Page 1

Kit Instructions

ExactaBlend™ AGP Advanced Glazing Proportioner

332511A

Heated Platen Kit

For heating bulk supply of medium to high viscosity polysulfide and urethane materials.

For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

24R200

Heated platen kit, high volume

Refer to ExactaBlend AGP Advanced Glazing Proportioner, Setup-Operation manual for maximum working pressure

and model information.

Important Safety Instructions

Read all warnings and instructions in this

manual and the ExactaBlend AGP Advanced

Glazing Proportioner, Setup-Operation manual. Save all instructions.

EN

Page 2

Related Manuals

Related Manuals

Refer to ExactaBlend AGP Advanced Glazing Proportioner, Setup-Operation manual for the complete list of

related manuals.

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Description . . . . . . . . . . . . . . . . . . . . . . . 3

Power Requirements . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 4

Heated Platen Kit . . . . . . . . . . . . . . . . . . . . . . . . 4

Heat Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Platen Maintenance . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Common Problems . . . . . . . . . . . . . . . . . . . . . . 16

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replace Platen Heaters and Sensor . . . . . . . . . 18

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Heated Platen Kit, 24R200 . . . . . . . . . . . . . . . . 20

Heat Enclosure, 24R870 . . . . . . . . . . . . . . . . . . 24

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 28

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 28

2 332511A

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

WARNINGWARNINGWARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

Overview

System Description

The heated platen kit is a field installed kit to add heat to

the platen. The additional heat may change the viscosity

properties of the material and allow the material to flow

easier through the system.

Power Requirements

A 25A (minimum) - 30A (maximum) circuit breaker must

be installed on the incoming power supply.

Nominal Voltage** Wattage Amps*

240 V 3,500 per Platen 20

* Add to power requirements of ExactaBlend AGP

Advanced Glazing Proportioner system. Amps maximum per leg shown.

** 190-264 voltage range acceptable.

332511A 3

Page 4

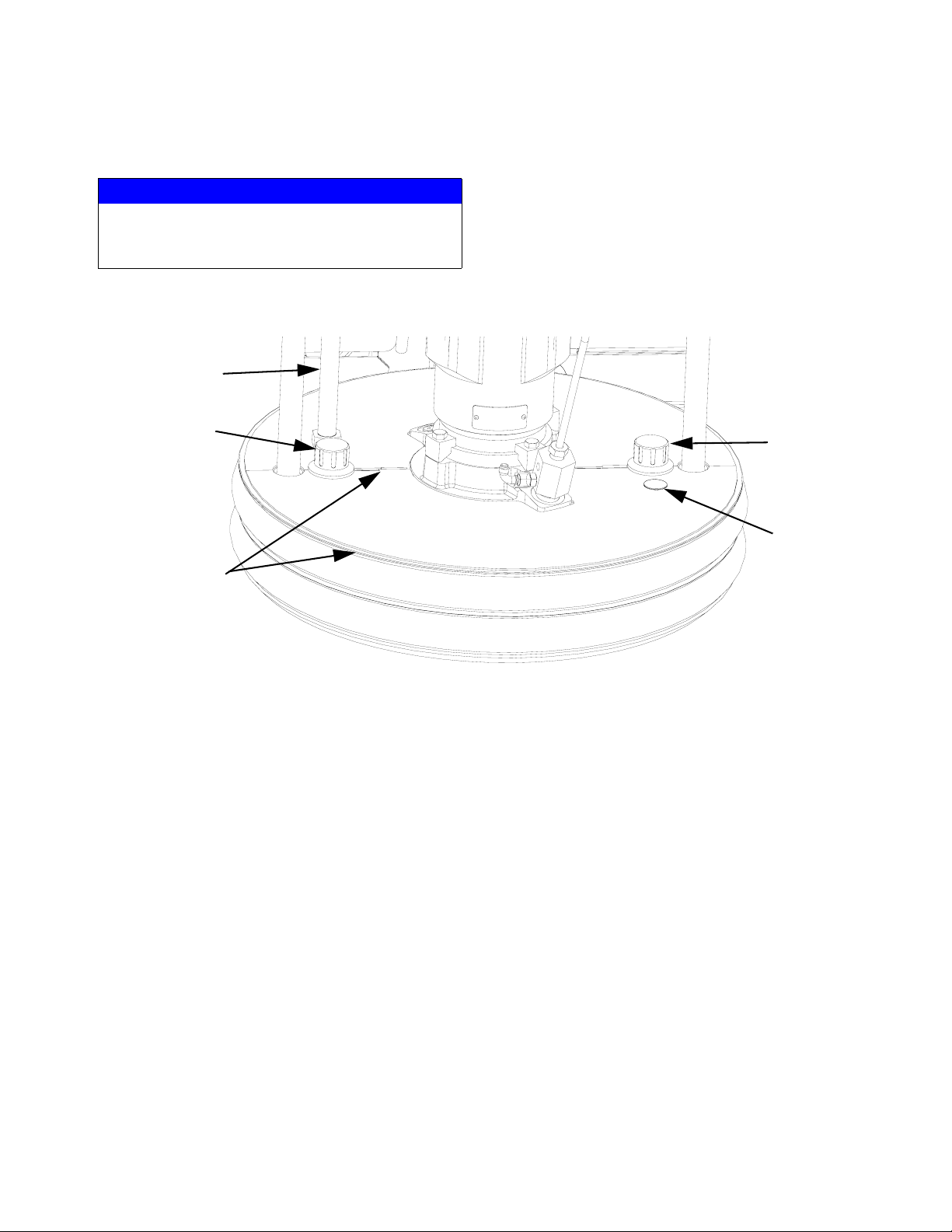

Component Identification

Component Identification

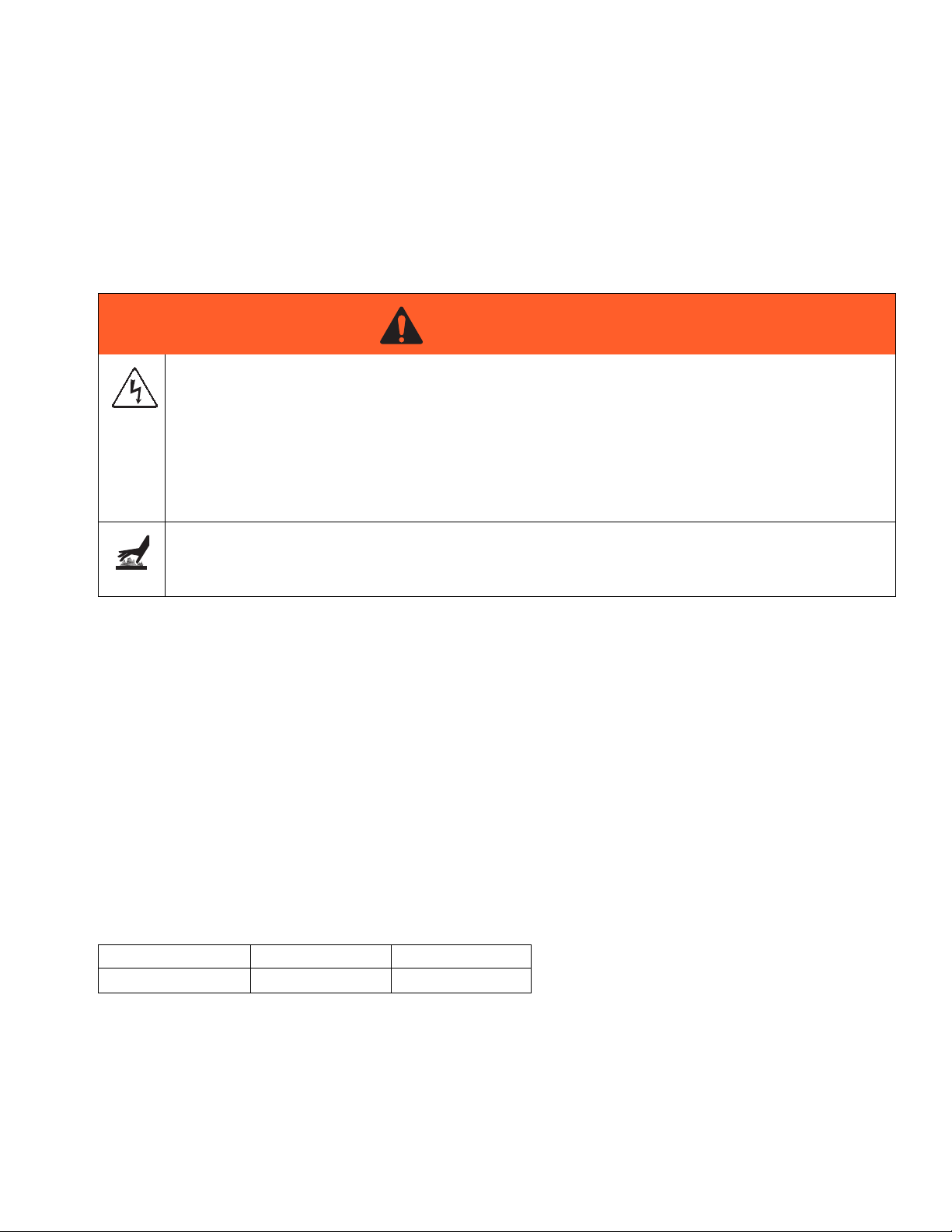

Heated Platen Kit

C

A

B

D

FIG. 1: Heated Platen Kit

F

E

H

G

Key:

A RTD Temperature Sensor

BHeater Coil

C Temperature Limit Switch

D Junction Box

E Heat Electrical Enclosure

FMain Power Switch

4 332511A

G Heater Power Switch

HHeat Controller

Page 5

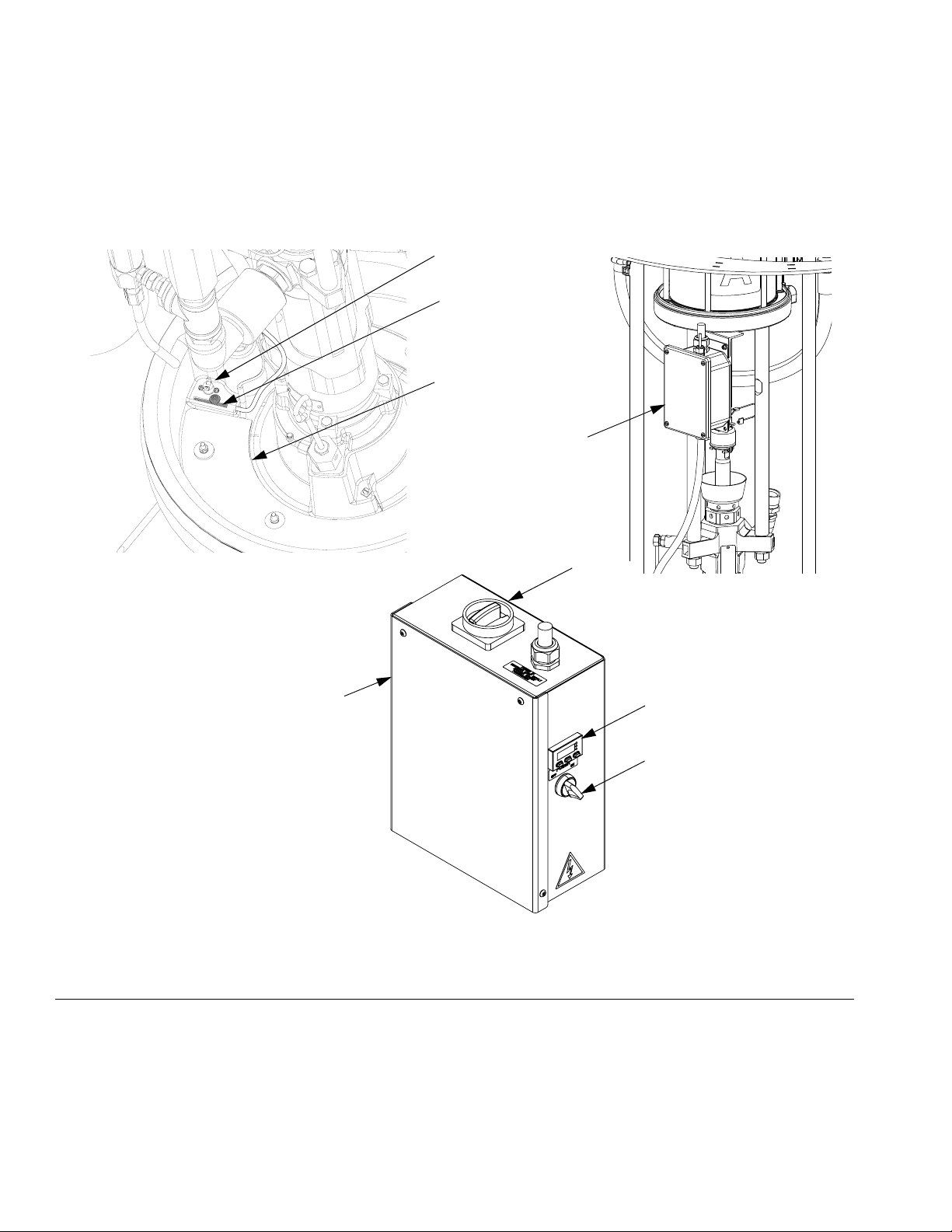

Heat Controller

AA

AB

AC

1 2

Component Identification

AD

FIG. 2: Heat Controller

Key:

AA Current Temperature

AB Power is Supplied to Heater

AC Power is Supplied to Heat Overtemp Contactor

AD Desired Temperature

AE Temperature Adjustment

70

90

AE

332511A 5

Page 6

Installation

Installation

To avoid serious injury or machine damage, all

electrical connections need to be done by a qualified

electrician in compliance with local codes.

Grounding

Ground the system as instructed within this manual.

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

1. Access the Platen

a. Perform Change Drums procedure in the

Air-Powered Ram manual. Do not load a new

drum.

b. Perform Shutdown procedure in the Exact-

aBlend AGP Advanced Glazing Proportioner,

Setup-Operation manual.

c. Thoroughly clean all material that may be found

on the top of the platen.

d. Turn off all sources of power to the machine.

6 332511A

Page 7

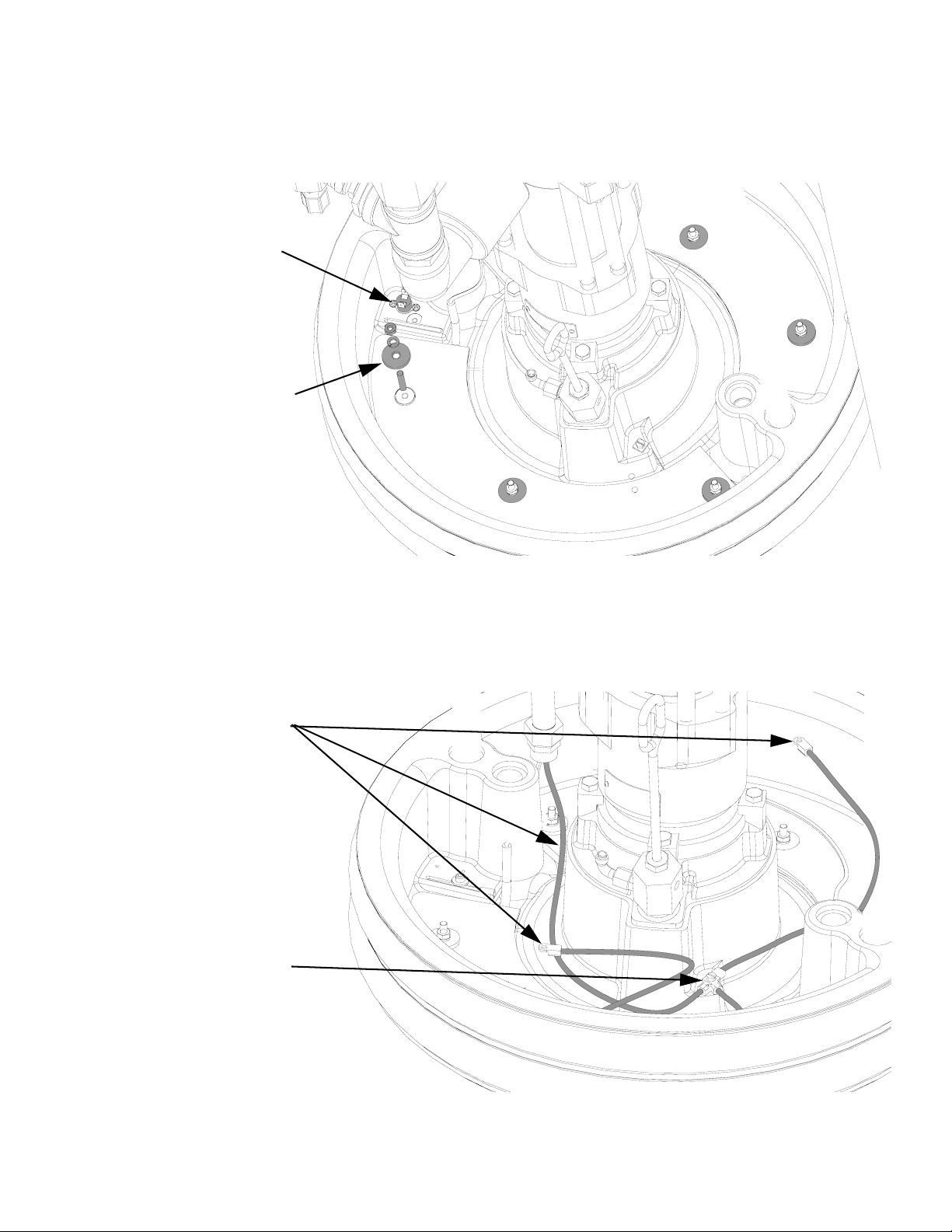

2. Install the Heat Coils and the Thermostat Switch.

- (1) Thermostat

- (2) Washers

- (2) Screws

- (6) 1/4-20 Studs

- (6) Flat Washers

- (6) Lock Washers

- (6) Nuts

Installation

3. Connect the Ground Wires.

Connect the ground wires to the terminal lug and to the platen covers (not shown in view). Attach the conduit to the

platen cover and route the wires through the conduit when connections are complete.

- (3) Ground Wires

- (2) Lock Washers

- (2) Nuts

- (1) Terminal Lug

332511A 7

Page 8

Installation

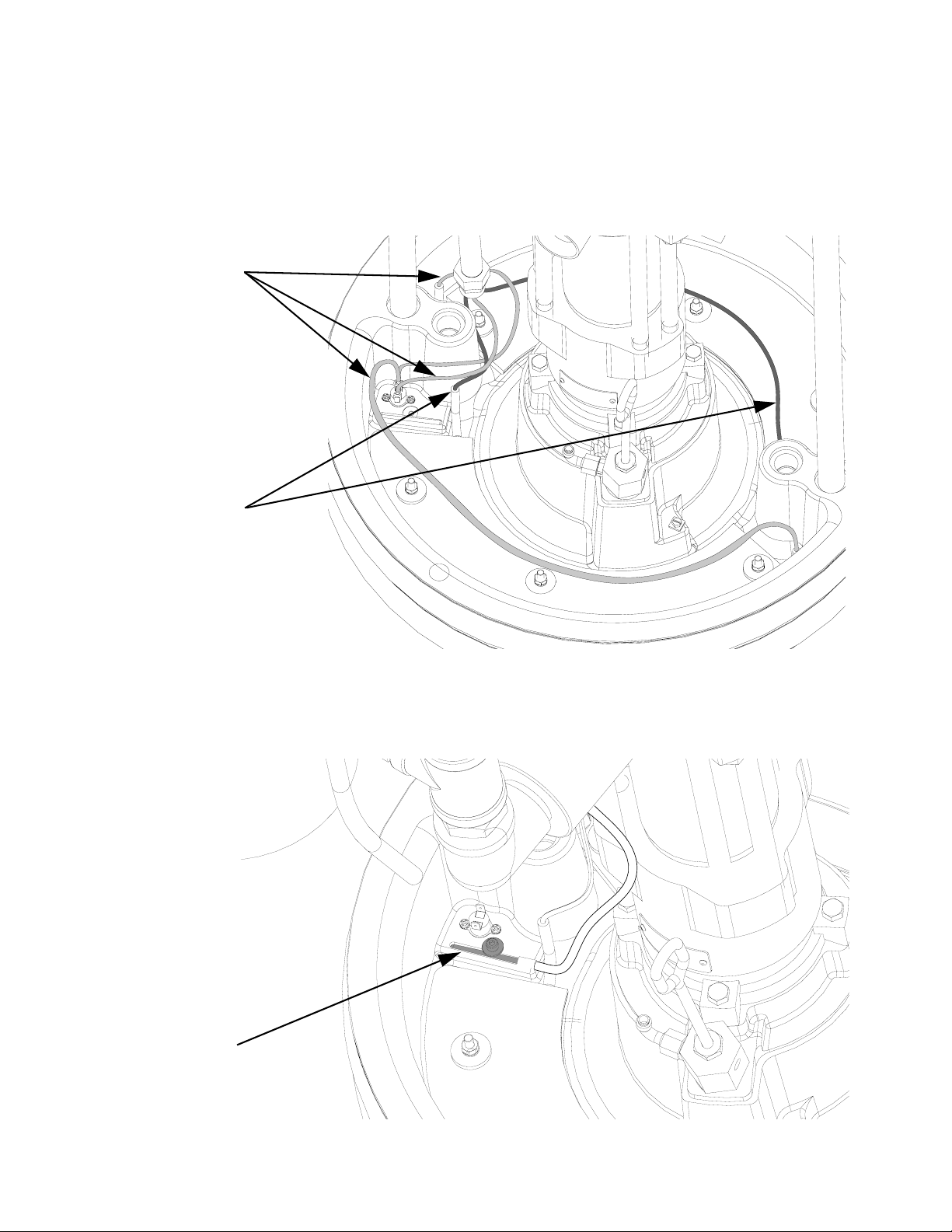

4. Connect the Power Leads.

Label “A” and “B” leads for identification in step 10. Route all the wires through the conduit when connections are

complete.

- (3) “A” Leads

- (2) “B” Leads

5. Mount the RTD.

Route the wire through the conduit when connections are complete.

- (1) RTD

- (1) Washer

- (1) M5 Screw

8 332511A

Page 9

6. Attach the Platen Covers.

NOTICE

To prevent damage to wires, ensure wires are not

pinched when assembling and securing platen covers.

NOTE: Torque the platen cover fasteners to

60 +/- 10 in-lbs (6.8 +/- 1.1 N•m).

- (1) Conduit

Installation

- (1) Fastener

- (2) Covers

- (1) Fastener

- (1) Plug

332511A 9

Page 10

Installation

7. Mount the Junction Box.

a. Mount the junction box to the air motor located on the 55 gallon (208 liter) ram.

b. Route the conduit to the junction box from the platen.

- (2) #8-32 Screws

- (2) Lock Washers

- (1) 3/8-16 Bolt (Urethane)

- (1) M8 Bolt (Polysulfide)

- (1) Lock Washer

8. Mount the Heat Electrical Panel on the 5 Gallon (19 liter) Ram.

- (8) M6x16 Bolts

- (8) Washers

- (8) Lock Washers

- (8) Nuts

- (8) M6x25 Bolts

- (8) Washers

- (8) Lock Washers

- (8) Nuts

10 332511A

Page 11

9. Route the Power Cord and Signal Cable to the Junction Box.

Secure the power cord and signal cable to the base (A) cross bar.

Routing

Installation

10.Connect the Leads in the Junction Box.

Connect “A” leads, “B” leads, ground, and signal cable within the junction box. Replace the cover.

332511A 11

Page 12

Installation

11.Connect the Power Cable from the Heat Electrical Enclosure to

the Main Electrical Enclosure.

12.Connect Power to the Terminals and Ground.

12 332511A

Page 13

Setup

1. Turn the power on at the heated platen electrical

enclosure.

2. Turn the power on at the heater power switch.

Setup

3. Set the desired platen temperature by pressing

either the up or down arrow keys.

NOTE: Temperature is displayed in Fahrenheit.

Desired Temperature

1 2

70

90

332511A 13

Page 14

Operation

Operation

Startup

1. Turn the power on at the heated platen electrical

enclosure.

2. Turn the power on at the heater power switch.

Shutdown

1. Turn the power off at the heater power switch.

NOTE: If the entire machine is to be disconnected from

electrical power, turn the power off at the heated platen

electrical enclosure.

3. Set the desired temperature. Refer to page 5 for

details.

14 332511A

Page 15

Maintenance

Maintenance

Platen Maintenance

If the platen does not come out of the pail easily when

the pump is being raised, the air assist tube or check

valve may be plugged. A plugged valve prevents air from

reaching the underside of the plate to assist in raising it

from the pail.

1. Turn off main disconnect at the machine.

2. Allow equipment to cool.

3. Relieve pressure and disassemble air assist valve.

Refer to Supply Systems Repair-Parts manual.

4. Clear air assist tube in platen. Clean all parts of

valve and reassemble. Refer to Supply Systems

Repair-Parts manual.

5. Remove bleed stick from platen. Push bleed stick

through bleed relieve port (P) to remove material

residue. See F

IG. 3.

Remove and Reinstall Platen Wipers

Refer to Supply Units Repair-Parts manual for instructions.

F

C

Bleed

Stick

P

FIG. 3: Remove Platen Covers and Heaters

B

H

6. Remove platen covers. See F

a. Remove platen cover fasteners (F).

b. Remove both platen covers (C) and ground wire

from platen.

7. Remove any excess fluid. Use a soft wire brush on

heater coils (H). See F

8. Inspect platen heater blocks (B) or heater (H) for

burn or melt spots. Replace platen heater if necessary. See F

9. Check for loose connections and damaged wires.

10. Follow steps in reverse order to reassemble platen.

NOTE: Torque platen cover fasteners (F) to 60 +/- 10

in-lbs (6.8 +/- 1.1 N•m) for 55 gallon platen.

IG. 3.

IG. 3.

IG. 3.

332511A 15

Page 16

Troubleshooting

Troubleshooting

Before performing any troubleshooting procedure:

1. Perform Pressure Relief Procedure In the ExactaBlend AGP Advanced Glazing Proportioner,

Setup-Operation manual.

2. Turn off main disconnect at the machine.

3. Allow equipment to cool.

Try the recommended solutions in the order given for

each problem, to avoid unnecessary repairs. Also,

determine that all circuit breakers, switches, and controls are properly set and wiring is correct before assuming there is a problem.

Common Problems

Problem Cause Verification Solution

Heating is slow. Low power. Measure voltage across cir-

cuit breakers. Voltage

should measure between

190 and 264 Vac.

Heating over shoots. Defective solid state relay. Verify for given zone that

temperature does not

increase when zone is disabled.

1. If voltage is lower than

expected, use electrical

schematic to locate

faulty wiring or connection.

2. Have a qualified electrician service electrical

components.

Verify RTD wire or heater

power cord is attached to

correct heat module.

Replace relay.

16 332511A

Page 17

Problem Cause Verification Solution

No heat. Tripped circuit breaker. Visually check circuit

breaker for a tripped condition.

Low power. Measure voltage across cir-

cuit breakers. Voltage

should measure between

190 and 264 Vac.

Cable unplugged/loose

wire.

Incorrect temperature set

point.

Check for loose or disconnected wires and plugs.

Verify zone has a correct

temperature setting on the

controller.

Contactor not closing. Turn on heat for zone A1

and ensure contactor

closes.

Troubleshooting

Determine cause of tripped

circuit breaker. Then repair

fault and reset main circuit

breaker.

1. If voltage is lower than

expected, use electrical

schematic to locate

faulty wiring or connection.

2. Have a qualified electrician service electrical

components.

Attach plug/wire.

Enter Setup and enter correct temperature.

1. Verify that there are no

other error conditions

that would prevent

heater from starting.

2. Replace contactor.

332511A 17

Page 18

Repair

Repair

Replace Platen Heaters and Sensor

55 Gallon Platen Heater and Sensor

1. Turn off main disconnect at the machine.

2. Allow equipment to cool.

3. Remove both platen cover fasteners (F).

4. Remove both platen covers (C) and ground wire

from platen.

F

C

c. Disconnect four platen heater wires (labeled A

and B) and RTD sensor (R) connector in the terminal box.

d. Remove screws and washers. Remove platen

heater blocks (B) and RTD sensor (R).

6. Install new platen heaters and RTD sensor (R).

Secure RTD sensor (R) with screw and washer.

Secure platen heater blocks with nuts and washers.

7. Label platen heater wires A and B. Reroute platen

heater wires and platen RTD sensor (R) through the

conduit to the junction box. Reconnect the four wires

to the appropriate terminal block A and B. Reconnect the platen RTD sensor (R).

8. Reinstall junction box cover. Secure with screws and

tighten strain relief nut.

9. Reconnect ground wire, and install platen covers.

Secure platen covers with fasteners. Torque platen

cover fasteners to 60 in-lbs +/- 10 in-lbs (6.8 +/-

1.1 N•m).

N

L

W

R

FIG. 4: Replace Platen Heaters and RTD sensor (R)

5. Remove platen heater blocks (B).

a. Use a hex wrench to remove three nuts (N) and

washers (L, W) from each heater block.

b. Remove screws from junction box cover.

Loosen strain relief nut, and remove junction

box cover.

B

18 332511A

Page 19

Schematic

Schematic

TC-1

HARNESS

16A522

3

+24VDC

4

SIGNAL

GND

1371

HARNESS

16A574

255733

1371

1392

R-1

RTD

16D383

24E265

5

7

6

HARNESS

(16D383)

1371

SIGNAL

EXC

432

1

432

1

1370

1

2

8

HARNESS

16U356

15B137

THERM SW

GND

1391

GND

1390

1392

HARNESS

HARNESS

16U365

HARNESS

16U356

16A356

HARNESS

16A574

255733

B

A

GND

A

B

GND

1PH/

220V/

50-60HZ

CUSTOMER MUST SUPPLY BRANCH CIRCUIT PROTECTION

1

DISC100

GND

L21L2

L11L1

103

102

100

101

104

HARNESS

16U353

106

105

C1

C2

HARNESS

16U345

108

109

107

1180

1100

1L1

BLU

1300

A2

SSR130

A1

1280

BRN

OX

CRM

1120

5A

CB

CB

16U345

HARNESS

1L2

110

114

112

111

113

120

118

116

119

115

117

SW-1

SW-1

POWER

OFF ON

126

124

125

123

122

121

HARNESS

132

130

128

131

129

127

T1

L1

16U354

HARNESS

16U358

134

135

133

1361

1360

1L1

1382

T1

SSR130

L1

1381

T3

T2

L3

L2

CON120

HARNESS

16U354

1380

CB

CB

20A

HARNESS

16U358

1L2

SEE XXXXXX FOR LABELS

LABEL WITH WIRE NUMBERS MARKED AS SHOWN

1

149

147

145

142

138

136

140

141

139

137

148

144

146

143

332511A 19

Page 20

Parts

Parts

Heated Platen Kit, 24R200

2

6

2

5,

26

11

14

3

5

22

23

28

11

7

14

FIG. 5: Heated Platen Kit

20 332511A

Page 21

32

33

34

35

25

36

Parts

30

19

16,

45

27

17

21

4

18

8

24

8

10

3

44

39

1

43

40

42

37

44

38

41

43

40

FIG. 6: Heated Platen Kit

332511A 21

Page 22

Parts

Ref Part Description Quantity

1 --- FERRULE, wire, 14awg 2

2 --- FASTENER, platen, cover 2

3 --- COUPLER, conduit 2

4 --- ENCLOSURE, platen, heated 1

5 --- COVER, platen front, assembly 2

6 --- PLUG, finishing, 13/16, nickel plate 1

7 --- STUD, 1/4-20 x 1.25 6

8 16D383 SENSOR, RTD, 1k ohm, shielded 1

9 --- NUT, full hex, 10-32 2

10 --- FERRULE, wire, 14awg, twin 1

11 --- CONDUCTOR, block, heater 2

12 --- WIRE, ground 2

13 --- WIRE, ground 1

14 15V427 HEATER, coil 2

15 --- CONDUIT, 12.9mm 2.70

16 --- SCREW, cap, 3/8-19x3/4 1

17 --- WASHER, M5 1

18 --- SCREW, cap, 8-32x1/2 2

19 --- WASHER, lock, 3/8 1

20 --- WASHER, lock, internal, M5 2

21 --- WASHER, flat, #6 2

22 --- NUT, hex, 1/4-20 6

23 --- WASHER, lock, 1/4 6

24 261821 CONNECTOR, wire, 6awg 2

25 --- GRIP, cord, 0.39-0.56, 1/2 1

26 ▲ 15J075 LABEL, safety, hot surface & energized 1

27 --- SCREW, M5-0.8x12mm 1

28 --- WASHER, flat, special 6

29 --- SCREW, ground, M5-0.8x13mm 1

30 --- BRACKET, enclosure, platen 1

32 --- TUBE, shrink 1

33 --- SCREW, machine, 6-32x3/8 2

34 --- WASHER, lock external, #6 2

35 15B137 SWITCH, over temperature 1

36 --- GRIP, cord, straight 1

22 332511A

Page 23

Ref Part Description Quantity

37 --- BRACKET, mount, top 2

38 --- BRACKET, mounting, ram 2

39 24R870 MODULE, heat 1

40 --- WASHER, M6 16

41 --- SCREW, socket head, M6x25mm 8

42 --- SCREW, socket head, M6x16mm 8

43 --- WASHER, lock, M6 16

44 --- NUT, hex, M6 16

45 --- SCREW, cap, M8x20mm 1

▲ Replacement Danger and Warning labels, tags and

cards are available at no cost.

--- Not available for individual sale.

Parts

332511A 23

Page 24

Parts

Heat Enclosure, 24R870

128

109

107

108

110

109

101,

112,

113

132

106

134

111

116

127

136

108

109

FIG. 7: Heat Module

24 332511A

Page 25

117

130

Parts

118

114,

115

130

130

124

126

102,

104

139

119

121

125

102,

103

131

129

122

122

123

118

120

FIG. 8: Heat Module

332511A 25

Page 26

Parts

Ref Part Description Quantity

101 --- NUT, machine hex, M4-0.7 2

102 --- NUT, hex, M5-0.8 5

103 --- WASHER, lock, external, M5 3

104 --- WASHER, plain, #10 2

106 --- RETAINER, cord 1

107 121148 HANDLE, disconnect, electrical 1

108 --- GRIP, cord 2

109 --- SCREW, M5-0.8x10mm 4

110 126999 SWITCH, disconnect, 32a 1

111 24R941 MODULE, controller, heat, program 1

112 127106 RELAY, solid-state, 240v/50a 1

113 127107 COVER, relay, solid-state, 240v/50 1

114 --- LATCH, operator 1

115 --- BLOCK, contact, normally open 1

116 --- SWITCH, operator, selector 1

117 --- HARNESS, single, 16ga, black 2

118 --- HARNESS, single, 16ga, black 3

119 --- HARNESS, single, 10ga, green/yellow 1

120 --- HARNESS, single, 10ga, black, 2

121 --- HARNESS, single, 10ga, green/yellow 1

122 --- HARNESS, single, 16ga, black 2

123 --- HARNESS, single, 16ga, green/yellow 1

124 --- HARNESS, double, 10ga, black 2

125 --- HARNESS, 3 connector, 12ga 1

126 --- MODULE, din 1

127 --- BRACKET, mounting, heat, ram 1

128 --- COVER, bracket, mounting, heat, ram 1

129 --- HARNESS, sing, 16ga, black 2

130 --- HARNESS, sing, 16ga, black 3

131 --- HARNESS, m8, 4pin 1

132 --- CONNECTOR, power, panel mount 1

134 --- GRIP, cord 1

136 ▲ 196548 LABEL, warning, shock 1

139 121599 CORD, power, v-lock 1

▲ Replacement Danger and Warning labels, tags and

cards are available at no cost.

--- Not available for individual sale.

26 332511A

Page 27

Parts

332511A 27

Page 28

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-746-1334 Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2013, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 332511

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Loading...

Loading...