Page 1

Instructions - Parts List

™

IM5

Inline

308687L

Electronic Meter

For use with petroleum-based and synthetic oil, antifreeze, and windshield washer fluid

only.

Model: 239824

500 psi (3.4 MPa, 34 bar) Maximum Working Pressure

5 gpm (19 lpm) Maximum Flow Rate

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

EN

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual

where applicable.

+

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgi-

cal treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Ground all equipment in the work area.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

PRESSURIZED EQUIPMENT HAZARD

Over-pressurization can result in equipment rupture and serious injury.

• Do not exceed the maximum air input pressure.

• Fill slowly to avoid over pressurizing reservoir.

• Use tubing, hoses and other components with pressure ratings equal to or higher than the pump

rating.

2 308687L

Page 3

Warnings

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in

all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request SDS from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes

but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

308687L 3

Page 4

Installation

Installation

The meters must be installed in-line as part of a dispense system as shown in Fig. 1. The typical installation shown

is only a guide for selecting and installing an in-line meter; it is not an actual system design. Contact your Graco distributor for assistance in designing a system to suit your needs.

NOTICE

Do not use PTFE tape on threaded connections to

the meter. Such use could contribute to over-tight-

All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

Do not use the IM5 In-line Electronic Meter in systems where the operating pressure exceeds the maximum pressure of the meter or any other component

in the system.

ening of the parts and cause the meter housing to

crack. Standard pipe thread compound is recommended.

FIG. 1

Key:

A Shut-off valve

B Thermal relief valve (required; Part No. 235998) Install

downstream from the pump

C In-line filter

D In-line electronic meter

4 308687L

Page 5

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes

to ignite or explode. Grounding provides an escape

wire for the electric current.

Pump: follow the manufacturer’s recommendations.

Air and fluid hoses: use only grounded hoses.

Air compressor: follow manufacturer’s recommenda-

tions.

Fluid supply container: follow local code.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Installation

Factory Settings

The meter is factory calibrated for 10W-30 oil, and the

default unit of measurement is quarts. For other fluids

and different units of measurement, see Changing the

Measurement Units and Calibration Factor on page 8.

308687L 5

Page 6

Operation

Operation

Sleep Mode

The meter automatically shuts down the display after

one minute of non-use.

Activation Mode

There are two ways to activate the display:

• Press any button on the keypad to wake up the dig-

ital display. The amount displayed is the value

stored when the meter went into sleep mode.

FIG. 2: Example of Total for Last Dispense Cycle

• Dispense fluid through the meter to wake up the

digital display. Dispensing fluid through the meter

causes the meter to count up from the last dis-

played value. See Fig. 2.

Function of TOTAL

Press and hold the TOTAL key to see the accumulated

total of fluid dispensed through the meter.

The accumulated total is shown in gallons when the unit

of measurement is set in gallons, quarts, or pints. The

accumulated total is shown in liters when the measurement is set in liters. The meter accumulates a running

total of up to 99,999 gallons (or liters) dispensed before

returning to zero. See Fig. 3.

Function of RESET

Press and hold the RESET key to clear the digital display after each dispense cycle.

NOTE: Always press the RESET key to clear the digital

display before each new dispense cycle.

FIG. 3: Example of Accumulated Total

FIG. 4: Example of Measurement Units

For Maximum Dispensing Accuracy

Set the meter to dispense in pints or quarts when dispensing 1 gallon (3.8 liters) or less.

Measurement Units

Fig. 4 shows the various measurement units as they

appear on the display.

6 308687L

Page 7

Operation

Changing the Measurement Units and

Calibration Factor

NOTE: A one liter Weights and Measures approved

container is required for calibration.

This meter is factory calibrated to dispense 10W-30

motor oil at 70_ F (21_ C) at 2.0 gpm (7.6 lpm) and is

acceptably accurate for most common fluids over a

typical temperature range. If you will use the meter to

dispense antifreeze or other approved fluids, you may

have to recalibrate it for greater accuracy.

1. Press and hold both the TOTAL and RESET but-

tons for four seconds.

The numbers on the display turn off, and the L (for

liters) and CAL (for calibration) icons turn on.

2. Set the units of measurement by repeatedly pressing the RESET button until the correct unit of measurement is displayed. See the list below:

GAL = gallons

QTS = quarts

PTS = pints

L = liters

number may vary slightly due to temperature or

flow rate.

Calibration

Fluid

oil (10W-30) 389

gear lube 389

automatic transmission fluid 389

antifreeze 367

windshield washer solvent 341

Calibration factors at 70°F (21°C) at 2.0 gpm (7.6 lpm)

Number

3. Press the TOTAL button to go to the CALIBRA-

TION menu.

NOTE: If you do not want to change the calibration

factor, press the TOTAL button again to use the

existing calibration factor and to resume normal

operation. To change the calibration factor, do

steps 4 and 5.

4. Dispense exactly one liter of fluid into a calibrated

1-liter container. For proper calibration, you must

dispense exactly 1 liter according to the markings

on the container.

NOTE: If you dispense more than 1 liter, press the

TOTAL button to exit the CALIBRATION menu.

Pressing the TOTAL button at this point does not

save the new calibration factor. You must complete

steps 1 to 5 change the calibration factor.

5. Press the RESET button to store the new calibration factor and resume normal operation.

NOTE: The number on the display is the calibration

factor number. It must be in the range of 311 to

466. The following table lists approximate calibration factors for different fluids. Your calibration

308687L 7

Page 8

Service

Service

NOTICE

To avoid damaging the electronic components of the

control:

• Do not remove the black cover over the electronic

area when you replace the battery. There are no

user-replaceable components under this cover.

• Do not lay anything on the electronics.

• Do not twist or force parts. Align parts properly as

instructed.

To avoid malfunction or high-pressure fluid spray, do

not remove the metal cover of the metering unit.

There are no user-serviceable part inside.

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

1. Turn off power supply to the pump.

2. Trigger the dispense valve into a waste container to

relieve pressure.

3. Open any bleed-type master air valves and fluid

drain valves in the system.

4. Leave the drain valve open until you are ready to

pressurize the system.

NOTE: Before you check or repair the meter, be sure all

other valves, controls and the pump are operating correctly.

8 308687L

Page 9

Service

Battery Replacement Procedure

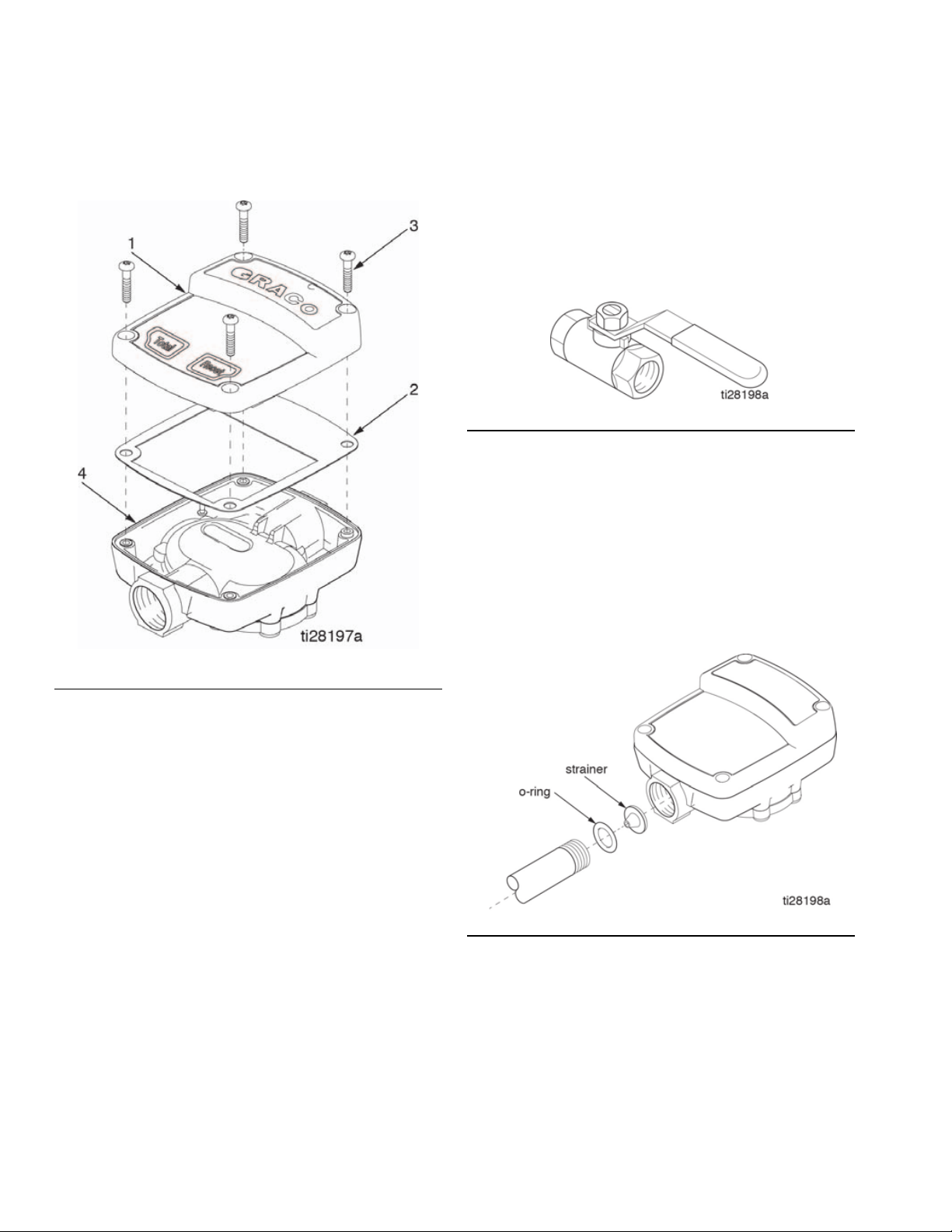

(FIG. 5)

1. Relieve Pressure, (see procedure in previous sec-

tion).

5. Install the electronic control to the metering unit (4),

aligning the longer screws boss on the meter housing with the counter bore in the plastic housing.

6. Install the four screws (3) holding the electronic

control (1) to the metering unit (4) together. Torque

the screws to 15-20 in-lb (1.7 to 2.3 N•m) or until

no gap exists between the electronic control and

the metering unit.

NOTICE

Closing the gap between the electronic control and

the metering unit is very important; it ensures that

no moisture can enter the electronics.

Electronic Control Replacement

Procedure (FIG. 6)

FIG. 5

2. Remove the four screws (3) holding the electronic

control (1) and metering unit (4) together.

3. Remove the battery.

4. Install the new battery.

NOTE: See Technical Data, page 13 for recommended

batteries.

NOTICE

To avoid pinching the battery wires, install the battery as shown in FIG. 5. The battery wire should

extend to the far side of the battery compartment.

1. Relieve Pressure, (see procedure in previous sec-

tion).

FIG. 6

2. Remove the four screws (3) holding the electronic

control (1) and metering unit (4) together.

3. Remove the battery. (See Battery Replacement

Procedure in the previous section).

308687L 9

Page 10

Service

4. Remove all gasket material from the metering unit

(4).

5. Assemble adhesive side of new gasket (2) to metering unit (4).

6. Replace battery (see Battery Replacement Procedure, page 9).

NOTICE

To avoid pinching the battery wires, install the battery as shown in FIG. 5. The battery wire should

extend to the far side of the battery compartment.

7. Install the electronic control to the metering unit (4),

aligning the longer screws boss on the meter housing with the counter bore in the plastic housing.

8. Install the four screws (3) holding the electronic

control (1) to the metering unit (4) together. Torque

the screws to 15-20 in-lb (1.7 to 2.3 N•m) or until

no gap exists between the electronic control and

the metering unit.

NOTICE

Closing the gap between the electronic control and

the metering unit is very important; it ensures that

no moisture can enter the electronics.

10 308687L

Page 11

Troubleshooting

Troubleshooting

Problem Cause Solution

Battery icon is shown on the display Battery is low Replace the battery. See Battery

Replacement Procedure, page 9

and Technical Data, page 13 for

recommended battery.

Digital display does not activate Battery is low Replace the battery. See Battery

Replacement Procedure, page 9

and Technical Data, page 13 for

recommended battery.

Electronic control is malfunctioning Replace electronic control. See

Electronic Control Replacement

Procedure, page 9.

There is no fluid flow Metering unit is malfunctioning Replace the meter.

Strainer (if used) is clogged Remove and clean or replace

strainer using Strainer Kit 239876.

See Accessories, page 12.

Pump is not turned on. Turn on pump.

308687L 11

Page 12

Parts

Parts

Accessories

Shutoff Valve: 108458

Install upstream from the meter. Shuts off fluid supply

from the pump.1/2-14 npt(f) both ends.

FIG. 8

Strainer Kit: 239876

Includes strainer and o-ring.

Install the strainer before the meter or before the valve

on the meter/valve combination.

Install the o-ring after the strainer to hold the strainer in

place. See FIG. 9.

FIG. 7

Part No./Description

Qty

Ref. Part Description

1 245598* CONTROL, electronic 1

2 113930 GASKET 1

3 113941 SCREW 4

4 UNIT, metering (cannot be sold

separately)

*Screws (3) and Gasket (2) are included with Control (1)

.

1

FIG. 9

Thermal Relief Kit: 235998

1/2 - 14 npt(m) x 1/2-14 npt(f).

Install downstream from the pump.

12 308687L

Page 13

Technical Data

IM5 Inline Electronic Meter

US Metric

Flow range 0.5 to 5 gpm 1.9 to 19 lpm

Maximum working pressure 500 psi 3.4 MPa, 34 bar

Minimum working pressure 5 psi 34 kPa, 0.3 bar

Weight

Weight

Units of Measurement

Factory-setting quarts

Accuracy +/- 0.5 percent

Measured at 2.5 gpm (9.5 lpm), at 70°F (21°C), with 10-weight oil and 1 gallon dispensed. May require

calibration; out-of-box accuracy is +/- 1.25 percent.

Repeatability +/- 0.15 percent

Measured at 2.5 gpm (9.5 lpm), at 70°F (21°C), with 10-weight oil and 1 gallon dispensed.

Inlet / Outlet: Meter can be installed with flow

in either direction

Temperature

Operating temperature range -4°F to 122°F -20°C to 50°C

Storage temperature range -13°F to 122°F -25°C to 50°C

Materials of Construction

Wetted parts nickel, zinc, LCP, nitrile rubber

Battery Information

Battery

Duracell® is a registered trademark of Duracell Inc.

1.8 lbs

1/2 npt

standard 9V alkaline: Duracell® MN1604, Duracell PC1604,

Eveready® EN22, Eveready 522

0.82 kg

Technical Data

Eveready® is a registered trademark of the Eveready Battery Co., Inc.

308687L 13

Page 14

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification

of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be

returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or

workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental

or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder,

or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered

into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu

que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés,

à la suite de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2001, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM308687

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

February, 2021

Loading...

Loading...