Page 1

Instructions/Parts

Air

Air Air

Radial

Radial Radial

paints

paints paints

70psi(0.5MPa,5bar)Maximum

RecommendedWorkingPressure

Seepage3formodelpartnumbersand

approvalsinformation.

Driven

- --Driven Driven

piston,

piston, piston,

and

coatings.

and and

coatings. coatings.

Important

Important Important

Readallwarningsandinstructionsinthismanualandinyour

associatedcomponentmanualsbeforeusingtheequipment.Save

theseinstructions.

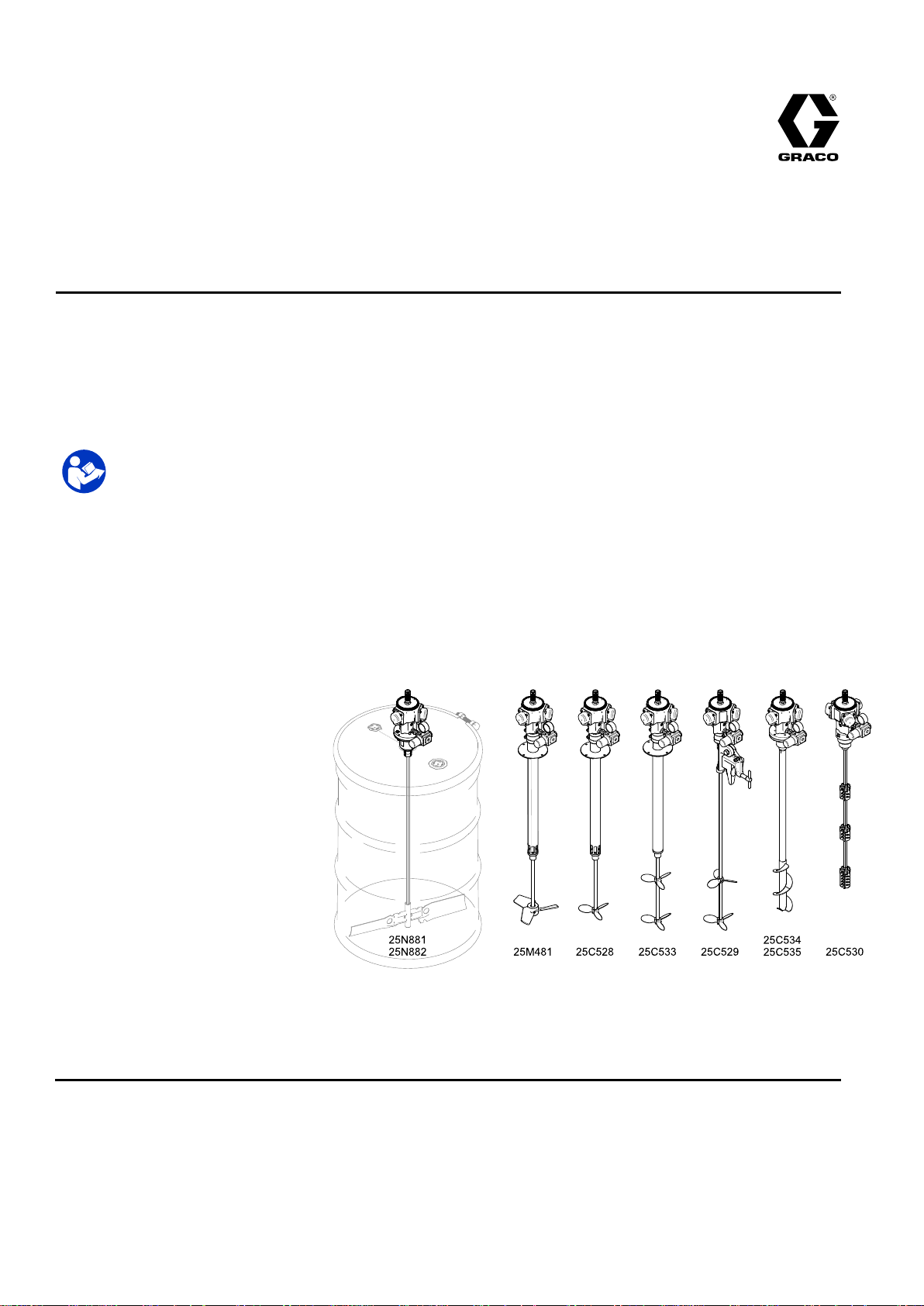

Agitators

Agitators Agitators

pneumatic

pneumatic pneumatic

Safety

Safety Safety

motor

motor motor

For

professional

For For

professional professional

Instructions

Instructions Instructions

3A4792C

EN

driven

driven driven

agitators

agitators agitators

use

use use

for

maintaining

for for

maintaining maintaining

only.

only. only.

suspension

suspension suspension

and

even

and and

mixing

even even

mixing mixing

industrial

in ininindustrial industrial

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................3

RelatedManuals................................................3

Warnings...........................................................4

Installation..........................................................6

AirRegulatorandMufers............................7

Agitator.......................................................8

Grounding...................................................9

AirLineAccessories.....................................11

AirRequirements.........................................11

Operation...........................................................12

AgitatorOperation........................................12

FindingtheProperAgitatorSpeed................12

PressureReliefProcedure............................12

Maintenance......................................................13

GreasingtheAirMotor.................................13

AirMotorMufer..........................................13

CleaningtheShaft.......................................13

Service..............................................................14

RemovingtheAirMotor................................14

AligningtheOutletHousing—25C534,

25C535Only..................................15

InspectingtheShaftandAgitatorBlades—

Model25C530Only........................15

Parts..................................................................16

Model25C528.............................................16

Model25C533.............................................17

Model25M481.............................................18

Model25C529.............................................19

Models25C534and25C535........................20

Model25C530.............................................21

Models25N881and25N882........................22

Accessories........................................................22

SensorKit25C373.......................................22

Dimensions........................................................23

MountingHoleLayout.........................................25

AirConsumption.................................................25

TechnicalSpecications......................................26

CaliforniaProposition65...............................27

2

3A4792C

Page 3

Models

Models

Models Models

Part

No.

Part Part

No. No.

25C528

25C533

25M481

25C534

25C535

Description

Description Description

StainlessSteelDirectDrive,

30/55Gallon,

OneSS5.5"Propeller

CarbonSteelDirectDrive,

30/55Gallon,

TwoAlum5.5"Propellers

StainlessSteelDirectDrive,

30/55Gallon,

OneSS8"Impeller

StainlessSteelDirectDrive,

Helix,

BungMount

CarbonSteelDirectDrive,

Helix,

BungMount

Recommended

Recommended Recommended

Agitator

Agitator Agitator

Rotation

Rotation Rotation

Clockwise

Clockwise

Clockwise

2575

Clockwise

Clockwise

2575 2575

Approvals

Approvals Approvals

1/2

G

II IIII1/2 1/2

G G

Ex

IIB

T4

Ex Ex

h hhIIB IIB

IECEx

IECEx IECEx

ITS17ATEX1001809

ITS17ATEX1001809 ITS17ATEX1001809

0 00°C CC≤Tamb Tamb

Ga/Gb

T4 T4

Ga/Gb Ga/Gb

ETL

17.0019

ETL ETL

17.0019 17.0019

Tamb

50

C

≤50 50

°C C

StainlessSteelDirectDrive,

25C530

25N881

25N882

25C529

25C765

Related

Related Related

ManualNumberTitle

306287

55Gallon,

BungMount,

ExpandingBlade

In-Drum,

1.5”BungMount

In-Drum,

2”BungMount

CarbonSteelDirectDrive,

55Gallon,

SideMount,

TwoAluminum5.5"

Propellers

Kit,MotorwithAirRegulator

(toreplacedrivemotoron

existingagitators)

Manuals

Manuals Manuals

ElevatorsandPumpSupports

Counter

Clockwise

Clockwise

Ex

IIB

T4

II IIII2 22G GGEx Ex

Clockwise

Clockwise

II IIII2 22G GGEx Ex

h hhIIB IIB

Ex

h hhIIB IIB

Gb

T4 T4

Gb Gb

IIB

T4

Gb

T4 T4

Gb Gb

308466

3A5050MotorRepairManual

StainlessSteel,PassivatedDrumCovers

3A4792C3

Page 4

Warnings

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.Theexclamation

pointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specicrisks.Whenthese

symbolsappearinthebodyofthismanual,referbacktotheseWarnings.Product-specichazardsymbolsand

warningsnotcoveredinthissectionmayappearthroughoutthebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

solventowingthroughtheequipmentcancausestaticsparking.Tohelppreventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,andplastic

dropcloths(potentialstaticarc).

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Neversprayorushsolventathighpressure.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepaillinersunlessthey

areantistaticorconductive.

Stop

•Stop Stop

youidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

MOVING

MOVING MOVING

EXPLOSION

AND AND

EXPLOSION EXPLOSION

operation

operation operation

PARTS

PARTS PARTS

immediately

immediately immediately

HAZARD

HAZARD HAZARD

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Paintor

Grounding

ifstaticsparkingoccursoryoufeelashock,Donotuseequipmentuntil

instructions.

Movingpartscanpinch,cut,oramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Donotwearlooseclothing,jewelry,orlonghairwhileoperatingequipment.

•Equipmentcanstartwithoutwarning.Beforechecking,moving,orservicingequipment,followthe

Pressure

Pressure Pressure

PRESSURIZED

PRESSURIZED PRESSURIZED

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskinand

causeseriousinjury.

•FollowthePressure Pressure

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

Relief

Procedure

Relief Relief

Procedure Procedure

EQUIPMENT

EQUIPMENT EQUIPMENT

Pressure

anddisconnectallpowersources.

HAZARD

HAZARD HAZARD

Relief

Procedure

Relief Relief

Procedure Procedure

whenyoustopspraying/dispensingandbeforecleaning,

4

3A4792C

Page 5

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestratedsystem

component.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Specications

Specications Specications

completeinformationaboutyourmaterial,requestSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovalsand

createsafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

TOXIC

TOXIC TOXIC

MISUSE

MISUSE MISUSE

FLUID

FLUID FLUID

OR

OR OR

HAZARD

HAZARD HAZARD

Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.For

FUMES

FUMES FUMES

Specications

Specications Specications

HAZARD

HAZARD HAZARD

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Technical

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Warnings

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,inhaled,or

swallowed.

•ReadSafetyDataSheet(SDS)toknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicableguidelines.

BURN

BURN BURN

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoidsevere

burns:

•Donottouchhotuidorequipment.

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,including

eyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protectiveequipmentincludesbut

isnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolventmanufacturer.

HAZARD

HAZARD HAZARD

PROTECTIVE

PROTECTIVE PROTECTIVE

EQUIPMENT

EQUIPMENT EQUIPMENT

3A4792C5

Page 6

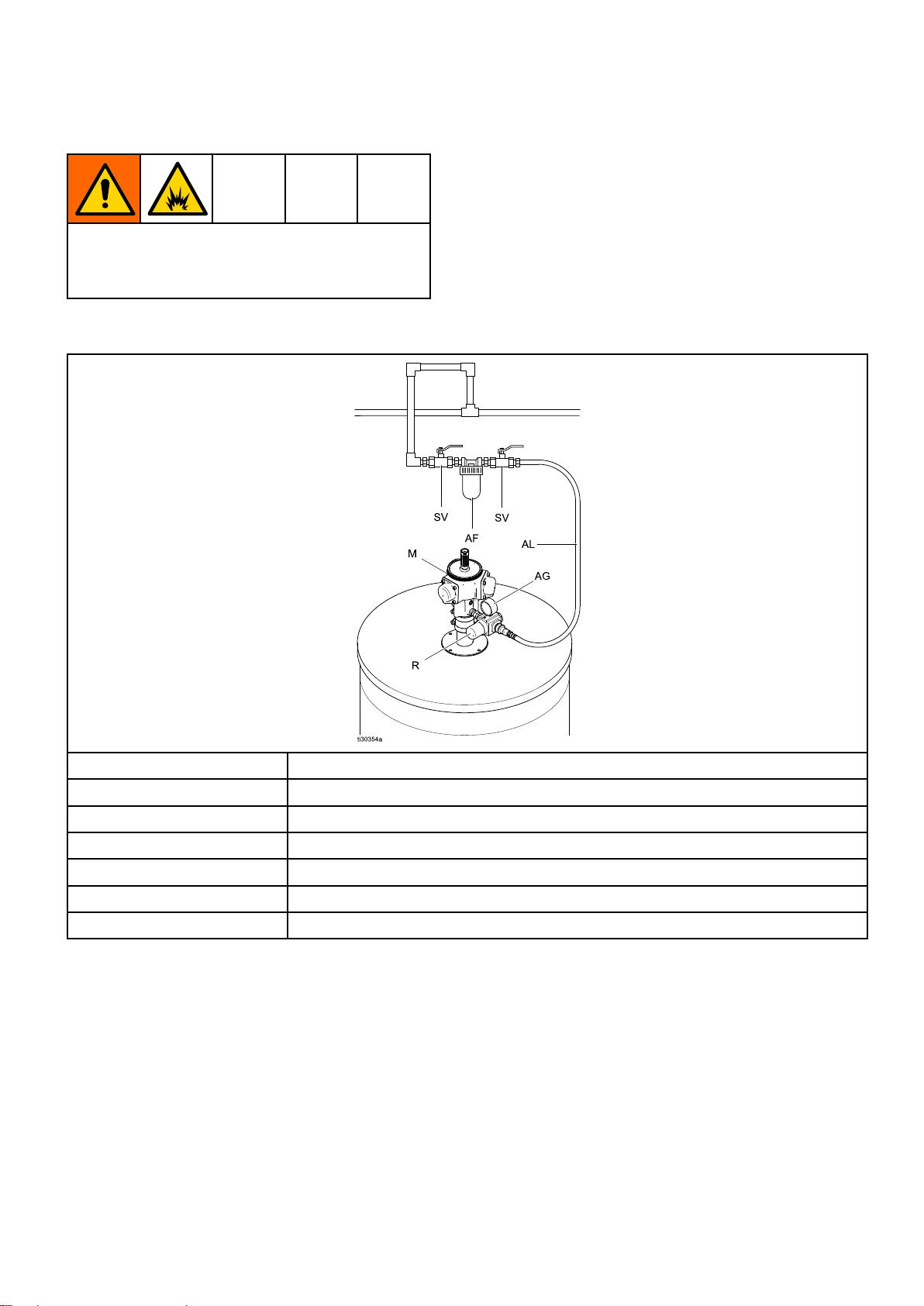

Installation

Installation

Installation Installation

NOTE:Throughoutthemanual,referencenumbers

andlettersinparenthesesrefertocalloutsingures

andthepartsdrawings.

Toreducetheriskofreandexplosion,always

maintainaminimumof1in.(25.4mm)clearance

betweentherotatingagitatorpartsandthe

containertopreventsparksfromcontact.

Table

Table Table

Typical

1 11Typical Typical

Installation

Installation Installation

SeeAirLineAccessories,page11forpartsnot

includedinyoursystem.

Reference

SVAirShutoffValve

AFAirLineFilter

MMotor

AL

AGAirPressureGauge

RRegulator

Description

SupplyLine,Air-In

63A4792C

Page 7

Air

Regulator

Air Air

Regulator Regulator

Theairmotoriscapableofoperatinginaclockwise

orcounterclockwisedirection,dependingonwhere

theairregulatorismounted.

•Whentheairregulatorisinstalledinoneofthe

twolowerportsonthemotor,aclockwiserotation

results,asviewedfromthetopofthemotor.

•Wheninstalledoneithersideinoneofthetwo

upperports,acounterclockwiserotationresults.

•Theportoppositetheregulatormustbeplugged

forthemotortooperate.

Theairregulator,mufers,airgauge,nipple

connector,andswivelconnectorarenotfactory

installed.Followthedirectionsbelowtoinstallthese

items:

1.Screwtheswivelconnector(F)intothedesired

port(upperorlower)inthemotor(K).

2.Screwthenippleconnector(G)intotheair

regulator(H)outlet.Notearrowdirectionson

theregulator.

and

Mufers

and and

Mufers Mufers

Installation

3.Attachtheairregulatorbyscrewingitintothe

swivelconnector.

4.Installaplug(E)intheportoppositetheregulator

(thisisnecessaryformotoroperation).

5.Attachtheairgauge(J)byscrewingitintothe

holeinthetopoftheairregulator.

6.Installaplug(E)intheregulatorintheport

oppositetheairgauge.

7.Screwonemufer(D)intothetopofthemotor.

8.Screwthesecondmuferintotheopenporton

thefarsideofthemotorfromtheregulator.

9.Installthethirdmuferintheopenportabove

orbelowtheregulator.Anadditionalttingmay

beneeded(notprovided)tospacetheregulator

fartherawayfromthemotor.

NOTE:

NOTE: NOTE:

butisbenecialforincreasedaircirculationin

humidconditions.Ifathirdmuferisnotused,

theholemustbeplugged(E).

Useofthethirdmuferisnotnecessary,

Clockwise

Clockwise Clockwise

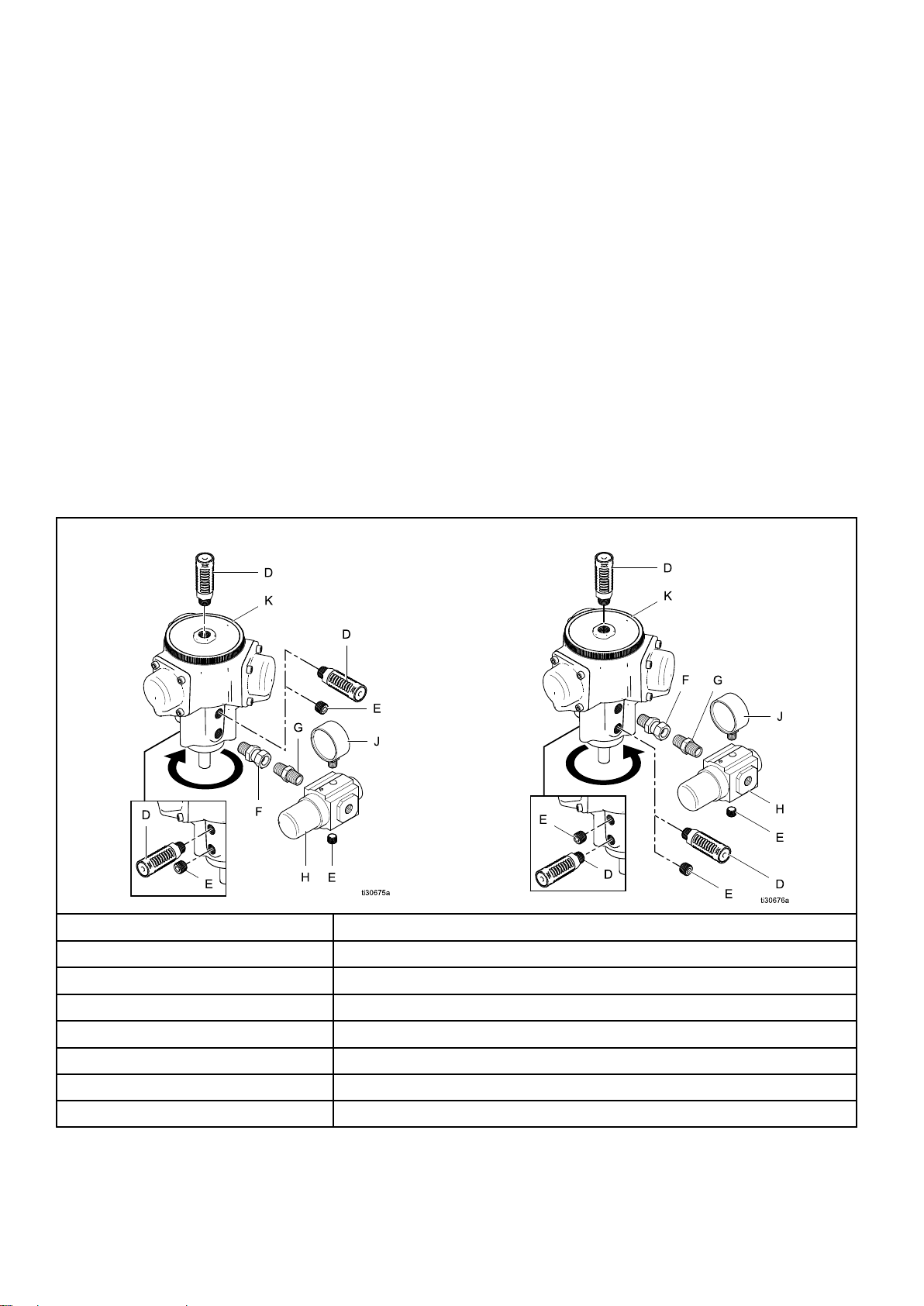

Reference

Reference Reference

D

Agitator

Agitator Agitator

Letter

Letter Letter

Rotation

Rotation Rotation

Description

Description Description

Mufers

Counterclockwise

Counterclockwise Counterclockwise

Agitator

Agitator Agitator

Rotation

Rotation Rotation

EPlugs

F

G

HAirregulator

JAirgauge

KAirmotor

3A4792C

Swivelconnector

Nippleconnector

7

Page 8

Installation

Agitator

Agitator Agitator

Positiontheairmotorsotheairlineeasilyattaches

totheairregulatorinletwithoutobstructinganyother

systemcomponents.

Toreducetheriskofreandexplosion,always

maintainaminimumof1in.(25.4mm)clearance

betweentherotatingagitatorpartsandthe

containertopreventsparksfromcontact.

Models

Models Models

1.Markanddrillholesinthecovertomountthe

2.Installtheagitatorinthecoveroftheuid

3.Positiontheairmotorsotheairlineeasily

4.Boltinplace(mountingboltsnotincluded).

Model

Model Model

Mounttheagitatorontheedgeofthedrumortank

andsecurelytightentheclampscrew(6).Squeeze

theendoftheretainer(17)tosetinplace.See

Model25C529,page19.

Toadjusttheangleoftheagitatorinthedrum,loosen

thebracketscrew(4),andpositiontheairmotorso

theairlineeasilyattachestotheairregulatorinlet

withoutobstructinganyothersystemcomponents.

25C528,

25C528, 25C528,

agitator.SeeMountingHoleLayout,page25for

dimensions.

supplytankwiththegasket(29)inplace.See

Model25C528,page16,Model25C533,page17,

andModel25M481,page18.

attachestotheairregulatorinletwithout

obstructinganyothersystemcomponents.

25C529

25C529 25C529

25C533,

25C533, 25C533,

and

25M481

and and

25M481 25M481

Duetovariabilityindrumheights,thelowestsetof

bladesmaycontactthebottomofthedrum.Ifthe

bungadapter(4)doesnotfullyseat,orifresistance

isfeltwheninstallingtheagitator,movetheblades

uptheshaft.

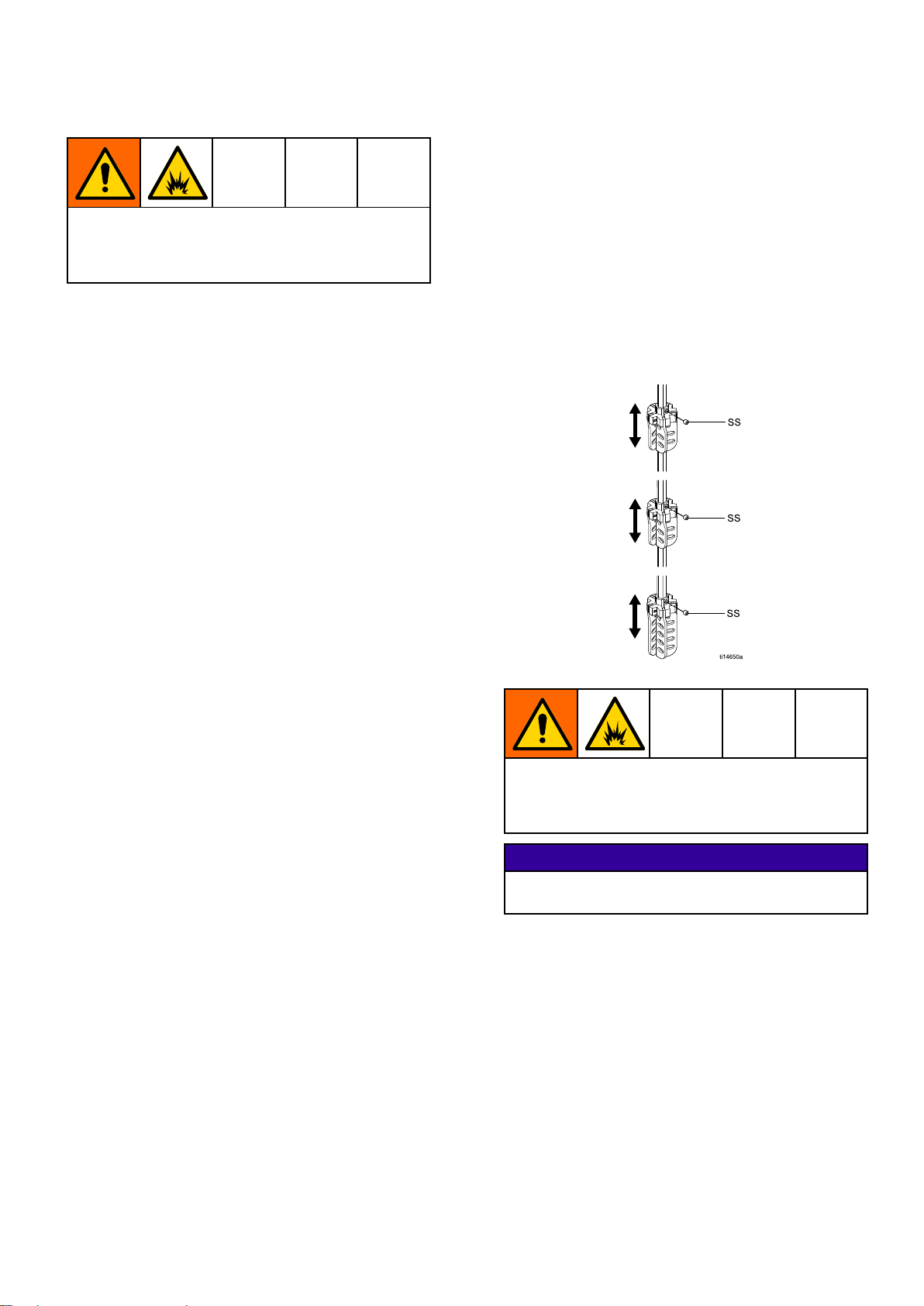

Tomovetheblades,loosenthesetscrews(SS)in

thecouplerandslidetheassemblyupordowntothe

desiredposition.Thesetscrewmustalwaysremain

onthetop,withthebladeshangingdown,sothe

bladesareabletopassintoandoutofthebunghole.

Figure1AdjustableBladeAssemblies

Models

Models Models

Installtheagitatorinthecontainercoverbyscrewing

thehelix(5)throughthedrumbungholeand

screwingtheagitatorhousing(3)intothebung

hole.Torquethesocketheadscrew(2)to150–170

in-lbs(17–19N•m).Torquethehexheadcap

screw(14)to80–100in-lbs(9–11N•m).See

Models25C534and25C535,page20.

Positiontheairmotorsotheairlineeasilyattaches

totheairregulatorinletwithoutobstructinganyother

systemcomponents.

Model

Model Model

Toinstalltheagitatorinthecontainercover,lowerthe

shaft(2)withfoldingbladeassemblies(5,6)through

thedrumbunghole,thenscrewthebungadapter(4)

intothebunghole.SeeModel25C530,page21.

25C534

25C534 25C534

25C530

25C530 25C530

and

25C535

and and

25C535 25C535

Toreducetheriskofreandexplosion,when

usingamodieddrum,checkthatthereisno

interferencebetweenthebaseofthedrumandthe

shaftoftheagitatortoavoidsparksfromcontact.

NOTICE

NOTICE NOTICE

Keeptheagitatortightlymountedtothedrumbung

topreventdamagetothethreadsfromvibration.

Angled

Angled Angled

only

only only

Iftheagitatorisusedonadrumwithanoff-center

bungandthebladescontactthesideofthedrum,the

angledadapter16H294mustbeused.

1.Threadthelockingring(28)ontotheangled

Adapter

Adapter Adapter

adapter(27)byhand,asfarasitwillgo.

16H294

16H294 16H294

—

Model

— —

Model Model

25C530

25C530 25C530

83A4792C

Page 9

Installation

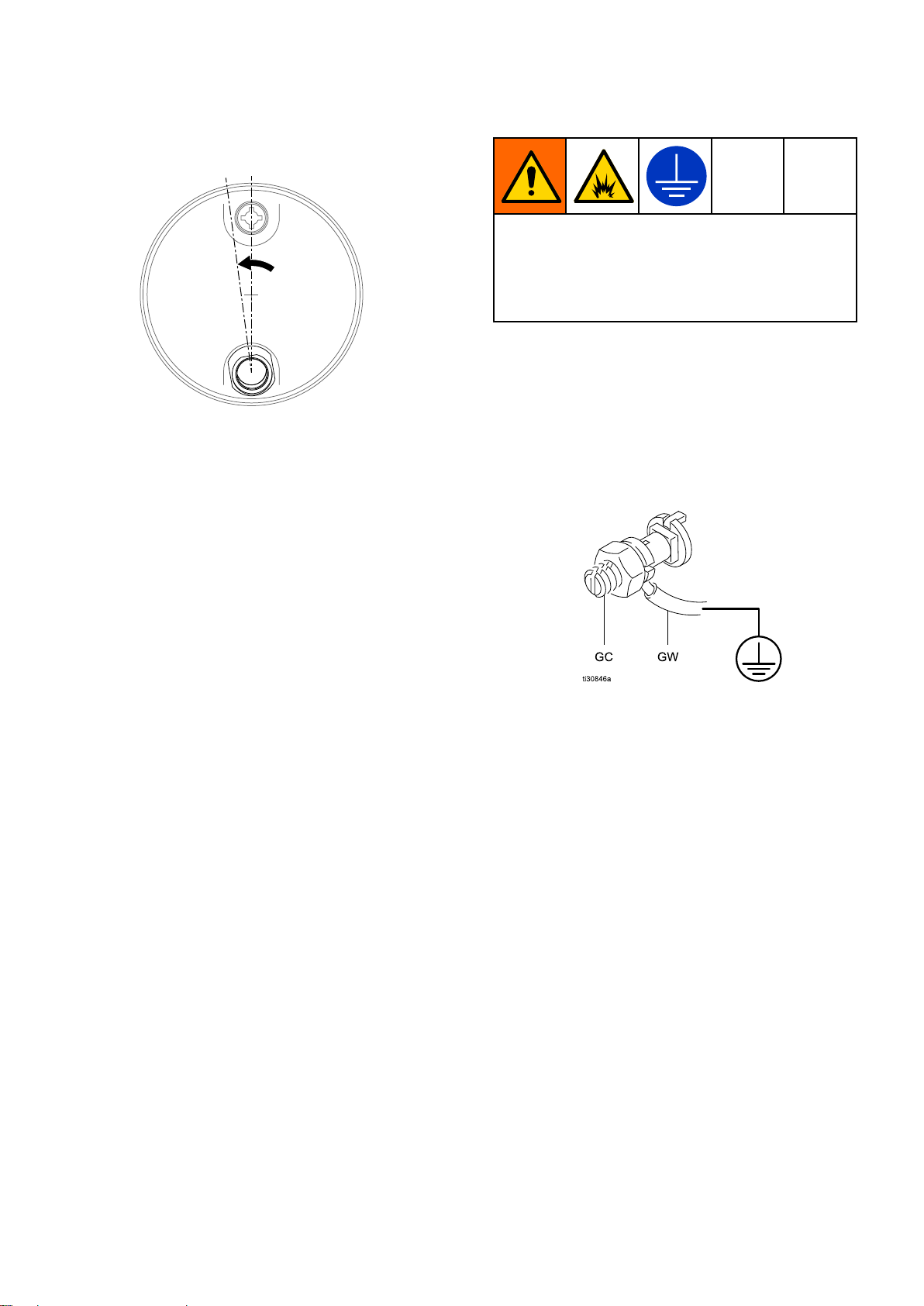

2.Threadtheangledadapterintothebunguntil

itbottomsout,thenbackitoutuntilthewidest

portionoftheadaptertopispointingjusttothe

leftofdrumcenter.

Figure2AngledAdapterJustLeftofCenter

3.Turndownthelockingringuntilitcontactsthe

drum.Useanappropriatelysizedpipewrenchor

adjustablewrenchtotightentheadapteruntilthe

widestportionoftheadaptertopisinlinewiththe

drumcenter.

Models

Models Models

25N881

25N881 25N881

and

25N882

and and

25N882 25N882

Grounding

Grounding Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparking.Staticsparkingcancause

fumestoigniteorexplode.Toreducetherisk

ofstaticsparking,themountingcoverandall

electricallyconductiveobjectsordevicesinthe

sprayareamustbeproperlygrounded.

Agroundwireandclamparenotincluded.Fora

groundwireandclamp,orderpartnumber237569.

Togroundtheagitator,dothefollowing:

For

models

•For For

models models

Connectoneendofthegroundwire(GW)tothe

groundconnector(GC)ontherimofthedrum

cover.Connecttheotherendofthegroundwireto

atrueearthground.

25C528,

25C528, 25C528,

25C533,

25C533, 25C533,

and

25M481:

and and

25M481: 25M481:

SeeModels25N881and25N882,page22.

1.Determinetheagitatorshaftsize:7/16"(11.1

mm)or1/2"(12.4mm)square.Determinethe

sizeoftheshaftadapter(9).Selectthesizeby

placingtheadaptersontothebuilt-inagitator

shaftinsidethedrum.Usethesmallestadapter

thatwillt.Thereshouldonlybeasmallamount

ofslipbetweentheadapternutandtheshaft.

2.Attachtheshaftadapter(9)totheatsideof

themotorshaftclosetothebottomofthemotor.

Tightenthesetscrew(12)securelyto8–9ft-lbs

(11–12N•m).NOTE:Thereisapproximately1/2"

(12mm)ofadjustmenttraveloftheadaptershaft

onthemotorshaftifneededforlateradjustment.

3.Torquethesocketheadscrew(8)to12.5–14

ft-lbs(17–19N•m).

4.Placethethreadedhousingadapter(6)ontothe

motorplate(7)andsecurewithwashers(13)and

screws(11).Torqueto8–9ft-lbs(11–12N•m).

5.Aligntheadapternuttoengagethebuilt-inshaft

inthe55-gallondrum.

6.Slowlyscrewtheunitontothethreadsonthe

centerbungttingofthe55-gallondrum.Secure

tightlysothemotordoesnotrotateinthebung.

Figure3GroundConnector-Models25C528,

25C533,and25M481

Motor

Motor Motor

Motorreplacementkit25C765isadrop-in

replacementforrotaryvaneairmotorPN101140.

Onpage16—Parts,RefNo.1liststheitems

includedwiththekit.Usetheagitatormanualmotor

replacementprocedureorpartspagediagramto

installthenewmotor.

Replacement

Replacement Replacement

Kit

25C765

Kit Kit

25C765 25C765

3A4792C9

Page 10

Installation

For

models

•For For

models models

25N881,

25N881, 25N881,

groundwire(GW)totheagitatorgroundconnector

(GC).Connecttheotherendofthegroundwireto

atrueearthground.

Figure4GroundConnector-Model25C529

25C529,

25C529, 25C529,

and

25N882:

and and

25N882: 25N882:

25C530,

25C530, 25C530,

Connectoneendofthe

25C534,

25C534, 25C534,

25C535,

25C535, 25C535,

Figure6GroundConnector-Models25C534,

25C535

Figure5GroundConnector-Model25C530

Figure7GroundConnector-Models25N881,

25N882

103A4792C

Page 11

Installation

Air

Line

Air Air

Line Line

Accessories

Accessories Accessories

Air

Requirements

Air Air

Requirements Requirements

Installthefollowingaccessoriesintheordershown

below,usingadaptersasnecessary.

Air

Shut

off

Air Air

Shut Shut

Ableed-typemasterairshutoffvalve(A)formounting

location)isolatestheairlinecomponentsfor

servicing.Anairshutoffvalveshouldbeinstalledin

thesupplylineandusedtostopandstarttheagitator.

Ifthevalveisinstalled,youdonotneedtosetthe

agitatorspeedeachtimeitisused.

Orderbleed-typeairshutoffvalvesusingthepart

numberslistedbelow:

Table

Table Table

2 22Bleed Bleed

Part

No.

110223

110223 110223

110224

110224 110224

110225

110225 110225

110226

110226 110226

113163

113163 113163

107142

107142 107142

107141

107141 107141

Valve

- --off off

Valve Valve

Bleed

Type

Outletnpt

1/4(fxf)

3/8(fxf)

1/2(fxf)

3/4(fxf)

1/2(mxf)

3/4(mxf)

Shutoff

- --Type Type

Shutoff Shutoff

Inlet/

1(fxf)

Valves

Valves Valves

MaxWPR

psibarMPa

25017.21.7Brass

25017.21.7Brass

25017.21.7Brass

25017.21.7Brass

25017.21.7Brass

25017.21.7Brass

25017.21.7Brass

Mate-

Theairmotordoesnotrequirelubricatedair.See

AirConsumption,page25forrequirements.

Connectthesupplyairtotheinletsideoftheair

regulator.

rial

Figure8SupplyAirHoseConnection

Air

Line

Air Air

Airlineltersremoveharmfuldirt,moisture,andoil

fromthecompressedairsupply.Orderpart106148

for3/8nptor106149for1/2npt.

Installanairlinelter(AF)toremovecontaminants

suchasdirt,moisture,andoilfromthecompressed

airsupply.Airlinelters(AF)removeharmfuldirt

andmoisturefromthecompressedairsupply.Order

part106148for3/8nptor106149for1/2npt.See

Installation,page6.

Filter

Line Line

Filter Filter

3A4792C

11

Page 12

Operation

Operation

Operation Operation

Personalinjury,suchassplashingintheeyes,

mayresultfrompressureinthetank.Alwaysfollow

thePressureReliefProcedure,page12before

openingthetankcoverorllport.

Personalinjuryorequipmentdamagemayresult

fromlifting/fallingheavyequipment.Toavoid

personalinjuryorequipmentdamage:

•Donotliftthedrumcoverandagitatorwithout

properassistance.

•Donotwalkorstandbeneatharaisedelevator.

Agitator

Agitator Agitator

1.Starttheagitatorbyopeningtheairshutoffvalve

(SV).Regulatethespeedwiththeairregulator

knob(R).

2.Operatetheagitatorcontinuouslywhensupplying

paintsorotheruidstothesystem.

3.Stoptheagitatorbyclosingtheairshutoffvalve

orbyreducingpressurewiththeairregulator

knob.

Operation

Operation Operation

useashakerorsomeotherdevicetothoroughly

agitatetheuidbeforeinstallingandoperatingthe

agitator.

Belowisageneralproceduretondthesuggested

agitatorspeed.Consultyourmaterialsupplier

forspecicrecommendationsonrecommended

agitationspeeds.

1.Besuregroundwireisattached.See

Grounding,page9.

2.Filltheuidsupplycontainertoabout3or4

inches(75to100mm)abovetheagitatorblade.

3.Opentheairshutoffvalve(SV).

4.Starttheagitatorbygraduallyturningtheair

regulatorknob(R)toincreaseairpressureuntila

vortexbeginstoforminthepaint.

5.Reducethespeedslightly,thenlltheuid

container.

Whenthecontainerisfullavortexshouldnotbe

seen.Materialshouldonlybemovingatafast

enoughspeedtoensureadequatemixing.

6.Operatetheagitatorcontinuouslywhilesupplying

paintsorotheruidstothesystem.

Pressure

Pressure Pressure

Relief

Relief Relief

Procedure

Procedure Procedure

Finding

Finding Finding

Toavoiddamagingtheequipment,donotoperate

theagitatoratahighspeedforalongperiodof

time.Excessiveagitatorspeedcancausefoaming

ofuid(makingtheuidunusable),vibration,and

increasedwearonparts.Onlyagitatetheuid

enoughtomaintainevenmixing.

Agitatorsareusedtokeepsolidsinsuspension,

whichassistsinkeepingsolidsfromcloggingthe

siphontube.Ifsolidshavesettledinthecontainer,

the

Proper

the the

Proper Proper

Agitator

Agitator Agitator

NOTICE

NOTICE NOTICE

Speed

Speed Speed

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfromsplashinguidandmovingparts,follow

thePressureReliefProcedurebeforecleaning,

checking,orservicingtheequipment.

1.Disconnecttheairline.

2.Closethebleed-typeairshutoffvalve(A)to

relievepressuretotheairregulator.

12

3A4792C

Page 13

Maintenance

Maintenance

Maintenance Maintenance

Movingparts,suchasanimpellerblade,cancut

oramputatengers.Toreducetheriskofserious

injury,alwaysshutofftheagitatoranddisconnect

theairlinebeforecheckingorrepairingtheagitator.

Beforeperforminganymaintenanceprocedure,

followthePressureReliefProcedure,page12.

Greasing

Greasing Greasing

Afterapproximately20millionrevolutionsorevery

threetofourmonths(whichevercomesrst),grease

themotorneedlebearing.Recommendedgrease:

MOBILGREASEXHP222SPECIALorequivalent

withminimumashpointtemperatureof399.2°F

(204°C).

1.FollowthePressureReliefProcedure,page12.

2.Removethemotortopcover(103).

3.Usingamanualgreasegun,pushgreaseinto

the21RCtting(102)untilgreaseisseenbelow

thetopwasher(109a).

the

Air

the the

Motor

Air Air

Motor Motor

Cleaning

Cleaning Cleaning

For

models

For For

models models

Eachweek,cleananydrieduidfromaroundthe

bearing(6)areaoftheshaft(7)andinspectthe

bearingforcrackingorexcessivewear.

For

model

For For

model model

Eachweek,cleananydrieduidfromaroundthe

bearing(18)andbracket(23)areaoftheshaft(21).

Lubricatewithseveraldropsoflightoil.

the

Shaft

the the

Shaft Shaft

25C528,

25C528, 25C528,

25C529

25C529 25C529

25C533,

25C533, 25C533,

25M481

25M481 25M481

Air

Motor

Air Air

Motor Motor

Dependingontheenvironmentofthemotor,

periodicallycheckthecleanlinessoftheairmotor

mufer.Dirtyorcloggedairmufersresultin

decreasedmotorefciencyandmaycausethemotor

torunirregularly.Ifthemuferisdirtyorclogged,

replaceitwithanewmufer.

3A4792C13

Mufer

Mufer Mufer

Page 14

Service

Service

Service Service

Movingparts,suchasanimpellerblade,cancut

oramputatengers.Toreducetheriskofserious

injury,alwaysshutofftheagitatoranddisconnect

theairlinebeforecheckingorrepairingtheagitator.

Iftheairmotorrequiresmorethaninstallationofa

servicekit,itisusuallyquickestandeasiesttosend

ittoaGracodistributorforrepairorreplacement.A

motorrebuildkit(25M535)isavailable.Seemanual

3A5050formoreinformation.

2.Removetheairregulatorby

unscrewingtheswiveltting(11).See

Models25C534and25C535,page20.

3.Removethescrews(14)holdingthemotor

mountingplate(13)totheoutlethousing(3).

4.Removethesocketheadscrews(2)holdingthe

motor(1)tothemountingplate.

5.Raisethemotorsothetwosetscrews(9)inthe

shaft(4)areaccessible.Usea1/8inchhexto

removethesetscrewsfromtheshaft.

6.Lifttheairmotorstraightupofftheshaft.

Model

Model Model

25C530

25C530 25C530

Removing

Removing Removing

Model

Model Model

25M481

25M481 25M481

1.FollowthePressureReliefProcedure,page12.

2.Removetheairregulatorbyunscrewingthe

swiveltting(12).

a.SeeModel25C528,page16

b.SeeModel25C529,page19

c.SeeModel25C533,page17

d.SeeModel25M481,page18

3.Loosentheupperclamp(2)andraisethemotor

sotheuppertwosetscrews(3)areaccessible.

Usea1/8inchhextoremovethesetscrews

fromtheshaft.

4.Lifttheairmotorstraightupofftheshaft.

Model

Model Model

1.FollowthePressureReliefProcedure,page12.

25C534 25C534

the

Air

the the

25C528,

25C528, 25C528,

25C534

and

and and

Motor

Air Air

Motor Motor

25C529,

25C529, 25C529,

25C535

25C535 25C535

25C533,

25C533, 25C533,

and

and and

1.FollowthePressureReliefProcedure,page12.

2.Removetheairregulatorbyunscrewingthe

swiveltting(9).SeeModel25C530,page21.

3.Usinga3/16inchhex,removethethreeset

screws(8)onthebungadapter(4).

4.Raisethemotorsothetoptwosetscrews(7)in

thecoupler(3)areaccessible.Usea1/8inch

hextoremovethetoptwosetscrews.

5.Lifttheairmotor(1)straightupoffthecoupler.

Model

Model Model

1.FollowthePressureReliefProcedure,page12.

2.Removetheairregulatorby

3.Removethescrews(11)holdingthebung

4.Liftthemotoroffthebungadapter(6)and

25N881

25N881 25N881

unscrewingtheswiveltting(5).See

Models25N881and25N882,page22.

adapter(6)tothemotorplate(7).

removethescrews(8)thatattachthemotorplate

(7)tothemotor(1).

and

25N882

and and

25N882 25N882

14

3A4792C

Page 15

Service

Aligning

Aligning Aligning

25C534,

25C534, 25C534,

Improperinstallationoftheoutlethousingcould

causetheagitatorshafttobindagainsttheoutlet

housingbearinganddamageit.

Afterrepairingorreplacingtheoutlethousingorair

motor,performthefollowingsteps:

1.FollowthePressureReliefProcedure,page12.

2.Placetheagitatorinaverticalpositionand

loosenthethreeoutlethousingscrews(14).See

Models25C534and25C535,page20.

3.Apply25psi(1.7bar)minimumairpressureto

theairregulator(12).Adjusttheairregulatorso

theagitatorshaftisbarelyturning.

4.Whiletheagitatorshaftisturning,torquethe

threeoutlethousingscrewsto80to100in-lbs(9

to11.3N•m).

5.Iftheagitatorshaftbinds,repeatsteps1to3

above.

Inspecting

Inspecting Inspecting

Blades

Blades Blades

1.FollowthePressureReliefProcedure,page12.

2.Turnoff/disconnectpowertotheagitator.

3.Removetheagitator.

4.Cleanwithacompatiblesolventandinspectthe

shaft(2)andblades(5,6)forwearordamage.

SeeModel25C530,page21.

5.Ifnowearordamageisdetected,reinstallthe

agitatorintodrum.

the

Outlet

the the

Outlet Outlet

25C535

25C535 25C535

the

the the

—

Model

— —

Model Model

Housing

Housing Housing

Only

Only Only

NOTICE

NOTICE NOTICE

Shaft

Shaft Shaft

and

and and

25C530

25C530 25C530

—

— —

Agitator

Agitator Agitator

Only

Only Only

6.Iftheshaftneedsreplacing:

a.Removetheairmotorfollowingthestepsin

RemovingtheAirMotor,page14.

b.Raisethebungadapter(4)toexposethe

bottomtwosetscrews(7)inthecoupler(3).

Usethe1/8inchhextoremovethem.

c.Slidetheshaft(2)outofthecoupler.

d.Slidethenewshaftintothecoupler.Use

a1/8inchhextotightenthetwolower

setscrewsinthecoupler.Torqueto65in-lb

(7.3N•m).

e.Lowerthebungadapterontheshaftorraise

theshaftthroughthebungadapterandinsert

theairmotorintothecoupler.Usethe1/8

inchhextotightenthetwouppersetscrews

(SS)inthecoupler.Torqueto65in-lb(7.3

N•m).SeeModel25C530,page21.

f.Raisethebungadapterandusea3/16inch

hextotightenthethreesetscrews(8)intothe

bungadapter.Torqueto80in-lb(9N•m).

g.Reinstallagitatorintothedrum.

7.Ifthebladeneedsreplacing:

a.Usea3mm(1/8inch)hextoremovethe

setscrewinthelong(6)orshort(5)blade

hubandslidethehub/bladeassemblyoffthe

shaft.

b.Toinstallanewhub/bladeassembly,slideit

ontotheshaftandtightenthesetscrew.The

setscrewmustalwaysremainonthetop,

withthebladeshangingdown,sotheblades

passintoandoutofthebunghole.

c.Reinstalltheagitatorintothedrum.

3A4792C15

Page 16

Parts

Parts

Parts Parts

Model

Model Model

25C528

25C528 25C528

Ref

Ref Ref

Part

No.

Part Part

No.

No. No.

1

25C765

2101368

3100053

4158865

5

222696

115166

6

7185389

185401

8

185398

9

10110248

Description

No. No.

Description Description

MOTOR,Air,Rotary

Piston;includes12,13,

14,and30.

CLAMP,Hose

SCREW,Set,Socket

Head;5/16-18x0.25”;

torqueto96–132in-lb

(11–15N•m)

COUPLING,Motor

GUIDE,Agitator

BEARING,Agitator,

PressFit

SHAFT,Agitator

PIN,Shear

PROPELLER,Agitator

SCREW,Set,Socket

Head;#10–24x0.25”;

torqueto15–20in-lb

(1.7–2.3N•m)

Qty

Qty Qty

1

2

4

1

1

1

1

1

1

1

100579

11

156823

12

156971

13

116513

14

159858

15

100633

19

101369

20

065251

27

190192

29

104655

30

▲

32

▲

cardsareavailableatnocost.

17P806

Replacementsafetylabels,signs,tags,and

PIN,Cotter

FITTING,Union,Swivel

FITTING,Nipple,Short

REGULATOR,Air

COUPLING

TOOL,Wrench,Allen

(notshown)

TOOL,Wrench,Allen

(notshown)

CABLE,Copper,Flat

Braid,0.33ft

GASKET,Guide,Agitator

GAUGE,Pressure,Air

SafetyTag(notshown)

1

1

1

1

1

1

1

1

1

1

1

163A4792C

Page 17

Parts

Model

Model Model

25C533

25C533 25C533

Ref

Ref Ref

Part

No.

Part Part

No.

No. No.

1

25C765

2101368

3100053

4100579

5

207622

6166565

7

172313

8100633

9101369

Description

No. No.

Description Description

MOTOR,Air,Rotary

Piston;includes12,13,

14,and30.

CLAMP,Hose

SCREW,Set,Socket

Head;5/16-18x0.25”;

torqueto96–132in-lb

(11–15N•m)

PIN,Cotter

GUIDE,Agitator

BEARING,Agitator,

PressFit

SHAFT,Agitator

TOOL,Wrench,Allen

(notshown)

TOOL,Wrench,Allen

(notshown)

Qty

Qty Qty

1

2

4

2

1

1

1

1

1

11158865

12156823

13159858

14156971

15160077

16159854

17101118

22116513

23104655

27065251

29190192

▲

35

▲

cardsareavailableatnocost.

17P806

Replacementsafetylabels,signs,tags,and

COUPLING,Motor

FITTING,Union,Swivel

COUPLING

FITTING,Nipple,Short

PIN,Shear

PROPELLER,Agitator

SCREW,Set,Socket

Head;#10–24x0.25”;

torqueto15–20in-lb

(1.7–2.3N•m)

REGULATOR,Air

GAUGE,Pressure,Air

CABLE,Copper,Flat

Braid,0.33ft

GASKET,Guide,

Agitator

SafetyTag(notshown)

1

1

1

1

2

2

2

1

1

1

1

1

3A4792C

17

Page 18

Parts

Model

Model Model

25M481

25M481 25M481

Ref

Ref Ref

Part

No.

Part Part

No.

No. No.

1

25C765

2101368

3100053

4158865

5

222696

6115166

7

185389

917N708

———

10

Description

No. No.

Description Description

MOTOR,Air,Rotary

Piston;includes12,13,

14,and30.

CLAMP,Hose

SCREW,Set,Socket

Head;5/16-18x0.25”;

torqueto96–132in-lb

(11–15N•m)

COUPLING,Motor

GUIDE,Agitator

BEARING,Agitator,

PressFit

SHAFT,Agitator

IMPELLER,Hydrafoil;8”

StainlessSteel;includes

item10

SCREW,Set,Socket

Head;3/8–16x0.5”;

torqueto180–200in-lb

(20–23N•m)

Qty

Qty Qty

1

2

4

1

1

1

1

1

2

1117R167

12156823

13156971

14116513

15159858

19100633

20101369

27065251

29190192

30104655

32

17P806

▲

▲

Replacementsafetylabels,signs,tags,and

cardsareavailableatnocost.

SPACER,Shaft

FITTING,Union,Swivel

FITTING,Nipple,Short

REGULATOR,Air

COUPLING

TOOL,Wrench,Allen(not

shown)

TOOL,Wrench,Allen(not

shown)

CABLE,Copper,Flat

Braid,0.33ft

GASKET,Guide,Agitator

GAUGE,Pressure,Air

SafetyTag(notshown)

1

1

1

1

1

1

1

1

1

1

1

183A4792C

Page 19

Parts

Model

Model Model

25C529

25C529 25C529

Ref

Ref Ref

No.

No. No.

6203399

7

8101118

9160077

10156971

11101369

12156823

13116513

14104655

15158865

16159056

Part

Part Part

No.

No. No.

100633

Description

Description Description

CLAMP,Screw

TOOL,Wrench,Allen(not

shown)

SCREW,Set,Socket

Head;#10–24x0.25”;

torqueto15–20in-lb

(1.7–2.3N•m)

PIN,Shear

FITTING,Nipple,Short

TOOL,Wrench,Allen(not

shown)

FITTING,Union,Swivel

REGULATOR,Air

GAUGE,Pressure,Air

COUPLING,Motor

PAD,Mounting,Screw

Qty

Qty Qty

1

1

3

2

1

1

1

1

1

1

1

17159057RETAINER1

18104391

19159704

20159854

21172311

22159858

23159863

Ref

Ref Ref

No.

No. No.

1

2101368

3100053

4100017

5

Part

Part Part

No.

No. No.

25C765

100018

Description

Description Description

MOTOR,Air,Rotary

Piston;includes12,13,

14,and30.

CLAMP,Hose

SCREW,Set,Socket

Head;5/16-18x0.25”;

torqueto96–132in-lb

(11–15N•m)

SCREW,Cap,Hex

Head;1/2–13x1.5”;

tightensecurely;donot

over-tighten

WASHER,Lock,Spring

Qty

Qty Qty

1

2

4

1

1

24159864

25100579

31104029

32104582

33100718

34110911NUT,Hex;M5x81

37186620

39065251

▲

43

▲

cardsareavailableatnocost.

17P806

Replacementsafetylabels,signs,tags,and

BEARING,Agitator,Press

Fit

CUP,Protector,Bearing

PROPELLER,Agitator

SHAFT,Agitator

COUPLING

BRACKET,Mounting

CLAMP,Agitator

PIN,Cotter

CLAMP,Ground,Electric

WASHER,Tab

WASHER,Lock

LABEL,Symbol,Ground

(notshown)

CABLE,Copper,Flat

Braid,0.33ft

SafetyTag(notshown)

1

1

2

1

1

1

1

2

1

1

1

1

1

1

3A4792C19

Page 20

Parts

Models

Models Models

25C534

25C534 25C534

and

25C535

and and

25C535 25C535

Ref

Ref Ref

Part

No.

Part Part

No.

No. No.

1

25C765

2124313

235535

3

224876

235530

4

224852

5

224393HELIX,Agitator1

6187054

Description

No. No.

Description Description

MOTOR,Air,Rotary

Piston;includes12,13,

14,and30.

SCREW,SocketHead;

M6–1x16mm,Stainless

Steel;torqueto80–100

in-lb(9–11N•m)

HOUSING,Agitator

Outlet,StainlessSteel

(model25C534)

HOUSING,Agitator

Outlet,CarbonSteel

(model25C535)

SHAFT,Agitator(model

25C534)

SHAFT,Agitator(model

25C535)

PLUG,Tube,Fluid

Qty

Qty Qty

1

3

1

1

1

1

1

7

101946

8111312

9112364

10156823

11156971

12116513

13187577PLATE,Mounting,Motor1

14102023

16104655

17111593

18157021

19186620

PIN,Cotter;Stainless

Steel

PACKING,O-ring

SCREW,Set,Socket

Head;1/4–20x0.38”;

torqueto35–40in-lb(4–5

N•m)

FITTING,Nipple,Short

FITTING,Union,Swivel

REGULATOR,Air

SCREW,Cap,HexHead;

1/4–20x0.75”;torqueto

80–100in-lb(9–11N•m)

GAUGE,Pressure,Air

SCREW,Grounding,

SlottedHexWasher

Head;#8–32x0.375”

WASHER,Lock,Internal

LABEL,Symbol,Ground

(notshown)

1

1

2

1

1

1

3

1

1

1

1

27403123

▲

30

▲

cardsareavailableatnocost.

17P806

Replacementsafetylabels,signs,tags,and

CAP,Plug(notshown)

SafetyTag(notshown)

203A4792C

1

1

Page 21

Parts

Model

Model Model

25C530

25C530 25C530

Ref

Ref Ref

Part

No.

Part Part

No.

No. No.

———

SS

1

25C765

216A867

316A868

416A872ADAPTER,Bung,Double1

5

24C860AGITATOR,Arm,Short

6

24C861AGITATOR,Arm,Long

7

102207

8101679

Description

No. No.

Description Description

SCREW,BladeSet;

tightensecurelyafter

adjusting;donot

over-tighten

MOTOR,Air,Rotary

Piston;includes12,13,14,

and30.

SHAFT,Agitator

COUPLER,Agitator

SCREW,Set,Socket

Head;1/4–20x0.25”;

torqueto96–132in-lb

(11–15N•m)

SCREW,Set,Socket

Head;3/8–24x0.5”;

torqueto80–100in-lb

(9–11N•m)

Qty

Qty Qty

3

1

1

1

2

1

4

3

9156823

10156971

11116513

12104655

13116343

25186620

26113082

2716H294

2816H295

▲

30

17P806

▲

Replacementsafetylabels,signs,tags,and

cardsareavailableatnocost.

FITTING,Union,Swivel

FITTING,Nipple,Short

REGULATOR,Air

GAUGE,Pressure,Air

SCREW,Ground;M5x.8

LABEL,Symbol,Ground

(notshown)

PACKING,O-ring

ADAPTER,Angled,

ExpandingBlade(not

shown)

RING,Locking(notshown)

SafetyTag(notshown)

1

1

1

1

1

1

1

1

1

1

3A4792C

21

Page 22

Accessories

Models

Models Models

25N881

25N881 25N881

and

25N882

and and

25N882 25N882

Ref

Ref Ref

Part

No.

Part Part

No.

No. No.

1

25C765

2116513

3104655

4156971

5

156823

16A521

6

16A754

7

18A192

8117028

Description

No. No.

Description Description

MOTOR,Air,Radial

Piston;includesitems2,

3,4,and5

REGULATOR,Air

GAUGE,Pressure,Air

FITTING,Nipple,Short

FITTING,Union,Swivel

HOUSING,Adapter,1

1/2–11.5NPSM(model

25N881)

HOUSING,Adapter,

2–11.5NPSM(model

25N882)

PLATE,In-Drum

Mounting

SCREW,SocketHead,

M6–1x16mm;torqueto

80–100in-lb(9–11N•m)

Qty

Qty Qty

1

1

1

2

1

1

1

3

17X562

9

17X563

11555337

12131497

13100016

22116343

▲

24

▲

cardsareavailableatnocost.

Accessories

Accessories Accessories

17P806

Replacementsafetylabels,signs,tags,and

ADAPTER,Shaft,7/16”

Square

ADAPTER,Shaft,1/2”

Square

SCREW,HexHead

1/4–20x.750;torqueto

80–100in-lb(9–11N•m)

SCREW,Set,Cuppt,

1/4–20x.500;Tighten

securelyonatofmotor

shaft.;usealightstrength

anaerobicsealant

WASHER,Lock

SCREW,Ground

SafetyTag(notshown)

1

1

3

1

3

1

1

Sensor

Sensor Sensor

Usethesensorkitforsensingmotorrevolution.The

kitincludesasensorandsensorbracketformounting

totheairmotor.

22

Kit

25C373

Kit Kit

25C373 25C373

3A4792C

Page 23

Dimensions

Dimensions

Dimensions Dimensions

Models

Models Models

25C528

25C528 25C528

and

25C533

and and

25C533 25C533

Model

Model Model

25M481

25M481 25M481

Model

Model Model

25C529

25C529 25C529

ReferenceA=11.5in.(29.3cm)ReferenceA=11.5in.(29.3cm)ReferenceA=45.6in.(115.8

cm)

ReferenceBReferenceB=31.9in(81.0cm)

Model25C528=31.9in(81.0

cm)

Model25C533=34.3in.(87.2

cm)

3A4792C23

Page 24

Dimensions

Models

Models Models

25C534

25C534 25C534

and

25C535

and and

25C535 25C535

Model

Model Model

25C530

25C530 25C530

Models

Models Models

25N881

25N881 25N881

and

25N882

and and

25N882 25N882

ReferenceA=10.4in.(26.3cm)ReferenceA=8.5in.(21.6cm)ReferenceA=10.4in.(26.3

cm)

ReferenceB=32.2in.(81.8cm)ReferenceB=29.8in.(75.6cm)ReferenceB=32.2(81.8cm)

24

3A4792C

Page 25

MountingHoleLayout

0

5

10

15

20

0

8.5

17.0

25.5

34.0

0 200 400 600 800 1000 1200

A

B

C

D

Mounting

Mounting Mounting

Models25C528,25C533,25M481

Hole

Hole Hole

Layout

Layout Layout

Air

Air Air

Consumption

Consumption Consumption

SCFM

A—20psi(1.4bar,0.14MPa)

B—40psi(2.8bar,0.28MPa)

C—60psi(4.1bar,0.41MPa)

D—80psi(5.5bar,0.55MPa)

Standard

Cubic

Meters/Hr

AirMotorRPM

3A4792C25

Page 26

TechnicalSpecications

Technical

Technical Technical

Note:Operatingaboverecommendedmaximumspeedsincreaseswearoncomponentsanddecreasesoperating

efciencies.

Models

Models Models

Air

Air Air

- --Driven Driven

MaximumRecommendedWorking

Pressure

AirConsumption

MaximumRecommendedSpeed

MaximumAllowableProcessFluid

Temperature

MaximumRecommendedMaterial

Viscosity

WettedParts

Weight

SoundPressureLevelat70psig,

MaximumRecommendedSpeed

25C528,

25C528, 25C528,

Driven

Agitators,

Agitators, Agitators,

Specications

Specications Specications

25C533,

25C533, 25C533,

Standard

Standard Standard

and

25M481

and and

25M481 25M481

25C528

25C528 25C528

500rpm500rpm

1000cP500cP

StainlessSteel,

PolyetherEther

Keytone

11lb(5kg)12lb(5.4kg)13lb(5.9kg)

CarbonSteel,

Aluminum,

25C533

25C533 25C533

70psig(5bar)

194°F(90°C)

PTFE

Lessthan75dBA

Seechart

StainlessSteel,Polyether

EtherKeytone

25M481

25M481 25M481

Model

Model Model

Air

Air Air

MaximumRecommendedWorkingPressure

AirConsumption

MaximumRecommendedSpeed

MaximumRecommendedMaterialViscosity

WettedParts

Weight

SoundPressureLevelat70psig,MaximumRecommendedSpeed

Models

Models Models

Air

Air Air

MaximumRecommendedWorkingPressure

AirConsumption

MaximumRecommendedSpeed

MaximumAllowableProcessFluidTemperature158°F(70°C)

MaximumRecommendedMaterialViscosity

WettedParts

Weight

SoundPressureLevelat70psig,MaximumRecommendedSpeed

25C529

25C529 25C529

Driven

- --Driven Driven

Driven

- --Driven Driven

Agitator,

Agitator, Agitator,

25C534

25C534 25C534

Agitators,

Agitators, Agitators,

Outboard

Outboard Outboard

70psig(5bar)

Seechart

500rpm

1000cP

Aluminum,carbonsteel,ductile

iron,bronze

15lb(6.8kg)

Lessthan75dBA

and

25C535

and and

25C535 25C535

Twistork

Twistork Twistork

Helix

® ®®Helix Helix

Mixer

Mixer Mixer

70psig(5bar)

Seechart

500rpm

1000cP

25C534

25C535

CarbonSteel,Fluoroelastomer,

Acetal

304and316StainlessSteel,

Fluoroelastomer,Acetal

16lb(7.3kg)

Lessthan75dBA

263A4792C

Page 27

TechnicalSpecications

Model

Model Model

Air

Air Air

MaximumRecommendedWorkingPressure

AirConsumption

MaximumRecommendedSpeed

MaximumAllowableProcessFluidTemperature194°F(90°C)

MaximumRecommendedMaterialViscosity

BungAdapterSizes11/2–11.5npsmand2–11.5npsm

WettedParts303,304,18–8stainlesssteel

Weight

SoundPressureLevelat70psig,MaximumRecommendedSpeed

Models

Models Models

Air

Air Air

MaximumRecommendedWorkingPressure

AirConsumption

MaximumRecommendedSpeed

MaximumAllowableProcessFluidTemperature194°F(90°C)

MaximumRecommendedMaterialViscosity

BungAdapterSizes11/2–11.5npsmand2–11.5npsm

WettedPartsN/A

Weight

SoundPressureLevelat70psig,MaximumRecommendedSpeed

25C530

25C530 25C530

Driven

- --Driven Driven

Driven

- --Driven Driven

Agitators,

Agitators, Agitators,

25N881

25N881 25N881

Agitators,

Agitators, Agitators,

Expanding

Expanding Expanding

and

and and

Drum

In InInDrum Drum

Blade

Mixer

Blade Blade

Mixer Mixer

70psig(5bar)

Seechart

500rpm

1000cP

12lb(5.4kg)

Lessthan75dBA

25N882

25N882 25N882

70psig(5bar)

Seechart

100rpm

500cP

7lb(3.2kg)

Lessthan75dBA

California

California California

WARNING:

WARNING: WARNING:

Proposition

Proposition Proposition

65

65 65

ThisproductcanexposeyoutochemicalsknowntotheStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.Formoreinformation,goto

www.P65warnings.ca.gov.

3A4792C

27

Page 28

Graco

Graco Graco

GracowarrantsallequipmentreferencedinthisdocumentwhichismanufacturedbyGracoand

bearingitsnametobefreefromdefectsinmaterialandworkmanshiponthedateofsaletotheoriginal

purchaserforuse.Withtheexceptionofanyspecial,extended,orlimitedwarrantypublishedby

Graco,Gracowill,foraperiodoftwelvemonthsfromthedateofsale,repairorreplaceanypartofthe

equipmentdeterminedbyGracotobedefective.Thiswarrantyappliesonlywhentheequipmentis

installed,operatedandmaintainedinaccordancewithGraco’swrittenrecommendations.

Thiswarrantydoesnotcover,andGracoshallnotbeliableforgeneralwearandtear,orany

malfunction,damageorwearcausedbyfaultyinstallation,misapplication,abrasion,corrosion,

inadequateorimpropermaintenance,negligence,accident,tampering,orsubstitutionofnon-Graco

componentparts.NorshallGracobeliableformalfunction,damageorwearcausedbythe

incompatibilityofGracoequipmentwithstructures,accessories,equipmentormaterialsnotsupplied

byGraco,ortheimproperdesign,manufacture,installation,operationormaintenanceofstructures,

accessories,equipmentormaterialsnotsuppliedbyGraco.

Thiswarrantyisconditionedupontheprepaidreturnoftheequipmentclaimedtobedefectivetoan

authorizedGracodistributorforvericationoftheclaimeddefect.Iftheclaimeddefectisveried,

Gracowillrepairorreplacefreeofchargeanydefectiveparts.Theequipmentwillbereturnedto

theoriginalpurchasertransportationprepaid.Ifinspectionoftheequipmentdoesnotdiscloseany

defectinmaterialorworkmanship,repairswillbemadeatareasonablecharge,whichchargesmay

includethecostsofparts,labor,andtransportation.

THIS

WARRANTY

THIS THIS

WARRANTY WARRANTY

OR

IMPLIED,

OR OR

IMPLIED, IMPLIED,

WARRANTY

WARRANTY WARRANTY

Graco’ssoleobligationandbuyer’ssoleremedyforanybreachofwarrantyshallbeassetforthabove.

Thebuyeragreesthatnootherremedy(including,butnotlimitedto,incidentalorconsequential

damagesforlostprots,lostsales,injurytopersonorproperty,oranyotherincidentalorconsequential

loss)shallbeavailable.Anyactionforbreachofwarrantymustbebroughtwithintwo(2)yearsof

thedateofsale.

GRACO

GRACO GRACO

MERCHANTABILITY

MERCHANTABILITY MERCHANTABILITY

ACCESSORIES,

ACCESSORIES, ACCESSORIES,

BY

BY BY

hose,etc.),aresubjecttothewarranty,ifany,oftheirmanufacturer.Gracowillprovidepurchaserwith

reasonableassistanceinmakinganyclaimforbreachofthesewarranties.

InnoeventwillGracobeliableforindirect,incidental,specialorconsequentialdamagesresulting

fromGracosupplyingequipmenthereunder,orthefurnishing,performance,oruseofanyproductsor

othergoodssoldhereto,whetherduetoabreachofcontract,breachofwarranty,thenegligenceof

Graco,orotherwise.

FORGRACOCANADACUSTOMERS

ThePartiesacknowledgethattheyhaverequiredthatthepresentdocument,aswellasalldocuments,

noticesandlegalproceedingsenteredinto,givenorinstitutedpursuantheretoorrelatingdirectlyor

indirectlyhereto,bedrawnupinEnglish.Lespartiesreconnaissentavoirconvenuquelarédaction

duprésentedocumentseraenAnglais,ainsiquetousdocuments,avisetprocéduresjudiciaires

exécutés,donnésouintentés,àlasuitedeouenrapport,directementouindirectement,avecles

procéduresconcernées.

MAKES

MAKES MAKES

GRACO.

GRACO. GRACO.

IS

EXCLUSIVE,

IS IS

INCLUDING

INCLUDING INCLUDING

OF

OF OF

Theseitemssold,butnotmanufacturedbyGraco(suchaselectricmotors,switches,

EXCLUSIVE, EXCLUSIVE,

BUT

FITNESS

FITNESS FITNESS

NO

NO NO

EQUIPMENT,

EQUIPMENT, EQUIPMENT,

BUT BUT

FOR

FOR FOR

WARRANTY,

WARRANTY, WARRANTY,

AND

FITNESS

AND AND

FITNESS FITNESS

Standard

Standard Standard

AND

IS

IN

AND AND

NOT

LIMITED

NOT NOT

LIMITED LIMITED

PARTICULAR

A AAPARTICULAR PARTICULAR

AND

AND AND

FOR

FOR FOR

MATERIALS

MATERIALS MATERIALS

LIEU

IS IS

IN IN

LIEU LIEU

TO

WARRANTY

TO TO

WARRANTY WARRANTY

PURPOSE.

PURPOSE. PURPOSE.

DISCLAIMS

DISCLAIMS DISCLAIMS

PARTICULAR

A AAPARTICULAR PARTICULAR

OR

COMPONENTS

OR OR

COMPONENTS COMPONENTS

Warranty

Warranty Warranty

OF

ANY

OF OF

ALL

ALL ALL

OTHER

ANY ANY

OTHER OTHER

IMPLIED

IMPLIED IMPLIED

PURPOSE,

PURPOSE, PURPOSE,

WARRANTIES,

WARRANTIES, WARRANTIES,

OF

MERCHANTABILITY

OF OF

MERCHANTABILITY MERCHANTABILITY

WARRANTIES

WARRANTIES WARRANTIES

IN

CONNECTION

IN IN

SOLD

SOLD SOLD

CONNECTION CONNECTION

BUT

NOT

BUT BUT

NOT NOT

EXPRESS

EXPRESS EXPRESS

OR

OR OR

OF

OF OF

WITH

MANUFACTURED

MANUFACTURED MANUFACTURED

WITH WITH

Graco

Graco Graco

ForthelatestinformationaboutGracoproducts,visitwww.graco.com.

Forpatentinformation,seewww.graco.com/patents.

To

To To

Phone:

Phone: Phone:

Allwrittenandvisualdatacontainedinthisdocumentreectsthelatestproductinformationavailableatthetimeofpublication.

Information

Information Information

place

an

place place

an an

612-623-6921or ororToll Toll

GRACO

GRACO GRACO

order,

order, order,

contactyourGracoDistributororcalltoidentifythenearestdistributor.

Toll

Free:

Free: Free:

1-800-328-0211Fax: Fax:

Gracoreservestherighttomakechangesatanytimewithoutnotice.

OriginalInstructions.ThismanualcontainsEnglish.MM3A4792

Graco

International

International International

INC.

AND

INC. INC.

Copyright

Copyright Copyright

SUBSIDIARIES

AND AND

SUBSIDIARIES SUBSIDIARIES

2016,

Graco

2016, 2016,

Graco Graco

Graco Graco

Inc.

Inc. Inc.

Headquarters:

Headquarters: Headquarters:

Ofces:

Ofces: Ofces:

P.O.

• ••P.O. P.O.

All

Graco

All All

manufacturing

Graco Graco

manufacturing manufacturing

www.graco.com

RevisionC,2019–05

Fax:

612-378-3505

Belgium,China,Japan,Korea

BOX

BOX BOX

Minneapolis

1441

MINNEAPOLIS

1441 1441

• ••MINNEAPOLIS MINNEAPOLIS

locations

locations locations

MN

55440-1441

MN MN

are

are are

55440-1441 55440-1441

registered

registered registered

USA

• ••USA USA

ISO

9001.

to totoISO ISO

9001. 9001.

Loading...

Loading...