Page 1

Instructions - Parts

24P822 E-Flo® D

C Control

Module Kit

User Interface for E-Flo® DC Pumps with an Advanced Motor.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual, the supplied

ADCM manual, and the E-Flo DC manuals.

Save these instructions.

See the se

for complete warnings and approvals

information about the 24L097 Advanced

Display

parate manual (supplied)

Control Module (ADCM).

3A2527D

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Control Module...................................................3

Installation.......................................................... 3

Install the Control Module............................. 3

Install Optional Accessory Kits ...................... 4

Cable Connection ........................................ 5

Operation........................................................... 6

Module Scre

Module Keys

Icons...........................................................8

Screen Navi

Initial Se

Screen Map........................................................ 10

Run Screens ......................................................12

Run Screen 1 .............................................. 12

Run Screen 2 .............................................. 13

Run Screen 3 .............................................. 13

Run Screen 4 .............................................. 14

Run Screens 5–8 ......................................... 14

Setup Sc

reens.................................................... 16

ens........................................... 6

................................................ 6

gation and Editing...................... 9

tup ................................................. 9

Setup Screen 1 ............................................ 16

Setup Screen 2 ............................................ 18

Setup Screen 3 ............................................ 19

Setup Screen 4 ............................................ 20

Setup Screen 5 ............................................ 22

Setup Screen 6 ............................................ 23

Setup Screen 7 ............................................ 23

Setup Screens 8 and 9 ................................. 24

Setup Screens 10 and 11 ............................. 25

Setup Screen 12 .......................................... 26

Setup Screen 13 .......................................... 27

Setup Screen 14 .......................................... 28

Setup Screen 15 .......................................... 29

Error Code Troubleshooting ................................ 30

Parts.................................................................. 32

24P822 Co

Appendix A - Modbus Variable Map ..................... 34

Appendix B. Pump Control from a PLC ................ 38

Graco St

andard Warranty.................................... 40

ntrol Module Kit ........................... 32

2

3A2527D

Page 3

Control Module

Control Modul

The Control Module provides the interface for users

to enter selections and view information related to

setup and operation.

The screen backlight is factory set to remain on,

even without screen activity. See Setup Screen 4

to set the backlight timer to your preference. Press

any key to restore.

Keys are used to input numerical data, enter setup

screens, navigate within a screen, scroll through

screens, and select setup values.

e

Installation

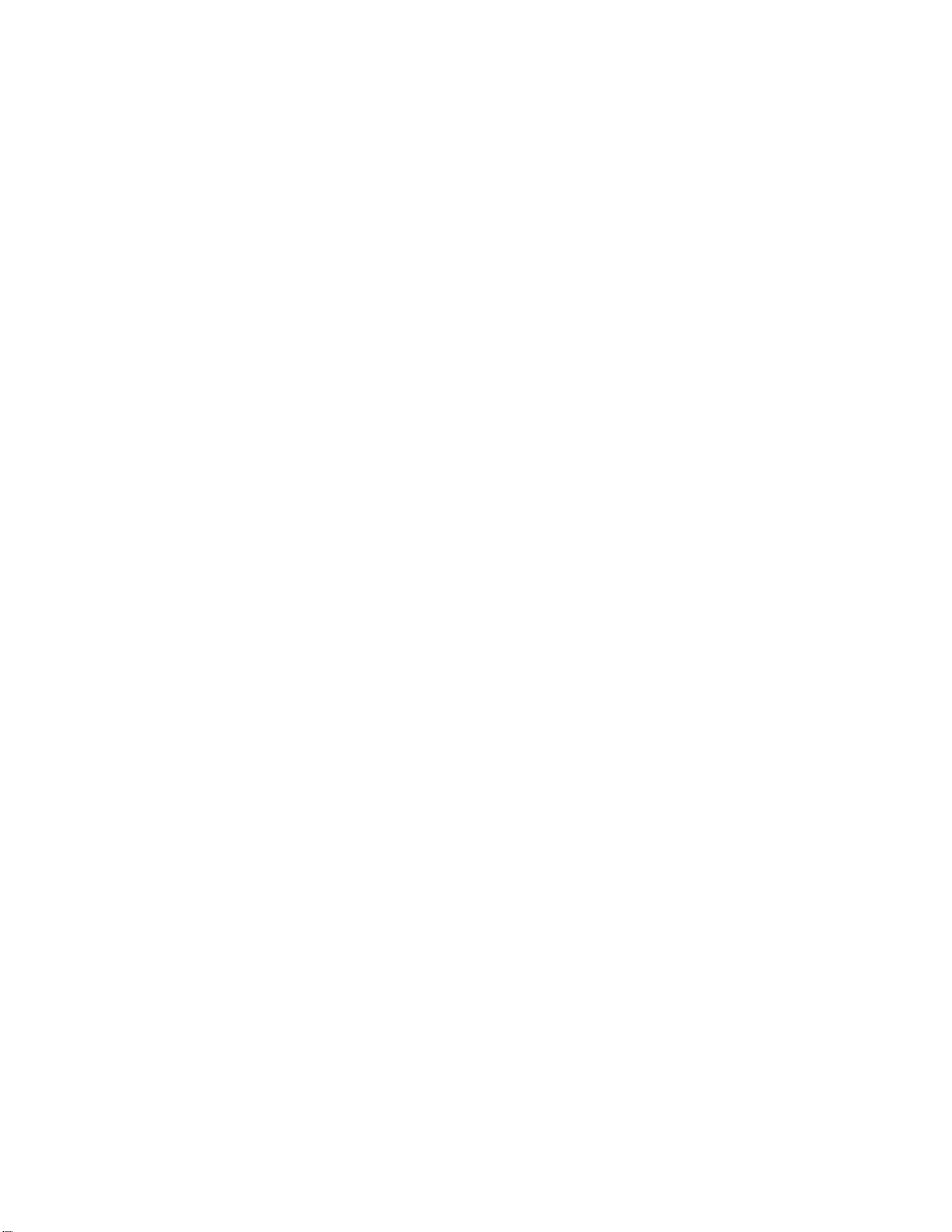

Install the Control Module

1. Shut off and lock out power to the motor.

4. Install the module (1) in the bracket (6a), making

sure the tabs at the bottom of the bracket engage

the slots in the module, and the lip at the top of

the bracket holds the module securely in place.

5. Connect the accessory cable (C), using the

tie (12) as a strain relief as shown. See

Cable Connection, page 5 .

6. Restore power to the motor.

2. Install the jumper connector (5) over the top two

terminals of the motor, using the screw (5a).

NOTE: To connect up to 8 motors together, see

Appendix A in the E-Flo DC Motor Manual, where

the control module is the referenced intrinsically

safe (IS) apparatus.

3. Assemble the bracket kit (6a-6f) and the holder

and tie (11, 12) as shown.

Figure 1 Install the Control Module

3A2527D 3

Page 4

Installation

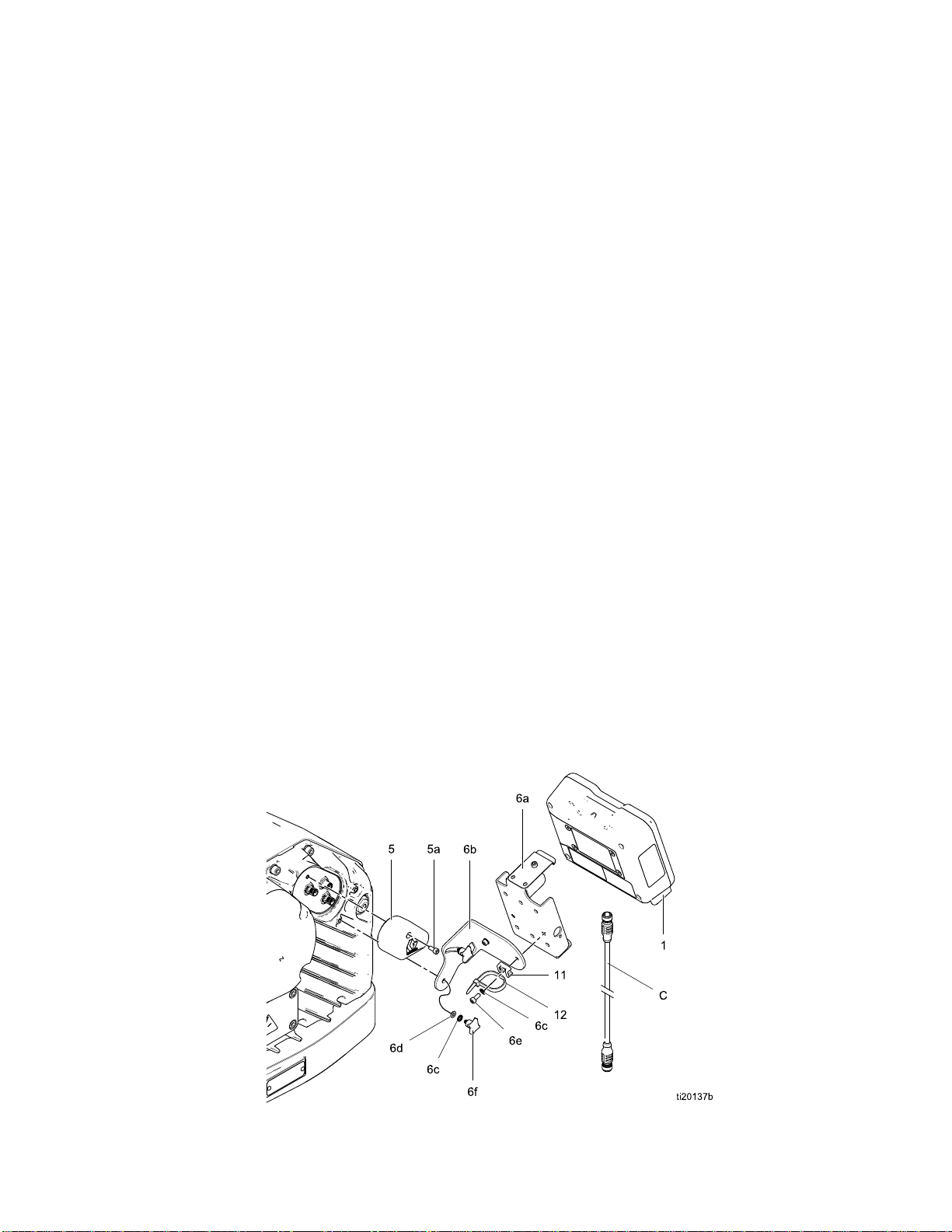

Install Optio

Optional accessory kits are available for purchase

separately, including a pressure transducer kit (PN

24R050), a start/stop switch kit (PN 16U729), and a

controller kit (24V001 ) for a back pressure regulator.

nal Accessory Kits

Pressure Transducer Kit

1. To measure fluid pressure, install the pressure

transducer in the fluid line with a tee fitting.

Option

Closed Loop Control

Enabled

Closed Loop Control

Not Enabled

Description

If closed loop control

is enabled on Setup

Screen 8 (transducer

1) or Setup Screen 9

(transducer 2), install

the transducer near the

pump outlet, not near

the end of the circulation

line.

the transducer

Install

where ne

eded.

BPR Controller

The BPR (back pressure regulator) controller enables

theusertocontrolthebackfluidpressurefromthe

control module.

1. Mount the BPR

provided.

2. Connect a su

air inlet (1

To prevent equipment damage, always apply

air pressure to the BPR controller before

applying power to the system.

3. Connect an air line from the BPR controller air

output (108) to the BPR.

4. Connect the BPR controller input cable (102) to

Port 8 on the control module.

controller using the bracket

pply air line to the BPR controller

05).

NOTICE

2. Connec

ducer 1) or Port 10 (transducer 2) on the

(trans

l module.

contro

/Stop Switch Kit

Start

1. Mount

the br

2. Conn

modu

the switch near the control module, using

acket provided.

ect the switch cable to Port 4 on the control

le.

t the transducer cable to Port 7

4

3A2527D

Page 5

Installation

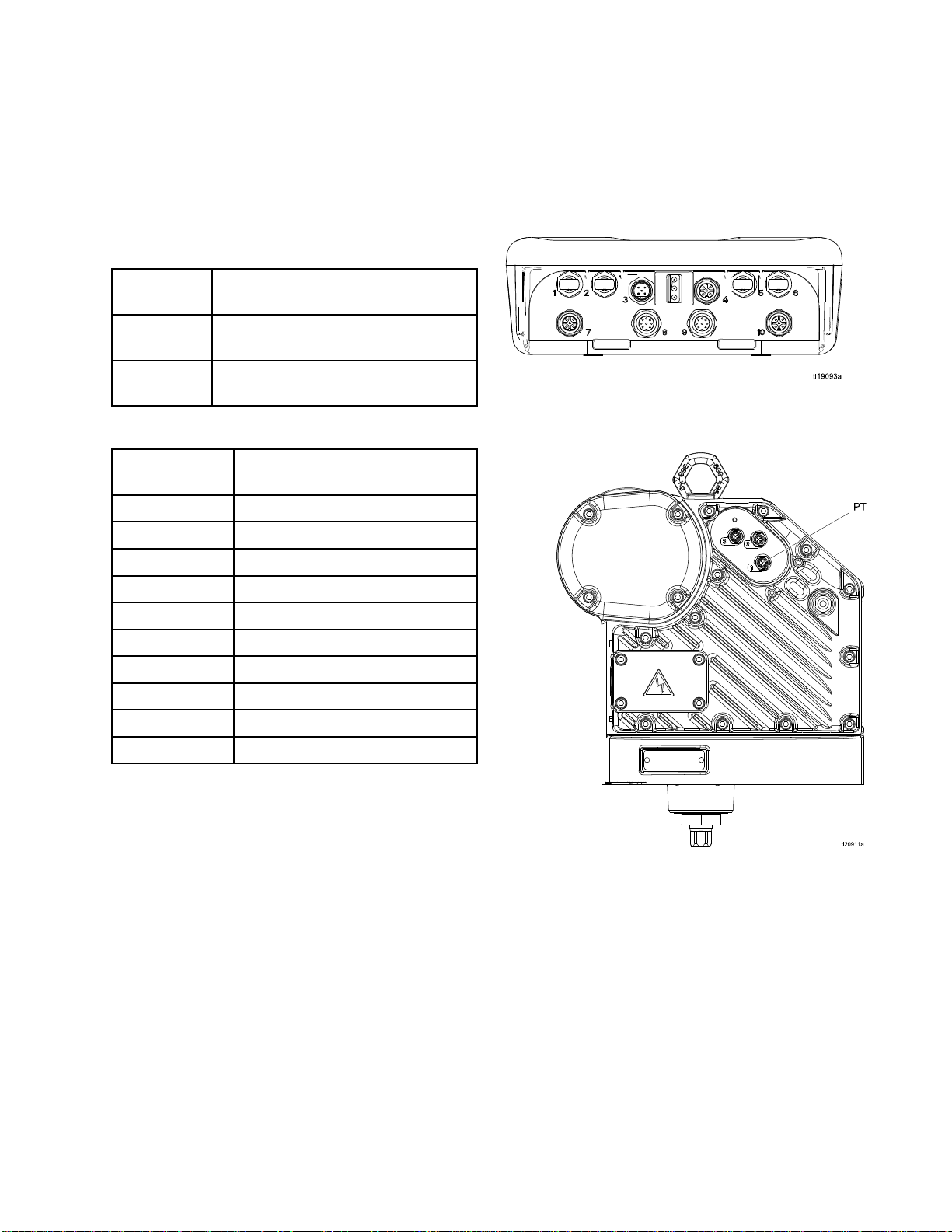

Cable Connect

Order an accessory cable (C) from Table 1. Connect the cable to Port 3 on the bottom of the control module

(see Fig. 2). Connect the other end to the power terminal (PT) on the motor (see Fig. 3). Connect other

cables as described in Table 2.

Table 1 CAN Cables

Cable Part

No.

16P911

16P912

Table 2 AD

ADCM Port

Number

1

2

3

CM Cable Connections

ion

Description

Intrinsically safe CAN cable, female

x female, 3 ft (1 m)

Intrinsically safe CAN cable, female

x female, 25 ft (8 m)

Connector Purpose

Fiber Op

Fiber Optic TX - to PLC

Power and CAN communication

tic RX - to PLC

Figure 2 ADCM Connectors

4

5

6

7

8 BPR

9 Not used

10 Pressure transducer 2

/stop input

Start

Fiber Optic RX - to next ADCM

Fiber Optic TX - tos next ADCM

Pressure transducer 1

control 4-20mA output

Figure 3 Motor Power Terminal

3A2527D 5

Page 6

Operation

Operation

Module Screen

The Control Module has two sets of screens:

Run and Setup. For detailed information see

Run Screens, page 12, and Setup Screens, page 16.

Press

the Setup screens.

to toggle between the Run screens and

s

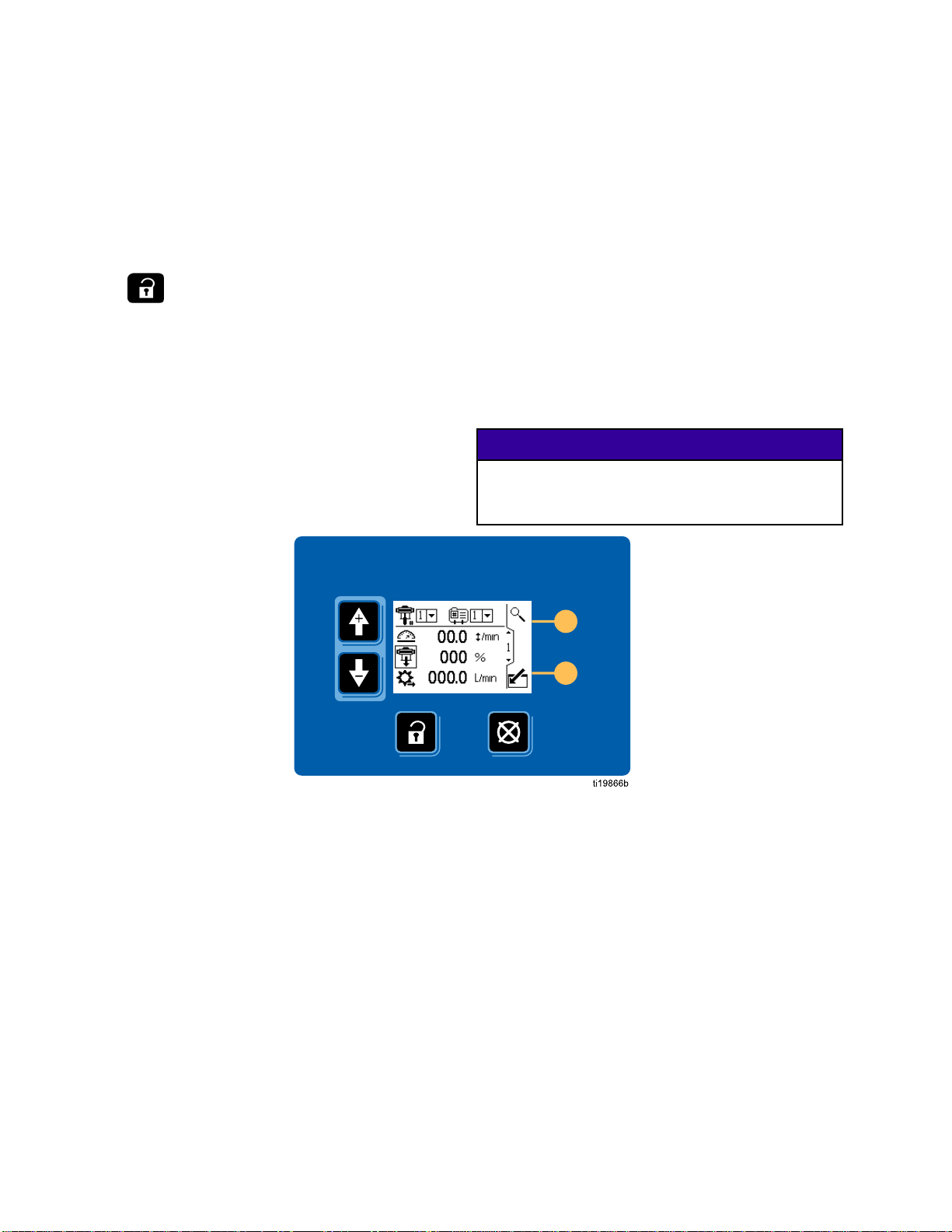

Module Keys

Fig. 4 is a view of the control module display and

keys. Table 2 explains the function of the membrane

keys on the control module. As you move through

the screens, you will notice that most information

is communicated using icons rather than words

to simplify global communication. The detailed

screen descriptions in Run Screens, page 12,and

Setup Screens, page 16, explain what each icon

represents. The two softkeys are membrane buttons

whose function correlates with the screen content to

the immediate left of the button.

NOTICE

To preven

press the

plastic

t damage to the softkey buttons, do not

buttons with sharp objects such as pens,

cards, or fingernails.

Figure 4 Control Module Keypad and Display

6 3A2527D

Page 7

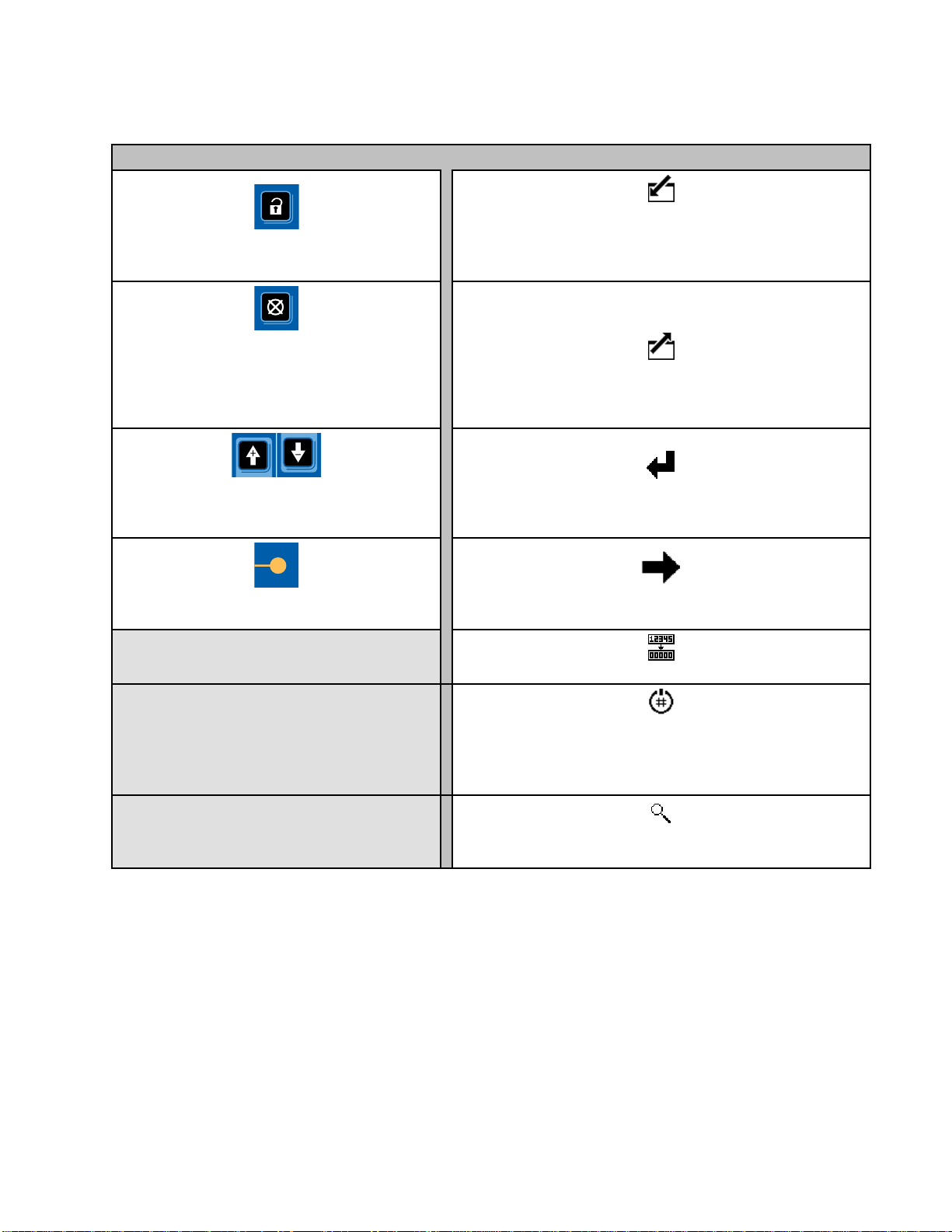

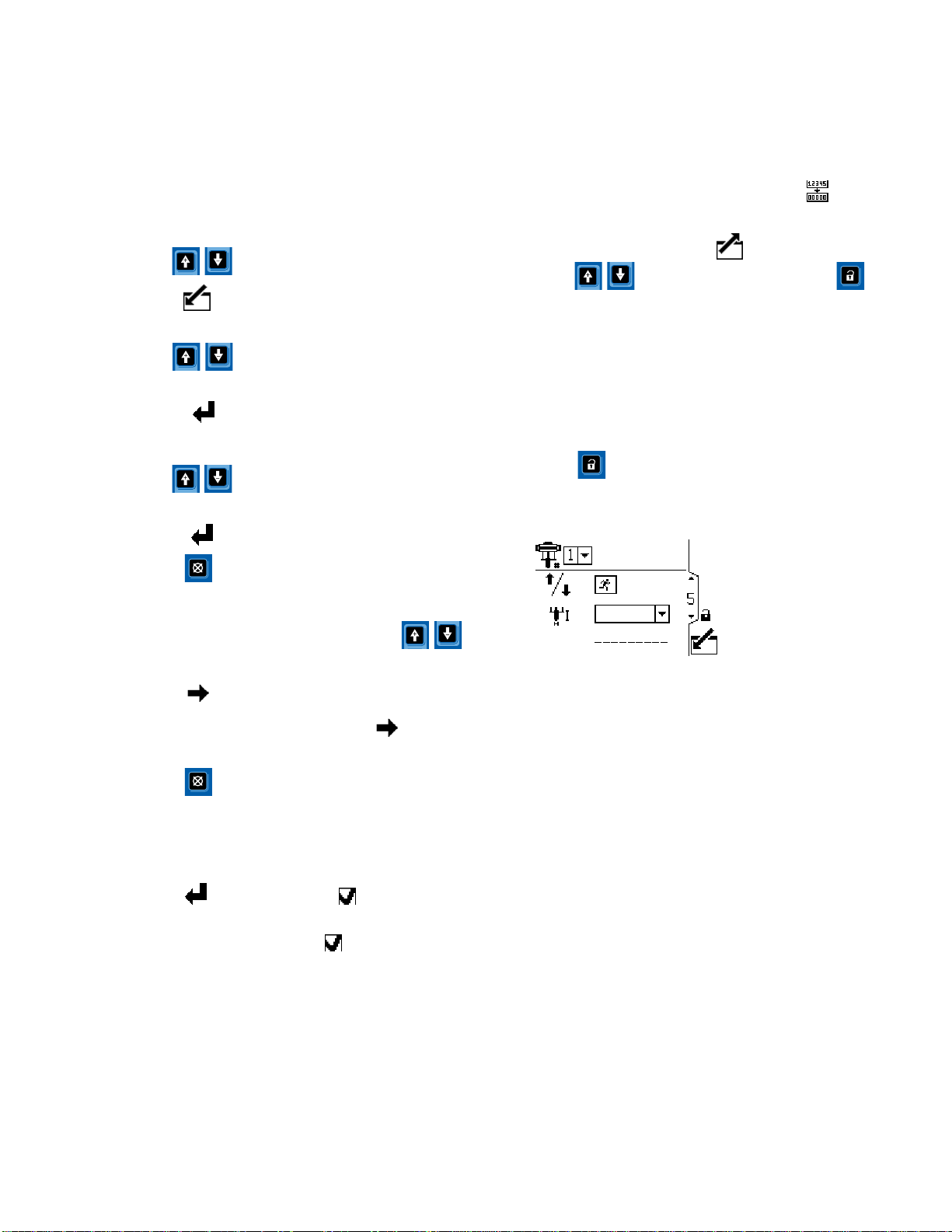

Table 3 Module Keys

Operation

Membrane Keys

Press to toggle between Run screens

and Setup screens.

:

Error Reset

has been fix

clear, thi

profile to S

entered an

Up/Down Arrows:

screens or fields on a screen, or to increment

or decrement the digits in a settable field.

Softkeys:

Use to clear alarm after cause

ed. When there is no alarm to

s key will set the active pump’s

top. Also used to cancel data

d return to original data.

Use to move between

Use varies by screen.

See columns at right.

Softkeys

Enter Screen.

Also changes the function of the Up/Down

arrows so they move between data fields on

the screen, rather than between screens.

Enter.

Right.

Press to activate a field for editing or to accept

the highlighted selection on a dropdown menu.

Move to the right when editing number fields. Press

again to accept the entry when all digits are correct.

Highlight data that can be edited.

Exit Screen.

Exit data editing.

Reset.

Activate Profile.

default, and only appears if the “Profile Lock”

box is checked on Setup Screen 15, page 29.

Press to activate the profile just edited.

Search.

active pump blink for identification.

Reset totalizer to zero.

This softkey is disabled by

PressinRunScreen1tomakethe

3A2527D

7

Page 8

Operation

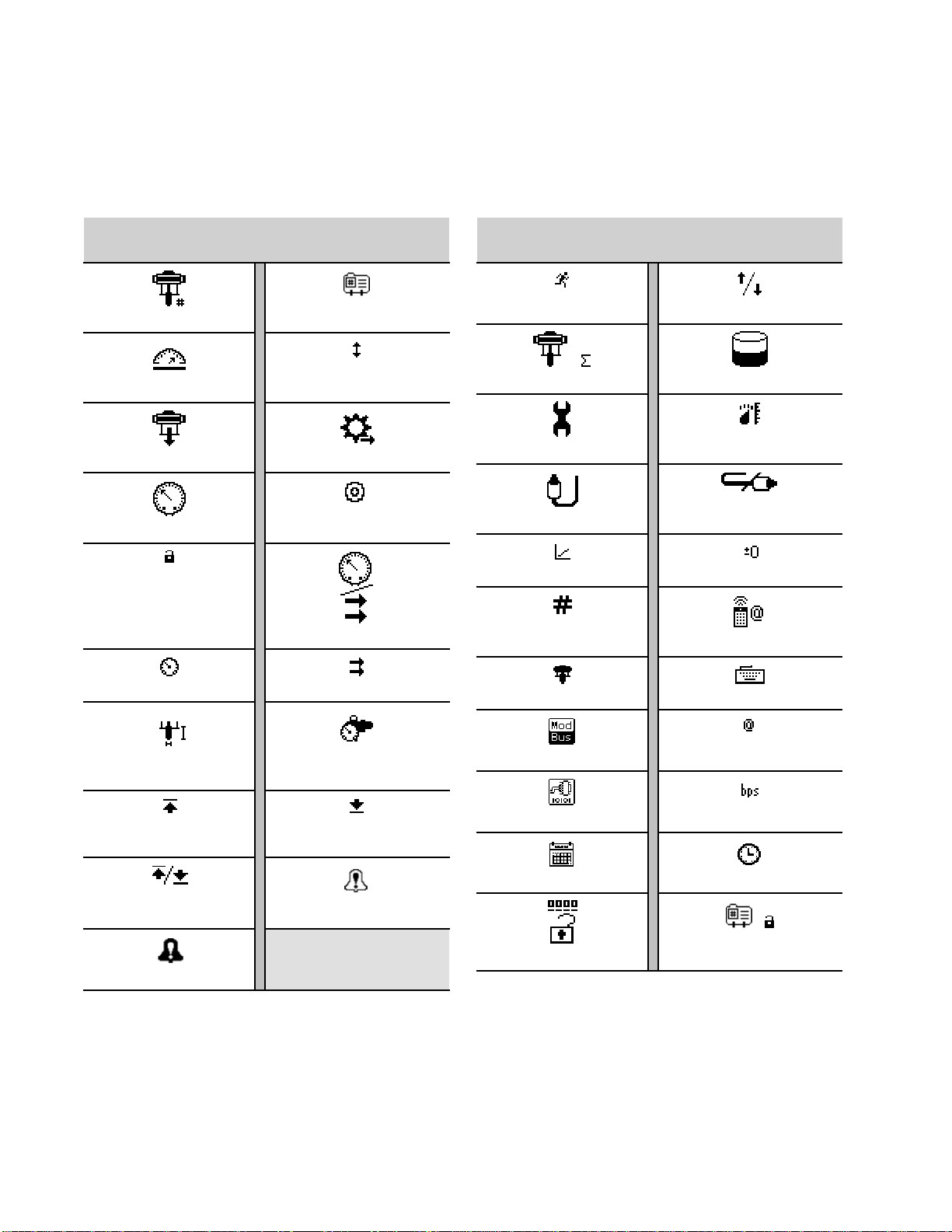

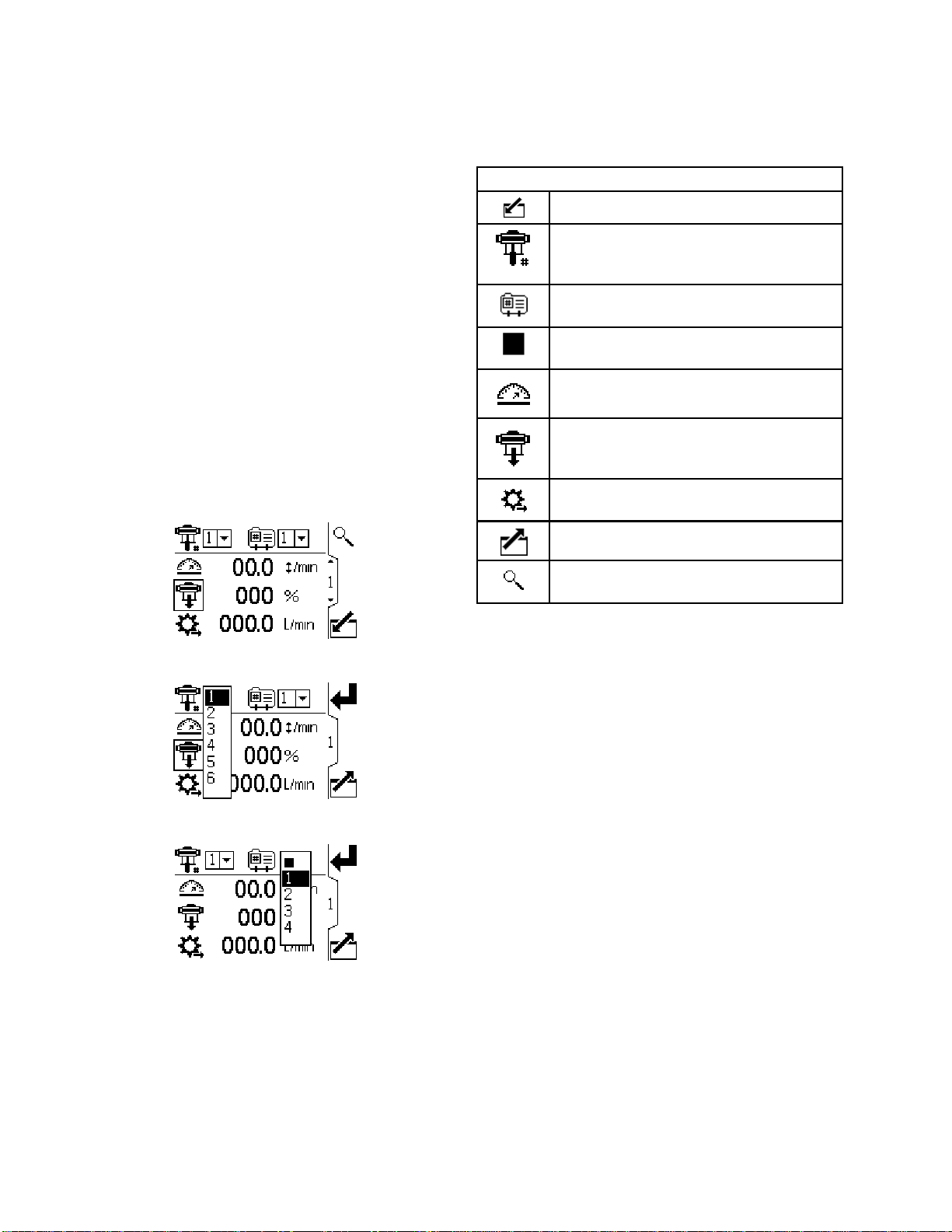

Icons

Asyoumovethr

than words to s

Setup Screens

ough the screens, you will notice that most information is communicated using icons rather

implify global communication. The detailed screen descriptions in RunScreens,page12, and

,page16, explain what each icon represents.

Screen Icons

Pump Number

Speed

Pump Pressure Flow Rate

Pressure

In Setup Mode

Profile Number

Cycles

Target

Screen Icons

Jog Mode

Cycles Total Volume

Maintenance

Transducer

Calibration Scale Zero Offset

Jog Up/Down

Units

Pressure Transducer Off

Mode Select

Pressure Mode Flow Mode

Lower Size Back Pressure

Regulator

Maximum

Limit

Maximum and

Minimum Limits

rm Enable

Ala

Minimum

Limit

Deviation Enable

Serial Number

Control Location

Local C

Modbus Device

ontrol

Serial Port

Calendar Clock

Password

PLC/Re

Modbus Address

Serial Baudrate

Lock Profile

mote Control

8 3A2527D

Page 9

Operation

Screen Naviga

Refer to this section if you have questions about

screen navigation or about how to enter information

and make selections.

All Screens

1. Use

2. Press

on the screen will highlight.

3. Use

change.

4. Press

Drop Down Field

1. Use

the dropdown menu.

2. Press

tion and Editing

to move between screens.

to enter a screen. The first data field

to highlight the data you wish to

to edit.

to highlight the correct choice from

to select.

Reset Field

The reset field is used for totalizers. Press

reset the field to zero.

When all data is correct, press

Then use

to move between Setup screens and Run screens.

Initial Se

NOTE: Before creating the pump profiles in Setup

Screens 1 through 4, you must set up the system

parameters in Setup Screens 5 through 15, as

follows.

1. Press

Screen 1 will appear.

2. Scroll to Setup Screen 5.

tup

to move to a new screen, or

to enter the Setup screens. Setup

to exit the screen.

to

3. Press

Number Field

1. The first digit will be highlighted. Use

to change the number.

2. Press

3. When all digits are correct, press

accept.

4. Press

Check Box Field

A check box field is used to enable or disable features

in the software.

1. Press

box.

2. The feature is enabled if a

to cancel.

to move to the next digit.

again to

to cancel.

to toggle between andanempty

is in the box.

3. See Setup Screen 5, page 22,andselectthe

lower used in your system.

4. Continue setting the system parameters

on Setup Screen 6, page 23 through

Setup Screen 15, page 29.

5. Scroll to Setup Screen 1. Establish

the profiles for each pump. See

Setup Screen 1, page 16 through

SetupScreen4,page20.

3A2527D 9

Page 10

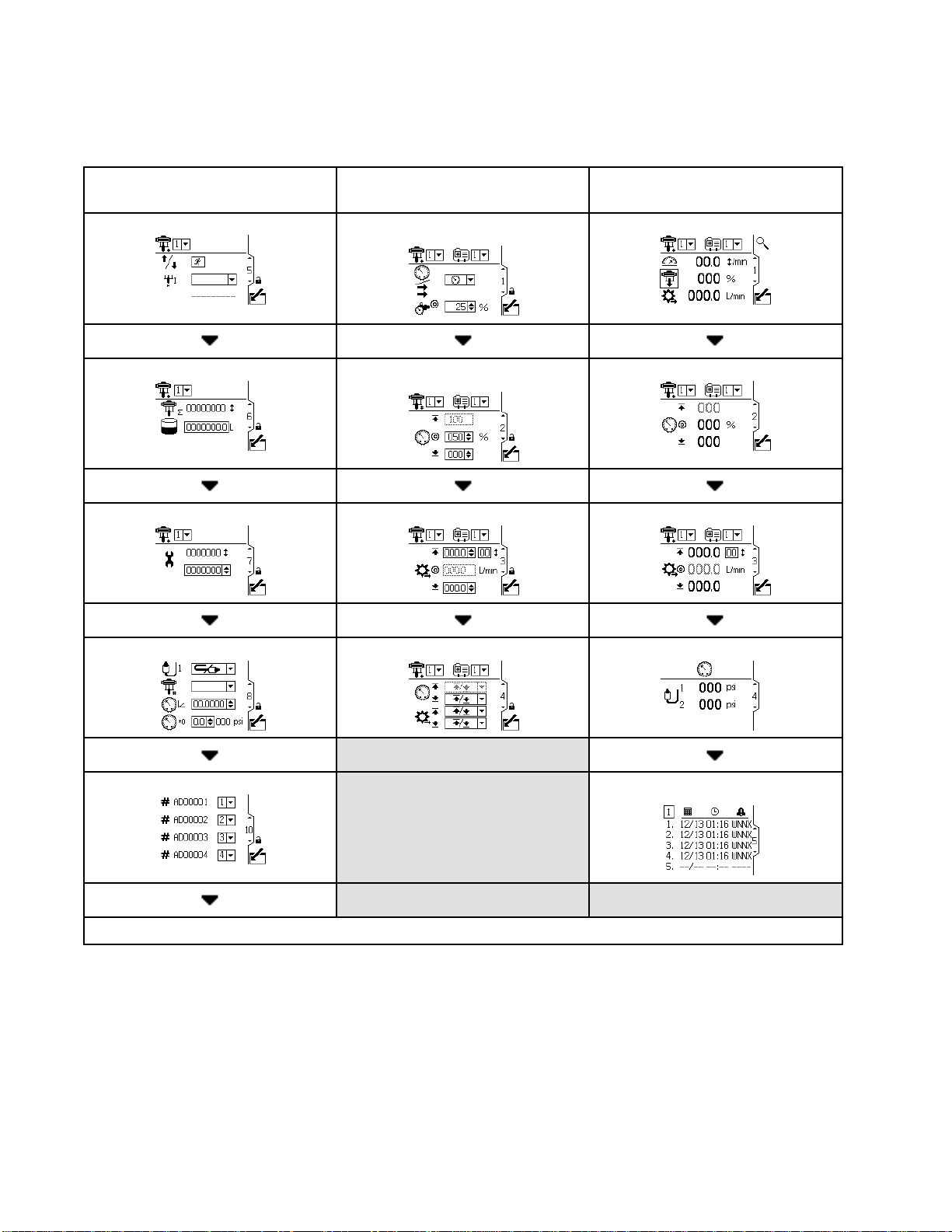

Screen Map

Screen Map

INITIAL SETUP

(Setup Screens 5–14)

Setup Screen 5, page 22 Setup Screen 1, page 16 Run Screen 1, page 12

Setup Scr

Setup Screen 7, page 23 Setup Screen 3, page 19 Run Screen 3, page 13

een 6, page 23

SETUP AND EDIT PROFILES

(Setup Screens 1–4)

Setup Scr

een 2, page 18

(Run Screens 1–8)

Run Scree

RUN

n2,page13

p Screens 8 and 9, page 24

Setu

Setup Screens 10 and 11, page 25 Run Screens 5–8, page 14

p Screen 4, page 20

Setu

creen 4, page 14

Run S

CONTINUED ON THE NEXT PAGE.

10 3A2527D

Page 11

Screen Map

INITIAL SETUP

(Setup Screens 5–14)

SetupScreen1

Setup Screen 13, page 27

Setup Screen 14, page 28

Screen 15, page 29

Setup

2, page 26

SETUP AND EDIT PROFILES

(Setup Screens 1–4)

RUN

(Run Screens 1–8)

3A2527D

11

Page 12

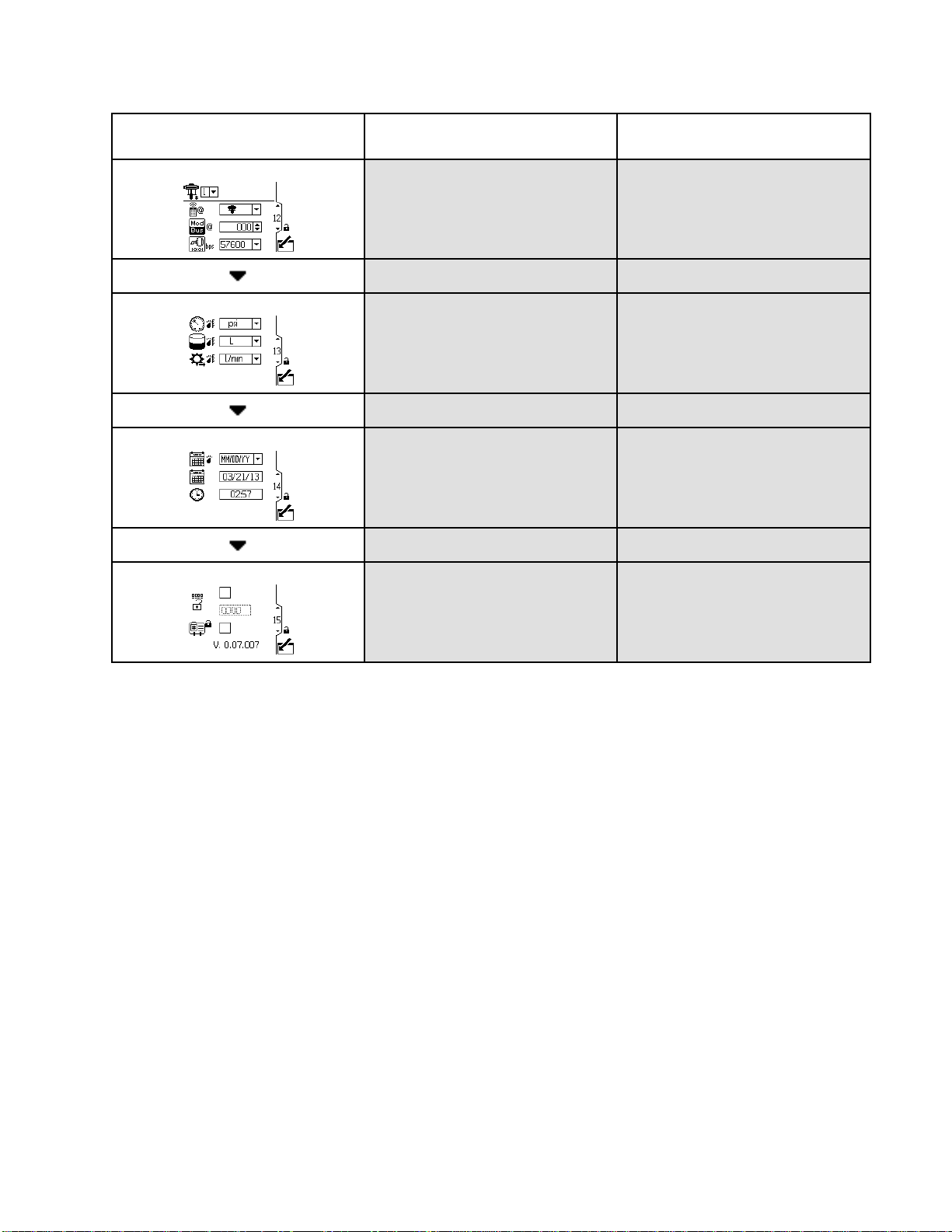

Run Screens

Run Screens

The Run screens display current target values and

performance for a selected pump and profile. Any

alarms will display in the sidebar at the right of the

screen. Screens 5–8 display a log of the last 20

alarms for the active pump.

Information

correspond

Appendix A -

TheactivepumpandprofilemaybechangedinRun

Screens 1, 2, and 3.

Run Screen

This screen displays information for a selected

pump and profile. A box around an icon indicates

which mode the active pump and profile is running

(pressure or flow).

displayedontheRunscreens

s to the Modbus Registers. See

Modbus Variable Map, page 34.

1

RunScreen1Key

Enter the scre

For systems with multiple pumps and

one display, select the desired pump (1

to 8), using the pull-down menu.

Select the desired profile (1 to 4), using

the pull-down menu.

Select from the profile drop-down menu

to stop the pump.

Displays current pump speed in cycles

per minute.

Displays current pump pressure as a

percentage. If a transducer is used, this

icon is replaced by the pressure icon.

Displays current flow rate, in units as

selected in Setup Screen 13, page 27.

Exit the screen.

Signals the active pump to blink code 9

for identification.

en.

Figure 5 Run Screen 1

re 6 Select a Pump

Figu

Figure 7 Select a Profile

2

1

3A2527D

Page 13

Run Screens

Run Screen 2

This screen displays pressure settings for the active

pump and profile.

NOTE: Some fie

setup select

Figure 8 Run Screen 2, in Pressure Mode

Figure 9

Run Screen 2, in Flow Mode

lds are grayed out, depending on

ions.

Run Screen 3

This screen displays fluid flow settings for the active

pump and profile.

NOTE: Some fie

setup select

Figure10 RunScreen3,inPressureMode

Figure 1

1 Run Screen 3, in Flow Mode

lds are grayed out, depending on

ions.

Run Screen 2 Key

Enter the screen.

For systems with multiple pumps and

one display, select the desired pump (1

to 8), using the pull-down menu.

Select the desired profile (1 to 4), using

the pull-down menu.

Select from the profile drop-down menu

to stop the pump.

Displays pressure maximum (first data

field), target (second data field), and

minimum (third data field), as selected

in Setup Screen 2, page 18.See

Setup Screen 4, page 20 to set or

disable the pressure alarms.

it the screen.

Ex

RunScreen3Key

Enter the screen.

For systems with multiple pumps and

one display, select the desired pump (1

to 8), using the pull-down menu.

Select the desired profile (1 to 4), using

the pull-down menu.

Select from the profile drop-down menu

to stop the pump.

The first line displays the maximum

flow rate and maximum cycle rate

(displayed as a cpm conversion of the

maximum flow setting). The second

line displays the target flow rate. The

third line displays the minimum flow

rate. See SetupScreen3,page19to

establish these settings. See

Setup Screen 4, page 20 to set or

disable the flow alarms.

xit the screen.

E

3A2527D 13

Page 14

Run Screens

Run Screen 4

This screen displays the current pressure readings of

transducers 1 and 2. Pressure can be displayed as

psi, bar, or MPa. See Setup Screen 13, page 27.

Figure 12 Run Screen 4

Run Screens 5–

Run Screens 5–8 display a log of the last 20 alarms,

with date and time. The currently active pump is

displayed in a box at the top left of the screen.

Figure 13 Run Screens 5–8 (Screen 5 shown)

8

4

1

3A2527D

Page 15

Notes

Notes

3A2527D 15

Page 16

Setup Screens

Setup Screens

Use the Setup screens to set control

parameters for the motor. See

Screen Navigation and Editing, page 9 ,for

information on how to make selections and enter

data.

Inactive fiel

Information displayed on the Setup screens

corresponds to the Modbus Registers. See

Appendix A - Modbus Variable Map, page 34.

NOTE: Before setting up profiles on Setup Screens

1–4, do the initial setup on Setup Screens 5–15.

Screens 5–15 establish the configuration for your

system and affect the displayed data.

ds are grayed-out on a screen.

SetupScreen1

Use this s

selecte

creen to set the operating mode for a

d pump and profile.

SetupScreen1Key

Enter the scre

Pump selection — See Step 1.

Profile selection — See Step 2.

Pressure mode or Flow mode — See

Step 3

Setting for Back Pressure Regulator —

SeeStep4.

Press to accept the selections.

This softkey is disabled by default, and

only appears if the “Profile Lock” box is

checked on Setup Screen 15, page 29.

Press to activate the profile just edited.

Exit the screen.

en.

Figure 14 Setup Screen 1

16 3A2527D

Page 17

Setup Screens

1. For systems with multiple pumps and one

display, select the desired pump (1 to 8), using

the pull-down menu.

Figure 15 Select Pump Number

2. Select the desired profile (1 to 4), using the

pull-down menu.

Figure 16 Select Profile Number

3. Select

flow), u

the desired operating mode (pressure or

sing the pull-down menu.

• In flow mode, the motor will maintain a

constant speed to maintain the target flow rate

set on Setup Screen 3, regardless of the fluid

pressure, up to the pump’s maximum working

pressure.

Figure 17 Select Mode (Pressure Mode Shown)

4. If the system is equipped with a back pressure

regulator (BPR), set the target air pressure to the

BPR from 0 to 100 percent (approximately 1 to

100 psi). Leave the field set to 000 for a system

with no BPR. See manual 332142 for information

on the BPR control kit.

• In pressure mode, the motor will adjust the

pump speed to maintain the fluid pressure

percentage set on Setup Screen 2. If the flow

limit is reached before the target pressure, the

unit will stop driving to the pressure (if set as

an alarm).

Figure 18 Set Back Pressure Regulator

3A2527D

17

Page 18

Setup Screens

Setup Screen 2

Use this screen to set the maximum, target, and

minimum fluid pressure for a selected pump and

profile. In pressure mode, you will set a target fluid

pressure. In flow mode, you will set a maximum

fluid pressure. In either pressure or flow mode,

a minimum pressure may be set if desired. See

Setup Screen 4, page 20, to specify how the system

will respond if the pump begins to operate outside of

the set boundaries.

SetupScreen2Key

Enter the screen.

Pump selection — See Step 1.

Profile selection — See Step 2.

Fluid pressure maximum— See Step 3.

Fluid pressure target — See Step 4.

Fluid pressure minimum — See Step 5.

Press to accept the selections.

1. For systems with multiple pumps and one

display, select the desired pump (1 to 8), using

the pull-down menu.

2. Select the desired profile (1 to 4), using the

pull-down menu.

3. In flow mode, set the desired maximum pump

fluid pressure, as a percentage of the maximum

pressure of your pump. NOTE: The motor will

not run if the profile does not have a maximum

pressure setting. This field is not used in

pressure mode.

4. In press

target a

of your p

ure mode, set the desired fluid pressure

s a percentage of the maximum pressure

ump. This field is not used in flow mode.

This softkey is disabled by default, and

only appears if the “Profile Lock” box is

checked on Setup Screen 15, page 29.

Press to activate the profile just edited.

Exit the screen.

NOTE: If closed loop pressure is enabled, the

target pressure will be displayed as a pressure

value rather than a percentage of maximum

pressure. See Setup Screens 8 and 9, page 24 to

enable closed loop pressure control.

5. If desired, set a minimum pump fluid pressure,

as a percentage of the maximum fluid pressure

of your pump.

18 3A2527D

Page 19

Setup Screen 3

Setup Screens

Use this screen to set your flow rate settings for a

selected pump and profile. In pressure mode, you

will set a maximum flow rate. In flow mode, you

will set a target flow rate. In either pressure or flow

mode, a minimum flow rate may be set if desired.

SeeSetupScreen4tospecifyhowthesystemwill

respond if the pump begins to operate outside of the

set boundaries.

SetupScreen3Key

Enter the screen to set or change

preferences.

Pump selection — See Step 1.

Profile selection — See Step 2.

Flow rate maximum— See Step 3.

Flow rat

Flow rate minimum — See Step 5.

Press to accept the selections.

etarget—SeeStep4.

1. For systems with multiple pumps and one

display, select the desired pump (1 to 8), using

the pull-down menu.

2. Select the desired profile (1 to 4), using the

pull-down menu.

3. In flow mode, set a target flow rate. This field is

not used in pressure mode.

Figure 19 Flow Mode: Flow Rate Settings

4. In pressure mode, set the maximum flow rate.The

software will calculate the number of pump cycles

needed to achieve that flow rate. This field is not

used in flow mode.

NOTE: The motor will not run if the profile does

not have a maximum flow rate setting.

This softkey is disabled by default, and

only appears if the “Profile Lock” box is

checked on Setup Screen 15, page 29.

Press to activate the profile just edited.

Exit data editing.

NOTE: With flow rate units of cc/min, the maximum

value that can be displayed is 9999. If the field

displays ####, the saved value is out of range. Go to

Setup Screen 13, page 27 and change the flow rate

to a larger unit. Return to this screen and reduce the

setting to a lower value that will be within the display’s

range, then reset the flow rate units to cc/min.

Figure 20 Pressure Mode: Flow Rate Settingss

5. If desired, set a minimum flow rate.

3A2527D 19

Page 20

Setup Screens

Setup Screen 4

Use this screen to specify how the system will

respond if the pump begins to operate outside of

the pressure and flow settings established on Setup

Screen 2 and Setup Screen 3. The operating mode

(pressure or flow, set on Setup Screen 1) determines

which fields are active.

Figure 21 Alarm Preference Menu

•

/ Limit: T

no alert.

– Maximum pressure set to Limit: The system

reduces the flow if necessary to prevent the

pressure from exceeding the limit.

– Maximum flow set to Limit: The system reduces

thepressureifnecessarytopreventtheflow

from exceeding the limit.

– Minimum pressure or flow set to Limit: The

system takes no action. Use this setting if no

minimum pressure or flow setting is desired.

he pump continues to run and issues

SetupScreen4Key

Enter the scre

preferences

Pressure Alarm Enable

Line 1 (Press

dropdown me

Deviation,

Line 2 (Pressure Minimum): use

dropdown menu to set as Limit,

Deviation, or Alarm.

Flow Rate A

Line 3 (Flow Maximum): use dropdown

menu to set as Limit, Deviation, or Alarm.

Line 4 (Flow Minimum): use dropdown

menu to set as Limit, Deviation, or Alarm.

Press to accept the selections.

This softkey is disabled by default, and

only appears if the “Profile Lock” box is

checked on Setup Screen 15, page 29.

Press to activate the profile just edited.

Exit data editing.

en to set or change

.

ure Maximum): use

nu to set as Limit,

or Alarm.

larm Enable

•

Deviation: The system alerts you to the

problem, but the pump may continue to run

past the maximum or minimum settings until the

system’s absolute pressure or flow boundaries are

reached.

•

Alarm: The system alerts you to the alarm

cause and shuts down the pump.

Figure 22 Setup Screen 4 (In Pressure Mode)

Figure 23 Setup Screen 4 (In Flow Mode)

20 3A2527D

Page 21

Setup Screens

Pressure Mode Examples

• Runaway Contr

maximum flow to

the maximum en

symbol

shut down.

• Detect a Plu

choose to se

the flow rate

Setup Scre

on screen t

taken. The

ol: The user may choose to set the

Alarm. If the flow rate exceeds

tered on Setup Screen 3, an Alarm

how on screen and the pump will

will s

gged Filter or Pipe: The user may

t the minimum flow to Deviation. If

drops below the minimum entered on

en 3, a Deviation symbol

o warn the user that action should be

pump continues to run.

will show

Flow Mode Examples

• Runaway Contr

the minimum pr

the pump will n

pressure will

the minimum en

symbol

shut down.

• Protect Con

choosetose

prevent the

pressure.

• Detect a Pl

choosetos

When the pr

on Setup S

show on sc

be taken

. The pump continues to run.

ol: Theusermaychoosetoset

essure to Alarm. If a hose bursts,

ot change speed, but the back

fall. When the pressure falls below

tered on Setup Screen 2, an Alarm

how on screen and the pump will

will s

nected Equipment: The user may

t the maximum pressure to Limit to

connected equipment from excessive

ugged Filter or Pipe: The user may

et the maximum pressure to Deviation.

essure exceeds the maximum entered

creen 2, a Deviation symbol

reen to warn the user that action should

will

3A2527D

21

Page 22

Setup Screens

Setup Screen 5

Use this screen to set the lower pump size (cc) of

each pump. The default is blank; select the correct

lower size, or custom. If custom is selected, enter the

size of the lower in cc. This screen also activates jog

mode, allowing you to position the motor/pump shaft

for connection or disconnection.

NOTE: The mo

the selecte

pressure ra

Figure 24 Setup Screen 5

tor will limit its pressure output when

d lower is 750cc, to prevent exceeding the

ting of the lower.

Figure 27 Se

Enter the screen.

For systems with multiple pumps and

one display, select the desired pump (1

to 8), using the pull-down menu.

Select to enable jog mode. Use the

arrow keys to move the motor/pump

shaft up or down.

Select the correct pump lower size from

the drop-down menu. The default is

blank. If custom is selected, a field will

open to input the size of the lower in cc.

Press t

lect a Custom Lower

SetupScreen5Key

o accept the selections.

Figure 25 Select Jog Mode

Figure 26 Select Pump Lower

Exit the screen.

2

2

3A2527D

Page 23

Setup Screens

Setup Screen 6

Usethisscreentoviewthegrandtotalizervalueand

set or reset the batch totalizer.

Figure 28 Setup Screen 6

Figure 29 Reset the Totalizer

SetupScreen6Key

Enter the screen to set or change

preferences.

Grand Totalizer - displays the current

grand total of pump cycles. Not

resettable.

Batch Totalizer - displays the batch total

in selected volume units.

SetupScreen7

Use this screen to set the desired maintenance

interval (in cycles) for each pump. The screen also

displays the current cycle count. An Advisory is

issued when the counter reaches 0 (zero).

Figure 30 Setup Screen 7

Setup Scre

Enter the screen.

For systems with multiple pumps and

one display, select the desired pump (1

to 8), using the pull-down menu.

Set the desired maintenance interval (in

cycles) for each pump.

Press to accept the selections.

Exit the screen.

en7Key

t Batch Totalizer - resets the batch

Rese

lizer to zero.

tota

Press to accept the selections.

Exit data editing.

3A2527D 23

Page 24

Setup Screens

Setup Screens

Use these screens to set up the pressure transducers.

The screens are identical, except Screen 8 is for

transducer 1 and Screen 9 is for transducer 2.

Selecting a transducer and a pump activates closed

loop pressure control.

Figure 31 Setup Screens 8 and 9 (Screen 8 shown)

Setup Screens 8 and 9 Key

Select from the dropdown options to

enable the transducer.

For systems with multiple pumps and

one display, select the desired pump (1

to 8), using the pull-down menu. Enables

closed loop pressure control and assigns

the transducer to a pump.

Enter the calibration scale factor from the

transducer label.

8 and 9

Figure 32 Select Pressure Transducer

Figure 33 Select Pump, to Enable Closed Loop

Pressure Control

Figure 3

4 Enter Calibration Scale Factor

the calibration offset value from the

Enter

ducer label.

trans

Displays the current transducer reading.

Exit data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

Figure 35 Enter Calibration Offset Value

4

2

3A2527D

Page 25

Setup Screens

Setup Screens

These screens are auto-populated by the software.

Screen 10 displays the serial numbers of motors 1–4,

and Screen 11 displays the serial numbers of motors

5–8.

NOTE: Changi

pump up one po

changed to b

1, AD00003 w

Figure 36 Setup Screens 10 and 11 (Screen 10

shown)

ng the pump order will shift every other

e pump 4, AD00002 will become pump

ill become pump 2, and so on.

10 and 11

sition. For example, if AD00001 is

Figure 37 Select a Pump Number for Each Serial

Number

3A2527D 25

Page 26

Setup Screens

Setup Screen 1

Use this screen to set your modbus preferences.

Figure 38 Setup Screen 12

Enter the screen.

For systems with multiple pumps and

one display, select the desired pump (1

to 8), using the pull-down menu.

Control location. Select local or

remote

options. Setting applies to the selected

pump only.

Enter or change the Modbus node ID.

Value is between 1 and 247. Each

pump requires a unique node ID, which

identifies that pump if more than one

pump is connected to the display..

Select serial port baud rate from the

dropdown options: 57600 or 115200.

This is a system-wide setting.

Press to accept the selections.

2

Setup Scre

control from the dropdown

en 12 Key

Figure 40 Se

Figure 41 Set Baud Rate (Bits Per Second)

NOTE:The following are fixed modbus settings,

which cannot be set or changed by the user: 8 data

bits, 2 stop bits, no parity.

t Modbus Node ID

data editing.

Exit

Figure 39 Select Local or Remote Control

26 3A2527D

Page 27

Setup Screens

SetupScreen1

Use this screen to set the desired units for pressure,

totals, and flow.

Figure 42 Setup Screen 13

Setup Screen 13 Key

Select desired pressure units (psi, bar,

or MPa)

Select desired volume units (liters or

gallons)

Select desired flow rate units (L/min,

gpm, cc/min, oz/min, or cycles/min)

Exit data editing.

3

Figure 43 Se

Figure 44 Select Desired Volume Units

lect Desired Pressure Units

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

Figure

45 Select Desired Flow Rate Units

3A2527D

27

Page 28

Setup Screens

Setup Screen 1

Use this screen to set your date format, date, and

time.

Figure 46 Setup Screen 14

Enter the s

preferenc

Select yo

the dropd

MM/DD/YY

DD/MM/YY

YY/MM/D

Set the

4

SetupScreen14Key

creen to set or change

es.

ur preferred date format from

own menu.

D

correct date.

Figure 47 Se

Figure 48 Set the Date

lecttheDateFormat

Set the correct time.

Press t

Exit data editing.

o accept the selections.

Figure

49 Set the Time

28 3A2527D

Page 29

Setup Screens

SetupScreen1

Use this screen to enter a password that will be

required to access the Setup screens. This screen

also displays the software version.

Figure 50 Setup Screen 15

Setup Scre

Enter the screen to set the password.

When the top box of the screen is

checked, the password is active. To

temporarily disable the password,

uncheck the box. The password field will

be grayed-out.

Enter the desired 4–digit password.

5

en 15 Key

Figure 51 Se

Figure 52 Disable the Password

tthePassword

Check t

in the R

Exit data editing.

he box to lock out the profile field

un screens.

Figure

53 Lock the Profile

3A2527D 29

Page 30

Error Code Troub

leshooting

Error Code Tro

Error codes can take three forms:

•Alarm

down the pump.

• Deviation

may continue to run past the set limits until the

system’s absolute limits are reached.

• Advisory: information only. Pump will continue to

operate.

NOTE: On A

pressure

deviatio

Display

Code

None Basic 6 Alarm

: alerts you to the alarm cause and shuts

: alerts you to the problem, but pump

dvanced motors, flow (K codes) and

(P codes) can be designated as alarms or

ns. See Setup Screen 4, page 20.

Applicable

Motor

ubleshooting

Blink

Code

Alarm or

Deviation

The Mode Select knob is set between Pressure

Flow

NOTE: In the error codes listed below, an “X” means

the code is associated with the display only.

NOTE: In the e

code is a plac

where the eve

NOTE: The blink code is displayed using the power

indicator on the motor. The blink code given below

indicates the sequence. For example, blink code 1–2

indicates 1 blink, then 2 blinks; the sequence then

repeats.

NOTE: A blink code of 9 is not an error code, but an

indicator of which pump is active (

been pushed, see RunScreen1,page12).

. Set knob to the desired mode.

rror codes listed below, a “_” in the

eholder for the number of the pump

nt occurred.

softkey has

Description

and

None Basic and

Advanced

CAC_

CAD_

CAG_

CCN_

K1D_

K2D_

K3D_

K4D_

Advanced None Alarm

Advanced 2–3 Alarm

Advanced 2–4 Alarm

Basic and

Advanced

Advanced 1–2 Alarm Flow is below minimum limit.

Advanced None Deviation Flow is below minimum limit.

Advanced None Deviation Flow exceeds maximum target; also indicates pump runaway

Basic and

Advanced

9 None

3–6 Alarm

1 Alarm Flow exceeds maximum target; also indicates pump runaway

A blink code of 9 is not an error code, but an indicator of

which pump is active.

Display detects a loss of CAN communication. Flashing

alarm appears on the display, and the blink code occurs.

Unit detects a loss of CAN communication. This alarm is only

logged. No flashing alarm appears on the display, but the

blinkcodedoesoccur.

Display detects a loss of modbus communication when

control access is set to modbus.

Circuit board communication failure.

condition exists.

condition exists.

30 3A2527D

Page 31

Error Code Troub

leshooting

Display

Code

MND_

P1I_

P2I_

P3I_

P4I_

P5DX

P6CA or

P6CB

P6D_

T2D_

T3D_

Applicable

Motor

Advanced None Advisory Maintenance counter is enabled and countdown reached

Advanced 1–3 Alarm Pressure is below minimum limit.

Advanced None Deviation Pressure is b

Advanced None Deviation Pressure exceeds maximum target.

Advanced 1–4 Alarm Pressure exceeds maximum target.

Advanced None Deviation More than on

Advanced None Deviation

Advanced 1–6 Alarm For units with closed loop pressure control: Transduceris

Basic and

Advance

Basic and

Advanced

Blink

Code

3–5 Alarm Internal

d

5

Alarm or

Deviation

Deviation

Description

zero (0).

elow minimum limit.

epumpisassignedtoatransducer. The

assignment

this condi

For units without closed loop pressure control: Transducer (A

or B) is enabled but not detected.

enabled but not detected.

Over temperature.

for that transducer is automatically cleared under

tion. User must reassign.

thermistor disconnected.

V1I_

V1M_

V4I_

WMC_

WNC_

WSC_

WSD_

WXD_

Basic and

Advanced

Basic a

Advanc

Basic and

Advanced

Basic and

Advanced

Basi

Adva

Advanced None Deviation

Advanced 1–5 Alarm

Basic and

Advanced

nd

ed

c and

nced

2 Alarm Brown out; voltage supplied to motor is too low.

2–6 Alarm

3 Alarm Voltage supplied to motor is too high.

4–5 Alarm

3–4 Alar

4Alarm

m

AC power is lost.

rnal software error.

Inte

Software versions do not match.

Profile is set to 0 pressure or 0 flow.

alid lower size; occurs if the unit is operated before setting

Inv

he lower size.

up t

An internal circuit board hardware failure is detected.

3A2527D 31

Page 32

Parts

Parts

24P822 Control Module Kit

Part Description

Ref

1 24P821

1a▲ 16P265 LABEL, warning,

1b▲ 16P265 LABEL, warning,

1c▲ 16P265 LABEL, warning,

5

24N910

———

5a

6 24P823

DISPLAY KIT, control

module; includes

item 1a; see manual

332013 for approvals

information about the

bare ADCM module

English

French

Spanish (shipped

loose)

CONNECTOR,

jumper; includes

item 5a

SCREW, cap, socket

head; M5 x 40 mm

BRACKET KIT,

control module;

includes items 6a-6f

Qty

1

1

1

1

1

1

1

Part Description

Ref

———

6a

———

6b

———

6c

———

6d

———

6e

———

6f

———

11

———

12

▲ Replacement Danger and Warning labels, tags,

and cards are available at no cost.

Items marked — — — are not available separately.

Cable (C) is shown for reference but is not included

in the kit. Order desired length separately. See

Cable Connection, page 5 .

BRACKET, control

module

BRACKET, mounting

LOCKWASHER,

external tooth; M5

WASHER; M5

SCREW, cap, socket

head; M5 x 12 mm

KNOB; M5 x 0.8

HOLDER, tie

STRAP, tie

Qty

1

1

4

2

2

2

1

1

32 3A2527D

Page 33

Accessory Kits

Parts

BPR Cont

Ref

101

102

103 110436

104 100030

105 19817

t/Stop Switch Kit 16U729

Star

The kit includes the switch and enclosure, a mounting bracket, and cables. Parts are not sold separately.

roller Kit 24V001

Part Description

———

———

TRANSDUCER,

miniature

CABLE, F/C, I.S., 8 M

GAUGE, pressure, air

BUSHING

8

ELBOW

Qty

1

1

1

1

1

Part Description

Ref

106 110207

107

C19466

108 198171

———

Parts no

ELBOW

TEE 1

ELBOW

t sold separately.

Pressure Transducer Kit 24R050

kit includes the fluid pressure sensor with cable, an adaptor, and an o-ring. Parts are not sold separately.

The

Qty

1

1

3A2527D 33

Page 34

Appendix A - Modb

us Variable Map

Appendix A - Modbus Variable Map

To communicat

DC Control Mod

hardware as sh

manual indic

fiber optic ca

non-hazardo

Modbus regis

the non-haz

Table 4 Modb

Modbus

Register

404100

404101

404102 Actual Pump Flow Rate

404103 Actual Pump Pressure

404104 Transdu

404105 Transducer 2 Pressure

404106 Batch Total High Word

7

40410

e through fiber optics with the E-Flo

ule, reference the appropriate

own in manual 332356. That

ates various options for connecting

bles from the control module to the

us area. The following table lists

tersavailabletoaPCorPLClocatedin

ardous area.

us Registers

Variable Register

Pump Status Bits Read Only

Actual Pump Speed Read Only

cer 1 Pressure

Total Low Word

Batch

Table 4 shows t

operation, mo

Tables 5 and 6 p

certain regi

convert the r

Reference the Modbus communication settings

selected in Setup Screen 12, page 26.

Access

Read Only

Read Only

Read Only

Read On

Read Only

Read Only

ly

he registers needed for basic

nitoring, and alarm control features.

rovide bit definitions as needed for

sters. Table 7 shows the units and how to

egister value to a unit value.

Size

16 Bit

16 Bit

16 Bit Flow units, see Table 7..

16 Bit Percent pressure, see Table 7.

16 Bit Pressur

16 Bit Pressure units, see Table 7.

16 Bit Volume units, see Table 7.

16 Bit Volum

Notes/Unit

See Table 5 for bit definitions.

Speed units, see Table 7.

s

e units, see Table 7.

e units, see Table 7.

404108

404109

110

404

404111 Maintenance Total Low Word

404112 Pump Alarms High Word

04113

4

404114 Display Alarms High Word

404115 Display Alarms Low Word

404200

404201

404202

404203 Maintenance Interval High Word Read / Write 16 Bit Pump cycles, see Table 7.

404204 Maintenance Interval Low Word Read / Write 16 Bit Pump cycles, see Table 7.

403102 Display seconds

d Total High Word

Gran

Grand Total Low Word Read Only

ntenance Total High Word

Mai

ump Alarms Low Word

P

Local/Remote Control

Active Profile Number

Pump Control Bitfield

Only

Read

Read Only

ad Only

Re

Read Only

Read Only

ead Only

R

Read Only

Read / Write 16 Bit

Read / Write 16 Bit 0 = stopped, 1, 2, 3, 4

Read / Write 16 Bit

Read Only

16 Bit Pump cycles, see Table 7.

16 Bit Pump cycles, see Table 7.

it

16 B

16 Bit Pump cycles, see Table 7.

16 Bit

6Bit

1

16 Bit

16 Bit

16 Bit Use as heartbeat.

p cycles, see Table 7.

Pum

See Table 5 for bit definitions.

See Table 5 for bit definitions.

ee Table 5 for bit definitions.

S

See Table 5 for bit definitions.

0 = local, 1 = remote/PLC

See Table 5 for bit definitions.

34 3A2527D

Page 35

Appendix A - Modb

NOTE: See Error Code Troubleshooting, page 30, for a description of each alarm.

Table 5 Alarm Bits

us Variable Map

404112 - Pump A

Bit Event Type

0 Deviation T3D_

2 Alarm P6D_ Pressure Transducer Missing

3 Deviation ERR_

4 Advisory MND_

5

6 Alarm T2D_ Low Tempe

7

8Alarm

9Alarm

10 Deviation P5D_ Multiple Pumps Assigned to Transducer

11 Deviation

others Reserved

4041

Bit Event Type

0Ala

Alarm V1M_

Alarm

13 - Pump Alarms Word 2

larms Word 1

rm

Event Code

WNC_

CCN_ IPC Communication

WMC_ Intern

WSC_ Zero s

Event Code

_

K1D

Event Name

Over Temperature

Internal Software Error

Maintenan

AC Power Loss

Version Mismatch

Event Name

Minimum Speed

ce Count

rature

al software error

etting on active profile

1 Deviation K2D_

2Alarm K4D_

3D

4 Alarm P1I_ Minimum Pressure

5

6 Alarm P4I_ Maximum Pressure

7

8 Alarm V1I_ Under Voltage

9Alarm V4I_

10 Alarm V4I_ High Pressure 120V

11 Alarm

13 Alarm WXD_ Board Hardware

14 Alarm

others Reserved

eviation

Deviation P2I_ Minimum Pressure

Deviation P3I_ Maximum Pressure

3D_

K

CAD_ CAN Communication Pump

WSD_ Invalid Lower Size

nimum Speed

Mi

Maximum Speed

Maximum Speed

Over Voltage

3A2527D 35

Page 36

Appendix A - Modb

404114 - Display Alarms Word 1

us Variable Map

Bit Event Type

1 Deviation

others Reserved

404115 - Display Alarms Word 2

Bit Event Type

12 Alarm

15 Alarm

others Reserved

Table 6 Pump Status and Control Bits

404100 -

Bit Meaning

0

1

2

3

4

oth

Pump Status Bits

Reads 1

Reads 1 if the pump is actually moving

Reads 1 if there are any active alarms

Read

Reads 1 if there are any active advisories

ers

Reserved for future use

ifthepumpistryingtomove

s 1 if there are any active deviations

Event Code

P6C_

Event Code

CAG_ Modbus Com

CAC_ CAN Communication Display

Event Name

Pressure Transducer Missing

Event Name

munication

4202 - Pump Control Bits

40

Bit Meaning

0

1

2

others

eads 0 for an active alarm or deviation. Reset to 1 to clear.

R

Setto1toresetthebatchtotal

Set to 1 to reset the maintenance counter

Reserved for future use - only write 0

36 3A2527D

Page 37

Table 7 Units

Appendix A - Modb

us Variable Map

Unit Type

Pressure Percent n/a Pressure = Register

Pressure

Speed Cycles/min

Flow

Volume✝

s✝✝

Cycle

Selectable Un

psi 403208 = 0 Pressure = Re

Bar 403208 = 1 Pressure = Register/10 10 = 1.0 Bar

MPa 403208 = 2 Pressure =

Liters/min 403210 = 0 Flow = Register/10 10 = 1.0 L/min

Gallons/min

cc/min 403210 = 2 Flow = Register 1 = 1 cc/min

oz/min 403210 =

Cycles/min

Liters 403209 = 0

Gallons

Pump C

ycles

Units Register

its

n/a

403210 = 1 Flow = Reg

3

403210 = 4 Flow = Register/10 10 = 1.0 cycle/min

403209

n/a

=1

Converting re

unit values

Register/100

Speed = Register/10

Flow = Re

Volume = 1000*High +

Low/10

Volume = 1000*High +

Low/10

s = 10000*High

Cycle

+Low

gisters to

gister

ister/10

gister

Register valu

unit

1=1%Pressure

1=1psi

100 = 1.00 Mpa

10 = 1.0 cycl

10 = 1.0 Gal/min

1=1oz/m

0 (High) / 10 (Low) =

1.0 L

0 (High) / 10 (Low) =

1.0 Gal

h) / 1 (Low) = 1

0(Hig

cycle

efor1

e/min

in

✝ Exam

word

1000

✝✝ Example of converting cycles register reading to units: If the reading for register 404108 (cycles high

word) is 75, and the reading for register 404109 (cycles low word) is 8000, the volume is 758,000 cycles.

75 * 10000 + 8000 = 758000.

ple of converting volume register reading to units: If the reading for register 404106 (volume high

) is 12, and the reading for register 404107 (volume low word) is 34, the volume is 12003.4 liters. 12 *

+ 34/10 = 12003.4.

3A2527D 37

Page 38

Appendix B. Pump

Control from a PLC

Appendix B. Pu

This guide shows how to use the information in

Appendix A to control a pump remotely from a PLC.

The steps progress from basic pump control to more

advanced monitoring and alarm control features.

It is importa

Setup Screen

Test that th

from the Dis

communicat

properly. R

Setup Scre

your modbu

1. Enable PLC control: Set register 404200 to 1.

2. Run a pump: Set register 404201. Enter 0 for

stopped,1 to 4 for the desired profile.

3. View pump profile: Read register 404201. This

register updates automatically to reflect the

actual pump status. If the profile is changed from

the display, this register changes as well. If the

pump stops due to an alarm, this register will

read 0.

4. View pump status: Read register 404100 to see

the status of the pump. See Appendix A, Table

6, for a description of each bit.

• Example 1: Register 404100, bit 1, reads 1 if

• Example 2: Register 404100, bit 2 reads 1 if

nt that you first follow all directions in the

s to configure your system properly.

e pump operates correctly when controlled

play. Make sure the display, fiber optics,

ion gateway, and PLC are connected

efer to Communication KIt manual. Use

en 12 to enable remote control and set

s preferences.

the pump is currently moving.

the pump has an active alarm.

mp Control from a PLC

5. Monitor alarms and deviations: Read register

404112 to 404115. Each bit in these registers

corresponds to an alarm or deviation. See

Appendix A, Table 5. I

• Example 1: Pressure falls below the minimum

setting entered on Setup Screen 2. It will show

on bit 4 of register 404113 if minimum pressure

is set to Alarm, and on bit 5 of register 404113

if minimum pressure is set to Deviation.

•Example2:

pressure t

transduce

register 4

6. Monitor pump cycle rate, flow rate, and pressure:

Read registers 404101 to 404105. Note that

pressure is available only if a pressure transducer

is connected to the display. Register 404104

shows the pressure on transducer 1. Register

404105 shows the pressure on transducer 2. See

Appendix A, Table 7 for units for these registers.

• Example 1: If register 404101 reads 75, the

pump speed is 7.5 cycles/minute.

•Exampl

pump is

7. Reset active alarms and deviations: Clear the

condition that caused the alarm. Set register

404202, bit 0, to 1 to clear the alarm. The pump

will be in profile 0 due to the alarm. Set 404201

to the desired profile to run the pump again.

The system is set up for a

ransducer on Setup Screen 8, but no

r is detected. It will show on bit 1 of

04114.

e 2: If register 404103 reads 67, the

operating at 67 percent pressure.

38 3A2527D

Page 39

Notes

Notes

3A2527D 39

Page 40

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for

use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a

period of twelve months from the date of sale, repair or replace any part of the equipment determined

by Graco to be defective. This warranty applies only when the equipment is installed, operated and

maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall

Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment

with structures, accessories, equipment or materials not supplied by Graco, or the improper design,

manufacture, installation, operation or maintenance of structures, accessories, equipment or materials

not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an

authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco

will repair or replace free of charge any defective parts. The equipment will be returned to the original

purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of

parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

The buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages

for lost profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall

be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY

GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.),

are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from

Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other

goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or

otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents,

notices and legal proceedings entered into, given or instituted pursuant hereto or relating directly or

indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du

présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés,

donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les procédures

concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

To place an order, contact your Graco Distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication. Graco

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2013, Graco, Inc. All Graco manufacturing locations are registered to ISO 9001.

reserves the right to make changes at any time without notice

Original Instructions. This manual contains English. MM 3A2527

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision D, July 2014

Loading...

Loading...