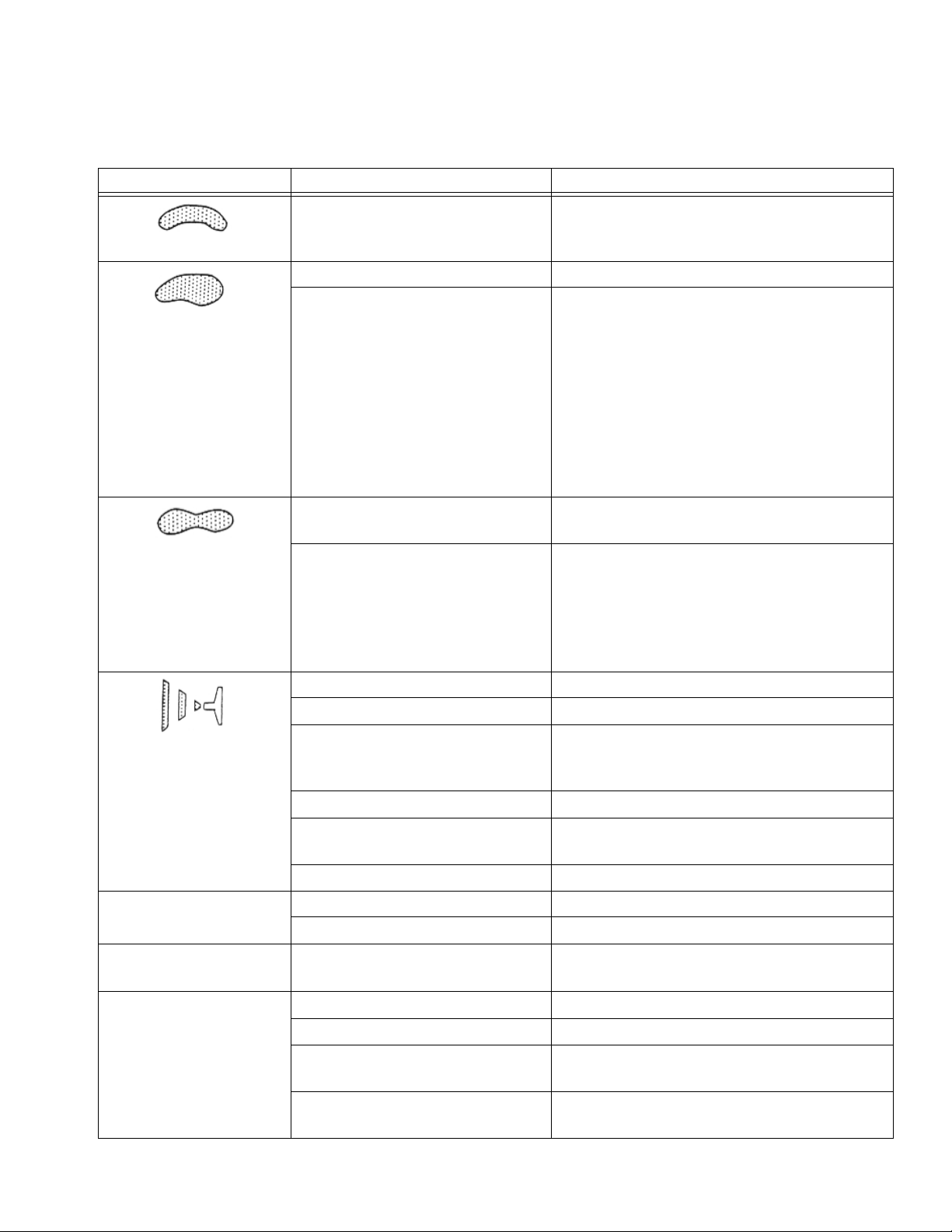

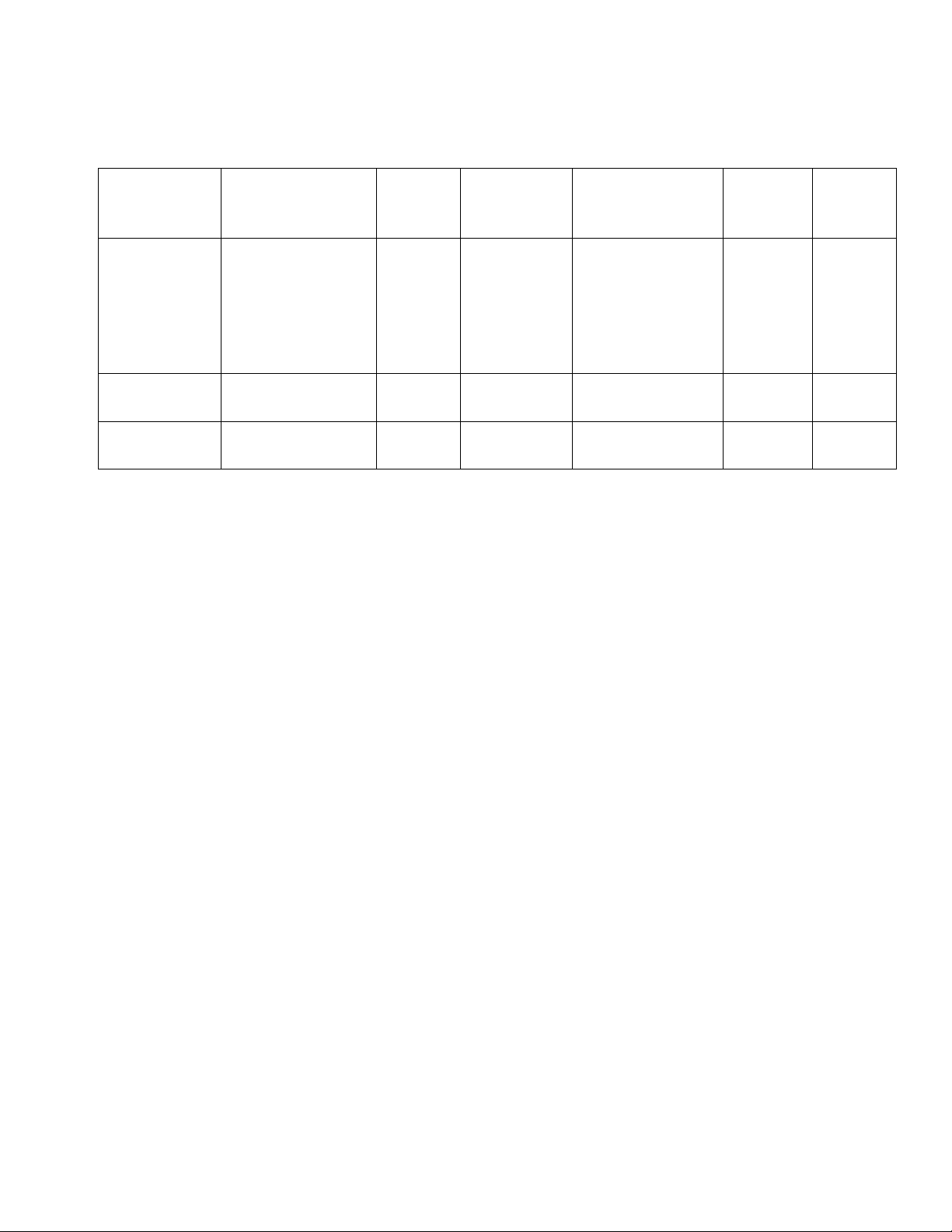

Models

Models

Gun Style Part No.

289256 0.024 (0.6)

Gravity Feed

Mini-HVLP

Gravity Feed

Conventional

Gravity Feed

HVLP

289257 0.031 (0.8)

289258 0.039 (1.0)

289259 0.047 (1.2)

289260 0.055 (1.4)

289242 0.039 (1.0)

289243 0.051 (1.3)

289244 0.055 (1.4)

289245 0.059 (1.5)

289246 0.071 (1.8)

289237 0.039 (1.0)

289238 0.051 (1.3)

289239 0.055 (1.4)

289240 0.059 (1.5)

289241 0.071 (1.8)

Needle/Nozzle Size

in (mm)

Gun Style Part No.

289247 0.039 (1.0)

Pressure

Feed HVLP

Pressure

Feed

Conventional

289248 0.047 (1.2)

289249 0.055 (1.4)

289250 0.071 (1.8)

289251 0.031 (0.8)

289252 0.039 (1.0)

289253 0.047 (1.2)

289254 0.055 (1.4)

289255 0.071 (1.8)

Needle/Nozzle Size

in (mm)

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol

refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific

warnings may be found throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode.

To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps,

and plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• If there is static sparking or you feel a shock, stop operation immediately. Do not

use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

2 312388K

Page 3

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest

rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See

Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s

warnings. For complete information about your material, request MSDS forms from

distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with

genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot

surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the

eyes or on skin and cause serious injury.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and

before cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts

immediately.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes

or on skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to

applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in

the operating area of the equipment to help protect you from serious injury, including

eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes

but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

312388K 3

Page 4

Setup

Setup

Reference numbers and letters in parentheses in the text refer to numbers and

letters in the illustrations.

Connecting Air Line

1. Install an air pressure regulator on gun air

supply line to control air pressure.

2. Install a shutoff valve downstream of the air

regulator to shut off gun air.

3. Connect a clean, dry, filtered air supply to

air inlet fitting (13). Connect other end to

shutoff valve.

Gravity feed guns:

1. Install fluid filter

(24) into fluid

inlet (A).

2. Screw on gravity

cup.

3. Remove gravity

cup cover and fill

cup with solvent

to flush if this is

first time using

equipment. (See

Flushing, page

6.)

4. After flushing, fill

cup with fluid and

attach cover.

A

1

5

8-2

13

Connecting Fluid Supply

Pressure feed guns:

1. To control fluid

pressure to the gun,

install a fluid regulator

on the fluid line.

2. Connect the fluid hose

to the gun fluid inlet,

3/8-18 npsm (R3/8-19)

(21).

3. Connect other end to a

regulated fluid supply line.

21

4 312388K

Page 5

Operation

Pressure Relief Procedure

1. Turn off air and fluid supply.

2. Hold a metal part of the gun firmly to

a grounded metal pail. Trigger the gun

to relieve pressure.

Adjust Spray Pattern

Operation

4. Pressure Feed only: Adjust fluid pressure

to achieve desired fluid flow rate.

5. Test spray pattern and atomization

while holding gun about 6 to 8 inches

(150 to 200 mm) from test piece.

a. If pattern is too wide, turn pattern

adjustment knob (5) clockwise to

narrow pattern.

b. To create a round pattern, turn pattern

adjustment knob (5) fully clockwise.

c. If pattern is too narrow, turn knob (5)

counterclockwise.

Do not exceed maximum working air pressure

shown on front cover. Read warnings.

1. Rotate air cap to change spray pattern

direction.

2. For maximum fluid flow and to prevent

premature fluid nozzle wear, turn fluid

adjustment knob (8-2) counterclockwise

until no trigger restriction is felt. Then turn

knob out 1/2 turn more.

3. If further fluid flow restriction is needed,

use different size needle/nozzle/air cap

combination.

If necessary, fluid adjustment knob (8-2)

can be turned clockwise to reduce volume

of fluid output. However, continuously

spraying with fluid adjustment knob closed

causes accelerated abrasive wear on fluid

needle and trigger/air valve shaft interface.

d. Check atomization. Increase gun

air supply pressure in 5 psi (34 kPa,

0.3 bar) increments until you have

the desired atomization.

Applying the Fluid

For the best results:

• Keep gun perpendicular to surface and

consistent distance of about 6 to 8 inches

(150 to 200 mm). Do not angle the gun as

you spray.

• Use smooth, even strokes, with about 50%

overlap.

• HVLP Guns: Use a slightly slower hand

movement and make fewer passes than

you would with a conventional air spray

gun. Take care to avoid runs or sags.

If fluid adjustment knob (8-2) is turned in

all the way, the gun emits only air.

312388K 5

Page 6

Maintenance

Maintenance

Flushing

Flush before changing colors, before fluid can

dry in the equipment, at the end of the day,

before storing, and before repairing equipment. Use a solvent that is compatible with gun

wetted parts and fluid that will be sprayed.

Gravity Feed Guns:

1. Follow Pressure Relief Procedure,

page 5.

2. Dispose of any paint in the cup.

3. Fill the cup with a small amount of solvent.

Daily Cleaning

CAUTION

• Do not submerge gun in solvent. Solvent

dissolves lubricant, dries out packings, and

may clog air passages. You can immerse

front end of gun in solvent just until cup

connection is covered.

• Do not use metal tools to clean air cap

holes as this may scratch them and distort

the spray pattern.

• Use a compatible solvent.

1. Follow Pressure Relief Procedure,

page 5.

2. Clean fluid and air line filters.

3. Check for fluid leakage from gun and

fluid hoses. Tighten fittings or replace

equipment as needed.

4. Spray into a grounded metal waste

container until clean solvent dispenses.

5. Follow Pressure Relief Procedure,

page 5.

Pressure Feed Guns:

1. Follow Pressure Relief Procedure,

page 5.

2. Disconnect fluid supply hose and air supply

hose from gun.

3. Connect solvent supply hose to gun.

4. Hold metal part of gun against a grounded

metal container, trigger, and flush the gun

with solvent until all traces of paint are

removed from the gun passages.

5. Turn off the solvent supply.

6. Follow Pressure Relief Procedure,

page 5.

4. Flush gun before changing colors and

when you are done spraying.

5. Remove cup and filter and clean them

(gravity feed models only).

6. Remove air cap (1) and nozzle (2) as

instructed on page 8 and soak them in

compatible solvent.

CAUTION

Trigger gun and use gun tool (27) whenever

you tighten or remove nozzle (2) to avoid

damaging needle seat and nozzle.

7. Use a rag moistened in solvent to wipe

down outside of gun.

8. Before reinstalling air cap and nozzle, clean

them and front of gun with a soft-bristle

brush dipped into compatible solvent.

Do not use a wire brush or metal tools.

To clean out air cap holes, use a soft

implement, such as a toothpick.

7. Disconnect solvent supply hose from gun.

6 312388K

9. Lubricate gun.

Page 7

Troubleshooting

Problem Cause Solution

One side of air cap (1) dirty or

clogged.

a. Loose air cap (1). a. Tighten.

b. Dried or damaged air

cap (1) or fluid nozzle (2).

a. Atomization air pressure

set too high.

b. Spraying a thin material in

too wide of a pattern.

Air getting into paint stream.

a. Cup almost empty. a. Fill cup.

Troubleshooting

Clean air cap orifices. See page 6. Blow

air through orifices until clean. If air cap

holes are damaged, replace air cap.

b. Rotate air cap 180°.

If pattern follows air cap, problem is

in air cap. Clean and inspect. See

page 6. If pattern is not corrected,

replace air cap.

If pattern does not follow the air cap,

the problem is with the fluid nozzle.

Clean and inspect the nozzle. See

page 6. If the pattern is not corrected,

replace nozzle.

a. Reduce air pressure.

b. Increase material control by turning

fluid adjustment knob (8-2) counterclockwise while reducing spray width

by turning pattern adjustment

knob (5) clockwise.

Or increase material viscosity.

Spitting

b. Dry needle packing (3-1,

3-2).

b. Loosen packing seat and put a few

drops of machine oil on packing (3-1,

3-2). Retighten seat (4).

c. Fluid nozzle (2) too loose. c. Tighten.

d. Dried material between

nozzle (2) and gun body.

d. Clean nozzle and front of gun. See

page 6.

e. Damaged needle seal. e. Replace seal. See page 8.

Other spray pattern

problems.

Unable to get round

pattern.

a. Gun not properly adjusted. a. See page 5.

b. Sluggish needle (10). b. Clean and lubricate.

Pattern adjustment knob (5)

Clean or replace knob.

not seating properly.

Will not spray. a. No air pressure at gun. a. Check air supply and air lines.

b. Cup empty. b. Fill cup.

c. Fluid adjustment knob (8-2)

c. Adjust knob (8-2) counterclockwise.

turned too far clockwise.

d. Fluid too thick for gravity

d. Thin material.

feed.

312388K 7

Page 8

Service

Problem Cause Solution

Fluid leaking from

packing nut (4).

Fluid nozzle (2)

dripping.

Thin, coarse finish. a. Gun held too far from

Thick, dimpled finish

(resembling orange

peel).

a. Packing nut (4) loose. a. Tighten, but not so tight as to grip

b. Packing (3-1, 3-2) worn or

dry.

a. Dry packing (3-1, 3-2). a. Lubricate.

b. Sluggish needle (10). b. Clean and lubricate.

c. Packing nut (4) too tight. c. Loosen.

d. Worn fluid nozzle or

needle.

surface.

b. Atomization air pressure

set too high.

Gun held too close to surface. Hold gun about 6 to 8 inches

needle.

b. Lubricate or replace.

d. Replace.

a. Hold gun about 6 to 8 inches

(150 to 200 mm) from surface.

b. Reduce air pressure.

(150 to 200 mm) from surface.

Service

Preparation

1. Flush and clean gun before servicing.

2. Follow Pressure Relief Procedure,

page 5.

Air Cap, Nozzle, and Needle

1. Unscrew air cap (1).

2. Trigger gun while you remove the

nozzle (2) with gun tool (27).

Trigger gun and use gun tool (27) whenever you tighten or remove the nozzle (2)

to avoid damage.

3. Remove fluid adjustment knob (8-2) and

spring (9).

4. Pull fluid needle (10) out the back of the

gun.

Air Valve and Needle Packings

1. Remove retaining rings (15), pin (16), and

trigger (17).

2. Remove packing nut (4) and fluid needle

packings (3-1, 3-2).

3. Remove fluid needle guide (7).

4. Remove fluid adjusting guide (8-1).

5. Remove spring (18) and air valve (19).

6. Remove air valve seat (20) and o-rings.

7. Replace parts as needed.

8. Assemble gun in reverse order. Lubricate

needle and o-rings. Be sure to trigger gun

when installing nozzle (2).

8 312388K

Page 9

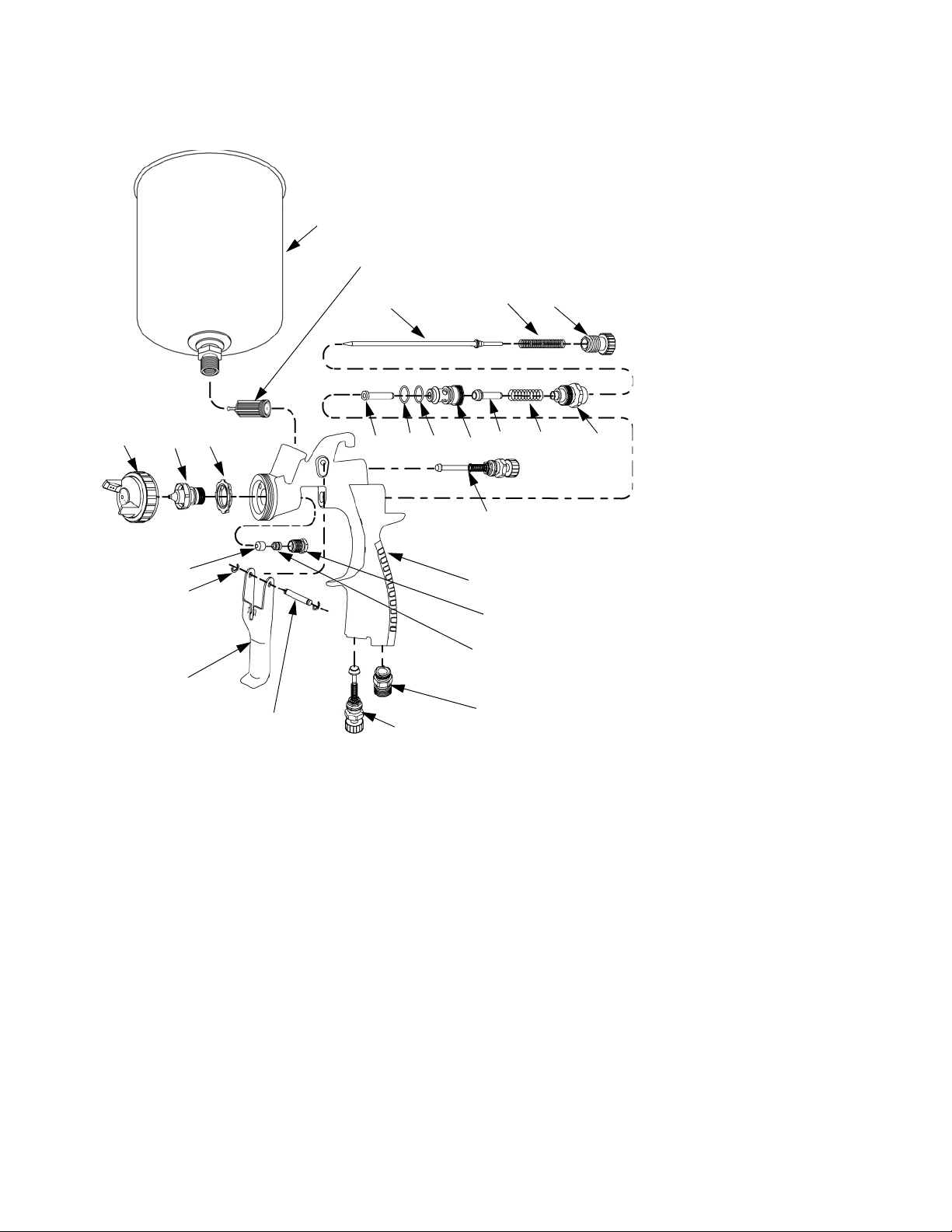

Parts

Parts

Gravity Feed Models

26

24

9

10

2

1

12-2

19

20

11

6

7

8-2

18

8-1

5

3-1

12-1

15

4

3-2

17

16

14

13

ti10444a

Ref. Description Qty

1CAP, air 1

2 NOZZLE, fluid 1

3-1* PACKING, fluid needle 1

3-2* PACKING, fluid needle 1

4* NUT, packing 1

5* KNOB, pattern

adjustment

6* O-RING 1

7* GUIDE, fluid needle 1

8-1* GUIDE, fluid adjusting 1

8-2* KNOB, fluid adjusting 1

9* SPRING, fluid needle 1

10 NEEDLE, fluid 1

11* O-RING 1

12-1 BODY, gun 1

12-2* DISTRIBUTOR, air 1

13* FITTING, air inlet 1

14* VALVE, air adjustment 1

15* RING, retaining 2

16* PIN, trigger 1

17* TRIGGER 1

18* SPRING, air valve 1

19* VALVE, air 1

20* SEAT, air valve 1

21 CONNECTOR, fluid,

(pressure feed models

only, not shown)

24* FILTER, fluid 1

26 CUP, gravity, plastic,

(gravity feed models

only)

27 TOOL, gun (not

shown)

1

1

1

1

312388K 9

Page 10

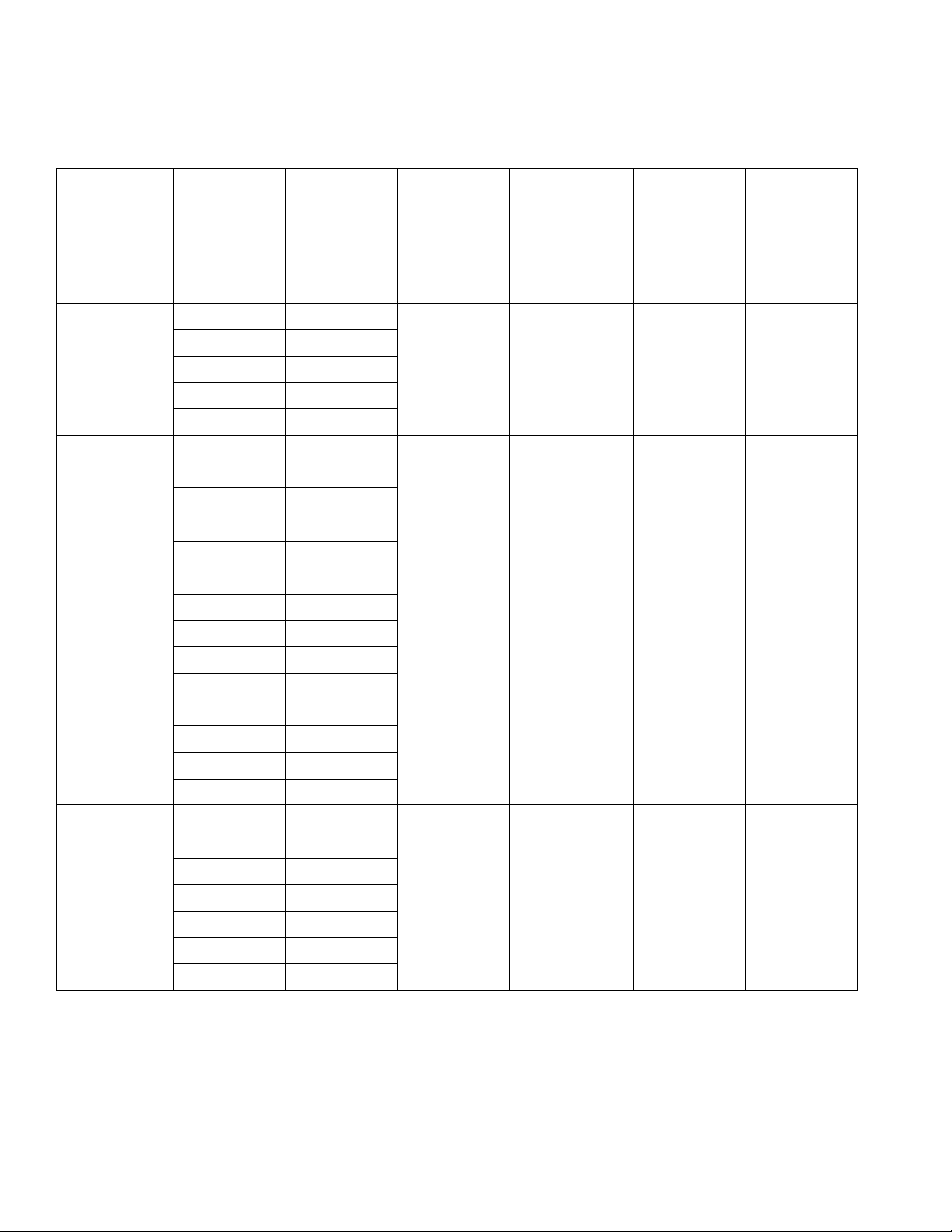

Repair Kits

Repair Kits

Needle/

Nozzle Size

Gun Style

Gravity Feed

Mini-HVLP

Gravity Feed

Conventional

Gravity Feed

HVLP

Pressure

Feed

HVLP

Pressure

Feed

Conventional

in. (mm)

0.024 (0.6)

0.031 (0.8)

0.039 (1.0)

0.047 (1.2)

0.055 (1.4)

0.039 (1.0)

0.051 (1.3)

0.055 (1.4)

0.059 (1.5)

0.071 (1.8)

0.039 (1.0)

0.051 (1.3)

0.055 (1.4)

0.059 (1.5)

0.071 (1.8)

0.039 (1.0)

0.047 (1.2)

0.055 (1.4)

0.071 (1.8)

0.031 (0.8)

0.039 (1.0)

0.047 (1.2)

0.055 (1.4)

0.071 (1.8)

0.086 (2.2)

0.098 (2.5)

Needle,

Nozzle, Air

Cap Kit

(includes

parts 1, 2,

and 10)

289286

289287

289288

289289

289290

289291

289292

289293

289294

289295

289296

289297

289298

289299

289300

289301

289302

289303

289304

289305

289306

289307

289308

289309

289677

289678

Needle

Packing Kit

(includes

parts 3-1, 3-2

and 4)

288890 288895 24C308 24F059

288891 288896 24C309 24F061

288891 288896 24C309 24F060

288891 288897 24C309 24F060

288891 288897 24C309 24F061

Gun Rebuild

Kit

(includes parts

marked *)

Air

Distributor

Kit

(pack of 5)

Trigger

Repair Kit

10 312388K

Page 11

Accessories

Accessories

Gun Style

Mini-HVLP

Conventional

HVLP

Gravity Cup Kits

(includes part 26)

289323

(125 cc)

289322

(600 cc)

289322

(600 cc)

PPS

Adapter

289520

289520

289520

Gravity Cup

(Aluminum)

289858

(125 cc)

Standard

289859

(250 cc)

289860

(600 cc)

289860

(600 cc)

Gravity Cup Lid

(for Aluminum

Cup)

289816

(125 cc)

289817

(250 cc)

289818

(600 cc)

289818

(600 cc)

Fluid

Filter

(10 pack)

24A230 24B616

24A230 N/A

24A230 24B615

HVLP

Test Kit

312388K 11

Page 12

Technical Data

Technical Data

Maximum air inlet pressure . . . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Maximum fluid working pressure . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Gravity Feed:

Maximum HVLP inbound air pressure . . . . . . . . . . .

Pressure Feed:

Maximum HVLP inbound air pressure . . . . . . . . . . .

Air consumption

Mini HVLP Gravity. . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventional Gravity. . . . . . . . . . . . . . . . . . . . . . . . .

HVLP Gravity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HVLP Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventional Pressure . . . . . . . . . . . . . . . . . . . . . . .

Fluid and air operating temperature range . . . . . . . . . . . 32-109°F (0-43° C)

Spray Gun

Air inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid inlet (pressure feed) . . . . . . . . . . . . . . . . . . . . .

Mini HVLP Gravity weight with cup . . . . . . . . . . . . . .

Gravity Feed weight with cup . . . . . . . . . . . . . . . . . .

Pressure Feed weight. . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum, stainless steel, engineered

Noise data**

Mini HVLP Gravity Feed

sound pressure at 29 psi (0.2 MPa, 2.0 bar) . . .

sound power at 29 psi (0.2 MPa, 2.0 bar) . . . . .

Conventional Gravity Feed

sound pressure at 43 psi (0.3 MPa, 3.0 bar) . . .

sound power at 43 psi (0.3 MPa, 3.0 bar) . . . . .

HVLP Gravity Feed

sound pressure at 29 psi (0.2 MPa, 2.0 bar) . . .

sound power at 29 psi (0.2 MPa, 2.0 bar) . . . . .

Conventional Pressure Feed

sound pressure at 50 psi (0.34 MPa, 3.4 bar) . .

sound power at 50 psi (0.34 MPa, 3.4 bar) . . . .

HVLP Pressure Feed

sound pressure at 24 psi (0.17 MPa, 1.7 bar) . .

sound power at 24 psi (0.17 MPa, 1.7 bar) . . . .

Gravity Cup Size

Mini HVLP Gravity. . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventional/HVLP Gravity . . . . . . . . . . . . . . . . . . .

29 psi (0.2 MPa, 2 bar)*

24 psi (0.17 MPa, 1.7 bar)*

7.0 SCFM at 29 psi (0.2 MPa, 2.0 bar)

9.5 SCFM at 43 psi (0.3 MPa, 3.0 bar)

9.5 SCFM at 29 psi (0.2 MPa, 2.0 bar)

11.8 SCFM at 24 psi (0.17 MPa, 1.7 bar)

11.0 SCFM at 50 psi (0.34 MPa, 3.4 bar)

1/4 npsm (R1/4-19)

3/8-18 npsm (R3/8-19)

0.9 lb (0.4 kg)

1.1 lb (0.5 kg)

0.8 lb (0.37 kg)

plastic

78.17 dB(A)

85.32 dB(A)

81.91 dB(A)

89.23 dB(A)

80.60 dB(A)

87.74 dB(A)

83.49 dB(A)

90.70 dB(A)

81.96 dB(A)

88.88 dB(A)

4 oz (125 cc)

20 oz (600 cc)

* Produces 10 psi (0.07 MPa, 0.7 bar) spraying pressure at aircap.

** All readings were taken with the fan valve fully open (fan full size) at the assumed operator

position. Sound power measured per ISO 9614-2.

12 312388K

Page 13

Modèles

Modèles

Style de

pistolet

Mini-HVLP

alimenté par

gravité

Conventional

alimenté par

gravité

HVLP

alimenté par

gravité

Diamètre

Pièce

No.

pointeau/buse

in. (mm)

289256 0,024 (0,6)

289257 0,031 (0,8)

289258 0,039 (1,0)

289259 0,047 (1,2)

289260 0,055 (1,4)

289242 0,039 (1,0)

289243 0,051 (1,3)

289244 0,055 (1,4)

289245 0,059 (1,5)

289246 0,071 (1,8)

289237 0,039 (1,0)

289238 0,051 (1,3)

289239 0,055 (1,4)

289240 0,059 (1,5)

289241 0,071 (1,8)

Style de

pistolet

HVLP

alimenté par

pression

Conventional

alimenté par

pression

Diamètre

Pièce

No.

pointeau/buse

in. (mm)

289247 0,039 (1,0)

289248 0,047 (1,2)

289249 0,055 (1,4)

289250 0,071 (1,8)

289251 0,031 (0,8)

289252 0,039 (1,0)

289253 0,047 (1,2)

289254 0,055 (1,4)

289255 0,071 (1,8)

Mises en garde

Les mises en garde suivantes sont des mises en garde de sécurité relatives à la configuration,

utilisation, mise à la terre, maintenance et réparation de ce matériel. Le point d’exclamation est

une mise en garde générale et le symbole de danger fait référence à des risques spécifiques aux

procédures. Voir ces Mises en garde. D’autres mises en garde spécifiques aux produits figurent

aux endroits concernés.

MISE EN GARDE

RISQUES D’INCENDIE ET D’EXPLOSION

Les vapeurs inflammables, vapeurs de solvant et de peinture par exemple, sur le lieu de travail

peuvent s’enflammer ou exploser. Pour prévenir un incendie ou une explosion :

• N’utiliser l’équipement que dans des locaux bien ventilés.

• Supprimer toutes les sources de feu, telles que les veilleuses, cigarettes, lampes de poche

et bâches plastique (risque d’électricité statique).

• Veiller à débarrasser la zone de travail de tout résidu, comme les solvants, les chiffons et

l’essence.

• Ne pas brancher ni débrancher de cordons d’alimentation électrique ni allumer ou éteindre

la lumière en présence de vapeurs inflammables.

• Mettre tous les appareils de la zone de travail à la terre. Voir Instructions de Mise à la terre.

• Si l’on remarque la moindre étincelle d’électricité statique ou si l’on ressent une décharge

électrique, arrêter le travail immédiatement. Ne pas utiliser le matériel tant que le problème n’a pas été identifié et résolu.

• La présence d’un extincteur opérationnel est obligatoire dans la zone de travail.

312388K 13

Page 14

Mises en garde

DANGER EN CAS DE MAUVAISE UTILISATION DE L’ÉQUIPEMENT

Toute mauvaise utilisation du matériel peut provoquer des blessures graves, voire mortelles.

• Ne pas utiliser l’appareil si l’on est fatigué ou sous l’influence de drogue ou d’alcool

• Ne pas dépasser la pression ou température de service maximum spécifiée de l’élément

• Utiliser des produits et solvants compatibles avec les pièces en contact avec le produit.

• Vérifier le matériel quotidiennement. Réparer ou remplacer immédiatement toutes les

• Ne pas modifier cet équipement.

• N’utiliser ce matériel que pour l’usage auquel il est destiné. Contactez votre distributeur

• Écarter les flexibles et câbles électriques des zones de circulation, des bords coupants,

• Ne pas plier ni trop cintrer les flexibles ni les utiliser pour tirer l’appareil.

• Tenir les enfants et animaux à l’écart du site de travail.

• Se conformer à toutes les règles de sécurité applicables.

MISE EN GARDE

le plus faible du système. Voir les Caractéristiques techniques de tous les manuels de

l’appareil.

Voir les Caractéristiques techniques de tous les manuels d’équipement. Lire les mises en

garde du fabricant de produit et de solvant. Pour plus d’informations sur votre produit,

demandez la fiche de sécurité sur les produits à votre distributeur ou revendeur de produit.

pièces usées ou endommagées uniquement par des pièces d’origine du fabricant.

pour plus de renseignements.

des pièces en mouvement et des surfaces chaudes.

DANGER DES ÉQUIPEMENTS SOUS PRESSION

Tout jet de produit provenant du pistolet/de la vanne de distribution, de fuites ou de composants défectueux risque d’atteindre les yeux ou la peau et peut causer des blessures graves.

• Suivre la Procédure de décompression de ce manuel à chaque interruption de la pulvéri-

sation et avant le nettoyage, la vérification ou l’entretien du matériel.

• Serrer tous les raccords produit avant d’utiliser l’équipement.

• Vérifier les flexibles, tuyaux et raccords quotidiennement. Remplacer immédiatement tout

élément usé ou endommagé.

DANGERS PRESENTES PAR LES PRODUITS OU VAPEURS TOXIQUES

Les produits ou vapeurs toxiques peuvent causer de graves blessures ou entraîner la mort en

cas de projection dans les yeux ou sur la peau, en cas d’inhalation ou d’ingestion.

• Lire la fiche de sécurité produit (MSDS) pour prendre connaissance des risques spécifiques

aux produits utilisés.

• Stocker les produits dangereux dans des récipients homologués et les éliminer conformément à la réglementation en vigueur.

• Toujours porter des gants imperméables lors de la pulvérisation ou du nettoyage de l’équipement.

ÉQUIPEMENT DE PROTECTION DU PERSONNEL

Il est impératif que le personnel porte un équipement de protection approprié quand il travaille

ou se trouve dans la zone de fonctionnement de l’installation pour éviter des blessures graves

telles que des lésions oculaires, inhalation de fumées toxiques, brûlures et perte de l’ouïe

notamment. Cet équipement comprend ce qui suit, la liste n’étant pas exhaustive :

• Lunettes de sécurité

• Le port de vêtements de sécurité et d’un respirateur est conseillé par le fabricant de produit

et de solvant

• Gants

• Casque antibruit

14 312388K

Page 15

Installation

Installation

Les numéros de référence et les lettres

entre parenthèses dans le texte renvoient

aux nombres et lettres des figures.

Raccordement de la conduite pneumatique

1. Monter le régulateur de la pression d’air sur

la conduite d’alimentation pneumatique

pour réguler la pression d’air.

2. Installer une vanne d’arrêt d’air en aval du

régulateur d’air pour couper l’arrivée d’air

au pistolet.

3. Brancher une alimentation en air propre,

sec et filtré sur le raccord d’arrivée d’air

(13). Raccorder l’autre extrémité sur la

vanne d’arrêt.

Pistolets alimentés par gravité :

1. Monter un filtre

produit (24) sur

l’entrée produit

(A).

2. Visser le réservoir

à gravité.

3. Enlever le couvercle du réservoir à

gravité et remplir

ce réservoir avec

du solvant de rinçage si l’équipement est utilise

pour la première

fois. (Voir Rin-

çage, page 17).

4. Après le rinçage, remplir le réservoir avec

du produit et remettre le couvercle.

A

1

5

8-2

13

Raccordement de la conduite de produit

Pistolets alimentés sous pression :

1. Pour réguler la

pression produit du

pistolet, installer un

régulateur sur la

conduite produit.

2. Brancher le flexible produit sur

l’entrée produit du

pistolet, 3/8-18

npsm (R3/8-19)

(21).

3. Raccorder l’autre extrémité à une conduite

d’alimentation produit régulée.

21

312388K 15

Page 16

Fonctionnement

Fonctionnement

Si le bouton de réglage du produit (8-2)

est tourné à fond, le pistolet n’émet que

de l’air.

Procédure de décompression

1. Couper l’alimentation d’air et de produit.

2. Tenir fermement la partie métallique du pistolet contre les parois d’un seau métallique

relié à la terre. Déclencher le pistolet pour

décompresser.

Réglage du jet

Ne pas dépasser la pression pneumatique

de service maximale figurant sur la première

page. Prendre connaissance des mises en

garde.

1. Tourner le chapeau d’air pour changer

la direction du jet.

2. Pour un débit maximal et pour empêcher

une usure prématurée de la buse produit,

tourner le bouton de réglage du produit

(8-2) dans le sens antihoraire jusqu’à ce

que la course de la gâchette ne rencontre

plus de pression. Ensuite, tourner le bouton

encore d’un 1/2 tour.

4. Alimentation sous pression uniquement :

Régler la pression produit pour obtenir le

débit désiré.

5. Tester le jet et l’atomisation en tenant le

pistolet à environ 150 à 200 mm de la pièce

d’essai.

a. Si le jet est trop large, tourner le bouton

de réglage du jet (5) dans le sens

horaire pour le rétrécir.

b. Pour obtenir un jet rond, entièrement

tourner le bouton de réglage du jet (5)

dans le sens horaire.

c. Si le jet est trop étroit, tourner le bouton

(5) dans le sens antihoraire.

d. Recontrôler l’atomisation. Augmenter la

pression d’alimentation d’air par incréments de 5 psi (34 kPa, 0,3 bar) jusqu’à

obtenir l’atomisation désirée.

Pulvérisation du produit

Pour obtenir les meilleurs résultats :

3. Si l’on a besoin de limiter le débit, essayer

des combinaisons pointeau/buse/chapeau

d’air de dimensions différentes.

Si nécessaire, tourner le bouton de réglage

produit (8-2) dans le sens horaire pour

réduire le débit de produit en sortie. Toutefois, une pulvérisation en continu avec le

bouton de réglage fermé augmente l’usure

du pointeau produit et sur les faces entre la

gâchette et l’axe de la vanne d’air.

16 312388K

• Tenir le pistolet perpendiculairement à la

surface et à une distance constante d’env.

6 à 8 pouces (150 à 200 mm). Ne pas

pencher le pistolet pendant l’application.

• Effectuer des passes lisses et égales se

recouvrant d’env. 50 %.

• Pistolets HVLP : Adopter un mouvement de

la main légèrement plus lent et faire moins

de passes qu’avec un pistolet pneumatique

classique. Éviter les coulures.

Page 17

Entretien

Entretien

Rinçage

Rincer avant de changer de couleur, avant que

le produit ne sèche dans l’équipement, à la fin

de la journée, avant l’entreposage et avant de

réparer l’équipement. Utiliser un solvant compatible avec les pièces du pistolet en contact

avec le produit, ainsi qu’avec le produit qui

sera pulvérisé.

Pistolets alimentés par gravité :

1. Observer la Procédure de décompression page 16.

2. Éliminer toute peinture dans le réservoir.

3. Remplir le réservoir avec une petite quantité de solvant.

4. Pulvériser dans un conteneur de déchets

métallique relié à la terre jusqu’à ce que le

solvant sortant du pistolet soit entièrement

propre.

5. Observer la Procédure de décompres-

sion page 16.

Pistolets alimentés sous pression :

1. Observer la Procédure de décompression page 16.

Nettoyage quotidien

ATTENTION

• Ne pas plonger le pistolet dans du solvant.

Le solvant dissout le lubrifiant, dessèche

les joints et risque de boucher les passages d’air. Il est permis de plonger l’avant

du pistolet dans le solvant, mais juste

jusqu’au point de jonction avec le réservoir.

• Ne pas utiliser d’outils métalliques pour

déboucher les trous du chapeau d’air car

cela risque de les rayer et de déformer le

profil du jet.

• Utiliser un solvant compatible.

1. Observer la Procédure de décompres-

sion, page 16.

2. Nettoyer les filtres à produit et à air.

3. Vérifier si le pistolet et les flexibles produit

ne fuient pas. Resserrer les raccords ou

remplacer l’équipement si nécessaire.

4. Rincer le pistolet avant tout changement de

couleur et après une pulvérisation.

5. Démonter le réservoir et le filtre et les

nettoyer (uniquement pour les modèles

alimentés par gravité).

6. Enlever le chapeau d’air (1) et la buse (2)

comme indiqué à la page 19 et les plonger

dans un solvant compatible.

ATTENTION

2. Débrancher les flexibles d’alimentation

pneumatique et en produit du pistolet.

3. Raccorder le flexible d’alimentation en

solvant sur le pistolet.

4. Appuyer une partie métallique du pistolet

contre un récipient métallique mis à la

terre, appuyer sur la gâchette et rincer le

pistolet avec du solvant jusqu’à ce que

toute trace de peinture ait disparu des

conduits du pistolet.

5. Couper l’alimentation en solvant.

6. Observer la Procédure de décompres-

sion page 16.

7. Débrancher le flexible d’alimentation en

solvant du pistolet.

312388K 17

Actionner le pistolet et utiliser l’instrument

prévu (27) à chaque serrage ou démontage

de la buse (2) afin d’éviter d’endommager le

siège et la buse.

7. Utiliser un chiffon imbibé de solvant pour

essuyer l’extérieur du pistolet.

8. Avant de replacer le chapeau d’air et la

buse, les nettoyer et nettoyer l’avant du pistolet à l’aide d’un pinceau souple trempé

dans un solvant compatible. Ne pas utiliser

de brosse ni d’instrument métalliques. Pour

nettoyer les trous du chapeau d’air, utiliser

un instrument doux, comme un cure-dents.

9. Lubrification du pistolet.

Page 18

Guide de dépannage

Guide de dépannage

Problème Cause Solution

Un côté du chapeau d’air (1) est

sale ou bouché.

a. Chapeau d’air (1) desserré. a. Resserrer.

b. Chapeau d’air (1) ou buse (2)

endommagé ou orifices

obstrués par produit séché.

a. Pression d’atomisation réglée

à un niveau trop élevé.

b. Pulvérisation d’un produit trop

liquide pour un jet trop large.

Présence d’air dans la peinture.

a. Réservoir presque vide. a. Remplir le réservoir.

Crachotements

Autres problèmes de jet. a. Pistolet mal réglé. a. Voir page 16.

Jet rond impossible à

obtenir.

Pas de pulvérisation. a. Pas de pression pneumatique

b. Joint du pointeau sec (3-1,

3-2).

c. Buse (2) trop desserrée. c. Resserrer.

d. Produit séché entre la buse

(2) et le corps du pistolet.

e. Joint du pointeau endom-

magé.

b. Pointeau lent (10). b. Nettoyer et lubrifier.

Mauvaise mise en place du

bouton de réglage du jet (5).

au niveau du pistolet.

b. Réservoir vide. b. Remplir le réservoir.

c. Bouton de régulation produit

(8-2) trop tourné dans le sens

horaire.

d. Produit trop épais pour une

alimentation par gravité.

Nettoyer les orifices du chapeau d’air. Voir

page 17. Insuffler de l’air dans les orifices

jusqu’à ce qu’ils soient propres. Si les

orifices du chapeau d’air sont endommagés,

remplacer le chapeau d’air.

b. Faire pivoter le chapeau d’air de 180°.

Si le profil du jet suit le chapeau d’air,

le problème se situe à l’intérieur du chapeau. Nettoyer et examiner. Voir page 17.

Si le jet n’est pas corrigé, remplacer le

chapeau d’air.

Si le profil du jet ne suit pas le chapeau

d’air, le problème se situe au niveau de

la buse. Nettoyer et examiner la buse.

Voir page 17. Si le jet n’est pas corrigé,

remplacer la buse.

a. Réduire la pression d’air.

b. Augmenter le réglage du produit en tour-

nant le bouton de réglage (8-2) dans le

sens antihoraire tout en réduisant la largeur du jet en tournant le bouton de

réglage (5) dans le sens horaire.

Ou bien augmenter la viscosité du produit.

b. Desserrer le siège du joint et mettre

quelques gouttes d’huile machine sur le

joint (3-1, 3-2). Resserrer le siège (4).

d. Nettoyer la buse et la partie avant du

pistolet. Voir la page 17.

e. Remplacer le joint. Voir page 19.

Nettoyer ou remplacer le bouton.

a. Contrôler l’arrivée et les conduites d’air.

c. Tourner le bouton (8-2) dans le sens

antihoraire.

d. Diluer le produit.

18 312388K

Page 19

Problème Cause Solution

Fuite de produit au

niveau de l’écrou du

presse-étoupe (4).

La buse (2) goutte. a. Joint sec (3-1, 3-2). a. Lubrifier.

Couche de finition mince

et grossière.

Couche de finition

épaisse et piquetée

(comme une peau

d’orange).

a. Écrou du presse-étoupe (4)

desserré.

b. Joint (3-1, 3-2) usé ou sec. b. Lubrifier ou remplacer.

b. Pointeau lent (10). b. Nettoyer et lubrifier.

c. Écrou du presse-étoupe (4)

trop serré.

d. Buse produit ou pointeau usé. d. Remplacer.

a. Pistolet trop loin de la surface. a. Tenir le pistolet à une distance d’environ

b. Pression d’atomisation réglée

à un niveau trop élevé.

Pistolet tenu trop près de la

surface.

a. Resserrer, mais pas trop pour ne pas

gripper le pointeau.

c. Desserrer.

6 à 8 pouces (150 à 200 mm) de la

surface.

b. Réduire la pression d’air.

Tenir le pistolet à une distance d’environ

6 à 8 pouces (150 à 200 mm) de la surface.

Entretien

Entretien

Préparation

1. Rincer et nettoyer le pistolet avant un

entretien.

2. Observer la Procédure de décompres-

sion page 16.

Chapeau d’air, buse et pointeau

1. Dévisser le chapeau d’air (1).

2. Actionner le pistolet pendant le démontage

de la buse (2) à l’aide de la clé (27).

4. Sortir le pointeau produit (10) par l’arrière

du pistolet.

Vanne d’air et joints du pointeau

1. Enlever les circlips (15), la broche (16) et la

gâchette (17).

2. Déposer l’écrou du presse-étoupe (4) et

retirer les joints produit (3-1, 3-2) du pointeau.

3. Retirer le guide produit (7) du pointeau.

4. Retirer le guide de réglage (8-1) du produit.

5. Sortir le ressort (18) et la vanne d’air (19).

6. Déposer les joints toriques et le siège (20)

de la vanne d’air.

7. Remplacer les pièces si nécessaire.

Actionner le pistolet et utiliser la clé (27) à

chaque serrage ou démontage de la buse

(2) afin d’éviter tout dommage.

8. Remonter le pistolet dans l’ordre inverse.

Lubrifier le pointeau et les joints toriques.

Veiller à actionner le pistolet lors du

montage de la buse (2).

3. Enlever le bouton de réglage produit (8-2)

et le ressort (9).

312388K 19

Page 20

Pièces

Pièces

Modèles alimentés par gravité

26

24

9

19

8-2

18

8-1

10

2

1

12-2

20

11

6

7

5

3-1

12-1

15

4

3-2

17

16

14

13

ti10444a

Ref. Description Qty

1CAP, air 1

2 NOZZLE, fluid 1

3-1* PACKING, fluid needle 1

3-2* PACKING, fluid needle 1

4* NUT, packing 1

5* KNOB, pattern

adjustment

6* O-RING 1

7* GUIDE, fluid needle 1

8-1* GUIDE, fluid adjusting 1

8-2* KNOB, fluid adjusting 1

9* SPRING, fluid needle 1

10 NEEDLE, fluid 1

11* O-RING 1

12-1 BODY, gun 1

12-2*DISTRIBUTOR, air 1

13* FITTING, air inlet 1

14* VALVE, air adjustment 1

15* RING, retaining 2

16* PIN, trigger 1

17* TRIGGER 1

18* SPRING, air valve 1

19* VALVE, air 1

20* SEAT, air valve 1

21 CONNECTOR, fluid,

(pressure feed mod-

els only, not shown)

24* FILTER, fluid 1

26 CUP, gravity, plastic,

(gravity feed models

only)

27 TOOL, gun (not

shown)

1

1

1

1

20 312388K

Page 21

Kits de réparation

Kits de réparation

Style de

pistolet

Mini-HVLP

alimenté par

gravité

Conventional

alimenté par

gravité

HVLP

alimenté par

gravité

HVLP

alimenté par

pression

Conventional

alimenté par

pression

Diamètre

pointeau/buse

in. (mm)

0,024 (0,6)

0,031 (0,8)

0,039 (1,0)

0,047 (1,2)

0,055 (1,4)

0,039 (1,0)

0,051 (1,3)

0,055 (1,4)

0,059 (1,5)

0,071 (1,8)

0,039 (1,0)

0,051 (1,3)

0,055 (1,4)

0,059 (1,5)

0,071 (1,8)

0,039 (1,0)

0,047 (1,2)

0,055 (1,4)

0,071 (1,8)

0,031 (0,8)

0,039 (1,0)

0,047 (1,2)

0,055 (1,4)

0,071 (1,8)

0,086 (2,2)

0,098 (2,5)

Kit pointeau,

buse, chapeau

d’air (comprend

les pièces

1, 2 et 10)

289286

289287

289288

289289

289290

289291

289292

289293

289294

289295

289296

289297

289298

289299

289300

289301

289302

289303

289304

289305

289306

289307

289308

289309

289677

289678

Kit garniture

pour pointeau

(comprend

les pièces

3-1, 3-2 et 4)

Kit de réparation

du pistolet

(comprend

les pièces

marquées d’un *)

Kit de

distributeur d'air

(pack de 5)

Kit de

rechange

gâchette

288890 288895 24C308 24F059

288891 288896 24C309 24F061

288891 288896 24C309 24F060

288891 288897 24C309 24F060

288891 288897 24C309 24F061

312388K 21

Page 22

Accessoires

Accessoires

Kits réservoir à

Style de

pistolet

Mini-HVLP

Conventional

HVLP

(comprend la pièce 26)

gravité

289323

(125 cc)

289322

(600 cc)

289322

(600 cc)

Adaptateur

PPS

289520

289520

289520

Réservoir

à gravité

(aluminium)

289858

(125 cc)

Standard

289859

(250 cc)

289860

(600 cc)

289860

(600 cc)

Couvercle du

réservoir à gravité

(pour le réservoir

aluminium)

289816

(125 cc)

289817

(250 cc)

289818

(600 cc)

289818

(600 cc)

Filtre produit

(pack de 10)

Kit d’essai

de HVLP

24A230 24B616

24A230 N/A

24A230 24B615

22 312388K

Page 23

Caractéristiques techniques

Caractéristiques techniques

Pression d’arrivée d’air maximum . . . . . . . . . . . . . . . . . 100 psi (0,7 MPa, 7 bars)

Pression maximale de service produit . . . . . . . . . . . . . 100 psi (0,7 MPa, 7 bars)

Alimentation par gravité :

Pression maximale d’entrée d’air pour

le modèle HVLP . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alimentation sous pression :

Pression maximale d’entrée d’air pour

le modèle HVLP . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Consommation d’air

Mini HVLP alimenté par gravité . . . . . . . . . . . . . . . .

Conventional alimenté par gravité. . . . . . . . . . . . . . .

HVLP alimenté par gravité . . . . . . . . . . . . . . . . . . . .

HVLP alimenté par pression . . . . . . . . . . . . . . . . . . .

Conventional alimenté par pression . . . . . . . . . . . . .

Plage de températures de produit et d’air de service. . . 32-109°F (0-43° C)

Pistolet pulvérisateur

Entrée d’air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entrée produit (alimentation par pression) . . . . . . . .

Poids du Mini HVLP alimenté par gravité,

avec réservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Poids alimentation par gravité, avec réservoir . . . . .

Poids alimentation par pression . . . . . . . . . . . . . . . .

Pièces en contact avec le produit. . . . . . . . . . . . . . . . . . Aluminium, acier inoxydable,

Caractéristiques sonores**

Mini HVLP alimenté par gravité

pression sonore à 29 psi (0,2 MPa, 2,0 bars) . . . .

puissance sonore à 29 psi (0,2 MPa, 2,0 bars) . . .

Conventional alimenté par gravité

pression sonore à 43 psi (0,3 MPa, 3,0 bars) . . . .

puissance sonore à 43 psi (0,3 MPa, 3,0 bars) . . .

HVLP alimenté par gravité

pression sonore à 29 psi (0,2 MPa, 2,0 bars) . . . .

puissance sonore à 29 psi (0,2 MPa, 2,0 bars) . . .

Conventional alimenté par pression

pression sonore à 50 psi (0,34 MPa, 3,4 bars) . . .

puissance sonore à 50 psi (0,34 MPa, 3,4 bars) . .

HVLP alimenté par pression

pression sonore à 24 psi (0,17 MPa, 1,7 bars) . . .

puissance sonore à 24 psi (0,17 MPa, 1,7 bars) . .

Taille du réservoir à gravité

Mini HVLP alimenté par gravité . . . . . . . . . . . . . . . .

Conventional/HVLP alimenté par gravité . . . . . . . . .

29 psi (0,2 MPa, 2 bar)*

24 psi (0,17 MPa, 1,7 bar)*

7,0 SCFM à 29 psi (0,2 MPa, 2,0 bars)

9,5 SCFM à 43 psi (0,3 MPa, 3,0 bars)

9,5 SCFM à 29 psi (0,2 MPa, 2,0 bars)

11,8 SCFM à 24 psi (0,17 MPa, 1,7 bars)

11,0 SCFM à 50 psi (0,34 MPa, 3,4 bars)

1/4 npsm (R1/4-19)

3/8-18 npsm (R3/8-19)

0,9 lb (0,4 kg)

1,1 lb (0,5 kg)

0,8 lb (0,37 kg)

plastique de hautes performances

78,17 dB(A)

85,32 dB(A)

81,91 dB(A)

89,23 dB(A)

80,60 dB(A)

87,74 dB(A)

83,49 dB(A)

90,70 dB(A)

81,96 dB(A)

88,88 dB(A)

4 oz (125 cc)

20 oz (600 cc)

* Production d’une pression de pulvérisation de 10 psi (0,07 MPa, 0,7 bar) au chapeau d’air.

** Toutes les mesures ont été prises avec la vanne de projection complètement ouverte (taille maximale du

jet) à l’emplacement supposé de l’opérateur. La puissance sonore a été mesurée selon la norme ISO 9614-2.

312388K 23

Page 24

Caractéristiques techniques

24 312388K

Page 25

Modelos

Modelos

Tipo de

pistola

Alimentación

por gravedad

Mini-HVLP

Alimentación

por gravedad

convencional

Alimentación

por gravedad

HVLP

Tamaño de la

Ref.

pieza

aguja/boquilla

pulg. (mm)

289256 0,024 (0,6)

289257 0,031 (0,8)

289258 0,039 (1,0)

289259 0,047 (1,2)

289260 0,055 (1,4)

289242 0,039 (1,0)

289243 0,051 (1,3)

289244 0,055 (1,4)

289245 0,059 (1,5)

289246 0,071 (1,8)

289237 0,039 (1,0)

289238 0,051 (1,3)

289239 0,055 (1,4)

289240 0,059 (1,5)

289241 0,071 (1,8)

Tipo de

pistola

Alimentación

a presión

HVLP

Alimentación

a presión

convencional

Tamaño de la

Ref.

pieza

aguja/boquilla

pulg. (mm)

289247 0,039 (1,0)

289248 0,047 (1,2)

289249 0,055 (1,4)

289250 0,071 (1,8)

289251 0,031 (0,8)

289252 0,039 (1,0)

289253 0,047 (1,2)

289254 0,055 (1,4)

289255 0,071 (1,8)

Advertencias

A continuación se ofrecen advertencias relacionadas con la seguridad de la puesta en marcha,

utilización, conexión a tierra, mantenimiento y reparación de este equipo. El símbolo acompañado de una exclamación le indica que se trata de una advertencia y el símbolo de peligro

se refiere a un riesgo específico. Consulte estas Advertencias. Siempre que sea pertinente,

en este manual encontrará advertencias específicas del producto.

ADVERTENCIA

PELIGRO DE INCENDIOS Y EXPLOSIONES

Vapores inflamables, como los vapores de disolventes o de pinturas en la zona de trabajo

pueden incendiarse o explotar. Para evitar un incendio o explosión:

• Utilice el equipo únicamente en áreas bien ventiladas.

• Elimine toda fuente de ignición, tales como las luces piloto, los cigarrillos, lámparas

eléctricas portátiles y las cubiertas de plástico (arcos estáticos potenciales).

• Mantenga limpia la zona de trabajo, sin disolventes, trapos o gasolina.

• No enchufe ni desenchufe cables de alimentación ni apague ni encienda las luces en el

área de pulverización.

• Conecte a tierra todo el equipo de la zona de trabajo. Vea instrucciones de Conexión

a tierra.

• Si se aprecia la formación de electricidad estática durante el uso de este equipo, deje de

trabajar inmediatamente. No utilice el sistema hasta haber identificado y corregido el

problema.

• Guarde un extintor de incendios que funcione correctamente en la zona de trabajo.

312388K 25

Page 26

Advertencias

ADVERTENCIA

PELIGROS DEBIDOS A LA UTILIZACIÓN INCORRECTA DEL EQUIPO

El uso incorrecto puede causar la muerte o heridas graves.

• No utilice el equipo si está cansado o bajo los efectos de medicamentos o del alcohol.

• No exceda la presión máxima de trabajo o la temperatura del componente con menor valor

nominal del sistema. Consulte la sección Características técnicas de todos los manuales

del equipo.

• Utilice fluidos y disolventes que sean compatibles con las piezas húmedas del equipo. Con-

sulte las Características técnicas de todos los manuales del equipo. Lea las advertencias

de los fabricantes de los fluidos y los disolventes. Para obtener información completa sobre

su material, pida las hojas de MSDS a su distribuidor o detallista.

• Revise el equipo a diario. Repare o cambie inmediatamente las piezas desgastadas

o dañadas únicamente con piezas de repuesto originales del fabricante.

• No altere ni modifique el equipo.

• Utilice el equipo únicamente para el fin para el que ha sido destinado. Si desea información,

póngase en contacto con su distribuidor.

• Desvíe las mangueras de zonas de tráfico intenso, de curvas pronunciadas, de piezas

movibles y superficies calientes.

• No retuerza ni doble las mangueras, ni las utilice para arrastrar el equipo.

• Mantenga a los niños y a los animales lejos de la zona de trabajo.

• Respete todas las normas relativas a la seguridad.

PELIGROS DEL EQUIPO A PRESIÓN

El fluido procedente de la pistola/válvula dispensadora, y las fugas de las mangueras o de

piezas rotas pueden salpicar fluido en los ojos o en la piel y causar lesiones graves.

• Siga el Procedimiento de descompresión de este manual, cuando deje de pulverizar

y antes de limpiar, revisar o reparar el equipo.

• Apriete todas las conexiones antes de accionar el equipo.

• Compruebe diariamente las mangueras, los tubos y los acoplamientos. Reemplace inmediatamente las piezas desgastadas o dañadas.

PELIGRO DE VAPORES O LÍQUIDOS TÓXICOS

Los líquidos o los vapores tóxicos pueden provocar serios daños o incluso la muerte si entran

en contacto con los ojos o la piel, se inhalan o se ingieren.

• Lea la Hoja de datos de seguridad del material (MSDS) para conocer los peligros específicos de los líquidos que esté utilizando.

• Guarde los fluidos peligrosos en un envase adecuado que haya sido aprobado. Proceda

a su evacuación siguiendo las directrices pertinentes.

• Utilice siempre guantes impermeables cuando pulverice o limpie el equipo.

EQUIPO DE PROTECCIÓN PERSONAL

Debe utilizar equipo de protección adecuado cuando trabaje, revise o esté en la zona de

funcionamiento del equipo, con el fin de protegerse contra la posibilidad de lesionarse gravemente, incluyendo lesiones oculares, la inhalación de vapores tóxicos, quemaduras o la

pérdida auditiva. Este equipo incluye, pero no está limitado a:

• Gafas de protección

• Ropas protectoras y un respirador, tal como recomiendan los fabricantes del fluido y del

disolvente

• Guantes

• Protección auditiva

26 312388K

Page 27

Puesta en marcha

Puesta en marcha

Los números de referencia y las letras

entre paréntesis en el texto se refieren

a los números y las letras de las ilustraciones.

Conexión del tubo de aire

1. Instale un regulador de aire en la tubería

de alimentación de aire de la pistola para

controlar la presión de aire.

2. Instale una válvula de cierre corriente

abajo del regulador de aire para cerrar

el aire de la pistola.

3. Conecte un suministro de aire filtrado, seco

y limpio al racor de entrada de aire (13).

Conecte el otro extremo a la válvula de

cierre.

3. Conecte el otro extremo a una tubería de

suministro de fluido regulada.

Pistolas con alimentación por gravedad:

1. Instale el filtro de

fluido (24) en la

entrada de fluido

(A).

2. Enrosque la copela

de gravedad.

3. Si es la primera

vez que utiliza el

equipo, retire la

tapa de la copela

de gravedad

y rellene la copela

con disolvente

para lavarla. (Vea

Lavado, página

29.)

4. Después de lavar, llene la copela de fluido

y coloque la tapa.

A

1

5

8-2

13

Conexión del suministro de fluido

Pistolas con alimentación a presión:

1. Instale un

regulador de fluido

en la línea de

fluido para

controlar

la presión de

fluido destinada a

la pistola.

2. Conecte la

manguera de fluido a la entrada de

fluido de la pistola,

3/8-18 npsm (R3/8-19) (21).

21

312388K 27

Page 28

Funcionamiento

Funcionamiento

Procedimiento de descompresión

1. Apague el suministro de aire y de fluido.

2. Sujete firmemente una pieza metálica de

la pistola contra el borde de una cubeta

metálica conectada a tierra. Dispare la

pistola para liberar la presión.

Ajuste del chorro de pulverización

4. Sólo sistemas con alimentación a presión:

Ajuste la presión de fluido hasta conseguir

el caudal de fluido deseado.

5. Ensaye el chorro de pulverización

y la atomización mientras mantiene la

pistola a una distancia aproximada de

150 a 200 mm de la pieza de prueba.

a. Si el chorro es demasiado ancho, gire

la perilla de ajuste del chorro (5) en

sentido horario para estrecharlo.

b. Para crear un chorro redondo, des-

conecte el aire del chorro girando la

perilla de ajuste (5) completamente

en el sentido horario.

No excede la presión máxima de trabajo de

aire que se muestra en la cubierta delantera.

Lea las advertencias.

1. Gire el cabezal aire para cambiar la

dirección del chorro de pulverización.

2. Para conseguir el caudal máximo de fluido

y evitar el desgaste prematuro de la

boquilla de fluido, gire la perilla de ajuste

del fluido (8-2) en sentido antihorario hasta

que no sienta resistencia en el gatillo.

Después gire la perilla hacia afuera

1/2 vuelta más.

3. Si fuera necesario restringir más el caudal

de fluido, utilice una combinación diferente

de tamaño de aguja/boquilla/cabezal de

aire.

Si fuera necesario, puede girar la perilla

de ajuste de fluido (8-2) en sentido horario

para reducir el volumen de la salida de

fluido. Sin embargo, la pulverización continua con la perilla de ajuste de fluido completamente cerrada provoca el desgaste

abrasivo acelerado de la aguja de fluido y el

interfaz del gatillo/eje de la válvula de aire.

Si el botón de ajuste del fluido (8-2) se gira

completamente, la pistola sólo emite aire.

c. Si el chorro de pulverización es

demasiado estrecho, gire el mando (5)

en sentido antihorario.

d. Compruebe la atomización. Aumente

la presión de suministro de aire a la

pistola en incrementos de 5 psi (34 kPa,

0,3 bar) hasta que obtenga la atomización deseada.

Aplicación del fluido

Para obtener los mejores resultados:

• Mantenga la pistola perpendicular

a la superficie y a una distancia uniforme

de aproximadamente 150-200 mm

(6-8 pulgadas). No incline la pistola

mientras pulveriza.

• Utilice pasadas uniformes y suaves, con

una superposición aproximada del 50%.

• Pistolas HVLP: Utilice un movimiento de

las manos ligeramente más lento y dé

menos pasadas para cubrir la pieza que

cuando utilice una pistola de pulverización

convencional. Evite ir demasiado deprisa

o bajar demasiado la pistola.

28 312388K

Page 29

Mantenimiento

Mantenimiento

Lavado

Lave el equipo pistola antes de cambiar de

color, antes de que el fluido pueda secarse

en el equipo, al final de la jornada de trabajo,

antes de guardarlo y antes de repararlo. Utilice

un disolvente que sea compatible con las

piezas húmedas de la pistola y con fluido

que vaya a pulverizar.

Pistolas con alimentación por gravedad:

1. Siga el Procedimiento de descompresión, página 28.

2. Elimine la pintura que queda en la copela.

3. Llene la copela con una pequeña cantidad

de disolvente.

4. Pulverice hacia el interior de un recipiente

metálico de desecho conectado a tierra,

hasta que salga disolvente limpio.

5. Siga el Procedimiento de descompre-

sión, página 28.

Limpieza diaria

PRECAUCIÓN

• No sumerja la pistola en disolvente. El disolvente

disuelve el lubricante, seca las empaquetaduras,

y podría obstruir los conductos de aire. Puede

sumergir el extremo delantero de la pistola en

disolvente sólo hasta que haya cubierto la

conexión de la copela.

• No utilice herramientas de metal para limpiar los

orificios del casquillo de aire y de la boquilla

de pulverización ya que pueden rayarse y distorsionar la forma del chorro de pulverización.

• Utilice un disolvente compatible.

1. Siga el Procedimiento de descompre-

sión, en la página 28.

2. Limpie los filtros de la tubería de aire del fluido.

3. Verifique que no existan fugas de producto

en la pistola y mangueras de producto.

Apriete las conexiones o cambie las piezas

si fuera necesario.

4. Lave la pistola antes de cambiar de producto o de color y cuando haya acabado

de pulverizar.

5. Desmonte la copela y el filtro y límpielos

(sólo modelos de alimentación por gravedad).

Pistolas con alimentación a presión:

1. Siga el Procedimiento de descompresión, página 28.

2. Desconecte la manguera de suministro de

fluido y la manguera de suministro de aire

de la pistola.

3. Conecte la manguera de suministro de

disolvente a la pistola.

4. Sujete la parte metálica de la pistola contra

un recipiente metálico conectado a tierra,

dispare, y lávela con el disolvente hasta que

desaparezca de los conductos de la pistola

todo rastro de pintura.

5. Cierre el suministro de disolvente.

6. Siga el Procedimiento de descompre-

sión, página 28.

7. Desconecte la manguera de suministro de

disolvente de la pistola.

6. Retire el cabezal de aire (1) y la boquilla (2)

tal como se indica en la página 31 y sumérjalos en un disolvente compatible.

PRECAUCIÓN

Dispare la pistola y utilice la herramienta para

pistolas (27) siempre que apriete o desmonte la

boquilla (2) para evitar el dañar el asiento de la

aguja y la boquilla.

7. Utilice un trapo humedecido en disolvente

para limpiar la parte exterior de la pistola.

8. Antes de volver a instalar el cabezal de aire

y la boquilla, límpielos así como la parte

delantera de la pistola con un cepillo de

cerda suave mojado en un disolvente compatible. No utilice un cepillo de alambre ni

herramientas metálicas. Para limpiar los orificios del cabezal de aire, utilice un accesorio suave, como un palillo de dientes.

9. Lubrique la pistola.

312388K 29

Page 30

Localización de averías

Localización de averías

Problema Causa Solución

Un lado del cabezal de aire (1) está

sucio o atascado.

a. Afloje el cabezal de aire (1). a. Apriete.

b. Cabezal de aire (1) o boquilla de

fluido (2) secos o dañados.

a. Presión del aire de pulverización

demasiado alto.

b. Se pulveriza un material poco

viscoso con un chorro demasiado ancho.

Entra aire en la corriente de pintura.

a. La copela está casi vacía. a. Llene la copela.

Salpicaduras

Otros problemas del

chorro de pulverización.

Incapaz de conseguir un

chorro redondo.

No pulveriza. a. No llega presión de aire a la

Fugas de fluido por la

tuerca prensaestopas (4).

b. Empaquetadura de la aguja

seca (3-1, 3-2).

c. La boquilla de fluido (2) está

demasiado floja.

d. Material seco entre la boquilla (2)

y el cuerpo de la pistola.

e. Junta de la aguja dañada. e. Reemplace el sello. Vea la página 31.

a. La pistola no está bien ajustada. a. Vea la página 28.

b. Aguja lenta (10). b. Limpie y lubrique.

La perilla de ajuste del chorro (5)

no asienta correctamente.

pistola.

b. Copela vacía. b. Llene la copela.

c. Se ha girado la perilla de ajuste

del fluido (8-2) demasiado en

sentido horario.

d. Fluido demasiado espeso para la

alimentación por gravedad.

a. Tuerca prensaestopas (4) floja. a. Apriete, pero no tan fuerte como para

b. Empaquetadura (3-1, 3-2) des-

gastada o seca.

Limpie los orificios del cabezal de aire. Vea la

página 29. Sople aire por los orificios hasta que

estén limpios. Si los orificios del cabezal de aire

están dañados, reemplace el cabezal de aire.

b. Gire el cabezal de aire 180°.

Si el chorro sigue el cabezal de aire, el problema está en el cabezal de aire. Límpielo e

inspecciónelo. Vea la página 29. Si el chorro

no es correcto, reemplace el cabezal de aire.

Si el chorro no sigue el cabezal de aire, el

problema está en la boquilla de fluido. Límpiela e inspecciónela. Vea la página 29. Si el

chorro no es correcto, reemplace la boquilla.

a. Reduzca la presión de aire.

b. Aumente el control del material girando la

perilla de ajuste del fluido (8-2) en sentido

antihorario, mientras reduce la anchura del

chorro girando la perilla de ajuste (5) en

sentido horario.

O aumente la viscosidad del material.

b. Afloje el asiento de la empaquetadura y eche

unas gotas de aceite de máquina en la

empaquetadura (3-1, 3-2). Vuelva a apretar

el asiento (4).

c. Apriete.

d. Limpie la boquilla y la parte delantera de la

pistola. Vea la página 29.

Limpie o reemplace la perilla.

a. Inspeccione el suministro y las líneas de aire.

c. Ajuste la perilla (8-2) en sentido antihorario.

d. Diluya el material.

agarrotar la aguja.

b. Lubrique o reemplace.

30 312388K

Page 31

Problema Causa Solución

Goteo por la boquilla de

fluido (2).

Acabado fino, rugoso. a. La pistola se mantiene demasi-

Acabado espeso, con

hoyuelos (parecido a la

piel de naranja).

a. Empaquetadura seca (3-1, 3-2). a. Lubricar.

b. Aguja lenta (10). b. Limpie y lubrique.

c. Tuerca de la empaquetadura (4)

demasiado apretada.

d. Boquilla o aguja de fluido

desgastada.

ado lejos de la superficie.

b. Presión del aire de pulverización

demasiado alto.

Se sujeta la pistola demasiado cerca

de la superficie.

Servicio

c. Aflojar.

d. Reemplace.

a. Mantenga la pistola a unos 150 – 200 mm

(6 – 8 pulgadas) de la superficie.

b. Reduzca la presión de aire.

Mantenga la pistola a unos 150 – 200 mm

(6 – 8 pulgadas) de la superficie.

Servicio

Preparación

1. Lave y limpie la pistola ates de revisarla.

2. Siga el Procedimiento de descompre-

sión, página 28.

Cabezal de aire, boquilla y aguja

1. Desenrosque el cabezal de aire (1).

2. Dispare la pistola mientras desmonta

la boquilla (2) con la herramienta para

pistolas (27).

Empaquetaduras de la válvula de aire y de la aguja

1. Retire los anillos de retención (15),

el pasador (16) y el gatillo (17).

2. Retire la tuerca prensaestopas (4) y las

empaquetaduras de la aguja de fluido (3-1,

3-2).

3. Retire la guía de la aguja de fluido (7).

4. Retire la guía de ajuste de fluido (8-1).

5. Retire el muelle (18) y la válvula neumática

(19).

6. Desmonte el asiento de la válvula

neumática (20) y las juntas tóricas.

7. Reemplace las piezas según sea

necesario.

Dispare la pistola y utilice la herramienta

para pistolas (27) siempre que apriete

o desmonte la boquilla (2) para evitar

daños.

8. Vuelva a montar la pistola en el orden

inverso. Lubrique la aguja y las juntas tóricas. Asegúrese de disparar la pistola

cuando instale la boquilla (2).

3. Retire la perilla de ajuste de fluido (8-2)

y el muelle (9).

4. Saque la aguja de fluido (10) por la parte

trasera de la pistola.

312388K 31

Page 32

Piezas

Piezas

Modelos de alimentación por gravedad

26

24

9

19

8-2

18

8-1

10

2

1

12-2

20

11

6

7

5

3-1

12-1

15

4

3-2

17

16

14

13

ti10444a

Ref. Description Qty

1CAP, air 1

2 NOZZLE, fluid 1

3-1* PACKING, fluid needle 1

3-2* PACKING, fluid needle

4* NUT, packing 1

5* KNOB, pattern

adjustment

6* O-RING 1

7* GUIDE, fluid needle 1

8-1* GUIDE, fluid adjusting 1

8-2* KNOB, fluid adjusting 1

9* SPRING, fluid needle 1

10 NEEDLE, fluid 1

11* O-RING 1

12-1 BODY, gun 1

12-2*DISTRIBUTOR, air 1

13* FITTING, air inlet 1

14* VALVE, air adjustment 1

15* RING, retaining 2

16* PIN, trigger 1

17* TRIGGER 1

18* SPRING, air valve 1

19* VALVE, air 1

20* SEAT, air valve 1

21 CONNECTOR, fluid,

(pressure feed mod-

els only, not shown)

24* FILTER, fluid 1

26 CUP, gravity, plastic,

(gravity feed models

only)

27 TOOL, gun (not

shown)

1

1

1

1

32 312388K

Page 33

Kits de reparación

Kits de reparación

Tipo de

pistola

Alimentación

por gravedad

Mini-HVLP

Alimentación

por gravedad

convencional

Alimentación

por gravedad

HVLP

Alimentación

a presión

HVLP

Alimentación

a presión

convencional

Tamaño de

la aguja/

boquilla

pulg. (mm)

0,024 (0,6)

0,031 (0,8)

0,039 (1,0)

0,047 (1,2)

0,055 (1,4)

0,039 (1,0)

0,051 (1,3)

0,055 (1,4)

0,059 (1,5)

0,071 (1,8)

0,039 (1,0)

0,051 (1,3)

0,055 (1,4)

0,059 (1,5)

0,071 (1,8)

0,039 (1,0)

0,047 (1,2)

0,055 (1,4)

0,071 (1,8)

0,031 (0,8)

0,039 (1,0)

0,047 (1,2)

0,055 (1,4)

0,071 (1,8)

0,086 (2,2)

0,098 (2,5)

Kit de aguja,

boquilla y

casquillo de

aire (incluye las

piezas 1, 2 y

10)

289286

289287

289288

289289

289290

289291

289292

289293

289294

289295

289296

289297

289298

289299

289300

289301

289302

289303

289304

289305

289306

289307

289308

289309

289677

289678

Kit de

empaqueta-

duras de la

aguja (incluye las

piezas 3-1, 3-2 y

4)

Kit de

reconstrucción

de la pistola

(incluye las piezas

marcadas *)

Kit de

distribuidor

de aire

(paquete de 5)

reparación del

288890 288895 24C308 24F059

288891 288896 24C309 24F061

288891 288896 24C309 24F060

288891 288897 24C309 24F060

288891 288897 24C309 24F061

Kit de

gatillo

312388K 33

Page 34

Accesorios

Accesorios

Kits de copelas

Tipo de

pistola

Mini-HVLP

Convencional

HVLP

de gravedad

(incluye pieza 26)

289323

(125 cc)

289322

(600 cc)

289322

(600 cc)

Adaptador

PPS

289520

289520

289520

Copela de

gravedad

(aluminio)

289858

(125 cc)

Estándar

289859

(250 cc)

289860

(600 cc)

289860

(600 cc)

Tapa de la copela de

gravedad

(para la copela

aluminio)

289816

(125 cc)

289817

(250 cc)

289818

(600 cc)

289818

(600 cc)

Filtro de fluido

(paquete de 10)

de HVLP

24A230 24B616

24A230 N/A

24A230 24B615

Kit de

prueba

34 312388K

Page 35

Características técnicas

Características técnicas

Presión máxima de entrada de aire . . . . . . . . . . . . . . . . 100 psi (0,7 MPa, 7 bar)

Presión máxima de trabajo del fluido . . . . . . . . . . . . . . . 100 psi (0,7 MPa, 7 bar)

Alimentación por gravedad:

Presión de entrada de aire de HVLP máxima. . . . . .

Alimentación a presión:

Presión de entrada de aire de HVLP máxima. . . . . .

Consumo de aire

Mini HVLP por gravedad. . . . . . . . . . . . . . . . . . . . . .

Convencional por gravedad . . . . . . . . . . . . . . . . . . .

HVLP por gravedad. . . . . . . . . . . . . . . . . . . . . . . . . .

HVLP a presión. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Presión convencional . . . . . . . . . . . . . . . . . . . . . . . .

Gama de temperaturas de funcionamiento del fluido

y de aire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32-109°F (0-43° C)

Pistola de pulverización

Entrada de aire . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entrada de fluido (alimentación a presión) . . . . . . . .

Peso de mini HVLP por gravedad con copela. . . . . .

Peso de sist. de alimentación por gravedad con

copela . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Peso de sist, de alimentación a presión . . . . . . . . . .

Piezas húmedas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminio, acero inoxidable,

Datos de ruido**

Mini HVLP con alimentación por gravedad

Presión de sonido a 29 psi (0,2 MPa, 2,0 bar) . .

Potencia de sonido a 29 psi (0,2 MPa, 2,0 bar). .

Alimentación convencional por gravedad

Presión de sonido a 43 psi (0,3 MPa, 3,0 bar) . .

Potencia de sonido a 43 psi (0,3 MPa, 3,0 bar). .

HVLP con alimentación por gravedad

Presión de sonido a 29 psi (0,2 MPa, 2,0 bar) . .

Potencia de sonido a 29 psi (0,2 MPa, 2,0 bar). .

Alimentación por presión convencional

Presión de sonido a 50 psi (0,34 MPa, 3,4 bar) .

Potencia de sonido a 50 psi (0,34 MPa, 3,4 bar).

HVLP con alimentación a presión

Presión de sonido a 24 psi (0,17 MPa, 1,7 bar) .

Potencia de sonido a 24 psi (0,17 MPa, 1,7 bar).

Tamaño de la copela de gravedad

Mini HVLP por gravedad. . . . . . . . . . . . . . . . . . . . . .

Convencional/HVLP por gravedad . . . . . . . . . . . . . .

29 psi (0,2 MPa, 2 bar)*

24 psi (0,17 MPa, 1,7 bar)*

7,0 SCFM a 29 psi (0,2 MPa, 2,0 bar)

9,5 SCFM a 43 psi (0,3 MPa, 3,0 bar)

9,5 SCFM a 29 psi (0,2 MPa, 2,0 bar)

11.8 SCFM a 24 psi (0,17 MPa, 1,7 bar)

11,0 SCFM a 50 psi (0,34 MPa, 3,4 bar)

1/4 npsm (R1/4-19)

3/8-18 npsm (R3/8-19)

0,9 kg (0,4 lb)

1,1 kg (0,5 lb)

0,37 kg (0,8 lb)

plástico modificado

78,17 dB(A)

85,32 dB(A)

81,91 dB(A)

89,23 dB(A)

80,60 dB(A)

87,74 dB(A)

83,49 dB(A)

90,70 dB(A)

81,96 dB(A)

88,88 dB(A)

4 oz (125 cc)

20 oz (600 cc)

* Produce una presión de pulverización de 10 psi (0,07 MPa, 0,7 bar) en el cabezal de aire.

** Todas las lecturas fueron tomadas con la válvula de abanico completamente abierta (tamaño máximo

del abanico) y en la posición normal del operario. La potencia de sonido fue medida según la ISO 9614-2.

312388K 35

Page 36

Graco Standard Warranty Garantie Graco standard Garantía Estándard de Graco

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty