Page 1

Repair

™

GH

Korean patent: 10-0647761

4000 psi (27.6 MPa, 275.8 bar) Maximum Working Pressure

Model: 249318, 249617, 253471, 253472

833 Sprayers

- Use with Architectural Coatings, Paints, Roof Coatings

and Below Grade Coatings -

Important Safety Instructions. Read all

warnings and instructions in this manual. Save

these instructions.

311283D

ENG

Related Manuals

311279

311484

311485

311254

ti7107b

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2006, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Warning

Warning

The following are general warning related to the safe setup, use, grounding, maintenance and repair of this equipment.

Additional, more specific warnings may be found throughout the body of this manual where applicable. Symbols appearing in the body of the manual refer to these general warnings. When these symbols appear throughout the manual, refer back to these pages for a description of the specific hazard.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable

and can ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

RECOIL HAZARD

Brace yourself; gun may recoil when triggered and cause you to fall, which could cause serious injury.

2 311283D

Page 3

Warning

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine Manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

SUCTION HAZARD

Never place hands near the pump fluid inlet when pump is operating or pressurized. Powerful suction

could cause serious injury.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon

monoxide can cause death. Do not operate in an enclosed area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

311283D 3

Page 4

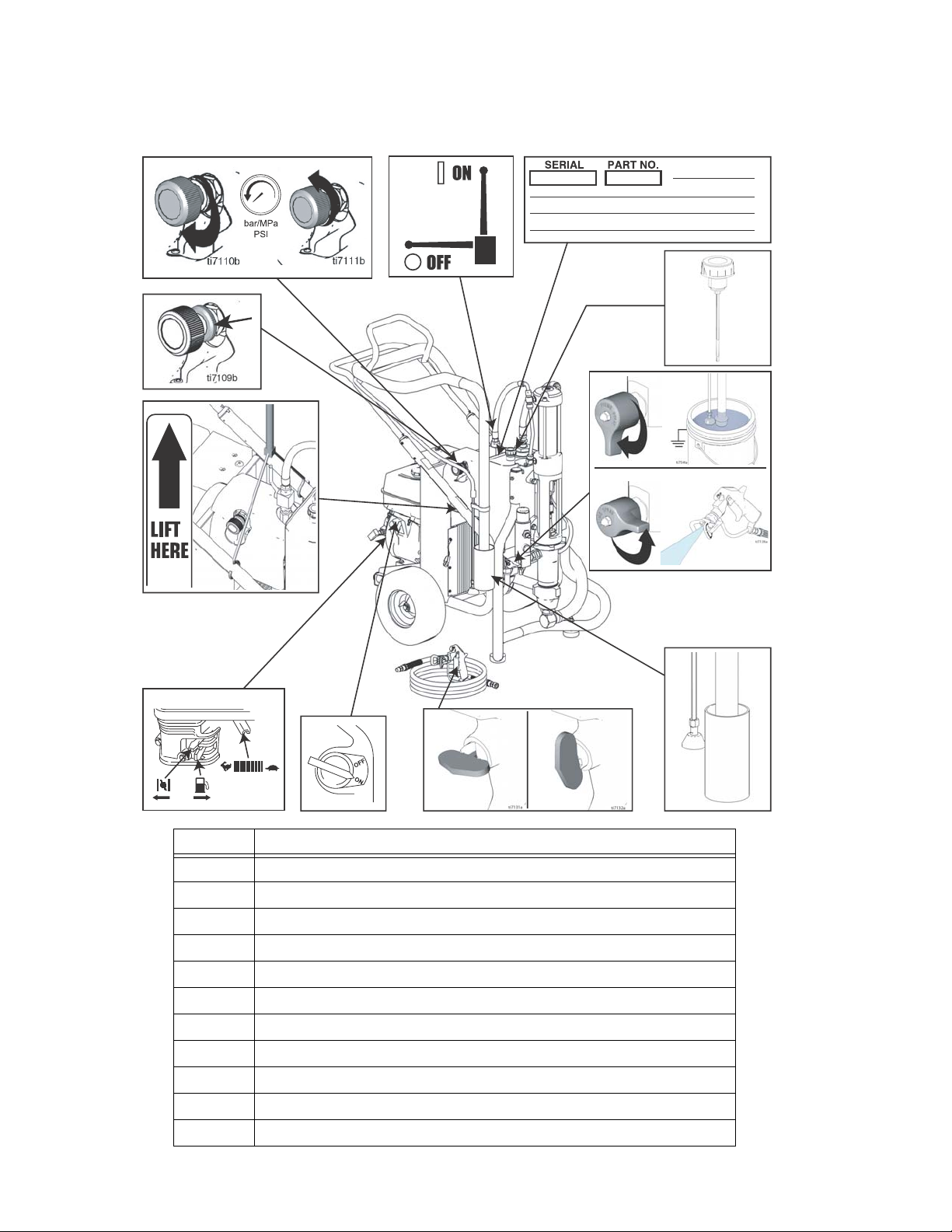

Component Identification

,

2

3

9

1

Component Identification

8

11

4

6

5

Ref Description

1 Hydraulic pump valve

2 Pressure control

3 Lock ring

4 Drain valve

5 Engine ON/OFF switch

6 Engine controls

7 Trigger lock

8 Serial number ID label

9 Lift locations

7

ti7107b

ti7133

10

ti7133b

10 Suction holder

11 Hydraulic oil fill

4 311283D

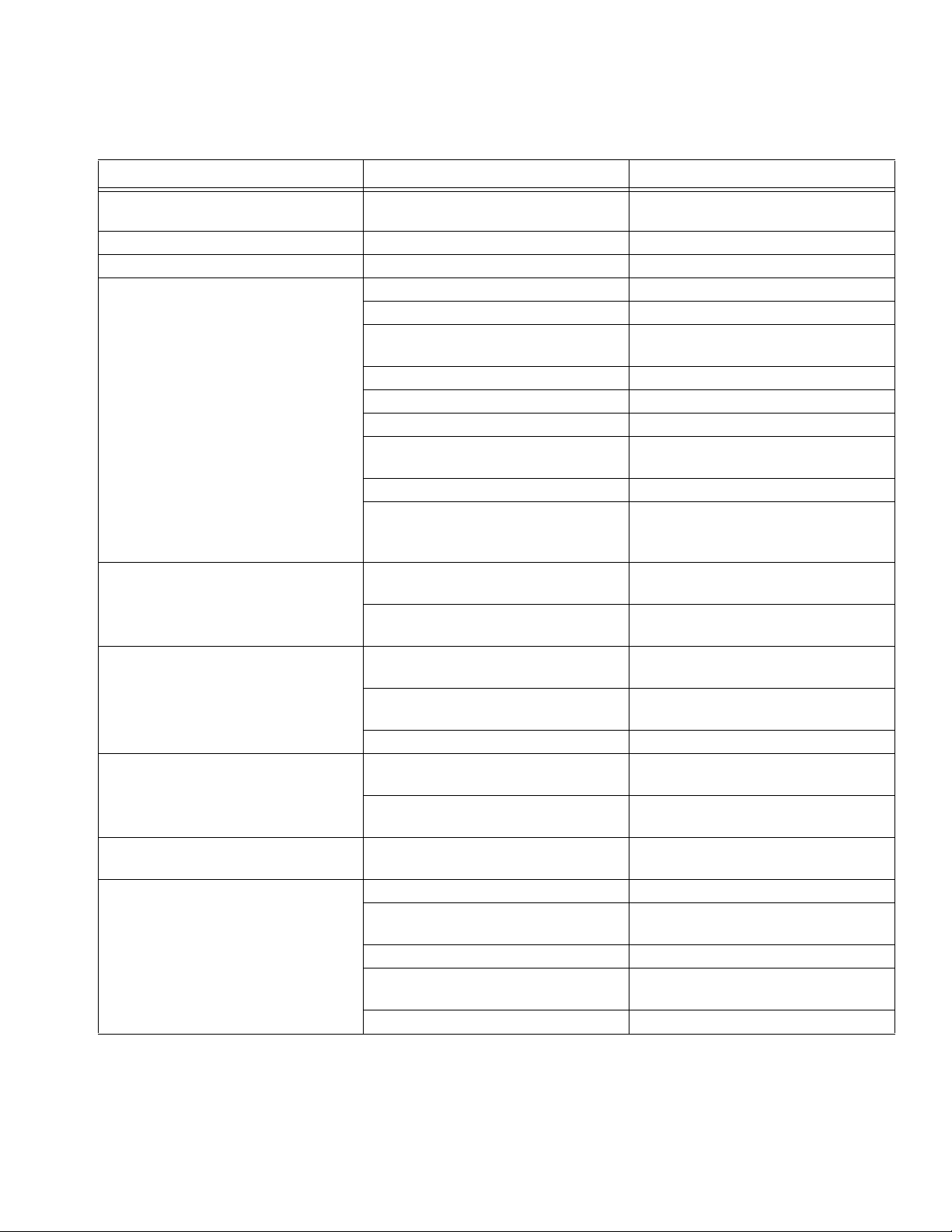

Page 5

Operation

Operation

Pressure Relief Procedure

System pressure must be manually relieved to prevent

it from starting or spraying accidentally. Fluid under

high pressure can be injected into the skin and cause

serious injury. To reduce risk of injury from injection,

follow this procedure whenever you are instructed to

relieve pressure, stop spraying, service equipment or

install or clean spray tip. Read warnings, page 4.

1 Set pump valve OFF. Turn engine OFF.

TIA

2 Turn pressure to lowest setting. Trigger gun into pail to

relieve pressure.

General Repair Information

• Hydraulic system and engine may become very

hot during operation and could burn skin if

touched. Flammable materials spilled on hot, bare

motor could cause fire or explosion. Have belt

guard in place during operation to reduce risk of

pinching or loss of fingers.

• Install belt guard before operation of sprayer and

replace if damaged. Belt guard reduces risk of

pinching and loss of fingers.

To reduce risk of serious injury,:

• Keep all screws, nuts, washers, etc. removed during

repair procedures. These parts usually are not provided with replacement kits.

• Test repairs after problems are corrected.

• If sprayer does not operate properly, review repair

procedure to verify you did it correctly. See Trouble-

shooting, page 7.

• Do not touch moving parts with fingers or tools while

testing repair.

3 Open prime valve (vertical).

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved after

following the steps above, VERY SLOWLY, loosen tip

guard retaining nut or hose end coupling to relieve pressure gradually, then loosen completely. Then clean tip

and hose.

311283D 5

Grounding

Ground sprayer with grounding clamp to earth ground

for safe sprayer operation.

Page 6

Maintenance

Maintenance

Spark Plug:

• Use BPR6ES (NGK) or W20EPR-U (NIPPONDENSO) plug, only.

For detailed engine maintenance and

specifications, refer to separate Honda

Engines Owner’s Manual, supplied.

Frequency Procedure

Daily Check engine oil level and fill as necessary.

Daily Check hydraulic oil level and fill as necessary.

Daily Check hose for wear and damage.

Daily Check gun safety for proper operation.

Daily Check pressure drain valve for proper operation.

Daily Check and fill gas tank.

Daily Check that displacement pump is tight.

Daily Check level of TSL in displacement pump packing nut. Fill nut, if neces-

sary. Keep TSL in nut to help prevent fluid build up on piston rod and

premature wear of packings and pump corrosion.

After first 20 hours

of operation

Weekly Remove engine air filter cover and clean element. Replace element, if

Drain engine oil and refill with clean oil. Reference Honda Engines

Owner’s Manual for correct oil viscosity.

necessary. If operating in an unusually dusty environment; check filter

daily and replace, if necessary.

• Gap plug to 0.028 to 0.031 in. (0.7 to 0.8 mm).

• Use spark plug wrench when installing and removing plug.

Replacement elements can be purchased from your local Honda dealer.

Weekly/Daily Remove and debris or media from hydraulic rod.

After each 100

hours of operation

Semi-annually Check belt wear; replace if necessary.

Yearly or 2000

hours

6 311283D

Change engine oil. Reference Honda Engines Owner’s Manual for cor-

rect oil viscosity.

Replace hydraulic oil and filter element with Graco ISO 46 Hydraulic Oil

169236; 5 gallon/20 liter or 207428; 1 gallon/3.8 liter) and filter element

287871.

Page 7

Troubleshooting

Troubleshooting

PROBLEM CAUSE SOLUTION

Gas engine pulls hard (won't start) Hydraulic pressure is too high Turn hydraulic pressure knob coun-

terclockwise to lowest setting

Gas engine does not start Switch OFF, low oil, no gasoline Consult engine manual, supplied

Gas engine doesn't work properly Faulty engine Consult engine manual, supplied

Gas engine operates, but displace-

ment pump doesn't operate

Displacement pump operates, but

output is low on upstroke

Displacement pump operates but

output is low on downstroke and/or

on both strokes

Paint leaks and runs over side of wetcup

Excessive leakage around hydraulic

motor piston rod wiper

Fluid delivery is low Pressure setting too low Increase pressure

Pump valve is OFF Set pump valve ON

Pressure setting too low Increase pressure

Displacement pump outlet filter (if

used) is dirty or clogged

Tip or tip filter (if used) is clogged Remove tip and/or filter and clean

Hydraulic fluid too low Shut off sprayer. Add fluid*.

Belt worn, broken or off Replace belt.

Hydraulic pump worn or damaged Bring sprayer to Graco distributor for

Dried paint seized paint pump rod Service pump. See manual 311485

Hydraulic motor not shifting Set pump valve OFF. Turn pressure

Piston ball check not seating properly Service piston ball check. See man-

Piston packings worn or damaged Replace packings. See manual

Piston packings worn or damaged Tighten packing nut or replace pack-

Intake valve ball check not seating

properly

Suction tube air leak

Loose wet-cup Tighten wet-cup enough to stop leak-

Throat packings worn or damaged Replace packings. See manual

Piston rod seal worn or damaged Replace these parts.

Displacement pump outlet filter (if

used) is dirty or clogged

Intake line to pump inlet is not tight Tighten

Hydraulic motor is worn or damaged Bring sprayer to Graco distributor for

Large pressure drop in fluid hose Use larger diameter or shorter hose

Clean the filter

repair

down. Turn engine OFF. Pry rod up or

down until hydraulic motor shifts.

ual 311485

311485

ings. See manual 311485

Service intake valve ball check. See

manual 311485

age

311485

Clean filter

repair

311283D 7

Page 8

Troubleshooting

PROBLEM CAUSE SOLUTION

The sprayer overheats Paint buildup on hydraulic compo-

Clean

nents

Oil level is low Fill with oil.

Spitting from gun Air in fluid pump or hose Check for loose connections on

siphon assembly, tighten, then rep-

rime pump.

Loose intake suction Tighten.

Fluid supply is low or empty Refill supply container.

Excessive hydraulic pump noise Low hydraulic fluid level Turn sprayer OFF. Add fluid*.

*Check hydraulic fluid level often. Do not allow it to become too low. Use only Graco approved hydraulic fluid, page 6.

8 311283D

Page 9

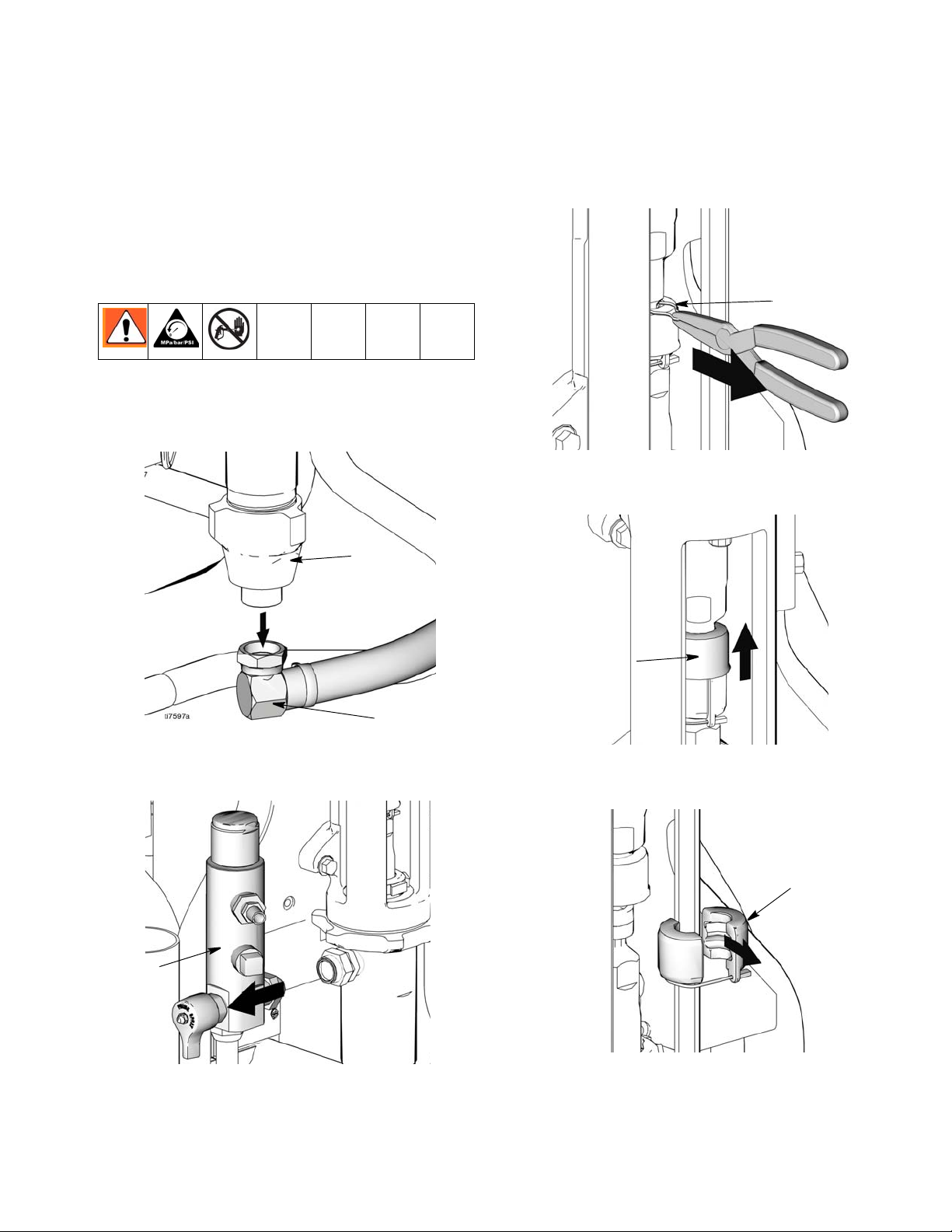

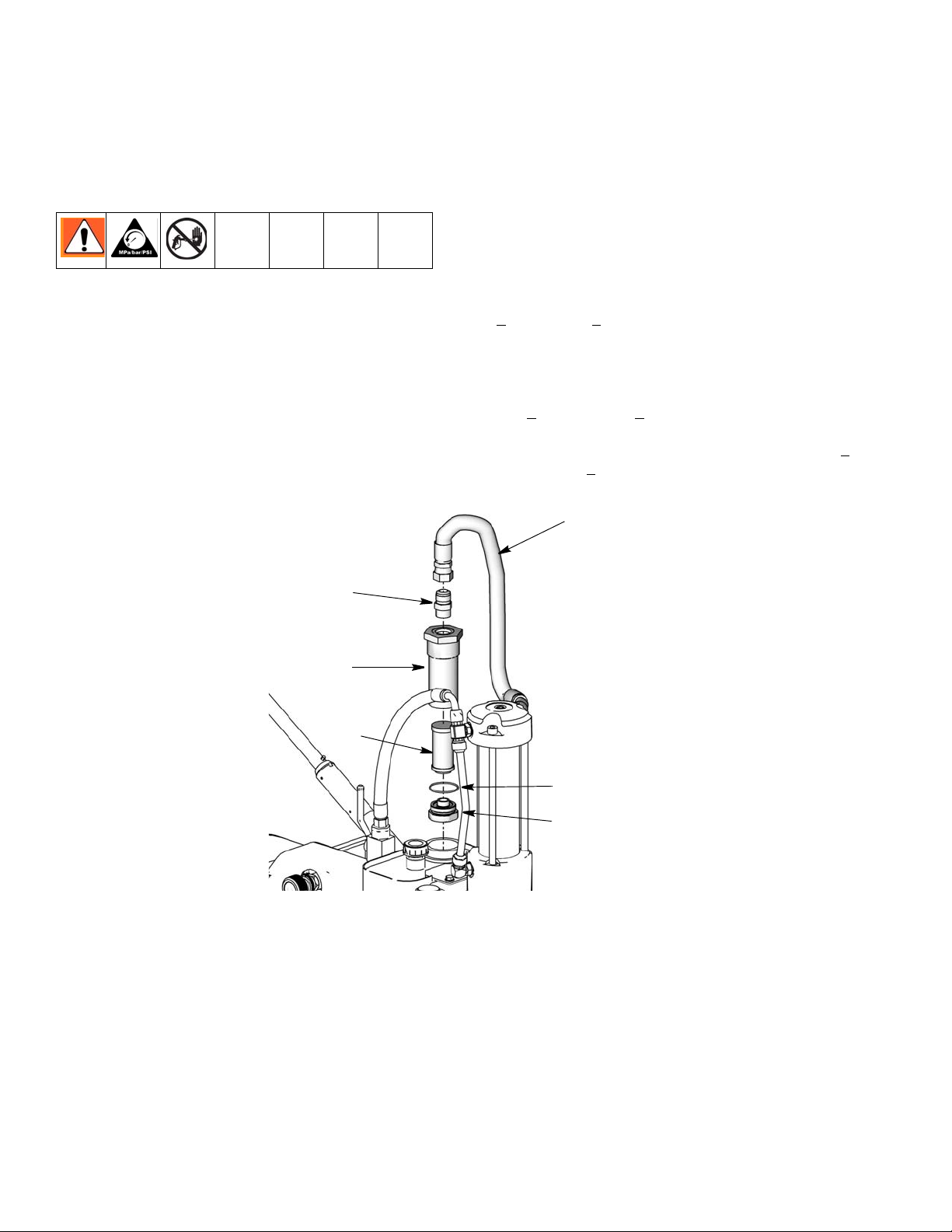

Displacement Pump Replacement

Displacement Pump Replacement

See manual 311485 for pump repair instructions.

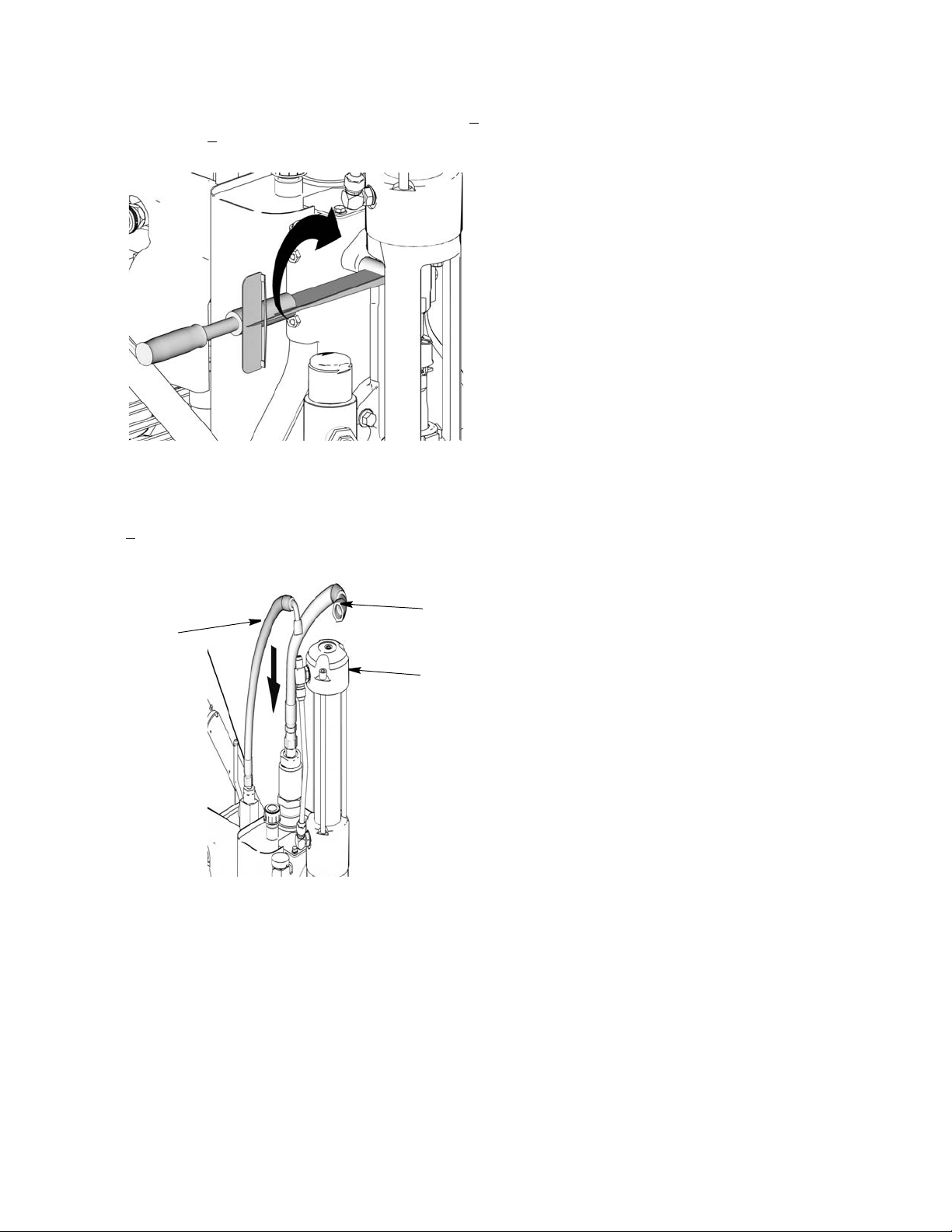

Removal

1. Flush pump (36). Stop pump on down stroke if

possible.

2. Relieve pressure, page 5.

3. Remove suction set (147) from pump (36).

36

5. Remove clip (121).

121

ti7789

6. Slide cover up (124).

4. Remove filter housing (110), page 15.

110

147

ti7119

124

ti7816

7. Separate coupling (125) and remove.

125

ti7814

311283D 9

Page 10

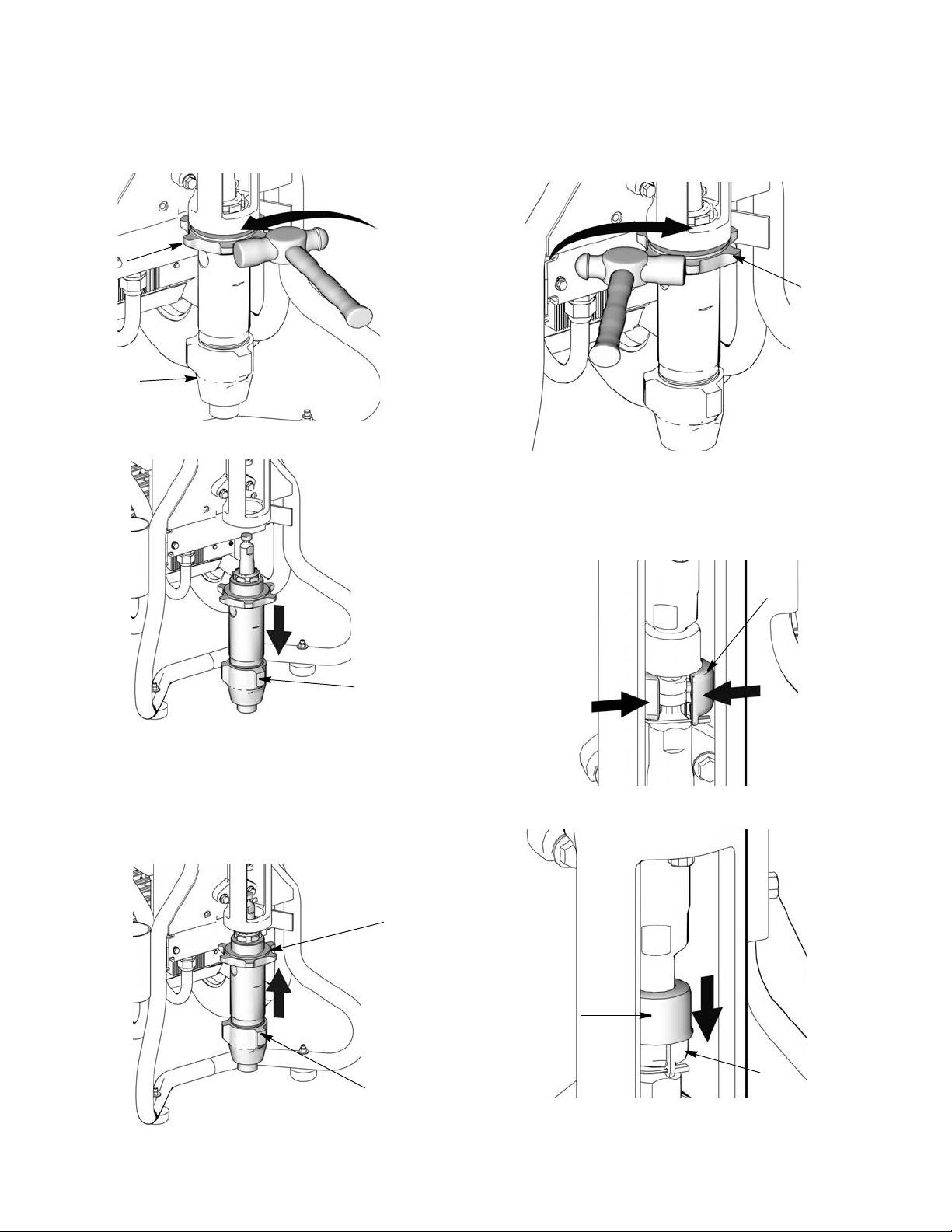

Displacement Pump Replacement

8. Loosen jam nut (122) with a hammer. Unscrew

pump (36) from power head.

122

36

ti7782

9. Remove pump (36).

3. Hand tighten jam nut (122). Then tighten securely

1/8 to 1/4 turn with hammer or torque to 330 ft-lb

(447.4 N•m).

122

ti7817

4. Slide cover (124) up over pump rod. With engine in

OFF position, pull recoil starter to move rod until it

contacts pump rod.

5. Install coupling (125) around pump rod.

36

ti7804

Installation

1. Screw jam nut (122) to bottom of pump threads (36).

2. Slide cover (124) up over pump rod. Screw pump

completely up into power head.

122

125

ti7771

6. Slide cover (124) over coupling (125).

124

ti7815

36

ti7779

10 311283D

125

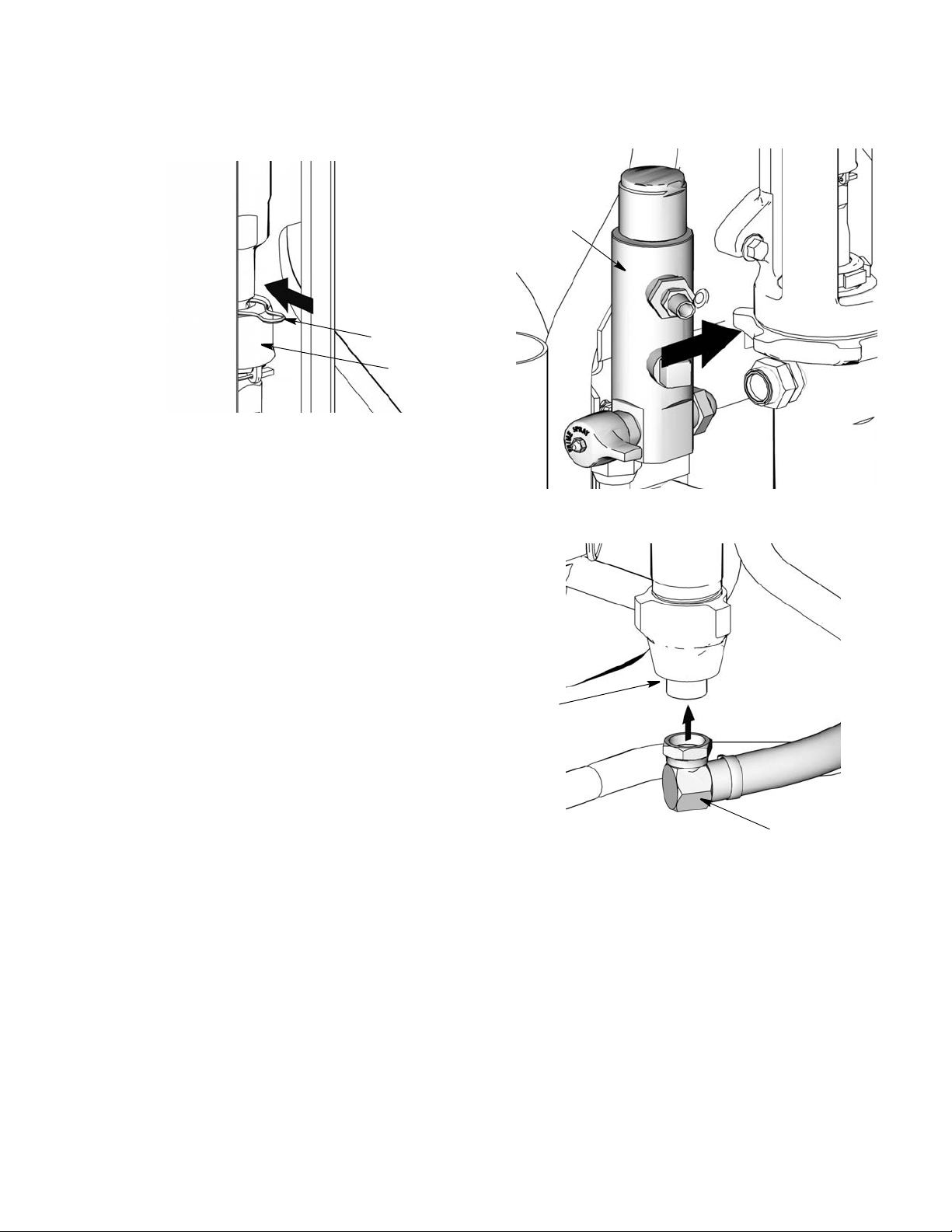

Page 11

Displacement Pump Replacement

7. Install clip pin (121) to secure. 8. Install filter housing (110), page 15.

110

121

125

ti7809

ti7772

9. Connect suction hose (147) to pump outlet (36).

36

147

311283D 11

Page 12

Pump Power Head Replacement

Pump Power Head Replacement

Removal

1. Relieve pressure, page 5.

2. Remove hydraulic lines (100, 101) from head (75).

100 101

75

4. Remove power head from unit.

ti7847

Installation

1. Install power head on unit.

ti7803

3. Loosen (4) mounting bolts (7) on the adapter

enough to lift and remove assembly.

7

ti7841

ti7851

12 311283D

Page 13

2. Tighten power head bolts (7). Torque bolts to 400 +

10 in-lb (45 +

1 N•m).

ti7853

Pump Power Head Replacement

3. Attach hoses (100, 101) to head (75). Torque to 450

+

10 in-lb (50.84 N•m).

101

100

75

ti7777

4. To purge air from hydraulic lines, increase pressure

enough to start hydraulic motor stroking and allow

fluid to circulate for 15 seconds.Turn pressure

down. Turn prime valve horizontal (closed).

311283D 13

Page 14

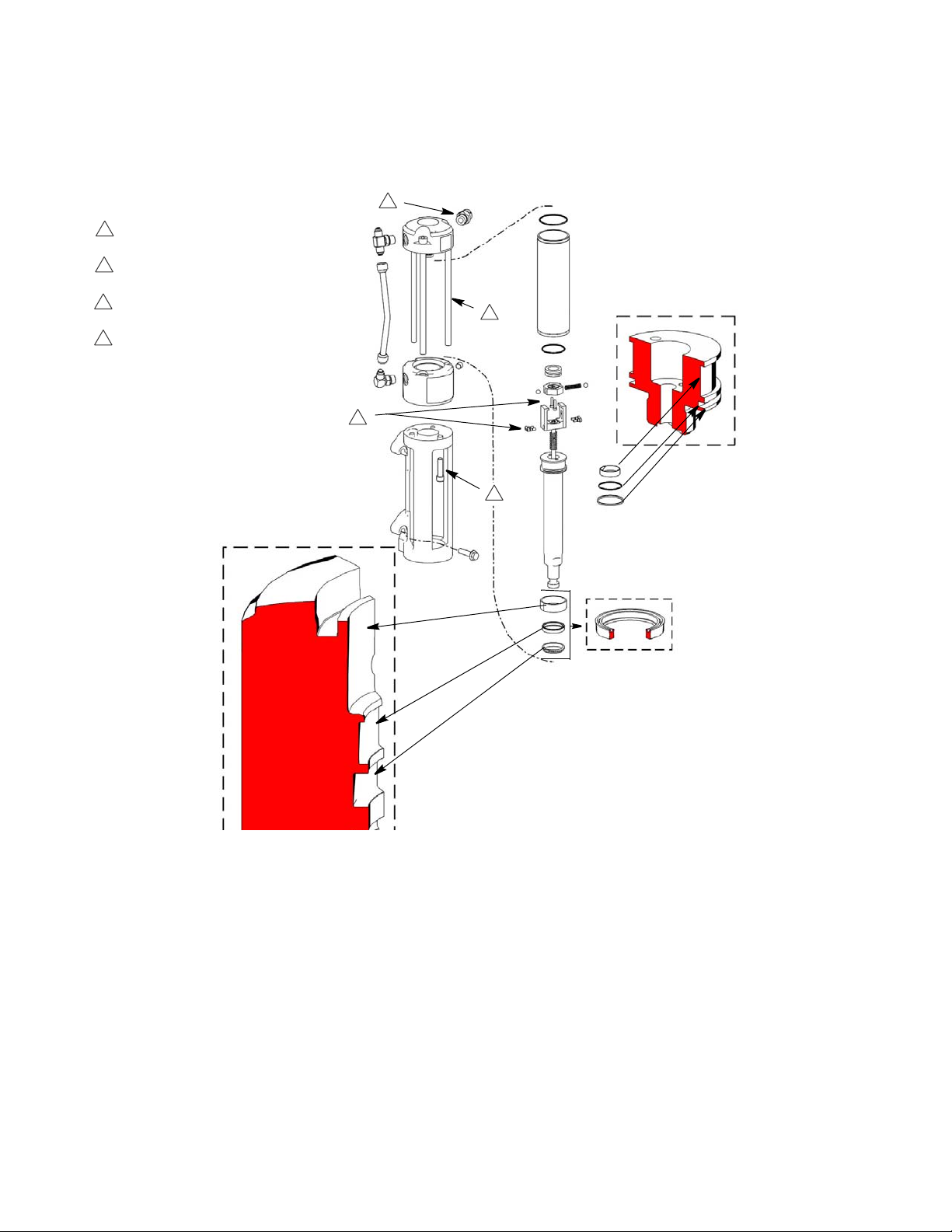

Hydraulic Motor

1

450 in-lb (51 N.m)

2

600 in-lb (68 N.m)

3

60 in-lb (7 N.m)

4

930 in-lb (105 N.m)

Torqued in 3 steps

Hydraulic Motor

2

4

3

1

ti7868

14 311283D

Page 15

Filter Housing Replacement

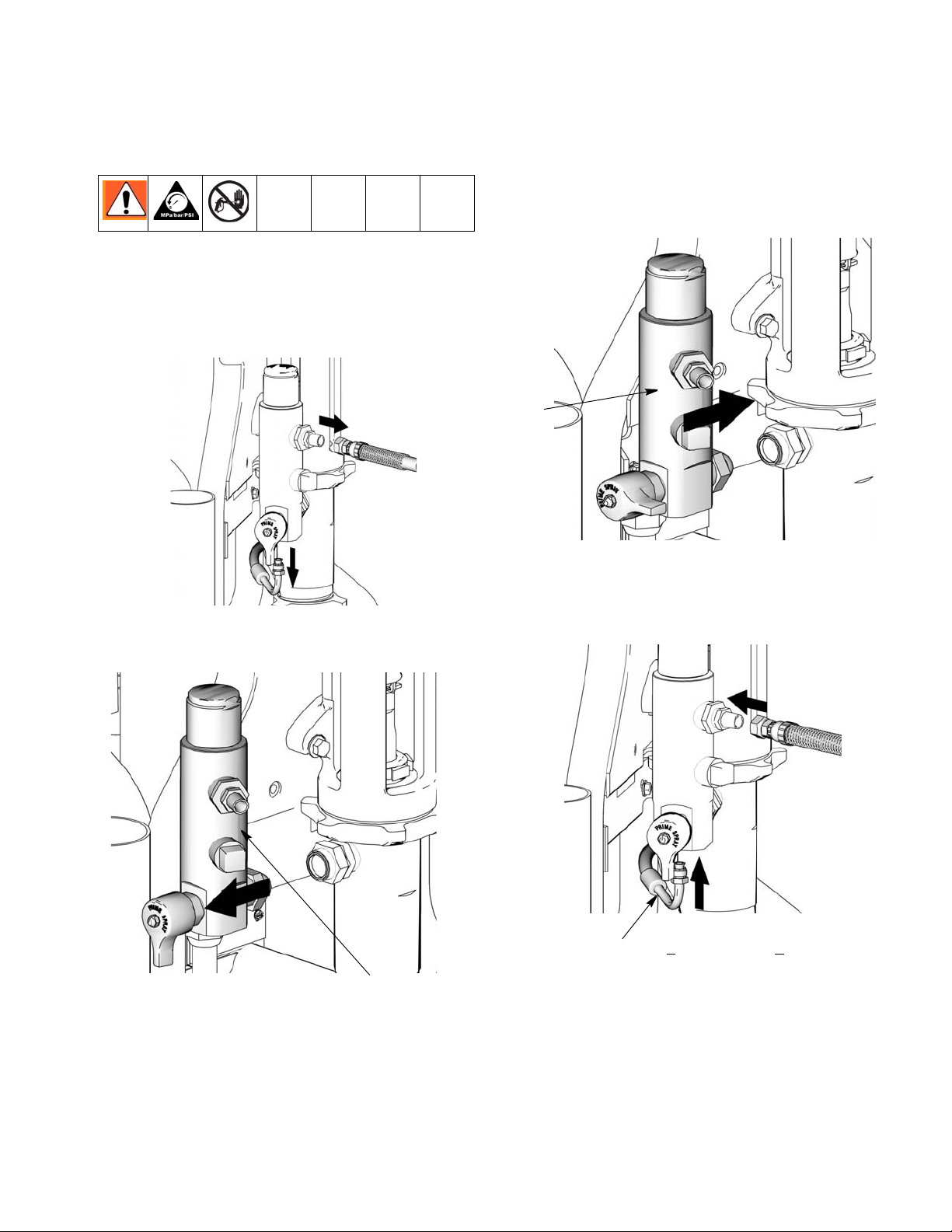

Removal

1. Relieve pressure, page 5.

2. Remove paint and drain lines from filter housing.

Filter Housing Replacement

Installation

1. Install filter housing (110) in pump opening.

110

ti7772

ti7845

3. Loosen filter housing fitting (110) until housing and

remove housing from pump.

ti7119

110

2. Tighten fitting.

3. Attach paint and drain lines.

ti7850

Torque to 225 + 10 in-lb. (25.4+ 1.1 N.m)

311283D 15

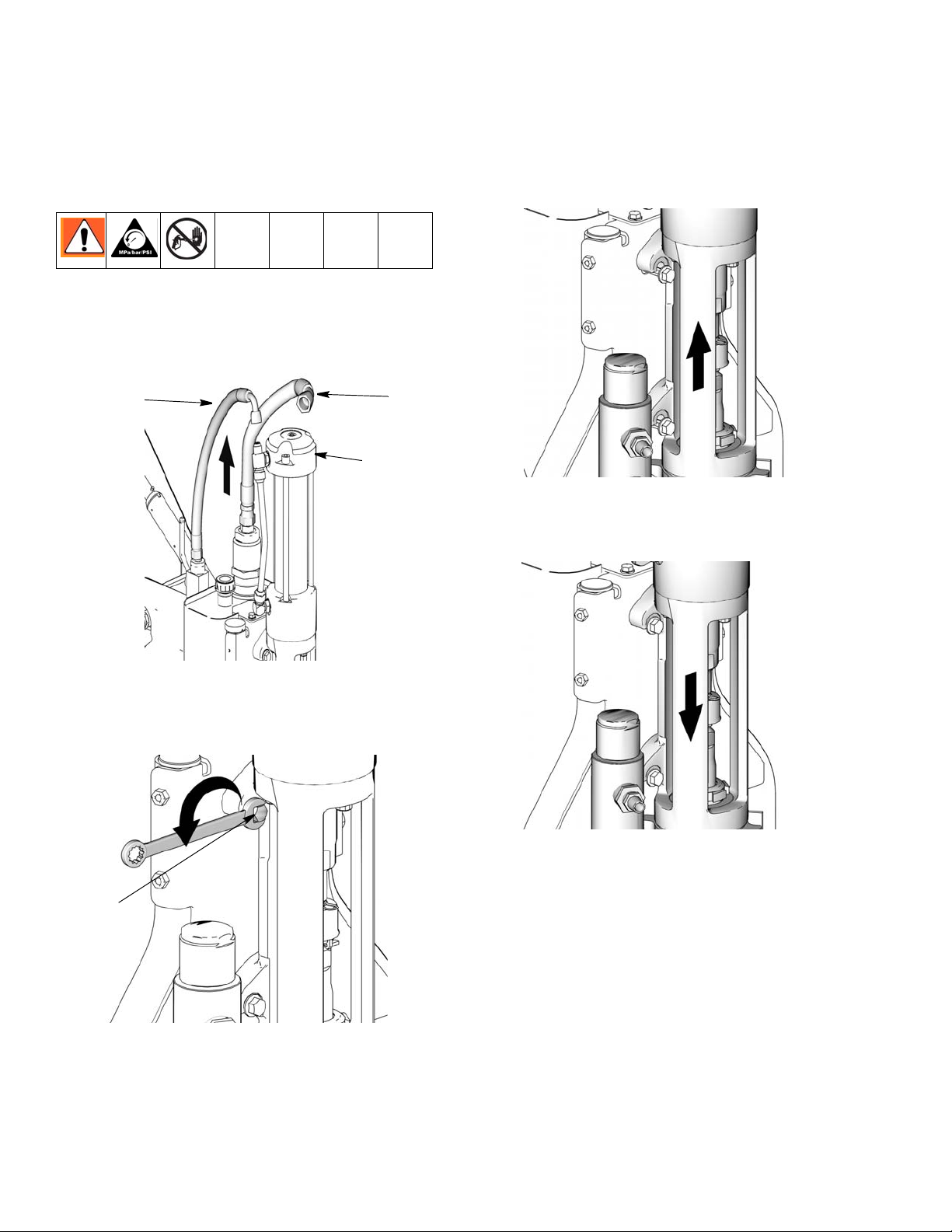

Page 16

Hydraulic Pump Replacement

Hydraulic Pump Replacement

Changing Hydraulic Oil

Draining Oil

a. Place drain pan under oil tank and drain plug.

b. Unscrew reservoir (64) drain plug and drain oil

from reservoir.

drain

plug

3. Remove screw (197) and pump handle cover (196).

Remove four cover bolts (79) and cover (140). (It is

not necessary to remove the hydraulic lines before

removing cover. The cover is designed to provide

ample room for the cover to fit over the hose.)

196

197

79

140

ti7805b

4. Unscrew suction line connections to hydraulic

pump. Place a container under hoses to catch any

dripping oil.

ti7784

Refilling Oil

a. Replace drain plug.

b. Fill tank with Graco Hydraulic Oil, ISO 46. Tank

holds approximately 4 gallons.

Removal

1. Relieve pressure, page 5. Allow hydraulic system

to cool before beginning the service procedure.

2. Drain oil, Changing Hydraulic Oil procedure,

page 16.

ti7790

ti7801

16 311283D

Page 17

Hydraulic Pump Replacement

5. Remove (4) belt cover screws (79), washers (78)

and grommets (80) (2 each side).

80

78

79

67

ti7796

6. Remove belt cover (67).

67

7. Remove belt (19), page 20.

8. Loosen set-screws (87) on front of large pulley (4).

4

87

ti7783

9. Remove pulley (4) from hydraulic pump shaft.

ti7795

4

ti7807

10. Remove nuts (10) and screws (9) holding pump to

frame.

9

10

ti7788

311283D 17

Page 18

Hydraulic Pump Replacement

11. Remove hydraulic pump (3).

3

ti7800

12. Remove fittings (30, 34, 35) from pump (3) and set

aside to use on the new pump.

34

(

3

35

2. Install new pump (3) in frame.

3. Install screws (9) and nuts (10). Torque to 225 +

in-lb (25.42 N.m).

9

10

ti7778

4. Replace large pulley (4) on hydraulic pump shaft.

10

3

30

ti7816

Installation

1. Install fittings (30, 34, 35) from old pump on new

pump. Torque fitting 30 and 35 to 600 +

(67.8 N.m). Torque fitting 34 to 450 in-lb (50.8 N.m).

34

10 in-lb

3

35

4

ti7813

5. Align pulley (4) on shaft. When properly positioned

approximately 1/8 inch of shaft (139) will protrude.

1/8 inch

30

ti7816

139

4

NOTE: Fill pump casing with hyraulic oil before installing

fitting (34).

ti7835

18 311283D

Page 19

Hydraulic Pump Replacement

6. Replace set-screws (87). Tighten and torque to 60 +

2 in-lb (6.8 +

0.2 N•m).

NOTE: Tighten set-screw on shaft before tightening

set-screw on pump shaft.

7. Position belt (19) over pulleys (4, 6); Installing Belt,

page 20.

8. Replace belt cover (67) and grommets (80), washers (78) and screws (79), (2 each side). Torque

screws to 25-30 in-lb (2.8 -3.4 N•m).

67

80

9. Install suction lines. Tighten fittings. Torque fitting A

to 225 +

+

10 in-lb (50.1 + 1.1. N.m). Fitting C to 225 in-lb

10 in-lb (25.4 + 1.1 N.m). Fitting B to 450

(25.4 N.m).

A

B

ti7767

C

ti7889

10. Install cover (140) and with four screws (79). Torque

to 25-30 in-lb (2.8 - 3.4 N•m). Install pump handle

cover (196) with screw (197).

ti7810

ti7812

79

78

197 196

79

140

ti7111b

11. Fill oil tank following Refilling Oil procedure on

page 16.

311283D 19

Page 20

Hydraulic Pump Replacement

Belt Removal and Replacement

(recommended method)

Removing Belt

a. Place a ziptie around belt (19).

19

ziptie

ti7843

Moving parts can pinch or amputate fingers and other

body parts. To avoid serious injury be sure engine is in

OFF position before pulling engine recoil.

b. Slowly pull ziptie toward you while at the same

time slowly pulling engine recoil to rotate pulleys. It may be necessary to reposition zip tie

and repeat this procedure a few times to completely remove belt from pulley.

Installing Belt

a. Put belt over lower pulley (6) and align correctly.

b. Line up belt over top left side of large pulley (4).

ti7869

c. With the palm of your hand, hold the belt snug

to large pulley while at the same time slowly pull

engine recoil to rotate pulleys.

d. Check belt (19) alignment on both large (4) and

small pulley (6). When properly positioned over

pulleys, belt is centered on pulleys and completely over all grooves.

ti7842

ti7834

Properly Aligned

Not Aligned Properly

NOTE: If belt is not aligned properly, to adjust belt, slowly

ti7837

pull engine recoil while at the same time pushing or pulling belt to reposition over pulley.

20 311283D

Page 21

Hydraulic Pump Replacement

Alternate Belt Removal and Installation

Removing Belt

a. Loosen engine bolts (21) to relieve tension on

belt.

b. Slide belt off pulleys.

Installing Belt

a. Install belt (19) over small (6) and large (4)

pulleys.

b. Tighten engine bolts (21). Torque to 225 +

in-lb (25.4 +

1.1 N.m).

10

c. Check belt (19) alignment on both large (4) and

small pulley (6). When properly positioned over

pulleys, belt should be centered on pulleys and

completely over all grooves.

ti7834

Properly Aligned

Not Aligned Properly

ti7837

21

NOTE: If belt is not aligned properly, to adjust belt, slowly

pull engine recoil while at the same time pushing or pulling belt to reposition over pulley.

4

19

6

ti7870

311283D 21

Page 22

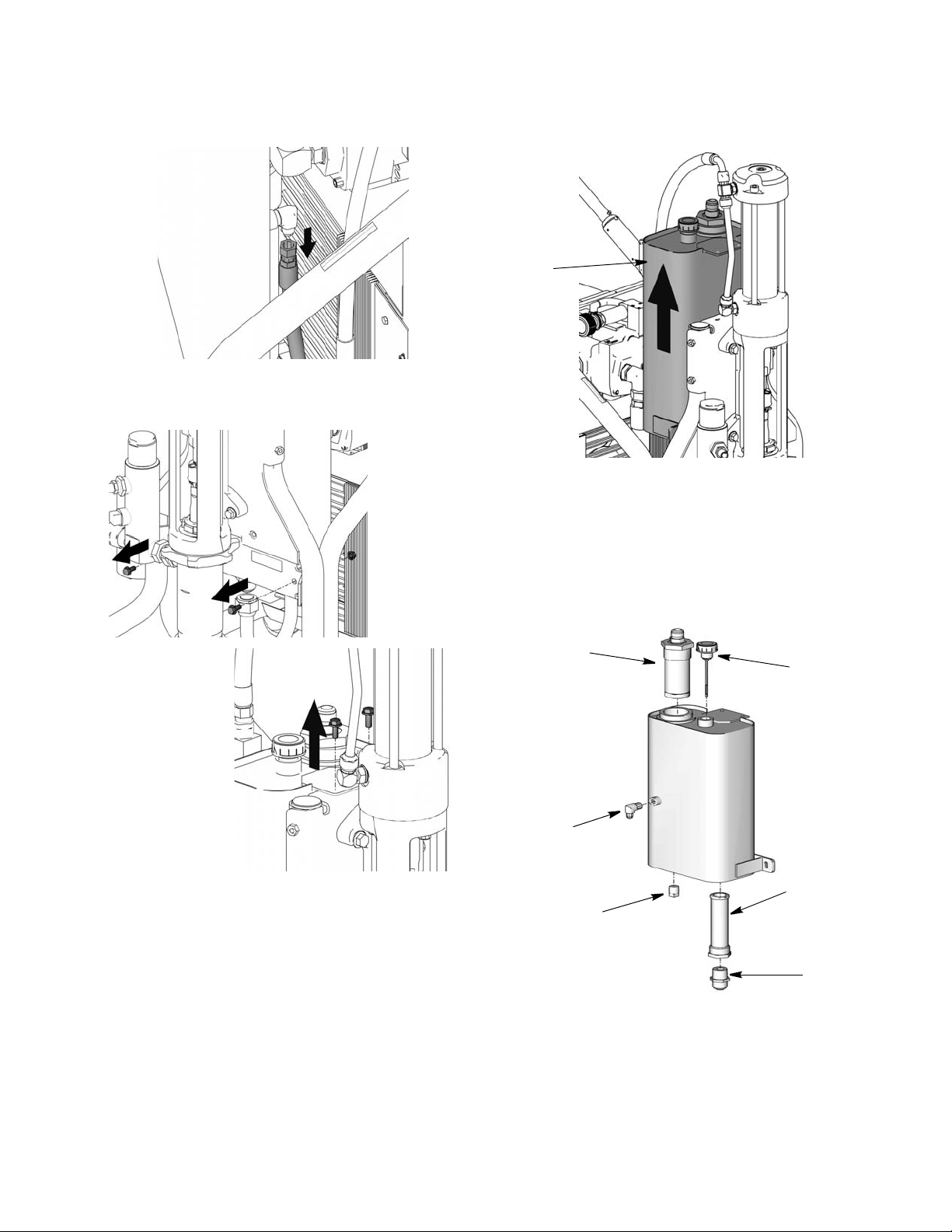

Replacing Oil Reservoir

Removal

1. Relieve pressure, page 5.

Hydraulic Pump Replacement

4. Loosen and remove suction hose (153).

2. Drain oil from reservoir (64) following Draining Oil

procedure, page 16. Keep plug for use on new reservoir.

Drain Plug

ti 7784

3. Remove fill cap (27) and filter assembly (111). Keep

for use on new reservoir.

32

153

ti7785

5. Remove and keep suction fitting (32) for use on new

reservoir.

6. Loosen and remove return lines (100, 101).

100

101

111

27

ti7785

ti7803

7. Remove cooler line from reservoir (64).

22 311283D

Page 23

ti7791

8. Remove (2) top bolts (86) and 2 bottom nuts (84)

securing reservoir (64) to frame.

Hydraulic Pump Replacement

9. Lift reservoir (64) out of frame.

64

ti7806

ti7786

Installation

1. Install plug (102), return elbow (31), suction fitting

(32), inlet screen (89) and filter assembly (111) in

new reservoir (64).

ti7846

111

27

31

89

102

32

311283D 23

Page 24

Hydraulic Pump Replacement

2. Install new reservoir (64) in frame.

64

ti7781

3. Replace bolts (86) and nuts (84). Tighten bolts.

Torque to 125 +

10 in-lb 14 + 1.1 N•m).

4. Connect coolant line to reservoir (64). Torque to 225

in-lb (14.1 N.m).

5. Reattach return lines (100, 101). Torque to 450 +

in-lb (51 +

6. Reattach suction hose (153). Toque to 600 +

in-lb (68 +

1.1 N•m).

100

1.1 N•m).

101

ti7777

10

10

ti7766

153

ti7785

24 311283D

Page 25

7. Verify drain plug has been replaced. Fill oil reservoir

with oil to high mark on dip stick (approximately 3.5

gallons).

ti7784

Drain Plug

Hydraulic Pump Replacement

8. Replace cap (27).

27

ti7785

311283D 25

Page 26

Changing Hydraulic Fluid Filter

Changing Hydraulic Fluid Filter

Removal

1. Relieve pressure, page 5.

2. Loosen and remove hose (101) from fitting (103).

3. Remove filter housing (111) from reservoir (64).

4. Remove bottom filer cap (155) from housing (111).

5. Pull filter (108) off cap (155).

103

Installation

1. Install new o-ring (113) from kit.

2. Install new filter (108) over cap (155).

3. Install cap (155) and filter (108) in filter housing

(111). Hand tighten cap till snug. Then torque to 375

+

10 in-lb (42 + 1.1 N•m).

4. Install filter housing (111) into reservoir.

5. Install fitting (103) in filter housing (111). Torque to

600 +

10 in-lb (67.8 + 1.1 N.m).

6. Reattach hose (101) to fitting (103). Torque to 450 +

10 in-lbs (51 +

1.1 N•m).

101

111

108

113

155

ti7763

26 311283D

Page 27

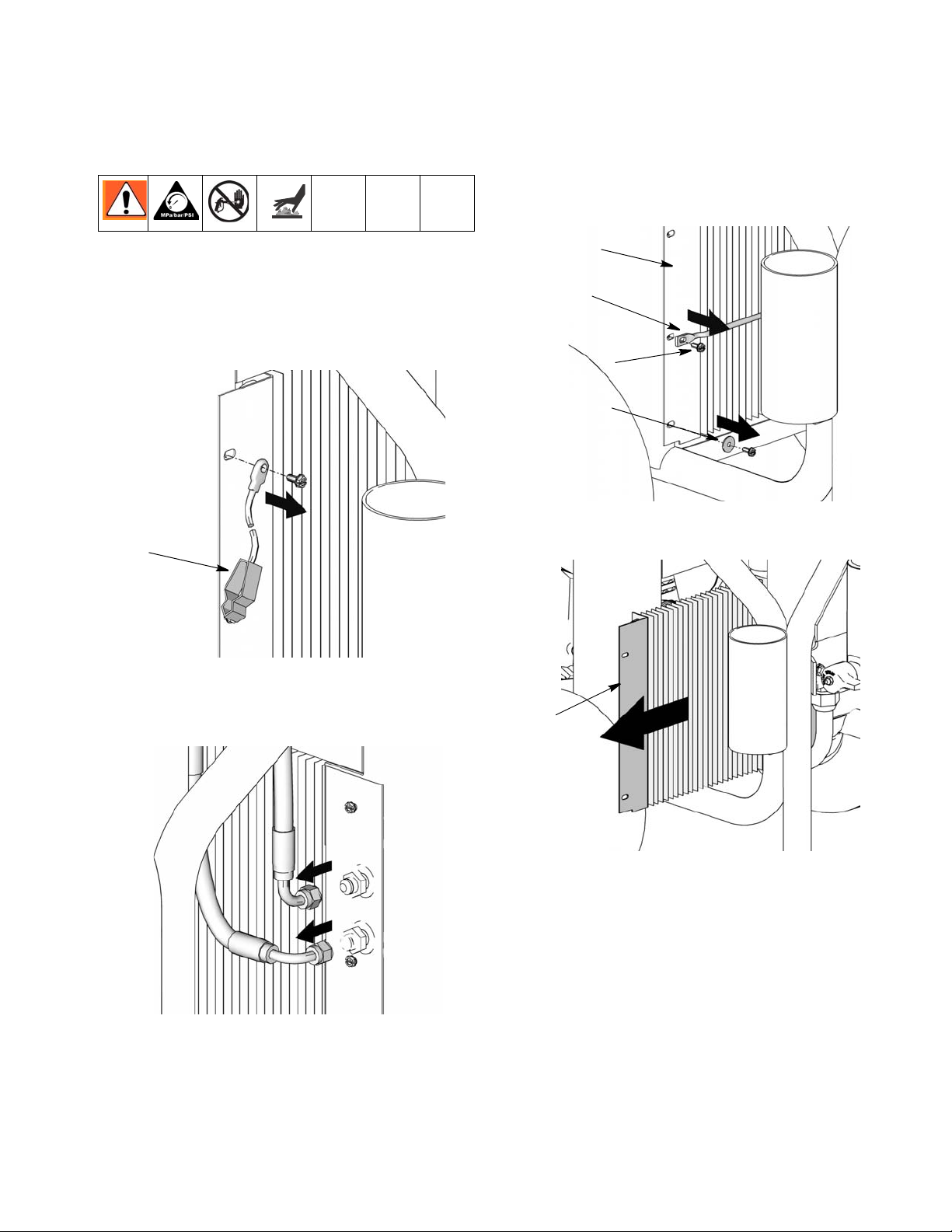

Cooler Replacement

Cooler Replacement

4. Remove screws (79), washers (78) and support bar

(77) from cooling coil (72).

Removal

1. Relieve pressure, page 5.

2. Loosen ground screw and remove ground clamp

(95) from sprayer.

95

ti7799

3. Loosen and remove return line to oil tank and

hydraulic line to cooler.

72

77

79

78

ti7794

5. Remove coil (72) from sprayer frame.

72

ti7792

ti7802

311283D 27

Page 28

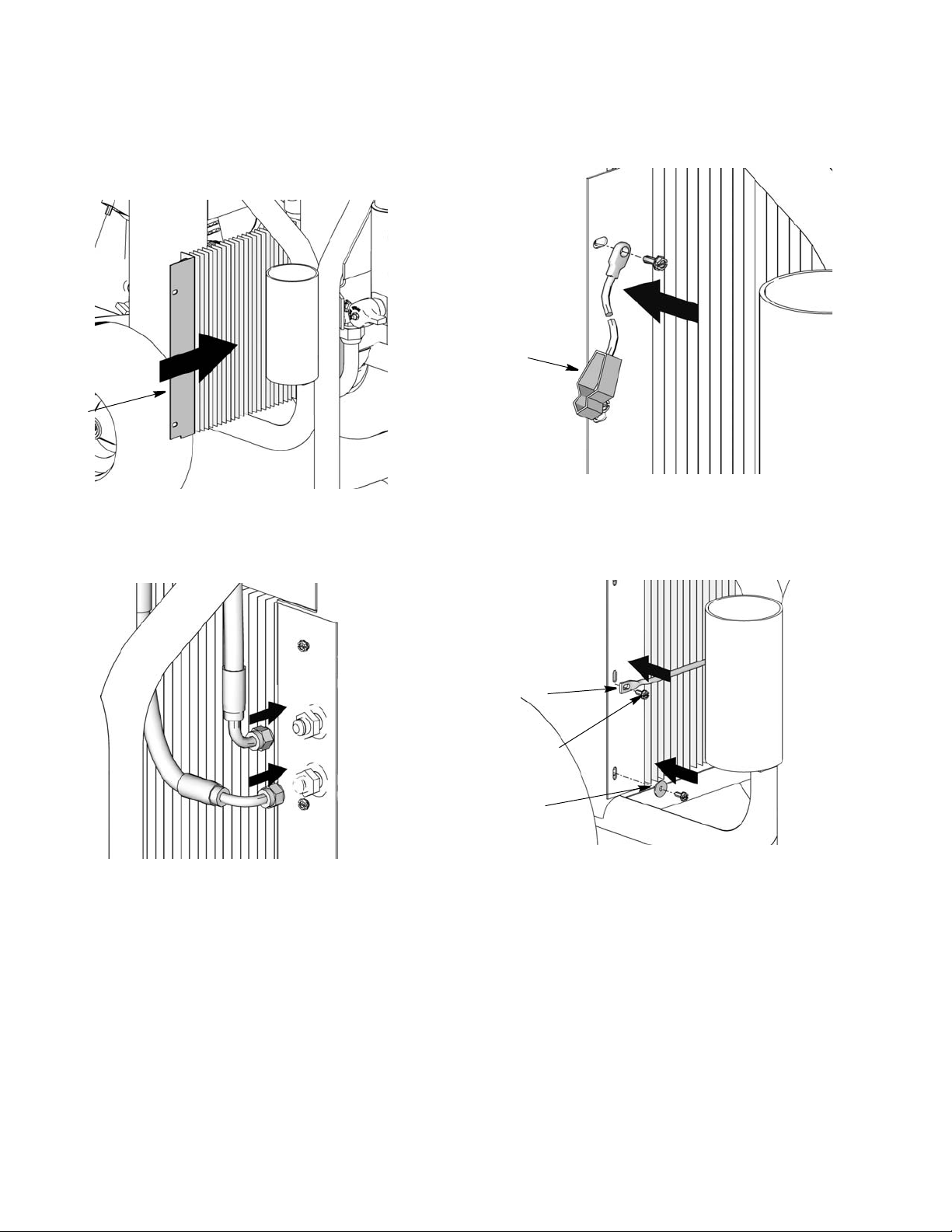

Cooler Replacement

Installation

1. Install new coil (72). Replace support bar (77),

washers (78) and screws (79). Tighten screws.

72

ti776 8

2. Reconnect return line to oil tank and hydraulic line

to cooler. Torque to 225 in-lb (25.4 N.m).

3. Replace ground wire (95) and tighten screw. Torque

to 25-30 in-lbs (2.8 - 3.4 N.m).

95

ti7774

4. Replace bar and screws. Torque to 25-30 in-lb

(2.8-3.4 N.m).

ti7776

77

79

78

28 311283D

Page 29

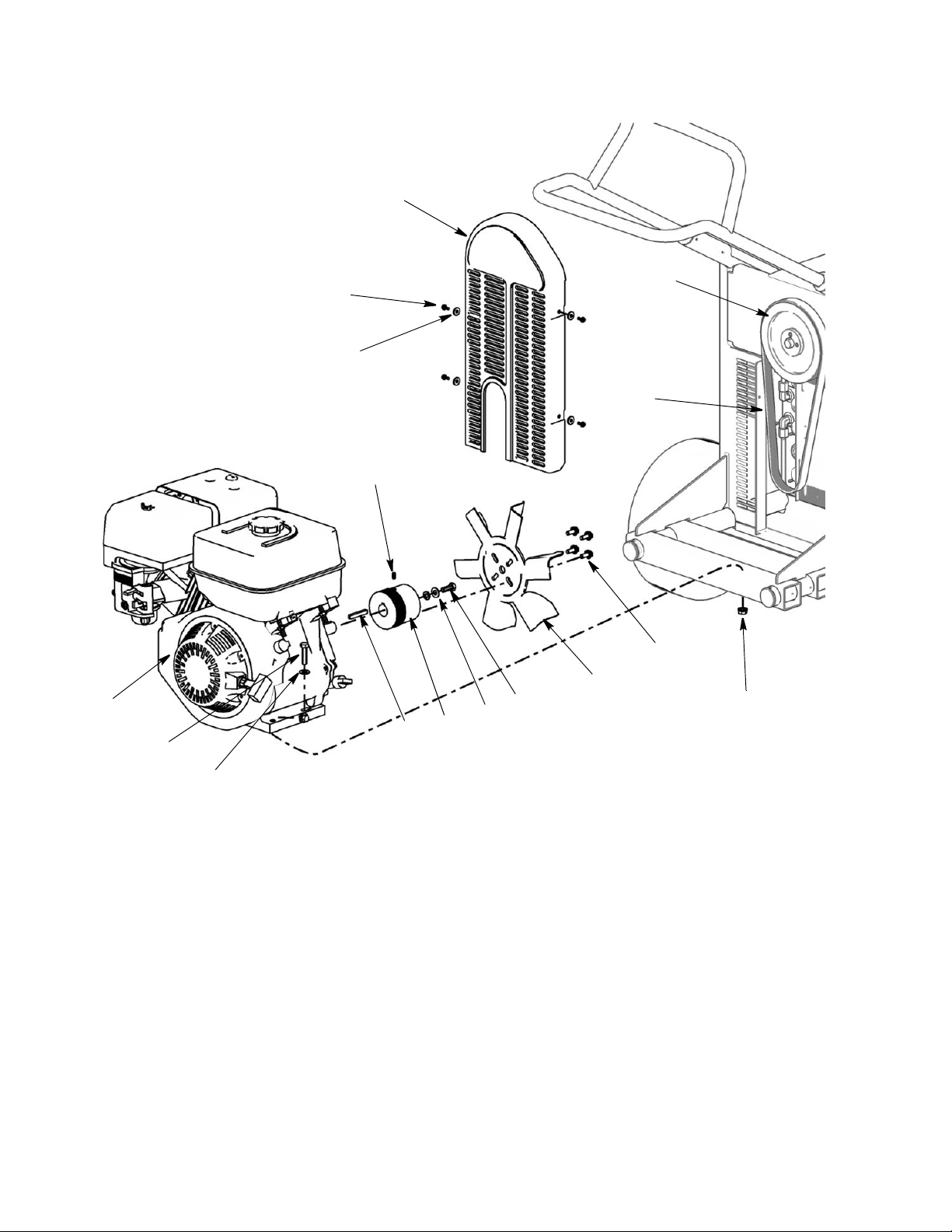

Motor Replacement

Removal

1. Relieve pressure, page 5.

2. Remove screws (79) and washers (78) and belt

cover (67).

3. Remove belt (19), page 20.

Motor Replacement

Removing Pulley (6)

NOTE: This procedure is only necessary if you

are replacing the motor. When you install a new

motor you reuse the existing pulley.

Removal

a. Loosen set screw (87) located on the side of the

pulley (6).

b. Remove large bolt (24) in the center of pulley

(6).

4. Remove screws (21), washers (70) and nuts (10)

securing motor (5) to frame.

5. Remove motor (5) from frame.

Replacing Motor Fan

Removal

a. Loosen and remove bolts (86) on front of fan

(14).

b. Pull fan (14) off small pulley (6).

Installation

a. Position new fan (14) over small pulley (6).

b. Replace bolts (86) and tighten securely.Torque

to 125 +

10 in-lb (14.1 + 1.1 N.m).

c. Pull pulley (6) off motor (5).

Installation

a. Position new pulley (6) on motor (5).

b. Install large bolt (24) and washer (65) in center

of pulley (6). Torque to 125 +

N.m).

c. Tighten set screw (87). Torque to 60 +

(25.4 N.m).

10 in-lb (14.1 + 1.1

2 in-lb

Installation

1. Install motor (5) in frame.

2. Replace all screws (21), washers (70) and nuts (10).

Tighten securely.

3. Install belt (19) over pulleys (4, 6), page 20.

4. Replace belt cover (67) and screws (79) and washers (78) (2 each side). Using a wrench tighten bolts.

Torque to 25-30 in-lb (2.8-3.4 N.m).

311283D 29

Page 30

79

Motor Replacement

67

4

78

19

87

86

14

5

6

21

80

24

65

10

ti7797

70

30 311283D

Page 31

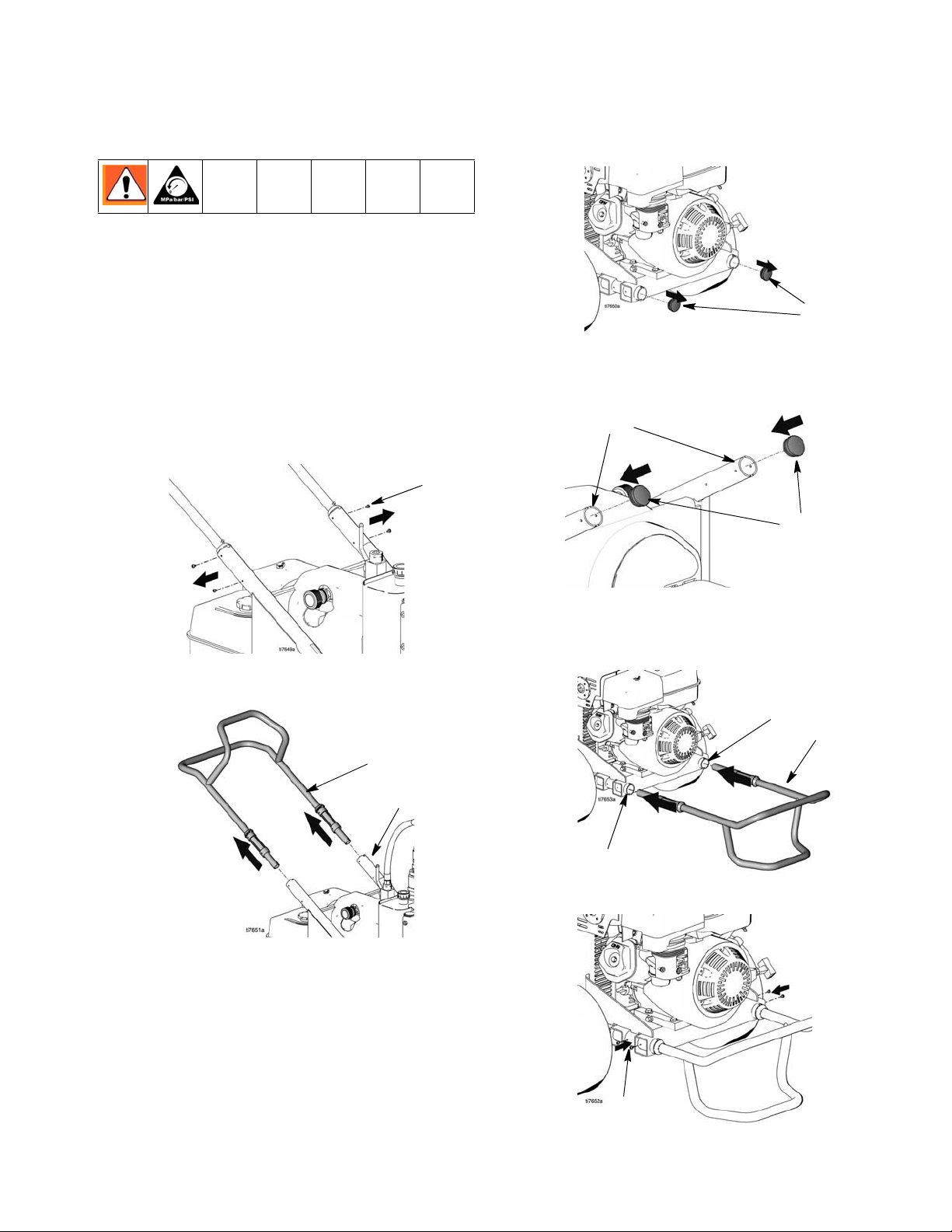

Removing Handle

Removing Handle

Fixed Mounting (optional)

To prevent damaging the unit when transporting it in

a truck or on a trailer, Graco recommends fixed

mounting to the vehicle.

Repositioning Handle

Before you can secure the unit to a truck or trailer bed,

you must reposition the handle.

1. Remove the 4 handle sleeve screws (143).

143

3. Remove frame tube plugs (120) located behind the

wheels.

120

4. Insert plugs (120) in upper frame handle tubes (a).

(a)

120

2. Remove handle assembly (25) by pulling it out of

upper frame tubes (1).

25

1

5. Insert handle assembly (25) into lower frame tubes

(b). The hose bracket should face down. Adjust to

appropriate in/out location.

(b)

25

25

(b)

6. Install sleeve screws (143) in lower frame tubes.

143

311283D 31

Page 32

Securing Unit to Vehicle Bed

Removing Handle

For fixed mounting, fasten U-bolts over sprayer frame as

indicated in the following illustration.

1. Reposition handle, steps 1-5, page 31.

2. Place U-bolts over sprayer frame and through holes

in vehicle bed. Place a washer and nut over bolt

end. Using a wrench, tighten nut securely.

Reposition Handle

U-bolts

U-bolts

32 311283D

Page 33

Technical Data

Sprayer GH833 Gas

Hydraulic Pressure psi (bar) 2750 (19.0)

Hydraulic Reservoir Capacity Gallon (liters) 4.0 (15.1)

Motor HP (kW) Honda 13 (9.7)

Maximum Delivery gpm (lpm) 4.0 (15.1)

Maximum Tip Size

• 1 gun .065

• 2 guns .046

• 3 guns .037

• 4 guns .032

• 5 guns .028

• 6 guns .026

Fluid Inlet inches 1-1/2 to 11-1/2 NPT (m)

Fluid Outlet inches 1 to 11-1/2 NPT (f)

Dimensions

Weight lb (kg) 360 (163)

Height inch (cm) 40 (101.6)

Width inch (cm) 27 (68.6)

Length inch (cm) 47 (119.3)

Sound Levels*

Sound Pressure 91 dB(A)

Sound Power 106 dB(A)

*measured at maximum normal load conditions

Technical Data

Graco-Approved Hydraulic Oil

169236 - 5 gallons (19 liters)

207428 - 1 gallon (3.8 liters)

311283D 33

Page 34

Warranty

Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material

and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published

by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty Program”.

mm 311283

This manual contains English

TO PLACE AN ORDER, contact your Graco distributor, or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

34 311283D

Graco reserves the right to make changes at any time without notice.

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Korea, Japan

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

3/2006, Rev 2/2007

Loading...

Loading...