Page 1

Instructions

Important Safety Instructions.

Read all warnings and instructions in this

manual. Save these instructions.

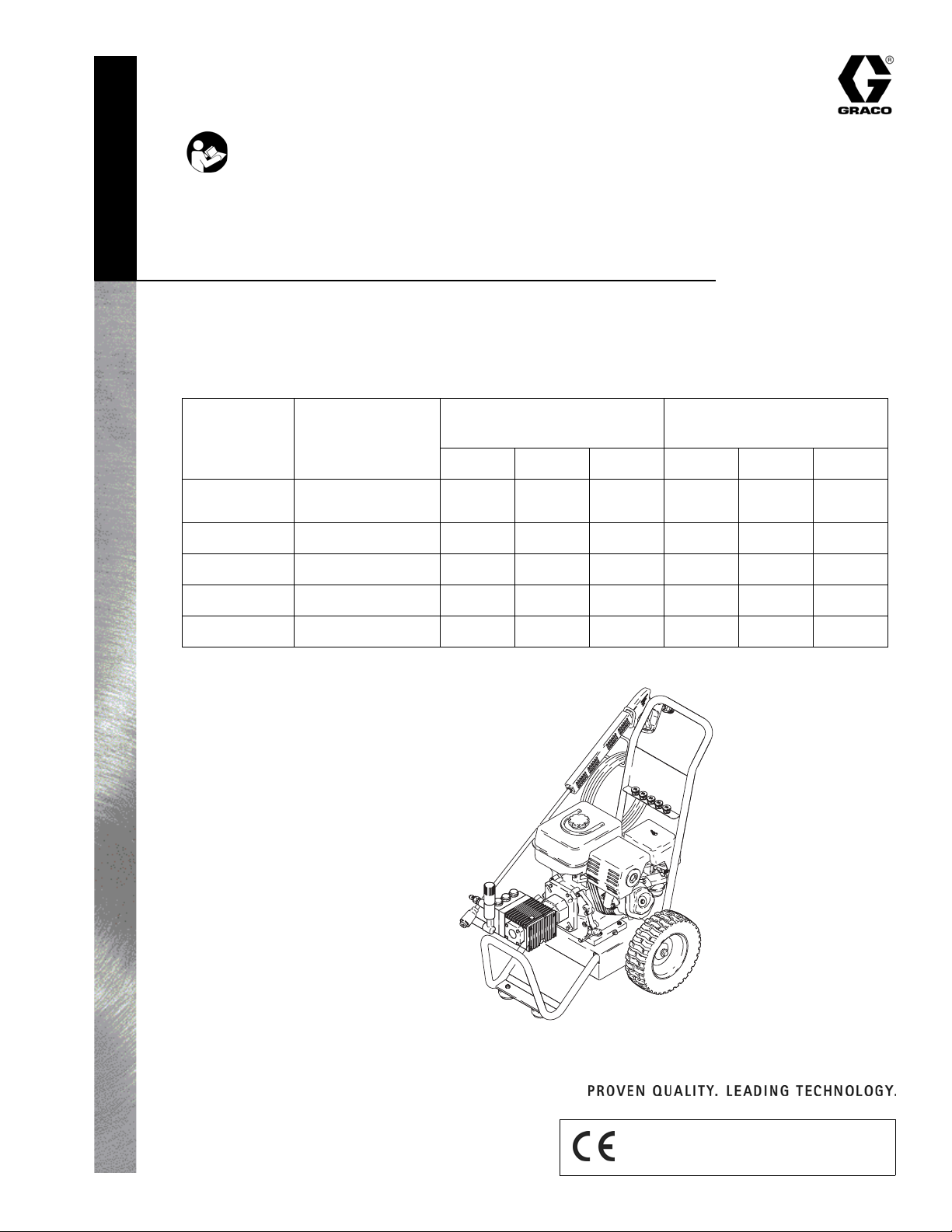

Direct Drive Pressure Washer

- For high pressure water cleaning -

Models:

Operating Pressure

PSI MPa bar PSI MPa bar

2700 18.6 186 3000 20.6 206

Model

2730B

2730H

3030

3340

3540

Horse Power and

Motor Brand

6.5 hp Briggs &

Stratton

6.5 hp Honda 2700 18.6 186 3000 20.6 206

9 hp Honda 3000 20.6 206 3300 22.75 227.5

11 hp Honda 3300 22.75 227.5 3600 24.0 248

13 hp Honda 3500 24.1 241 3800 26.2 262

309286K

Maximum Working

Pressure

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2004, Graco Inc. is registered to I.S. EN ISO 9001

ti5418a

Page 2

Warnings

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable

and can ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground equipment and conductive objects in work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a fire extinguisher in the work area.

Warnings

WARNING

INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the end of the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide can cause death. Do not operate in an enclosed area.

2 309286K

Page 3

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

309286K 3

Page 4

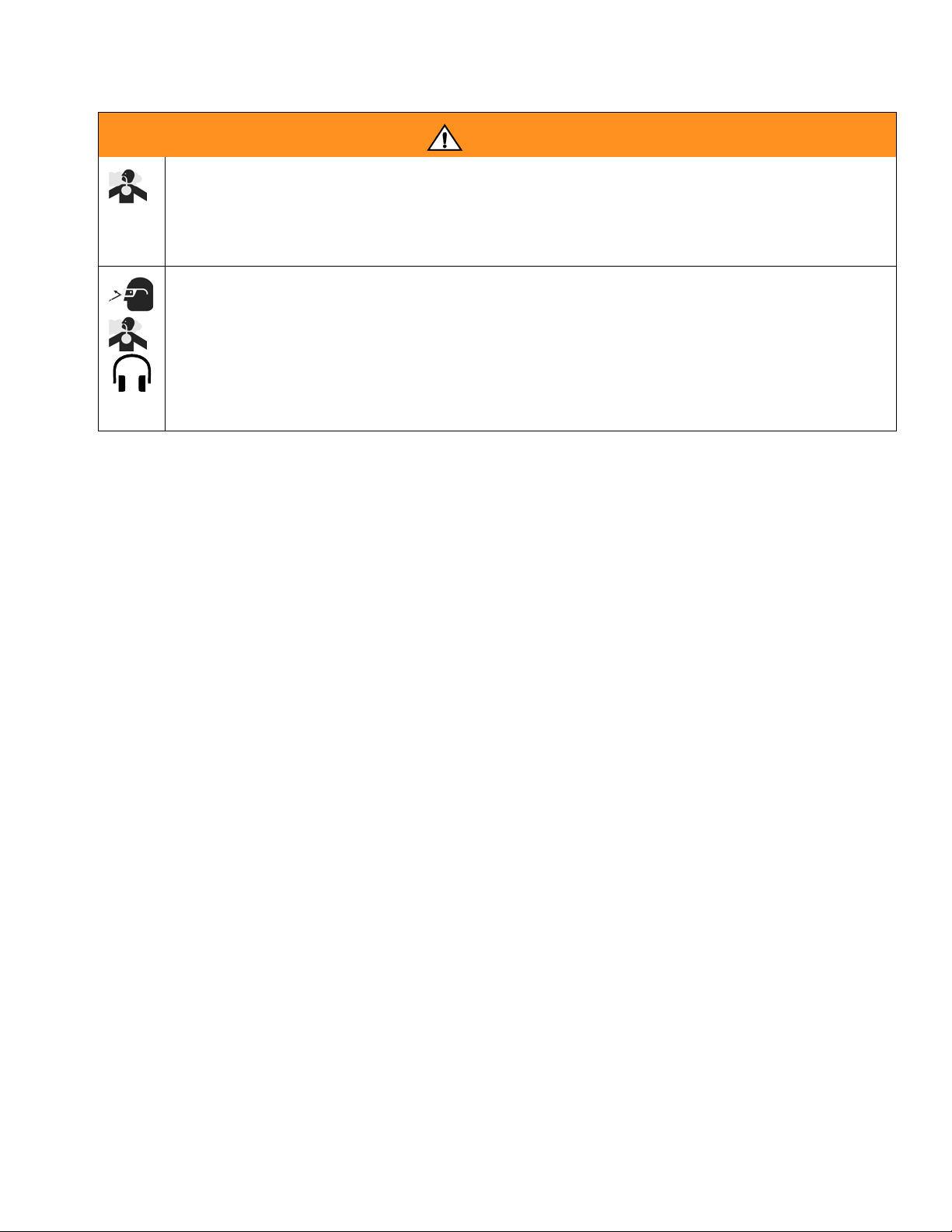

Component Identification

Component Identification

A

D

C

B

M

E

L

K

Key:

AHose

B Hose Rack

C Gun Holder

D Gun and Wand

E Tip Storage

F Engine Oil Fill

G Water Pump Oil Fill

F

A

HJ

H Oil Level Site Gage

J Pressure Unloader Adjustment Knob

K Garden Hose Connection

L High Pressure Hose Connection

M Engine ON/OFF Switch

G

4 309286K

Page 5

Setup

Setup

Shipping Damage

Check pressure washer for shipping damage. Notify the

carrier immediately if there is any damage.

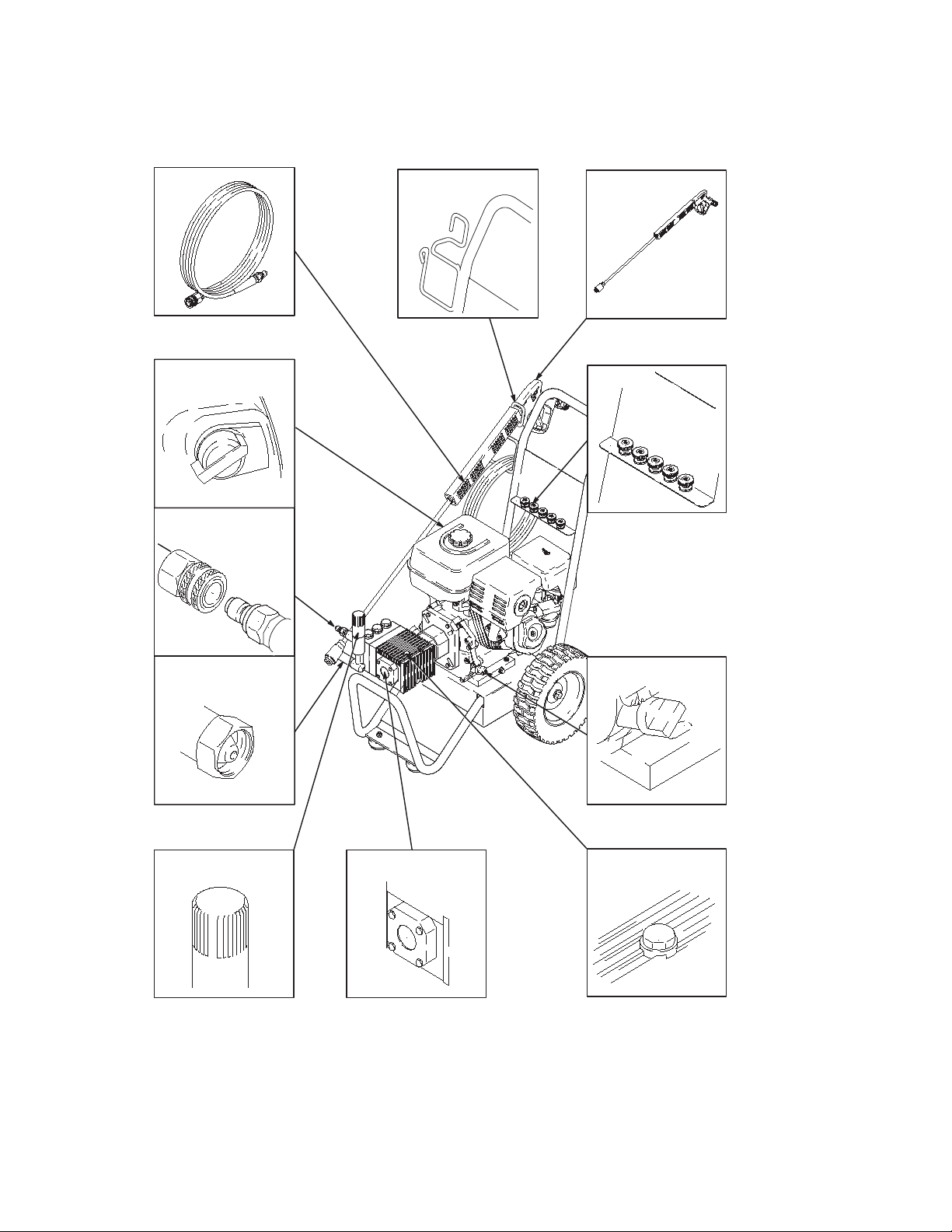

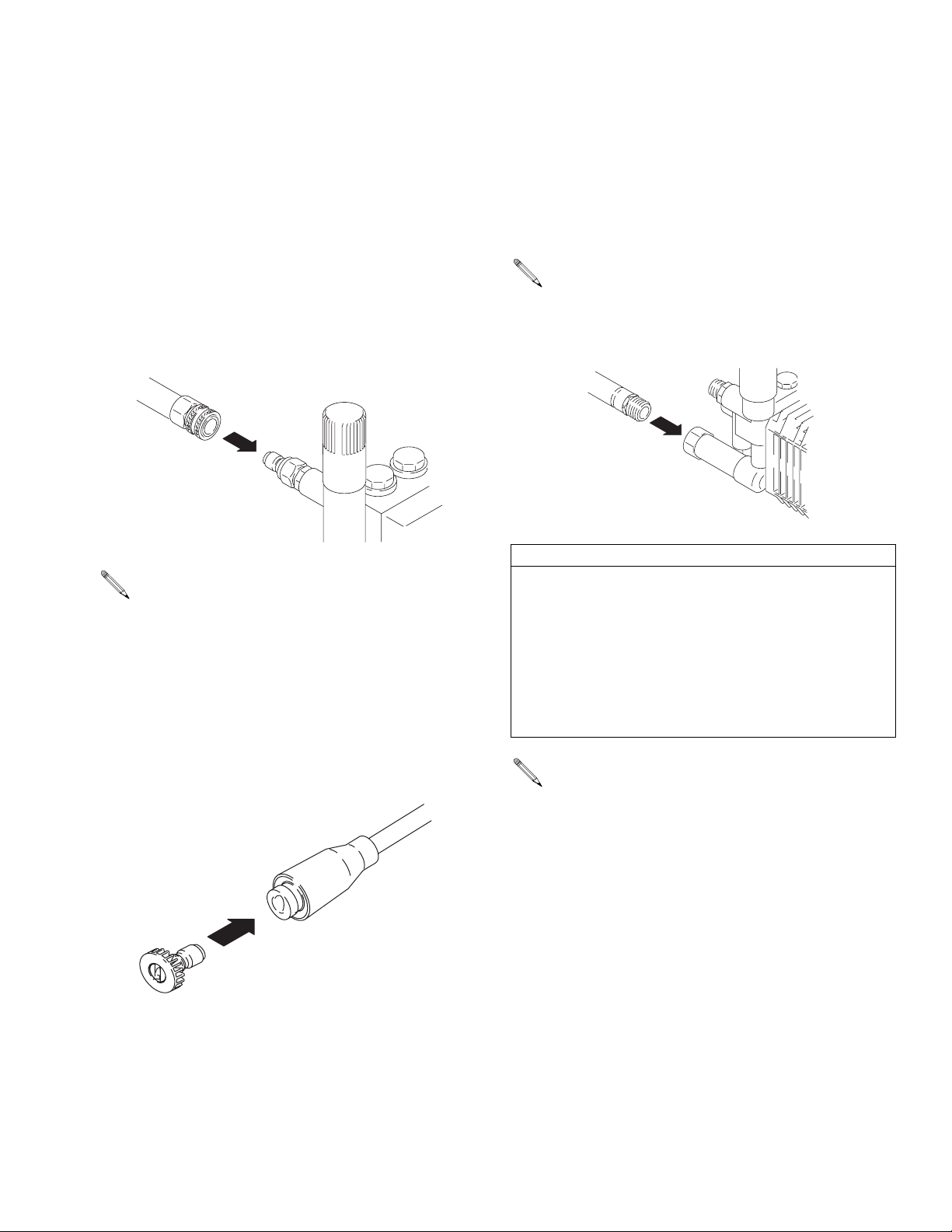

Connecting High-Pressure Hose and Gun

Connect high-pressure hose between pump outlet and

gun inlet. Both of these connections are made with quick

couplers.

ti5420a

Up to 100 ft (30 m) of 3/8 in. high-pressure hose

may be used. Longer hoses could affect pressure

washer and chemical injector performance

balance.

Installing Spray Tip

Install spray tip on wand. (Installing and Changing Spray

Tips, page.) If you are using a Sandblasting Kit, see its

separate manual for installation instructions.

Connect to Water Supply

Connect hose from water supply to the garden hose

inlet on the pressure washer.

• The supply hose should not be longer than 50

ft (15 m) in length.

• Inside diameter of hose should measure at

least a 3/4 in. (19 mm).

ti5422a

CAUTION

• Before you connect garden hose to pressure

washer, check your local plumbing code regarding

cross-connection to the water supply. If required,

install a backflow preventer.

• If the inlet water pressure is over 60 psi (4.1 bar, 41

MPa), a regulating water valve must be installed at

the garden hose connection.

• Do not exceed 160° F (70° C) inlet water temperature.

The water source must have a minimum flow rate

equal to that of the pressure washer.

ti5421a

309286K 5

Page 6

Operation

ti5427a

Operation

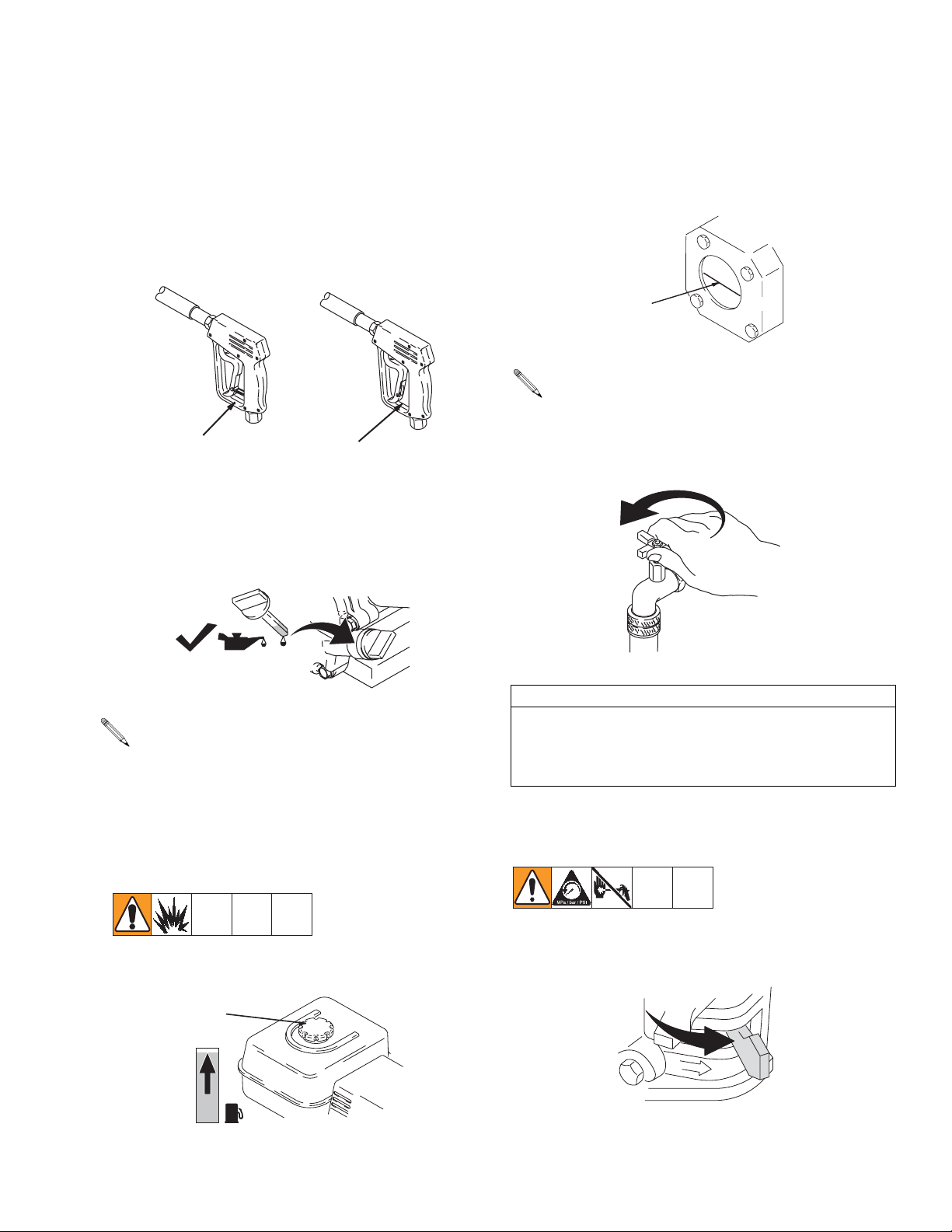

Pressure Relief Procedure

Follow this procedure when you stop spraying and

before cleaning, checking, servicing or transporting

equipment.

1. Engage trigger lock.

TIA

4. Turn off water supply and disconnect pressure

washer from water.

ti5425a

5. Unlock trigger lock. Trigger gun to relieve pressure.

Engage trigger lock.

2. Turn pressure washer OFF.

ON

OFF

ti5424a

3. Remove ignition cap from spark plug.

If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the pressure relief procedure, VERY

SLOWLY loosen tip guard retaining nut or hose end

coupling to relieve pressure gradually, then loosen

completely. Clear hose or tip obstruction.

6 309286K

Page 7

Operation

ti5431a

Startup

• Always engage the gun trigger safety latch when

you stop spraying. This reduces the risk of fluid

injection or splashing in eyes or on skin if the gun is

bumped or triggered accidentally. Be sure latch is

pushed fully down or it will not prevent the gun from

being triggered.

ti5437a

engaged

• When using a sandblasting kit, refer the sandblaster

kit instruction manual for detailed operating and

cleaning information.

1. Check oil level of engine and pump.

disengaged

3. Check oil level in pump. It should be half way up the

sight glass, located on the front of the pump. Add

pump oil as necessary. The system is equipped with

a thermal overload to help prevent severe damage.

Oil level

ti5430a

After the first 50 hours of operation, drain and refill

pump oil.

4. Turn on water supply.

ti5428a

• All Honda engine-powered pressure washers

are equipped with an engine low-oil sensor that

shuts the engine off when the oil level falls

below a certain level.

• If the engine stops unexpectedly, check the oil

and fuel levels.

• Check the oil level each time you add fuel.

2. Check fuel level.

Fuel level

ti5429a

.

CAUTION

Always be sure the water supply is completely turned

on before you run the pressure washer. Never run

pressure washer without water. Costly pump damage

will result.

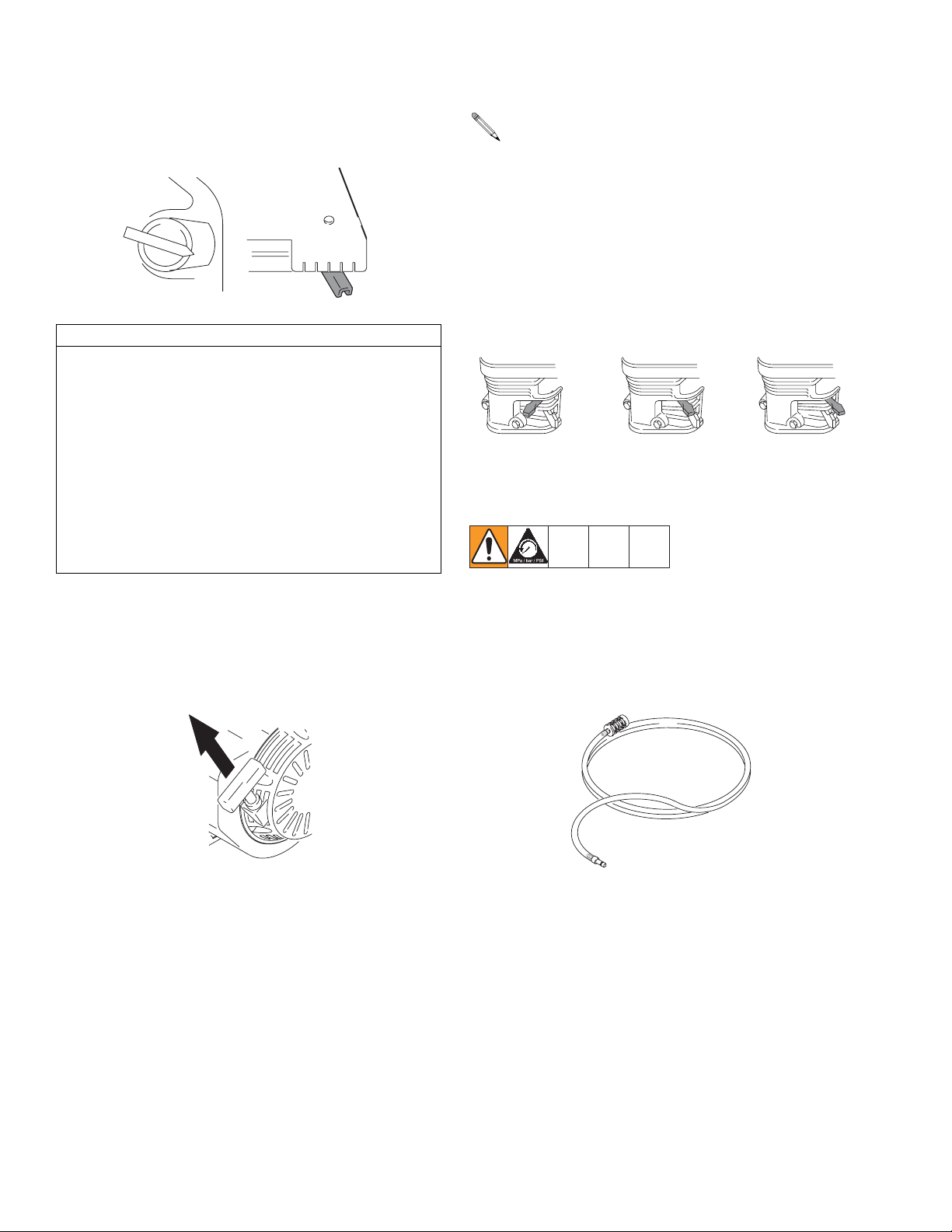

5. Trigger gun until a constant stream of water sprays

from the tip, indicating air is purged from the system.

6. Open fuel shutoff valve. Be sure spark plug ignition

cable is pushed firmly on the spark plug.

ON

ti5433a

309286K 7

Page 8

Operation

7. Move switch to ON position and set throttle to HALF

throttle position.

OFF

ON

ti5434a

CAUTION

• Do not allow pressure washer to idle for more than

10 minutes. This causes the recirculating water to

overheat and can seriously damage the pump.

• Turn off pressure washer if it will not be spraying at

least every 10 minutes. If heated inlet water is used,

reduce this time more.

• Do not operate pressure washer with inlet water

screen removed. This screen help keep abrasive

sediment out of pump. This sediment could clog

pump or damage cylinders. Keep screen clean.

• Do not pump caustic materials which could corrode

pump components.

• For easier starting, have one person start pressure washer while another triggers gun.

• If engine is cold, before starting engine, close

choke completely. In cool weather you might

have to run engine for the first 10-30 seconds

with the choke closed. In warm weather, open

choke completely as soon as engine starts.

• If engine is warm, start engine with choke

completely open or only partially closed. When

engine starts, open choke completely.

CLOSED

HALF

ti5436a

Chemical Injector Operation

OPEN

8. Trigger gun to produce a constant stream of water

and, at the same time, pull starter rope quickly to

start the engine. Pull and return rope until the

engine starts. HINT: Placing one foot on the pressure washer as a brace provides better leverage.

ti5435a

1. Follow Pressure Relief Procedure (page 6).

2. Insert chemical filter (attached with clear tubing to

chemical injector) into the chemical container. Insert

brass coupler into chemical injector.

ti5438a

8 309286K

Page 9

Operation

3. Install black (large orifice) chemical tip (Installing

and Changing Spray Tips, page 9).

The large orifice of the chemical tip causes a drop

in pressure that actuates the chemical injector.

Changing back to a small orifice spray tip, deactivates the chemical injector and produces high pressure for rinsing. The chemical filter can be left in the

chemical container during high pressure spraying.

To regulate the flow rate of the chemical, turn the

chemical adjustment knob on the injector.

ti5439a

Installing and Changing Spray

Tips

Spray tips have 4- or 5-digit numbers on them. The first

two digits are the spray angle.

Spray Tip No. Spray Pattern Fan Angle

00XXX 0° blaster (red)

15XXX 15° (yellow)

25XXX 25° (green)

40XXX 40° (white)

Chemical* XX° (black)

*The chemical injector tip is brass and has a larger

opening and a black plastic cap.

1. Follow Pressure Relief Procedure, page 6.

2. Lock trigger safety.

3. Without holding your hand over the spray tip (A), pull

back the quick coupler ring (B). Remove the current

tip. Install a different tip. Push quick coupler ring

back into place.

B

A

CAUTION

To avoid the high pressure blowing the o-ring out of

the quick coupler, never operate the pressure washer

without a tip securely mounted in the quick coupler.

ti5440a

309286K 9

Page 10

Shutdown, Flushing and Storage

Shutdown, Flushing and Storage

Short-term Storage (less than 30

days)

• Before you store the pressure washer overnight or

transport it, disconnect the water supply and

CLOSE the fuel supply valve.

ti5441a

• After each use, wipe all pressure washer surfaces

with a clean, damp cloth.

Long-term (more than 30

days)/Winter Storage

• Do not store unit outside where it can be exposed to

rain, dirt or adverse weather conditions.

• Do not expose pressure washer to freezing temperatures or allow water to freeze in pressure washer

components which could cause the pump to

lock-up. If this happens, allow the pump to thaw naturally in a WARM ENVIRONMENT. Do not attempt

to speed up this process by pouring warm water on

the pump. This could cause additional damage to

the pump.

ENGINE:

1. Run engine until gas is gone or stabilize fuel and run

it through fuel system and carburetor.

2. Drain water out of pressure washer hose.

3. Turn fuel system of OFF position.

PUMP:

ti5442a

1. Place an antifreeze solution approximately 1 foot off

the ground. Attach one end of a 4- or 5-foot section

of hose to pump inlet and other end in the antifreeze

solution.

2. Pull starter rope on engine until antifreeze comes

out of pump outlet.

STORAGE LOCATION

Store pressure washer in garage, basement, or in an

area where it is protected from freezing temperatures.

10 309286K

Page 11

Maintenance Chart

Follow Pressure Relief Procedure, page 6.

Interval What to do

Daily • Clean water inlet screen and filter.

• Check engine and pump oil levels. Fill as necessary.

• Check gasoline level. Fill as necessary.

After first 5 hours of

operation

After every 25 hours

of operation

After first 50 hours

of operation

After every 100

hours of operation or

every 3 months

After every 500

hours of operation or

every 6 months

Change engine break-in oil. Drain oil when warm. Use SAE 30 or10W-30 detergent oil.

Clean and remove air cleaner foam. Wash with water and detergent. Dry thoroughly. Rub with

oil and squeeze to distribute oil.

Change pump break-in oil. Use approved SAE 20/30 pump oil.

• Clean or replace paper air cleaner cartridge. Tap gently to remove dirt.

• Change engine oil. Use SAE 30 or 10W-30 detergent oil.

Change pump oil. Use approved SAE 20/30 pump oil.

Maintenance Chart

309286K 11

Page 12

Troubleshooting

T

Problem Cause Solution

Engine will not start or it is hard to

start

Engine misses or lacks power Partially plugged air cleaner filter Remove and clean.

Pressure is too low and/or pump runs

roughly

Water leaks from under pump manifold

Water on oil side of pump Humid air condensing inside crank-

No gasoline in fuel tank or carburetor Fill tank with gasoline, open fuel shut-

off valve. Check fuel line and carburetor.

Low oil Add oil to proper level.

Engine ON/OFF switch in OFF position

Water in fuel or old fuel Drain fuel tank and carburetor. Use

Engine flooded or improperly choked Open choke. Pull engine starter rope

Dirty air cleaner filter Remove and clean filter.

Spark plug dirty, wrong gap or wrong

type

Gun not triggered Trigger gun while starting engine.

6.5 hp Briggs and Stratton model

may experience “vapor lock” due to

gas type and temperature

Valve adjustment (lash) worn Adjust valve (lash) to manufacturer’s

Spark plug dirty, wrong gap or wrong

type

Worn or wrong size tip Replace with tip of proper size.

Inlet filter clogged Clean. Check more frequently.

Worn packings, abrasives in water or

natural wear

Inadequate water supply Check water flow rate to pump.

Fouled or dirty inlet or discharge

valves

Restricted inlet Garden hose might be collapsed or

Worn inlet or discharge valves Replace worn valves.

Leaking high-pressure hose Replace high-pressure hose.

Worn packings Install new packings.

case

Worn packings Install new packings.

Oil seals leaking Install new oil seals.

Turn switch to ON position.

new fuel and make sure spark plug is

dry.

several times to clear out fuel. Make

sure spark plug is dry.

Clean, adjust gap or replace spark

plug.

Allow unit to cool approximately 15

minutes and restart.

specifications.

Clean, adjust gap or replace spark

plug.

Check filter. Replace packing.

Clean inlet and discharge valve

assemblies. Check filter.

kinked. Check hose and straighten to

remove kinks.

Change oil as specified in Maintenance Chart, page 11.

Troubleshooting

12 309286K

Page 13

Problem Cause Solution

Packings are failing frequently or prematurely

Strong surging at inlet and low pressure on discharge side

Troubleshooting

Scored, damaged, or worn plungers Install new plungers.

Abrasive material in fluid being

pumped

Install proper filtration on pump inlet

plumbing.

Inlet water temperature too high Check water temperatures. It should

not exceed 160°F (70°C).

Pump running too long without spraying

Never run pump more than 10 minutes without spraying.

Running pump dry Do not run pump without water.

Foreign particles in inlet or discharge

Clean or replace valves.

valve or worn inlet and/or discharge

valves

309286K 13

Page 14

Pump Service: 2730B/2730H Model Pressure Washers

Pump Service: 2730B/2730H Model Pressure Washers

Repair kits are available. See the Parts List, page 18 (2730B) or page 20 (2830H). For the best results, use all parts

in kits.

Servicing Plungers

1. Loosen plunger retaining nut five or six turns using a

13mm wrench. Push plunger toward the crankcase

• The following metric wrenches are needed:

5mm, 13mm, and 22mm.

• Drain and refill pump after 50 hours of operation.

Follow Pressure Relief Procedure, page 6.

Valves

For a set of six valves, order Valve Assembly Kit

804402.

1. Remove hex plug from the manifold using a 22mm

wrench.

2. Examine o-ring located under hex plug. Replace if

cut or distorted.

3. Remove valve assembly from cavity. The assembly

may come apart!

4. Install new valve, o-ring and hex plug. Torque to 33

ft-lb (45 N◆m).

Retorque the plug after 5 hours operation.

to separate plunger and retaining screw.

2. Remove nut from plunger and examine and clean

o-ring, backup ring, and copper bearing/gasket

washer.

3. Remove plunger and flinger from plunger shaft.

Clean parts as necessary.

4. Inspect plunger shaft for oil leaks from crankcase. If

leaking is obvious, replace oil seals. Otherwise, DO

NOT remove these seals because they cannot be

reused. Oil Seal Kits are available for replacing

seals.

5. Lightly grease the flinger (and oil seal if it is being

replaced) on plunger shaft. Then install plunger.

6. Lightly grease the retaining screw and outer end of

the plunger. Place washer, o-ring and backup ring

around screw and install nut through plunger.

Torque to 11 ft-lb (15 N◆m).

If replacing packings, see Servicing V-Packings,

page 15.

Pumping Section

1. Remove capscrews and lock washers from manifold

using a 5mm wrench.

2. Carefully separate manifold from the crankcase. You

may have to lightly tap the manifold with a soft mallet to loosen it.

CAUTION

To avoid damage to plunger or seals, keep manifold

properly aligned with the ceramic plungers when you

remove it.

3. Carefully examine each plunger for any scoring or

cracking. Replace as necessary.

14 309286K

7. Lubricate outside of each plunger. Slide the manifold on the crankcase, being careful not to damage

seals.

8. Install capscrews and washers finger tight. Torque

screws to 8.8 ft-lb (12 N◆m) following the tightening

pattern in the following figure.

5

8

14

3

2

7

6

ti5443a

Page 15

Uneven tightening could cause the manifold to bind

or jam.

Servicing V-Packings

1. Remove manifold as described in Pumping Section,

page 14.

2. Carefully pull packing retainer from manifold. Examine o-ring. Replace o-ring if cut or damaged.

Pump Service: 2730B/2730H Model Pressure Washers

6. Lightly grease packing cavities. Replace packings in

the following order:

• head ring

• v-packing

• intermediate ring

• head ring

• v-packing

• packing retainer

• o-ring in retainer groove

3. Remove V-packing and head ring. Pull out retainer

ring. Remove second V-packing and second head

ring.

4. Inspect all parts and replace as necessary.

5. Thoroughly clean packing cavities and inspect for

damage.

Packings must be installed in the proper order and

facing the correct direction. Improperly installed

parts will cause the pump to malfunction.

7. Reassemble manifold following procedure

described in Servicing Plungers, page 14.

309286K 15

Page 16

Pump Service: 3030, 3340, and 3540 Model Pressure Washers

Pump Service: 3030, 3340, and 3540 Model Pressure

Washers

Repair kits are available. See the Parts List, page 22. For the best results, use all parts in kits.

3. Carefully examine each plunger for any scoring or

cracking. Replace as necessary.

Servicing Plungers

Follow Pressure Relief Procedure, page 6.

• The following metric wrenches are needed:

6mm, 13mm, and 27mm.

• Drain and refill pump after 50 hours of operation.

Valves

For a set of six valves, order Valve Assembly Kit

804402.

1. Remove hex plug from the manifold using a 27mm

wrench.

2. Examine o-ring located under hex plug. Replace if

cut or distorted.

3. Remove valve assembly from cavity. The assembly

may come apart!

4. Install new valve, o-ring and hex plug. Torque to 73

ft-lb (99 N◆m).

Retorque the plug after 5 hours operation.

Pumping Section

1. Remove capscrews and lock washers from manifold

using a 6mm wrench.

2. Carefully separate manifold from the crankcase. You

may have to lightly tap the manifold with a soft mallet to loosen it.

CAUTION

To avoid damage to plunger or seals, keep manifold

properly aligned with the ceramic plungers when you

remove it.

Plunger Repair Kit 243430 is available to replace retainers, o-rings, washers, and backup rings for three cylinders.

1. Loosen plunger retaining nut five or six turns using a

13mm wrench. Push plunger toward the crankcase

to separate plunger and retaining screw.

2. Remove nut from plunger and examine and clean

o-ring, backup ring, and copper bearing/gasket

washer. Replace these parts if necessary using

Plunger Repair Kit 243430.

3. Remove plunger and flinger from plunger shaft.

Clean parts as necessary.

4. Inspect plunger shaft for oil leaks from crankcase. If

leaking is obvious, replace oil seals. Otherwise, DO

NOT remove these seals because they cannot be

reused. Oil Seal Kits are available for replacing

seals.

5. Lightly grease the flinger (and oil seal if it is being

replaced) on plunger shaft. Then install plunger.

6. Lightly grease the retaining screw and outer end of

the plunger. Place washer, o-ring and backup ring

around screw and install nut through plunger.

Torque to 14.4 ft-lb (19.5 N◆m).

If replacing packings, see Servicing V-Packings,

page 17.

7. Lubricate outside of each plunger. Slide the manifold on the crankcase, being careful not to damage

seals.

16 309286K

Page 17

Pump Service: 3030, 3340, and 3540 Model Pressure Washers

8. Install capscrews and washers finger tight. Torque

screws to 8.8 ft-lb (12 N◆m) following the tightening

pattern in the following figure.

5

8

14

3

2

7

6

ti5443a

Uneven tightening could cause the manifold to bind

or jam.

Servicing V-Packings

Two packing kits are available: one kit contains packings

only. The other includes packings, rings and retainers.

1. Remove manifold as described in Pumping Section,

page 16.

2. Carefully pull packing retainer from manifold. Examine o-ring. Replace o-ring if cut or damaged.

3. Remove V-packing and head ring. Pull out retainer

ring. Remove second V-packing and second head

ring.

4. Inspect all parts and replace as necessary.

5. Thoroughly clean packing cavities and inspect for

damage.

6. Lightly grease packing cavities. Replace packings in

the following order:

• head ring

• v-packing

• intermediate ring

• head ring

• v-packing

• packing retainer

• o-ring in retainer groove

Packings must be installed in the proper order and

facing the correct direction. Improperly installed

parts will cause the pump to malfunction.

7. Reassemble manifold following procedure

described in Servicing Plungers, page 16.

309286K 17

Page 18

Parts

244389, Series A - 2730B with Briggs and Stratton 6.5 HP Motor

Parts

TIC

18 309286K

Page 19

244389, Series A - 2730B with Briggs and Stratton 6.5 HP Motor

Parts

Ref.

No. Part No. Description Qty.

1 116299 ENGINE, gasoline, 6.5 HP Briggs

and Stratton

2 244749 PUMP, water, 2700, complete 1

3 244767 KIT, frame, includes wheels, feet

and tip grommets

4 244784 GUN 1

5 244783 HOSE, 4000 1

7 804511 WHEEL, pneumatic 2

8 805535 TIP, spray, red, 0° 1

9 805536 TIP, spray, yellow, 15° 1

10 805537 TIP, spray, green, 25° 1

11 805538 TIP, spray, white, 40° 1

244768 KIT, tip, 4-pack 1

12 805634 TIP, spray, chemical 1

13 804275 TUBING, chemical, 5/16 in. ID x 8 ft 1

15 101242 RING, retaining 2

16 110837 SCREW 4

17 111040 NUT 4

18 197428 COUPLING, quick release 1

19 116411 SPRING, compression 2

Ref.

No. Part No. Description Qty.

20 801546 SCREW, cap 2

1

21 100132 WASHER, flat 2

22 101566 NUT, lock 2

23 801504 FOOT, rubber 2

1

25 197792 KEY, square 1

26 116477 WASHER, nylon 2

27 244803 KIT, repair, unloader, preset, 2700 1

28 116460 VALVE, thermal 1

29 244741 KIT, repair, chemical injector 1

30 116557 MANIFOLD, pump, replacement 1

31 116558 COUPLING, chemical injector 1

32 804037 KIT, pump, packing (3 cylinders) 1

33 804402 KIT, pump, valve (3 cylinders) 1

34 804011 KIT, pump, plunger (order 3 to ser-

vice complete pump)

35 804033 KIT, pump, oil seal 1

37 244746 FITTING, pump, inlet 1

38 116563 NUT, push on (not shown) 2

39 244821 INJECTOR, chemical, complete 1

40 801012 GROMMETS 5

1

309286K 19

Page 20

Parts

244390, Series A - 2730H with Honda 6.5 HP Motor

Parts

WLF

20 309286K

Page 21

244390, Series A - 2730H with Honda 6.5 HP Motor

Parts

Ref.

No. Part No. Description Qty.

1 116298 ENGINE, gasoline, 6.5 HP Honda 1

2 244749 PUMP, water, 2700, complete 1

3 244767 KIT, frame, includes wheels, feet

and tip grommets

4 244784 GUN 1

5 244783 HOSE, 4000 1

7 804511 WHEEL, pneumatic 2

8 805535 TIP, spray, red, 0° 1

9 805536 TIP, spray, yellow, 15° 1

10 805537 TIP, spray, green, 25° 1

11 805538 TIP, spray, white, 40° 1

244768 KIT, tip, 4-pack 1

12 805634 TIP, spray, chemical 1

13 804275 TUBING, chemical, 5/16 in. ID x 8 ft 1

15 101242 RING, retaining 2

16 110837 SCREW 4

17 111040 NUT 4

18 197428 COUPLING, quick release 1

19 116411 SPRING, compression 2

20 801546 SCREW, cap 2

Ref.

No. Part No. Description Qty.

21 100132 WASHER, flat 2

22 101566 NUT, lock 2

23 801504 FOOT, rubber 2

1

25 197792 KEY, square 1

26 116477 WASHER, nylon 2

27 244803 KIT, repair, unloader, preset, 2700 1

28 116460 VALVE, thermal 1

29 244741 KIT, repair, chemical injector 1

30 116557 MANIFOLD, pump, replacement 1

31 116558 COUPLING, chemical injector 1

32 804037 KIT, pump, packing (3 cylinders) 1

33 804402 KIT, pump, valve (3 cylinders) 1

34 804011 KIT, pump, plunger (order 3 to ser-

vice complete pump)

35 804033 KIT, pump, oil seal 1

37 244746 FITTING, pump, inlet 1

38 116563 NUT, push on (not shown) 2

39 244821 INJECTOR, chemical, complete 1

40 801012 GROMMETS 5

41 804002 KNOB 1

1

309286K 21

Page 22

Parts

244391, Series A - 3030 with Honda 9 HP Motor

244392, Series A - 3340 with Honda 11 HP Motor

244393, Series A - 3340 with Honda 13 HP Motor

Parts

#

TIC

,QWHUQDOUHSODFHPHQWSDUWV

# Fastening bolts supplied with pump. Not sold separately.

22 309286K

Page 23

244391, Series A - 3030 Honda 9 HP Motor†

244392, Series A - 3340 Honda 11 HP Motor★

244393, Series A - 3540 Honda 13 HP Motor✓

Sound Data

Ref.

No. Part No. Description Qty.

1 803900† ENGINE, gasoline, GX270, 9 HP 1

803158★ ENGINE, gasoline, GX340, 11

HP

114703✓ ENGINE, gasoline, 13 HP 1

2 244750† PUMP, water, 3000, complete 1

244751★ PUMP, water, 3300, complete 1

244752✓ PUMP, water, 3500, complete 1

3 244767 KIT, frame, includes wheels, feet

and tip grommets

4 244784 GUN 1

5 244783 HOSE, 4000 1

7 804511† WHEEL, pneumatic 2

116478★✓ WHEEL, pneumatic 2

8 805539†★ TIP, spray, red, 0° 1

805543✓ TIP, spray, red, 0° 1

9 805540★ TIP, spray, yellow, 15° 1

805544✓ TIP, spray, yellow, 15° 1

10 805541†★ TIP, spray, green, 25° 1

805545✓ TIP, spray, green, 25° 1

11 805542†★ TIP, spray, white, 40° 1

805546✓ TIP, spray, white, 40° 1

244768†★ KIT, tip, 4-pack 1

800708✓ KIT, tip, 4-pack 1

12 805634 TIP, spray, chemical 1

13 804275 TUBING, chemical, 5/16 in. ID x

8 ft

15 101242 RING, retaining 2

16 110837 SCREW 4

17 111040 NUT 4

18 197428 COUPLING, quick release 1

Ref.

No. Part No. Description Qty.

19 116411 SPRING, compression 2

20 801546 SCREW, cap 2

1

21 100132 WASHER, flat 2

22 101566 NUT, lock 2

23 801504 FOOT, rubber 2

25 801137 KEY, square 1

26 116477 WASHER, nylon 2

27 244804† KIT, repair, unloader, preset,

1

244805★ KIT, repair, unloader, preset,

244806✓ KIT, repair, unloader, preset,

28 116461 VALVE, thermal 1

29 244741 KIT, repair, chemical injector 1

30 116559 MANIFOLD, pump, replacement 1

31 116558 COUPLING, chemical injector 1

32 804404 KIT, pump, packing (order 3 to

33 804402 KIT, pump, valve (3 cylinders) 1

34 804415 KIT, pump, plunger (order 3 to

35 804033 KIT, pump, oil seal 1

37 244746 FITTING, pump, inlet 1

38 198055✓ BRACKET, model 3540 only 1

1

39 116563 NUT, push on (not shown) 2

40 244821 INJECTOR, chemical, complete 1

41 801012 GROMMETS 5

42 804002 KNOB 1

3000

3300

3500

service complete pump)

service complete pump)

1

1

1

1

1

Sound Data

Sound Data Direct Drive Pressure Washer Models

2730B 2730H 3030 3340 3540

Sound Pressure 92.5 dB(A) 89.0 dB(A) 93.3 dB(A) 90.4 dB(A) 90.7 dB(A)

Sound Level 106.8 dB(A) 103.3 dB(A) 107.6 dB(A) 104.7 dB(A) 105.0 dB(A)

309286K 23

Page 24

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

24 309286K

Graco reserves the right to make changes at any time without notice.

MM 309286

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

Written in USA

2/2001 Rev 10/2006

Loading...

Loading...