Page 1

Operation, Repair, Parts

LineDriver™ ES

3A6623D

For the propulsion of line striping and removal equipment. Not approved for use in

explosive atmospheres or hazardous locations. For professional use only.

Models: 25N555, 25N556

10 mph (16 kph) Maximum Operating Speed

Important Safety Instructions

Read all warnings and instructions in this manual and in related LineLazer,

GrindLazer and ThermoLazer manuals before using the equipment. Save

these instructions.

Related Manuals:

710-0138 Delta-Q Battery Charger

3A6720 Hitch Receiver Kit

LineDriver ES

EN

Model Series Cord Adapter

--- 25N555 B North America

North America

Australia

CEE 7/7

25N556 B

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Denmark

Italy

Switzerland

United Kingdom

Page 2

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 5

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

12V Auxiliary Ports . . . . . . . . . . . . . . . . . . . . . . . 6

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Know Your Controls . . . . . . . . . . . . . . . . . . . . . . 7

Daily Inspections . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Differences in Operation . . . . . . . . . . . . . . . . . . . 9

How to Operate . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating on Inclines . . . . . . . . . . . . . . . . . . . . 10

Trailer Loading & Unloading . . . . . . . . . . . . . . . 10

Charging the Batteries . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parking/Emergency Brake Adjustment or

Replacement . . . . . . . . . . . . . . . . . . . . . . . 13

Throttle Linkage Adjustment . . . . . . . . . . . . . . . 14

Coupler Adjustment . . . . . . . . . . . . . . . . . . . . . 15

Accelerator Calibration (Using Kit 25N880) . . . 15

Transaxle Service . . . . . . . . . . . . . . . . . . . . . . . 17

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Battery Pack Replacement . . . . . . . . . . . . . . . . 18

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . 18

Transaxle Replacement . . . . . . . . . . . . . . . . . . . 19

Traction Motor Replacement . . . . . . . . . . . . . . . 19

Motor Controller Replacement . . . . . . . . . . . . . . 19

Troubleshooting - LineDriver . . . . . . . . . . . . . . . . 20

Troubleshooting - Motor Controller . . . . . . . . . . . 21

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Parts Drawing - Detail Views . . . . . . . . . . . . . . . . . 28

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring Diagram - Harness 25N661 . . . . . . . . . . . . 32

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Wiring Diagram - Harness 25E406 . . . . . . . . . . . . 34

Technical Specifications . . . . . . . . . . . . . . . . . . . . 35

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 36

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 36

2 3A6623D

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard sym-

bols and warnings not covered in this section may appear throughout the body of this manual where applicable.

MOVING VEHICLE HAZARD

Careless and reckless behavior causes accidents. Falling from vehicle, running into people or objects, or being

struck by other vehicles may result in serious injury or death.

•

Do not operate unless attached to line striping or line removal equipment.

•

Do not step on Direction/Speed Pedals.

•

Make turns slowly. Do not make turns greater than 45°.

•

Loss of traction may occur going downhill.

•

Do not operate on inclines greater than 7.5°.

•

Do not carry passengers.

•

Do not tow.

•

Use with line striping or line removal equipment only.

•

Use appropriate traffic control in all traffic areas. Refer to manual on Uniform Traffic Control Devices (MUTCD), U.S.

Department of Transportation, Federal Highway Administration or local highway and transportation regulations.

TRAFFIC HAZARD

Vehicle strikes may result in serious injury or death.

• Do not operate in traffic.

• Use traffic control.

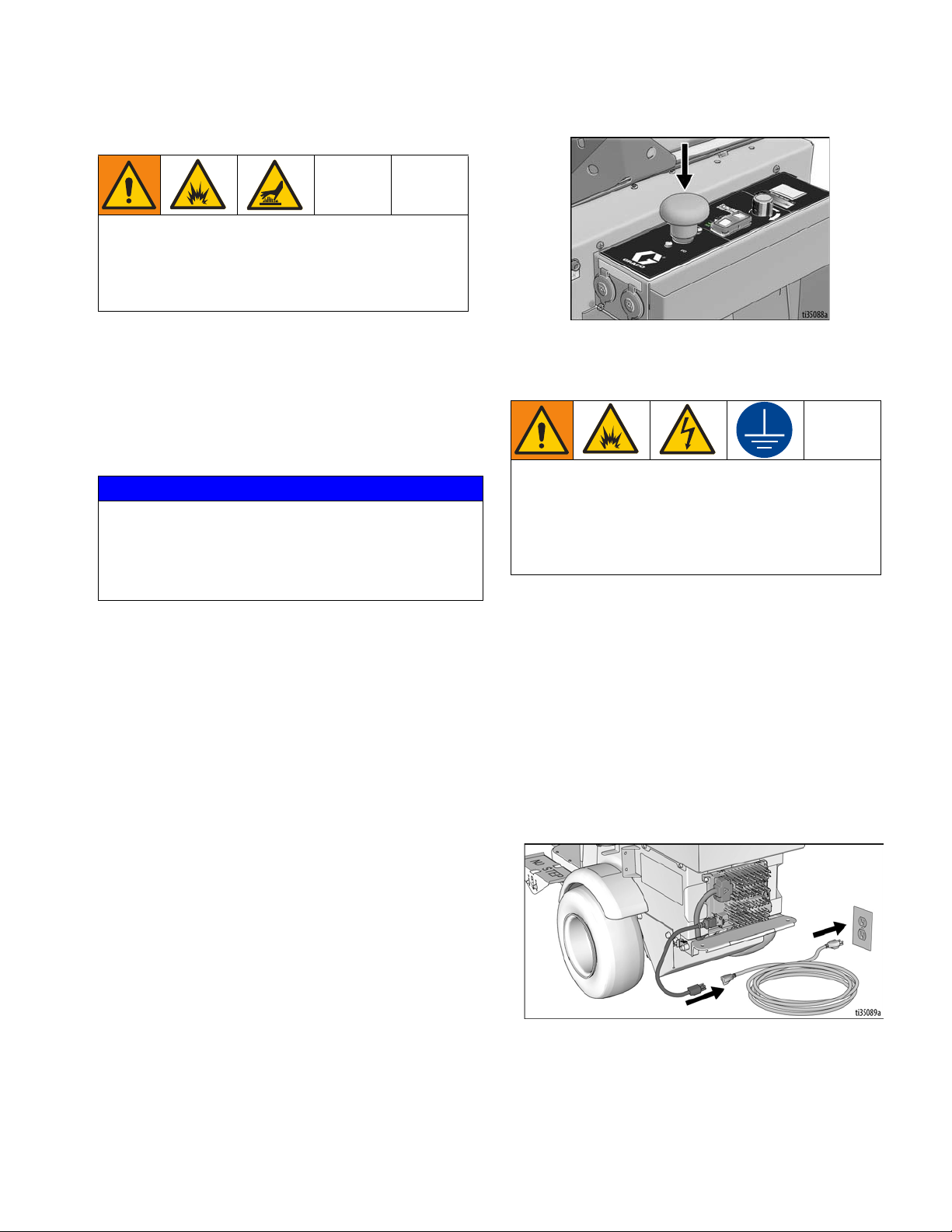

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

3A6623D 3

Page 4

Warnings

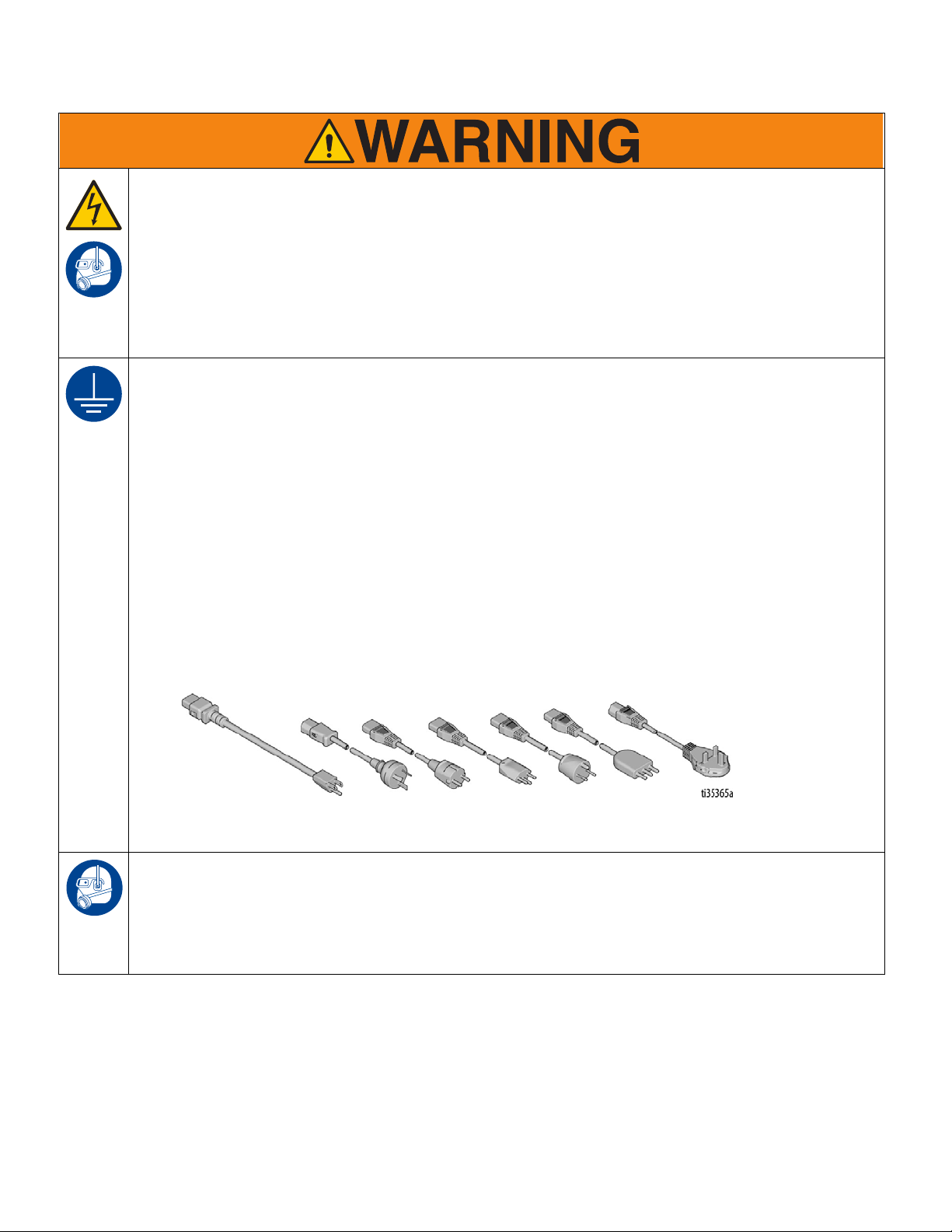

120V US

230V

BATTERY HAZARD

Lead-acid batteries produce explosive gases and contain sulfuric acid that can cause severe burns. To avoid

sparks and injury when handling or working with a lead-acid battery:

• Only use the battery type specified for use with the equipment. See Technical Data.

• Read and follow the battery manufacturer’s warnings.

• Exercise caution when working with metallic tools or conductors to prevent short circuits and sparks.

• Keep all sparks, flames, and cigarettes away from batteries.

• Always wear protective eyewear and protective equipment for face, hands, and body.

• If you have direct contact with battery fluid, flush with water and consult a physician immediately.

• Installation and maintenance must be performed by knowledgeable personnel only.

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a

grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to either flat

blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding

wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified

electrician.

• This product is for use on a nominal 120V or 230V circuit and has a grounding plug similar to the plugs illustrated below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 3A6623D

Page 5

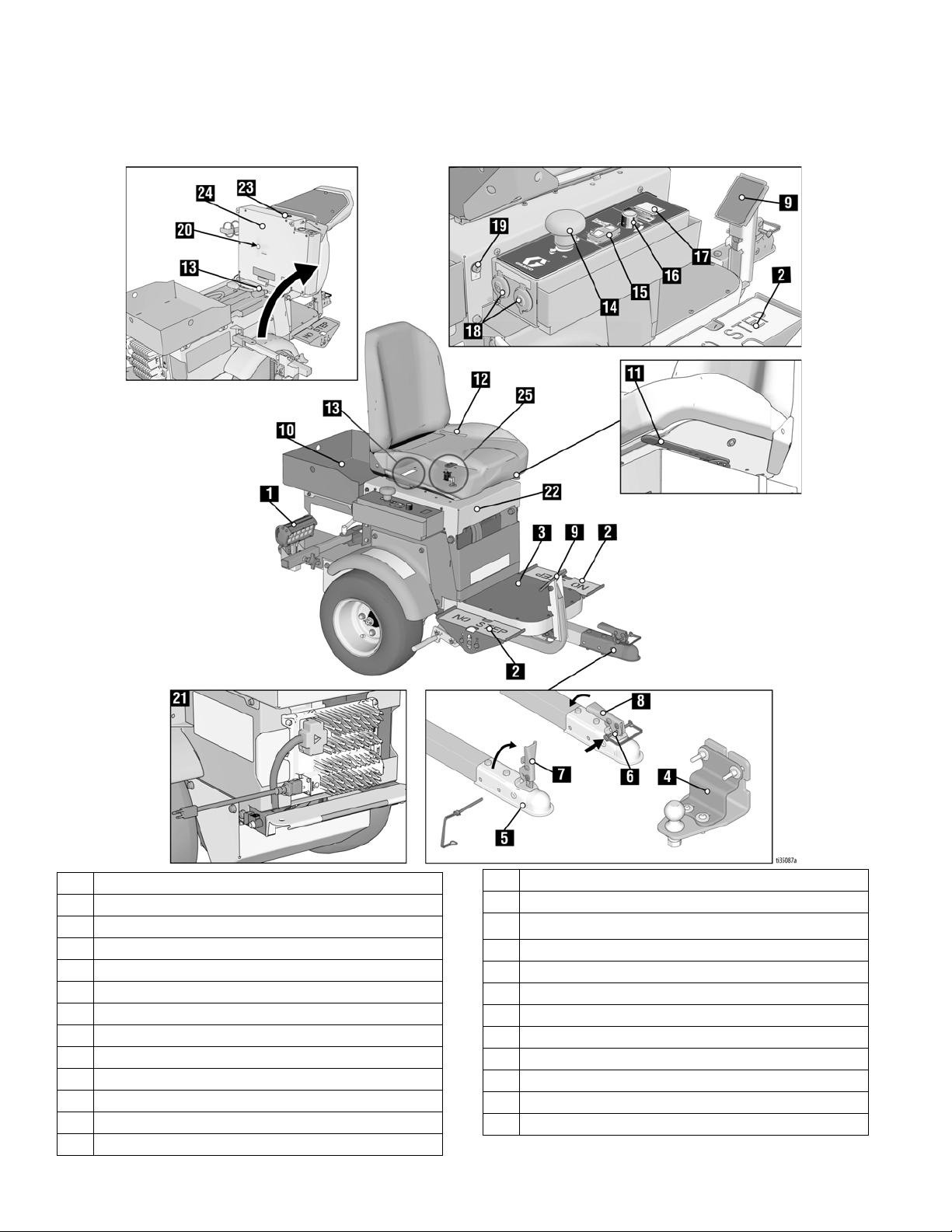

Component Identification

Component Identification

1 Headlight

2 Direction/Speed Pedals

3 Step Plate

4Hitch

5 Coupler

6 Safety Pin Location

7 Handle Open

8 Handle Locked

9 Parking/Emergency Brake

10 Tool Tray

11 Seat Adjustment

12 Operator Seat

13 Serial ID

3A6623D 5

14 Power Switch

15 Speed Switch

16

ExactMil

17 Voltage Meter

18 12V Aux. Power

19 Light Socket

20 Motor Controller Diagnostic Light

21 Battery Charger

22 Seat Lid

23 Buzzer

24 Seat Cover

25 Seat Interlock Switch

™

Speed Control

Page 6

Setup

ti11087a

ti10936a

M

ti11086a

ti11085a

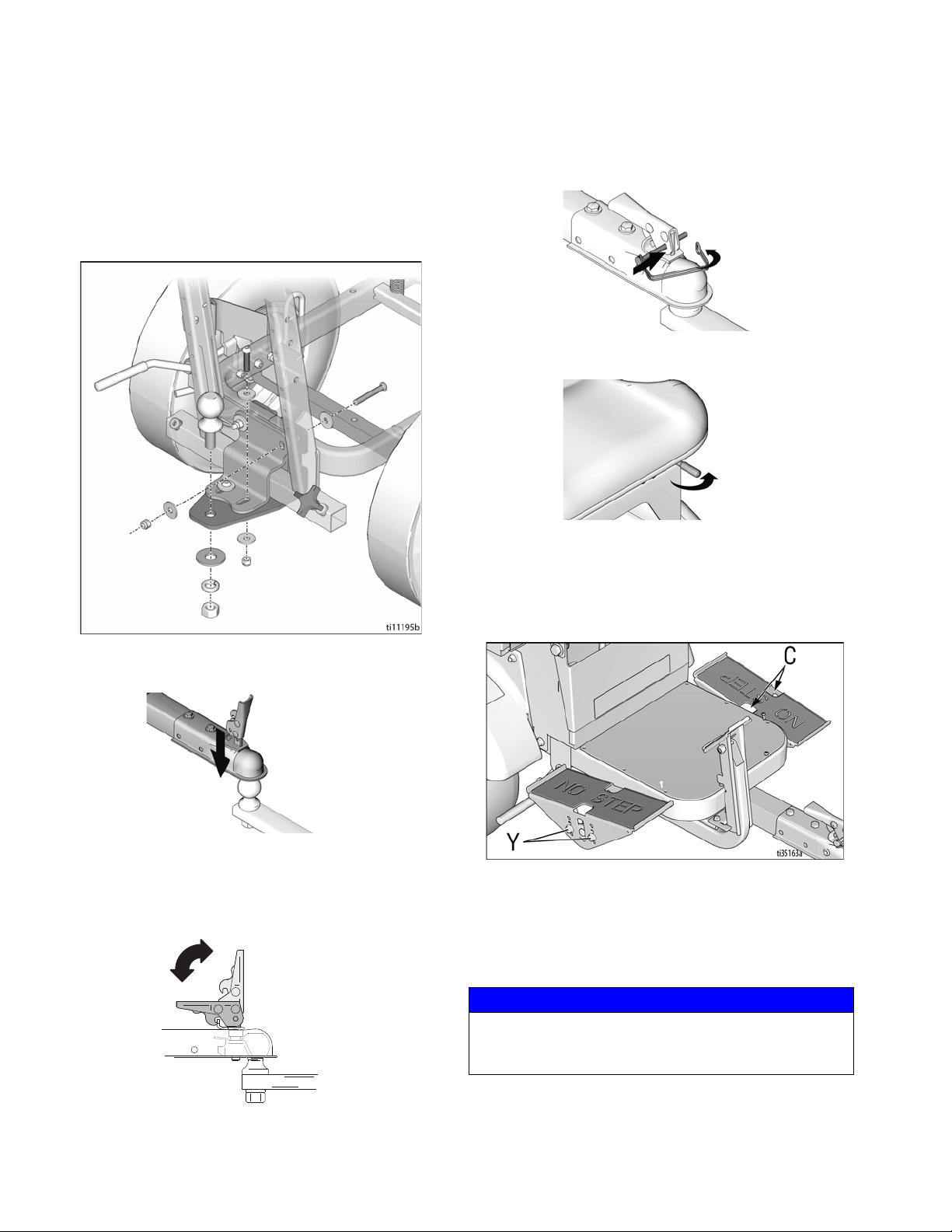

Setup

1. Install supplied ramp onto pallet.

2. Connect Hitch Receiver to line striping or line

removal equipment - Hitch Receiver Kit 25N787;

Manual 3A6720.

5. Insert safety pin in latch

6. Adjust seat forward/backward with lever below seat.

7. Adjust height of pedals to desired position by

removing/replacing bolts (Y).

8. Loosen two bolts (C) on topside of pedals. Rotate

pedal to desired position. Tighten bolts.

3. Install LineDriver Coupler to striper or grinder hitch

ball.

4. Latch Coupler to locked position (M).

NOTE: If Coupler is too tight to latch or is loose after

latching, Coupler needs adjustment. Refer to Coupler

Adjustment, page 15.

12V Auxiliary Ports

12V auxiliary power ports are provided to power accessories.

NOTICE

12V auxiliary ports must be used to power accessories.

Battery damage can result if other means are used to

power accessories.

6 3A6623D

Page 7

Startup

Startup

Know Your Controls

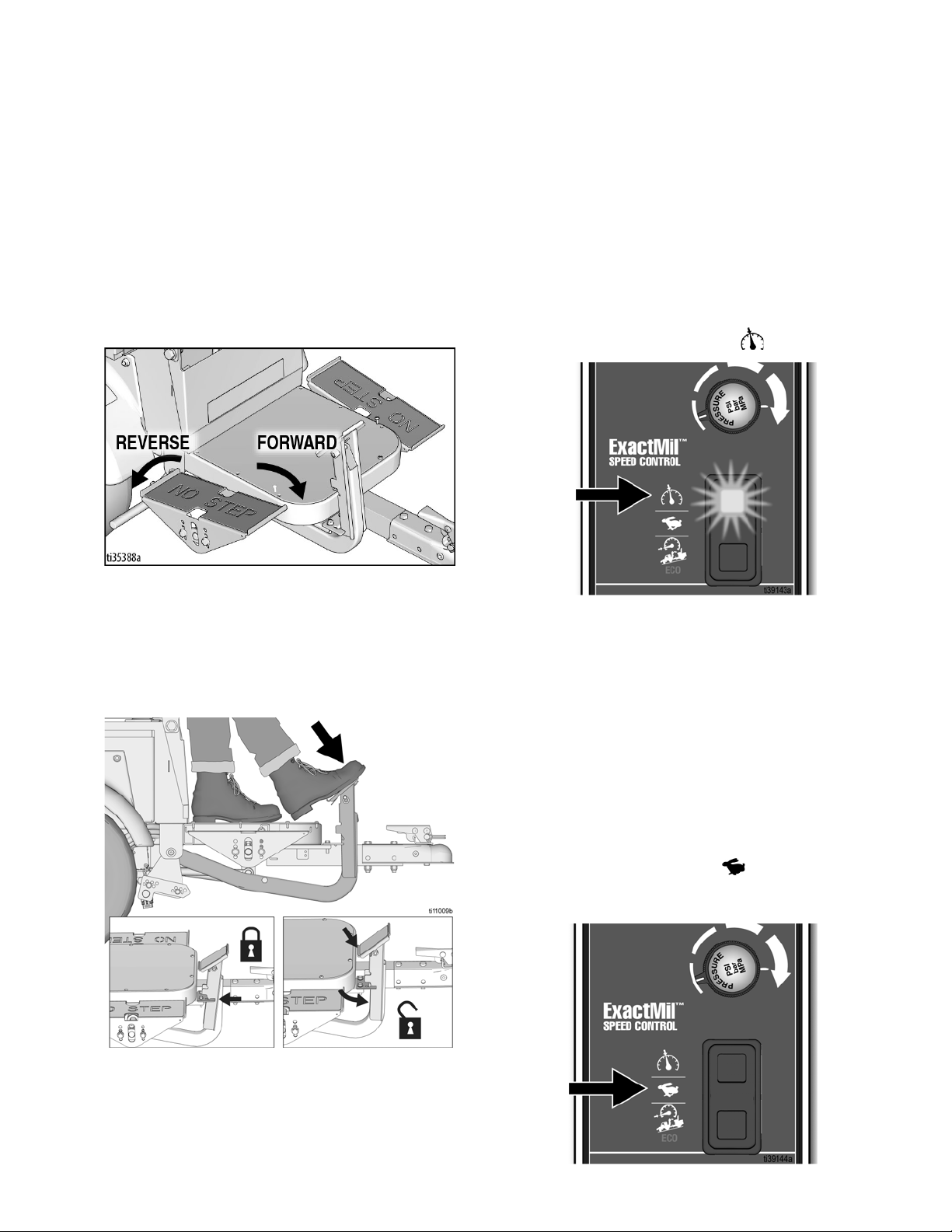

Direction/Speed Pedals

The Direction/Speed Pedals drive the LineDriver forward

and in reverse. Switching from forward to reverse creates

a braking action. When both feet are removed from the

pedals, the LineDriver stops. Use one or both feet to

operate the pedals.

Parking/Emergency Brake

The Parking/Emergency Brake stops the machine in an

emergency and prevents it from rolling when parked. To

engage the Parking/Emergency Brake, press brake

pedal firmly until it latches. To release, press the lower

edge of the brake pedal.

Speed Switch

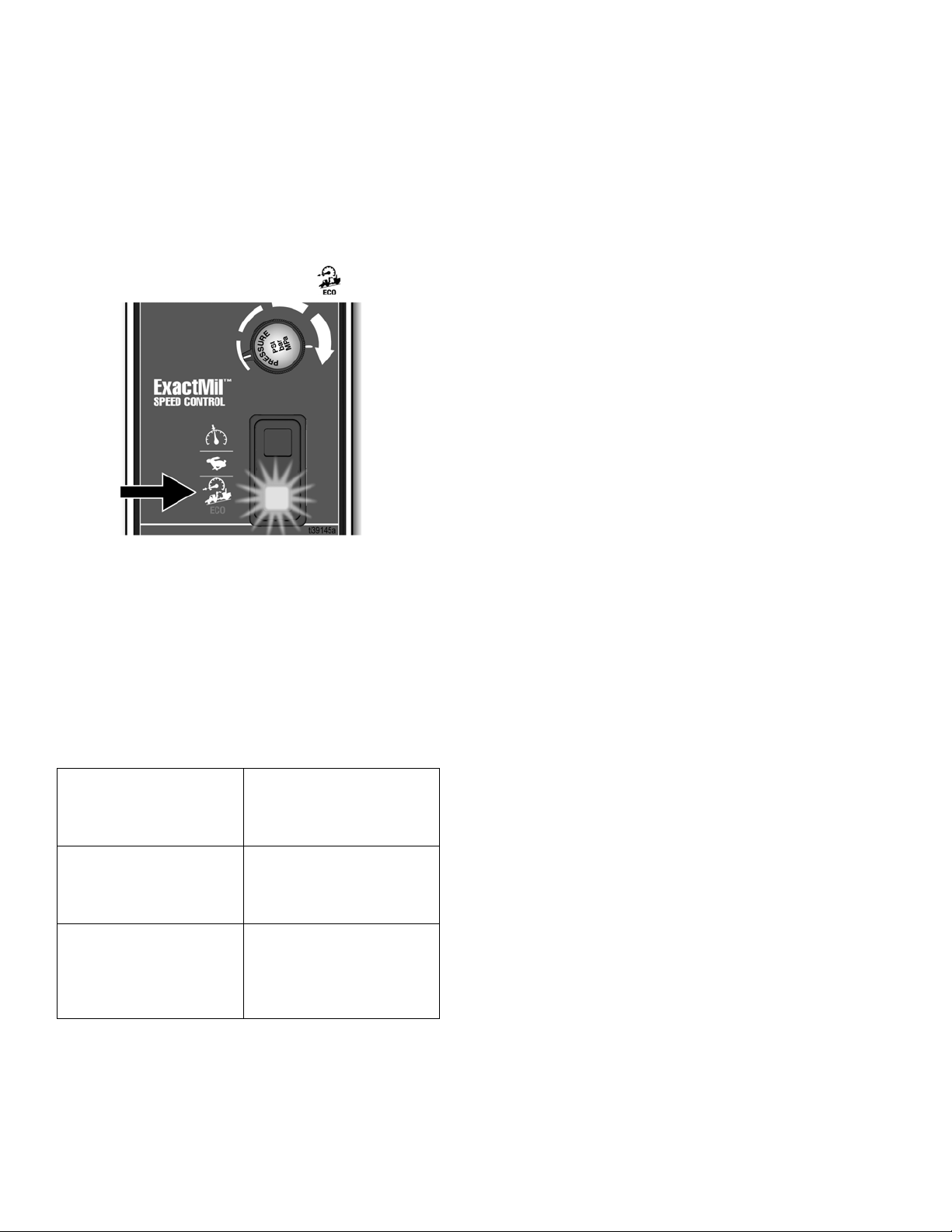

ExactMil™ (Speed Control) Mode

ExactMil Mode ensures a consistent paint thickness by

holding the speed steady. To enable ExactMil mode:

1. Stop moving. Turn speed control knob all the way

counterclockwise.

2. Set Speed Switch to ExactMil position.

3. Depress foot pedal to go forward. Adjust speed control knob to desired speed setting.

NOTE: ExactMil speed control is only active when moving forward. Reverse speed is not impacted. ExactMil

speed control limits the maximum speed that can be

obtained with the pedal.

To disable ExactMil Mode:

• Return Speed Switch to center position.

Full Speed Mode

Set Speed Switch to the center position. This allows

a forward speed of 10 mph (16 kph) and a reverse speed

of 7 mph (11 kph).

3A6623D 7

Page 8

Startup

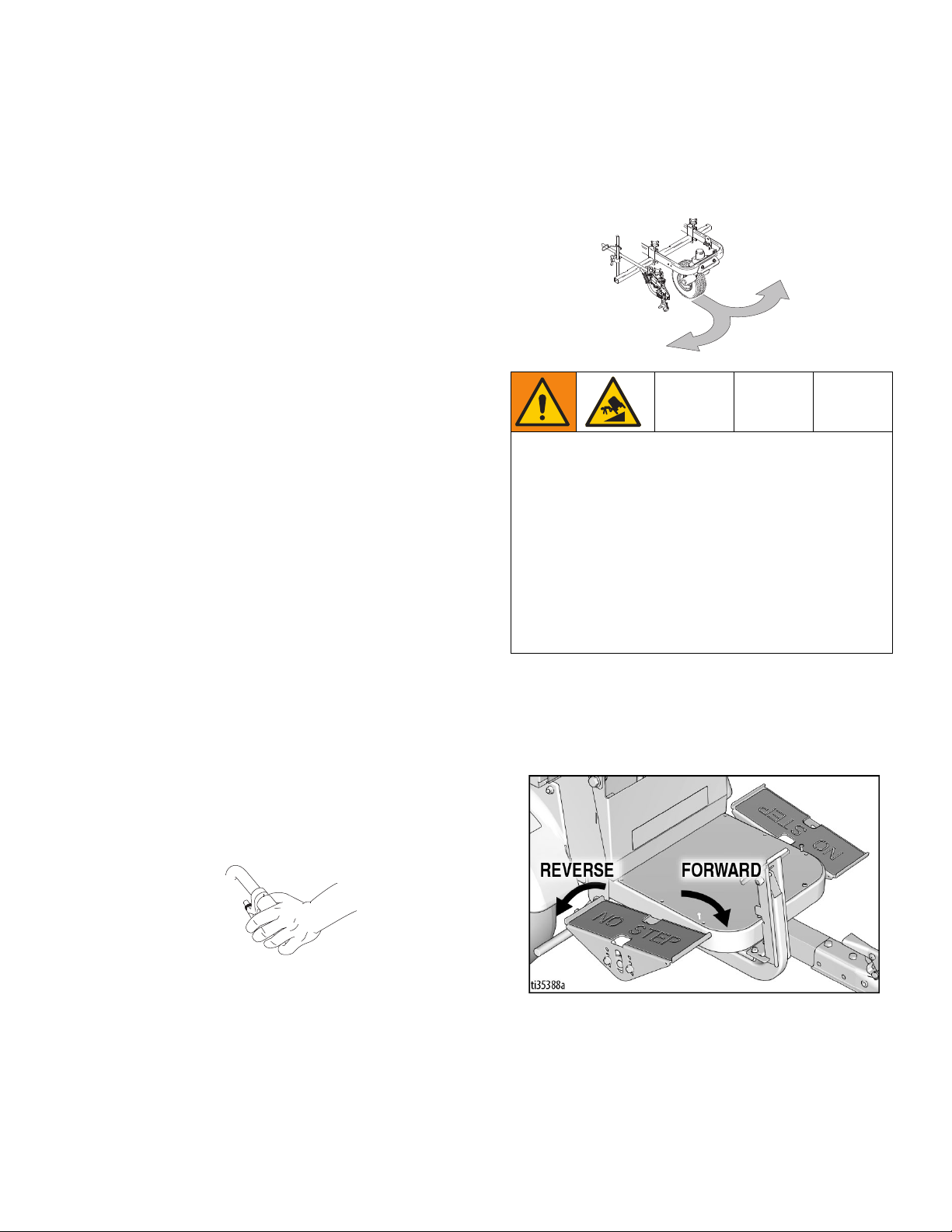

Incline/ECO Mode

Incline/ECO Mode is the recommended default mode for

all operations. It is helpful when greater control is

needed such as during loading or unloading and in congested areas. Incline/ECO mode should be used when

operating on inclines. It also extends battery life. To

enable Incline/ECO mode:

• Set Speed Switch to Incline/ECO position.

NOTE: Incline/ECO Mode limits forward speed to 5.5

mph (9 kph) and reverse speed to 4 mph (6 kph).

To disable Incline/ECO Mode:

• Return Speed Switch to center position.

Buzzer

A buzzer will sound to indicate different operating

conditions.

Single tone, about one

second long, after

turning the Power Switch

ON.

Repeating tone, about

every second.

Continuous tone while

traveling faster than 6.5

mph (10 kph).

Direction/Speed control

pedals now active.

Batteries are deeply

discharged. See

Charging the Batteries,

page 11.

Reduced braking available

from Direction/Speed

Pedals. See warning in

Extended Braking

Distance, page 10.

Daily Inspections

Perform the following inspections each day before using

the LineDriver ES.

1. Check battery charge level. Charge if not fully

charged.

2. Inspect Coupler for excess movement. Adjust if

needed. See Coupler Adjustment, page 15.

Replace Coupler when it is no longer adjustable.

3. Check function of the Seat Interlock Switch. The

Seat Interlock Switch stops the ES Driver when the

operator leaves the seat, and disables the Direction/Speed Pedals.

a. With the Parking/Emergency Brake ON, move

the Power Switch to the ON position while

standing next to the LineDriver ES.

b. Gently tap the Direction/Speed Pedals. The

LineDriver ES should not attempt to travel.

c. Sit on the seat and gently tap the Direc-

tion/Speed Pedals. The unit should attempt to

travel.

d. Service the Seat Interlock Switch if the Line-

Driver does not respond as described in steps b

and c above.

4. Test Parking/Emergency Brake function and adjustment.

a. Choose a flat open area. Accelerate unit to 3

mph (5 kph).

b. Cause the LineDriver ES to roll freely (free-

wheel) by moving the Power Switch to the OFF

position.

c. Stop unit by applying Parking/Emergency

Brake. To adjust brakes, see Parking/Emer-

gency Brake Adjustment or Replacement,

page 13.

8 3A6623D

Page 9

Operation

ti10937a

ti10935a

Operation

Differences in Operation

The LineDriver ES operates differently than a gasoline

powered LineDriver.

1. LineDriver ES rolls freely, especially on inclines,

when the power is off. Set Parking/Emergency

Brake before turning off.

2. Turn power on before releasing Parking/Emergency

Brake.

3. Performance drops when the battery charge

becomes low. When there is about one hour of runtime remaining, the Voltage Meter begins to flash.

When the batteries are deeply discharged and the

LineDriver ES is about to shut down, the buzzer

sounds about once per second.

4. The response of the Direction/Speed pedals is

softer. Learn this softer response before operating

on a job site.

How to Operate

1. Sit on seat to actuate Seat Interlock Switch. Ensure

Direction/Speed Pedals are not depressed.

2. Turn Power Switch ON. Buzzer will sound in a few

seconds, indicating that the Direction/Speed Pedals

are now active.

3. Disengage Parking/Emergency Brake on LineDriver

and any brakes on attached equipment.

5. Push striper or grinder handle bars to begin desired

turn.

FREEWHEEL HAZARD

Turning the Power Switch OFF will result in loss of

drive power. Loss of drive power causes LineDriver to

freewheel, which allows it to roll freely.

• Do not turn Power Switch OFF while LineDriver is in

motion.

• If loss of drive power occurs while LineDriver is in

motion, use the Parking/Emergency Brake to bring

LineDriver to a stop.

• Always engage Parking/Emergency Brake before

turning Power Switch OFF or standing up from

seat.

6. Move Direction/Speed pedals to drive the LineDriver, as shown below. Switching from forward to

reverse creates a braking action.

NOTE: LineDriver stops when both feet are removed

from pedals.

4. Squeeze hand control to release caster wheel of

attached equipment.

NOTE: LineDriver motion is forward and reverse. Turns

are made with the striper or grinder.

3A6623D 9

Page 10

Operation

7. Engage Parking/Emergency Brake when not operating LineDriver. This prevents rolling when on an

incline.

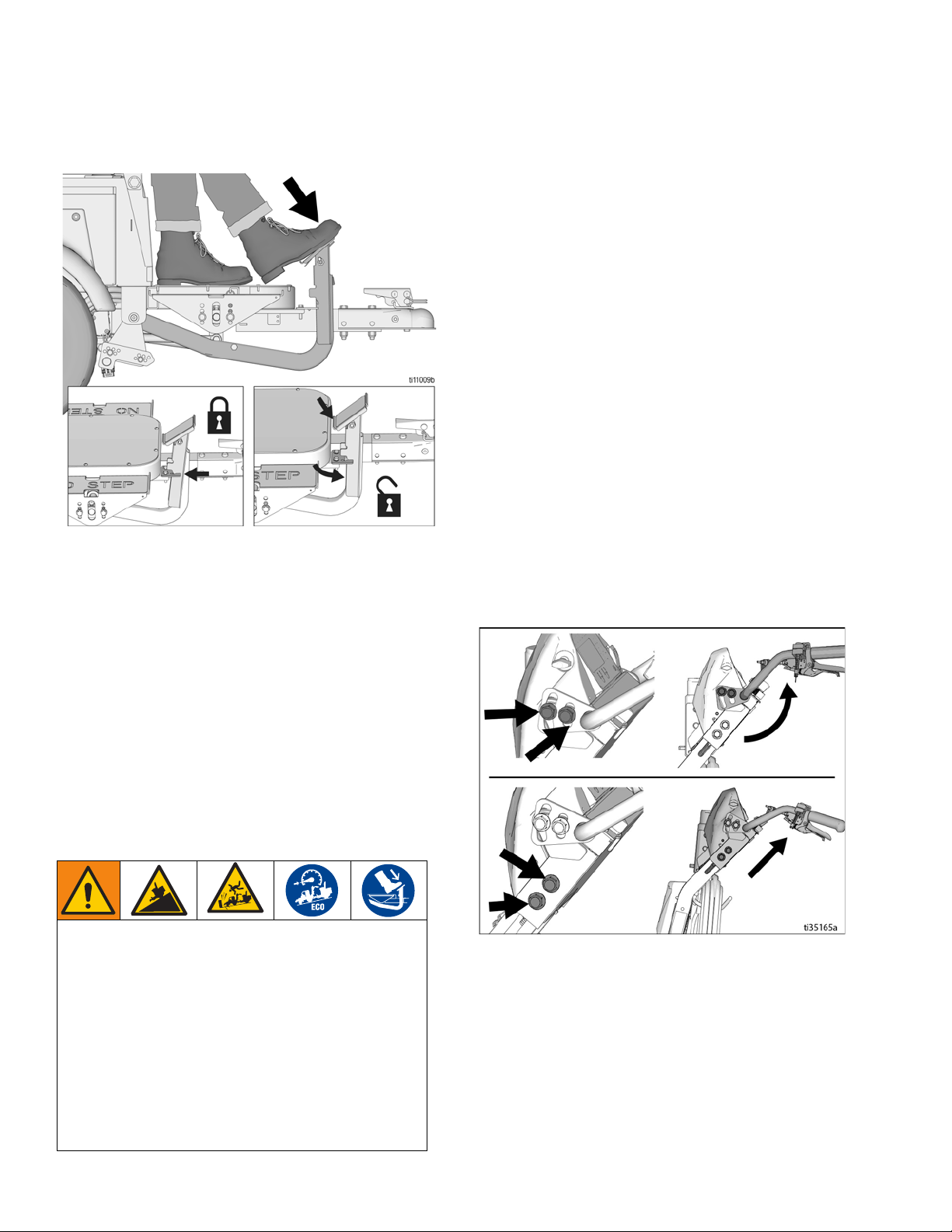

Operating on Inclines

Extended Braking Distance

Starting and Stopping on an Incline

1. Engage the Parking/Emergency Brake before turning the Power Switch to OFF when parking on an

incline.

2. Turn the Power Switch to ON, and allow the

machine to initialize before releasing the Parking/Emergency Brake when starting on an incline.

Trailer Loading & Unloading

NOTE: LineDriver ES rolls freely, especially on inclines,

when the power is off. Set Parking/Emergency Brake

before turning off. Turn power on before releasing Parking/Emergency Brake.

1. Always keep LineDriver connected to striper or

grinder.

2. Use a level surface to load and unload. Leave sufficient space behind ramps.

3. Use loading ramps of sufficient length and capable

of handling weight of unit and operator.

4. Adjust striper or grinder handlebar to highest position. Slide seat back as far as possible.

Operating on inclines results in extended braking distances.

1. Select Incline/ECO mode on Speed Switch when

operating on inclines.

2. Be prepared to use the Parking/Emergency Brake

when operating on inclines.

NOTE: Do not operate on inclines greater than 7.5

(13%).

REDUCED BRAKING HAZARD

The braking from the Direction/Speed pedals can be

significantly reduced when going down inclines at

speeds over 6.5 mph (10 kph). This reduced braking

results in longer braking distance than normal, which

could lead to an accident.

A continuous buzzer alarm will sound when this

reduced braking condition occurs. If this alarm

sounds, apply the Parking/Emergency Brake to slow

down. Failure to do so could result in serious injury.

• Do not drive in a manner that causes this alarm to

sound.

°

5. Use right foot to engage Parking/Emergency Brake.

Use left foot to control speed. Use ECO Mode to

limit speed.

6. Slowly drive straight up/down ramps (do not drive at

an angle).

7. Keep a firm grip on handlebars as the ramp is negotiated.

NOTE: Striper or grinder handlebars swing up/down as

the ramp is engaged/disengaged. Keep legs clear.

10 3A6623D

Page 11

Operation

Charging the Batteries

Replace and charge battery only in well-ventilated

area and away from flammable or combustible materials, including paints and solvents. The charger may

become hot while charging. Do not touch. Refer to

Charger Manual for additional information.

The charger may be used any time the LineDriver is not

being used. When the batteries are fully charged, the

charger automatically stops. If the LineDriver is stored

for an extended period, the batteries may self-discharge

enough for the charger to automatically recharge the

batteries. For optimum battery life, always leave the

charger plugged in.

NOTICE

Lead acid batteries can self-discharge in as little as 3

months depending on storage temperatures. The hotter

the storage temperature, the faster the self-discharge

occurs. To prevent damage to the battery, it is important to keep the battery in a charged state.

Batteries are fully charged when leaving the factory.

Due to self-discharging of the battery, charge battery

before first use. It takes ~18 hours to charge a fully

depleted battery, and ~8 hours to charge the battery 3/4

full.

3. Ensure Power Switch is in OFF position.

4. Plug charging cord into charging port on the unit.

Connect an extension cord, per charger manual, to

the charging cord and plug it into wall power.

This equipment must be grounded to reduce the risk

of static sparking and electric shock. An electric

shock or static spark can cause fumes to ignite or

explode. An improper ground can cause electric

shock. A good ground provides an escape wire for

the electric current.

Always use an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided; if it does not fit the

outlet, have the proper outlet installed by a qualified

electrician.

NOTE: Battery life depends on the depth of discharge

per cycle. A battery that is discharged to 50% depth will

get over twice as many cycles in its life compared to it

being discharged to 100% depth each cycle.

1. Place unit in dry, well-ventilated area and away from

flammable or combustible materials, including

paints and solvents.

2. Position the driver so the wheels are on a true

grounded surface, not on pavement.

3A6623D 11

Power Requirements

• All models use the same battery charger. Refer to

Technical Specifications, page 35, for power

requirements.

Page 12

Operation

DISPLAY

CHARGING

OUTPUT

INICATOR

USB PORT

STATE OF

CHARGE

INDICATOR

FAULT

INDICATOR

5. The Charging Output Indicator means that the charger output is active.

6. When power is connected, charger will immediately

begin charging.

NOTE: Battery will charge to ~30 volts while charging

and then it will come back down to ~27 volts after fully

charging.

ti35137a

NOTE: The Charge Display may show codes to indicate

different conditions. Refer to charger manual for addi-

tional information.

• ‘F’ codes meaning that an internal fault condition

has caused charging to stop.

• ‘E’ codes meaning that an external error condition

has caused charging to stop.

7. When battery charge indicator is solid green, the

charge is complete.

12 3A6623D

Page 13

Maintenance

Maintenance

Parking/Emergency Brake

Adjustment or Replacement

1. Block tires so LineDriver will not move. Release

Parking/Emergency Brake.

2. Ensure Power Switch is in OFF position.

3. Inflate tires to operating pressure per tire sidewall.

Remove two bolts securing brake rod.

4. Select a hole pattern that positions the brake rod 1/8

to 1/4 in. from the tire.

5. Install two bolts and secure brake rod. Repeat for

second tire.

NOTE: Brake rods are not interchangeable from side to

side. Model shown in the graphic above is the right side

version.

3A6623D 13

Page 14

Maintenance

Throttle Linkage Adjustment

14 3A6623D

Page 15

Coupler Adjustment

Maintenance

A Coupler too tight or too loose needs to be adjusted.

Before adjusting, check ball and Coupler for wear.

Replace entire Coupler if unable to tighten it.

Ensure Power Switch is in OFF position.

3A6623D 15

Page 16

Maintenance

Accelerator Calibration (Using Kit 25N880)

1. Turn power OFF. Engage Parking/Emergency

Brake.

2. Slowly raise hitch Coupler until LineDriver rests on

rear bumper.

3. Remove accelerator from LineDriver.

4. Connect calibration cable per illustration. Use a Digital Multi-Meter to measure volts DC.

5. Mount accelerator to calibration plate and plate to

pedal. This makes it easier to torque fasteners.

6. Ensure nothing is on the operator’s seat so the Seat

Interlock Switch prevents wheel movement. Turn

power ON.

7. Loosen adjustment fastener and set neutral position

voltage to 2.45 ± .05 volts. Use calibration plate to

hold accelerator in this position. Torque adjustment

fastener to 90-100 in-lbs.

8. Rotate accelerator arm back and forth, then return it

to neutral position. Re-adjust voltage if necessary.

Turn power OFF.

9. Install accelerator onto LineDriver. When connecting linkage, adjust tie rod end so no pressure is

needed to align parts. Otherwise the LineDriver will

creep.

10. LineDriver may creep forward or reverse when

turned on. As a precaution, jack unit up and use jack

stands to support it (two under the frame in the rear

and one under the Coupler).

11. Connect the LineDriver to a striper or grinder, sit on

the seat and turn on. If wheels do not turn (with no

pressure on speed pedals), calibration is complete.

If they do turn, follow Throttle Linkage Adjust-

ment, page 14.

16 3A6623D

Page 17

Transaxle Service

Maintenance

Check Oil Level (Annually)

1. Turn power OFF. Engage Parking/Emergency

Brake.

2. Slowly raise hitch Coupler until LineDriver rests on

rear bumper.

3. Remove fill plug from transaxle cover.

5. Reinstall plug.

Change Oil (recommended every 3 years)

1. Turn power OFF. Engage Parking/Emergency

Brake.

2. Slowly raise hitch Coupler until LineDriver rests on

rear bumper.

3. Place pan under transaxle cover. Remove screws

and cover.

NOTE: Sealant may hold cover on. If necessary, pry

cover off.

4. Allow oil to drain completely. Follow local ordinances and regulations for disposal.

5. Clean cover and housing where sealant is used.

Apply new sealant (recommended is RTV silicone).

6. Reinstall cover with screws.

7. Remove drain plug. Fill with 22 oz. of Mobilfluid™

424.

4. Slowly lower hitch Coupler. Oil will begin to flow out

of transaxle when hitch Coupler is lowered to 10.5 -

12.5” from the floor. Add or remove oil as needed.

8. Check oil level per above. Reinstall plug.

9. Check for oil leaks. Fix if necessary.

3A6623D 17

Page 18

Repair

Repair

Battery Pack Replacement

NOTE: Prior to replacing batteries, use Troubleshooting - LineDriver, page 20, to determine if the batteries

are the cause of the problem. Also, use a battery load

tester to confirm the batteries need replacement. Always

replace all four batteries.

1. Turn Power Switch OFF. Turn lights OFF. Disconnect 12V accessories.

2. Remove Tool Tray.

3. Remove rear screws of Seat Lid.

4. Pivot Operator Seat forward slowly.

6. Remove battery holders. Remove batteries and

recycle according to below.

7. Install new batteries in orientation shown. Install

holders and cables.

8. Reinstall seat and Tool Tray.

5. Remove battery cables.

9. Charge batteries. See

11.

Charging the Batteries

, page

Battery Disposal

Do not place batteries in the trash. Recycle batteries

according to local regulations.

18 3A6623D

Page 19

Repair

Transaxle Replacement

1. Turn power OFF.

2. Remove rear screws of Seat Lid. Pivot seat forward

slowly.

3. Disconnect battery cables to motor controller.

4. Jack unit up and use jack stands to support unit (two

jacks at the rear and one jack in the front). Raise

wheels about 2 inches off the floor, leaving enough

room to pull the transaxle out.

5. Remove wheels.

6. Remove motor cover.

7. Disconnect wires attached to motor.

8. Place a support under motor and remove transaxle.

9. Place new transaxle under unit. Lay motor wires on

transaxle.

10. Bolt new transaxle to frame.

11. Connect wires to motor. Take care when attaching

the three large cables to prevent damage to the

plastic terminal block on the motor.

Motor Controller Replacement

1. Turn power OFF.

2. Remove rear screws of Seat Lid. Pivot seat forward

slowly.

3. Disconnect battery cables to motor controller. Tape

over terminals to prevent accidental contact.

4. Remove Seat Cover to expose motor controller.

5. Disconnect wires from motor controller.

6. Remove nuts holding motor controller in place.

7. Install new motor controller.

8. Connect wires to new motor controller. Be sure 35

pin connector latches.

9. Install Seat Cover.

10. Reconnect battery cables. Pivot seat back and reinstall rear screws of Seat Lid.

11. LineDriver may creep forward or reverse when

turned on. As a precaution, jack unit up and use jack

stands to support it (two under the frame in the rear

and one under the Coupler).

12. Install motor cover.

13. Install wheels.

14. Lower unit to the floor and reconnect the battery

cables.

15. Reinstall Operator Seat.

Traction Motor Replacement

Follow Transaxle Replacement, page 19.

12. Sit on the seat and turn on. If wheels turn with no

pressure on speed pedals, follow the Accelerator

Calibration Procedure, page 16.

3A6623D 19

Page 20

Troubleshooting - LineDriver

Troubleshooting - LineDriver

PROBLEM CAUSE SOLUTION

Parking/Emergency Brake

Driver from moving

LineDriver creeps in forward or reverse direction Throttle linkage too long or too short Adjust throttle linkage

Head light does not turn on Connections Repair connections

LineDriver does not move forward or reverse Voltage Meter ON

LineDriver does not move forward or reverse Voltage Meter OFF

LineDriver only moves slowly

Battery charger not charging Batteries already charged Charge batteries after voltage drops below

Batteries discharge within 6 hours of usage

(even when charged overnight)

Hitch Coupler too tight to latch or too loose after

latching

Voltmeter flashes ON/OFF Batteries discharged and less than one hour of

Buzzer sounds about once per second Batteries deeply discharged and system about

does not keep Line-

Buzzer sounds continuously when traveling

over 6.5 mph (10 kph).

Parking Brake needs adjustment Adjust Parking Brake

Tire pressure too low Adjust pressure per tire sidewall

LED Replace light

Open 10 amp fuse Address cause of high current Replace fuse

Switch Replace switch

Batteries discharged Charge batteries at least 2 hours

Seat Interlock Switch Sit on seat

Speed pedals engaged while turning unit on Disengage pedals then turn unit on

Speed pedals engaged for 15 seconds with no

LineDriver movement

Motor Controller fault Follow Troubleshooting - Motor Controller

Batteries discharged Charge batteries at least 2 hours

Power Switch OFF Pull knob up

Open 20 amp fuse Address cause of high current Replace fuse

Open 300 amp fuse Address cause of high current Replace fuse

Turn Power Switch OFF then back ON to reset

motor controller

instructions, page 21

Parking/Emergency Brake engaged Disengage Parking/Emergency Brake

Batteries discharged Charge batteries at least 2 hours

™

ExactMil

ECO Mode ON Turn OFF

Motor Controller fault Follow Troubleshooting - Motor Controller

Charger has error or fault code Clear code. See charger manual

Speed Control ON

Parking/Emergency Brake engaged

Wheels rubbing Clear material away from wheels

Batteries unable to hold charge Replace all four batteries

Charger has error or fault code Clear code. See charger manual

LineDriver hitch Coupler too loose or tight on

ball

runtime left

to shut off

Braking from Direction/Speed Control pedals

is significantly reduced.

Increase speed setting or turn OFF

instructions, page 21

25.0V

Disengage brake while operating

Adjust Coupler

Charge batteries at least 2 hours

Charge batteries at least 2 hours

Slow down. Apply Parking/Emergency Brake

as needed.

20 3A6623D

Page 21

Troubleshooting - Motor Controller

Troubleshooting - Motor Controller

Diagnostics

Diagnostics information can be obtained by observing

the fault codes issued by the Status LEDs. See Table 1

for a summary of LED display formats.

The pair of LEDs built into the controller (one red, one

yellow) produce flash codes displaying all the currently

set faults in a repeating cycle. Each code consists of two

digits. The red LED flashes once to indicate that the first

digit of the code will follow: the yellow LED then flashes

the appropriate number of times for the first digit. The

red LED flashed twice to indicate that the second digit of

the code will follow; the yellow LED flashes the appropriate number of times for the second digit.

Example:

B+ Under voltage Cutback (code 23) and Stall Detected

(code 73).

The controller’s two LEDs will display this repeating pattern:

Code Display

23 One red, two yellow, two red, three yellow

73 One red, seven yellow, two red, three yellow

Summary of LED Display Formats

The two LEDs have four different display modes, indicating the type of information they are providing.

Table 1

Display Status

Neither LED illuminated

Yellow LED flashing

Yellow and red

LEDs both on solid

Red LED on solid Internal hardware fault detected by the

Red LED and yellow LED flashing

alternately

Controller is not powered on, or

Vehicle has dead battery, or

Severe damage

Controller is operating normally

Controller is in Flash program mode

Supervisor or Primary microprocessor.

Missing or corrupt software. Interrupting

a software download may cause corruption of the software. Cycle Power Switch

to clear. Reload software or replace controller if necessary.

Controller has detected a fault. 2-digit

code flashed by yellow LED identifies

the specific fault; one or two flashes by

red LED indicate whether first or second

code digit will follow.

The numerical codes used by the yellow LED are listed

in Table 2, page 22, which also lists possible fault

causes and describes the conditions that set and clear

each fault.

NOTE: If there are more than one errors active at one

time, the control will cycle through them and repeat.

3A6623D 21

Page 22

Troubleshooting - Motor Controller

NOTE: When a fault is encountered, shut off the Power Switch and turn it back on to see if the fault clears. If it

does not, shut off the Power Switch and remove the 35-pin connector. Check the connector for corrosion or

damage, clean if necessary, and re-insert connector. If the fault persists, follow the instructions below. When

inspecting a cable, always check for a loose terminal fastener, a loose crimp, corrosion, and connector or insulation damage. Repair or replace components as needed.

Table 2

CODE DESCRIPTION POSSIBLE CAUSE SET / CLEAR CONDITIONS SOLUTION

1. Inspect motor cables U,V,W.

Visually inspect motor terminal block for external short circuit.

2. Measure resistance between

U, V, W cables and frame of

motor. If resistance is less

than 1 megohm, replace

motor or controller.

1. Inspect motor cables U,V,W.

Visually inspect motor terminal block for external short circuit.

2. Measure resistance between

U, V, W cables and frame of

motor. If resistance is less

than 1 megohm, replace

motor or controller.

1. Inspect all cables and connectors from batteries to controller.

2. Remove any after market

devices that could draw power

during system power up. Only

use designated auxiliary ports

for after market devices.

1. Move the unit to a warmer

area.

1. Move the unit to a cooler area.

2. Reduce operating load on

vehicle.

3. Inspect controller heatsink

mounting for air gaps and

tighten fasteners.

Controller Overcur-

12

rent

Current Sensor

13

Fault

14 Pre-charge Failed

Controller Severe

15

Undertemp

Controller Severe

16

Overtemp

1. External short of phase

U, V, or W motor connections.

2. Controller defective.

1. Leakage to vehicle

frame from phase U, V,

or W (short in motor

stator).

2. Controller defective.

1. External load on battery pack (B+ connection terminal) that

prevents the controller

from charging.

1. Controller is operating

in an extreme environment.

1. Controller is operating

in an extreme environment.

2. Excessive load on

vehicle.

3. Improper mounting of

controller.

Set: Phase current exceeded the

current measurement limit.

Clear: Cycle Power Switch.

Set: Controller current sensors

have invalid offset reading.

Clear: Cycle Power Switch.

Set: The pre-charge failed to

charge the capacitor bank.

Clear: Cycle Power Switch.

Set: Heatsink temperature below

-40°C.

Clear: Bring heatsink temperature above -40°C, and cycle

Power Switch.

Set: Heatsink temperature above

+95°C.

Clear: Bring heatsink temperature below +95°C, and cycle

Power Switch.

22 3A6623D

Page 23

Troubleshooting - Motor Controller

CODE DESCRIPTION POSSIBLE CAUSE SET / CLEAR CONDITIONS SOLUTION

Severe B+ Undervoltage

17

1. Non-controller system

drain on battery.

2. Battery resistance too

high.

3. Battery disconnected

while driving.

4. Open B+ fuse or main

contractor did not close

Set: Battery pack voltage

dropped below the Severe

Undervoltage limit with FET

bridge enabled.

Clear: Bring battery pack voltage

above Severe Undervoltage limit.

1. Inspect all cables and connectors from batteries to controller.

2. Let battery cool then fully

recharge battery. If error happens again, load test battery

and replace if needed.

3. Inspect 300 amp fuse and

replace if open.

4. Inspect contactor for corroded contacts and replace if

needed.

1. Non-controller system

Set: Below Brownout Voltage for

2 seconds.

Clear: Bring Power Switch voltage above Brownout Voltage.

1. Inspect all Power Switch

cables and connectors.

2. Inspect 20 amp fuse and

replace if open.

Severe Power

Switch Undervoltage

drain on battery/Power

Switch circuit wiring.

2. Power Switch disconnected while driving.

3. Open 20 amp fuse.

Severe B+ Overvoltage

18

Severe Power

Switch Overvoltage

1. Battery resistance too

high for given regen

current.

2. Battery disconnected

while regen braking.

1. Incorrect (too high) battery-voltage applied to

Power Switch (pin 1).

NOTE: Prevents Main Contactor closure if Power

Switch is greater than the

Severe Overvoltage limit.

Set: Battery pack voltage

exceeded the Severe Overvoltage limit with FET bridge

enabled.

Clear: Bring battery pack voltage

below Severe Overvoltage limit,

and then cycle Power Switch.

Set: Power Switch voltage

exceeded Severe Overvoltage

limit.

Clear: Bring Power Switch voltage below the Severe Overvoltage limit.

1. Let battery cool then fully

recharge battery. If error happens again, load test batteries

and replace if needed.

2. Inspect all cables and connectors from batteries to controller.

1. Check the voltage of each 6V

battery with a digital volt

meter. Inspect Power Switch

and battery wiring for insulation damage and proper wiring.

1. Controller is performance-limited at this

1. Move the unit to a cooler area.

2. Reduce operating load on

vehicle.

3. Inspect controller heatsink

mounting for air gaps and

tighten fasteners.

Controller Over-

22

temp Cutback

temperature.

2. Controller is operating

in an extreme environment.

3. Excessive load on

vehicle.

Set: Heatsink temperature

exceeded 85°C.

Clear: Bring heatsink temperature below 85°C.

4. Improper mounting of

controller.

3A6623D 23

Page 24

Troubleshooting - Motor Controller

CODE DESCRIPTION POSSIBLE CAUSE SET / CLEAR CONDITIONS SOLUTION

B+ Undervoltage

23

Cutback

1. Normal operation.

Fault indicates the batteries need recharging. Controller is

performance limited at

this voltage.

2. Battery resistance too

high.

3. Battery disconnected

while driving.

4. Open 300 amp fuse or

main contactor did not

close.

5. Non-controller system

drain on battery.

Set: Battery pack voltage

dropped below the Undervoltage

limit with the FET bridge enabled.

Clear: Bring battery pack voltage

above the Undervoltage limit

(19V).

1. Charge batteries.

2. Let battery cool then fully

recharge battery. If error happens again, load test batteries

and replace if needed.

3. Inspect all cables and connectors from batteries to controller.

4. Inspect 300 amp fuse and

replace if needed.

5. Inspect contactor for damaged, corroded or contaminated contacts. Repair or

replace as needed.

1. Normal operation.

Fault shows that regen

B+ Overvoltage Cut-

24

back

braking currents elevated the battery voltage during regen

braking. Controller is

performance limited at

this voltage.

Set: Battery pack voltage

exceeded the Overvoltage limit.

Clear: Bring battery pack voltage

below the Overvoltage limit

(30V).

1. Continue using the unit.

2. Inspect all cables and connectors from batteries to controller.

2. Battery disconnected

while regen braking.

1. Inspect motor encoder/thermistor cable and connector. Disconnect motor encoder and

cycle unit power. If the 5V

supply fault clears, replace the

motor. If the 5V supply fault

persists, reconnect encoder

and repeat this process for the

throttle assembly and Exact-

25 +5V Supply Failure

1. Bad crimps or faulty

wiring.

2. Shorted motor

encoder.

3. Shorted throttle.

4. Shorted ExactMil

potentiometer.

Set: +5V supply (pin 26) outside

the 5 V±10% range.

Clear: Bring voltage within range.

Mil potentiometer.

Motor Temp Hot

28

Cutback

1. Motor temperature is at

or above the programmed Temperature Hot setting, and

the current is being cut

back.

Set: Motor temperature is at or

above the Temperature Hot

parameter setting.

Clear: Bring the motor temperature within range.

1. Move to cooler area, reduce

operating load.

Set: Motor thermistor input (pin

Motor Temp Sensor

29

Fault

1. Motor thermistor is not

connected properly.

8) is at the voltage rail (0V or 10

V).

Clear: Bring the motor thermistor

1. Inspect motor encoder/thermistor cable and connector.

input voltage within range.

Set: Main contactor driver (pin 6)

is either open or shorted. This

fault can be set only when Main

Enable = ON.

Clear: Correct open or short, and

cycle Power Switch.

Set: Motor encoder phase failure

detected.

Clear: Cycle Power Switch.

1. Inspect contactor coil cables

and connectors.

2. Test the contactor coil and

replace contactor if needed.

1. Inspect motor encoder/thermistor cable and connector.

2. Replace motor.

Main Contactor

31

Open/Short

36 Encoder Fault

1. Open or short across

contractor coil.

2. Dirty connector pins.

3. Bad crimps or faulty

wiring.

1. Motor encoder failure.

2. Bad crimps or faulty

wiring.

24 3A6623D

Page 25

Troubleshooting - Motor Controller

CODE DESCRIPTION POSSIBLE CAUSE SET / CLEAR CONDITIONS SOLUTION

Set: Motor phase U, V, or W

detected open.

Clear: Cycle Power Switch.

1. Inspect U, V, W cables.

2. Replace motor.

37 Motor Open

1. Motor phase is open.

2. Bad crimps or faulty

wiring.

1. Main contactor tips are

Main Contactor

38

Welded

welded closed.

2. Motor phase U or V is

disconnected or open.

3. An alternate voltage

path is bypassing the

contractor between

battery and B+ on the

controller before the

Set: Just prior to the main contactor closing, the battery pack

voltage (B+ connection terminal)

was loaded for a short time and

the voltage did not discharge.

Clear: Cycle Power Switch.

1. Inspect contactor for welded

contacts and replace if necessary.

2. Inspect all cables from the

battery pack to controller looking for insulation damage.

3. Inspect U, V, W cables.

contractor engages.

1. Main contactor did not

Main Contactor Did

39

Not Close

close.

2. Main contactor tips are

oxidized, burned, or

not making good contact.

3. External load on battery pack (B+ connection terminal) that

prevents battery pack

from charging.

4. Blown 300 amp fuse.

Set: With the main contactor

commanded closed, the battery

pack voltage (B+ connection terminal) did not charge to B+.

Clear: Cycle Power Switch.

1. Inspect contactor cable and

connectors.

2. Inspect all cables and connectors from batteries to controller.

3. Inspect contactor contacts for

damage or corrosion and

repair or replace contactor.

4. Inspect 300 amp fuse and

replace if needed.

41 Throttle Open

42 Throttle Short

HPD/Sequencing

47

Fault

73 Stall Detected

Encoder Pulse

88

Count Fault

1. Throttle wiper voltage

too high.

1. Throttle wiper voltage

too low.

1. Power Switch, seat,

and throttle inputs

applied in incorrect

sequence.

2. Faulty wiring, crimps,

or switches at Power

Switch, seat, or throttle

inputs.

1. Stalled motor.

2. Motor encoder failure.

3. Bad crimps or faulty

wiring.

4. Problems with power

supply for the motor

encoder.

1. Encoder Steps parameter does not match

the actual motor

encoder.

Set: Throttle wiper (pin 16) voltage is higher than the high fault

threshold.

Clear: Bring throttle wiper voltage

below the fault threshold.

Set: Throttle wiper (pin 16) voltage is lower than the low fault

threshold.

Clear: Bring throttle wiper voltage

above the fault threshold.

Set: HPD (High Pedal Disable) or

sequencing fault caused by

incorrect sequence of Power

Switch, seat, and throttle inputs.

Clear: Reapply inputs in correct

sequence (neutral throttle,

power, seat switch).

Set: No motor encoder movement detected.

Clear: Cycle Power Switch.

Set: Detected wrong setting of

the Encoder Steps parameter.

Clear: Cycle Power Switch.

1. Inspect throttle cable insulation and connectors for damage and repair or replace

where needed.

2. Replace throttle assembly.

1. Inspect throttle cable and connectors.

2. Replace throttle assembly.

1. Cycle power with no pressure

on Speed Pedals.

2. If error persists, inspect throttle and seat switch cables.

3. Recalibrate the accelerator

assembly. Refer to Accelera-

tor Calibration, page 16.

4. Replace throttle assembly.

1. Reduce load on driver so it

can move with applied throttle.

2. Inspect encoder/thermistor

cable. Verify motor wires U, V,

W are properly wired.

3. Replace motor.

4. Replace controller.

1. Inspect motor encoder/thermistor cable.

2. Replace motor.

3A6623D 25

Page 26

Parts Drawing

Torque cable cap screws or nuts

to 7-8 ft-lbs (9-11 N·m)

1

1

1

1

1

Parts Drawing

26 3A6623D

Page 27

Parts Drawing

Torque to 8-9 ft-lbs (11-12 N·m)

Torque to 40-60 ft-lbs (54-81 N·m) in

criss-cross sequence

Torque to 16-20 ft-lbs (22-27 N·m)

Torque to 10-11 ft-lbs (14-15 N·m)

Torque to 1.8-2.3 ft-lbs (2.5-3.2 N·m)

1

2

3

4

5

2

1

3

4

4

5

Parts Drawing

3A6623D 27

Page 28

Parts Drawing - Detail Views

Torque to 6-7 ft-lbs. (8-9 N·m)

Torque to 20-25 ft-lbs (27-34 N·m)

Torque to 90-115 ft-lbs (122-156 N·m)

Torque to 95-105 in-lbs (10.7-11.9 N·m)

Use a wrench to support backup nuts firmly

while tightening.

1

2

3

4

1

2

3

4

181

Parts Drawing - Detail Views

28 3A6623D

Page 29

Parts Drawing

Clamped parts must move

freely after tightening

1

1

1

1

Parts Drawing

3A6623D 29

Page 30

Parts List

Parts List

Ref. Part Description Qty

1 25N649 FRAME, electric LineDriver

2 15N470 PLATE, floor

3 25N776 KIT, throttle, includes 180

4 15R872 INSERT, bearing, flange

5 116887 BEARING, flanged, bronze

6 15R794 SHAFT, foot pedal

7 247901 PLATE, linkage

8 25N760 PEDAL, foot, adjustment

9 121234 PAD, non-slip, pedal

10 109570 WASHER, plain

11 116889 COUPLER, ball

12 113696 PIN, ball coupler

13 247571 BRACKET, brake

14 15R123 SPRING

15 15R068 LATCH, brake

16 247572 PEDAL, foot brake

17 15R409 PAD, non-slip, brake

18 15R122 SPRING

19 19B111 BRAKE, adjustment, right

20 19B112 BRAKE, adjustment, left

21 290159 LABEL, reflective

22 17C773 BALL, joint, rod end

23 17Z351 ROD, straight linkage

24 25N527 DAMPENER, pedal

25 103746 NUT, jam, hex, 3/8-24

26 104541 NUT, lock, M8

27 15R472 FASTENER, hex hd, flanged

28 110037 SCREW, mach, pnh

29 125585 SCREW, cap, hex hd

30 102040 NUT, lock, hex

31 100527 WASHER, plain

32 121280 SCREW, cap, hex hd

33 115348 SCREW, cap, 3/8-16 hex hd,

5/16-18

34 101566 NUT, lock, 3/8-16

35 100023 WASHER, flat

36 121256 SCREW, shoulder, skt hd

37 802127 SCREW, cap, hex hd

38 110838 NUT, lock

39 249083 WHEEL pneumatic, assy

40 125481 NUT, wheel

41 25N488 AXLE, transaxle, includes 155,

156, 157, 172, 173, 174, 175

42 25N521 MOTOR, transaxle, includes 158

43 17Y182 GUARD, motor

44 116780 SCREW, hexed, hd, flanged

45 16X378 SCREW, hex flange, M6

22

18

Ref. Part Description Qty

47 100521 SCREW, cap, hex head

1

48 111040 NUT, lock, insert, nylock, 5/16

1

49 25N471 CARRIAGE

2

2

50 25N476 LID, seat, paint

2

51 100424 SCREW, cap, hex hd

1

52 801020 NUT, lock, hex

1

53 113796 SCREW, flanged, hex hd

2

54 25N477 BASE, controls, paint

2

56 17X959 FENDER

2

57 112798 SCREW, thread forming, hex hd

1

58 247544 HOLDER, bottle

1

59 245341 SEAT, includes 69, 82 (x4)

1

61 25N483 CONVERTER, power

1

62 19C163 MOTOR, controller

1

63 25N487 BATTERY, contactor

1

64 17N816 HOLDER, fuse

1

65 131738 FUSE, 300 amp

1

66 25N482 SWITCH, push button, shut off

1

67 25N625 SWITCH, rocker

1

68 17N638 METER, volt, digital

1

69 116833 SWITCH, safety, seat

2

70 25E406 CABLE, harness, 12 vdc supply

1

71 25N649 PLUG, panel

1

72 25N475 COVER, seat, paint

2

73 17X949 TRAY, tool

2

74 17Y217 SOCKET, 12V

2

75 16P138 LABEL, energy source

76 198918 LABEL, warning

4

77 25N529 LABEL

78 25N526 POST, distribution

4

79 16V700 GROMMET

6

80 25N480 BATTERY, charger

2

81 15T120 LABEL, instruction

82 110996 NUT, hex, flange hd

2

83 125943 NUT, serrated flange, 7/16-14

2

84 17M849 BOLT, flange, serrated

2

85 103229 SCREW, cap sch

2

86 187797 SPACER, duct

2

87 17X783 ISOLATOR, hvlp

2

88 17P951 POTENTIOMETER, assy

8

89 17N957 KNOB, potentiometer

1

90 25N884 BATTERY, deep cycle, 6v,

includes 90a, 90b, 90c,112

1

90a M8x1.25x16mm capscrew

1

90b M8 lockwasher

8

90c M8 flatwasher

6

91 116895 CAP, tube, square

2

4

1

1

2

2

2

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

1

1

1

1

19

4

4

2

1

1

1

1

4

8

8

16

2

30 3A6623D

Page 31

Parts List

Ref. Part Description Qty

92 17X783 WASHER, nylon

93 15R063 BRACKET, light

94 15R064 SUPPORT, light

95 17R099 TUBE, bracket, light, LED

96 17R098 LIGHT, LED

97 111145 KNOB, pronged

98 114425 BUSHING, strain relief

99 15R308 CORD, power

100 15R864 KNOB

101 111800 SCREW, cap, hex hd

102 111930 SWITCH, toggle

103 107255 GUARD, switch

104 195428 BOOT, toggle

105 105658 RING, locking

106 17N758 CORD, power, 125V, US

107 278204 CLIP, drain line

108 129627 SPACER, nylon, 3/8 ID

109 15C753 SCREW, mach, hex wash hd

111 17Y311 LABEL, controls

112 17Y312 LABEL, battery, 6v

113 17Y313 LABEL, max wattage

115 17Y315 BRACKET, contactor

116 117018 WASHER

117 108050 WASHER, lock, spring

118 112117 SCREW, cap, hex hd, M6

119 15T112 LABEL

120 195793 LABEL, warning

121 17K396 LABEL, safety

122 17Y094 LABEL, safety, prop 65

123 129696 SCREW, pan hd

124 25N604 INDICATOR, buzzer

126 25E392 CABLE, red, dia. .525 x 15 in.

127 25E393 CABLE, black, dia. .525 x 13 in.

128 25E391 CABLE, red, dia. .525 x 10 in.

129 25E388 CABLE, black, dia. polarized

130 25E389 CABLE, black, dia. .525 x 20 in.

131 25E390 CABLE, red, dia. .525 x 20 in.

132 404989 STRAP, tie

133 25N661 HARNESS, controls

134 25N660 HARNESS, assembly

135 25N652 CLAMP, loop

136 25N647 HOLDER, battery

137 17Y588 SCREW, cap

138 15R608 SPACER, duct, .50 x .75 x .062

141 SERIAL ID

142 109032 SCREW, mach, pnh

143 25N750 PAD, adhesive mounting

146 25N758 BRACKET

147 25N757 FILTER, LED

148 25N759 COLLAR

Ref. Part Description Qty

1

149 110963 SCREW, cap, flange hd

1

153 126215 TRIM, edge, protection

1

155 17Z070 KIT, carrier, cover

1

156 17Z071 KIT, axle, hub

1

157 17Z072 AXLE, vent, cap

1

158 17Z073 KIT, terminal, block

1

159 25N762 KIT, transaxle, assembly, includes

1

1

160 25N778 KIT, LineDriver ES light

2

161 25N787 KIT, hitch

1

161a 17Z155 BRACKET, hitch mount

1

161b 17Z156 BRACKET, hitch brace

1

161c 17Z209 BOLT, button HD, 3/8-16 x 2.75

1

161d 129602 SCREW, cap, button hd, 3/8 x

1

161e 116913 BALL, trailer

1

161f 108851 WASHER, plain

1

161g 101566 NUT, lock

1

161h 110947 WASHER, plain

1

164 17P202 LABEL

4

170 17P925 LABEL, A+ service

1

171 16D576 LABEL, made in USA

1

172 120765 FITTING, plug

5

173 110963 SCREW, cap, flange head

5

174 867021 NUT, hex slotted, 5/8-18

5

175 100103 PIN, cotter

1

176 ARTWORK, identification

1

177a* 17S135 CORD, power, UK

1

177b* 17R033 CORD, power, Australia

1

177c* 17R034 CORD, power, CEE 7/7

2

177d* 17R035 CORD, power, Switzerland

1

177e* 17R036 CORD, power, Denmark

1

177f* 17R037 CORD, power, Italy

1

178 17Z423 LABEL, battery wiring

1

179 25N899 BRACKET, throttle adapter (used

3

1

180 25N722 HARNESS, accelerator

1

181 100214 WASHER, lock

1

41, 42, 45

1.75

on early models only)

1

* Included in 25N556

1

Replacement safety labels, tags, and cards are

1

available at no cost.

2

4

5

2

2

5

1

1

4

18

1.5

1

2

1

1

1

1

1

1

1

2

2

1

8

4

1

2

1

1

1

10

2

2

1

1

1

1

1

1

1

1

1

1

3

3A6623D 31

Page 32

Wiring Diagram - Harness 25N661

Wiring Diagram - Harness 25N661

32 3A6623D

Page 33

Wiring Diagram

Wiring Diagram

3A6623D 33

Page 34

Wiring Diagram - Harness 25E406

Wiring Diagram - Harness 25E406

34 3A6623D

Page 35

Technical Specifications

LineDriver ES

U.S. Metric

Dimensions

Height

Width

Length

Weight

Speed

Forward

Reverse

Batteries

Nominal Battery Pack Voltage

Quantity

Type

Voltage (Nominal)

Dimensions

Capacity (Nominal, 10hr rate)

Maximum Charging Current

Battery Charger

Input Voltage Range

Input Voltage Frequency

Nominal AC input current

Max. Charger Output

Charger Profile

Battery Temperature

Operating

Charging

Storaging

Noise Levels (dBa): measured at 3.1 ft (1 meter) per ISO 3744*

Sound Power:

Sound Pressure:

* Does not include sound from propelled equipment - see relevant manual.

48.5 in. 1232 mm

29.3 in. 744 mm

58.2 in. 1478 mm

620 lbs. 281 kg

0-10 mph 0-16 kph

0-6 mph 0-10 kph

Deep Cycle Absorbent Glass Mat (AGM)

12.6” x 6.93” x 8.86” 320 mm x 176 mm x 225 mm

6.0A @ 120VAC 3.1A @ 230VAC

-4-140°F -20-60°C

14-140°F -10-60°C

-4-140°F -20-60°C

Technical Specifications

24 VDC

4

6 VDC

225 Amp-hour

67.5 Amps

85-270 VAC

50-60 Hz

650 W

28

< 70

< 70

Vibration (m/s2) (8 hours daily exposure)*

Seat and Pedals

* Does not include vibration from propelled equipment - see relevant manual.

< 0.5

California Proposition 65

CALIFORNIA RESIDENTS

WARNING: Cancer and reproductive harm – www.P65warnings.ca.gov.

3A6623D 35

Page 36

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2018, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A6623

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision

D, December 2020

Loading...

Loading...