Page 1

Instructions

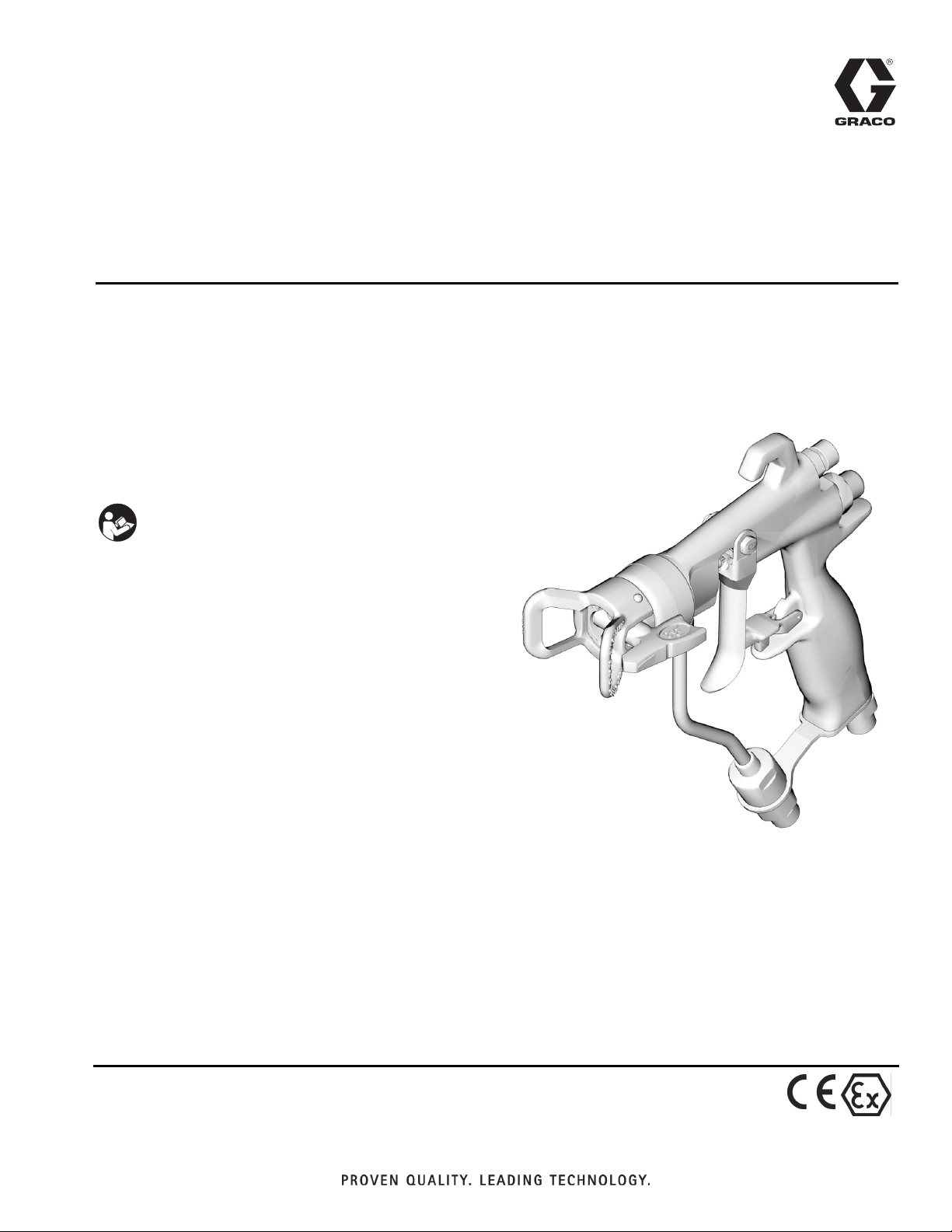

G40 Air Assisted Spray Gun

For the application of architectural paints and coatings. For professional use only.

Model: 288513, 289604

Maximum Working Pressure: 4000 psi (280 bar, 28 MPa)

Maximum Air Working Pressure: 100 psi (7 bar, 0.7

MPa)

IMPORTANT SAFETY INSTRUCTIONS. Refer to your

sprayer instruction manual for Pressure Relief, priming and

spray instructions. Keep these instructions.

311937G

EN

ti8835a

Page 2

Warnings

Warnings

The following Warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

exclamation point symbol alerts you to a general warning and hazard symbols refer to procedure-specific risks. Refer

back to these Warnings. Additional, product-specific warnings may be found throughout the body of this manual

where applicable.

WARNING

WARNINGWARNINGWARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a

cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking,

or servicing equipment.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

2 311937G

Page 3

Warnings

WARNING

WARNINGWARNINGWARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or in the operating area of the

equipment to help protect you from serious injury. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

• Gloves

• Hearing protection

311937G 3

Page 4

Warnings

Pressure Relief Procedure

Follow this Pressure Relief Procedure whenever instructed

to relieve pressure, stop spraying, check or service equipment,

or install or clean spray tip.

1. Lock trigger. Turn OFF power and turn pressure control to

lowest pressure setting.

2. Unlock trigger. Hold gun against side of flushing pail.

Trigger gun into pail to relieve pressure.

If you suspect spray tip or hose is clogged or that pressure has

not been fully relieved after following the steps above, VERY

SLOWLY loosen tip guard retaining nut or hose end coupling

to relieve pressure gradually, then loosen completely. Clear

hose or tip obstruction.

Gun Trigger Lock

To prevent injury when the gun is not in use, always lock the

trigger if unit is being shut down or left unattended.

Trigger Locked

(no spray)

Trigger Unlocked

(spray)

2. For Air-Assisted spraying,

black, coiled, air supply hose (a) to gun

air inlet fitting (17).

NOTE: The first time you set up the gun

for spraying you will have to cut the

black air hose to length desired.

3. Attach blue fluid supply hose (b) to gun

fluid inlet fitting(25).

4. Attach other end of air and fluid supply

hoses to sprayer. Use two wrenches to

tighten all connections securely (see

sprayer setup instructions in sprayer

operation manual 311905.)

first attach

a

ti9022a

25

b

Installing Tip (33) and Guard (6) on Gun

1. If equipment has recently been operated, relieve pressure.

2. Insert seat housing (35)

into guard (6).

3. Insert SwitchTip (33).

4. Insert seal (33b) over seat

(35a) and insert in seat

housing (25). Use black

seal for water-based materials and orange for solvent and

oil-based materials.

5. Install guard (6) over end of gun. Hand tighten.

If you notice fluid leaking from front of gun, replace the

seat (33a) and/or retighten the guard nut.

6

ti8249a

35

33a

33

17

33b

ti6581a ti6582a

Setup

Make sure sprayer is turned off and unplugged from power

source and trigger lock is locked. Refer to your sprayer

instruction manual for priming and spray instructions.

Operation

Note: The following instructions are for guns used with

Graco’s FinishPro Sprayers. See the sprayer instruction

manual 311905. If you are using a different sprayer, see your

equipment instruction manual.

If you are using a FinishPro

regulation is only provided at the gun. The FinishPro

Model Sprayers provide additional air regulation at the

sprayer.

™

390 Model Sprayer, air

™

395

Connect Gun to Sprayer

1. Attach air inlet fitting (17) and fluid

inlet fitting (25) to gun.

1. Unlock trigger (1a).

17

25

ti9444a

4 311937G

2. Be sure the arrow shaped tip (33) faces forward (spray).

3. Hold gun perpendicular and approximately 12-inches

(304 mm) from surface. Move gun first, then pull gun

trigger (3) to spray a test pattern.

4. Always hold gun at a right angle from the surface. Do not

make an arc with the gun. This causes an uneven coat of

fluid. To obtain an even finish, use smooth, even strokes

across the object being sprayed with a 50% overlap.

Page 5

Warnings

Clearing a Clog

1. Relieve pressure. Lock trigger (1a).

2. Rotate tip (33) 180°. Unlock trigger (1a). Trigger gun into

pail or onto ground to remove clog.

3. Lock trigger (1a). Rotate tip (33) 180° back to spray

position.

Spraying

Refer to your Sprayer Instruction manual. The following

instructions are for guns used with Graco’s FinishPro

Sprayers.

Air-Assisted Spraying

1. Set sprayer function selection switch to AIRLESS spraying.

2. Open gun air pressure regulator all the way.

3. Prime pump following priming instructions provided in

sprayer operation manual 311905.

4. Turn sprayer fluid pressure control to highest setting.

5. Unlock trigger (1a). While triggering gun, turn down

sprayer fluid pressure until you notice tails forming in

spray pattern.

6. Stop triggering gun.

7. Set sprayer toggle switch to AA (Air Assisted) spraying.

8. Trigger gun. While spraying increase gun air pressure

regulator until tails disappear.

9. Use gun air regulator to fine tune spray pattern.

Airless Spraying

1. Set sprayer function selection switch to AIRLESS spraying.

2. Prime pump following priming instructions provided in

sprayer operation manual 311905.

3. Start with sprayer pressure turned to lowest setting.

4. Spray a test pattern. Gradually increase sprayer pressure

until you achieve a consistent spray pattern, without

heavy edges. Use a smaller tip if pressure adjustment

alone does not eliminate edges.

Note: If you are getting an irregular spray

pattern, clean air holes with solvent and

a soft brush or toothpick. Do not use

metal tools to clean the air cap holes as

this may scratch them. Scratches can

distort the spray pattern.

TI8792a

Maintenance

Before performing any maintenance on gun, read all warnings

on front cover of this manual and relieve pressure, page 4.

Daily Maintenance

Flush gun after each work shift and store in a dry location.

Do not immerse the gun or any parts in water or cleaning

solvents.

• Do not point gun up while cleaning it.

• Do not wipe gun with cloth soaked in solvent; wring out

excess.

• Solvent left in gun air passages could result in a poor

quality paint finish. Do not use any cleaning method that

may allow solvent into gun air passages.

Flushing and Cleaning

• Flush gun before changing colors, before storing and before

repairing gun.

• Flush at lowest possible pressure. Check connectors for

leaks and tighten as necessary.

• Flush with fluid that is compatible with fluid being dispensed

and equipment’s wetted parts.

1. Relieve pressure, page 4. Unplug sprayer from outlet.

2. Remove tip (33) and guard (6).

3. Disconnect black air supply hose from gun.

4. Remove sprayer siphon tube set from paint and place in

flushing fluid. See Cleanup instructions in sprayer

operation manual 311905.

5. Plug sprayer in outlet. Set sprayer function selection

switch to AIRLESS.

6. Increase pressure slowly. Point gun down into a grounded

metal container. Pull gun trigger and flush gun with

solvent until all traces of fluid are removed from gun

passages.

7. Turn sprayer function selection switch to OFF.

8. Relieve pressure, page 4.

9. Disconnect fluid supply hose from gun.

10. If it is necessary to remove diffuser (5) to clean, trigger

gun while you remove the diffuser with the gun tool (30).

11. Dip the soft end of a soft-bristle brush into a compatible

solvent. Do not continuously soak the brush’s bristles

with solvent and do not use a wire brush.

12. With gun pointed down, clean front of the gun with the

soft-bristle brush and solvent.

13. Scrub the tip (33) and guard (6) with soft-bristle brush. To

clean out air cap holes, use a soft tool such as a

toothpick, to avoid damaging critical surfaces. Blow air

through the spray tip to ensure the orifice is clean.

311937G 5

Page 6

Warnings

14. If the diffuser (5) was removed, trigger the gun while you

reinstall the diffuser with the gun tool (30). Tighten the

diffuser securely to obtain a good seal. Torque to 155-165

in-lb (18-19 N.m). When properly tightened, the flange will

bottom out on the gun.

15. Install tip (33) and guard (6) on gun, page 4.

16. Using a soft cloth dampened in solvent, wipe off outside of

gun.

17. After cleaning, lubricate the

following parts weekly with

lubricant 111265.

A

• Trigger pivot pin (A)

• Both sides of gun where

trigger contacts gun (B)

• Fluid needle shaft, behind

trigger (C)

B

ti8835a

C

Cleaning/Replacing Filter (24)

1. Relieve pressure, page 4. Lock trigger (1a).

2. Unscrew fluid inlet fitting (25).

3. Remove inline fluid filter (24).

4. Clean filter with soft brush and compatible solvent.

Inspect filter and if damaged, replace it.

5. Install inline fluid filter (24) into base of fluid tube (16).

6. Screw fluid inlet fitting (25) into base of tube. Torque to

175-185 in-lb (20-21 N•m).

Repair

Seat Repair

Use Carbide Seat Repair Kit - 249456. For best results use all

new parts provided in kit.

1. Relieve the pressure, page 4. Remove the fluid and air

hoses from the gun.

2. Remove the guard (6) and spray tip (33).

3. Trigger gun to pull the needle housing off the seat while

you unscrew the diffuser (5) from the gun body (1), using

gun tool (30).

4. Inspect o-rings (5e, 5f, and 6a) in place. Carefully remove

the o-rings from the diffuser housing (5a) and replace if

necessary.

5. Remove the seat nut (5d), seat (5c) and seat gasket (5b)

using a 7/32 in. hex wrench.

6. Inspect seat (5c) and seat gasket (5b) and replace if

necessary.

7. Reinstall the seat gasket (5b) seat (5c) and seat nut (5d).

Torque to 45-50 in-lb (5.0-5.6 N•m). Be sure not to

overtighten nut.

• When reinstalling the carbide seat (5c), the tapered end

of the seat must point toward the gun tip.

Needle Repair (2)

1. Relieve pressure, page 4. Remove the diffuser (5), see

Seat Repair, page 6.

2. Remove the trigger pivot pin

nut (14), pivot pin (13), and

trigger (3) using the gun tool

(30) and nut driver (29).

13

3

TI6574A

3. Remove the fluid

needle assembly

(2) from the front of

2a

2

the gun by using

the nut driver tool

(29). If the needle

is bent or

29

ti6575a

damaged, or the

packing is worn or

leaking, replace the entire needle assembly. If

replacement is necessary, be sure to remove the o-ring

(2a) as it may stick inside the gun body.

Air Valve Repair (8)

1. Unscrew the spring cap (11) from the back of the gun

body (1) using the gun tool (30). Remove the two springs

(15 and 19), the shaft (9), and seat (10).

2. Push the air valve assembly (8) out the back of the gun.

3. Inspect the u-cup (7) in the gun body (1). If the u-cup is

worn or leaking, carefully remove the u-cup from the front

of the gun body, using a pick.

8

1

TI6577A

7

15

11

19

10

9

14

6 311937G

Page 7

Warnings

Fluid Tube Replacement (16)

1. Remove the air inlet fitting

(17) using the gun tool (30)

and remove the screw (20)

using a 3/16 in. hex wrench.

2. Unscrew the fluid inlet fitting

(25). Remove and clean or

replace the inline fluid filter

(24).

3. Unscrew fluid tube connector

(16a) from fluid inlet. Carefully

remove gasket (22).

Flat Tip Conversion Kit

(Optional)

The Flat Tip Conversion Kit allows

22

16a

16

24

25

ti6573a

17

AAM Flat Tips to be used with this

gun. Order part number 288514.

Reassembly

1. Install the tube gasket (22) in the gun. Hand tighten the

fluid tube connector (16a) into the gun’s fluid inlet. Antigens the air inlet fitting (17) and screw (20). Torque the

fluid tube connector to 150-160 in-lb (17-18 N•m). Torque

the air inlet fitting to 175-185 in-lb (20-21 N•m). Torque

the fluid tube bracket screw to 50-60 in-lb (6-7 N•m).

2. Install the inline fluid filter (24) into the base of the fluid

tube (16). Screw the fluid inlet fitting (25) into the base of

the tube. Torque to 175-185 in-lb (20-21 N•m).

3. Place the new u-cup (7) on the seal installation tool (28),

with the u-cup lips facing the tool. Push the u-cup into the

back of the gun until you feel a definite snap.

6. Install the two springs (15 and 19). Screw the spring cap

(11) into the back of the gun body. Torque to 175-185

in-lb (20-21 N•m).

7. Lightly lubricate the needle assembly o-rings and shaft

where the packing slides. Be sure that the o-ring (2a) is in

place in the gun body (1).

8. Insert the fluid needle assembly (2) into the front of the

gun. Use the nut driver (29) to screw the fluid needle

assembly into the gun body (1) and torque to 50-60 in-lb

(6-7 N•m).

1

2a

2

29

20

ti6575a

9. Install the trigger (3), pivot pin (13), and nut (14). Use low

strength thread locker and be sure that the brass piece of

the fluid needle assembly (2) is behind the trigger.

Lubricate both sides of the pivot pin where the trigger

contacts the pin and lubricate the boss on both sides of

the gun where the trigger contacts the gun body. Torque

the nut to 20-30 in-lb (2-3 N•m).

10. Trigger the gun to pull the needle back while you screw

the diffuser assembly (5) into the gun body (1) using the

gun tool (30). Torque to 155-165 in-lb (18-19 N•m). When

properly tightened, the flange will bottom out on the gun.

11. Attach the guard (6) and spray tip (33), page 4.

3

Lubricate lightly.

8

Lips face out of gun body.

7

8

3

28

ti6578a

4. Lubricate the front end of the air valve assembly (8).

Gently slide the air valve assembly into the back of the

gun, passing through the u-cup (7), as far as it will go. Be

careful not to damage the u-cup.

5. Slide the seat (10) onto the shaft (9). Be sure that the

Tranlated Manuals

Spanish - 311939 Estonian - 311957

French - 311938 Latvian - 311958

Dutch - 311941 Lithuanian - 311956

German - 311950 Polish - 311951

Italian - 311940 Hungarian - 311954

Turkish - 311942 Czech - 311953

Greek - 311943 Slovakian - 311959

Croatian - 311955 Portuguese - 311944

Danish - 311948 Finnish - 311946

Chinese - 311960 Swedish - 311947

Japanese - 311961 Norwegian - 311949

Korean - 311962 Russian - 311952

Translated manuals can be obtained from a distributor

or by visiting www.graco.com.

tapered end of the seat is toward the thicker end of the

shaft. Carefully insert the shaft (9) and seat (10) in the air

valve (8).

311937G 7

Page 8

Parts

Parts

33

5e

33b

5a

5f

35

33a

6a

6

2a

2

22

13

5b

5c

7

5d

15

11

4

8

19

10

9

1

1a

14

3

29

30

16

36

24

25

Ref. Part No. Description Qty.

24a

1 BODY, gun, assy 1

1a 249423 SAFETY, trigger 1

2◆ NEEDLE, assy; 3/32 carbide ball;

includes item 2a

2a* 110004 PACKING, o-ring; PTFE 1

3 249585 KIT, trigger, repair, includes 13 and 14 1

4 15G713 NUT, air plug 1

5 249877 DIFFUSER, assy, RAC 1

5a DIFFUSER, housing 1

5b◆ GASKET, seat; nylon 1

5c◆ SEAT; carbide 1

5d◆ NUT, seat 1

5e* 111457 PACKING, o-ring, seat; PTFE 1

5f* 109450 PACKING, o-ring; PTFE 1

6 288839 GUARD, RAC 1

6a* 109213 PACKING, o-ring, PTFE 1

7* 188493 PACKING, u-cup, gun; UHMWPE 1

8* VALVE, air, assy 1

9 15F193 SHAFT, fluid spring 1

10 15F194 SEAT, spring 1

11 15F195 CAP, spring 1

12 288715 VALVE, swivel with hose fitting 1

13 15F739 PIN, pivot 1

14 15F740 PIN, pivot, nut 1

15 114069 SPRING, compression 1

16 249136 TUBE, assy 1

17 15F202 FITTING, air inlet 1

17

20

Ref. Part No. Description Qty.

12

ti7203d

22* 115133 GASKET, tube, acetal 1

24 224453 FILTER 1

24a‡ 162863 GASKET, non-metallic (sold separately)

1

25 15F186 FITTING, fluid inlet 1

28* TOOL, installation; seal 1

29 117642 TOOL, nut driver 1

30 15F446 TOOL, gun 1

31▲ 222385 CARD, warning (not shown) 1

32▲ 172479 TAG, warning (not shown) 1

33 FFT210 SPRAY TIP (288513) 1

FFA210 SPRAY TIP (289604) 1

33a** SEAT, gasket 1

33b** SEAL 1

35† 15J770 HOUSING, cylinder 1

36 239663 SWIVEL 1

▲Replacement Danger and Warning labels, tags, and cards are

available at no cost.

◆ Included in Needle/Seat Repair Kit 255160 (purchase separately)

† Included in RAC Guard Kit 288839

*Included in Seal Repair Kit 249422 (purchase separately)

‡ If you want to remove the filter, order 162863 to use as a seal in its

place.

**Included in 246453 RAC X One Seal Kit (Standard)

**Included in 248936 RAC X One Seal Kit (Solvent)

28

19 115141 SPRING, compression 1

20 119996 SCREW, cap, socket hd; 1/4-20 x 3/8 in.

1

(10 mm)

8 311937G

Page 9

Technical Data

Technical Data

Maximum Working Fluid Pressure..............................................................4000 psi (28 MPa, 280 bar)

Maximum Working Air Pressure.................................................................100 psi (0.7 MPa, 7 bar)

Maximum Working Fluid Tempera-

ture........................................................

Fluid inlet.................................................................................................... 1/4-18 npsm

Air Inlet....................................................................................................... 1/4-18 npsm

Gun

Weight.................................................................................................

Sound Pressure*: 20 psi (140 kPa, 1.4 bar)...............................................66.9 dB(A)

Sound Pressure*: 100 psi (0.7 kPa, 7 bar).................................................80.0 dB(A)

Sound Power*: 20 psi (140 kPa, 1.4 bar)....................................................76.8 dB(A)

Sound Power*: 100 psi (0.7 kPa, 7 bar)......................................................89.9 dB(A)

Wetted Parts: Stainless Steel, Carbide, Ultra High Molecular Weight Polyethylene, Acetal, PTFE, Nylon, Flouroelastomer

110° F (43° C)

16 oz (450 grams)

*All readings were taken with fan valve fully closed, (full fan size) at 20 psi (140 kPa, 1.4 bar) and 100 psi (0.7 kPa, 7

bar) and at the assumed operator position. Sound Power tested to ISO 9614-2.

311937G 9

Page 10

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance

of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2006, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents

2ULJLQDOLQVWUXFWLRQV This manual contains English. MM 311937

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised 5/2013

Loading...

Loading...