Page 1

Operation

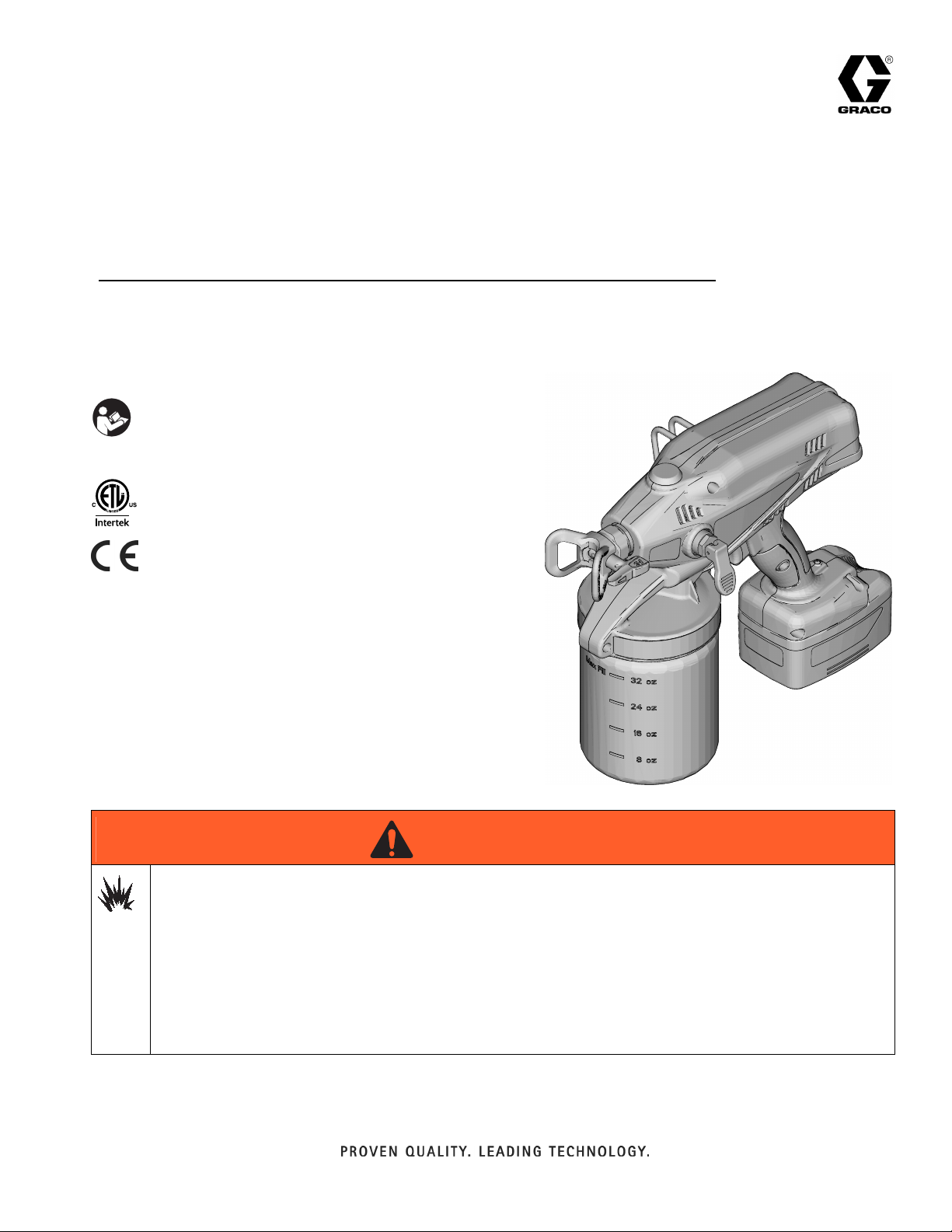

ProShot™ Cordless Paint Sprayer

U.S. Patent No. D625,775 S; U.S. Patent No. 6,619,569; U.S. Patent No. D630,708 S;

Community Registration #001228255; India Patent No. 230058; Taiwan Patent No. D142952

China Patent No. ZL201030238948.3; and other patents pending

- For portable spray applications of water-based and oil-based

(mineral spirit-type) architectural paints and coatings only -

- Not for use in explosive atmospheres -

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

Model 258865

Maximum Working Pressure 2000 psi (137 bar, 13.7 MPa)

3A0153E

EN

Model 258859

Maximum Working Pressure 2000 psi (137 bar, 13.7 MPa)

ti14773a

WARNING

WARNINGWARNINGWARNING

Use only water-based or oil-based (mineral spirit-type) materials with flash point greater than 100° F

(38° C). Do not use materials which state “FLAMMABLE” on the packaging. For more information about

your material, request MSDS from distributor or retailer.

Use oil-based material outdoors or in a well-ventilated indoor area with a flow of fresh air.

Spraying certain materials may cause static build-up in the sprayer that can result in static shock to

the user. If this occurs, first ensure the material has a flash point greater than 100° F (38° C) and does not

state that it is FLAMMABLE anywhere on the package. If still feeling a static shock, the material likely contains a non-mineral spirits fluid such as, but not limited to, xylene, toluene, or naphtha, which can build up

static. Switch to an alternative material.

Page 2

Table of Contents

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . 5

Common Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . 6

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Spray Tip Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Prime/Relief Valve Position . . . . . . . . . . . . . . . . . . . . . 6

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Charger Status Indicator Lights . . . . . . . . . . . . . . . . . . 7

Sprayer Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Suction Tube Selection . . . . . . . . . . . . . . . . . . . . . . . . . 8

Spraying Stains or Clear Coats (Fine-Finish Optimizer) 9

Sprayer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Install Tip/Guard Assembly

(if not installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Important User Information

Read this before using your sprayer. See the Operation Manual provided with

your sprayer for complete instructions on proper use and safety warnings.

Getting Started with Basic Techniques . . . . . . . . . . . . . 11

Triggering Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Aiming Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unclogging Spray Tip/Guard Assembly . . . . . . . . . . . . 12

Shutdown and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flushing Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning Sprayer Exterior . . . . . . . . . . . . . . . . . . . . . 15

Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replacement Parts and Kits . . . . . . . . . . . . . . . . . . . . . . 16

ProShot Repair Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Outlet Valve Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alternate Priming Method . . . . . . . . . . . . . . . . . . . . . . . . 18

Inlet Valve Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . 24

DO NOT RETURN THIS SPRAYER TO THE STORE!

If you experience problems, contact Graco Customer Service at www.graco.com.

Congratulations! You have purchased a high-quality paint sprayer made by Graco Inc. This sprayer is designed to

provide superior spray performance with water-based and oil-based (mineral spirit-type) architectural paints and

coatings. This user information sheet is intended to help you understand the types of materials that can and cannot be

used with your sprayer.

Before using this equipment, be sure to read and follow the information on your container label and ask for a Material

Safety Data Sheet (MSDS). The container label and MSDS will explain the contents of the material and the specific

precautions related to it.

Paints, coatings and clean-up materials generally fit into one of the following 3 basic categories:

WATER-BASED: The container label should indicate that the material can be cleaned up with soap and

water. Your sprayer is compatible with this type of material. Your sprayer is NOT compatible with harsh

cleaners such as chlorine bleach.

OIL-BASED: The container label should indicate that the material is combustible and can be cleaned up with

mineral spirits or paint thinner. The MSDS must indicate that the flash point of the material is above 100° F.

Your sprayer is compatible with this type of material. Use oil-based material outdoors or in a well-ventilated

indoor area with a flow of fresh air. See the safety warnings in your Operation Manual.

FLAMMABLE: This type of material contains flammable solvents such as xylene, toluene, naphtha, MEK,

lacquer thinner, acetone, denatured alcohol, and turpentine. The container label should indicate that this

material is FLAMMABLE. This type of material is NOT compatible with your sprayer and CANNOT be used.

2 3A0153E

Page 3

Warnings

Warnings

The following warnings are for the setup, use, maintenance, and repair of this equipment. The exclamation point symbol alerts you

to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear

throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire

and explosion:

• Sprayer generates sparks. Do not spray or flush with flammable liquids.

• Use only water-based or oil-based (mineral spirit-type) materials with a flash point greater than

100° F (38° C).

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

• Use oil-based material outdoors or in a well-ventilated indoor area with a flow of fresh air.

• Do not spray or flush with combustible materials near an open flame or sources of ignition.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity creates

a risk of fire or explosion in the presence of paint or solvent fumes. Keep sprayer at least 10 cm away from

objects while spraying or flushing.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets (MSDS)

and container labels provided with the paints and solvents. Follow the paint and solvents manufacturer’s

safety instructions.

• Fire extinguisher equipment shall be present and working.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the sprayer at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any

part of the body.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing the nozzle tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off

the unit and follow the Pressure Relief Procedure for turning off the unit.

• Check parts for signs of damage. Replace any damaged parts.

• This system is capable of producing 2000 psi. Use replacement parts or accessories that are rated a minimum of 2000 psi.

• Do not carry the tool with a finger on the trigger.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Use only in dry locations. Do not expose to water or rain.

• Use in well-lit areas.

3A0153E 3

Page 4

Warnings

WARNING

WARNINGWARNINGWARNING

BATTERY HAZARD

The battery may leak, explode, cause burns, or cause an explosion if mishandled. Contents of an open battery

can cause severe irritation and/or chemical burns. If on skin, wash with soap and water. If in eyes, flush with

water for at least 15 minutes and seek immediate medical attention.

• Do not short-circuit the terminals of the battery.

• Keep the battery away from fire.

• Charge only with Graco approved charger as listed in this manual.

• Do not expose to heat above 170° F (80° C).

• Do not expose battery to water or rain.

• Do not disassemble, crush, or penetrate the battery.

• Follow local ordinances and/or regulations for disposal.

CHARGER ELECTRIC SHOCK, FIRE AND EXPLOSION HAZARD

Improper setup or usage can cause electric shock, fire, and explosion.

• Charge only Graco 18V Lithium Ion batteries; other batteries may burst.

• Use only in dry locations. Do not expose to water or rain.

• If the supply cord is damaged, it must obtained from the manufacturer to avoid a hazard.

• Ensure that the outside surface of the battery is clean and dry before plugging into the charger.

• Do not attempt to charge non-rechargeable batteries.

• Place charger on flat non-flammable surfaces and keep away from flammable materials or fumes when

recharging battery.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property

damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow

the Pressure Relief Procedure in this manual. Disconnect power.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of

the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic

fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 3A0153E

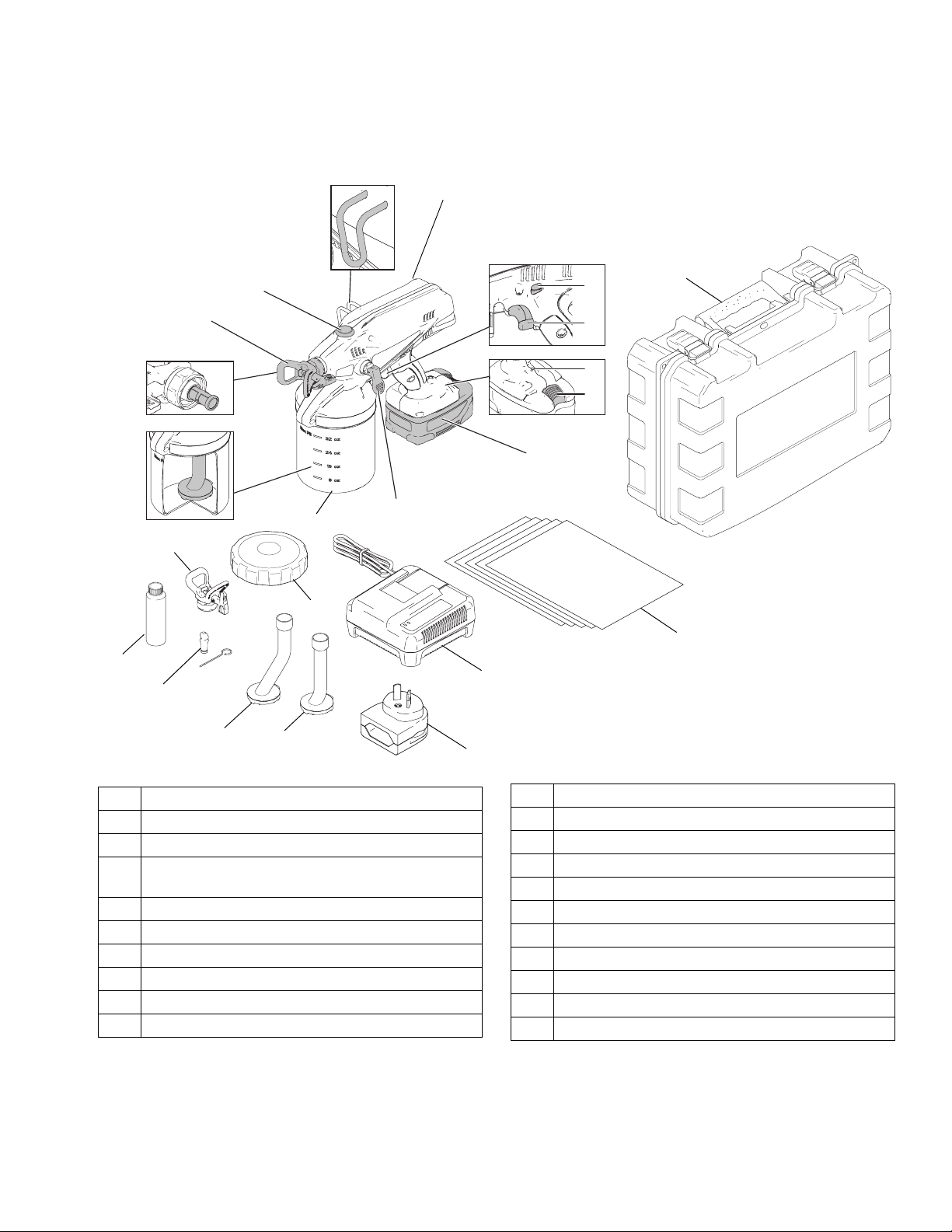

Page 5

Component Identification

Component Identification

A

B

G

E

Fa

H

D

D

C

K

Y

Z

W

T

S

R

M

ti15479a

J

P

N

Fb

Fa

L

A ProShot Cordless Paint Sprayer

B Sprayer Hook

C Outlet Valve Repair Access

ProShot Spray Tip/Guard Assembly

D

(411, 515 included)

E Tip Filter (*Reverse Threaded)

Fa Standard Suction Tube (sprays ceilings and walls)

Fb Specialized Suction Tube (sprays floors)

G Pump Armor Concentrate (4 oz.)

H Fine-Finish Optimizer with Storage/Cleaning Tool

J Material Cup Cover and Seal

*NOTE: Filter assembly is reverse-threaded. Turn left (or counter-clockwise) to tighten,

turn right (or clockwise) to loosen.

3A0153E 5

K Material Cup (32 oz)

L Power Cord Converter (258859 only)

M Prime/Relief Valve

N Lithium Ion Premium Power Battery Charger

P Material Cup Liners (5 included)

R Lithium Ion Premium Power Battery (2 included)

S Battery Release Button

T Battery Status Indicator Light

W Sprayer Trigger

Y Sprayer Trigger Lock

Z ProShot Case

Page 6

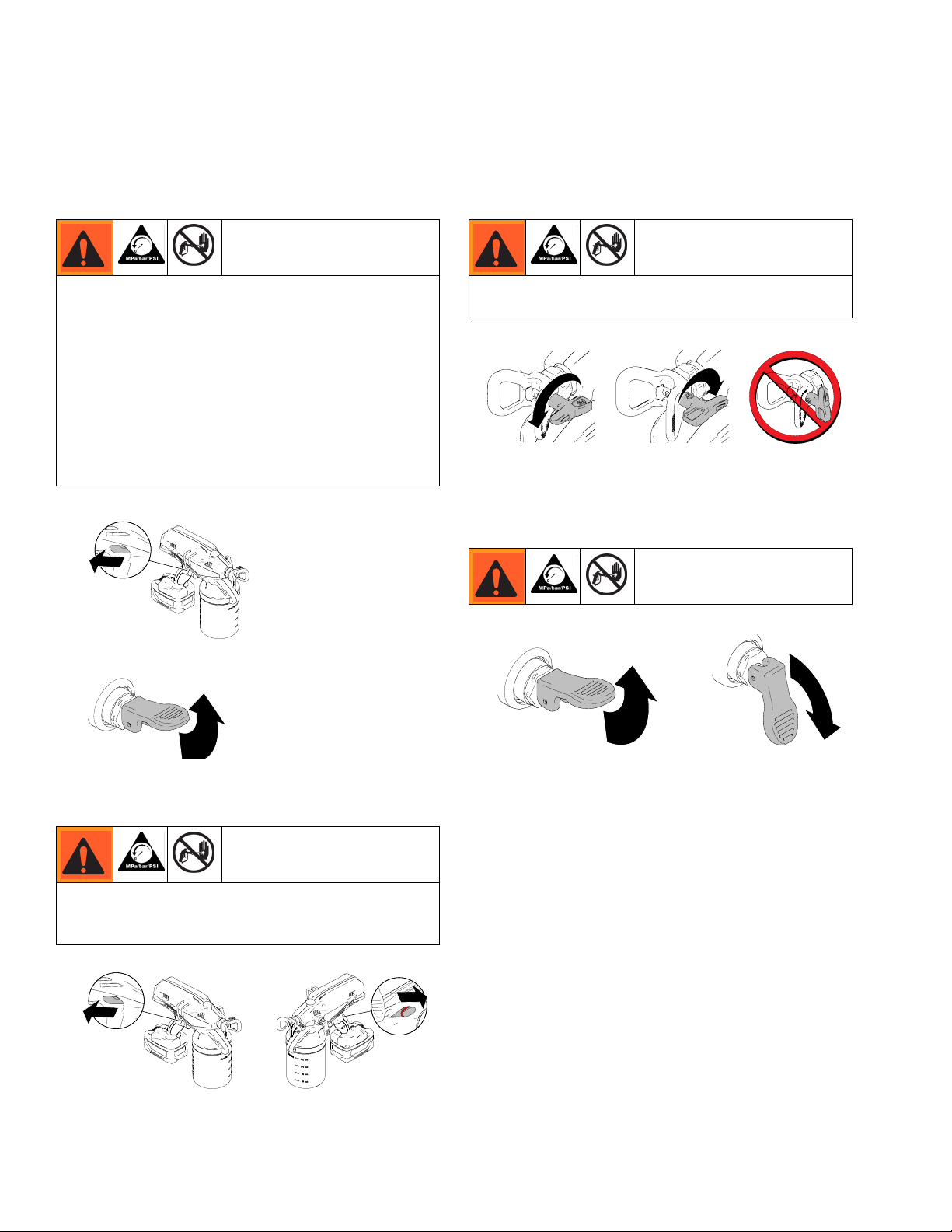

Common Procedures

Common Procedures

Pressure Relief Procedure

Do not operate or spray near children. Do not aim the

sprayer at, or spray any person or animal. Keep hands

and other body parts away from the front of the sprayer.

For example, do not try to stop the paint flow with any

part of the body.

This sprayer builds up an internal pressure of 2,000 psi

during use. Follow this Pressure Relief Procedure

whenever you stop spraying and before cleaning,

checking, servicing, or transporting equipment to

prevent serious injury.

1. Engage trigger lock.

Spray Tip Position

Always perform Pressure Relief Procedure before

adjusting spray tip position.

ti14985a

Tip Forward

(SPRAY position)

ti14991a

Tip Reversed

(UNCLOG position)

Prime/Relief Valve Position

ti15510a

2. Put prime/relief valve UP to release pressure.

ti14999a

Tri gger Lock

Always engage the trigger lock when you stop spraying

to prevent the sprayer from being triggered accidentally

by hand, or if dropped or bumped.

ti14994a

Trigger Locked

Trigger Unlocked

(red ring is visible)

ti14995a

ti14999a

UP position

(Releases pump pressure)

ti15425a

DOWN position

(Ready to spray)

6 3A0153E

Page 7

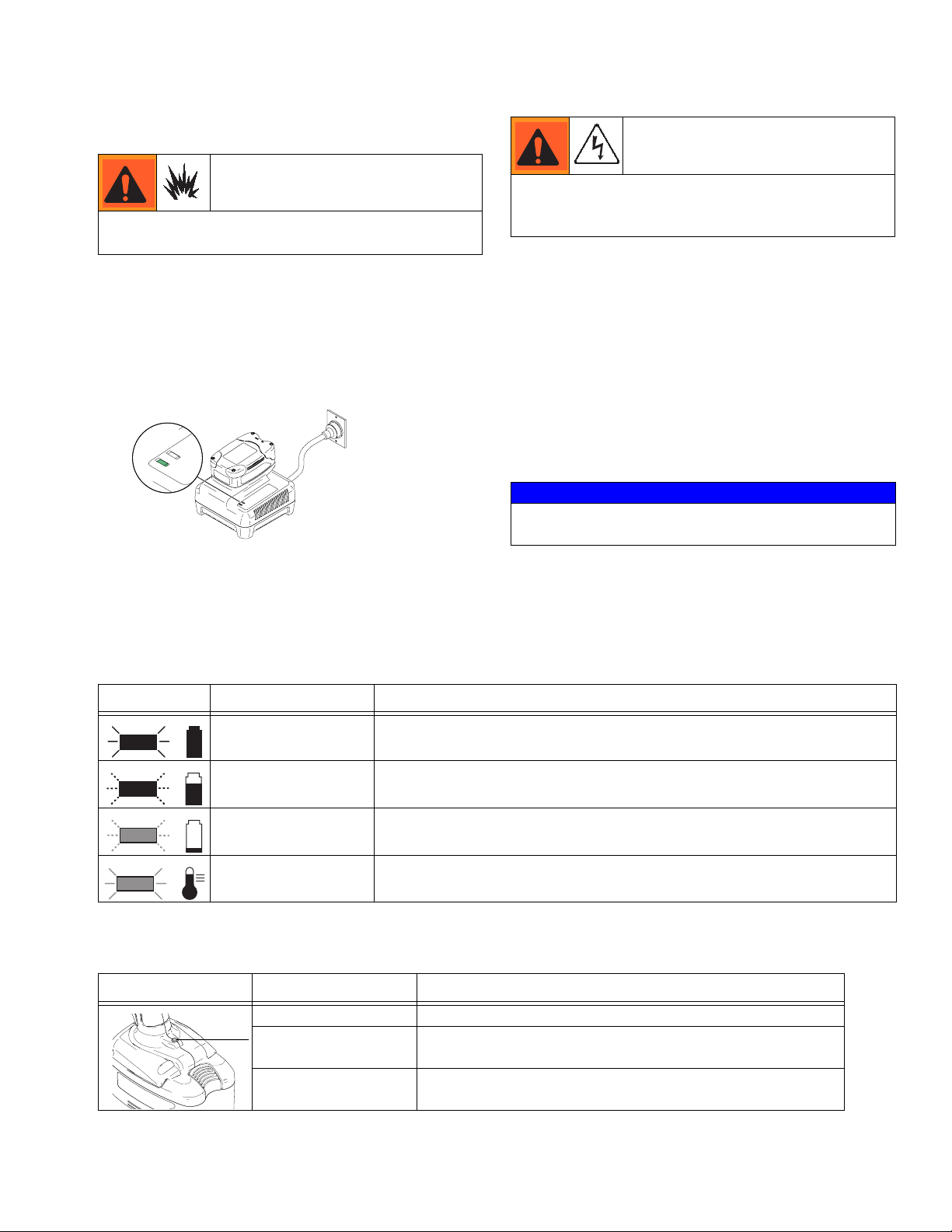

Charging the Battery

Charging the Battery

Batteries may leak, explode, cause burns or cause an

explosion if mishandled.

Batteries are initially 50% charges to provide optimum

battery life and require charging before first use. It takes

approximately 45 minutes to charge a dead battery to

80%, at which point it can be used.It will take approximately 75 minutes to fully charge a dead battery.

To reduce the risk of electric shock, only use Graco

batteries with the Graco charger. Do not insert any

foreign objects into the adapter cup.

NOTE: The amount sprayed with each battery varies

depending on material, tip size, battery charge, and battery temperature. 1 battery fully charged will spray

approximately 1 gallon when using the 515 tip with latex

paint. You will get less when using a smaller tip or thinner material.

1. Slide battery into charger as shown (light will turn on

within 5 seconds).

NOTE: Batteries can remain in the charger, which

automatically switches to maintenance mode. It is not

recommended to store the battery in the charger for

longer than one week.

NOTE: The charger supplied with model 258859 comes

with a power cord adapter connected to the power cord.

To switch from the AS3112 connector to the 2-pin Euro

CEE7 connector, pull off the adapter.

Do not place a wet battery in the charger. Damage to

equipment will occur.

Charger Status Indicator Lights

Label Appearance Description

Solid green light

Flashing green light

Flashing red light

Indicates a full charge. Use the battery or leave it in the charger.

The automatic Maintenance Mode holds the batteries at full charge.

Battery is charging, indicates 80% charge.

Battery can be used.

Battery is charging, indicates less than 80% charge.

Do NOT use battery.

NOTICE

Solid red light

Battery is too hot or too cold to charge and must cool down or warm up

before charging. Leave battery in charger.

Sprayer Status Indicator

Light Appearance Description

No light Normal operation.

Solid red Battery is low on power and needs to be charged, or battery

is too cold and must warm up before spraying.

Flashing red Battery temperature is too high, or tip is clogged.

See Troubleshooting, page 20.

NOTE: The indicator light is only visible when sprayer trigger is engaged. You must squeeze and hold the trigger to

see the Sprayer Status Indicator.

3A0153E 7

Page 8

Setup

Setup

Use only water-based or oil-based (mineral

spirit-type) materials with flash point greater than

100° F (38° C). Do not use materials which state

“FLAMMABLE” on the packaging. For more information

about your material, request MSDS from distributor or

retailer.

Spraying certain materials may cause static

build-up in the sprayer that can result in static

shock to the user. If this occurs, first ensure the mate-

rial has a flash point greater than 100° F (38° C) and

does not state that it is FLAMMABLE anywhere on the

package. If still feeling a static shock, the material likely

contains a non-mineral spirits fluid such as, but not limited to, xylene, toluene, or naphtha, which can build up

static. Switch to an alternative material.

Use oil-based material outdoors or in a well-ventilated

indoor area with a flow of fresh air.

Keep spray area well-ventilated. Keep a good supply

of fresh air moving through the area.

NOTICE

Your sprayer is NOT compatible with harsh cleaners

such as chlorine bleach. Using these cleaners will

cause damage to the sprayer.

When spraying ceilings, the inlet of the suction tube

should be aimed at the back of the material cup

(towards the trigger).

ti15475a

Specialized Suction Tube (sprays floors):

When spraying floors, the inlet of the suction tube

should be aimed at the front of the material cup (towards

Spray Tip/Guard Assembly).

ti15477a

NOTE: If the sprayer is angled or tilted too far, the

suction tube will lose contact with the material and

the sprayer will stop spraying.

Suction Tube Selection

This sprayer comes with two different suction tubes.

Standard Suction Tube (sprays ceilings and walls):

When spraying walls, the inlet of the suction tube should

be aimed at the front of the material cup.

ti15476a

8 3A0153E

ti15511a

Page 9

Setup

Spraying Stains or Clear Coats (Fine-Finish Optimizer)

The Fine-Finish Optimizer should be installed and used

when spraying thin material such as stain or clear coats.

The Fine-Finish Optimizer restricts the material flow

resulting in a finer quality finish.

Installation

1. Remove material cup and suction tube.

2. Push Fine-Finish Optimizer into pump inlet until

completely engaged and re-install suction tube.

2. Put prime/relief valve to UP position, then hold trigger in for 10 seconds.

ti14999a

3. Put prime/relief valve DOWN to spray position.

ti15425a

4. Reverse spray tip to UNCLOG position and trigger

sprayer into a waste area.

5. Engage trigger lock and put prime/relief valve UP to

release pressure.

Cleanup/Storage

Be sure to remove and clean the Fine-Finish Optimizer

immediately after use. Store the Fine-Finish Optimizer

on the Storage/cleaning Tool supplied to keep the hole

clear of dried material.

Sprayer Setup

This sprayer arrives from the factory with a small

amount of test material in the system. It is important

that you flush this material from the sprayer before

using it for the first time:

1. Fill material cup with water and thread onto sprayer.

ti14994a

ti14999a

6. Unscrew and remove material cup.

7. Disengage trigger lock, put prime/relief valve

DOWN, hold sprayer slightly above material cup,

and pull trigger to discharge fluid from pump.

ti15478a

8. Discard material in cup.

ti14992a

3A0153E 9

Page 10

Setup

Materials

Use only water-based or oil-based (mineral

spirit-type) materials with flash point greater than

100° F (38° C). Do not use materials which state

“FLAMMABLE” on the packaging. For more information

about your material, request MSDS from distributor or

retailer.

Spraying certain materials may cause static

build-up in the sprayer that can result in static

shock to the user. If this occurs, first ensure the mate-

rial has a flash point greater than 100° F (38° C) and

does not state that it is FLAMMABLE anywhere on the

package. If still feeling a static shock, the material likely

contains a non-mineral spirits fluid such as, but not limited to, xylene, toluene, or naphtha, which can build up

static. Switch to an alternative material.

Use oil-based material outdoors or in a well-ventilated

indoor area with a flow of fresh air.

Keep spray area well-ventilated. Keep a good supply

of fresh air moving through the area.

2. Use the Fine-Finish Optimizer cleaning tool to lightly

push on inlet valve to make sure it moves up and

down freely.

3. Install material cup liner, fill with material, and

thread onto sprayer.

ti15474a

4. To prime pump, disengage trigger lock and trigger

sprayer for 10 seconds. Then release trigger and

put prime/relief valve DOWN to spray position.

• When spraying water-based materials, flush the

sprayer thoroughly with water.

• When spraying non-water-based materials, flush

the sprayer thoroughly with mineral spirits or compatible, oil-based flushing fluid.

Starting a New Job (or Refilling the Cup)

1. Engage trigger lock and put prime/relief valve UP to

release pressure.

ti14994a

ti14999a

ti14995a

ti15418a

ti15425a

5. Reverse spray tip to UNCLOG position and spray

into waste area for five seconds. Then rotate tip

back to SPRAY position. NOTE: Failure to perform

this operation could result in poor spray pattern.

ti14991a

ti15491a

ti14985a

NOTE: If sprayer fails to prime, follow Alternative

Priming Method (page 18) and/or Inlet Valve

Cleaning (page 19).

10 3A0153E

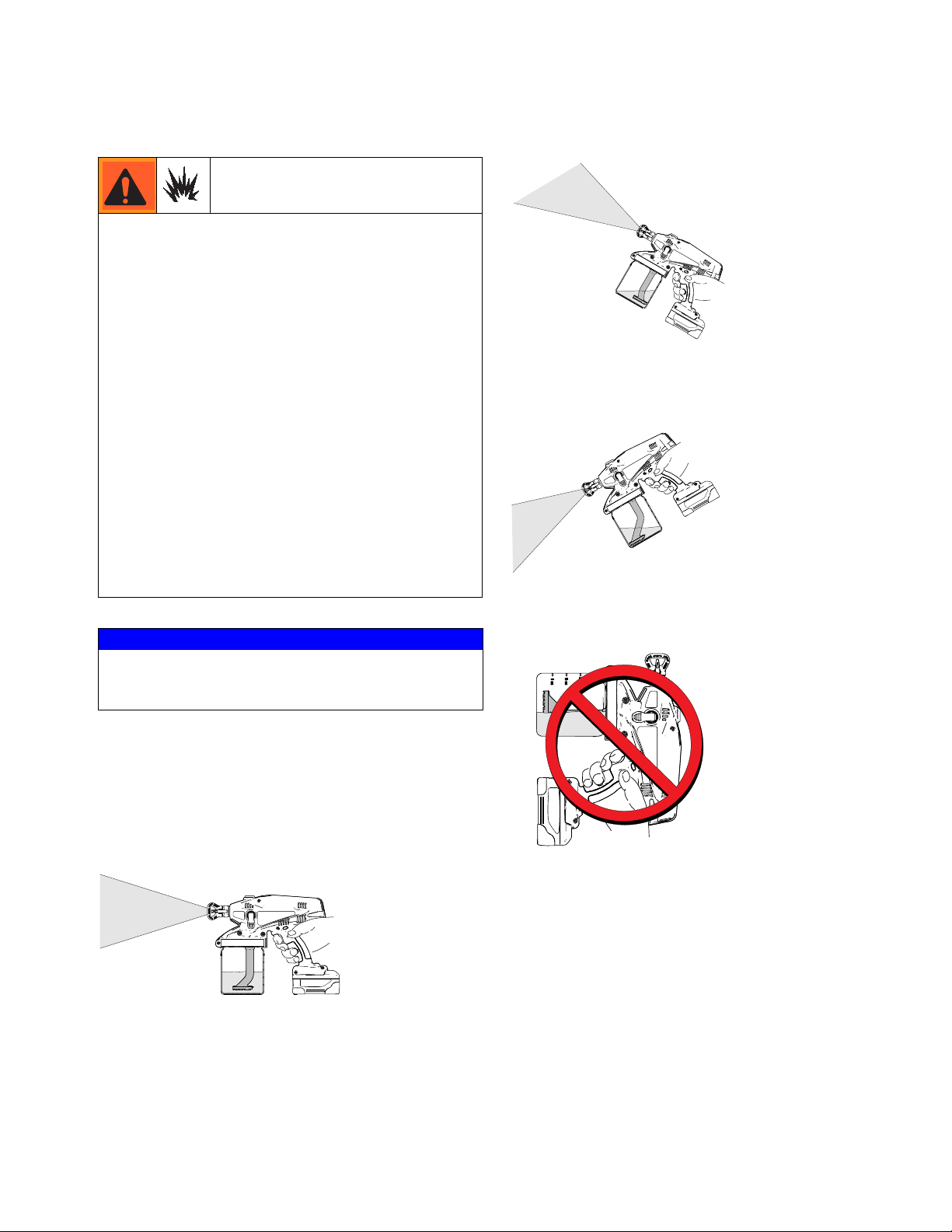

Page 11

Install Tip/Guard Assembly (if not installed)

8

Install Tip/Guard Assembly

(if not installed)

Reversible Tip Selection Chart

MATERIALS

*Thin Medium Heavy

Thin stains,

semi-transparent stains

211, 411 213, 413 315, 515, 517

*Install Fine-Finish Optimizer, see page 9.

1. Engage trigger lock and put prime/relief valve UP to

release pressure. Then remove Tip/Guard Assembly.

Enamels, solid

stains, thin latex

Heavy latex

Getting Started with Basic Techniques

Use a piece of scrap cardboard to practice these basic

spraying techniques before you begin spraying the

surface.

• Hold sprayer 10 in. (25 cm) from surface and aim

straight at surface. Tilting sprayer to direct spray angle

causes an uneven finish.

(25 cm)

10 in.

even

finish

• Flex wrist to keep sprayer pointed straight. Fanning

sprayer to direct spray at angle causes uneven

finish.

even finish thin thick thin

thick

thin

uneven

finish

ti147

ti14994a

2. Install filter to Spray Tip/Guard Assembly (make sure

filter is fully installed into sprayer). NOTE: Filter assem-

bly is reverse-threaded. Turn left (or counter-clockwise) to install. Turn right (or clockwise) to remove.

ti14775a

NOTICE

Make sure filter is completely screwed into the Tip/Guard

Assembly to avoid damage to the filter.

ti14999a

3. Screw Tip/Guard Assembly onto sprayer. Tighten

retaining nut until completely engaged with sprayer.

NOTE: How fast you move the sprayer will affect spray

application. If material is pulsating, you are moving too fast.

If material drips, you are moving too slow. See Trouble-

shooting, page 20.

Triggering Sprayer

Pull trigger after starting stroke. Release trigger before end

of stroke. Sprayer must be moving when trigger is pulled

and released.

ti14988a

Start Moving

Pull Trigger

Release Trigger

Aiming Sprayer

Aim tip of sprayer at bottom edge of previous stroke, overlapping each stroke by half.

ti14997a

NOTICE

The tip is a permanently attached to the Tip/Guard

Assembly. Removal will result in damage.

3A0153E 11

ti14782a

Page 12

Unclogging Spray Tip/Guard Assembly

Unclogging Spray

Tip/Guard Assembly

Do not operate or spray near children. Do not aim the

sprayer at, or spray any person or animal. Keep hands

and other body parts away from the discharge. For

example, do not try to stop leaks with any part of the

body.

1. To unclog tip obstruction, engage trigger lock and

pull relief valve UP to release pressure.

ti14994a

ti14999a

5. Disengage trigger lock, put prime/relief valve DOWN

to spray position, and resume spraying.

ti14995a

ti15425a

6. If tip is still clogged, you may have to repeat steps

1 - 5 and rotate the tip from SPRAY to UNCLOG

several times. Repeat step 1 to release pressure,

remove and clean filter, or replace with new tip

assembly.

ti14989a

2. Reverse spray tip to UNCLOG position.

ti14991a

3. Aim sprayer at waste area, disengage trigger lock,

and put prime/relief valve DOWN to spray position.

Pull trigger to clear clog.

ti14995a

ti15425a

4. Engage trigger lock. Put prime/relief valve UP to

release pressure and rotate spray tip back to

SPRAY position.

NOTE: Filter assembly is reverse-threaded:

Turn l eft (or counter-clockwise) to install.

Turn r igh t (or clockwise) to remove.

7. If obstruction is cleared, engage trigger lock and

rotate arrow-shaped handle back to SPRAY

position.

ti14994a

ti14985a

ti14994a

ti14999a

ti14985a

12 3A0153E

Page 13

Shutdown and Cleaning

Shutdown and Cleaning

NOTICE

Failure to properly clean sprayer after each use will result

in hardened materials, damage to the sprayer, and the

warranty will no longer be valid.

Flushing Sprayer

Use only water-based or mineral spirit-type materials

with flash point greater than 100° F (38° C). Do not use

materials which state “FLAMMABLE” on the packaging.

For more information about your material, request MSDS

from distributor or retailer.

Spraying certain materials may cause static build-up

in the sprayer that can result in static shock to the

user. If this occurs, first ensure the material has a flash

point greater than 100° F (38° C) and does not state that it

is FLAMMABLE anywhere on the package. If still feeling a

static shock, the material likely contains a non-mineral

spirits fluid such as, but not limited to, xylene, toluene, or

naphtha, which can build up static. Switch to an alternative material.

2. Remove material cup and properly dispose cup liner

or excess material.

ti15000a

3. Remove and clean sprayer intake tube and screen

with water (or flushing fluid) and a brush every time

you flush the sprayer. Reconnect intake tube.

ti15002a

4. Clean cup if not using a liner, and fill with water or

appropriate flushing fluid.

Use oil-based material outdoors or in a well-ventilated

indoor area with a flow of fresh air.

Keep spray area well-ventilated. Keep a good supply of

fresh air moving through the area.

NOTICE

Protect the internal parts of this sprayer from water.

Do not submerge the sprayer in cleaning fluid. Openings

in shroud allow cooling of mechanical parts and electronics inside. If water gets into these openings, the sprayer

could malfunction or become permanently damaged.

1. Engage trigger lock and pull relief valve UP to

release pressure.

ti14994a

ti14999a

ti15001a

5. Reconnect material cup and shake sprayer to move

clean water around and clean all areas inside of

cup.

ti15441a

3A0153E 13

Page 14

Shutdown and Cleaning

6. Disconnect trigger lock and trigger sprayer for

approximately 15 seconds. Engage trigger lock.

ti14994a

7. Discard contaminated fluid and refill with appropriate flushing fluid.

8. Disengage trigger lock, reverse tip to UNCLOG

position, and pull trigger for 5 seconds to prime

sprayer.

ti14995a

ti14991a

9. Put prime/relief valve DOWN to spray position.

Trigger sprayer into waste area until no paint

appears in water or flushing fluid.

10. Engage trigger lock and put prime/relief valve UP to

release pressure.

11. Remove material cup and discard used fluid.

12. Use a soft brush to clean the black rubber inlet seal.

If the vent holes become clogged, use the Fine Finish optimizer cleaning tool or a paper clip to clear

the holes.

ti15425a

ti15491a

To avoid serious injury or damage to equipment, do not

expose the sprayer electronics to flushing solvents.

Keep sprayer at least 10 in. above the rim of the container when flushing.

ti15529a

Keep spray area well-ventilated. Keep a good supply of

fresh air moving through the area.

13. Remove Spray Tip/Guard Assembly and clean with

water or flushing fluid. A soft brush can be used to

loosen and remove dried material if needed.

ti15003a

NOTICE

The tip is permanently attached to the guard. Removing

the tip from the guard will result in damage to the tip

assembly.

14. Replace tip assembly.

15. If you used the Fine-Finish Optimizer, remove and

clean optimizer with water (or flushing fluid) and a

brush. Reconnect intake tube.

14 3A0153E

Page 15

Storage

Cleaning Sprayer Exterior

• Wipe paint off outside of sprayer using a soft cloth

moistened with water or flushing fluid.

Do NOT submerge the sprayer.

Tips

• Tips will require replacement depending on

abrasiveness of paint.

• Do not spray with worn tip. See Troubleshooting,

page 20.

Storage

3. Reverse spray tip to UNCLOG position, put

prime/relief valve DOWN to spray position, and aim

sprayer into waste area. Pull trigger for 1-2 seconds.

ti14991a

ti15425a

ti15418a

4. Properly dispose of used Pump Armor mixture from

material cup and rinse cup with water.

NOTICE

Failure to store with sprayer with Pump Armor will

result in operational problems the next time you spray.

Always circulate Pump Armor through the sprayer

after cleaning. Water left in the sprayer will corrode

and damage the pump.

1. Dilute 4 oz. bottle of Pump Armor Concentrate with

an additional 4 oz. of water in material cup.

4 oz

ti15442a

2. Thread cup into sprayer, put prime/relief valve to UP

position and squeeze sprayer trigger for approximately 10 seconds.

ti15001a

5. Store sprayer indoors in a cool, dry place. Store in

an upright position only.

ti15438a

NOTE: For prolonged battery life, lithium batteries

should be stored at half charge in an environment

below 90° F (32° C).

3A0153E 15

Page 16

Replacement Parts and Kits

1

Replacement Parts and Kits

19

20

22

5

6

21

13

13a

23

4

24

17

11

9

8

13

7

3

12

10

13a

16

14

18

15

2

Ref. Part Description

1 262367 Sprayer, replacement (no tip, battery, suction

tube, or material cup)

2 16D562 Liner, replacement (10 pack)

3 24F045 Fine Finish Optimizer (with Cleaning Tool)

2-Pack

4 243103 Pump Armor (32 oz.)

5 24F042 Storage Case

6 16D563 Repair Kit

(includes inlet/outlet valve wrench)

7 ProShot Tip/Guard Assembly

PST211 211

PST213 213

PST315 315

PST411 411 (included with sprayer)

PST413 413

PST515 515 (factory-installed on sprayer)

PST517 517

8Tip Filter

24E376 Kit, 1-pack

24F039 Kit, 3-pack

9 24F044 Specialized Suction Tube with screens and

o-rings (for spraying floors)

10 24F043 Standard Suction Tube with screens and o-rings

(for walls and ceilings)

11 16D558 Lithium Ion Premium Power Battery

16 3A0153E

Ref. Part Description

12 16E403 Sprayer Cup Seal

13 24D425 Cover with seal (included in 16 and 17)

13a 16C650 Material Cup Cover Seal (included in 16 and 17)

14 16D559 Lithium Ion Battery Charger (120 VAC)

16G615 Lithium Ion Battery Charger (240 VAC)

15 ▲24E609 Warning Labels Kit (ENG/FRA/SPA)

▲24H616 Warning Labels Kit (SPA/POR/ITA)

16 16D560 Material Cup (32 oz) cover and seal

17 16D561 Material Cup (48 oz) cover and seal

18 24E377 Shoulder Strap

106553 Suction Tube o-ring (not shown)

19 262602 Inlet Valve Kit

20 262437 Needle Assembly Kit

21 262601 Prime Valve Handle

22 262677 Enclosure, replacement, kit (Includes

enclosure with hook, screws, cup gasket, status

indicator lens, air filter, Made-In-USA label, and

access plug) product labels NOT included

23 16E119 Label, brand, ProShot

24 16E964 Label, brand, Hand Held

▲ Replacement Danger and Warning labels, tags, and cards are

available at no cost.

ti16473c

ti15497a

Page 17

ProShot Repair Kit

ProShot Repair Kit

Outlet Valve Fitting

NOTE: Before doing any repair to pump, perform

Flushing Sprayer procedure, page 13.

Removal

1. Engage trigger lock and pull relief valve UP to

release pressure.

ti14994a

ti14999a

4. Use tool (supplied) to loosen and remove outlet

valve fitting.

ti15506a

Installation

1. Screw outlet valve fitting into threads. Use tool (supplied) and tighten to 8 ft-lb.

2. Remove battery.

3. Remove pump outlet cap.

ti15508a

2. Press new pump outlet cap into place.

ti14996a

ti15507a

ti15503a

3A0153E 17

Page 18

Alternate Priming Method

Alternate Priming Method

1. Engage trigger lock and put prime/relief valve UP to

release pressure.

ti14994a

2. Remove material cup and fill with flushing material.

ti14999a

4. Hold sprayer above sink or waste area, disengage

the trigger lock, and quickly trigger sprayer until

material comes out of the drain tube.

ti14995a

ti14991a

NOTE: Material can shoot out of the drain tube

when performing this procedure. Be sure to wear

appropriate safety equipment and point drain tube

away from yourself when pulling the trigger,

5. Thread the material cup back onto sprayer.

3. With sprayer in prime mode, turn sprayer

upside-down, remove strainer and slowly pour flushing material into the intake tube until full.

6. Trigger the gun for 10 seconds then release the trigger and put the prime/relief valve DOWN to spray

position.

ti15425a

7. Reverse spray tip to UNCLOG position and spray

into waste area for five seconds to ensure sprayer

has primed.

ti14995a

8. Sprayer is now ready to spray. Follow Starting New

Job instructions on page 10.

18 3A0153E

Page 19

Alternate Priming Method

Inlet Valve Cleaning

Removal

1. Engage trigger lock and pull relief valve UP to

release pressure.

ti14994a

2. Remove material cup and suction tube.

3. Hold sprayer upside-down and use wrench or

socket to loosen and remove inlet fitting, inlet valve,

and spring.

ti14999a

Installation

NOTE: Before installing, make sure o-ring (c) is installed

on inlet valve (b).

1. Place inlet valve (b) with spring (a) on top of inlet fitting (d). Push inlet fitting up into pump cavity.

a

b

c

d

ti15502a

2. Hold inlet in place and turn sprayer upside-down.

Remove inlet fitting and visually check to see that

inlet valve has seated correctly.

ti15500a

3. Replace inlet fitting and use wrench and socket to

tighten to 10 ft-lb.

ti15505a

NOTICE

Do NOT over-tighten inlet fitting. Damage to the

NOTE: Make sure the spring also comes out. Use

equipment will occur.

needle-nose pliers to remove if needed. Inlet cavity

should be completely empty (as shown below).

4. Use the Fine-Finish Optimizer cleaning tool to lightly

push on inlet valve to make sure it moves up and

ti15530a

down freely.

ti15509a

4. Clean as much excess material from pump cavity as

possible. Make sure you also clean spring (a), o-ring

(c), and top of inlet fitting (d).

3A0153E 19

Page 20

Troubleshooting

Problem Cause Solution

Troubleshooting

Check everything in this Troubleshooting Table before

you bring the sprayer to an authorized service center.

ProShot makes no sound when

trigger is pulled

ProShot makes sound but no

material is sprayed when trigger is pulled

Trigger is locked. Disengage trigger lock. See page 6.

Status Indicator Light is solid RED

when triggering, indicating that the

battery charge is low or the battery is

too cold.

Status Indicator Light is flashing RED

when triggering, indicating that the

battery is too hot to operate.

Status Indicator Light does not light

when sprayer is triggered.

Sprayer is not primed. Prime the pump. See Starting a new Job (or

Prime/relief valve is in UP position. Pull valve DOWN to spray position.

Suction Tube is missing or improperly

installed.

Inlet valve is stuck from material

residue left in sprayer.

Tip is not in SPRAY position. Turn tip to SPRAY position.

Tip is clogged. See Unclogging Tip/Guard

Suction Tube screen is clogged or vent

holes in black rubber inlet seal are

clogged.

Sprayer has been tilted too far and

suction tube has lost contact with

material.

No or low material in cup. Refill cup with material.

Tip filter is clogged. Remove and clean tip filter. See Unclogging

Fine Finish Optimizer is installed while

using an incompatible material.

Suction Tube o-rings are damaged or

missing.

Pump is clogged, frozen, or has debris

inside.

Sprayer has reached maximum life. ProShot only: purchase repair kit.

Material is leaking from hole in front of

sprayer.

Replace with charged battery and place old battery in charger or allow battery to warm up.

Allow battery to cool.

Battery is not installed or is

damaged.

Refilling the Cup), page 10. If sprayer fails to

prime, follow the Inlet Valve Cleaning proce-

dure, page 19 and/or Alternate Priming

Method, page 18.

Make sure Suction Tube is properly installed.

Use a pencil or thin rod to lightly push on inlet

valve to make sure it moves up and down freely.

See Inlet Valve Cleaning, page 19.

Assembly, page 12.

See Shutdown and Cleaning, page 13.

Make sure cup is filled with material. Do not tilt

the cup too far. Prime the pump. See Starting a

new Job (or Refilling the Cup), page 10.

Tip/Guard Assembly, page 12.

Make sure compatible material is being used.

See Reversible Tip Selection Chart, page 11.

Replace Suction Tube and o-rings.

See ProShot Repair, page 17.

All other models should be replaced.

Replace sprayer.

20 3A0153E

Page 21

Troubleshooting

Problem Cause Solution

ProShot sprays with poor

Tip is partially clogged See Unclogging Tip/Guard Assembly, page

results

Tip is not in correct position Rotate tip to SPRAY position.

Incorrect tip for application of

material.

Tip filter is partially clogged Clean or replace filter. See page 12.

Suction Tube screen is partially

clogged.

Fine Finish Optimizer is partially

clogged.

Fine Finish Optimizer is installed while

using an incompatible material.

Tip is worn or damaged Replace tip. See Install Tip/Guard Assembly,

Inlet or Outlet Valves are worn. See ProShot Repair, page 17.

Paint leaks from sprayer trig-

Sprayer has reached its maximum life. Replace sprayer.

ger area.

Battery is discharged but

Damaged battery. Replace battery.

charger still displays green

light when battery is inserted.

Spray Pattern Diagnostics

12.

See Reversible Tip Selection Chart, page 11.

Clean or replace Suction Tube. See page 13.

Clean or replace Fine Finish Optimizer. See

page 9.

Make sure compatible material is being used.

See Reversible Tip Selection Chart, page 11.

page 11.

Problem Cause Solution

Spray pattern is pulsating:

ti15524a

Spray pattern has tails:

ti15526a

Spray pattern has dripping:

ti15522a

Fine Finish Optimizer is installed while using

an incompatible material.

Operator is moving too fast while spraying.

Fine Finish Optimizer is installed while using

an incompatible material.

Fine Finish Optimizer is partially clogged.

Material not compatible with sprayer.

Inlet or Outlet Valves are worn.

Sprayer is moving too slow for material.

Sprayer is too close to target surface.

Holding trigger while changing spray

direction.

Incorrect tip for application of

material.

Tip is worn or damaged.

Make sure material is compatible. See

Reversible Tip Selection Chart, page 11.

Slow speed of movement.

Make sure compatible material is being used.

See Reversible Tip Selection Chart, page

11.

Clean or replace Fine Finish Optimizer.

See page 9.

Switch material.

See ProShot Repair, page 17.

Move sprayer faster while spraying.

Move sprayer away from surface (10 in).

Release trigger when changing directions.

See Reversible Tip Selection Chart, page

11.

Replace tip. See Install Tip/Guard Assembly,

page 11.

3A0153E 21

Page 22

Problem Cause Solution

Spray pattern is too narrow:

ti15523a

Spray pattern is too wide:

Sprayer is too close to target surface.

Incorrect tip for application of material.

Tip is worn or damaged.

Sprayer is too far away from target surface.

Incorrect tip for application of material.

Troubleshooting

Move sprayer away from surface (10 in).

See Reversible Tip Selection Chart, page

11.

Replace tip. See Install Tip/Guard Assembly,

page 11.

Move sprayer closer to surface.

See Reversible Tip Selection Chart, page

11.

Spray pattern “spits” at the

end:

ti15525a

Tip continues to drip or ooze

material after trigger is

released:

ti15528a

Spray pattern does not

adequately cover target

surface

Excess material has accumulated on Spray

Tip/Guard Assembly.

Tip filter is partially clogged.

Tip/Guard Assembly not threaded completely onto sprayer.

Seat is worn.

ProShot sprayer is worn out. Replace sprayer.

Fine Finish Optimizer is installed while using

an incompatible material.

ProShot sprayer is worn out.

See Shutdown and Cleaning, page 13.

Clean or replace filter. See page 12.

See Install Tip/Guard Assembly, page 11.

Replace Spray tip.

Make sure compatible material is being used.

See Reversible Tip Selection Chart, page

11.

Replace sprayer.

22 3A0153E

Page 23

Technical Data

Technical Data

Sprayer:

Maximum working pressure 2000 psi (137.8 bar, 13.7 MPa)

Weight 6.32 lb (2.87 kg)

Dimensions:

Length 13.25 in. (33.6 cm)

Width 5.0 in. (12.7 cm)

Height 10.375 in. (26.4 cm)

Storage temperature range ◆❖ 32° to 122°F (0° to 50°C)

Operating temperature range ✔ 40° to 90° F (4° to 32°C)

Storage Humidity Range 0% to 95% relative humidity, non-condensing

Sound Pressure Level 79.5 dBa† (for sound power level, add 11 dBa)

Vibration Level Acceleration

Charger:

Charging Time 45 - 75 minutes

Power Source 120 VAC 240 VAC

Battery:

Voltage 18 VDC, Lithium Ion

Capacity 2.4 Ah, 43.2 Wh

258865 258859

Less than 8.2 feet/s

2

2.5 m/s2††

Pump damage will occur if fluid freezes in pump.

◆

Damage to plastic parts may result if impact occurs in low temperature conditions.

❖

Changes in paint viscosity at very low or very high temperatures can affect sprayer performance.

✔

per ISO 3744 measured at 3.1 feet (1m)

†

per ISO 5349, no load condition

††

3A0153E 23

Page 24

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6926 or Toll Free: 1-800-690-2894 Fax: 612-623-6893 Toll Free Fa x : 1-800-334-6955

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2011, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A0153

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised 11/2011

Loading...

Loading...