Page 1

Operation

Displacement Pump

- Use with Architectural Coatings, Paints, Roof Coatings

and Below Grade Coatings -

Model 287834

4000 psi (27.6 MPa, 275.8 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

311485J

EN

ti7629a

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment and

follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

2 311485J

Page 3

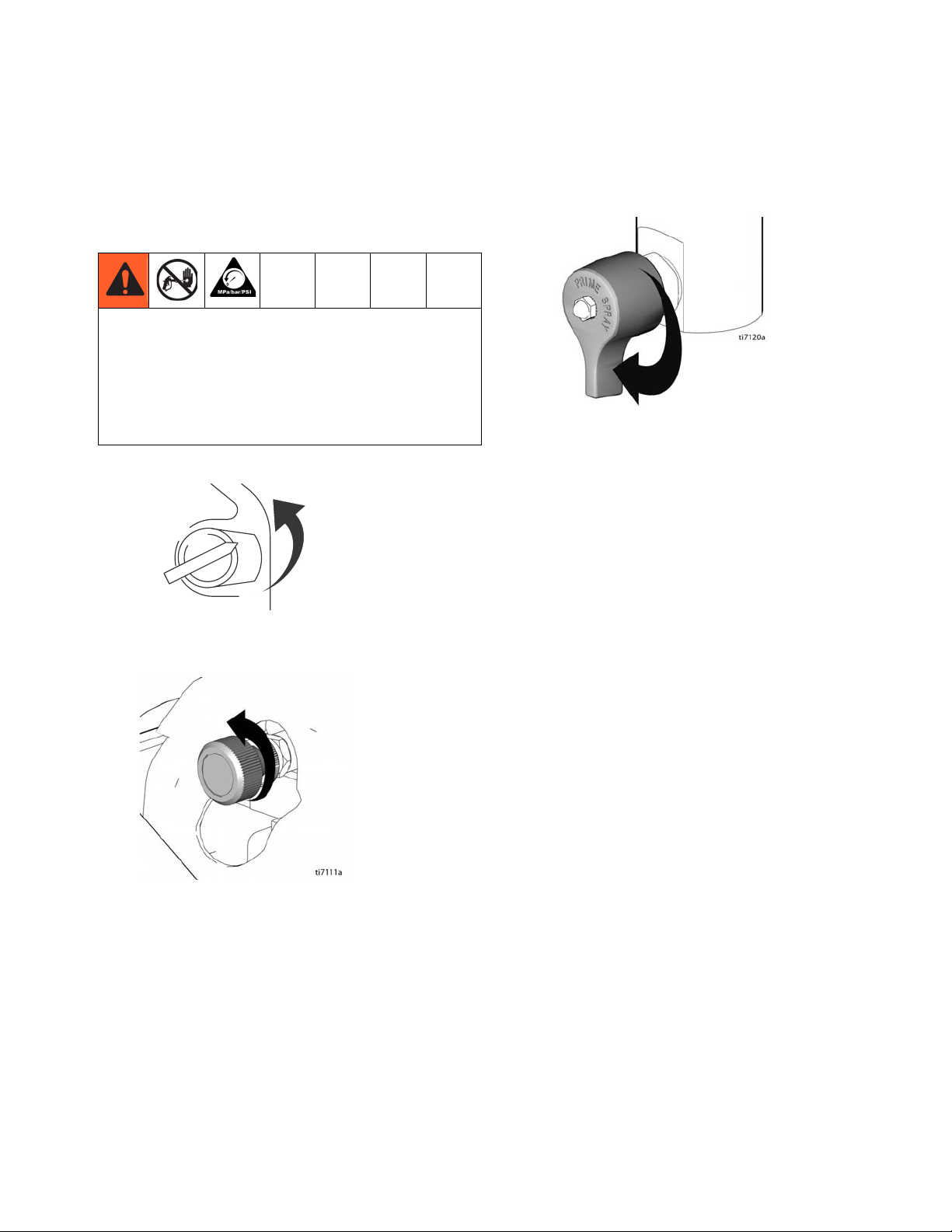

Operation

Operation

Pressure Relief Procedure

System pressure must be manually relieved to prevent

it from starting or spraying accidentally. Fluid under

high pressure can be injected into the skin and cause

serious injury. To reduce risk of injury from injection,

follow this procedure whenever you are instructed to

relieve pressure, stop spraying, service equipment or

install or clean spray tip (read Warnings, page 2).

1. Set pump valve OFF. Turn engine OFF.

TIA

2. Turn pressure to lowest setting. Trigger gun into pail

to relieve pressure.

3. Open prime valve (vertical).

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY, loosen

tip guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Then clean

tip and hose.

311485J 3

Page 4

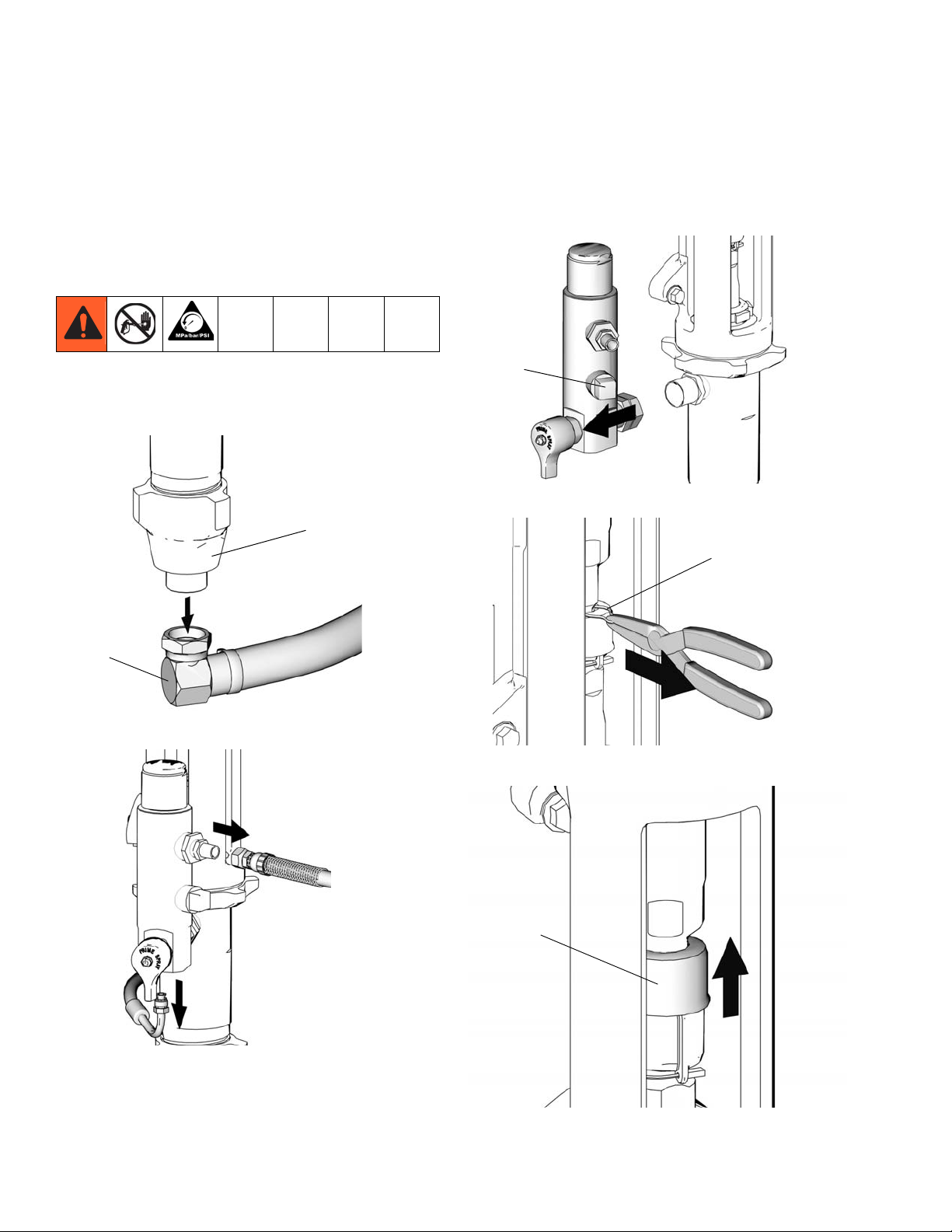

Service

Service

Removal

1. Flush pump (36). Stop pump on down stroke if possible.

2. Perform Pressure Relief Procedure, page 3.

3. Remove suction set (147) from pump (36).

36

5. Using a wrench, loosen filter housing fitting (110)

and remove housing from pump.

110

ti7119b

6. Using a pliers, remove clip (121).

121

147

ti7597b

4. Remove paint and drain lines from filter housing.

ti7845b

ti7789b

7. Slide cover (124) up.

124

ti7816b

4 311485J

Page 5

Service

8. Separate coupling (125) and remove.

125

ti7814b

9. Using a hammer, loosen jam nut (122). Unscrew

pump (36) from power head.

Ball Adjustment

1. Using a hammer, loosen and remove intake valve

(213).

213

ti7875b

2. Disassemble and clean all parts and o-rings (207).

209

215

122

36

10. Remove pump (36).

ti7782b

214

207

212

213

ti7879b

3. Select proper ball travel for material sprayed. Reassemble as shown.

Shortest Ball Travel

(for light material)

Longest Ball Travel

(for heavy material)

36

ti7804b

311485J 5

ti7881a

ti7874a

Page 6

Service

Piston Rod Assembly

1. Tap piston rod out of cylinder with a hammer or flip

over and tap piston rod out against bench.

NOTE: Sleeve may come out of cylinder with piston

rod.

2. If piston rod and sleeve did not separate, invert piston rod (222) and sleeve (220) and pound on hard

surface until piston rod comes out of sleeve.

ti7877a

4. Remove parts. Note orientation of parts for reassembly.

222

218

223

Lips Up

203

Lips Up

219

206

210

ti7878a

5. Clean all parts with a compatible solvent and

inspect them for wear or damage. Replace any worn

parts.

Component Rupture Hazard. Do not clean or wipe

piston valve threads. Cleaning the piston valve threads

could destroy the special sealing patch and cause the

piston valve to come loose during operation, causing

pump bursting and possible serious bodily injury.

3. Hold piston valve (210) securely in vice. Using a

wrench, separate piston valve (210) from rod (222).

Reassembly

1. Soak all leather packings (237) in SAE 30W oil for at

least 1 hour prior to assembly.

2. Alternately stack V-Packings (203) and V-Packings

(223).

208

Torque to 200

ft.-lb (272 N.m)

223

Lips Up

222

218

203

Lips Up

219

206

210

ti7880a

6 311485J

ti7878a

Page 7

Service

3. Grease piston rod (222) packings and top edge of

sleeve (220).

222

220

ti7898a

4. Carefully slide piston rod assembly (222) into top

edge of sleeve (220).

222

6. Grease o-ring (207) and place on sleeve. Slide one

o-ring (207) inside cylinder (205). Slide sleeve/piston rod assembly (222) into bottom of cylinder.

207

222

205

ti7895a

207

7. Install male gland (204) in cylinder (205).

8. Alternately stack UHMWPE packings (238) and

leather packings (237) (note orientation).

220

ti7896a

5. Grease top inch or two of piston rod (222) that will

go through the cylinder throat packings.

222

ti7897a

9. Place female gland (217) in top of cylinder. Loosely

install packing nut (202) and plug (201).

201

202

217

237

Lips Down

238

Lips Down

204

222

205

ti7884a

311485J 7

Page 8

Service

10. Reassemble intake valve (213) as shown.

209

215

214

207

212

213

ti7873a

11. Place intake valve (213) assembly in vice. Install

cylinder (205) assembly to intake valve. Torque to

350 ft-lb (475 N•m).

14. Hand tighten jam nut (122). Then tighten securely

1/8 to 1/4 turn with hammer or torque to 330 ft-lb

(447.4 N•m).

122

ti7817a

15. Install coupling (125) around pump rod.

125

ti7882a

12. Torque packing nut (202) down to 50 ft-lb (68 N•m).

13. Screw jam nut (122) to bottom of pump threads

(36). Screw pump completely up into power head.

122

ti7779a

36

ti7771a

16. Slide cover (124) over coupling (125).

124

125

ti7815a

8 311485J

Page 9

Service

17. Replace clip pin (121) to secure.

18. Reinstall filter housing (110).

110

ti7809a

19. Connect suction hose (147) to pump outlet (36).

36

121

125

ti7764a

147

ti7772a

311485J 9

Page 10

Parts

Parts

Ref. Part Description Qty.

201* 116385 PLUG 1

202 15G198 NUT, packing 1

203* 15G285 V-PACKING, UHMWPE, blue 3

204* 15H250 GLAND, male, throat 1

205 287836 CYLINDER, pump 1

206* 102972 BALL, sst, 0.875 in. 1

207*† 116377 PACKING, o-ring 3

208 15G196 GUIDE, ball 1

209 197306 SHIM, inlet 3

210 287837 VALVE, piston 1

212† 287838 SEAT, carbide, includes 214 and

207

213 15G195 HOUSING, intake (foo) 1

214*† 108001 BALL, sst, 1.5 in. 1

215 15G199 GUIDE, ball 1

Assemble with lips facing up

2

Assemble with lips facing down

1

201

202

217

1

237

Ref. Part Description Qty.

216 15H335 FITTING, nipple, 1 inch NPT 1

217* 15H251 GLAND, female, piston steel 1

218* 15G282 GLAND, male 1

219* 15G283 GLAND, female 1

220 287833 SLEEVE, cylinder 1

222 287832 ROD, piston 1

223* 15G284 V-PACKING, brown 2

237* 184307 PACKING, vee, leather 2

238* 108451 PACKING, vee, (UHMWPE) 3

* These parts are included in repair kit 287835, which

1

may be purchased separately.

† These parts are also included in Carbide Seat Kit

287838, which may be purchased separately.

238

1

205

2

208

218

203

219

204

222

206

210

223

216

207

220

207

209

215

2

214

207

212

213

ti7630a

10 311485J

Page 11

Notes

Notes

311485J 11

Page 12

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2006, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 311485

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised September 2012

Loading...

Loading...