Instructions

FLUID COMMANDER

Electronic Dispensing Control

For electronically controlled dispense of petroleum, synthetic--based oil, and

anti--freeze. For professional use only.

Not for use in explosive atmospheres.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

120 Vac, 60 Hz, 0.40 Amps

FOR INDOOR USE ONLY

308238S

EN

Model 235531, Series D

1 Fluid to 12 Stations; U.S. Measurement

Model 235532, Series D

2 Fluids to 6 Stations; U.S. Measurement

Model 232077, Series D

2 Fluids to 6 Stations; Metric Measurement

Model 241905, Series A

1 Fluid to 12 Stations; U.S. Measurement; Includes air

and fluid solenoid valves, pulse meter, and check valve

Model 232076, Series A

2 Fluids to 6 Stations; U.S. Measurement; Includes air

and fluid solenoid valves, pulse meter, and check valve

Model 240448, Series A

2 Fluids to 6 Stations; Metric Measurement; Includes air

and fluid solenoid valves, pulse meter, and check valve

01290

Table of Contents

Warnings 2......................................

Installation 4.....................................

Operation 10....................................

Maintenance 1 1..................................

Troubleshooting 14...............................

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

Accessories 16..................................

Technical Data 19................................

Warranty 20.....................................

Graco Information 20.............................

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component. See the

instruction manuals of the individual system components for their maximum working pressures.

D Handle hoses carefully. Do not pull on hoses to move equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 66_C (150_F) or below --40_C(--40_F).

D Do not stop or deflect fluid leaks with your hand, body , glove, or rag.

D Follow the Shutdown Procedure on page 12 whenever you stop dispensing; or clean, check, or

service the equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 308238

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury.

D Connect the electronic dispensing control to a grounded outlet. Ground the other equipment as

instructed in their separate instruction manuals.

D All electrical products must be wired by a qualified electrician.

D The control and all electrical products described in this manual must be installed in a non-hazard-

ous location.

D If there is any static sparking or you feel an electric shock while using this equipment, stop dis-

pensing immediately. Do not use the equipment until you identify and correct the problem.

D Keep liquids away from the electrical components.

D Disconnect electrical power at the main switch before servicing the equipment.

D Keep the dispense area free of debris, including solvent, rags, and gasoline.

D Do not smoke in the dispense area.

3308238

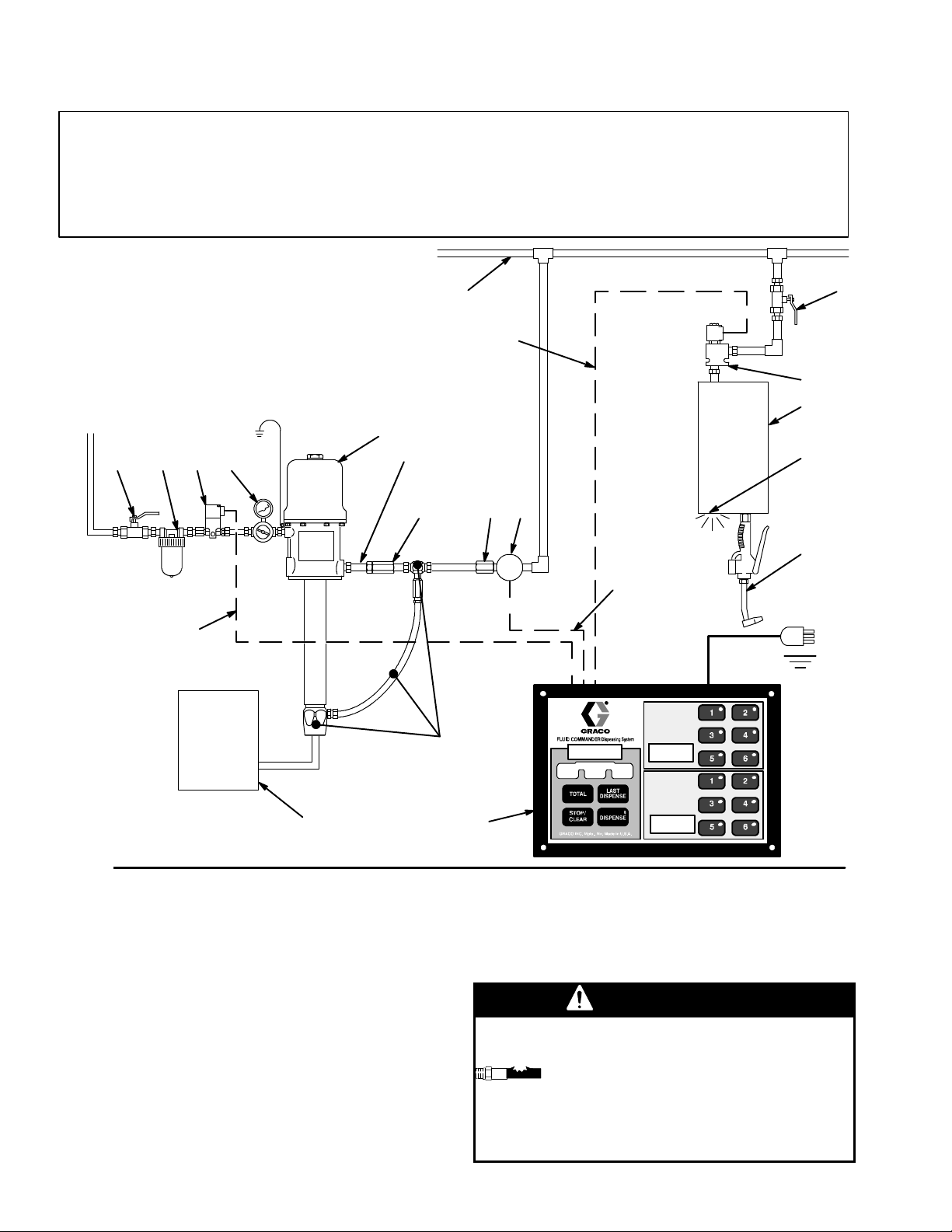

Installation

N

KEY

A* Control

B Pressure Relief Kit, 237893,

1--1/2 npt (m x f)

C Supply Tank

D Air Shutoff Valve, bleed-type

E Air Filter

DE*FG

AIR SUPPLY

F* Air Solenoid Valve, 215407

G Air Regulator, 202156

HPump

J Flexible Hose, 3--6 ft (0.9--1.8 m) long

K* Check Valve, 111620 (required)

L Fluid Filter, 223179

M* Pulse Meter, 236763 or 236764

N Fluid Shutoff Valve, 108458, 1/2”

FLUID LINE

FLUID SOLENOID

SIGNAL LINE

FLUID 1

H

J

K*

P* Fluid Solenoid Valve, 215487

Q Hose Reel

R Ready Light, 238996

S Dispense Valve

See pages 16-- 17 to order Accessories.

* These parts are included with Model

232076, 240448, or 241905.

P*

Q

FLUID 1

R

M*L

S

AIR SOLENOID

SIGNAL LINE

C

Fig. 1

NOTE: The Electronic Dispensing Control is referred

to as the “control” in this manual.

How the Fluid Commander System Works

The operator programs the control by selecting a fluid

and station and setting the quantity to dispense. When

the operator presses the DISPENSE key, the control

energizes the respective air and fluid solenoid valves.

As the fluid is dispensed, the pulse meter sends pulses

to the control in proportion to the amount of fluid

flowing through it. When the number of pulses counted

by the control is equivalent to the preset quantity, the

air and fluid solenoid valves shut off. Refer to Opera-

4 308238

PULSE UNIT

SIGNAL LINE

B

*A

FLUID 1

FLUID 2

tion for more detailed information on using the system.

NOTE: The Typical Installation shown above is only a

guide for a basic system, showing just one fluid. Call

your Graco representative to design a system to suit

your needs.

WARNING

COMPONENT RUPTURE HAZARD

A Pressure Relief Kit is required in your

system to reduce the risk of serious injury,

which can occur if excessive pressure

ruptures the lines and components. Install Kit

237893 as shown in Fig. 1. See page 18 for ordering

information.

0912

Installation

WARNING

COMPONENT RUPTURE HAZARD

Be sure that all accessories and system

components can withstand the pres-

sures developed. The maximum fluid

working pressure of the Fluid Commander System

is 1500 psi (10.4 MPa, 103 bar). Never exceed the

maximum working pressure of the lowest rated

accessory (valve, pipe, fitting, hose, etc.) in your

system.

NOTE: The accessories mentioned in this manual are

shown on pages 16 and 17.

Mount the Control

Place the control on a desktop or mount it on a wall,

and locate it at least 18 in. (441 mm) off the floor.

WARNING

FIRE, EXPLOSION, AND ELECTRIC

SHOCK HAZARD

To reduce the risk of fire or explosion,

and serious injury, including electric

shock:

The control and all electrical products

described in this manual must be

installed in a non-hazardous location.

CAUTION

If you do not use the recommended air and fluid

valves, verify that the valves do not exceed 0.6 amp

of supply current when operated with 24 Vdc.

Pages 7 and 8 show the alternative wiring schematic, using customer-supplied cables with Graco-supplied

valves and pulsers.

Page 8 shows where the wires connect at the rear of

the control, depending on the number of fluids you are

using. Fig. 2, below, shows how to make the electrical

connections at the control, using the supplied probe.

CAUTION

To ensure correct polarity of the electrical supply, use

only the power supply cord supplied with the control.

Any other power supply cord may permanently

damage the control.

Apply Labels to the Control

Determine what fluids will be dispensed, and apply the

appropriate labels within the raised area on the control,

next to the station pads. See Fig. 3, page 11.

WIRE

Strip back 1/4”

(6.35 mm) insulation

All electrical products must be wired by a qualified

electrician, following all local, state, and national

codes.

Connect the control only to a grounded outlet.

Connect the Electrical Wiring

Determine the wire gauge to use based on the length

of the run:

Up to 200 ft (61 m): 18 AWG

201 to 500 ft (152 m): 16 AWG

501 to 1000 ft (305 m): 14 AWG

Page 6 shows the recommended wiring schematic,

using Graco supplied cables, valves, and pulsers.

Top S l o t

Bottom

PROBE

(supplied with control)

Hook the probe into the bottom slot of the terminal block as

shown. Press the probe down. Insert the wire into the top

slot and remove the probe.

Fig. 2

Slot

01291A

5308238

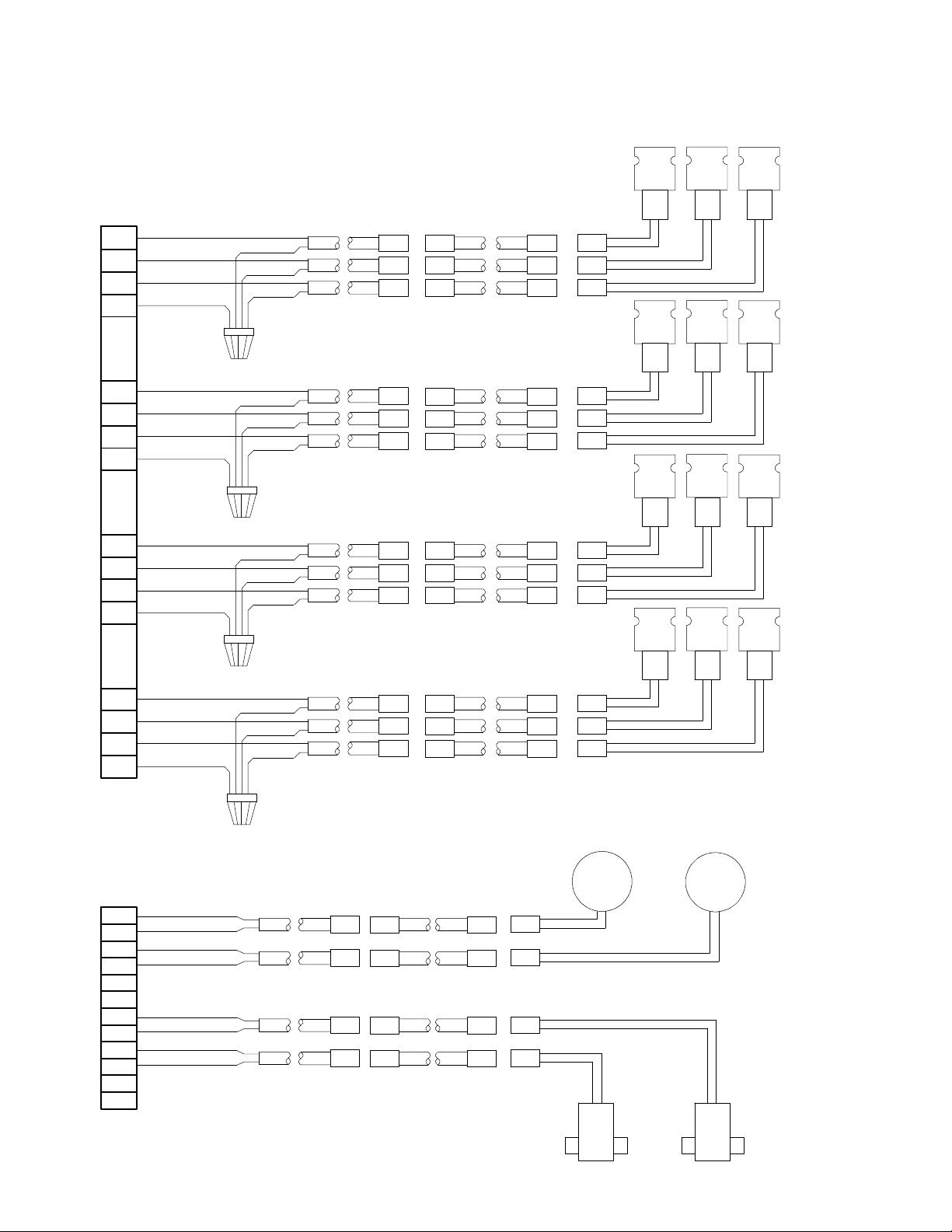

Installation -- Recommended Wiring

D

Example uses Graco supplied cables, valves and pulsers. SeeAccessories, pages 16--17.

Recommended Wiring for Fluid Solenoid Valves

STATION FLUID SOLENOID VALVES

STA. 1

P/N 215487

STA. 2

STA. 3

FLUID

ONE

13

14

15

215481

RED

1

RED

2

RED

3

BLACK

(1 foot,

305 mm)

RED

4

RED

5

RED

6

BLACK

(1 foot,

305 mm)

RED

7

RED

8

RED

9

BLACK

(1 foot,

305 mm)

BLACK

BLACK

BLACK

WIRE NUT

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

PRECONNECTED END

STA. 4

STA. 1

STA. 4

STA. 5

STA. 2

STA. 5

STA. 6

STA. 3

STA. 6

FLUID

TWO

10

11

12

16

Recommended Wiring for Fluid Pulsers and Air

Solenoid Valves

1

2

3

4

5

6

7

8

9

10

11

12

6 308238

RED

RED

RED

BLACK

(1 foot,

305 mm)

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

BLACK

BLACK

BLACK

FLUID2AIRSOLENOID

P/N 215407

FLUID 1 PULSER

P/N 236763 or 236764

FLUID 2 PULSER

P/N 236763 or 236764

FLUID1AIRSOLENOI

P/N 215407

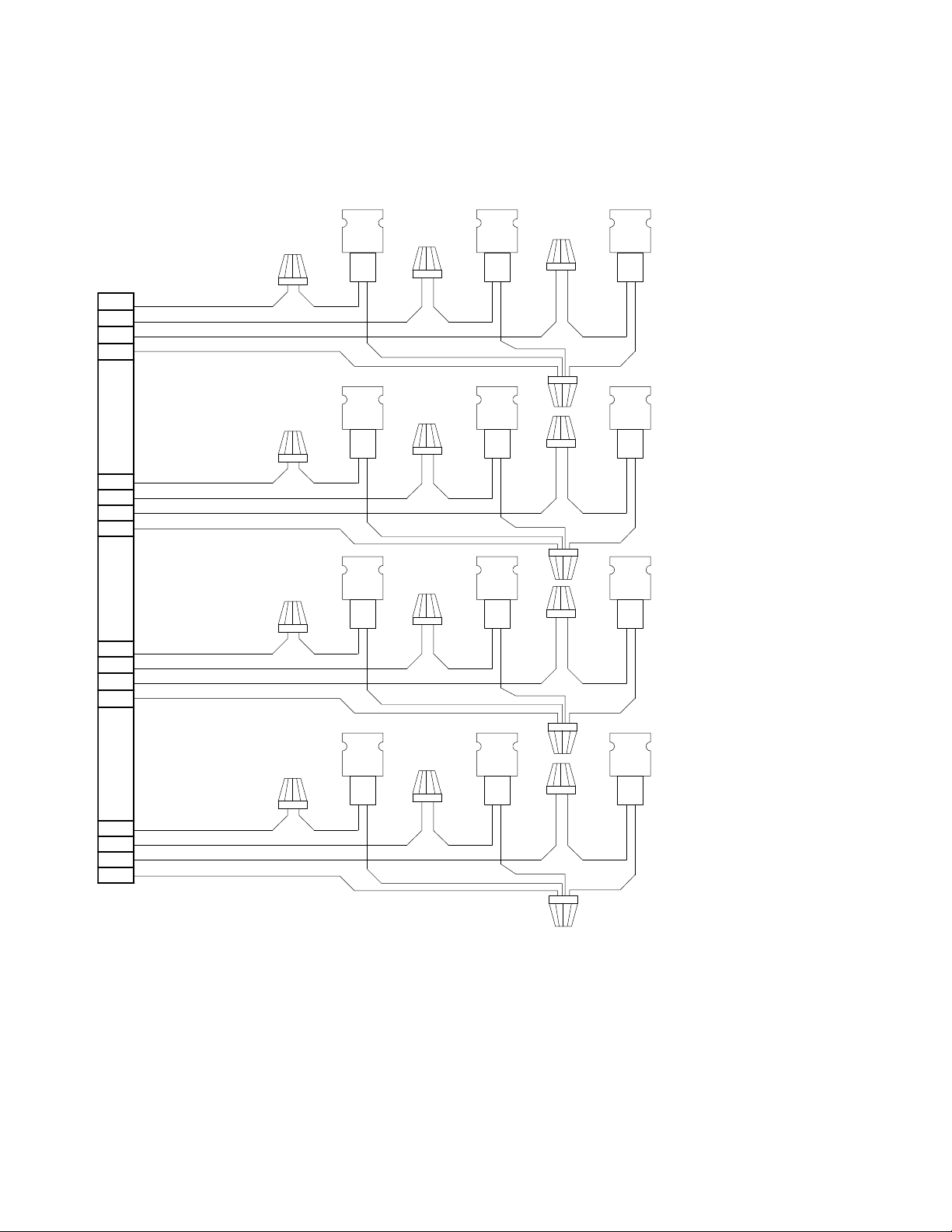

Installation -- Alternative Wiring Scheme

Example uses customer-supplied wires. Valves and pulsers supplied by Graco. SeeAccessories, pages 16--17.

NOTE: Wire size is dependent on distance from control module to solenoid valve.

Alternate Wiring for Fluid Solenoid Valves

1

2

3

13

4

5

6

14

WIRE NUT

STATION FLUID SOLENOID VALVES

STA. 1 STA. 2 STA. 3

STA. 4 STA. 5 STA. 6

P/N 215487

FLUID

ONE

7

8

9

15

10

11

12

16

STA. 1 STA. 2 STA. 3

STA. 4 STA. 5 STA. 6

FLUID

TWO

7308238

Loading...

Loading...