Page 1

Instructions-Parts

Contractor & FTx Spray Guns

Contractor Models: 288420, 288421, 288425, 288475, 288477, 288478, 826085, 288009

FTx Models: 288427, 288428, 288429, 288430, 288431, 288436, 288438, 288477,

288478, 826086, 288008,262114, 262116

For the application of architectural paints and coatings.

Maximum Working Pressure: 3600 psi (248 bar, 24.8 MPa)

IMPORTANT SAFETY INSTRUCTIONS. Read all

warnings and instructions in this manual. Refer to your

sprayer instruction manual for Pressure Relief, priming and

spray instructions. Save all instructions.

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol

alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional,

product-specific warnings may be found throughout the body of this manual where applicable.

ti8501b ti8522b

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a cut, but it

is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking, or

servicing equipment.

311861G

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and

explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you iden-

tify and correct the problem.

• Keep a working fire extinguisher in the work area.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause a serious chemical reation and

equipment rupture. Failure to follow this warning may result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents.

• Many other fluids may contain materials that are incompatible with aluminum. Contact your material supplier for

verification.

II 2 G

Page 2

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See

Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material,

request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or in the operating area of the equipment to help protect you from serious injury. This equipment includes but is not limited to:

• Protective eyewear, gloves, hearing protection

• Clothing and respirator as recommended by the fluid and solvent manufacturer

Pressure Relief Procedure

Follow this Pressure Relief Procedure whenever instructed

to relieve pressure, stop spraying, check or service equipment,

or install or clean spray tip.

1. Turn OFF power and turn sprayer pressure control to lowest pressure setting.

2. Hold gun against side of flushing pail. Trigger gun into pail

to relieve pressure.

If you suspect spray tip or hose is clogged or that pressure has

not been fully relieved after following the steps above, VERY

SLOWLY loosen tip guard retaining nut or hose end coupling

to relieve pressure gradually, then loosen completely. Clear

hose or tip obstruction.

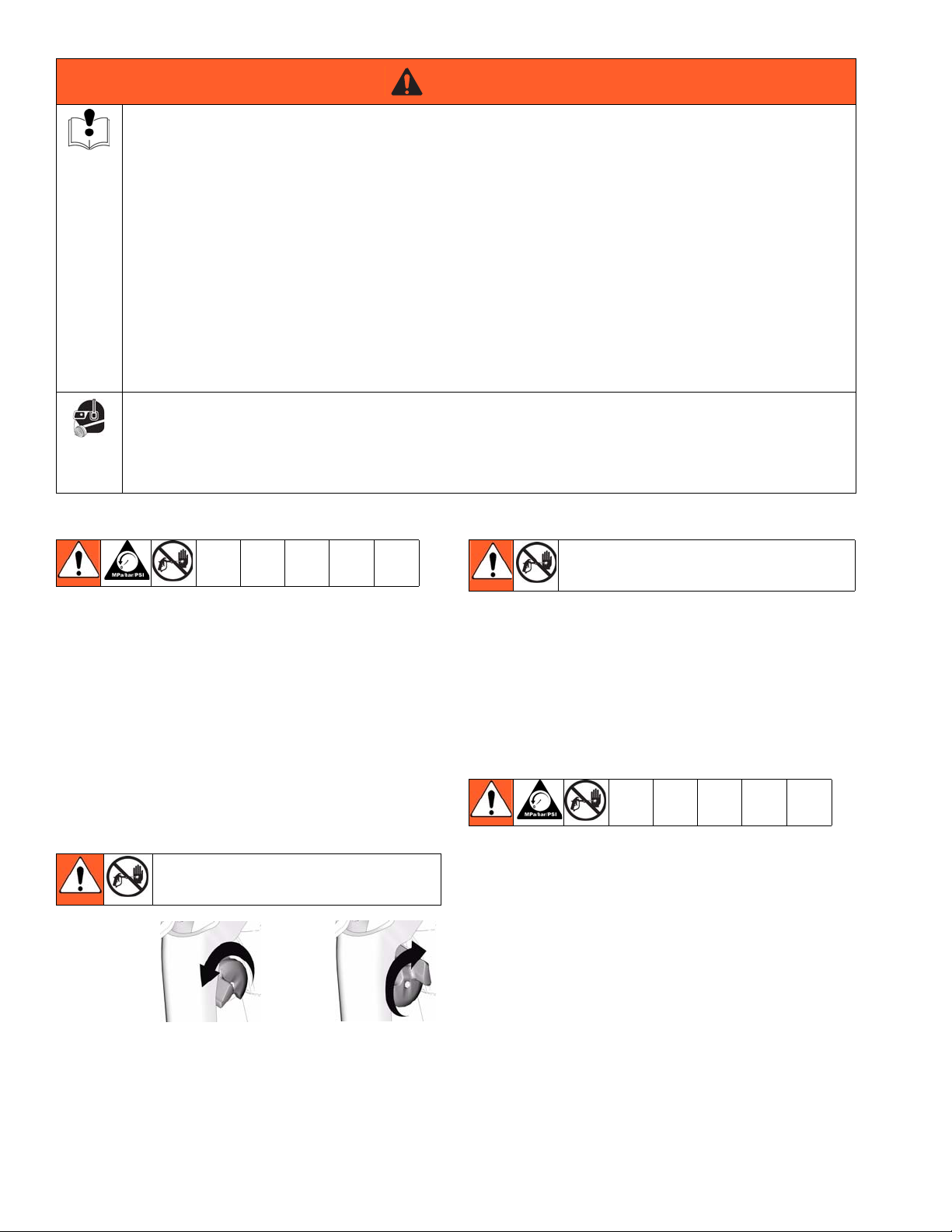

Gun Trigger Lock (2)

To prevent injury when the gun is not in use,

always set the gun’s trigger lock (2) if unit is

being shut down or left unattended.

Trigger Locked

(no spray)

ti10166a ti10167a

Tr i gg er

Unlocked

(spray)

Setup

Make sure sprayer is turned off and unplugged

from power source. Refer to your sprayer

manual for priming and spray instructions.

Connect Gun to Sprayer

1. Attach supply hose to sprayer fluid outlet.

2. Attach other end of supply hose to gun swivel (8). Use two

wrenches (one on the swivel (8) and one on the hose), to

tighten all connections securely.

3. Refer to sprayer instruction manual for priming

instructions.

Installing Tip (26) and Guard (25) on Gun

1. If equipment has recently been operated, relieve pressure. Set trigger lock (2).

2. Using a pencil or similar object, insert seal (24) into back

of guard (25).

3. Install guard (25) over end of gun (1).

4. Insert tip (26) in guard (25). Tighten retaining nut.

Operation

Spraying

1. Unlock trigger lock (2).

2. Be sure the arrow shaped tip (26) faces forward (spray).

3. Hold gun perpendicular and approximately 12-inches

(304 mm) from surface. Move gun first, then pull gun

trigger (13) to spray a test pattern.

4. Slowly increase pump pressure until coverage is uniform

and even (see sprayer instruction manual for additional

information).

2 311861G

Page 3

Aligning Spray

Clearing Clogs

Parts

1. Relieve pressure. Set trigger lock (2). Loosen guard

retaining nut.

2. Loosen guard retaining nut.

3. Align guard (25) horizontally to spray a horizontal pattern.

4. Align guard (25) vertically to spray a vertical pattern.

(3) Horizontal

ti9535B

(4) Vertical

ti9534B

Parts

22

21

20

(see page 4)

6

5

2

8

16/17

7b

ti8502b

15b

19

31

15a

14

13

12

1

11

7a

9

10

1. Relieve pressure. Set trigger lock (2).

2. Rotate tip (26) 180°. Unlock trigger lock (2). Trigger gun

into pail or onto ground to remove clog.

3. Set trigger lock (2). Rotate tip (26) 180° back to spray

position.

Cleanup

Flush gun after each work shift and store in a dry location. Do

not leave the gun or any parts in water or cleaning solvents.

Ref. Part Description Qty

1 288812 HOUSING, assy., Contractor 1

289914 HOUSING, assy., FTX 1

5 287032 FILTER, 60 mesh 1

287033 FILTER, 100 mesh 1

287034 FILTER, 60 and 100 mesh combo 1

6 120777 PACKING, o-ring 1

7 HANDLE 1

7a 15K282 Contractor Gun 1

7b 15J735 FTX Gun 1

15J736 FTX-A Gun (not shown) 1

8 288811 SWIVEL, assy, gun 1

9 120733 O-RING, urethane, clear 1

10 15J706 RETAINER, guard, trigger 1

11 15J698 TUBE, handle, Contractor Gun 1

12 120834 SCREW, set, Contractor Gun 1

13 15J409 TRIGGER, Contractor Gun 1

15J768 TRIGGER, Contractor Gun, 4-finger

(not shown)

15J769 TRIGGER, FTX Gun, 4-finger (not

shown)

14 117602 SCREW, shoulder, pan hd 2

15 288488 KIT, needle, repair 1

15a NEEDLE, assembly 1

15b DIFFUSER, assembly 1

16 15J696 PIN, trigger (page 4) 1

17 105334 NUT, lock, hex (page 4) 1

19 15J464 GUARD, trigger 1

20 15J528 GUIDE, spring 1

21 121093 SPRING, compression 1

22 15B549 NUT, end 1

31 119799 BRUSH, cleaning 1

1

1

Tip and Guard

RAC X

25

311861G 3

26

24

ti8505a

25

RAC 5

26

24

_

Ref. Part Description Qty

24 246453

243281

25 246215 GUARD, RAC X 1

243161 GUARD, RAC 5 1

26 LTX515 TIP, spray 515, RAC X 1

LTX517 TIP, spray 517, RAC X 1

286515 TIP, spray 515, RAC 5 1

286517 TIP, 517, RAC 5 1

PAA517 TIP, spray, latex, RAC X (517), Europe 1

PAA515 TIP, spray, latex, RAC X (515), Europe 1

262517 TIP, spray. 517, RAC 5, Europe 1

OneSeal

OneSeal™, RAC 5 (5-pack)

™

, RAC X (5-pack)

1

1

Page 4

Maintenance

Failure to clean or replace the

filter or damaged handle bore

can result in serious injury.

Before performing any maintenance on gun, read all warnings

on front cover of this manual and relieve pressure.

Cleaning/Replacing Filter (5)

A plugged filter reduces gun performance. Clean filter after

each use.

1. Relieve pressure. Set trigger lock (2).

2. Disconnect fluid hose from gun at swivel (8).

3. Disconnect trigger guard (19) from guard retainer (10).

4. Unscrew handle (7) from gun (1).

5. Remove filter (5) through top of handle (7).

6. Inspect filter (5) for damage to the filter mesh. Replace the

filter if the filter mesh has holes or voids.

7. Clean filter (5). Use a soft brush to loosen and remove

excess debris.

8. Inspect handle bore (7) for damage. Replace the handle

bore if it is corroded or pitted and check material for

compatibility with aluminum.

9. Insert clean filter (5) into handle (7).

10. Reattach handle (7) to gun (1). Tighten securely.

11. Reconnect trigger guard (19) to guard retainer (10).

Repair

Tools needed:

• 8-inch adjustable wrench

• 1/4-inch nut driver

Replacing Needle

15a

15b

16

17

1

1. Relieve pressure. Set trigger lock (2).

2. Remove tip (26) and guard (25) from gun (1).

3. Disconnect fluid hose from gun at swivel (8).

4. Remove nut (17) and trigger pin (16).

5. Unscrew diffuser (15a) from front of gun (1).

6. Remove needle assembly (15b) through front of gun (1).

7. Use a soft brush to clean out internal passages of gun.

8. Grease o-rings of new needle using a non-silicon grease.

9. Guide new needle (15b) through front of gun (1) making

sure the flat sides (a) of the needle assembly face the

sides of gun housing.

10. Install diffuser (15a). Torque diffuser to 26-30 ft-lbs

(35.25 - 43.38 N•m).

11. Replace pin (16) and nut (17).

Translated Manuals

Spanish - 312098 Estonian - 312277

French - 312099 Latvian - 312278

Dutch - 312265 Lithuanian - 312279

German - 312266 Polish - 312280

Italian - 312267 Hungarian - 312281

Turkish - 312268 Czech - 312282

Greek - 312269 Slovakian - 312283

Croatian - 312270 Slovenian - 312284

Portuguese - 312271 Romanian - 312285

Danish - 312272 Bulgarian - 312286

Finnish - 312273 Chinese - 312287

Swedish - 312274 Japanese - 312288

Norwegian - 312275 Korean - 312289

Russian - 312276

Translated manuals can be requested through a distributor or

at www.graco.com.

a

ti8510b

Technical Data

Maximum working pressure 3600 psi (248 bar, 24.8 MPa)

Fluid orifice size 0.125 in. (3.18 mm)

Weight (with tip and guard) 22 oz. (630 g)

Inlet 1/4 npsm swivel

Maximum material temperature 120°F (49°C)

Wetted parts Stainless steel, polyurethane, nylon, aluminum, tungsten carbide, solvent resistant elastomer, brass

Noise Level*

Sound power 87 dBa

Sound pressure 78 dBa

*Measured at 3.1 feet (1m) while spraying water-based paint, specific gravity 1.36, through a 517 tip at 3000 psi (207 bar, 20.7 MPa) per ISO 3744

For complete warranty information contact your Graco distributor, call Graco customer service: 1-800-690-2894 or visit our website: www.graco.com

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 311861

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2007, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 03/2009

Loading...

Loading...