Page 1

Repair

Drywall Feed Pump

U.S. Patents Pending: 61/315,288; 61/315/322; 61/316,013; 61/316,010

- For water-based materials only -

- Not for use in explosive atmospheres -

- Not for use with quick-set materials -

READ ALL WARNINGS AND INSTRUCTIONS

Read all warnings and instructions in this manual.

Save these instructions.

Maximum Working Pressure 2500 psi (17.2 MPa, 172 bar)

Model 257100: 120V NA ETL Listed

Model 258906: 240V Euro Multicord

Model 258907: 110V UK, CE

Model 262288: 120V NA

Model 262300: 240V Euro CE Cord

3A0246C

ENG

Agency Approvals:

257100 ✓✓✓

258906 ✓✓

258907 ✓

262288 ✓✓

262300 ✓✓

ti14873a

Page 2

Warning

Warning

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point

symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear

in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This may look like

just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Engage trigger lock when not dispensing.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or servicing

equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and

explosion:

• Do not dispense flammable or combustible materials near an open flame or sources of ignition such as cigarettes,

motors, and electrical equipment.

• Material or solvent flowing through the equipment is able to result in static electricity. Static electricity creates a

risk of fire or explosion in the presence of material or solvent fumes. All parts of the system, including the pump,

hose assembly, dispenser, and objects in and around the work area shall be properly grounded to protect against

static discharge and sparks. Use Graco conductive or grounded high-pressure airless material hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a material or a solvent containing halogenated hydrocarbons.

• Keep work area well-ventilated. Keep a good supply of fresh air moving through the area. Keep pump assembly in

a well ventilated area.

• Do not smoke in the work area.

• Do not operate light switches, engines, or similar spark producing products in the work area.

• Keep area clean and free of material or solvent containers, rags, and other flammable materials.

• Know the contents of the materials and solvents being dispensed. Read all Material Safety Data Sheets (MSDS)

and container labels provided with the materials and solvents. Follow the material and solvents manufacturer’s

safety instructions.

• Fire extinguisher equipment shall be present and working.

• Drywall feed pump generates sparks. When flammable liquid is used in or near the drywall feed pump or for

flushing or cleaning, keep unit at least 20 feet (6 m) away from explosive vapors.

2 3A0246C

Page 3

Warning

WARNING

WARNINGWARNINGWARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when dispensing.

• Do not operate or dispense near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off the unit and

follow the Pressure Relief Procedure for turning off the unit.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and

equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such

solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment

to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A0246C 3

Page 4

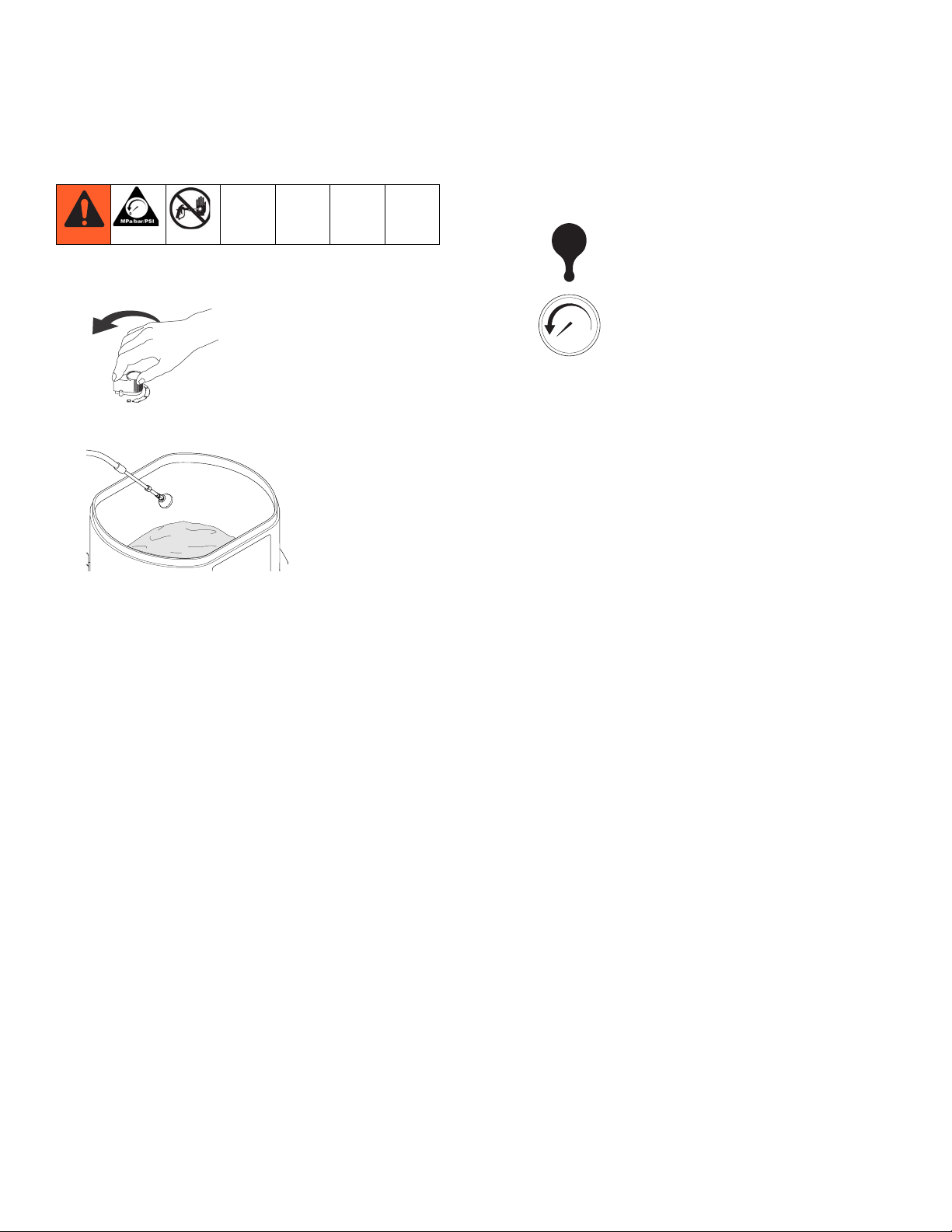

Pressure Relief Procedure

Pressure Relief Procedure

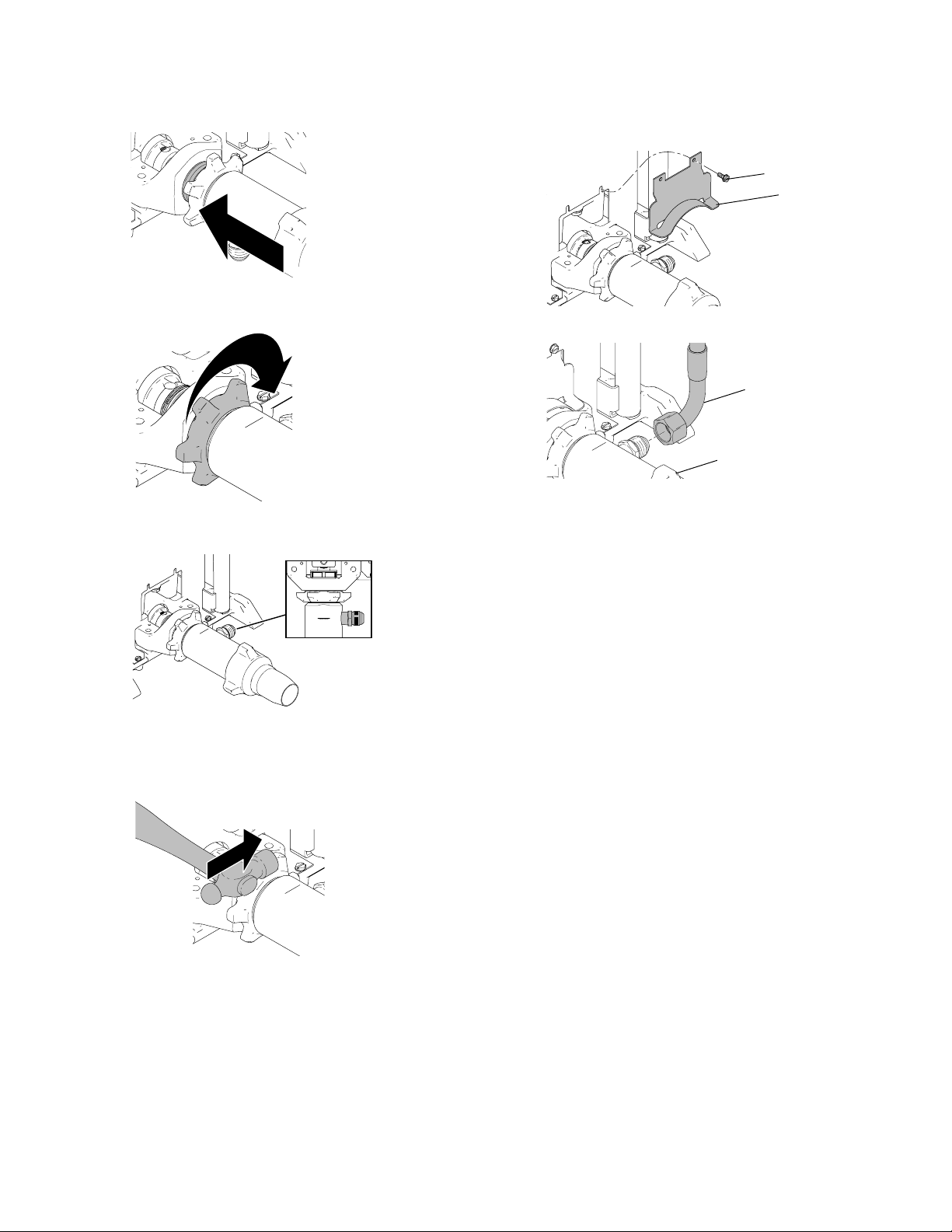

1. Turn flow control knob to fully counterclockwise to

OFF position.

3. Turn prime valve handle to PRESSURE RELIEF

position.

ti8793a

2. Place deflector in hopper or suitable container.

ti14876a

bar/psi

ti15614a

4. Display will read “----” when all pressure is relieved.

4 3A0246C

Page 5

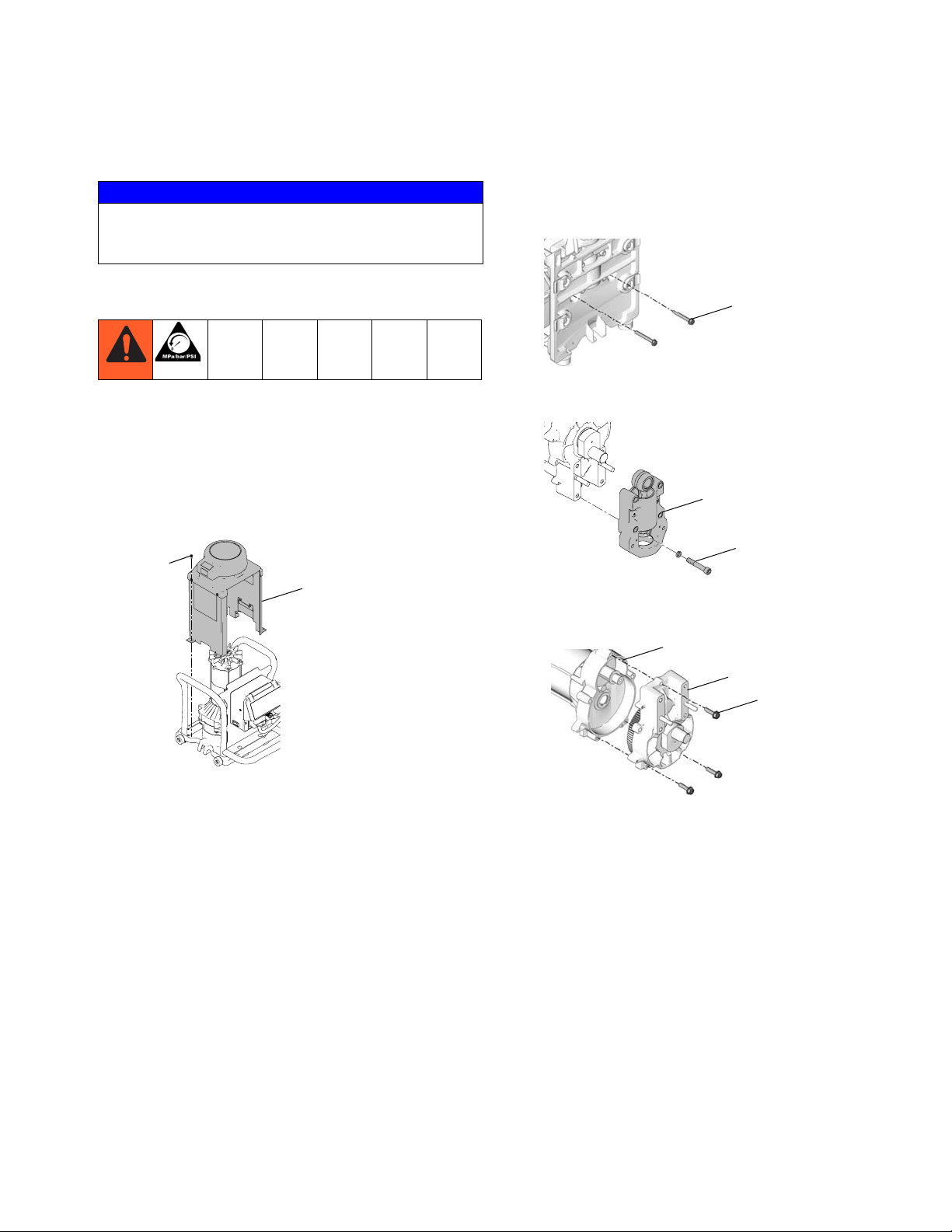

Drive and Bearing Housing

Drive and Bearing Housing

NOTICE

Do not drop gear cluster (17a) when removing drive

housing (5a). Gear cluster may stay engaged in motor

front end bell or drive housing.

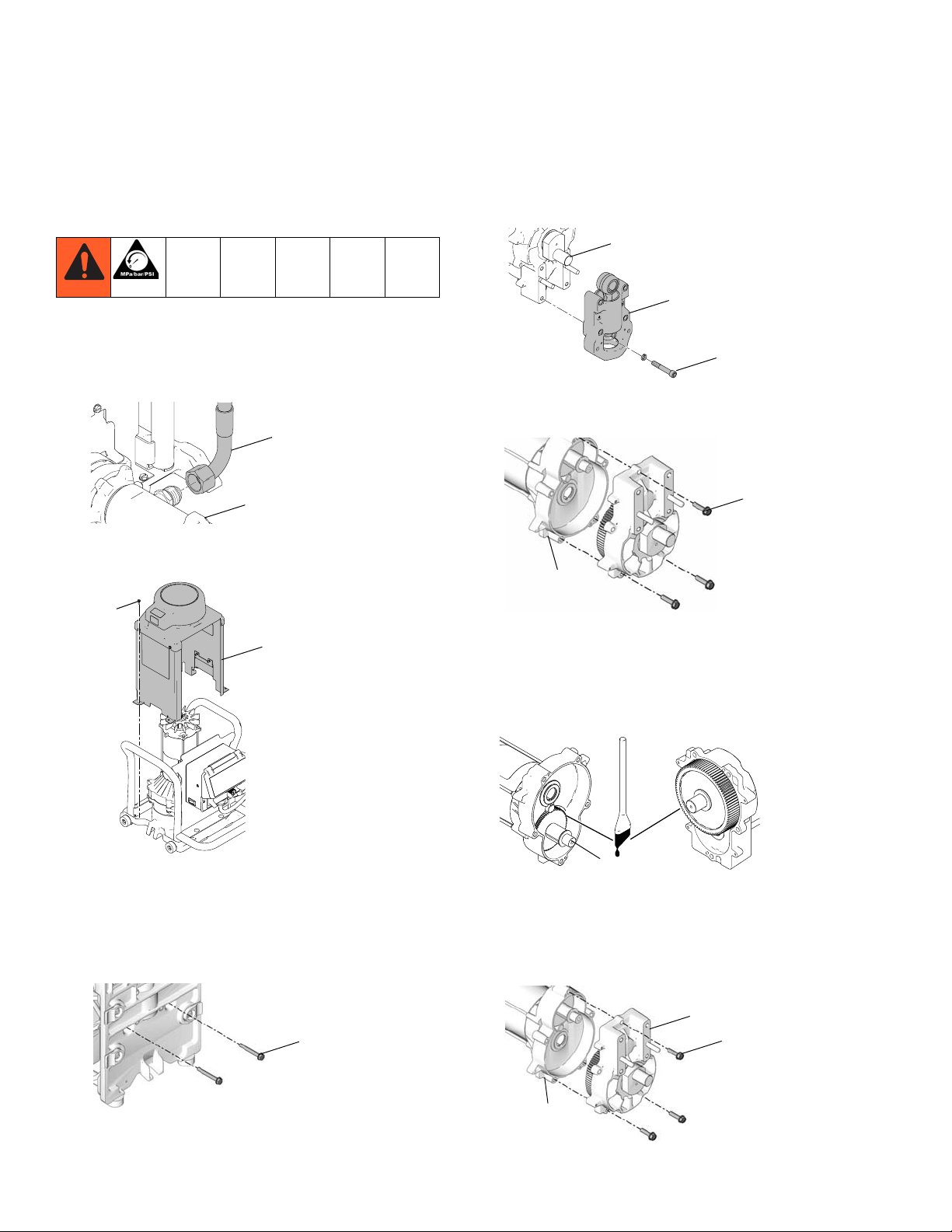

Removal

1. Perform Pressure Relief Procedure, page 4.

2. Remove Power Module, see page 7.

3. Remove Pump, page 8.

4. Remove four screws (40) and lift motor shroud (98)

off of motor.

40

98

6. Remove two screws (5b) from underneath motor

base plate. Lift and remove motor/pump assembly

from power module.

5b

ti11734a

7. Loosen four screws (19) on pump housing, and

remove bearing housing (9) from motor.

9

ti15630a

19

8. Remove three screws (5c) on motor (8a). Remove

motor (8a) from drive housing (5a).

8a

ti15624a

5. Disconnect three wire harnesses (see Wiring

Diagrams, pages 34-36).

5a

5c

ti11735a

3A0246C 5

Page 6

Drive and Bearing Housing

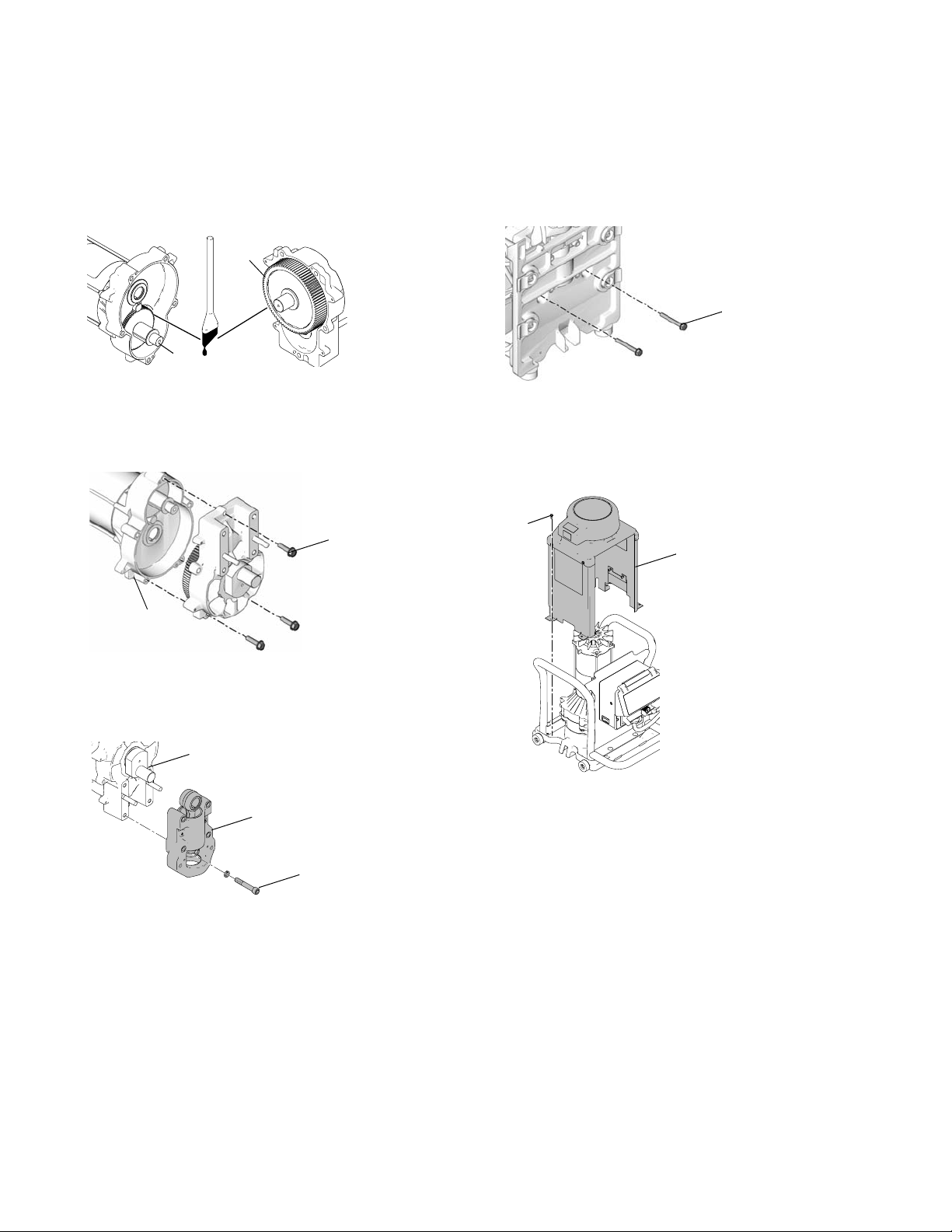

Installation

1. Apply brown lithium grease supplied with drive

housing kit (5) to gear cluster (17a) and inside of

motor cavity.

5a

17a

ti15629a

2. Align orientation tab on gear housing with slot on

motor and slide gears into motor.

3. Replace and tighten three screws (5c) on motor

(8a). Torque to 200-220 in-lb.

5c

8a

ti11735a

5. Replace motor/pump assembly into pump module.

Replace and tighten two screws (5b) underneath

motor base plate. Torque to 200 - 220 in-lb.

5b

ti11734a

6. Reconnect three wire harnesses (see Wiring

Diagrams, pages 34-36).

7. Replace motor shroud (98) and tighten four screws

(40). Torque to 30-34 in-lb.

40

98

4. Attach bearing housing (9) to gear housing (5a)

(slowly turn motor fan by hand to align gear into

pump connecting rod). Torque four bearing housing

screws (19) to 25-30 ft-lb.

5a

9

ti15630a

19

ti15624a

8. Replace Pump, page 8.

9. Replace Power Module, see page 7.

6 3A0246C

Page 7

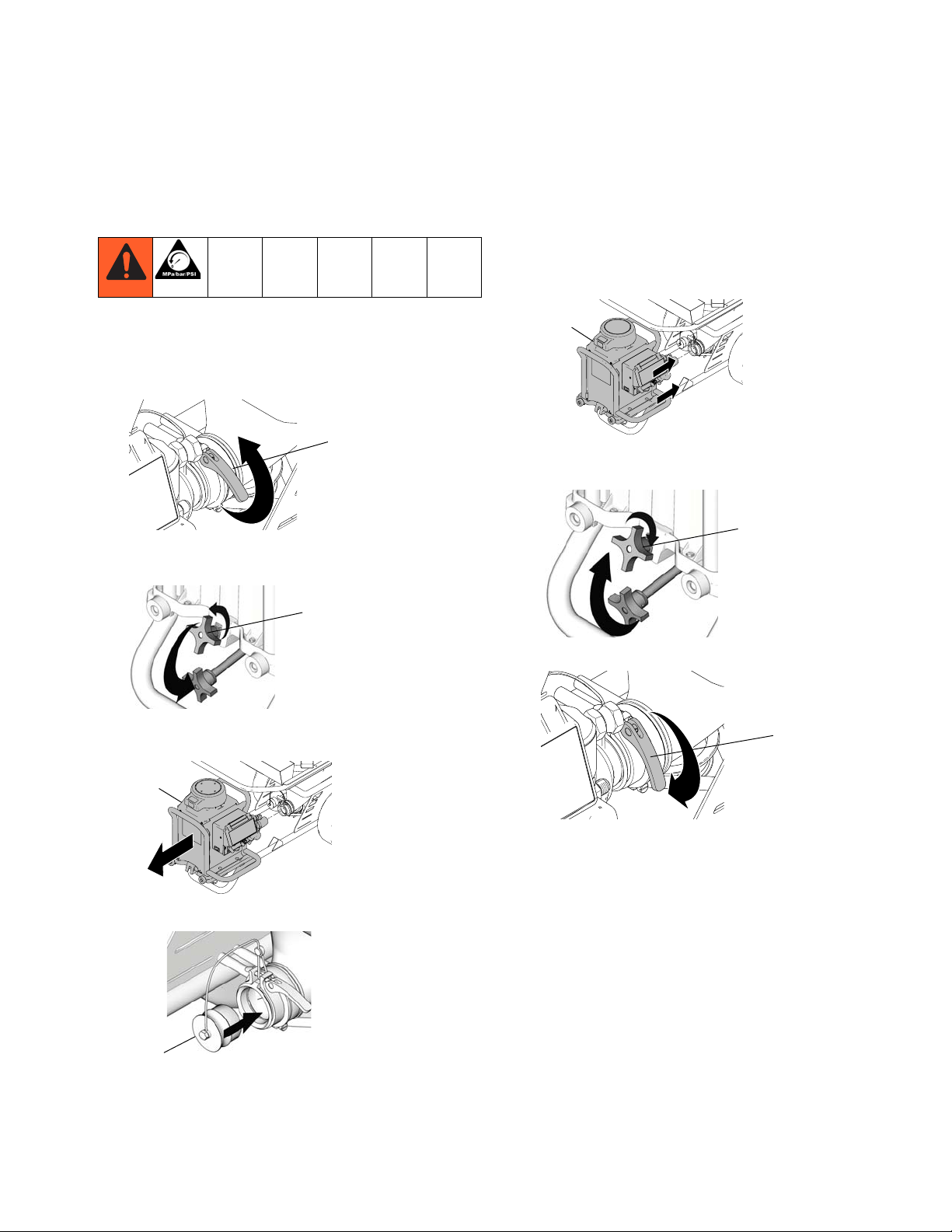

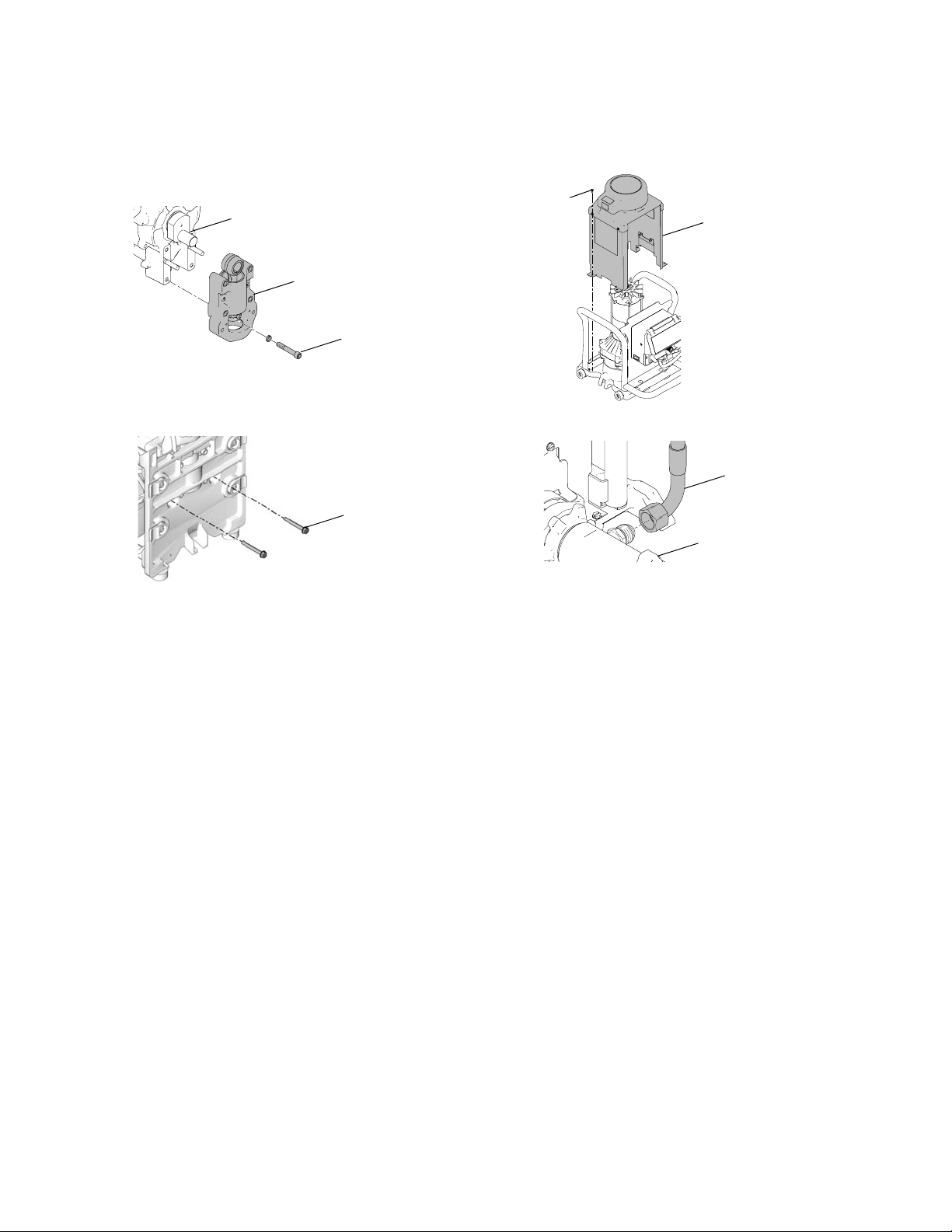

Power Module

Power Module

Removal

1. Perform Pressure Relief Procedure, see page 4.

Unplug power cord.

2. Release hopper adapter clamp (158).

158

ti15684a

3. Loosen rod clamp knob (112) on front of pump module and push rod down.

112

Installation

1. Remove hopper plug (117) if installed.

2. Replace power (153) module and insert pump outlet

into hopper inlet.

153

ti15625a

3. Pull rod clamp up and tighten knob (112) on front of

pump module.

112

ti11678a

ti11675a

4. Lift and pull power module (153) off of unit.

NOTE: Power module weighs approximately 85 lb.

153

ti15623a

5. Install hopper plug (117) if needed.

117

ti15623a

4. Fasten hopper adapter clamp (158).

158

ti15683a

3A0246C 7

Page 8

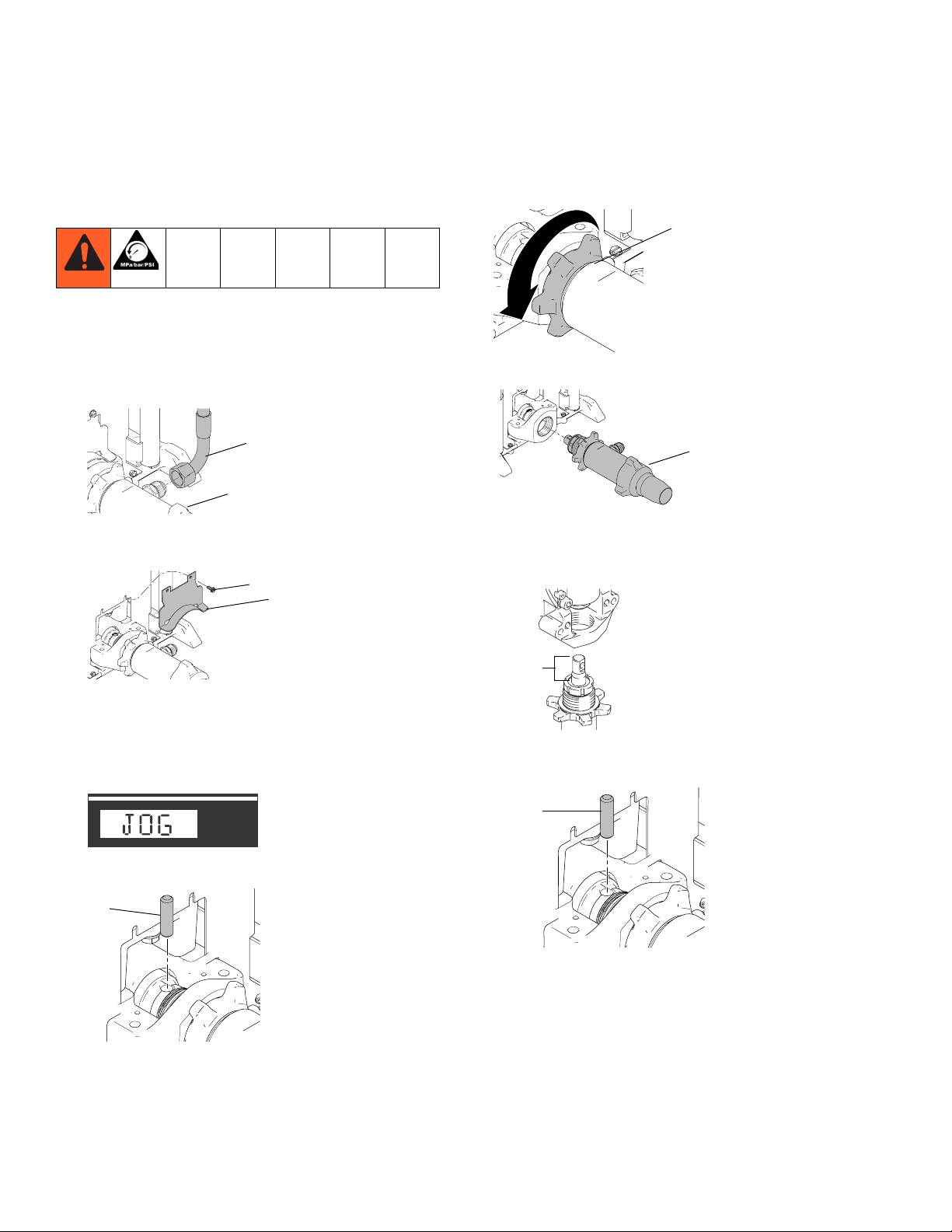

Pump

Pump

Removal

1. Perform Pressure Relief Procedure, see page 4.

2. Remove Power Module, see page 7.

3. Disconnect material hose (79) from pump (18a).

79

18a

ti15616a

4. Loosen two screws (40) and remove pump rod

shield (48).

40

48

7. Use hammer to loosen pump retaining nut (22).

22

ti15615a

8. Unscrew and remove pump (18a) from module.

18a

ti15618a

Installation

1. Extend pump piston rod 1.5 in.

ti15619a

5. Turn flow control knob to a very low setting and turn

prime valve handle to TOOL FILL position (JOG

mode will appear in display). Use ON/OFF switch or

turn control knob OFF to stop pump when pin is

visible.

ti15620a

6. Use screwdriver to press pin (7b) out of pump.

7b

ti15617a

NOTE: Pin should be removed by pressing the pin

out through the bottom side of the pump. Make sure

to control the pump pin when removing so that it

does not fall into the pump module.

1.5 in.

ti7171a

2. Install pump pin (7b). Verify retaining spring is in

groove of connecting rod.

7b

ti13093a

NOTE: Pin should be installed from the top side of the

pump. Make sure to control the pump pin when installing

so that it does not fall into the pump module.

8 3A0246C

Page 9

Pump

3. Push pump up until pump threads engage.

ti15924a

4. Screw in pump until threads are flush with drive

housing opening.

ti15621a

5. Align pump outlet to right side so that hose can be

reassembled.

7. Replace pump rod shield (48) and torque two

screws (40) to 30 - 34 in-lb.

40

48

ti15619a

8. Reconnect material hose (79) to pump (18a).

79

18a

ti15616a

9. Replace Power Module, see page 7.

ti15923a

6. Screw jam nut up toward drive housing until nut

stops. Tighten jam nut by hand, then tap 1/8

to 1/4 turn with a 20 oz. (maximum) hammer to

approximately 75± 5 ft-lb (102 N•m).

ti15925a

3A0246C 9

Page 10

Motor

Motor

Removal

1. Perform Pressure Relief Procedure, see page 4.

2. Remove Power Module, see page 7.

3. Disconnect material hose (79) from pump (18a).

79

18a

ti15616a

4. Remove four screws (40) and lift motor shroud (98)

off of motor.

40

98

7. Loosen four screws (19) on bearing housing (9),

and remove from gear housing.

5a

9

ti15630a

19

8. Remove three screws (5c) on motor (8a). Remove

motor from gear housing.

5c

8a

ti11735a

Installation

ti15624a

5. Disconnect three wire harnesses (see Wiring

Diagrams, pages 34-36).

6. Remove two screws (5b) from underneath motor

base plate. Lift and remove motor/pump assembly

from pump module.

5b

ti11734a

1. Apply brown lithium grease supplied with motor

repair kit (8) to gear cluster (17a) and inside of

motor cavity.

17a

ti15629a

2. Align orientation tab on gear housing with slot on

motor and slide gears into motor.

3. Replace three screws (5c) on motor (8a). Torque to

200-220 in-lb.

5a

5c

8a

ti11735a

10 3A0246C

Page 11

Motor

4. Attach bearing housing (9) to gear housing (5a)

(slowly turn motor fan by hand to align gear into

pump connecting rod). Torque four bearing housing

screws (19) to 25-30 ft-lb.

5a

9

ti15630a

19

5. Replace motor/pump assembly into pump module.

Replace and torque two screws (5b) underneath

motor base plate to 200 - 220 in-lb.

5b

ti11734a

6. Reconnect three wire harnesses (see Wiring

Diagrams, pages 34-36).

7. Replace motor shroud (98) and torque four screws

(40) to 30 - 34 in-lb.

40

98

ti15624a

8. Reconnect material hose (79) to pump (18a).

79

18a

ti15616a

9. Replace Power Module, see page 7.

3A0246C 11

Page 12

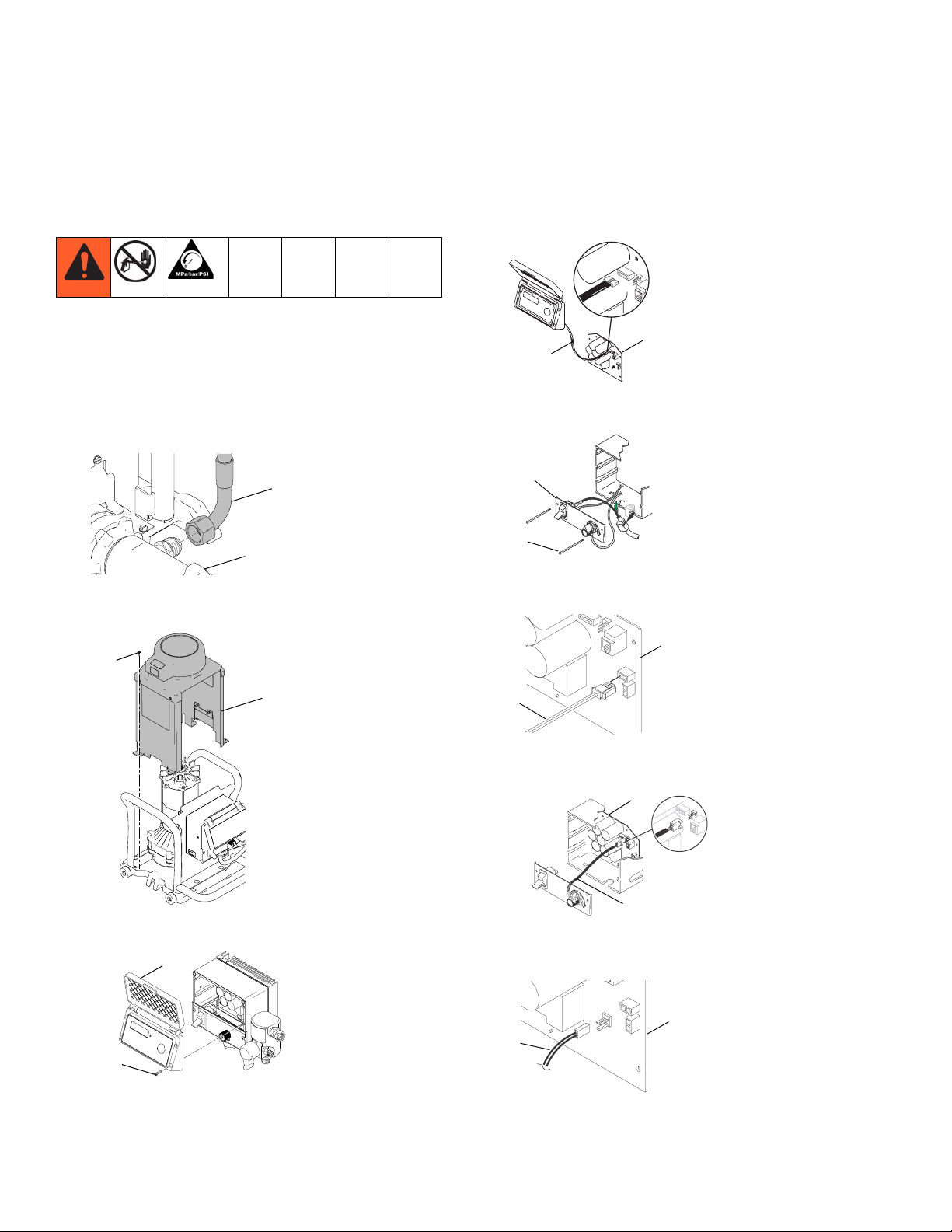

Motor Control Board

Motor Control Board

Removal

120V Models:

1. Perform Pressure Relief Procedure, see page 4.

Wait 5 minutes before servicing.

2. Remove Power Module, see page 7.

3. Disconnect material hose (79) from pump (18a).

79

18a

ti15616a

4. Remove four screws (40) and lift motor shroud (98)

off of motor.

40

6. Disconnect display connector (A) from motor control

board (24) and remove display.

ti13569a

24

A

7. Remove bottom two screws (61) and remove control

panel (37).

37

61

ti15795a

8. Disconnect Prime/Tool Fill/Recirculate reed switch

connector (E) from motor control board (24).

24

98

ti15624a

5. Remove four screws (33b) and display cover (33k).

33k

33b

ti15786a

E

ti13572a

9. Disconnect potentiometer connector (C) from motor

control board (24).

24

ti15791a

C

10. Disconnect 15/20A switch connector (X) from motor

control board (24).

24

X

ti15850a

12 3A0246C

Page 13

Motor Control Board

11. Disconnect white power cord conductor (D) from

motor control board (24).

24

ti15851a

D

12. Disconnect black power lead (J) on motor control

board (24) from ON/OFF switch.

J

ti15849a

13. Remove ground screw (58) from motor control

board/heat sink assembly.

16. Disconnect three motor connectors from motor control board to motor.

ti15847a

17. Remove two screws (83) holding motor control

board /heat sink assembly to power module frame.

Remove motor control board/heat sink assembly.

83

ti15845a

18. Remove six outer screws, two inner screws, and

remove control board (24) from heat sink.

58

ti15846a

14. Remove two top screws (61) and control box (3).

61

3

ti15912a

15. Disconnect transducer connector from motor control

board (24).

ti12999a

24

ti15844a

24

3A0246C 13

Page 14

Motor Control Board

110 UK and 240V Models:

1. Perform Pressure Relief Procedure, see page 4.

Wait 5 minutes before servicing.

2. Remove Power Module, see page 7.

3. Disconnect material hose (79) from pump (18a).

79

18a

ti15616a

4. Remove four screws (40) and lift motor shroud (98)

off of motor.

40

98

7. Remove bottom two screws (61) control panel (37).

37

61

ti15795a

8. Disconnect Prime/Tool Fill/Recirculate reed switch

connector (E) from motor control board (24).

24

E

ti13572a

9. Disconnect potentiometer connector (C) from motor

control board (24).

24

ti15624a

5. Remove four screws (33b) and display cover (33k).

33k

33b

ti15786a

6. Disconnect display from motor control board (24)

and remove display.

24

ti13569a

ti15791a

C

10. Disconnect black power lead (G) from motor control

board to filter board. Disconnect blue power lead (B)

from motor control board to filter board.

G

B

ti15848a

11. Remove ground screw (58) from motor control

board/heat sink assembly.

58

ti15846a

14 3A0246C

Page 15

Motor Control Board

12. Remove top two screws (61) and control box (3).

61

3

ti15912a

13. Disconnect transducer connector from motor control

board (24).

ti12999a

24

14. Disconnect three motor connectors from motor control board to motor.

15. Remove two screws (83) holding motor control

board / heat sink assembly to power module frame.

Remove motor control board/heat sink assembly.

83

ti15845a

16. Remove six outer screws, two inner screws, and

remove control board (24) from heat sink.

24

ti15844a

ti15847a

3A0246C 15

Page 16

Motor Control Board

Installation

120V Models:

1. Use acetone or equivalent cleaner to thoroughly

remove thermal paste from pockets on heat sink.

ti14695a

2. Apply new thermal paste into both pockets of heat

sink.

ti14693a

3. Replace two inner screws and washers to control

board and torque to 17 in-lb.

5. Connect motor control board lead connectors (F) to

leads from motor. Insert grommet in heat sink baffle.

Use zip tie or electrical tape (Z) to hold grommet

together on grommet end on the motor side of the

heat sink.

Z

F

ti15852a

6. Assemble gasket (94) to heat sink assembly.

94

ti15911a

7. Assemble two screws (83) to hold motor control

board/ heat sink assembly to power module frame.

Torque to 35-45 in-lb.

ti15926a

4. Replace six outer screws to control board and

torque to 11 in-lb.

ti14697a

NOTE: SW1 position setting does not matter.

83

ti15845a

8. Assemble ground screw (58) to heat sink. Torque to

30-34 in-lb.

58

ti15846a

9. Assemble control box enclosure (3) to power module and tighten two screws (61). Torque to 30-35

in-lb.

61

3

ti15912a

16 3A0246C

Page 17

Motor Control Board

10. Connect black power lead (J) on motor control

board to ON/OFF switch.

J

ti15849a

11. Connect white power cord conductor (D) to motor

control board (24).

24

ti15851a

D

12. Connect 15/20A switch connector (X) to motor control board (24).

15. Replace control panel (37) and tighten bottom two

screws (61). Torque to 30-35 in-lb.

37

61

ti15795a

16. Connect display connector to motor control board

(24).

ti13569a

24

17. Assemble display cover (33k). Spring tabs on noise

shield need to be assembled to the inside of the

control box enclosure. Torque screws (33b) to

30-35 in-lb.

33k

24

X

ti15850a

13. Connect potentiometer connector (C) to motor control board (24).

24

ti15791a

C

14. Connect Prime/Tool Fill/Recirculate reed switch connector (E) to motor control board (24).

24

E

ti13572a

33b

ti15786a

18. Remove four screws (40) and lift motor shroud (98)

off of motor.

40

98

ti15624a

19. Disconnect material hose (79) from pump (18a).

79

18a

ti15616a

20. Replace Power Module, see page 7.

3A0246C 17

Page 18

Motor Control Board

110 UK and 240V Models:

1. Use acetone or equivalent cleaner to thoroughly

remove thermal paste from pockets on heat sink.

ti14695a

2. Apply new thermal paste into both pockets of heat

sink.

ti14693a

3. Replace two inner screws and washers to control

board and torque to 17 in-lb.

6. Assemble gasket (94) to heat sink assembly.

94

ti15911a

7. Assemble two screws (83) to hold motor control

board/ heat sink assembly to power module frame.

Torque to 35-45 in-lb.

83

ti15845a

8. Assemble ground screw (58) to heat sink. Torque to

30-34 in-lb.

ti15926a

4. Replace six outer screws to control board and

torque to 11 in-lb.

ti14697a

NOTE: SW1 position setting does not matter.

5. Connect motor control board lead connectors (F) to

leads from motor. Insert grommet in heat sink baffle.

Use zip tie or electrical tape (Z) to hold grommet

together on grommet end on the motor side of the

heat sink.

Z

F

58

ti15846a

9. Assemble control box enclosure (3) to power module using two top screws (61). Torque to 30-35 in-lb.

61

3

ti15912a

10. Connect blue (B) and black (G) power leads from

motor control board (24) to filter board.

G

B

ti15848a

ti15852a

18 3A0246C

Page 19

Motor Control Board

11. Connect potentiometer connector (C) to motor control board (24).

24

ti15791a

C

12. Connect Prime/Tool Fill/Recirculate reed switch connector (E) to motor control board (24).

24

E

ti13572a

13. Replace control panel (37) and tighten bottom two

screws (61). Torque to 30-35 in-lb.

15. Assemble display cover (33k). Spring tabs on noise

shield need to be assembled to the inside of the

control box enclosure. Torque screws to 30-35 in-lb.

33k

ti15786a

16. Replace motor shroud (98) and torque four screws

(40) to 30 - 34 in-lb.

40

98

37

ti15795a

61

14. Connect display connector to motor control board

(24).

ti13569a

24

ti15624a

17. Reconnect material hose (79) to pump (18a).

79

18a

ti15616a

18. Replace Power Module, see page 7.

3A0246C 19

Page 20

Prime Valve Handle

Prime Valve Handle

Removal

1. Perform Pressure Relief Procedure, see page 4.

Wait 5 minutes before servicing.

2. Use 3/32 in. punch and hammer to tap out handle

pin (72c) (pliers may be required to pull out handle

pin). Pull off handle (72a) and base (72b).

3. Use crescent wrench to unscrew prime valve (71).

NOTE: Make sure that the seat and gasket are

removed from the manifold.

4. Clear out any material that is lodged in valve (71) or

manifold (70).

Installation

1. Tighten prime valve (71) into manifold (70). Use

thread sealant on housing threads and torque to

190 to 210 in-lb.

2. Install prime valve base (72b). Pin in base must

align with hole in manifold (70).

3. Orient hole in prime valve stem (71) vertically.

4. Place prime valve handle (72a) over prime valve

base (72b) with handle in “apply” mode. Align hole

in handle (72a) w/hole in prime valve stem (71).

5. Use hammer to tap prime valve handle pin (72c)

back into place.

71

72c

70

72a

72b

20 3A0246C

ti15633a

Page 21

Pressure Transducer

Pressure Transducer

Removal

1. Perform Pressure Relief Procedure, see page 4.

Wait 5 minutes before servicing.

2. Remove four screws (33b) and cover (33k).

33k

33b

3. Disconnect transducer connector (E) from motor

control board (24).

24

E

ti15786a

5. Remove four screws (61) and control box (3). Allow

control panel (37) to hang down freely.

3

37

61

ti15797a

61

ti15795a

6. Remove grommet (23) from control box (3).

23

ti15785a

3

7. Remove transducer (39) and o-ring (50) from manifold (70). Remove grommet (23) from transducer

and save for reuse.

70

23

39

50

ti12999a

4. Disconnect potentiometer connector (D) and reed

switch connector (87) from motor control board (24).

D

24

87

ti15792a

ti15788a

Installation

1. Install o-ring (50) and transducer (39) in manifold

(70). Torque to 35-45 ft-lb (47-61 N•m). Install grommet onto transducer (39) and transducer into control

box (3).

70

23

39

50

ti15783a

ti15793a

3

3A0246C 21

Page 22

Pressure Transducer

2. Connect transducer connector (E) and reed switch

connector to control board (24).

24

E

ti12999a

3. Install control box (3) and control panel (37) with

four screws (61). Torque to 30 - 35 in-lb.

3

37

61

ti15797a

61

ti15795a

5. Connect display connector (A) to motor control

board (24).

ti13569a

24

A

6. Install cover (33k) with four screws (33b). Torque to

30-35 in-lb. Make sure tabs on noise shield are

routed inside the control box when assembling.

4. Connect potentiometer connector (D) and reed

switch connector (87) to control board (24).

D

24

87

ti15792a

33k

ti15786a

33b

22 3A0246C

Page 23

Flow Control Adjust Potentiometer

Flow Control Adjust

Potentiometer

Removal

1. Perform Pressure Relief Procedure, see page 4.

Wait 5 minutes before servicing.

2. Remove four screws (33b) and cover (33k).

ti15786a

33k

33b

3. Remove bottom two screws (61) and remove control

panel (37).

37

6. Remove gasket (56), nut, spacer (88) and potentiometer (55) from control panel (37).

ti15794a

56

55

88

37

Installation

1. Install gasket (56), nut, spacer (88) and potentiometer (55) on control panel (37). Torque nut to 30-35

in-lb (3.25-4.0 N•m).

55

ti15794a

56

2. Install control knob (42): Check control knob alignment to potentiometer shaft. Turn shaft fully clockwise and attach knob in full ON position with a hex

wrench. Make sure set screw is tightened flat

against potentiometer shaft.

88

37

61

ti15795a

4. Disconnect potentiometer connector (D) from motor

control board (24).

24

ti15791a

D

5. Use hex wrench to remove control knob (42).

42

ti7258a

42

ti13338a

3. Connect potentiometer connector (D) to motor control board (24).

24

D

ti15791a

3A0246C 23

Page 24

Flow Control Adjust Potentiometer

4. Replace control panel (37) and tighten bottom two

screws (61). Torque to 30-35 in-lb.

37

61

ti15795a

5. Connect display connector (A) to motor control

board (24).

ti13569a

24

A

6. Install cover (33k) with four screws (33b). Torque to

30-35 in-lb. Make sure tabs on noise shield are

routed inside the control box when assembling.

33k

33b

ti15786a

24 3A0246C

Page 25

Prime/Tool Fill/Recirculation Reed Switch

Prime/Tool Fill/Recirculation Reed Switch

Removal

1. Perform Pressure Relief Procedure, see page 4.

Wait 5 minutes before servicing.

2. Remove four screws (33b) and remove display

cover (33k).

33k

ti15786a

33b

3. Remove bottom two screws (61) and remove control

panel (37).

Installation

1. Apply thread sealant to end of reed switch (87).

Hand-tighten reed switch until it is tight against

control panel (37).

37

87

ti13574a

2. Add thread sealant and tighten jam nut against

threaded bus.

ti13576a

3. Connect reed switch (87) to control board (24).

24

37

61

ti15795a

4. Unplug reed switch (87) from control board.

87

ti13572a

5. Unscrew reed switch (87) from control panel (37).

37

87

ti13573a

87

ti13572a

4. Replace control panel (37) and tighten bottom two

screws (61). Torque to 30-35 in-lb.

37

61

ti15795a

5. Replace display cover (33k) and torque four screws

(33b) to 30-35 in-lb.

33k

33b

ti15786a

NOTE: Make sure noise shield tabs are routed to the

inside of the control box when assembling.

3A0246C 25

Page 26

Digital Display

Digital Display

Removal

1. Turn off unit. Wait 5 minutes before servicing.

2. Remove four screws (33b) and remove display

cover (33k).

33k

ti15786a

33b

3. Unplug display board connector from motor control

board (24).

Installation

1. Plug display board connector (A) into motor control

board (24).

ti13569a

A

2. Replace display cover (33k) and torque four screws

(33b) to 30-35 in-lb.

24

ti13569a

33k

33b

24

A

NOTE: Make sure noise shield tabs are routed to the

inside of the control box when assembling.

ti15786a

26 3A0246C

Page 27

Inline Valve

Inline Valve

Changing the Needle

Removal

NOTE: Needle (404b), housing/seat (404c), and o-ring

(404a) must be replaced together. They are included in

repair kit 24F263.

1. Perform Pressure Relief Procedure, see page 4.

2. Squeeze trigger while unscrewing housing/seat

(404c) and o-ring (404a).

404c

ti15626a

3. Remove trigger stop (420) with hex wrench.

404a

ti15810a

404b

5. Tap rear of inline valve with a plastic mallet and

punch to push needle assembly (404b) out through

front of housing (401).

ti15809a

404b

401

Installation

1. Guide threaded end of needle assembly (404b) into

front of housing (401).

ti15804a

404b

2. Install bracket (413) and locknut (414) loosely on

threaded end of needle (404b). Squeeze trigger to

pull needle assembly into housing (401).

401

420

ti15806a

413

414

ti15862a

3. Squeeze trigger while installing o-ring (404a) and

4. Remove locknut (414) and bracket (413).

housing/seat (404c). Torque housing/seat to 26-32

ft-lb (35-43 N•m).

404a

t15805Xa

404b

ti15811a

413

404c

414

ti15626a

4. Adjust needle before using inline valve.

3A0246C 27

Page 28

Inline Valve

Needle Adjustment

1. Engage inline valve (135) with safety latch. Hold

inline valve with nozzle straight up.

2. Hold your finger against trigger (410) with light pressure. Use a 5/16 open-ended wrench to turn locknut

(414) clockwise until you feel trigger lift slightly.

3. Turn locknut (414) 3/4 turn counter-clockwise.

4. Connect fluid hose. Prime the system. Trigger inline

valve (135) and release it. The fluid flow should stop

immediately. Engage safety latch and try to trigger

inline valve. No fluid should flow. If the inline valve

fails either test, relieve pressure, disconnect hose

and readjust needle.

5. Install trigger stop (420) when needle has been

properly adjusted.

ti15862a

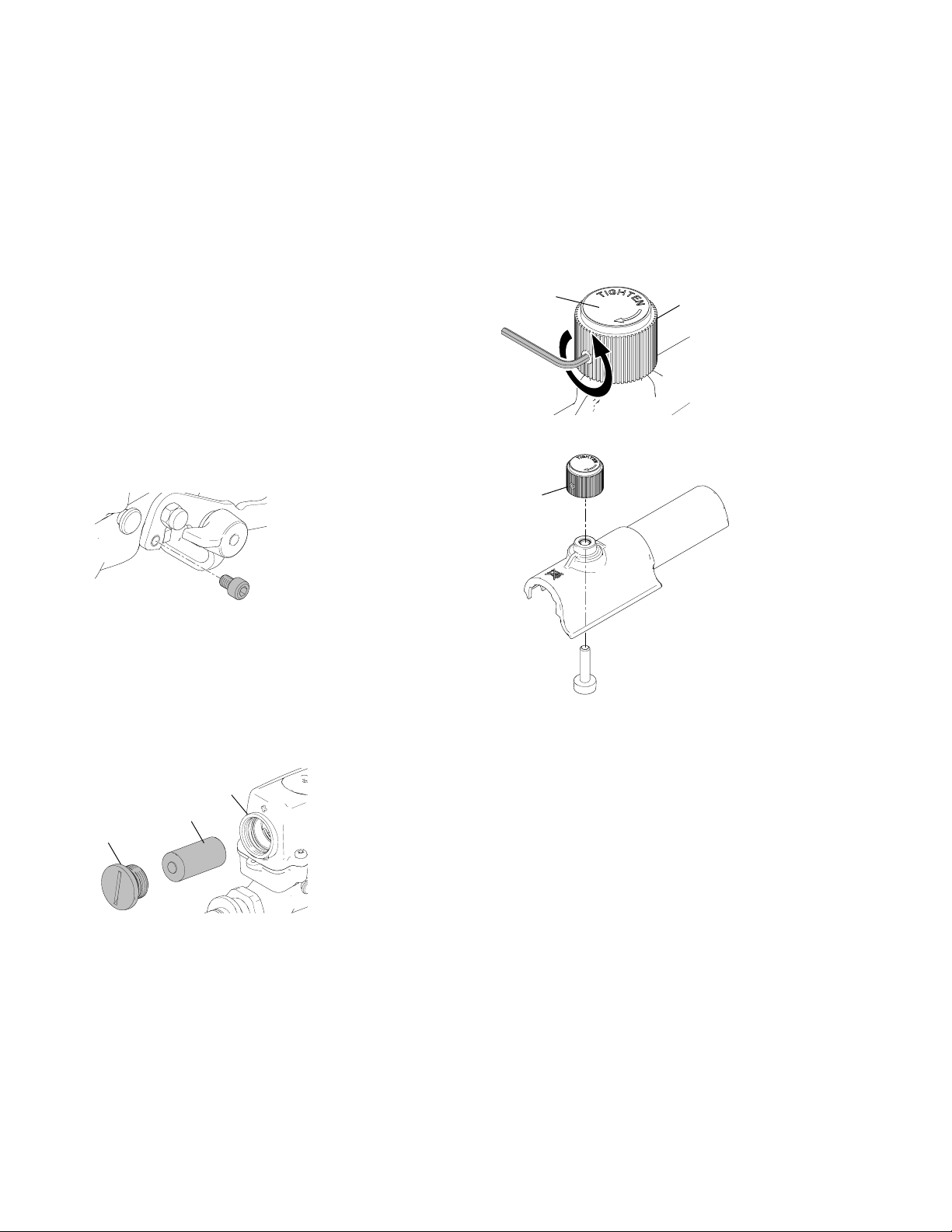

Box Slide Control

Use Brake Assembly Repair Kit 24F261

Removal

1. Remove set screw from brake knob (518b).

518a

2. Unthread brake knob (518b) from assembly.

518b

518b

ti15863a

Replacing the Battery

Removal

1. Unscrew battery cap (425a) from housing (411).

Remove battery and discard.

411

426

425a

ti15812a

Installation

1. Install battery (426) in housing (411) and screw in

battery cap (425a).

NOTE: Make sure o-ring (425b) is in place when

installing the battery cap (425a).

ti15865a

Installation

1. Thread brake knob (518b) onto assembly

2. Apply label (518a).

3. Torque set screw to 15-20 in-lb.

28 3A0246C

Page 29

Parts

Parts

112

160

152

113

114

116

115

163

162

156

138

161

111

146

147

119

126

155

148

117

154

118

155

154

157

171

170

158

153

127

141

128

139

129

Ref. Part Description Qty.

111 120211 RING, retaining, e-ring 2

112 15C799 ROD, clamp 1

113 104430 PIN, cotter 1

114 15C797 BRACKET, swivel 1

115 101566 NUT, lock 1

116 100004 SCREW, cap, hex HD 1

117 15D306 PLUG, adapter, hopper, texture 1

118 121458 TIE, lanyard 1

119 100333 SCREW, cap, hex HD 1

126 16C298 FILTER, hopper 1

127 257133 HOSE, cpld, 1/2 in. mxf 50 ft 1

128 223756 HOSE, cpld, 1/4 in. x 15 ft 1

129 24D166 SWIVEL, Z, complete 1

135 24F538 VALVE, inline, assembly 1

137 24E958 KIT, drain, hose 1

138 122267 WHEEL, foam 2

139 150287 COUPLING 1

141 162449 FITTING, nipple, reducing 1

146 16C794 SPACER, .75 OD X .4 ID X .625 1

137

135

ti15642a

180

Ref. Part Description Qty.

147 278204 CLIP, drain line 1

148 112785 SCREW, hex HD, flanged 1

152 15R633 FRAME, painted, TMAX 1

153 257047 MODULE, power, ETL listed 1

258890 MODULE, power, CE listed 1

258893 MODULE, power, UK CE listed 1

262289 MODULE, power, 120V 1

262299 MODULE, power, CE Cord 1

154 289668 HOPPER, assembly 1

155 16D307 LABEL, brand, drywall us, hopper 2

156 116038 WASHER, wave spring 2

157 121308 PLUG, expanding 1

158 234188 CLAMP, quick release 1

160 15R639 HANDLE, TMAX 1

161 112958 NUT, hex, flanged 1

162 121313 PIN, locking, 1/4 in. 2

163 156306 WASHER, flat 2

170 15R609 FITTING, hopper, adapter 1

171 102905 CLAMP, hose 1

180 24F463 KIT, control, box slide 1

3A0246C 29

Page 30

Parts

Pump Module Parts

102

99

105

40

21

8c

8b

101

24

58

94

29

83

104

84

ti15643a

23

75

39

25

74

50

79

70

4040

48

98

71

92

72b

36

46b

78

80

72c

72a

8a

17a

17b

5d

5a

5c

7c

7a

17c17c

79

18b

18a

7b

22

9

20

61

19

94

87

88

81

61

3

46c

108

32

4

6

28

109

110

3 ref

30 3A0246C

10

5b

182

43

181 183

54

46a

27

41

55

37

38

56

42

33e

33a

33c

33j

33m

33h

33b

33d

33k

Page 31

Pump Module Parts List

Parts

Ref. Part Description Qty.

3 15G700 BOX, control 1

15D431 BOX, control, CE and UK 1

4 277657 GUIDE, base 4

5 24E959 KIT, housing, drive 1

5a HOUSING, drive 1

5b 120981 SCREW, mach, hex washer HD 2

5c 15C753 SCREW, mach, hex wash HD 3

5d 116192 WASHER, thrust 1

6 100023 WASHER, flat 4

7 287720 KIT, rod, connecting 1

7a ROD, connecting 1

7b 15F856 PIN, pump 1

7c 119778 SPRING, retaining 1

8 24D362 KIT, motor, electric 1

8a MOTOR, electric 1

8b 15V577 FAN, motor 1

8c 122347 RING, retaining, external 1

9 240724 HOUSING, bearing 1

10 113817 BUMPER 2

17 287290 KIT, gear, combination 1

17a GEAR, combo 1

17b 114699 WASHER, thrust 1

17c 114672 WASHER, thrust 2

18 24E957 KIT, pump, displacement 1

18a PUMP, displacement 1

18b 15Y925 FITTING, 5/8 JIC / 1/2 NPT 1

19 114666 SCREW, cap, socket head 4

20 106115 WASHER, lock (hi-collar) 4

21 16D622 SHIELD, assy, painted 1

22 193031 NUT, retaining 1

23 15D033 GROMMET, transducer 1

24 258843† CONTROL, board, drywall feed 1

258889* CONTROL, board, drywall (240V) 1

25 100016 WASHER, lock 4

27 116171 BUSHING, strain relief 1

28 112746 NUT, lock, nylon, thin pattern 4

29 107129 BOLT, round head 4

32 260215 SCREW, hex HD 2

33 24F259 KIT, repair, display 1

33a 115522 SCREW, mach, PNH 3

33b 116252 SCREW, #10, taptite phil 4

33c CONTROL, board, receiver 1

33d 15X508 LABEL, brand, smartcontrol LCD 1

33e PAD, foam 1

33h 15X507 LABEL, smartcontrol 1

33j SEAL, extruded w/adhesive 1

33k COVER, control 1

33m 16D642 GASKET 1

36 15D036 GASKET, control box 1

37 15X617 PANEL, control 1

38 15C979 SWITCH, rocker 1

15D527 SWITCH, rocker (240V) 1

39 243222 TRANSDUCER, flow control 1

40 118444 SCREW, mach, slot hex wash HD 10

Ref. Part Description Qty.

41 15H066 CORD, power (Model 257047) 1

15H065 CORD, power (Model 262289) 1

15D528 CORD, power, CE 1

15D530 CORD, power, UK 1

15D529 CORD, power, global 1

42 116167 KNOB, potentiometer 1

43 120059 SWITCH, rocker 1

46 287943 KIT, repair, coil 1

46a COIL 1

46b 120223 SCREW, machine, flat head 1

46c 116969 NUT, lock 1

48 15T629 SHIELD, pump rod 1

50 111457 PACKING, o-ring 1

54 15G935 CONNECTOR, electrical 1

55 256219 POTENTIOMETR, assembly 1

56 15C973 GASKET 1

58 114391 SCREW, grounding 1

61 123128 SCREW, mach, pan head, 10-24X4 4

70 15X122 MANIFOLD, fluid 1

71 24B339 VALVE, prime, heavy duty 1

72 24E960 KIT, handle 1

72a HANDLE, valve, prime 1

72b 24A382 BASE, valve, heavy duty 1

72c 15C972 PIN, grooved 1

74 15Y934 FITTING, 5/8 JIC / 3/4 NPT 1

75 121112 SCREW, cap, socket head 4

78 190451 UNION, adapter 1

79 16C350 HOSE, coupled 1

80 118484 FITTING, connector 1

81 15X902 LABEL, euro 1

83 110637 SCREW, mach, panhead 2

84 16C993 GROMMET, motor lead 1

87 258644 KIT, reed switch (includes reed

switch and sealant)

88 198650 SPACER, shaft 1

92 16D004 LABEL, drywall dump valve indent 1

94 16D640 GASKET, control 2

98 16D624 SHIELD, base, painted 1

99 16C681 LABEL, no weight & no step 1

101 16E335 LABEL, graco 1

102 15U014 LABEL, cap 1

104 16D653 LABEL, drywall warning label 1

105 15Y118 LABEL, Made in the USA 1

108 116876 WASHER, flat 2

109 119228 SCREW, mach, flat hd 4

110 257905 CONTROL, board 1

181 195551 CLIP, retaining 1

182 242001 CORD SET, adapter, Europe 1

183 287121 CORD SET, adapter, Italy,

Denmark, Switzerland

† 257600 Repair Kit is available with control board only.

* 257601 Repair Kit is available with control board only.

1

1

3A0246C 31

Page 32

Parts

Inline Valve Parts 24F538

425a

425b

423

431

411

428

427

426

411

406

427

424

402

401

408c

408b

413

404b

404a

404c

406

408a

Ref. Part Description Qty.

401 15Y164 HOUSING, fluid 1

402 179733 SEAL, sleeve 1

403 15Y204 FLUID, tube 1

404 24F263 KIT, inline valve needle and seat 1

404a 104444 PACKING, o-ring 1

404b NEEDLE, gun, assembly 1

404c 257590 HOUSING, seat, .188 orifice 1

406† 103338 PACKING, o-ring 2

408 24F269 KIT, sanitary clamp 1

408a CLAMP, 1 in. sanitary 1

408b SLEEVE, oval 2

408c CABLE 1

410 257580 TRIGGER, w/magnet 1

411 257790 HOUSING, valve w/ overmold 1

413 197058 BRACKET, stem 1

414 107110 LOCKNUT 1

416 177538 STUD, trigger 1

437

403

431

411

439

410

414

417

420

ti15796a

416

Ref. Part Description Qty.

417 15Y526 NUT, lock, m4 sst 1

420 15Y200 FASTENER, pan head, 6-32 x .188

sst

423 256228 CONTROL, board, transmitter 1

424 15Y201 NUT, battery, wedged 1

425 24F260 KIT, battery cap 1

425a CAP PLUG, battery 1

425b 108284 PACKING, o-ring 1

426 15X949 BATTERY, CR123A, lithium, 3 volt 1

427 15X950 PAD, foam, isolator 2

428 15X951 PAD, foam, isolator 1

431 15Y263 FASTENER, self tapping, 6-32x.5

sst

437 16C346 ADAPTER, 3/8 nptf x 1.00 rad seal 1

439 16C952 PIN, clevis, fastener 1

† Repair Kit 24F262 is a 10-pack.

1

8

32 3A0246C

Page 33

Box Slide Parts 24F463

503

505b

505a

Parts

502

514

512

514

512

513

507

513

519

520

508

506

510

509

511

518a

518b

501

ti15834a

515

518c

Ref. Part Description Qty.

501 258993 BASE, hinge assembly 1

502 16D718 LID, slide control 1

503 15X949 BATTERY, CR123A, lithium, 3 volt 1

505 24F260 KIT, battery cap 1

505a CAP PLUG, battery 1

505b 108284 PACKING, o-ring 1

506 C20272 PACKING, o-ring 1

507 16D761 NUT, battery cap 1

508 256228 CONTROL, board, transmitter 1

509 101855 SCREW, tapping, pnhd 2

510 16D933 SWITCH, dual in-line reed 1

3A0246C 33

Ref. Part Description Qty.

511 16D937 WASHER, .12id x.38od x.04 thk 2

512 16D760 PIN, trigger 2

513 16D765 SPRING, trigger torsion 2

514 24E473 TRIGGER, magnet assembly 2

515 122665 SCREW, fhcs, 4-20 x .50 4

518 24F261 KIT, box slide control brake 1

518a 16E022 LABEL, drywall, round 1

518b 121591 KNOB, .25 dia. shaft, w/setscrew 1

518c 16D763 BRAKE, slide control 1

519 15X950 PAD, foam, isolator 1

520 15X951 PAD, foam, isolator 1

Page 34

Wiring Diagrams

Wiring Diagrams

100-120 VAC NA Units

Thermal

Switch

Motor

Digital Display

Potentiometer

Pressure

Transducer

Black

Motor

Leads

Motor

Sensor

Leads

Green/Ground

Control

Board

Green/Ground

Black

White

Prime/Fill Tool

Reed switch

20A/15A

Switch

ON/OFF

Switch

Black

ti14889a

34 3A0246C

Page 35

100-120 VAC UK

Thermal

Switch

Motor

Motor

Leads

Control

Board

Wiring Diagrams

Digital Display

Potentiometer

Pressure

Transducer

Black

Prime/Fill Tool

Reed switch

Motor

Sensor

Leads

Green/Ground

Black

Brown

Green/Ground

Blue

Blue

Blue

Brown

ti15686a

3A0246C 35

Page 36

Wiring Diagrams

220-240 VAC Units

Thermal

Switch

Motor

Digital Display

Potentiometer

Pressure

Transducer

Black

Motor

Leads

Motor

Sensor

Leads

Green/Ground

Blue

Control

Board

Black

Brown

Blue

Brown

Prime/Fill Tool

Reed switch

Blue

ti15685a

36 3A0246C

Page 37

Technical Data (Unit)

Technical Data (Unit)

Power requirements:

Models 257100, 262288

Models 258906, 262300

Model 258907

Motor HP (W) 2.5 (1864)

Maximum fluid working pressure 2500 psi (17.2 MPa, 172 bar)

Hopper capacity 25 gallons (95 liters)

Maximum delivery with texture

material

Maximum hose length 150 ft of 1/2 in. hose plus 15 ft of 1/4 in. hose

Fluid outlet size 1/2 in. NPT female swivel

Dimensions

Length 40 to 55 in. (102 cm to 140 cm) with handle

Width 22 in. (56 cm)

Height 31 in. (79 cm)

Weight (with hoses and applicator) 196 lb (89 kg)

Wetted parts Buna-N, aluminum, brass, polyethylene, neoprene, stainless steel,

Sound data for drywall feed pump

Sound pressure level * 80.0 dB(A)

Sound power level † 94.7 dB(A)

* Measured while dispensing at 1 m

† Measured per ISO-3744

100-120 VAC, 60 Hz, 15/20A

220-240 VAC, 50 Hz, 10A

100-120 VAC, 50/60 Hz, 15A

Up to 1.5 gpm (5.7 lpm) - varies depending on material

nickel-plated carbon steel, fluoroelastomer, nickel-plated iron, wool

felt, tungsten carbide, PTFE, nylon, zinc-plated carbon steel, paper,

PVC, UHMWPE, leather, rubber

Technical Data (Pump)

Maximum working pressure 2500 psi (172 bar, 17.2 MPa)

Fluid outlet size 1/2 npt(f)

3A0246C 37

Page 38

Notes

Notes

38 3A0246C

Page 39

Notes

Notes

3A0246C 39

Page 40

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A0246

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2010, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 02/2011

Loading...

Loading...