Page 1

Operation - Repair - Parts

ti24682a

WARNING

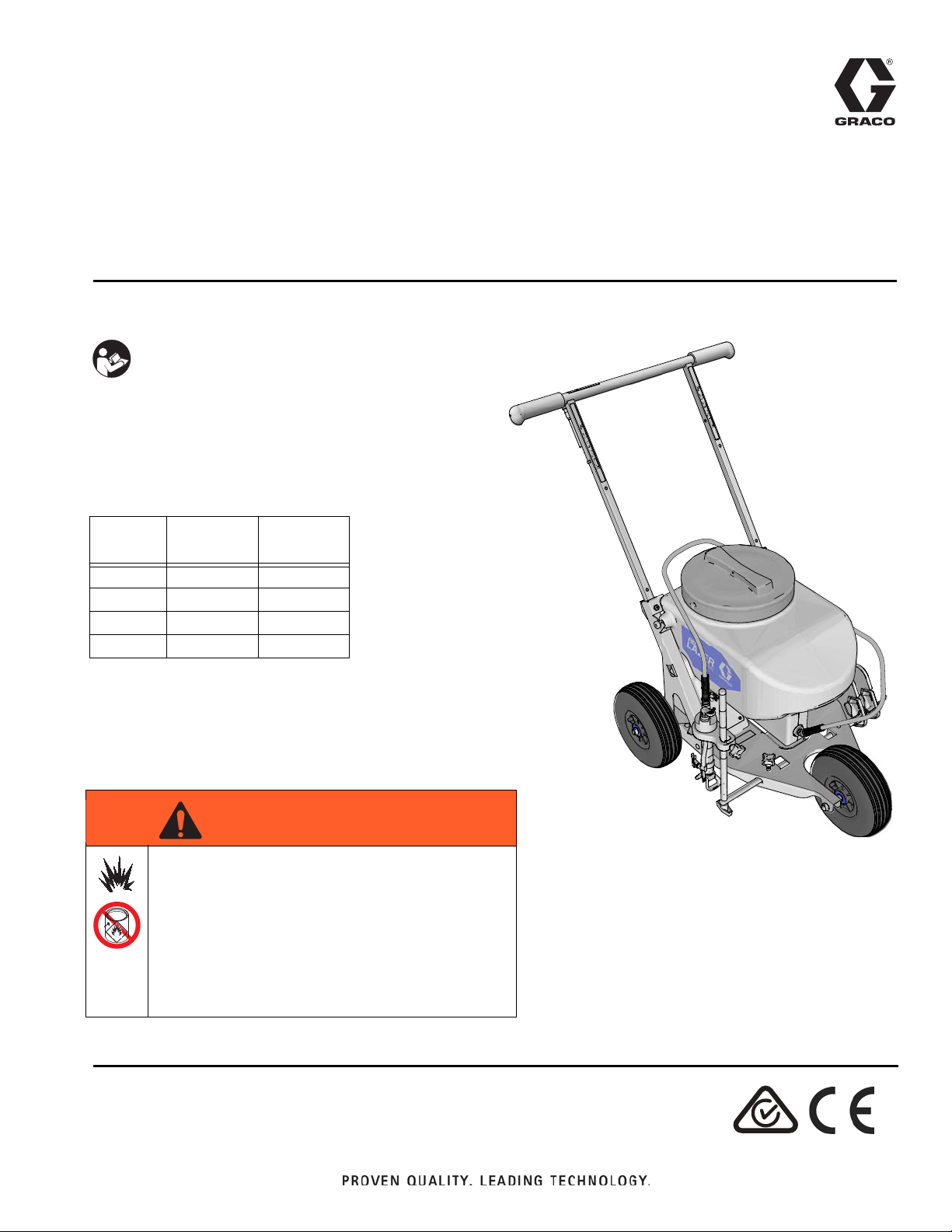

Sports Field Marker

For field marking applications only

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this manual

and on the unit. Be familiar with the controls and

the proper usage of the equipment.

Save these instructions.

All Models:

Maximum Working Pressure 1200 psi (8.3 MPa, 83 bar)

Model

24N950 120V B

24R023 240V B

24R370 240V B

24R371 120V/240V B

Charger

Voltage

Series

332119J

EN

FIRE AND EXPLOSION HAZARD

Solvent and paint fumes can ignite or explode.

• Use only water-based materials. Do not use

materials which state “FLAMMABLE” on the

packaging. For more information about your

material, request SDS from distributor or

retailer.

• Do not spray or flush with flammable materials.

Page 2

Contents

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 6

Component Identification List . . . . . . . . . . . . . . . 7

Charging the Battery (Series A) . . . . . . . . . . . . . . . 8

Charger Indicator Lights . . . . . . . . . . . . . . . . . . . 8

Charging the Battery (Series B) . . . . . . . . . . . . . . . 9

Charger Indicator Lights . . . . . . . . . . . . . . . . . . . 9

Common Procedures . . . . . . . . . . . . . . . . . . . . . . 10

Prime/Spray Valve . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

Install Spray Tip/Guard

Assembly (if not installed) . . . . . . . . . . . . . . 10

Reversible Spray Tip . . . . . . . . . . . . . . . . . . . . . 11

Filter Removal / Cleaning . . . . . . . . . . . . . . . . . 11

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Emptying the Paint Hopper . . . . . . . . . . . . . . . . 12

Starting a New Job . . . . . . . . . . . . . . . . . . . . . . . . 13

Adjusting Line Width . . . . . . . . . . . . . . . . . . . . . 14

Shutdown and Cleaning . . . . . . . . . . . . . . . . . . . . 15

Flushing Field Marker . . . . . . . . . . . . . . . . . . . . 15

Optional Cleanup: . . . . . . . . . . . . . . . . . . . . . . . 16

Unclogging Spray Tip/Guard Assembly . . . . . . 17

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tip Removal/Cleaning . . . . . . . . . . . . . . . . . . . . 19

CleanShot

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . 21

Battery Replacement . . . . . . . . . . . . . . . . . . . . . 22

Control Board Replacement . . . . . . . . . . . . . . . 24

Pump/Motor Removal . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 38

™

Cleaning (If applicable) . . . . . . . . . 19

2 332119J

Page 3

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with

any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while

spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure

before removing the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment energized or

under pressure while unattended. Follow the Pressure Relief Procedure when the equipment is

unattended or not in use, and before servicing, cleaning, or removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 1200 psi (8.3 MPa, 83 bar). Use Graco replacement parts or

accessories that are rated a minimum of 1200 psi (8.3 MPa, 83 bar).

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request SDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

332119J 3

Page 4

Warnings

WARNING

BATTERY HAZARD

The battery may leak, explode, cause burns, or cause an explosion if mishandled. Contents of an open

battery can cause severe irritation and/or chemical burns. If on skin, wash with soap and water. If in eyes,

flush with water for at least 15 minutes and get immediate medical attention.

• Only use the battery type specified for use with the equipment. See Technical Data.

• Replace battery only in a well-ventilated area and away from flammable or combustible materials,

including paints and solvents.

• When battery is not in use, keep it away from metal objects like keys, nails, screws or other metal

objects that can short circuit the battery terminals.

• Do not dispose of battery in fire or heat above 50 °C (122 °F). The battery is capable of exploding.

• Do not throw into fire.

• Charge only with Graco approved charger as listed in this manual.

• Do not expose battery to water or rain.

• Do not disassemble, crush, or penetrate the battery.

• Do not use or charge a battery that is cracked or damaged.

• Follow local ordinances and/or regulations for disposal.

CHARGER ELECTRIC SHOCK, FIRE AND EXPLOSION HAZARD

Improper setup or usage can cause electric shock, fire, and explosion.

• Charge only in a well-ventilated area and away from flammable or combustible materials, including

paints and solvents.

• Do not charge on a combustible or flammable surface.

• Do not leave battery unattended while charging.

• Immediately unplug charger and remove battery when charging is complete.

• Charge only Graco approved batteries listed in this manual; other batteries may burst.

• Use only in dry locations. Do not expose to water or rain.

• Do not use a charger that is cracked or damaged.

• If the supply cord is damaged, replace the charger or cord, depending on model.

• Never force the battery into the charger.

• When operating a charger outdoors, always provide a dry location and use an extension cord suitable for outdoor use.

• Disconnect the charger from the outlet before cleaning.

• Ensure that the outside surface of the battery is clean and dry before plugging into the charger.

• Do not attempt to charge non-rechargeable batteries.

• Do not disassemble the charger. Take charger to authorized service center when service or repair is

required.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read SDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

4 332119J

Page 5

PERSONAL PROTECTIVE EQUIPMENT

WARNING

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

Warnings

332119J 5

Page 6

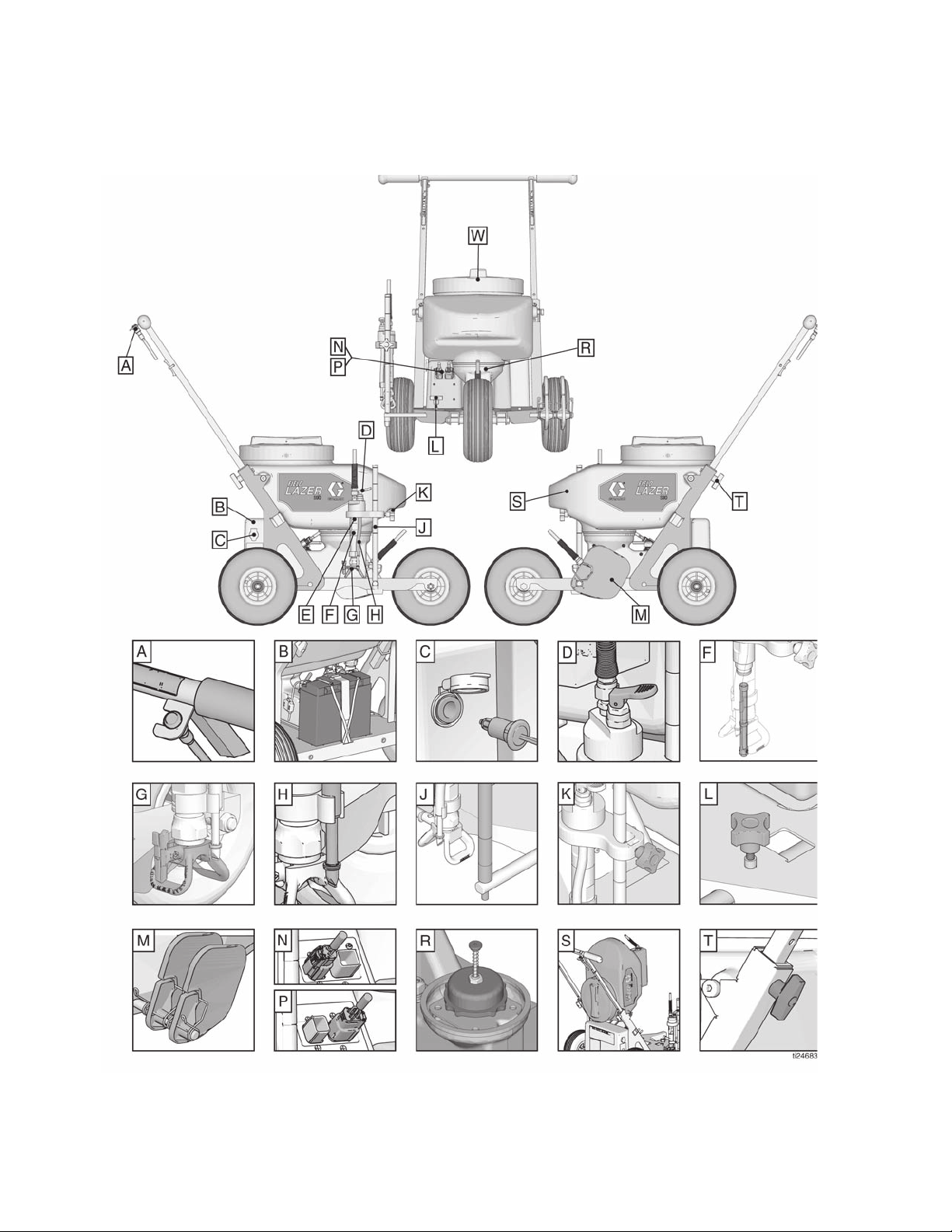

Component Identification

Component Identification

6 332119J

Page 7

Component Identification List

Component Identification

A Spray Button

B Battery Shroud (battery inside)

C Battery Charger Connection Port

D Prime/Spray Valve

E Material Dispenser

FFilter

G Spray Tip/Guard Assembly

HPrime Hose

J Height Adjustment Mount

K Material Dispenser Height Adjustment Knob

L Material Dispenser Arm Adjustment Knob

M Spray Shields

N Motor Plug

P Spray Button Plug

R Paint Hopper Screen/Ball Knocker

S Tilt-N-Pour Paint Hopper

T Adjustable Handlebar Knob

W Paint Hopper Lid

332119J 7

Page 8

Charging the Battery (Series A)

A

ti20194a

ti2810a

12V

ti20190a

C

ti7949a

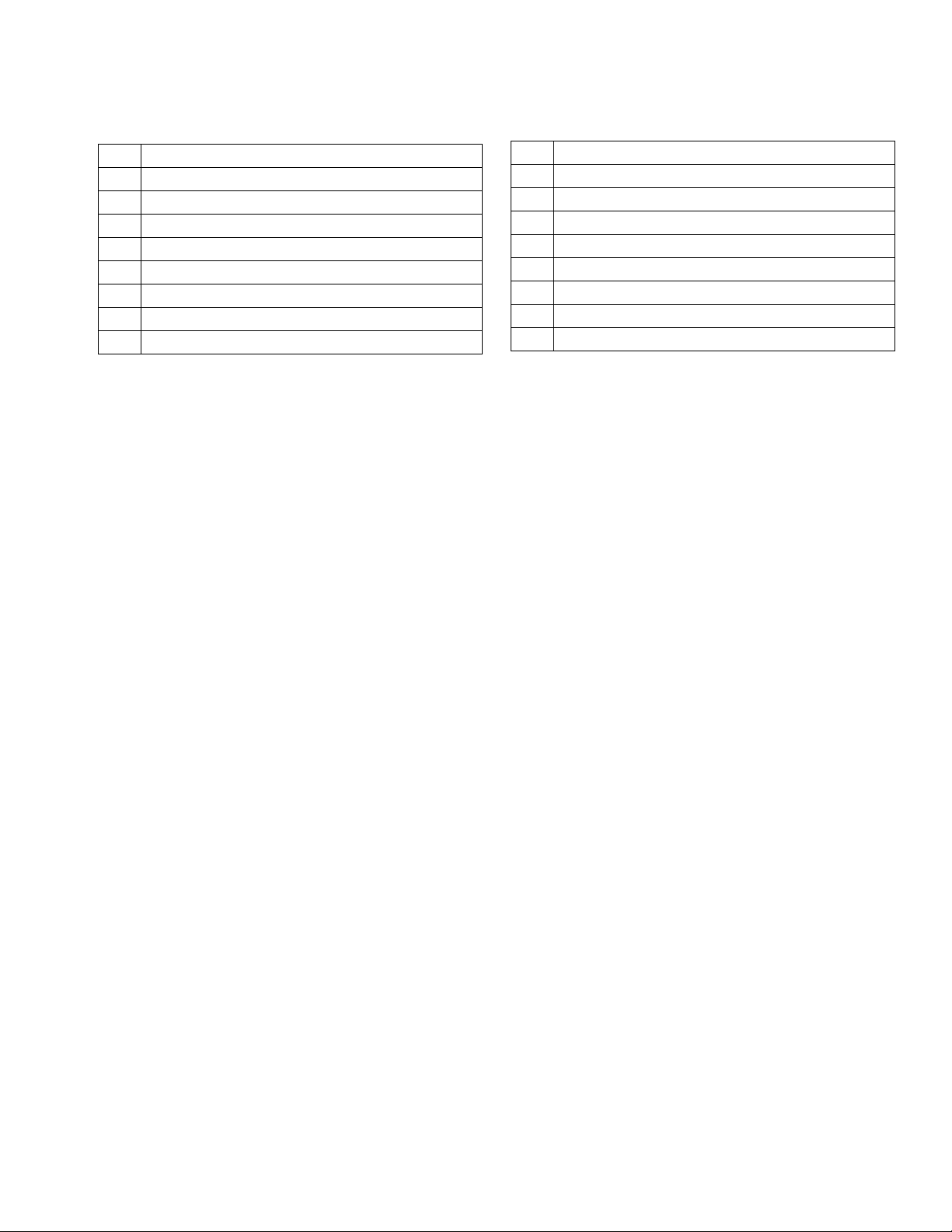

Charging the Battery (Series A)

4. Plug 12V charger jack into battery connection port

(C) on field marker.

Battery charger is for indoor use only. Do not expose

charger to rain or snow. Charge battery with

Graco-approved charger.

NOTE: Fully charge battery prior to first use.

1. Place field marker in a dry, well-ventilated area

away from flammable or combustible materials,

including paints and solvents.

2. Before charging, make sure spray button (A) is out

(OFF position).

5. When charging is complete, disconnect charger

from electrical outlet. Then disconnect charger from

battery connection port on field marker.

3. Plug charger into an electrical outlet.

Charger Indicator Lights

Appearance Description

RED Battery is being charged.

GREEN Charging is complete.

NOTE: Disconnect charger from field marker after battery is fully charged. Charge times will vary from 0 - 14 hours

depending on level of discharge.

NOTE: Green light on charger will be ON if:

• Charging is complete.

• Charger is NOT plugged into electrical outlet but is plugged into battery charger connection port on field marker.

• Charger is plugged into electrical outlet but is NOT plugged into battery charger connection port on field marker.

8 332119J

Page 9

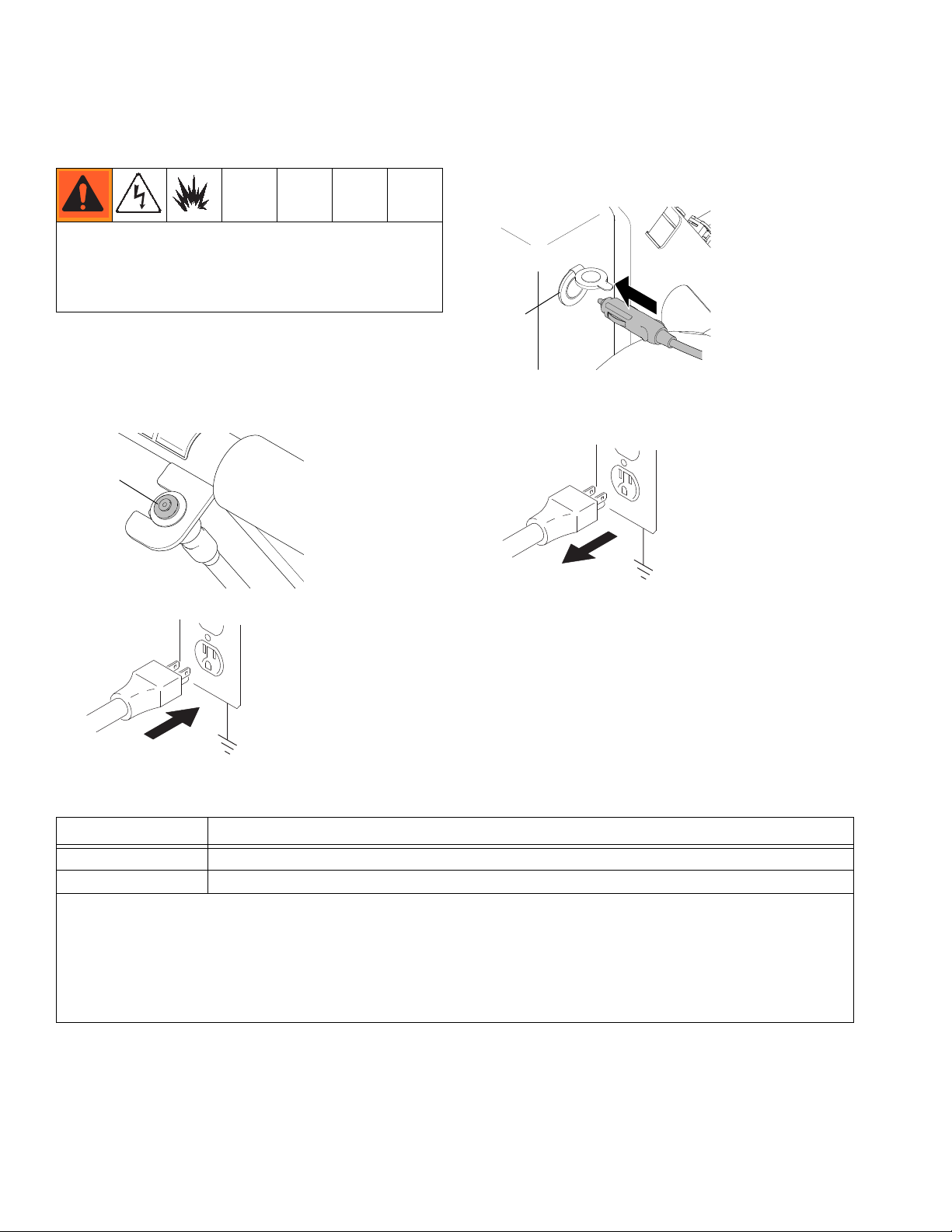

Charging the Battery (Series B)

A

ti20194a

ti2810a

ti24686a

ti7949a

4. Plug 12V charger jack into battery connection port

on field marker.

Battery charger is for indoor use only. Do not expose

charger to rain or snow. Charge battery with

Graco-approved charger.

NOTE: Fully charge battery prior to first use.

1. Place field marker in a dry, well-ventilated area

away from flammable or combustible materials,

including paints and solvents.

2. Before charging, make sure spray button (A) is out

(OFF position).

5. When charging is complete, disconnect charger

from electrical outlet. Then disconnect charger from

battery connection port on field marker.

Charging the Battery (Series B)

3. Plug charger into an electrical outlet.

Charger Indicator Lights

Description Appearance

Power on with no battery connected Power LED is red

Desulfating

Charging

Charged/Float charging All four charging lights are on solid.

Reverse polarity All four charging lights flash.

Sleep mode. If the battery is fully charged or the charged is

connected to a fully charged battery the charger may go into

the sleep mode.

NOTE: Disconnect charger from field marker after battery is fully charged. Charge times will vary from 0 - 14 hours

depending on level of discharge.

First charging light is green and stays on until the bulk

charge cycle starts.

Charging lights lite to indicate show the state of

charge.

All four charging lights dim and flash.

332119J 9

Page 10

Common Procedures

UP position

(For priming and releasing

DOWN position

(Ready to spray)

ti14999a

pump pressure)

ti20183a

ti20184a

ti20183a

D

ti20183a

D

ti20215a

G

Common Procedures

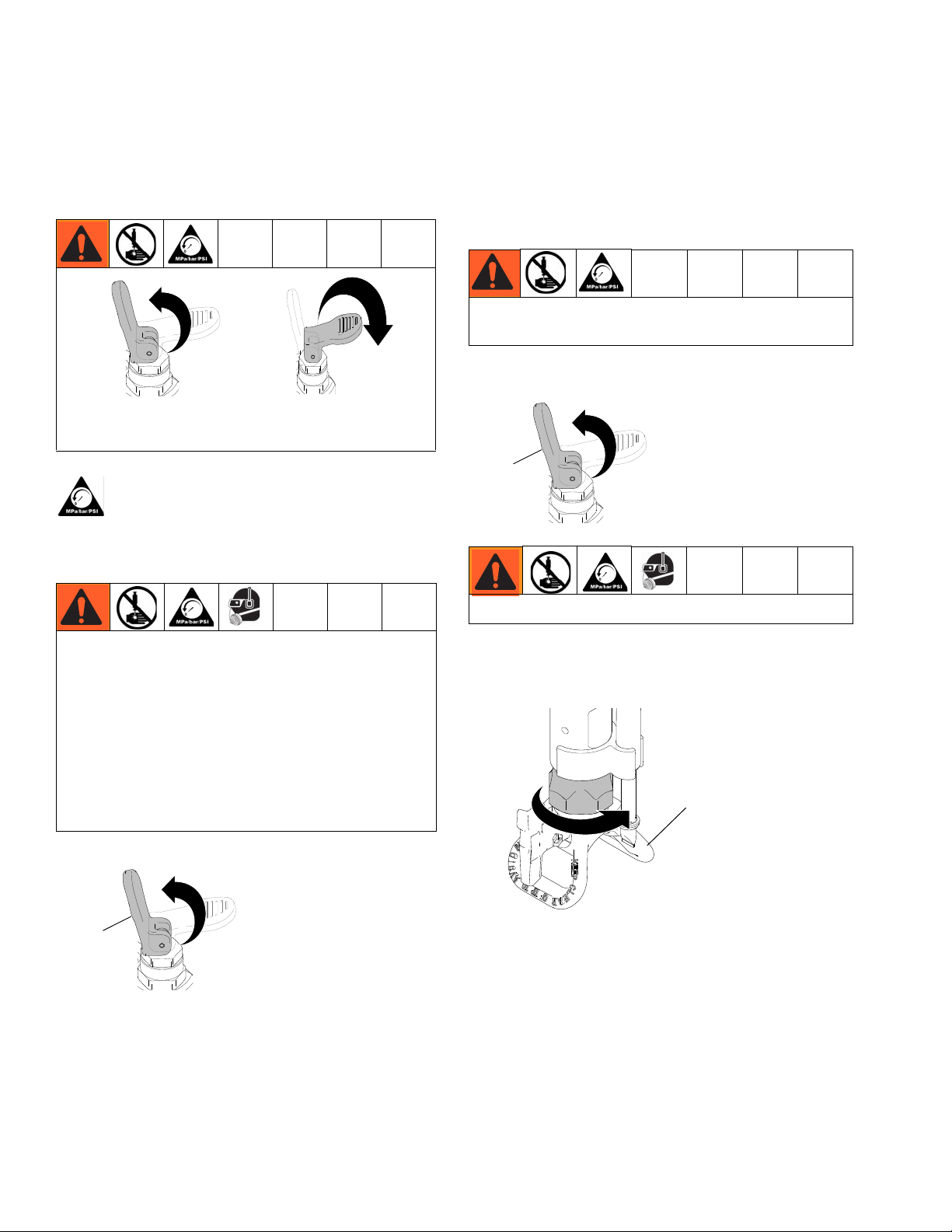

Prime/Spray Valve

Follow the Pressure Relief Procedure

whenever you see this symbol.

Pressure Relief Procedure

Install Spray Tip/Guard

Assembly (if not installed)

Perform the Pressure Relief Procedure before

installing spray tip/guard assembly.

1. Put prime/spray valve (D) UP to release pressure.

Do NOT place hands in front of tip.

Do not operate or spray near children. Do not aim the

field marker at, or spray any person or animal. Keep

hands and other body parts away from the discharge.

For example, do not try to stop the paint flow with any

part of the body.

This field marker builds up an internal pressure of

1200 psi (8.3 MPa, 83 bar) during use. Follow this

Pressure Relief Procedure whenever you stop

spraying and before cleaning, checking, servicing, or

transporting equipment to prevent serious injury.

1. Put prime/spray valve (D) UP to release pressure.

2. Screw spray/tip guard assembly (G) onto field marker.

Tighten retaining nut until completely engaged with

field marker. Do not overtighten nut.

10 332119J

Page 11

Common Procedures

Spray Tip Forward

(SPRAY position)

Spray Tip Reversed

(UNCLOG position)

ti20191a

ti20192a

ti21416a

ti20183a

ti20182a

ti20185a

F

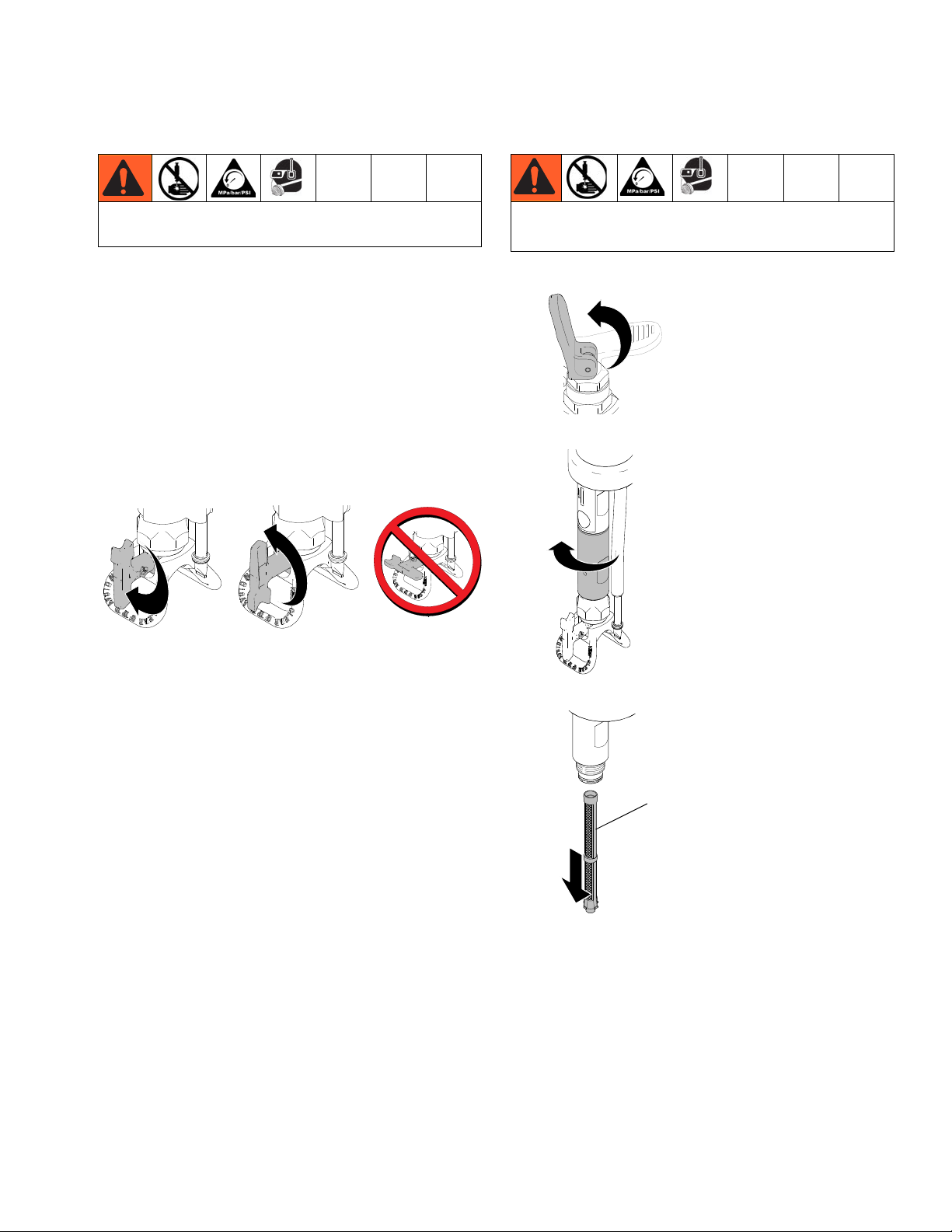

Reversible Spray Tip

Always perform Pressure Relief Procedure before

adjusting spray tip position.

In the event that particles or debris clog the spray tip,

this field marker is designed with a reversible spray tip

that can be used to quickly and easily clear the particles

and resume spraying as quickly as possible.

• Always point the reversible spray tip down when

spraying.

• When particles or debris get caught in the tip, it can

be reversed to quickly clean the tip.

• Only operate field marker with spray tip in forward or

reversed position.

Filter Removal / Cleaning

Always perform Pressure Relief Procedure before

removing filter.

1. Perform Pressure Relief Procedure, page 10.

2. Unscrew to remove filter.

3. Pull out filter (F).

4. Clean filter with water. Replace filter if damaged or

unable to clean.

5. Reinstall filter.

6. Install and tighten filter housing.

332119J 11

Page 12

Common Procedures

ti20212a

A

ti20193a

S

Spraying

Press spray button (A) to spray. Spray will continue until

spray button is pressed again to stop.

Emptying the Paint Hopper

1. Place striping machine near the material container.

2. Remove paint hopper lid.

3. Grab front of paint hopper (S) and slowly lift.

Material will pour back into the material container.

12 332119J

Page 13

Starting a New Job

ti20183a

ti24707a

ti20214a

S

ti20212a

ti21316a

A

ti20184a

D

ti20192a

ti20213a

X

ti20191a

ti20183a

D

X

ti20184a

D

Starting a New Job

1. Perform Pressure Relief Procedure, page 10.

NOTICE

If material fails to flow through prime hose, the inlet ball

check valve may be stuck due to improper cleaning and

storage. Reach into hopper. Press button to break the inlet

ball check free.

a. To fill field marker with fluid, press spray button

(A) and allow field marker to run until material

flows through prime hose.

b. Stop field marker by pressing spray button.

4. Put prime/spray valve (D) in DOWN position.

5. Reverse spray tip (X) to UNCLOG position, spray

for two seconds and then stop.

NOTE: Failure to perform this operation could result

in poor spray pattern.

6. Put prime/spray valve (D) UP to release pressure.

Then rotate spray tip (X) back to spray position.

2. Pour material into paint hopper (S).

7. Put prime/spray valve (D) down and you are ready

to spray.

3. Prime the Pump:

332119J 13

Page 14

Starting a New Job

ti20183a

ti21320a

J

ti21319a

M

ti21321a

J

ti20187a

M

ti20187a

ti20189a

Adjusting Line Width

With Shields

1. Perform Pressure Relief Procedure, page 10.

2. Remove height adjustment mount (J) and material

dispenser arm assembly.

5. Install outer spray shield assembly (M) by collapsing

spring and sliding shield onto horizontal D-bar.

6. Adjust shields to the desired line width. Spray tip

should be centered between shields. Spray pattern

should touch shields just above the bottom of the

shields.

3. Install inner spray shield assembly (M) by collapsing

spring and sliding shield onto horizontal D-bar.

4. Install height adjustment mount (J) and material dispenser arm assembly

Without Shields

1. Perform Pressure Relief Procedure, page 10.

2. Move vertical material dispenser bar holder to

outside position.

3. Adjust height of tip to adjust line width (raising tip

height will create wider lines).

NOTE: Different tip sizes are available for lines

14 332119J

greater than 6 in. (15 cm) wide. Use Graco part

number LL5417 for wider lines.

Page 15

Shutdown and Cleaning

ti20183a

ti20193a

S

ti20211a

ti20212a

A

ti20184a

D

ti20183a

D

Shutdown and Cleaning

NOTICE

Failure to properly clean field marker after each use will

result in hardened materials, damage to the field marker,

and the warranty will no longer be valid. Do not store

solvents in field marker. Always flush with Graco Pump

Armor prior to storage.

Flushing Field Marker

Use only water-based materials. Do not use materials

which state “FLAMMABLE” on the packaging. For more

information about your material, request SDS from distributor or retailer.

Do not operate or spray near children. Do not aim the

field marker at, or spray any person or animal. Keep

hands and other body parts away from the discharge.

For example, do not try to stop the paint flow with any

part of the body.

This field marker builds up an internal pressure of 1200

psi (8.3 MPa, 83 bar) during use. Follow this Pressure

Relief Procedure whenever you stop spraying and

before cleaning, checking, servicing, or transporting

equipment to prevent serious injury.

4. Clean inside of paint hopper with water. Optional: Tilt

paint hopper back and spray inside with water.

5. Fill paint hopper with 1/2 gallon (2 liters) water.

6. Put prime/spray valve (D) UP to clean prime hose.

7. Push spray button (A) to pump water through prime

hose. Pump until water is clear.

8. Push spray button to stop pumping water through

prime hose.

9. Put prime/spray valve (D) DOWN to spray position.

1. Perform Pressure Relief Procedure, page 10.

10. Push spray button to spray water through tip. Spray

until water is clear.

11. Push spray button to stop spraying water through tip.

12. Empty the paint hopper, see page 12.

2. Empty the paint hopper (S), see page 12.

3. Remove paint hopper screen and clean

332119J 15

13. Repeat steps 5-10 until water runs clear.

14. Put prime/spray valve (D) UP to release pressure.

15. Remove and clean filter, page 11.

Page 16

Shutdown and Cleaning

ti21484a

ti21485a

E

N

ti21363a

S

ti21487a

E

ti21483a

N

Optional Cleanup:

• Perform Pressure Relief Procedure, page 10.

• Empty the paint hopper, see page 12.

• Disconnect motor plug (N) and remove material

dispenser (E) from height adjustment mount.

• Remove paint hopper (S) from field marker.

• Clean out paint hopper at a sink.

• Install paint hopper onto field marker.

• Install material dispenser (E) and connect motor

plug (N).

•Perform Flushing Field Marker procedure steps 5 -

15, page 15.

16 332119J

Page 17

Unclogging Spray Tip/Guard Assembly

ti20183a

ti20192a

X

ti20184a

D

ti20212a

A

ti20191a

X

5. Push spray button again to stop field marker.

6. Perform Pressure Relief Procedure, page 10.

Shutdown and Cleaning

Always perform Pressure Relief Procedure before

unclogging spray tip/guard assembly.

1. Perform Pressure Relief Procedure, page 10.

2. Reverse spray tip (X) to UNCLOG position.

3. Put prime/spray valve (D) DOWN to spray position.

7. Rotate spray tip (X) back to SPRAY position.

8. Put prime/spray valve DOWN to spray position.

9. Push prime/spray button to start sprayer and resume

spraying.

10. If spray tip is still clogged, you may have to repeat

steps 1 - 9 several times.

11. If material still fails to be sprayed, perform Pressure

Relief Procedure, page 10.

12. Perform Tip Removal Cleaning, page 19.

13. Perform Filter Removal/Cleaning, page 11.

14. If applicable, perform CleanShot Cleaning, page 19.

4. Push spray button (A) to start field marker and clear

clog.

332119J 17

Page 18

Storage

ti20183a

D

ti20212aAti20184a

D

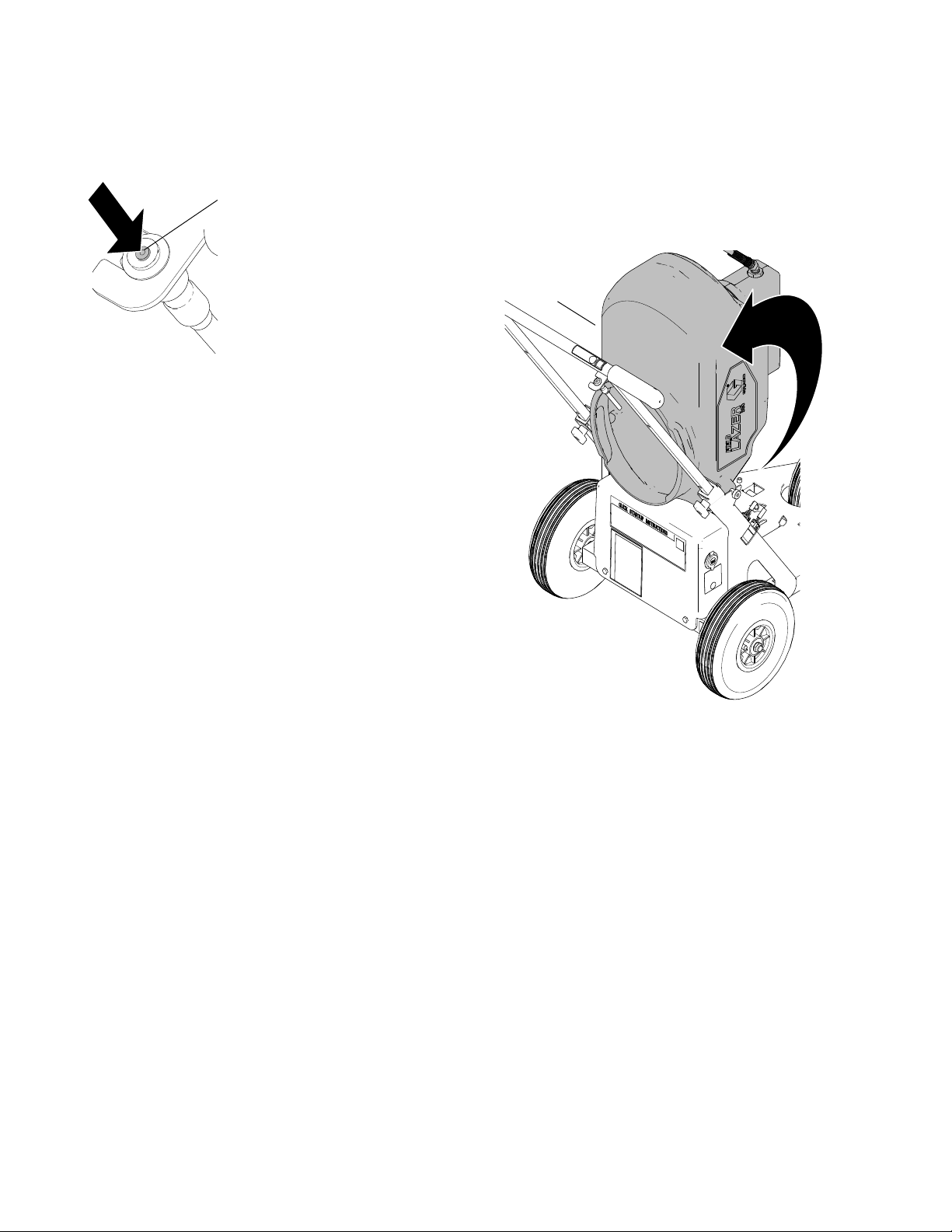

Storage

NOTICE

Failure to store field marker with Pump Armor will result

in operational problems the next time you spray. Always

circulate Pump Armor through the field marker after

cleaning. Water left in the field marker will damage

the pump due to freezing.

5. Press spray button to stop when Pump Armor flows

through prime hose.

6. Move prime/spray valve (D) DOWN to the spray

position.

1. Clean field marker. See Shutdown and Cleaning,

page 15.

2. Lift prime/spray valve (D) UP to the prime position.

3. Pour a small amount of Pump Armor into bottom of

paint hopper.

4. Push spray button (A) to pump the material.

7. Press spray button to spray material.

8. Press spray button to stop pump when Pump Armor

sprays through tip.

9. Plug charger into field marker. See Charging the

Battery, page 8. Charge to full charge and disconnect.

10. Store field marker indoors in a cool, dry place.

Always store field marker with some Pump Armor in

the paint pump/hopper. Never store field marker dry

or with paint in the pump/hopper.

18 332119J

Page 19

Repair

ti20183a

ti21497a

X

X

ti21361a

ti21360a

X

ti21382a

G

ti21383a

Y

ti21384a

Repair

Tip Removal/Cleaning

1. Perform Pressure Relief Procedure, page 10.

2. Rotate spray tip (X) 1/4 turn and remove.

CleanShot™ Cleaning (If

applicable)

1. Perform Pressure Relief Procedure, page 10.

2. Remove spray tip/guard assembly (G).

3. Remove CleanShot assembly (Y).

3. Wash tip in sink under running water. Use a brush or

pick to remove excess or dried material.

4. Use two wrenches to remove needle seat.

4. Use a pressurized air hose to blow out any remaining material from tip. NOTE: You should be able to

clearly see through the tip hole when cleaned.

5. Install spray tip (X) and position to spray as shown

below.

332119J 19

Page 20

Repair

ti21385a

ti21501a

ti21395a

ti21402a

G

5. Hold CleanShot over running water and clean. Work

needle in and out to free CleanShot from excess or

hardened material.

6. Use two wrenches to install needle seat.

8. Install CleanShot assembly.

9. Install spray tip/guard assembly (G).

7. Clean filter. See

Filter Removal/Cleaning

, page 11.

20 332119J

Page 21

Fuse Replacement

ti20183a

ti21362a

Motor Plug

Spray Button Plug

ti21363a

ti21485a

E

S

ti21369a

B

30 AMP

Automotive

Regulator ATO

ti21364a

ti21368a

ti21486a

ti21487a

S

E

ti21362a

Motor Plug

Spray Button Plug

Removal

1. Perform Pressure Relief Procedure, page 10.

Repair

Installation

1. Insert a new standard 30 A automotive fuse (Regular ATO) fuse into fuse case.

2. Place front tabs of battery shroud into slots, then

pivot back of shroud down. Use wrench to tighten

two bolts and secure shroud into place.

2. Disconnect motor plug and spray button plug.

3. Remove material dispenser (E) and paint hopper (S).

4. Use wrench to remove two bolts and remove battery

shroud (B).

NOTICE

When installing the battery shroud, wires can get

pinched between the shroud and frame and become

damaged. To avoid damage, make sure all wires are

kept in front of the battery when installing the shroud.

3. Install paint hopper (S) and material dispenser (E).

4. Connect spray button plug and motor plug.

5. Open fuse case and remove old fuse.

332119J 21

Page 22

Repair

ti20183a

ti21362a

Motor Plug

Spray Button Plug

ti21363a

ti21485a

S

E

ti21369a

B

ti21366b

BLACK

ORANGE, YELLOW

OR RED

For Battery with

Thru Hole Post

For Battery with

Threaded Post

ti21482a

Battery Replacement

5. Attach battery cables to battery.

For Battery with Thru Hole Post

Removal

1. Perform Pressure Relief Procedure, page 10.

2. Disconnect motor plug and spray button plug.

3. Remove material dispenser (E) and paint hopper (S).

Use two wrenches to remove serrated nut on negative (black) battery post. Then use wrenches to

remove serrated nut on positive (red) battery post.

For Battery with Threaded Post

Use wrench to remove screw on negative battery

post. Then use wrench to remove screw on positive

battery post.

6. If installed, clip plastic tie straps used for shipping.

Undo velcro strap from battery. Remove battery.

4. Use wrench to remove two bolts and remove battery

shroud (B).

7. Remove bolt and nut from each battery post.

22 332119J

Page 23

Installation

ti21367a

ti21366b

BLACK

ORANGE, YELLOW

OR RED

For Battery with

Thru Hole Post

For Battery with

Threaded Post

ti21368a

ti21486a

ti21487a

S

E

ti21362a

Motor Plug

Spray Button Plug

Repair

1. Install new battery. Install bolts and nuts onto

battery posts with terminals facing front of field

marker. Tighten velcro strap around battery to

secure into place.

2. Attach battery cables to battery.

For Battery with Thru Hole Post

Use two wrenches to attach battery cable to positive

(red) battery post. Then use wrenches to attach to

negative (black) battery post.

3. Place front tabs of battery shroud into slots, then

pivot back of shroud down. Use wrench to tighten

two bolts and secure shroud into place.

NOTICE

When installing the battery shroud, wires can get

pinched between the shroud and frame and become

damaged. To avoid damage, make sure all wires are

kept in front of the battery when installing the shroud.

4. Install paint hopper (S) and material dispenser (E).

For Battery with Threaded Post

Use wrench to attach battery cable to positive (red)

battery post. Then use wrench to attach to negative

(black) battery post.

NOTE: Star washer goes between battery post and

cable.

5. Connect spray button plug and motor plug.

332119J 23

Page 24

Repair

ti24688a

ti21370a

ti24688a

Control Board Replacement

Removal

1. Disconnect battery wires. See Battery

Removal steps 1 - 5, page 22.

2. Disconnect two wires from battery charger connection port.

Installation

1. Install new board into battery shroud. Tighten six

torx screws into board.

2. Connect negative wire (black) to outer connector of

charger jack. Connect positive wire (red) to inner

connector of charger jack.

3. Remove six torx screws from board. Remove board

from battery shroud.

3. Connect battery wires. See Battery

Installation steps 2 - 5, page 23.

24 332119J

Page 25

Pump/Motor Removal

ti20183a

ti21484a

N

ti21363a

S

ti21373a

ti21374a

ti21377a

ti21376a

ti21375a

ti21389a

S

Removal

1. Perform Pressure Relief Procedure, page 10.

2. Disconnect motor plug (N).

Repair

6. Disconnect motor wires and remove power cord.

7. Remove foam gasket and use wrench to remove

bulkhead nut.

3. Use wrench to disconnect hose to material

dispenser.

4. Remove paint hopper (S).

5. Remove six torx screws on motor shroud. Remove

motor shroud.

ti21377a

8. Loosen hose clamp below paint hopper.

9. Remove four screws from paint hopper bracket.

10. Remove paint hopper (S) from pump/motor assembly.

332119J 25

Page 26

Repair

ti24689a

ti24689a1

ti21394aSti21400a

ti21403a

ti21377a

ti21377a

11. Remove pump/motor assembly from hopper

bracket.

Installation

1. Loosely install hose clamp on pump before installing

pump/motor assembly onto pump bracket. Install

new Pump/Motor assembly into pump bracket.

2. Install Pump/Motor assembly into paint hopper (S).

3. Install and tighten four screws.

4. Install and tighten hose clamp to paint hopper.

5. Install and tighten bulkhead nut.

26 332119J

Page 27

Repair

ti21374a

Black

Wire

White

Wire

ti21401a

ti21486a

S

ti21398a

ti21483a

N

6. Install power cord and connect motor wires.

Connect white wire to post with red indicator mark.

Connect black wire to outside post.

7. Install motor shroud, capture wire strain relief and

tighten six torx screws.

8. Install paint hopper (S).

9. Reconnect hose to pump/motor outlet.

10. Connect motor plug (N).

332119J 27

Page 28

Troubleshooting

Troubleshooting

Problem Cause Solution

Pump/motor runs but

material is not being sprayed

Pump/motor runs but material comes out prime hose

Pump/motor does not run

when spray button is in

Paint hopper is empty Fill paint hopper with spray material.

Field marker is not primed Prime field marker. See Starting a New Job, page 13.

Field marker inlet ball check valve has

foreign material in passage way.

Field marker inlet ball check valve is

stuck shut due to improper cleaning

and storage.

Prime/spray valve is UP Move valve handle DOWN to spray position.

Material dispenser tip is plugged Clean material dispenser tip by reverse spraying. See

Material dispenser tip and/or filter is

plugged

CleanShot has foreign particles in passageway

Battery is discharged. Spray button is

red when button is in.

Motor plug is disconnected Connect motor plug on battery shroud. See (N)

Spray button plug is disconnected Connect spray button on battery shroud. See (P)

Battery fuse has faulted resulting in an

open circuit (blown fuse)

Wires to battery have become loose,

disconnected or damaged

Field marker fluid path is plugged

between pump and prime/spray valve

Pump/motor is damaged Remove pump/motor for repair. See Pump/Motor

Remove foreign material in the field marker inlet ball

check valve by:

1. Empty the paint hopper.

2. Remove paint hopper screen.

3. Add 0.5 gallons (2 liters) of water to the paint hopper.

4. Use a thin rod to move inlet ball check up and down.

NOTE: If paint particles seem to be settling in hopper

screen, strain paint with a paint sock prior to filling

hopper.

Reversible Spray Tip, page 11.

Clean material dispenser tip by reverse spraying and

clean filter. See Unclogging Spray Tip/Guard

Assembly, page 17.

If tip does not clean by using Reversible Spray Tip

procedure, remove tip and clean using a cleaning wire

pick, water and pressurized air or water (compressed air or

nozzle jetted city water). If tip cannot be cleaned, replace

tip.

See Tip Removal/Cleaning, page 19.

See CleanShot Removal/Cleaning, page 19.

Connect battery charger and recharge battery. See

Charging the Battery, page 8.

Component Identification, page 6.

Component Identification, page 6.

Remove battery shroud and check for pinched or shorted

wires before replacing fuse. See Fuse Replacement,

page 21.

Tighten wire connection or reconnect. See Battery

Replacement, page 22.

Perform

cannot be relieved as evidenced by material flowing out of

prime hose, STOP and contact Graco Technical Support or

bring field marker to Graco distributor for repair.

NOTE: Red light on spray button will be flashing.

Removal, page 25. Contact Graco Technical Support or

bring field marker to Graco distributor for repair.

Pressure Relief Procedure

, page 10. If pressure

28 332119J

Page 29

Problem Cause Solution

Pump/motor runs but red

light on spray button is on

Spray pattern width is

decreasing

Pump/motor randomly

stops; full spray pattern cannot be achieved

Material continues to flow

out of tip after stopping

spray

Battery did not fully charge Battery charger was disconnected too

Paint is leaking from

pump/motor shroud

Battery has been discharged to the

level that user is notified the battery is

low.

Incorrect material dispenser holder

height position.

Material dispenser tip is wearing out. Replace tip. See Tip Removal/Cleaning, page 19.

Material is too dense and/or too viscous.

Pump/motor is not operating at specified RPM.

Material needs to be strained to

remove solids.

Foreign material in CleanShot. Remove and clean CleanShot. See CleanShot

CleanShot is damaged. Contact Graco Technical Support or bring field marker to

early (charging was interrupted before

completing charge).

Wire terminals are loose or

disconnected on battery charger

connection port (C).

Battery is damaged or at the end of

the recharge life cycle.

Charger is damaged. Replace charger. Contact Graco distributor for

Seals on pump are worn out. Replace pump/motor assembly.

Troubleshooting

Recharge battery. Connect battery charger and recharge

battery. See

red light first comes on, user has approximately 15 minutes

of field marker run time left.

Readjust material dispenser holder until desired width is

achieved. See Adjusting Line Width, page 14.

Readjust material dispenser holder until desired width is

achieved. See Adjusting Line Width, page 14. Dilute

material as required.

Check spray pattern with water only. If spray pattern is

good, dilute material as required. If spray pattern is not

good with water, contact Graco Technical Support or bring

field marker to Graco distributor for repair.

Use a paint sock to filter material as it is being poured into

paint hopper.

Cleaning, page 19.

Graco distributor for repair.

Disconnect charger from field marker. Disconnect

charger from power outlet and allow charger to remain

unpowered for 5 - 10 minutes.

See

Charging the Battery

Reconnect terminals or replace terminals at battery port

(C). See Control Board Replacement, page 24.

Replace battery. See

correct replacement.

Charging the Battery

, page 8.

Battery Replacement

, page 8.

NOTE:

When

, page 22.

332119J 29

Page 30

Wiring Diagram

30A

FUSE

Automotive

Regulator ATO

ti21412a

WHITE

BLACK

RED DOT

MOTOR

CONTROL

BOARD

RED, ORANGE OR YELLOW

BLACK

BATTERY

BLACK

RED

SWITCH

Wiring Diagram

CHARGER JACK

30 332119J

Page 31

Parts

18

103a

103b

103c

52

1

45

45

115

114

48

49

45

8

8

8

21

9

17

19

4

27

27

111

OPTIONAL THRU-HOLE

TERMINAL BATTERY

110

32

13

99

96

97

98

102

6

14

15

16

46

46

39

39

39

7

5

11

10

20

109

28

7

7

28

113

ti24691b

Parts

332119J 31

Page 32

Parts

Parts List

Ref. Part Description Qty.

1 16U476 FRAME, stamped, S90 1

2 16U478 BRACKET, frame, right 1

3 16U477 BRACKET, frame, left 1

4 24R069 BAR, handle, weldment 1

5 16U580 AXLE, rear, S90 1

6 126946 BOLT, cap, hex head 1

7 195367 SPACER 4

8 126947 TIRE, 10 inch, pneumatic 3

9 24R882 KIT, shroud, battery,

includes 96, 97a, 97b, 98, 102

10 16U229 BAR, support 1

11 16U230 BAR, adjustment, height 1

13 15D862 NUT, hand 1

14† 16U231 SHIELD, spray, guide, plastic 2

15 15F142 GUIDE, wire, right shield 1

16 15F143 GUIDE, wire, left shield 1

17 JACK, charger, 12 volt, 15 Amp 1

126951 Series A

127926 Series B

18a CHARGER, 120V ac, USA 1

17C571 Series A, includes 17

17C565 Series B

18b KIT, charger, S90, 240V, Euro 1

17C572 Series A, includes 17. 103a, 103c

17C566 Series B

18d KIT, charger, S90, 240V, Asia/Aus 1

17C572 Series A, includes 17. 103a, 103c

17C568 Series B, includes 103a, 103c

19* 24R792 KIT, board, control, S90,

includes 43

20 127052 KNOB, T-handle 1

21 126949 STRAP, battery 1

27 114659 GRIP, handle 2

28 24P924 SWITCH, pushbutton 1

Ref. Part Description Qty.

32 24X370 KIT, battery, 18 ah, sealed 1

33 16U707 HARNESS, motor wire 1

39 119547 NUT, hex, lock, nylon, thin 3

40 100270 SCREW, cap, hex hd 2

43 119236 SCREW, mach, torx pan hd 6

45 111570 BOLT, carriage 6

46 115942 NUT, hex, flange head 6

48 24R664 KIT, handle bar fasteners 1

49 115480 KNOB, to handle 2

1

52 16U680 LABEL, brand, S90, handle, upright 2

96 16V158 LABEL, 12V battery charge 1

97a 16V162 LABEL, warning, iso, multiple 1

97b 16V507 LABEL, warning, iso, Europe 1

98 16V161 LABEL, quick start instructions 1

99 16V157 LABEL, indicator light 1

102 16D576 LABEL, Made in USA w/global

comp

103a 124783 PLUG, converter, Asia/Aus 1

103b 124507 PLUG, converter, UK 1

103c 127155 PLUG, converter, Japan 1

109 108774 STRAP, tie, wires 2

110 113505 BATTERY, terminal nut 4

111 125857 BATTERY, terminal bolt 2

113 16V701 BOOT, replacement 1

114 111307 WASHER 2

115 128131 SCREW 2

† 24P894 KIT, spray shield, S90, includes 14, 15, 16

1

* Fuse is a 30 Amp automotive fuse, Regular ATO

Replacement Warning and Safety labels are available

at no cost.

1

32 332119J

Page 33

22

25

25

54

53

33

35

84

94

44

36

42

37

62

41

29

30

119

43

26

26

22

24

94

55

56

49e

49d

49c

49b

49

49a

128

ti24693a

31

Parts

Parts

332119J 33

Page 34

Parts

Parts List

Ref. Part Description Qty

22‡ 24R795 KIT, hopper, S90,

includes 24, 25, 53, 54, 119

24 16U373 SEAL, lid, hopper 2

25 126108 SCREW, shoulder, socket head 2

26 24R883 KIT, cover, S90 pump, includes 43 1

29 16T186 BRACKET, pump 1

30 126954 FITTING, elbow, 45 deg, 1/4 npt 1

31 277183 HOSE, cpld, 3/16 in. x 6 ft, 3300 wp 1

33 16U707 HARNESS, motor wire, includes 35 1

35 126955 BUSHING, strain relief 1

36 113817 BUMPER 1

37 16T185 FITTING, pump adapter 1

41 100071 NUT, hex 1

42 117791 SCREW, cap, tri lobe 1

43 119236 SCREW, mach, torx pan hd 6

44 111800 SCREW, cap, hex hd 4

49 16U370 FILTER, hopper includes 49a – 49e 1

49a 17C933 BUSHING, ball knocker 1

Ref. Part Description Qty

49b 192348 NUT, head 1

1

49c 127962 SPRING 1

49d 17C934 STEM, ball knocker 1

49e 17C935 KNOB 1

53 16U679 LABEL, brand, S90, hopper, lside 1

54 16U677 LABEL, brand, S90, hopper, rside 1

55 16U602 HOUSING, inlet assembly 1

56 16T184 VALVE, outlet, ball check 1

62 109576 PACKING, o-ring 1

84 117464 CLAMP, hose, micro 1.75 max dia. 1

94 24R172 KIT, complete pump and motor 1

114 865663 STRAINER, mesh, hopper, 5 gallon

(12 pack) (item not shown)

119 17C502 SEAL, hopper, base 1

128 17W933 GASKET, hopper, base 1

‡ Lid Kit 24R820 is available (includes 24)

1

34 332119J

Page 35

Parts

31

63

60

13

30

67

66

61

71

79

62

95

68

62

69

70

72

76

73

75

74

70a

70b

78

77

65

64

62

ti24704a

125

Optional

CleanShot™ Valve

Parts

332119J 35

Replaces 70, 70a, 70b

Page 36

Parts

Parts List

Ref. Part Description Qty.

13 15D862 NUT, hand 1

30 24P124 KIT, holder, tip, includes 31-79 1

31 277183 HOSE, cpld, 3/16 in. x 6 ft, 3300 wp 1

60 16T159 MANIFOLD, filter 1

61 16U255 HOLDER, tip 1

62 109576 PACKING, o-ring 3

63 24R790 KIT, valve, prime, S90,

includes 62-65

64 119956 PIN, straight 1

65 HANDLE, drain valve 1

66 162453 FITTING, (1/4 npsm x 1/4 npt) 1

67 103147 PLUG, pipe 1

68 16T160 TUBE, filter 1

69 287033 FILTER, 100 mesh 1

Ref. Part Description Qty.

70 17C501 HOUSING, filter, turf 1

70a 103610 O-RING, packing 1

70b 17C500 HOUSING, restrictor 1

71 103875 ADAPTER, hose, barb 1

72 16U667 TUBE, drain 1

73 16C645 TUBE, drain 1

74 196467 VALVE 1

1

75 104893 PACKING, o-ring 1

76 195400 CLIP, spring 1

77 LL5315 TIP, spray, RAC 5, striping 1

78 243161 GUARD, RAC IV / 5 1

79 112774 SCREW, mach, sltd hex wash hd 2

95 16V159 LABEL, gun, filter 1

125 24P969 VALVE, CleanShot, turf, optional

36 332119J

Page 37

Technical Data

U.S. Metric

Maximum working pressure 1200 psi 8.3 MPa, 83 bar

Recommended Tip Size LL5315 LL5315

Maximum Tip Size LL5417 LL5417

Weight 60 lb 27.2 kg

Dimensions:

Length 40 in. 101.6 cm

Width 23 in. 58.4 cm

Height 36 in. 91.4 cm

Storage temperature range

Operating temperature range

Sound pressure level 79.2 dBa† sound pressure level

Vibration level acceleration

Charger:

Charging time 6 hours to 80%,

Power source 120/240 VAC 120 /240VAC

Battery (Sealed Lead Acid):

Voltage (DC) 12 V Maximum 12 V Maximum

Capacity 22 Ah, 264 Wh 22 Ah, 264 Wh

Fuse

Current rating 30 Amp 30 Amp

Type Automotive, Regular ATO Automotive, Regular ATO

?

?

33° to 120° F 1° to 48° C

33° to 120° F 1° to 48° C

79.2 dBa† sound pressure level

93.8 dBa† sound power level

Less than 5.5 feet/s

6 to 14 to 100%

2

†† Less than 1.7 m/s2††

93.8 dBa† sound power level

6 hours to 80%,

6 to 14 to 100%

Technical Data

Pump damage will occur if fluid freezes in pump.

?

Damage to plastic parts may result if impact occurs in low temperature conditions.

?

Changes in paint viscosity at very low or very high temperatures can affect field marker performance.

† per ISO 3744 measured at 3.3 feet (1m)

†† per ISO 5349, no load condition

332119J 37

Page 38

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to I.S. EN ISO 9001

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

This manual contains English. MM 332119

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision J - November 2018

Loading...

Loading...