Page 1

Instructions

Suction Model Shown

GBL 7500 Box Lubricator

Pump

GBL Shaft Rotation/Low Level

3A2257C

Alarm Pump

GBL 7500 Box Lubricator Pump: Fully enclosed, self-lubricating, precision, metering pump

capable of pumping small flows of either mineral or synthetic oil to machinery injection

points. For professional use only.

GBL Shaft Rotation/Low Level Alarm Pump: Fully enclosed, self-lubricating, precision,

alarm pump capable of sensing shaft rotation and oil low level. For professional use only.

3/16” models: 7500 psi (51.7 MPa, 517 bar) Maximum Working Pressure

1/4” models: 6000 psi (41.4 MPa, 414 bar) Maximum Working Pressure

3/8” models: 3500 psi (24.1 MPa, 241 bar) Maximum Working Pressure

Alarm Pump: 200 psi (1.4 MPa, 14 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

Models:

Suction Models

• 24J391 - 3/16”

• 24J392 - 1/4”

• 24J393 - 3/8”

Gravity Models

• 24J394 - 3/16”

• 24J395 - 1/4”

• 24J396 - 3/8”

Pressure Models

• 24J397 - 3/16”

• 24J398 - 1/4”

• 24J399 - 3/8”

Alarm Pump Model

• 24K466

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

SKIN INJECTION HAZARD

+

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treat-

ment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be aware

that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

2 3A2257C

Page 3

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system compo-

nent. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited to:

• Protective eye wear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

3A2257C 3

Page 4

Warnings

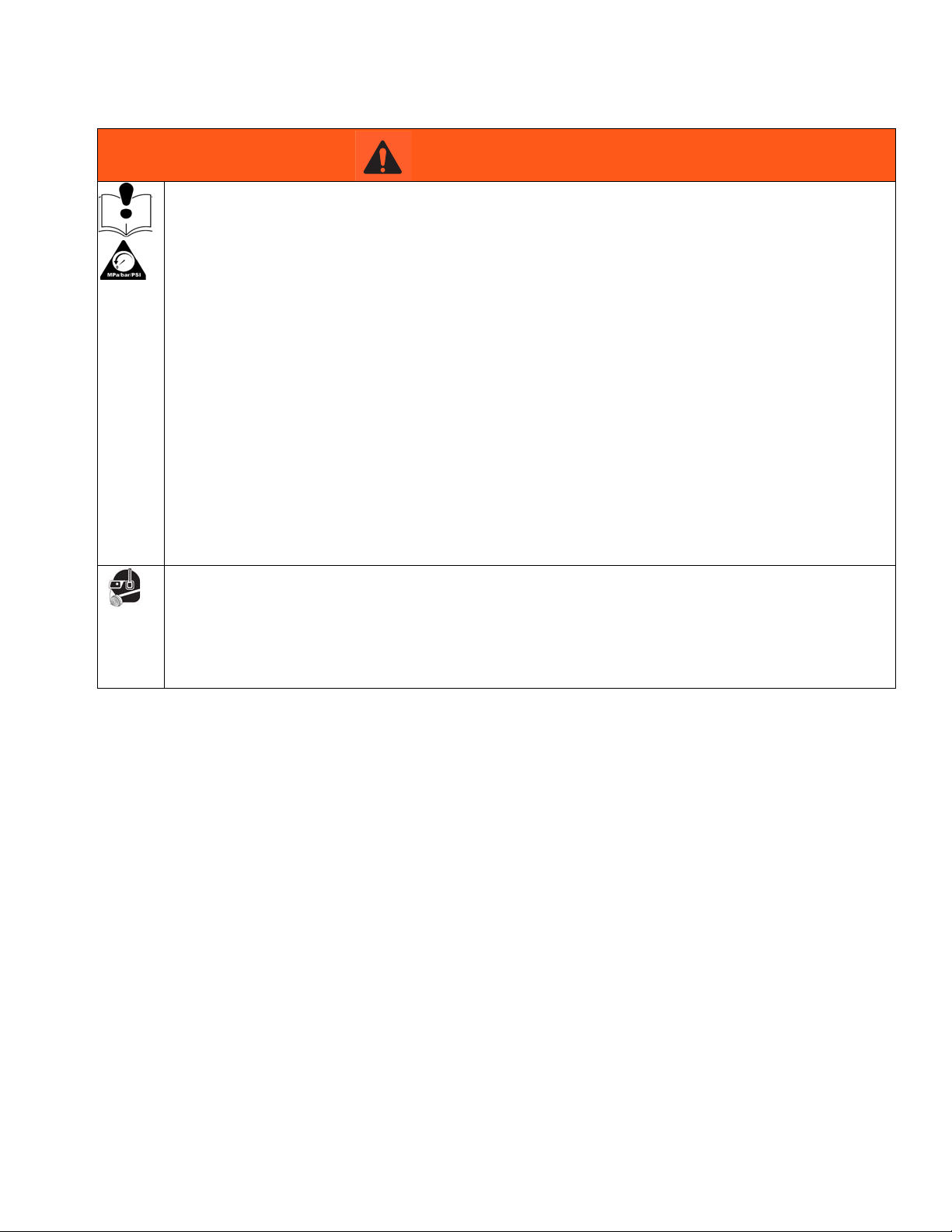

d

c

a

b

e

f

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

I

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop pumping and before

cleaning, checking or servicing the equipment.

1. Stop lube pump.

2. If installed, close oil supply valve located upstream

from pump.

FIG. 1

3. If installed, open drain valve located downstream

from the pump.

4. Slowly crack open fluid line fittings to relieve pressure.

Installing the Pump

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

Ensure the reservoir is properly grounded as the pump

is grounded through the mounting screws.

Mounting Pump

NOTE:

1. Ensure the pump mounting surface on the reservoir

cover is clean. Clean as needed.

2. Align gasket (a) with opening on the top of the reservoir cover making sure holes (b) on either end of the

gasket match mounting holes (c) in reservoir cover

(F

IG. 1).

NOTE: Alarm Pumps Only - For optimum performance, mount alarm pump in location furthest from

drive motor.

• For Gravity and Pressure Fed pumps, skip Step

3 and continue installation with Step 4.

• For Alarm pumps skip Step 3a and continue

installation with Step 3b.

• Pressure Fed pumps follow Step 3a and 3b.

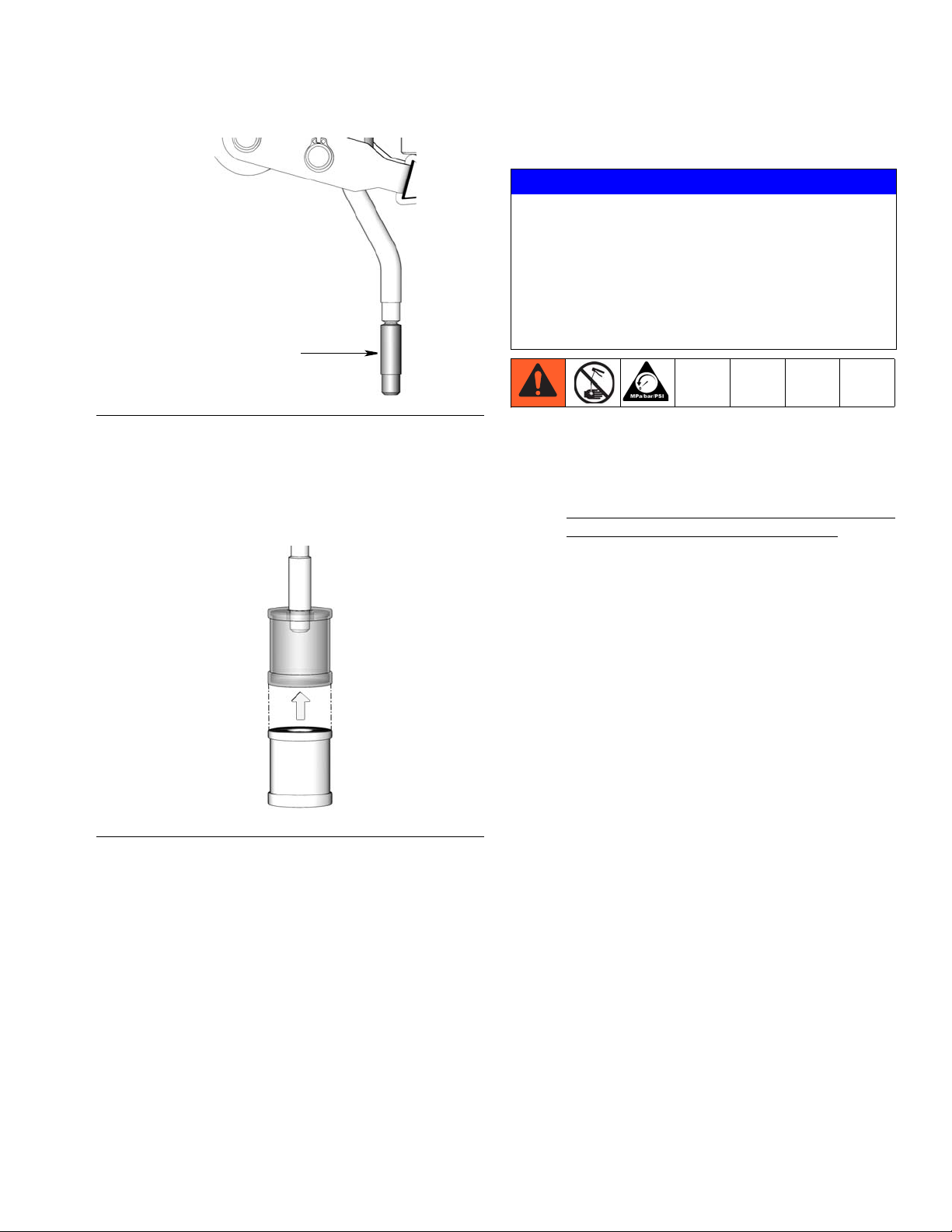

3. For Suction Fed Pumps install pump inlet strainer:

a. Check length of suction tube. If it is too long to

fit in the reservoir, use a pliers to break off the

lower section of the tube (a) (F

IG. 2).

• Ensure box and lube system are sized appropriately

for the selected pressure.

• Ensure an appropriate pressure relief device, suitable for your application, is installed in the system.

• Inspect your box lubricator and replace any damnaged or worn components.

4 3A2257C

Page 5

Setup

a

Setup

NOTICE

Any pressure applied to the pump inlet has the potential

to cause unrestricted flow from the pump outlet even in

a pump that is at rest or adjusted for zero stroke. To prevent this from happening, install a check valve of a comparable pressure rating at the pump outlet.

NOTE: The internal “discharge check valve” does not

have a spring and is rated at zero psi.

FIG. 2

b. For all installations (whether the tube needs to

be trimmed or can be used without trimming),

press strainer onto end of the suction tube until

it “bottoms” (F

IG. 3).

FIG. 3

4. Orient pump so the roller bearing on the bottom of

the pump is aligned with the cam inside the reservoir.

5. Install pump on the reservoir by aligning the holes

(d) on either end of the pump with the mounting

holes (c) in the reservoir cover (F

IG. 1).

6. Install washers (f) and bolts (e) and wrench tighten

them securely. Torque bolts as recommended in

your reservoir instruction manual.

I

1. Expel all air from pump and relieve pressure (page

4).

NOTE:

• Do not connect the oil line to the pump outlet or

lube point until all air has been expelled.

• Use filtered oil when priming the pump.

• Filter oil with minimum 25 micron strainer.

Machine requirements may require a higher

cleanliness level.

• Maximum allowable inlet pressure:

- Pressure Fed Pump: 100 psi (0.69 MPa, 6.9

bar)

- Gravity Fed Pump With Sight Glass: 10 psi

(0.07 MPa, 0.7 bar)

• Minimum required inlet pressure for priming:

- Pressure Fed Pump: 1 psi (0.007 MPa, 0.07

bar)

- Gravity Fed Pump: N/A

- Suction Fed Pump: N/A

- Alarm Pump: N/A

2. Prime the pump using the procedure described in

the following section that relates to your pump

model.

3A2257C 5

Page 6

Setup

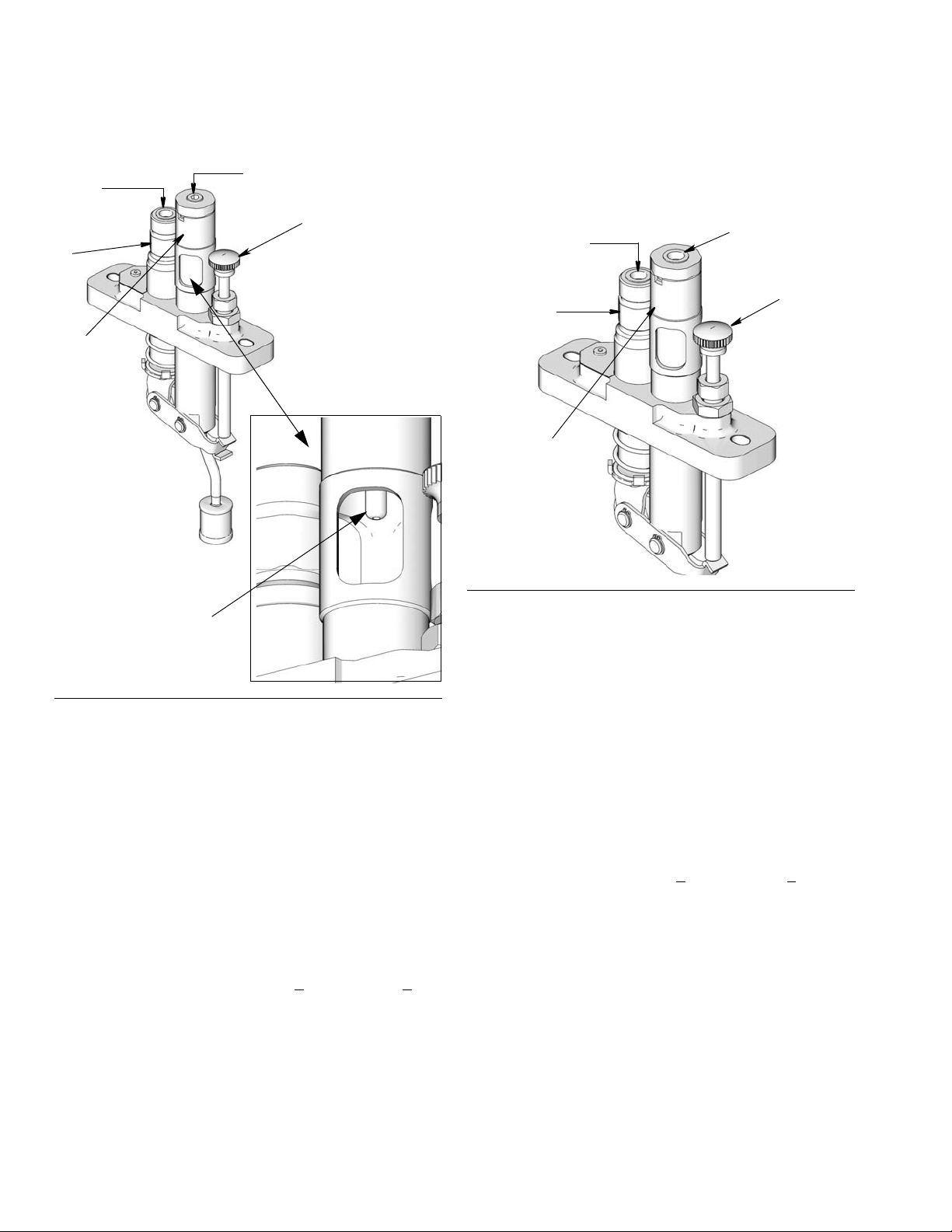

3

1

2

4

5

6

3

1

2

5

6

Suction Fed Models (FIG. 4)

Gravity Fed Models (FIG. 5)

NOTE: In the following instructions, the fill line refers to

the inlet line.

FIG. 5

1. Remove and discard the sight well plug (1) and outlet plug (5).

2. Fill the sight well (2) to the top with appropriately fil-

FIG. 4

1. Remove the sight well plug (1) and outlet plug (5).

Discard outlet plug (5).

2. Fill the sight well (2) to the top with appropriately filtered oil.

3. Operate the hand priming assembly (3) until the oil

level drops below the end of the drip tube (4).

4. Apply thread sealant (user supplied) to sight well

plug (1).

5. Replace the sight well plug (1), taking care to not

allow any thread sealant into the sight well (2).

6. Torque sight well plug (1) to 35 +

N.m).

7. Continue to hand prime until oil expelled from the

outlet (6) is free of air.

8. If all oil is evacuated from sight well (2), repeat steps

2 - 7 as often as necessary, until all air has been

expelled.

5 in. lbs (3.95 + 0.6

tered oil.

3. Operate the hand priming assembly (3) until the oil

level drops below the end of the drip tube (4) (F

4).

4. Apply thread sealant (user supplied) to fill line fitting.

5. Connect fill line to sight well (2), taking care to not

allow any thread sealant into the sight well.

6. Torque fill line fitting to 35 +

N.m).

7. If installed, open oil supply valve located upstream

from the pump.

8. Continue to hand prime until oil expelled from outlet

(6) is free of air.

9. If all oil is evacuated from sight well, repeat steps 2 8 as often as necessary, until all air has been

expelled.

5 in. lbs (3.95 + 0.6

IG.

6 3A2257C

Page 7

Setup

3

1

5

6

2

2

1

Pressure Fed Models (FIG. 6)

NOTE: In the following instructions, the fill line refers to

the inlet line.

FIG. 6

1. Remove and discard the inlet plug (1) and outlet

plug (5).

Alarm Pump Models (FIG. 7)

3

2. Apply thread sealant (user supplied) to fill line fitting.

3. Connect fill line to inlet (2).

4. Torque fill line fitting to 85 +

N.m).

5. If installed, open oil supply valve located upstream

from the pump.

6. Operate the hand priming assembly (3) until the oil

expelled from the outlet (6) if free of air.

10 in. lbs (9.60 + 1.13

FIG. 7

1. Remove the sight well plug (1).

2. Fill the sight well (2) to the top with appropriately filtered oil.

3. Apply thread sealant (user supplied) to sight well

plug (1).

4. Replace the sight well plug (1), taking care to not

allow any thread sealant into the sight well (2).

5. Torque sight well plug (1) to 35 +

N.m).

5 in. lbs (3.95 + 0.6

3A2257C 7

Page 8

Setup

6

9

8

Connecting Lube Lines to Pump: Suction,

Gravity and Pressure Fed Pump Models

Only

NOTE: The lube line refers to the outlet line supplying

lubricant to the lubrication points.

1. Apply thread sealant (user supplied) to lube line fitting.

2. Connect lube line to pump outlet (6), (F

see pages 15 and 16).

3. Torque lube line fitting to 50 +

5 in. lbs (5.65 + 0.6

N.m).

If inst

IG. 8)(also

3. After startup, ensure sensor is activating correctly.

Adjusting the Pump

I

Pump volume is controlled by an external adjusting

screw (8) (F

the length of the piston stroke which changes the pump

discharge volume.

1. Loosen the adjusting screw locknut (9) (F

IG. 9). Turning the adjusting screw changes

IG. 9).

FIG. 8

4. If installed, close the drain valve, located downstream from the pump.

5. Hand prime the pump until clean, air-free oil is flowing through the lube line.

6. Connect the lube line to the lube point.

7. After startup, adjust individual pumps to meet

required flow rates. See Adjusting the Pump, page

8.

Alarm Models Only: Installing Pressure

Sensor (see Alarm Pump, page 17)

1. Apply thread sealant (user supplied) to pressure

sensor.

2. Install pressure sensor into sensor output (3) (F

7).

NOTE: Sensor output will open at 100 - 200 psi

(6.89 bar, 0.68 MPa).

IG.

FIG. 9

2. Turn the adjusting screw (8) (F

IG. 9):

• Counterclockwise - increases discharge volume

(drops per stroke)

• Clockwise - decreases discharge volume (drops

per stroke)

8 3A2257C

Page 9

Setup

2

4

1XPEHURIGURSV0LQXWH

PLQGD\

;

1XPEHURI'URSVLQD3LQW

3LQWV3HU'D\

,QSXW6SHHG

*HDU5DWLR

3XPS2XWSXW

0LQRU0D[

GURSVVWURNH

PLQGD\

;;

1XPEHURI'URSVLQD3LQW

0LQRU0D[

3XPS2XWSXW

3LQWV3HU'D\

1725 RPM

300:1 Gear Ratio

Max 12 drops

per stroke

1440 min.

XX

14438(Number of Drops in a Pint)

=

Max 6.88

Pints/day

3. For Suction Fed and Gravity Fed models only:

With the lubricator operating, count the drops from

the drip tube (4) falling into the sight well (2) for one

minute.

FIG. 10

The number of drops seen falling in the sight well equals

the amount of oil discharged by the pump. See Specifications, page 10 for additional information on converting

drops to volumetric output.

For Pressure Fed models only

: Measure the output

volume at the lube point.

4. If any further adjustment is necessary, repeat Steps

2 and 3.

Calculating Output Capacity

The number of drops observed falling in the sight well

equals the amount of oil discharged by the pump. The

pump volume can be adjusted using the adjusting screw

(8) (F

IG. 9) to change the piston stroke. (See Adjusting

the Pump.)

Calculating Pints per Day

Calculating Minimum or Maximum Pump Output

Capacity in Pints per Day

* Minimum and Maximum drops per stroke listed in Specifications,

page 10.

Example:

The following example calculates the maximum and

minimum flow for a 1/4 inch pump model with an electric

motor and 300:1 gear ratio.

To calculate the Maximum Flow:

5. Once the pump is adjusted to the proper specification, tighten the adjusting screw locknut (9) (F

NOTE: Piston stroke length set near zero may cause an

inconsistent flow.

3A2257C 9

IG. 9).

To calculate the Minimum Flow:

Replace the maximum 12 drops per stroke (used in the

equation above) with the minimum 2 drops per stroke =

1.17 minimum pints per day.

Page 10

Specifications

Specifications

Table 1

Drops per Stroke Table Section of Table Applies to Suction and Gravity Fed Models Only

Piston Diameter Max Outlet Pressure† Drops/Stroke

inches mm psi MPa bar Min* Max Min* Max Min* Max

3/16 4.76 7500 51.7 517 0 7 0 0.014 0 0.229

1/4 6.35 6000 41.4 414 0 12 0 0.024 0 0.393

3/8 9.53 3500 24.1 241 0 27 0 0.054 0 0.885

* Pump adjusted to zero stroke

• Allowable viscosity range independent of temperature: 80-5000 SUS.

• Strokes/Minute - Maximum - 50; Minimum - 3

• Stroke Length - Maximum 1/2 inch (12.7 mm)

† Refer to your manufacturer’s specific instruction manuals to ensure your box and lubrication system are rated for

the selected pressure.

1

Based on 500 SUS oil at 70°F ambient. Heavier oil will produce fewer but larger drops.

2

When approaching maximum outputs, some oils will stream rather than form drops in sight glass.

1, 2

Cubic Inch/Stroke Cubic cm/Stroke

Table 2

Fluid Measurement Conversion Data

Fluid Measurement Conversion Data

(NOTE: All measurements are approximate values only)

# of Drops US Measurement Metric Measurement

1 drop 0.002 cubic inch 0.033 cubic centimeter (cc)

14,438 drops 1 pint 0.47 Liter (l)

28.875 cu. inch 1 pint 0.47 Liter (l)

500 drops 1 cubic inch 16.39 cubic centimeter (cc)

10 drops/minute 1 pint/24 hours 0.47 Liter (l)/24 hours

30 drops 0.061 cubic inch 1 cubic centimeter (cc)

10 3A2257C

Page 11

Troubleshooting

I

Problem Cause Solution

Troubleshooting

Pump stroke is adjusted to zero. Adjust pump stroke for desired out-

put. See page 8.

Pump does not flow

Pump has low flow

Pump has low discharge pressure

Fluid flow from pump outlet when

pump is not running

Sight well fills with oil*

Pump outlet is plugged. Clean/flush pump outlet.

Outlet check valve damaged.

Pump inlet check ball and/or seat is

damaged or worn.

Pump stroke is adjusted to minimal

travel.

Pump inlet check ball and/or seat is

damaged or worn.

Outlet check valve damaged.

Piston and bore are worn.

Pump inlet check valve and/or seat

are damaged or worn.

Inlet pressure exceeds outlet check

pressure.

Pump outlet check ball and/or seat

is damaged or worn.

Possible debris in inlet check Perform Maintenance, page 12.

Pump inlet check ball and/or seat is

damaged or worn

Replace pump.

Adjust pump stroke for desired output. See page 8.

Replace pump.

Replace pump.

Reduce inlet pressure to below outlet check pressure.

Replace pump.

Replace pump.

Piston and bore are worn

Sight well runs dry*

Sight well remains constant and no

lubricant drips from tube

Cloudy or broken sight glass (Suction or Gravity Fed Pumps only)

* Oil level in sight well will rise and fall during normal operation. If condition persists refer to Cause/Solution sections.

3A2257C 11

Restriction in Drip or Suction tube Perform Maintenance, page 12.

Air leak in sight well Replace pump.

Pump air bound Follow Setup section appropriate for

your pump model, pages 5-8.

Pump regulation set too low Increase pump regulation.

Camshaft speed too slow Increase camshaft speed (see Table

1, page 10.

NA Replace sight glass using GBL7500

Sight Glass Replacement Kit

24T306. See Maintenance, page

12.

Page 12

Maintenance

1

2

4

Maintenance

5. Torque sight well plug (1) to 35 +

N.m).

I

5 in. lbs (3.95 + 0.6

Sight Well Runs Dry

Should the oil level in the sight well (2) fall below the

pump body surface:

1. Remove the sight well plug (1).

2. Allow the pump to continue to operate and manually

fill the sight well (2) with filtered oil to below the end

of the drip tube (4).

3. Replace the sight well plug (1).

4. Torque sight well plug (1) to 35 +

N.m).

5 in. lbs (3.95 + 0.6

Sight Glass Replacement Kit

To replace a cloudy or broken sight glass in suction or

gravity fed pumps, order GBL7500 Sight Glass Replacement Kit 24T306. See instruction manual 332560

included with Kit 24T306 for repair and replacement

instructions.

Custom Socket Tool 16Y532

Used with the GBL7500 Sight Glass Replacement Kit for

removing, tightening and torquing the Sight Glass Body

(5). See instruction manual 332560 included with Kit

24T306 for repair and replacement instructions.

FIG. 11

Sight Well Fills With Oil

The oil level in the sight well (2) will rise and fall slightly

during pump operation. Should the oil level in the sight

well rise above the drip tube (4):

1. Remove the sight well plug (1).

2. Allow the pump to continue to operate until the oil

level has dropped below the drip tube (4).

3. Clean sight well plug threads (1). Apply thread sealant (user supplied) to sight well plug.

4. Replace the sight well plug (1), taking care to not

allow any thread sealant into the sight well (2).

12 3A2257C

Page 13

Technical Data

Technical Data

Suction, Gravity Pressure Fed Box Lubricator Pump or Shaft Rotation Alarm Pump

Maximum Working Pressure US Metric

All 3/16” Piston Models 7500 psi 51.7 MPa, 517 bar

All 1/4” Piston Models 6000 psi 41.4 MPa, 414 bar

All 3/8” Piston Models 3500 psi 24.1 MPa, 241 bar

Alarm Pump* 200 1.4 PMa, 14 bar

Inlet Size

Gravity Fed Models 1/8” - 27 NPTF

Pressure Fed Models 1/4” - 18 NPTF

Outlet Size (Suction, Gravity, Pressure Fed Models) 1/8” - 27 NPTF

Dimensions page 14

Weight

Suction Models 2.6 lbs 1.18 kg

Gravity Models 2.7 lbs 1.22 kg

Pressure Models 2.7 lbs 1.22 kg

Alarm Pump 4.8 lbs 2.18 kg

Temperature Rating -20°F to 140F° -29°C to 60°C

Wetted Parts carbon steel, stainless steel, aluminum, PTFE, Fluoro-

elastomer, pyrex

* Sensor output will open at 100-200 psi (0.68 MPa, 6.89 bar).

3A2257C 13

Page 14

Technical Data

K

L

See Detail A

Detail A

E

F Max

F Min

MG

H

J

Pump Dimensions

Dimension Inches mm

A 3.10 76.20

B 1.97 50.04

C 0.50 12.70

D

E5.37 136.40

F

G 1.50 38.10

H 0.50 12.70

J 0.50 12.70

K 0.39 9.90

L 0.92 23.37

M 0.28 7.11

N 5.40 137.20

P 3.85 97.79

R 10.13 257.18

Pump Min. 2.58

Pump Max. 3.18

Min. 4.14

Max 4.90

Pump Min. 65.53

Pump Max.78.23

Min. 105.20

Max 124.50

14 3A2257C

Page 15

Technical Data

Pressure Fed

Inlet

P

A

Outlet

C

D

Outlet

Inlet

A

B

C

D

Gravity Fed

3A2257C 15

Page 16

Technical Data

Outlet

C

D

A

P

N

Inlet

Suction Fed

16 3A2257C

Page 17

Alarm Pump

C

D

P

N

Inlet

R

Return to

Reservoir

1/4 NPT Sensor

Output

Technical Data

3A2257C 17

Page 18

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A2257

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised December 2013

Loading...

Loading...