Page 1

Operation

™

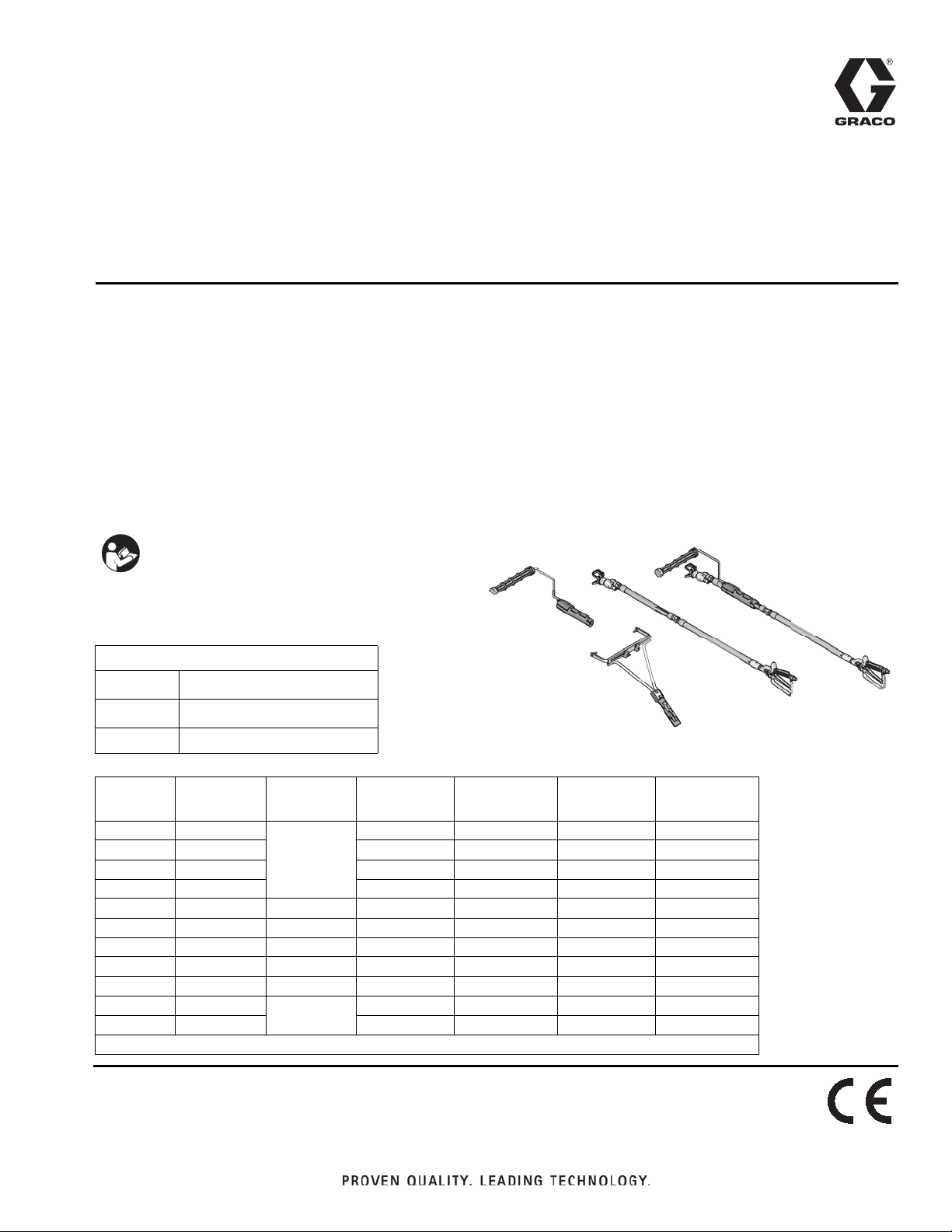

JetRoller

For spray rolled application of architectural paints and coatings.

Not approved for use in explosive atmospheres or hazardous locations.

Model 24U170, 24U172, 24V820, 24V926, 24X605, 24V490,

24V491, 24V492, 24V493, 24W128, 24W129

3600 psi (24.8 MPa, 248.2 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual and in your sprayer, in-line valve, and

CleanShot

Related Manuals

309642

309315

308244

™

manuals. Save all instructions.

CleanShot™ Shutoff Valve

Contractor™ In-Line Valve

180º Spray Nozzle

333428E

EN

ti23593b

Roller

Model

24U170 9”

24U172 9”

24V820 9”

24V926 9.5”

24X605 10.5” LTX821

24V490 18 cm PAA515

24V491 25 cm PAA721

24V492 18 cm PAA515

24V493 25 cm PAA721

24W128 12” - 18”

24W129 12” - 18”

* - For 18” setting, see page 5 for additional tip options.

Frame

Includes

TIP

LTX721

WR1223*

In-Line Valve 45° Swivel CleanShot 180° Swivel

Page 2

Warnings

DANGER

WARNINGWARNINGWARNING

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the

body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable

.

ELECTROCUTION HAZARD

To avoid death or serious injury, avoid contact with power lines.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and

explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are anti-static

or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until you iden-

tify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection

occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any part of

the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying, fol-

low the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing the nozzle

tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off the unit

and follow the Pressure Relief Procedure for turning off the unit.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3600 psi. Use Graco replacement parts or accessories that are rated a min-

imum of 3600 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

6

2 333428E

Page 3

Setup

WARNINGWARNINGWARNING

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See

Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request

MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety haz-

ards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and

equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids contain-

ing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for com-

patibility.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

Setup

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Engage trigger lock.

2. Remove roller handle.

3. Close the bleed-type master air valve. Disengage

the trigger lock.

4. Rotate the CleanShot knob fully counter-clockwise

to the FLUSH position.

5. Hold the metal extension firmly to a grounded metal

pail. Trigger the gun to relieve pressure.

6. Engage the trigger lock.

7. Open all fluid drain valves in the system, having a

waste container ready to catch drainage. Leave

drain valve(s) open until you are ready to spray

again.

8. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. VERY SLOWLY loosen tip guard retaining nut

or hose end coupling to relieve pressure gradually.

b. Loosen nut or coupling completely.

c. Clear hose or tip obstruction.

333428E 3

Page 4

Setup

ti23592a

1

Read your sprayer, in-line valve, and CleanShot manuals.

Assemble JetRoller as shown. Snug extension fittings with wrenches.

Then tighten another 1/4 turn [~100 in-lb (11 N•m)]. Attach to gun

sprayer hose. Prime sprayer as directed in sprayer manual.

500

2000

2500

3000

0

2000

3

0

bar

MPa

1000

OK

PSI

68.9

6.89

103.4

10.3

1500

2

For best results use sprayer

pressure shown below. Always spray at the lowest

pressure necessary to get desired results.

ti23598a

OK

Adjust CleanShot position so

spray fan hits below roller cover.

ti23643a

Quickly trigger once and release to check pattern. Pattern

should be as wide as roller.

NOTE: CleanShot knob may be adjusted to optimize spray fan.

To narrow pattern, loosen roller handle and

move roller cover toward CleanShot. To

widen pattern, loosen roller handle and

move roller cover away from CleanShot.

ti23640a

ti23647a

3

500

2500

000

4

4 333428E

Page 5

50%

12-24"

ti23630b

Spray and roll on down stroke, release trigger and roll on upstroke. For best

results near floors and baseboards, release trigger 12-24” (30-60 cm) above

floor and continue to roll to bottom on down stroke. Back roll on upstroke.

NOTE: See your in-line valve manual for changing the spray tip and for

clearing a clog.

5

Hand roll sensitive wall areas

(outside corners, adjacent walls,

etc.).

6

ti23614a

1

15

11

2

3

14

4

6

8

16

8

18

9

12

7

17

17a

17b

17c

17d

17e

Ref.

Part

Number Description Qty

12 224399 SWIVEL, 45° 1

13 222385 TAG, warning (not

shown)

1

14 235486 SWIVEL, 180° includes 8 1

15 17A078 PAD, friction 1

16 24W131 KIT, arm, 18” 2

17 24W130 KIT, handle, roller 18”

includes 16 qty 2, 17a-e

1

17a 24X633 KIT, cap

17b WR1223 TIP, spray, rac x 1

17c 17D651 KIT, nut, hex, flange,

head

1

17d 24X632 HANDLE 1

17e 24X631 KIT, handle includes 16

qty 2

1

18 17D695 TAG, instructions 1

Replacement Danger and Warning labels,

tags, and cards are available at no cost.

Ref.

Part

Number Description Qty

1 24V829 HANDLE, roller, 9” 1

24V937 HANDLE, roller, 9.5”

24X651 HANDLE, roller, 10.5”

24V830 HANDLE, roller, 18 cm

24V831 HANDLE, roller, 25 cm

2 24V832 EXTENSION, JetRoller

includes 8

1

3 287030 VALVE, spray,

CleanShot includes 8

1

4 LTX721 TIP, spray, latex, rac x,

9”, 9.5”, and 14”

1

LTX821 TIP, spray, latex, rac x,

10.5”

PAA515 TIP, spray, latex, rac x,

18 cm

PAA721 TIP, spray, latex, rac x,

25 cm

Ref.

Part

Number Description Qty

PAA821 TIP, spray, latex, rac x,

40 cm

WR1223 TIP, spray, latex, rac x,

18”

5 246215 GUARD, rac x w/ seat

and seal

1

6 232122 EXTENSION, roller,

fixed (0.5M) (includes 8)

1

7 244161 VALVE, in-line 1

8 15H622 GASKET 1

9 17B476 LABEL, warning 1

11 24V833 KIT, repair, 9” roller

frame

1

24V938 KIT, repair, 9.5” roller

frame

7

Read your sprayer, in-line valve,

and CleanShot manuals for cleaning instructions.

Setup

5

333428E 5

8

ti24116b

Page 6

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2014, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 333428

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision E, March 2015

Loading...

Loading...