Page 1

Instructions and Parts

SaniForce™ 6:

Specially de

only.

Maximum Working Air Pressure: 100

psi (0.7 MPa, 6.9 bar)

Maximum Working Fluid Pressure: 650

psi (4.5 MPa, 44.8 bar)

signed for use only in Graco SaniForce pail or drum unloader systems. For professional use

Important

Read all wa

system manuals. Save all instructions.

Safety Instructions

rnings and instructions in this manual and in related

1 Sanitary Pumps

3A5564A

EN

ROVEN QUALITY. LEADING TECHNOLOGY.

P

Page 2

Contents

Models............................................................... 2

Related Manuals ................................................ 2

Usage................................................................ 4

Cleaning ............................................................ 4

Priming Piston Service........................................ 5

Disconnect the Pump ................................... 5

Disassemble the Pump................................. 5

Reassemble After Cleaning .......................... 6

Parts.................................................................. 7

Models

Pump Model Pump Lower

Replacement

25M912 25M906

25M912C31 25M906C31

Kits.................................................................... 8

Priming Piston Displacement Pump Model

25M906, 25M906C31 ............................ 9

Product Dime

Performance chart .............................................. 12

Technical Data ...................................................13

Graco Stand

Pump Type Approvals

Priming Piston Pump

nsions............................................ 11

ard Warranty....................................14

EC 1935

/2004

Related Manuals

Manual Number Title

400

3A5

3A5401

3A5402

5404

3A

3A1211

SaniForce Pail Unloader (SPU) System, Operation

iForce Pail Unloader (SPU) System, Repair/Parts

San

SaniForce Drum Unloader, Operation

SaniForce Drum Unloader, Parts

aniForce Air Motors

S

2

3A5564A

Page 3

Related Manuals

3A5564A 3

Page 4

Usage

Usage

This pump must be used as part of a SaniForce pail

or drum unloader system. Refer to the appropriate

system manuals for operation instructions of this

pump when installed in those systems.

Cleaning

WARNING

PRESSURIZED FLUID HAZARD

This equi

relieved

from mov

as splas

Pressur

when you

check, o

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when

in the work area to help prevent serious injury,

including eye injury, hearing loss, or inhalation of

toxic fumes.

This procedure involves thoroughly disassembling

and cleaning the individual parts in the pump lower

unit. Prior to performing this procedure, flush the

pump and relieve pressure as described in the

system manuals, disconnect all hoses, and remove

thepumpfromthesystem.

pment stays pressurized until pressure is

manually. To help prevent serious injury

ing parts, or from pressurized fluid, such

hing in the eyes or on skin, follow the

e Relief Procedure in your system manual

stop pumping and before you clean,

r service the equipment.

Notes:

• Be sure to follo

standard code

• Use appropriate cleaning and disinfecting agents,

at intervals appropriate for product processed.

• Follow cleaning product manufacturer’s

instructions.

• The pump must

clean it.

1. Loosen the hand screw (13) and remove the

upper shield (6).

2. Clean thoroughly the surface between the upper

and lower shields.

3. Disassemble the fluid pump. See

Priming Piston Service, page 5 .

4. Wash all pump parts with an appropriate cleaning

solution at the cleaning product manufacturer’s

recommended temperature and concentration.

5. Rinse all pump parts again with water and allow

them to dry.

6. Inspect all pump parts and reclean if needed.

NOTE: Any damaged rubber parts must be

replaced as they could harbor microorganisms

that can contaminate the fluid.

7. Immerse all pump parts in an appropriate

sanitizer before assembly. Take the pump parts

out of the sanitizer one-by-one as needed.

8. Lubricate the moving pump parts and o-rings,

packings, and seals with appropriate waterproof

sanitary lubricant.

9. Circulate the sanitizing solution through the pump

and the system prior to use.

w your national and state sanitary

s and local regulations.

be disassembled to thoroughly

4

3A5564A

Page 5

Priming Piston S

ervice

Priming Pisto

Disconnect th

ePump

n Service

WARNING

PRESSURIZED FLUID HAZARD

This equipment stays pressurized until pressure is

relieved manually. To help prevent serious injury

from moving parts, or from pressurized fluid, such

as splashing in the eyes or on skin, follow the

Pressure Relief Procedure in your system manual

when you stop pumping and before you clean,

check, or service the equipment.

PERSONAL

Wear appropriate protective equipment when

intheworkareatohelppreventseriousinjury,

including eye injury, hearing loss, or inhalation of

toxic fumes.

This procedure involves thoroughly disassembling

and cleaning the individual parts in the pump lower

unit. Prior to performing this procedure, flush the

pump and relieve pressure as described in the

system manuals, disconnect all hoses, and remove

thepumpfromthesystem.

1. Release the upper clamp (123) holding the

displacement pump to the tie rod plate (122).

2. Slide the pump down from the air motor. Tilt the

pump and pull the displacement rod (117) out of

the coupler (C). Remove the gasket (102).

Note: Be careful not to scratch the displacement

rod.

PROTECTIVE EQUIPMENT

Figure 1 Remove displacement pump.

Disassemble the Pump

Note: Pump Repair Kit 24G550 is available.

Purchase the kit separately. Kit parts are

marked with an * in the parts section. See

Priming Piston Displacement Pump Model 25M906,

25M906C31, page 9 .

1. Remove the retaining pin (116) from the

connecting rod (109). Slide off the priming piston

(108).

2. Release the lower clamp (123) to remove the

intake valve housing (107) from the pump

cylinder (101). Remove the gasket (102).

3. Remove the poppet (114), spring (113), and

valve stop (111) off the connecting rod (109).

4. Remove the bearing (112) from the center of the

valvestop(111).

5. Remove the packings (115) from the cen

the poppet (114).

ter of

3A5564A 5

Figure 2 Remove priming piston.

6. Push the displacement rod (117) out through the

bottom of the cylinder (101).

Page 6

Priming Piston S

ervice

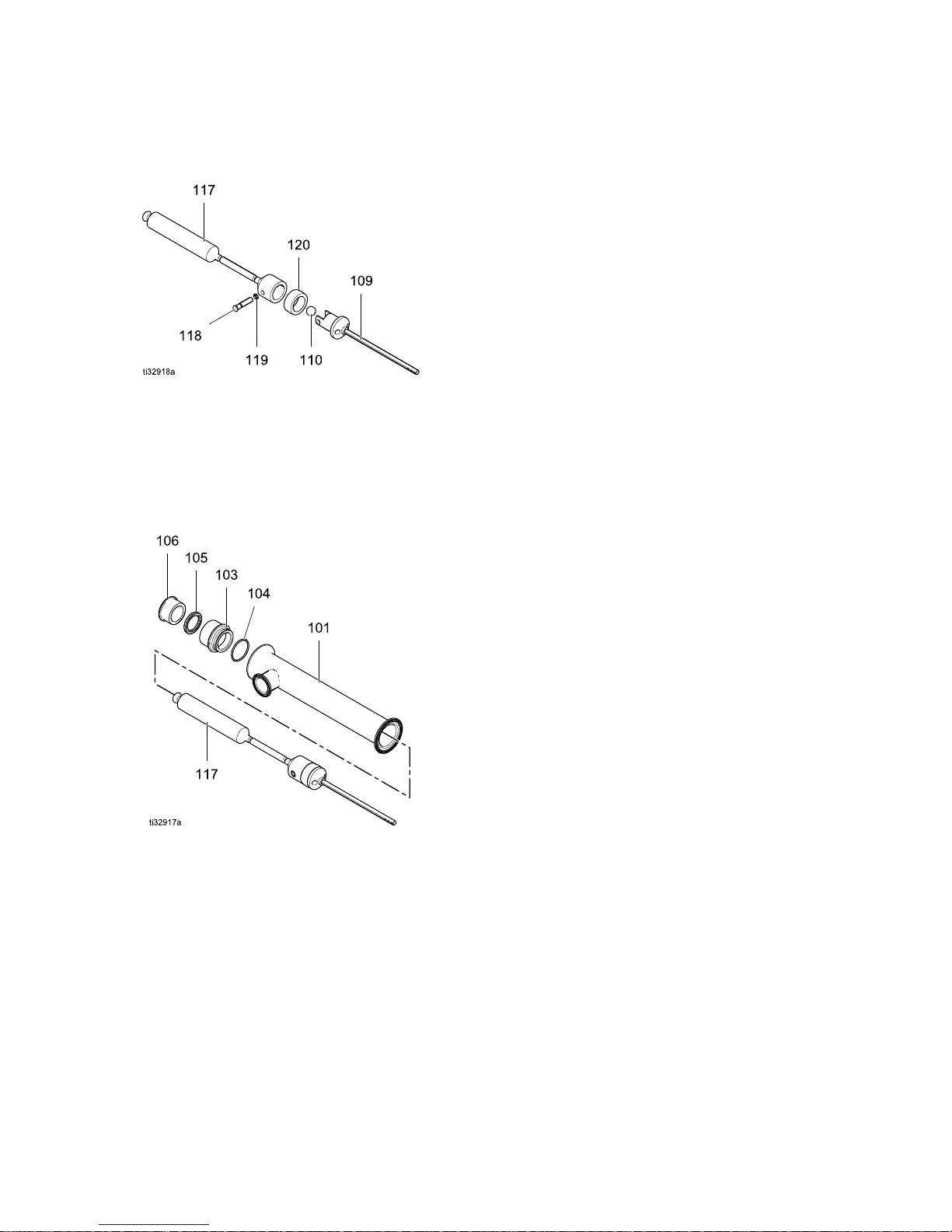

7. Remove the retaining pin (118), o-ring (119), and

ball (110). Pull the connecting rod (109) from the

displacement rod (117). Remove the seal (120).

Figure 3 Di

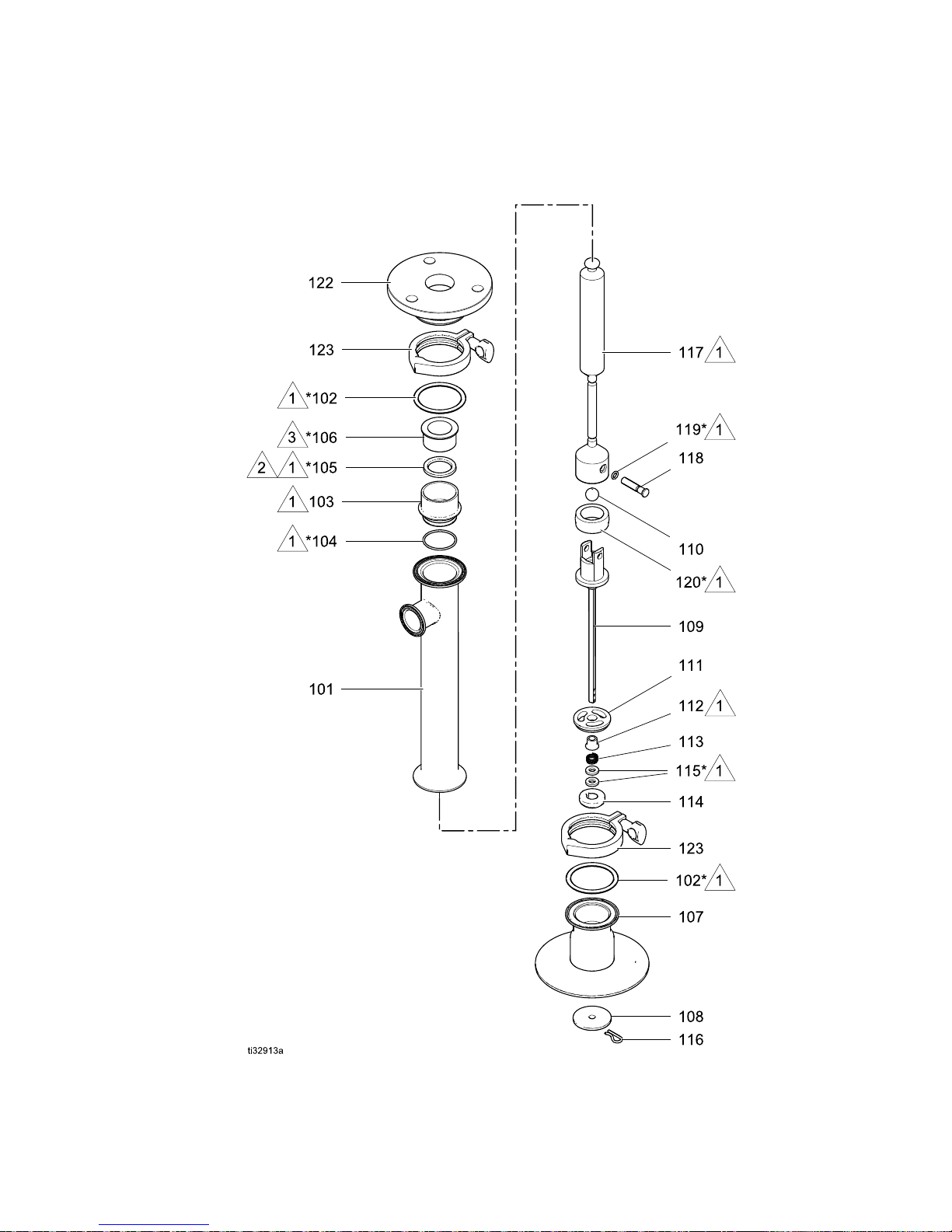

8. Remove the

of the cyli

packing (1

9. Clean and

Cleaning

necessar

Figure 4 Remove packing housing.

sassemble piston valve.

packing housing (103) from the top

nder (101). Remove the bearing (106),

05), and o-ring (104).

inspect all parts. Refer to

, page 4 . Replace the parts as

y.

Reassemble Af

Note: Any damaged parts must be replaced.

Note: Lubrica

piston seals w

lubricant.

1. Install the v-block packing (105) and bearing

(106) in the packing housing (103). The lips of

the packing must face down into the housing,

and the lip of the bearing must face up. Install

the o-ring (104) on the outside of the housing.

2. Install the seal (120) on the piston valve housing

at the top of the connecting rod (109). Place

the ball (110) on the seat of the housing. Install

the displacement rod (117) over the top of the

connecting rod so the holes in both parts align.

Secure with the retaining pin (118) and o-ring

(119).

3. Lubricate and place the packing housing (103) in

the top of the cylinder.

4. Lubricate and slide the displacement rod (117)

up through the cylinder so it protrudes from the

packing housing (103).

5. Lubricate and install the packings (115) into the

center of the poppet (114).

6. Lubricate and install the bearing (112) into the

center of the valve stop (111).

7. Slide the valve stop (111), spring (113), and

poppet (114) onto the connecting rod (109).

8. Install the gasket (102) and the intake valve

housing (107). Secure the housing (107) to the

cylinder (101) with the clamp (123).

9. Install the priming piston (108) and retaining pin

(116) on the connecting rod (109).

10. Slide the displacement rod (117) into the coupler.

Then, attach the clamp (123) to hold the pump

to the motor base.

te the o-rings, throat packings, and

ith appropriate waterproof sanitary

ter Cleaning

6 3A5564A

Page 7

Parts

Complete Pump Models

25M912

25M912C31

Parts

Apply PT

1

Hand tighten only.

2

Apply sanitary lubricant to ease

assembly.

3

Apply medium-strength (blue)

4

thread locker.

Apply an appropriate

medium-strength thread locker

5

on the nut (13) every time it

is installed to prevent it from

coming loose during operation.

Torque to 30-36 ft-lb (41–49

N-m). Do not over tighten.

FE tape to threads.

3A5564A

7

Page 8

Kits

Complete Pump

Ref. Part

1

2

3 16A938

4 16A947

5

6

7

8 118134

10

11

12 165053

13

15▲ 17W547 LABEL, warning, not shown 1

21

22

23 166702

24G785 MOTOR, SaniForce; 3.5 in; see manual 3A1211

25M906 EN 10204, type 2.1

25M906C31

102216 NUT, lock, 5/8-11, sst 3

16G464 SHIELD, upper; includes grommets (Ref. 21)

16G465 SHIELD, lower; includes fasteners (Ref. 8) and grommets (Ref. 21)

24G862 FITTING, air inlet, 1/2 npt, includes Ref. 23

16C946 FITTING, 3/4 npt

16C306

—

16G084 FITTING, air inlet, 1/2 npt

Model 25M912, 25M912C31

Description

DISPLACEMENT PUMP:

EN 10204, type 3.1

COUPLER

TIE ROD, 7 in. (178 mm) between shoulders

SCREW, cap; M8 x 1.25, sst

O-RING, PTFE

NUT, hand 1

GROMMET;

O-RING, air inlet, buna-n, included with Ref. 10

see Kits

Qty.

1

1

1

3

1

1

4

1

1

1

6

1

1

▲ Replacement Danger and Warning labels, tags, and cards are available at no cost.

‡

These parts are not used with Model 25D363.

Kits

Gromm

Ref.

21a*

21b

21c

* Order Kit 16H925 for qty. 3 of the piston rod grommet.

et Kit 16G628

Part Description

—

—

—

GROM

pist

GROMMET, air fitting

GROMMET, tie rod

MET, air motor

on rod

Qty.

1

2

3

8 3A5564A

Page 9

Priming Piston Displacement Pump Model 25M906, 25M906C31

Priming Pisto

25M906C31

n Displacement Pump Model 25M906,

3A5564A 9

Page 10

Priming Piston Displacement Pump Model 25M906, 25M906C31

Priming Piston Displacement Pump Model 25M906, 25M906C31

Ref. Part

101 902980

102*

103 180918

104*

105*

106*

107

108 195214

109

110 103462

111 195215

112*

113*

166117

166119

180238

605752

17S673 HOUSING, inlet valve

16C195 ROD, connecting

604016

501095

Description

CYLINDER, pum

GASKET, 2 1/2 i

buna-n

HOUSING, packing

CYLINDER SEAL, buna-n

THROAT PACKING, buna-n

BEARING, sleeve

PISTON, priming

BALL, 3/4 in. (19 mm),

stainless steel

STOP, inlet valve

BEARING, priming piston

SPRING, ball check

p

n. (64 mm),

Qty.

Ref. Part

114 604018

1

2

115*

1

116 604008 PIN, retaini

1

117 902983

1

118 169845 PIN, retain

1

119*

1

120*

1

122 16A945 PLATE, tie

1

123 620223

1

130 172687

1

* Parts included in Repair Kit 24G550.

1

1

603778

167972

167971

Description

POPPET, inlet

PACKING, inle

neoprene

ROD, displacement

O-RING

SEAL, piston, neoprene

CLAMP, 2 1/2 in. (64 mm)

TAG, Instruction, not shown

valve

tvalve,

ng, priming piston

er

rod

Qty.

1

2

1

1

1

1

1

1

2

1

10 3A5564A

Page 11

Product Dimensions

Product Dimensions

Model A

in. (cm)

25D363

* Add 2.5 in. (6.3 cm) to allow for full extension of the priming piston rod.

3A5564A

40.1 (102)* 20.6 (52)* 16.0 (41)* 2.5 (6.4)

B

in. (cm)

C

in. (cm)

D

in. (cm)

11

Page 12

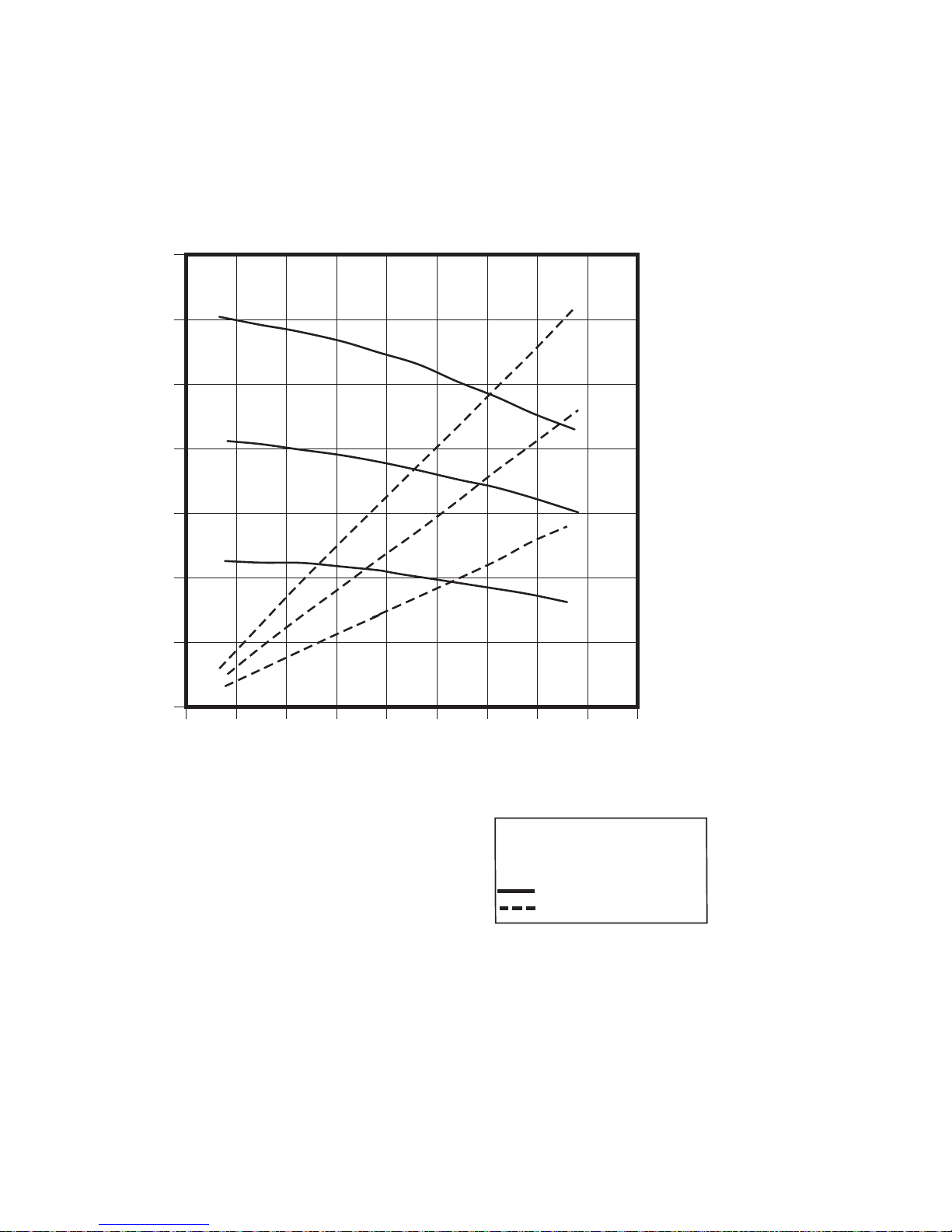

Performance cha

rt

Performance c

0

700

(4.8, 48)

600

(4.1, 41)

500

(3.4, 34)

400

(2.8, 28)

300

(2.1, 21)

200

(1.4, 14)

A

B

C

hart

Cycles per Minute

15 30

45 60

A

B

C

35

(1.0)

30

(0.85)

25

(0.71)

20

(0.57)

15

(0.42)

10

(0.28)

/min)

3

Air Flow scfm (m

100

Fluid Outlet Pressure psi (MPa, bar)

(0.7, 7)

0

0

1.0

(3.8)

2.0

(7.6)

Fluid Flow gpm (lpm) tested in No. 10 weight oil

3.0

(11.4)

5

(0.14)

4.0

(15.1)

A = 100 psi (0.7 MPa, 7 bar)

B = 70 psi (0.5 MPa, 5 bar)

C = 40 psi (0.3 MPa, 3 bar)

= fluid flow

= air consumption

2

1

3A5564A

Page 13

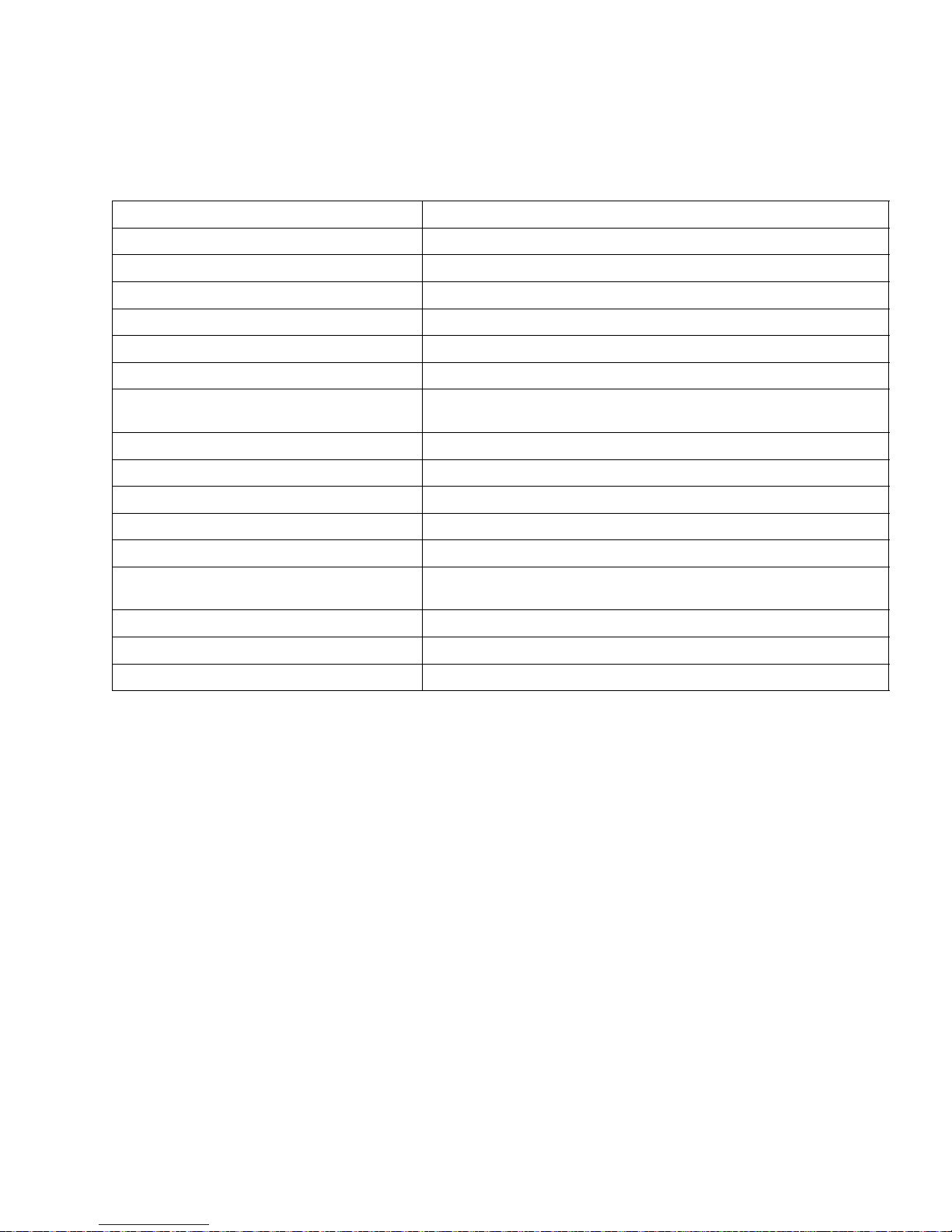

Technical Data

Technical Data

Maximum Fluid

Maximum Air Inlet Pressure

Maximum Recommended Pump Speed 60 cycles/min, 4 gpm (15 liters/min) delivery

Air Consumption

Pump Cycle

Ratio 6:1

Maximum Fluid Temperature

Maximum Ambient Temperature (Air

Motor)

Air Inle

Air Exhaust

Fluid Inlet Type

Fluid Outlet 1-1/2 in. (3.8 cm) Tri-clamp®

Weight

Wetted Parts

Sound data

t

Working Pressure

s per Gallon (3.8 Liters)

und power*

So

650 psi (4.5 MPa, 44.8 bar)

100 psi (0.7 M

Pa, 6.9 bar)

See Performance Chart

13.3

250°F (12

120°F (49°C)

1/2 npt (f)

3/4 npt

2.3 in (5.8 cm) Priming Piston with flange for 6 in. (15.2 cm) Clamp

35 lb

316 Stainless Steel, Buna-N, Polychloroprene, Nitrile, Nylon,

UHMWPE. Certain models have PTFE packings.

78.5 dBA

1°C)

(m)

(16 kg)

Sound pressure**

* Sound power at 70 psi (0.48 MPa, 4.8 bar), 20 cpm. Sound power measured per ISO-9614-2.

** Sound pressure was tested 3.28 feet (1 m) from equipment.

71.6 dBA

3A5564A 13

Page 14

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for

use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a

period of twelve months from the date of sale, repair or replace any part of the equipment determined

by Graco to be defective. This warranty applies only when the equipment is installed, operated and

maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall

Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment

with structures, accessories, equipment or materials not supplied by Graco, or the improper design,

manufacture, installation, operation or maintenance of structures, accessories, equipment or materials

not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an

authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco

will repair or replace free of charge any defective parts. The equipment will be returned to the original

purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of

parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

The buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages

for lost profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall

be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY

GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.),

are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from

Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other

goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or

otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents,

notices and legal proceedings entered into, given or instituted pursuant hereto or relating directly or

indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du

présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés,

donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les procédures

concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

To place an order, contact your Graco Distributor or

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original Instructions. This manual contains English. MM 3A5564

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2017, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

call to identify the nearest distributor.

Graco Headquarters: Minneapolis

www.graco.com

Revision A, March 2018

Loading...

Loading...