Page 1

Texture Guns

Models: 288628, 288629, and 245924

125 psi (8.75 bar, 0.875 MPa) Maximum Air Working Pressure

70 psi (4.9 bar, 0.49 MPa) Maximum Fluid Working Pressure

311777D

IMPORTANT SAFETY INSTRUCTIONS. Refer to your

sprayer instruction manual for Pressure Relief, priming and

spray instructions. Keep these instructions.

English

Model

288628,

no hopper

Model

245924,

with hopper

ti8808a

Model

288629

ti8508a

- For Water-Based Materials Only -

The following Warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point

symbol alerts you to a general warning and hazard symbols refer to procedure-specific risks. Refer back to these Warnings.

Additional, product-specific warnings may be found throughout the body of this manual where applicable.

EQUIPMENT MISUSE HAZARD

WARNINGS

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured

components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual when

you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the

equipment.

• Check hoses, tubes, and couplings daily. Replace worn

or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes,

in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Keep work area free of debris, including solvent, rags

and gasoline.

• Do not plug or unplug power cords, or turn power or light

switches on or off when flammable fumes are present.

• Ground all equipment in the work area. See Grounding

instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering

into pail.

• If there is static sparking or you feel a shock, stop oper-

ation immediately. Do not use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids that are compatible with equipment wetted

parts. See Technical Data in all equipment manuals.

Read fluid manufacturer’s warnings. For complete information about your material, request MSDS forms from

distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your

distributor for information.

• Route hoses and cables away from traffic areas, sharp

edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull

equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment

when operating, servicing, or in the operating area

of the equipment to help protect you from serious

injury. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and

solvent manufacturer

•Gloves

• Hearing protection

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2006, Graco Inc. is registered to I.S. EN ISO 9001

Repair

Page 2

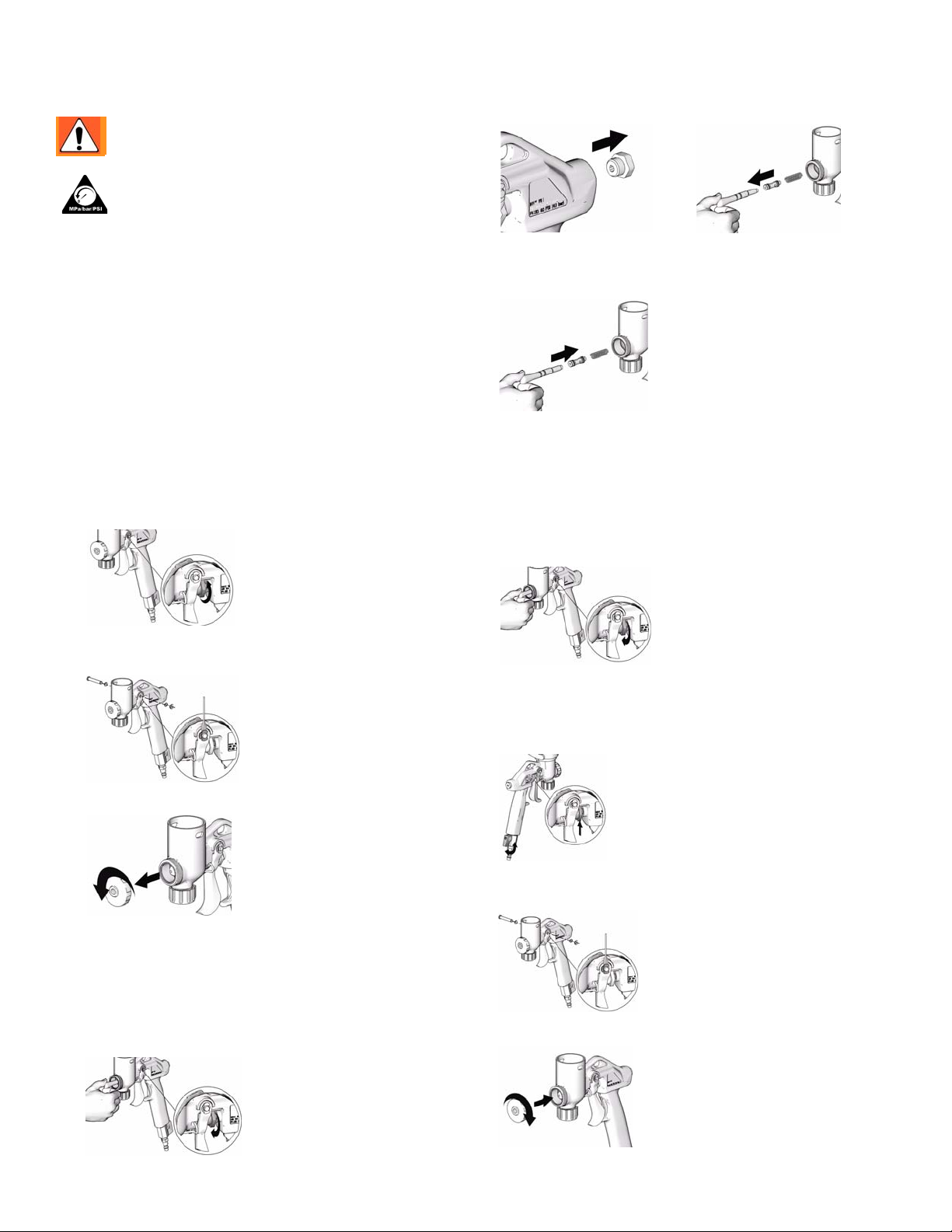

Pressure Relief Procedure

WARNING

Follow this Pressure Relief Procedure whenever

you are instructed to relieve pressure, stop spraying,

check or service equipment or install or clean spray

tip.

1. Turn OFF power and turn sprayer pressure control to

lowest pressure setting.

2. Trigger gun into pail to relieve pressure.

Cleaning and Lubricating

Disassemble needle assembly and clean and grease o-rings

regularly to prolong gun life.

Disassembly

1. Perform Pressure Relief Procedure (see above).

2. Remove hopper or material hose from gun.

3. Clean off as much material on gun body as possible.

4. Turn flow adjustment nut counter-clockwise to enable

trigger to have full range of travel.

9. Remove plug and use small screwdriver to remove all

components out front of gun.

ti8807a

ti8806a

Assembly

1. Hold gun as shown and insert spring in front of gun.

ti9271a

2. Insert spring guide with o-ring into flow adjustment nut.

Make sure the protruded end of the guide points out as

shown.

3. Position flow adjustment nut in seat on gun body.

4. Apply a generous amount of grease to o-rings.

5. Rest gun on air connection fitting. Slide needle into front

of gun.

ti8539a

5. Using a small flat screwdriver, pry retaining ring off of

trigger pin. Remove pin, washer, and trigger.

ti8530a

6. Unscrew nozzle and remove it from gun.

ti9273a

7. Hold needle securely in place so it does not turn while

turning flow control clockwise until needle is disengaged

from thread and released. Pull needle and o-rings out

front of gun.

8. Hold hand under trigger area to catch adjustment nut,

spring retainer, and spring. Tap gun lightly to loosen

spring or use a small screwdriver to loosen.

ti8538a

6. While pushing needle into gun, turn flow adjustment nut

counter-clockwise to tighten needle.

7. Pull back on flow adjustment nut or continue pushing

needle in to make room for trigger.

ti8532a

8. Insert pin through trigger and washers. Push the retaining

clip onto the pin.

ti8530a

9. Pull trigger and replace nozzle.

ti8538a

2 311777D

ti9272a

Page 3

Parts

Model 288628 and 245924

31

33

16a

26

20

8

(a,b,c,d)

3a

21

3d

3d

3e

27

1B

10

9

Model 288629

3f

20

21

3d

6

22

21

2

3a

8

(a,b,c,d)

32

3f

3d

22

ti8524a

3c

3e

1A

27

10

16c

3b

21

16b

2

6

9

3c

3b

ti8509a

Ref. Part Description Qty

A 288628 GUN, complete, (for use with hopper)

B 288629 GUN, complete, (non-hopper)

1A 277393 BODY, gun

1B 277394 BODY, gun

2 15F913 TRIGGER, gun, trigger

3 258000 KIT, needle, repair

includes 3a, 3b, 3c, 3d, 3e, 3f

3a NEEDLE, includes o-ring

3b NUT, flow adjuster

3c GUIDE, needle

3d O-RING

3e SPRING

3f TAPE, foam

6 15B168 LOCK, trigger

8 234153 KIT, nozzle, includes 8a, 8b, 8c, 8d

8a NOZZLE, fine, beige

Ref. Part Description Qty

9 169970 FITTING, line air

1

10 15B565 VALVE, ball

1

16 234162 KIT, plug, includes 16a, 16b, 16c

1

16a PLUG, hopper

1

16b PLUG, hose, port

1

16c O-RING

1

20 118717 PIN, clevis w/ring groove

21 107243 WASHER

22 115999 RING, retaining

26 287967 PIN, clip gun

27 15J635 PLUG

31 234225 KIT, hopper, 1.5 gallon (includes 32)

32 234188 CLAMP

33 234222 KIT, hopper, 0.75 gallon (includes 32)

1

1

Technical Data

8b NOZZLE, small, white

8c NOZZLE, medium, gray

8d NOZZLE, large, black

Air Consumption 3.5-11 cfm at 15 to 100 psi

Weight 35 oz (1600 g)

311777D 3

1

1

1

1

2

1

1

1

1

1

Page 4

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 311777

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

311777D

Revised 09/2007

Loading...

Loading...