Page 1

Instructions

GLC 2200 Wiring

3A2992B

Connector Kit

Used to interface the GLC2200 Lubrication Controller to pump and pump accessories. For

professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

Kit Nos.:

Single Connector Kit: 24P686

Multiple (5) Connectors Kit: 24P687

Kits are rated IP65.

EN

make

Important Safety Instructions

Read all warnings and instructions in this

manual and the GLC 2200 Lubrication

Controller instruction manual included with your

unit. Save these instructions.

Page 2

Instructions

a

b

c

5 4 3 2 1

9 8 7 610

Connector Installation

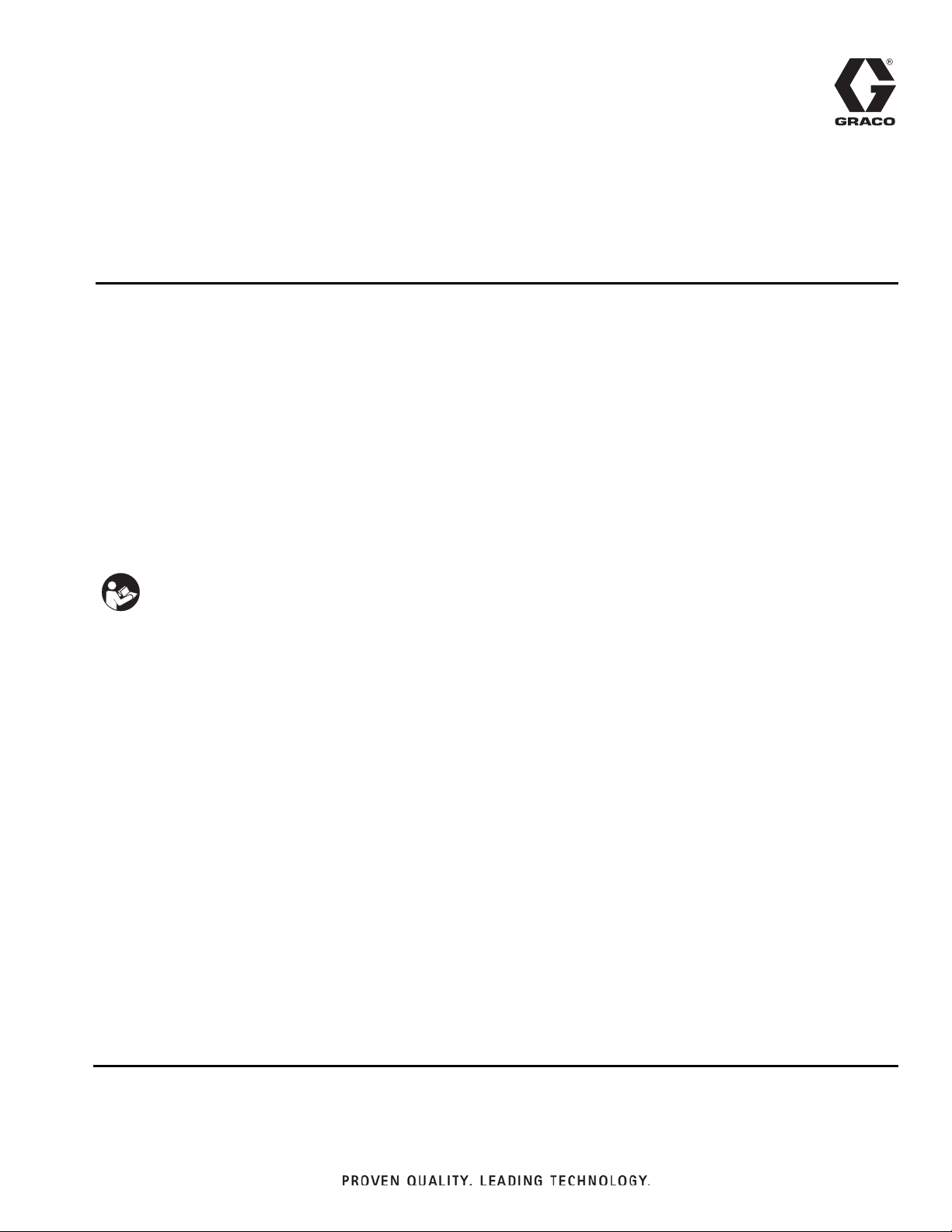

1. Remove 2 to 3 inches of the outer insulation from

one end of a user supplied cable (a) as shown in

F

IG. 1.

NOTE: The cable should contain multicolored wires

to ensure easy and accurate component installation.

.

FIG. 1

2. Strip each wire (b) to be crimped so approximately

0.08 - 0.012 inches (2- 3 mm) of bare wire (c) is

showing as shown in F

IG. 2.

4. (See F

5. Firmly squeeze the crimp tool to crimp and secure

6. Repeat steps 3 - 5 until all wires are crimped with

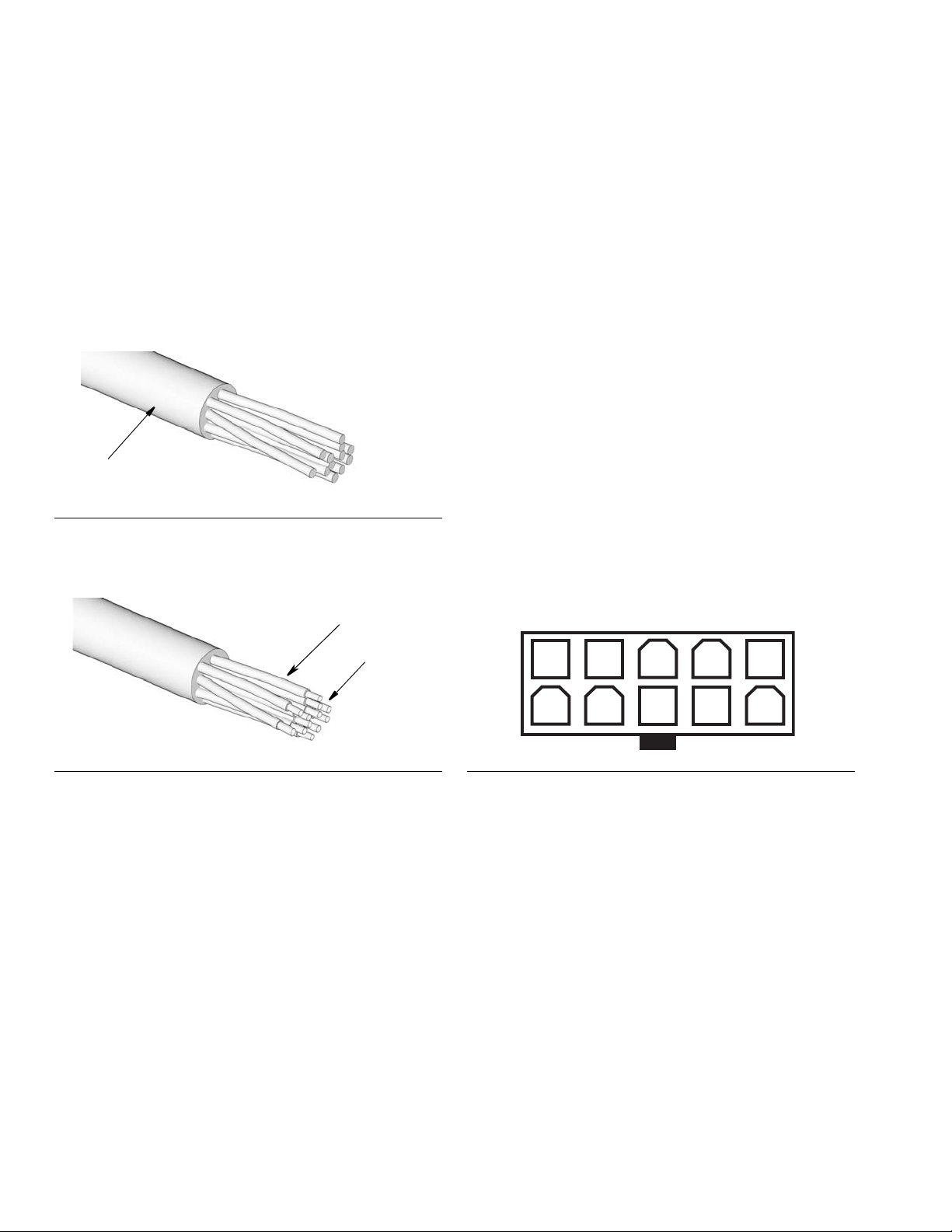

7. Insert pins into connector. When looking at the con-

IG. 2) Insert stripped end (c) of wire (b) into

pin. The edge of the insulation should be about 0.05

- 0.09 inches (1.2- 2.2 mm) into the pin.

NOTE: To ensure proper fit, ensure that the bare

wire and the insulator are crimped separately.

• If the insulation is too deep, the pin will not

make contact with the wire.

• If the insulation is not deep enough, the pin may

not fit inside the connector properly.

the pin to the wire.

pins.

nector, be sure you are plugging in pins in the correct side. Refer to F

pin locations. Use the Wiring Key provided on page

4 to identify related components.

IG. 3 for correct orientation and

FIG. 2

3. Insert one of the pins into the appropriately sized

slot of the hand crimp tool.

NOTE:

• A hand crimp tool is available from Graco. Order

part number 16T671.

• The pin must be placed all the way into the

crimper in the correct orientation.

FIG. 3

NOTE:

• The second column of the Wiring Key Table is

provided for the user to record the wire color

assigned to each component.

• There are 10 available PIN locations in the connector. Only use the pin locations necessary for

your installation. Refer to the Connector Identification Label and Wiring Key provided on page

4.

Page 3

Component Wiring

a

b

c

1 2 3 4 5

6 7 8 9 10

M

9A Fuse

+

-

V

Instructions

1. Before connecting wires to components verify the

Connector end of the cable is NOT plugged into the

GLC2200 controller.

2. Remove 2 to 3 inches of the outer insulation (a)

from bare end of the cable as shown F

.

FIG. 4

3. Strip each wire (b) you are using for the installation

as shown in F

NOTE: It is not necessary to strip all of the wires;

only strip the wires needed for your installation.

IG. 5.

IG. 4.

4. Using the Wiring Key Table, connect components to

wires matching each wire color and pin location.

Verify all negative and positive wire colors are correctly assigned.

NOTE: The second column of the Wiring Key Table

is provided for the user to record the wire color

assigned to each component.

5. Plug connector into the GLC2200 unit matching pin

numbers to Connector Identification Label.

NOTE: The connector can only be plugged into the

GLC2200 one way. The clip (c) should be facing

down when the connector is correctly oriented.

FIG. 6

FIG. 5

Wiring Diagram

FIG. 7

M = Motor pump power or solenoid

V = Electric vent valve for injector-based systems

3A2992B 3

Page 4

Wiring Key

9A 2A

P/C

+9V

+30V

1

2

Wire

Pin

1Pump

2Alarm

3Low Level

4 Pressure Cycle Switch

5 Voltage Input

6Pump

7Alarm

8Low Level

9 Pressure Cycle Switch

10 Voltage Input

* Use this column to record the wire color assigned to

each component used for your installation.

Color* Description

+/-

-

-

-

-

+

+

+

+

+

Parts

Connector Identification Label

(Adhered to GLC2200 controller)

PIN12345

PIN678910

Qty

Ref Description 24P686 24P687

PIN, socket, 18-24 AWG,

1

crimp, gold

CONNECTOR, receptacle,

2

dual, 10 position

12 60

15

Accessories

Crimping Tool - 16T671

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A2992

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

December 2013

Loading...

Loading...