Page 1

Instructions–Parts List

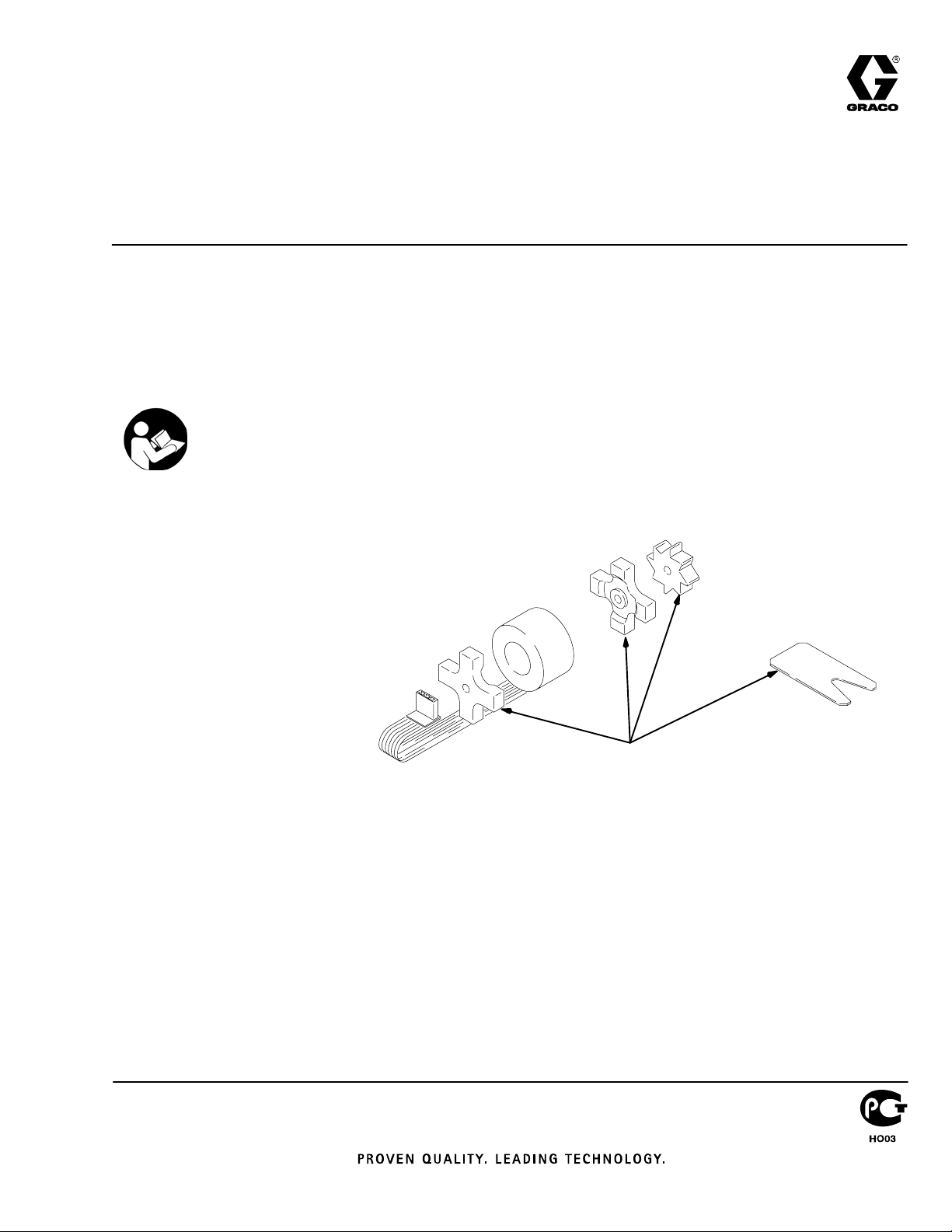

Turbine Alternator

Repair Kits

For repair of turbine alternator used with PRO Series Electrostatic

Spray Guns, with PRO Pulse Electronic Fluid Meter, and with

SuperCatt, Xtreme Mixt 185, ProMixt Easy, and ProMixt I

Proportioners. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

308034F

ENG

Part No. 223688 Bearing Repair Kit

223688

TI1884A

Page 2

INSTRUCTIONS

WARNING

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire, explosion, or electric shock.

D Electrostatic equipment must be used only by trained, qualified personnel who understand the

requirements stated in this instruction manual and in the spray gun instruction manual.

D Read all the instruction manuals, tags, and labels before operating the equipment.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in a serious injury.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check the equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component.

D Use fluids that are compatible with the equipment wetted parts. See the Technical Data section of

all the equipment manuals. Read the fluid manufacturer’s warnings.

D Comply with all applicable local, state, and national fire, electrical, and other safety regulations.

Turbine Alternator Service

Pressure Relief Procedure

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure in your spray gun

manual or in the SuperCat instruction manual.

Disassembly

1. Relieve the pressure.

2. See your spray gun manual to remove the power

cartridge. For the SuperCat alternator, remove six

screws, open the housing, and remove the power

cartridge.

3. Remove the turbine alternator.

4. Test the Coil: Measure the resistance between the

two outer terminals of the 3-pin connector (101a).

The resistance should be 2–5 ohms. Measure the

resistance between each outer terminal of the

3-pin connector and the turbine alternator housing

(B). The resistance should be infinite. If the readings vary from these values, replace the coil.

5. Remove the plastic plug (A).

6. Pro Xs Models only: Remove the retaining ring

(H) from the turbine alternator housing (B).

7. Insert a center punch or small metal shaft into the

hole in the back of the turbine alternator housing

(B). Hold the housing and lightly tap out the turbine

assembly (G).

8. Remove the larger bearing (2).

9. Slide the coil assembly (101) off the armature (D).

Inspect the coil for wear or damage and replace if

necessary.

NOTE: If only replacing the coil (101), continue by

following steps 5 through 11 on page 3.

10. Using a drift punch or small metal shaft, tap the

armature (D) out of the bearing (1) and fan (3).

CAUTION

To avoid demagnetization of the armature (D), never

place it in contact with, or in close proximity to, any

other armature or other ferromagnetic objects.

11. Clean the armature (D) shaft with a soft cloth.

Inspect the shaft for wear or damage. Replace the

armature (part no. 217590) if necessary.

2ą308034

Page 3

Turbine Alternator Service

KEY

A Plug

B Turbine Alternator Housing

D Armature

E O-Ring

G Turbine Assembly

H Retaining Ring (Pro Xs only)

1 Bearing

2 Bearing

3 Fan

101 Coil

101a 3-Wire Connector

PRO 3500 / 4500 / 5500, PRO Pulse,

and SuperCat, Xtreme Mix 185, ProMix Easy,

and ProMix I Proportioners

E

A

B

Exhaust Port

G

D

101

2

101a

H

PRO Xs

only

Fig. 1

Assembly

1. Remove the bearings (1 & 2) from the package

and wipe the excess oil off with a soft cloth. Do not

use solvent or air to wipe or blow off the excess oil.

2. Place the smaller bearing (1) [marked 197906] on

the long end of the armature (D), with the machined groove in the bearing facing the armature.

3. Install the fan (3) on the long end of the armature

(D), with the machined groove in the fan facing

away from the armature.

4. Insert the spacing tool (4) between the fan (3) and

bearing (1). Lightly tap on the end of the armature

(D) until the fan is pressed up against the spacing

tool and bearing. Remove the spacing tool. When

properly installed, the bearing (1) should spin

freely on the armature shaft.

5. Install the coil assembly (101) over the armature

(D), with the 3-wire connector (101a) facing away

from the fan (3).

3

1

B

PRO Xs Models

NOTE: The items referenced with

numbers are included with a kit.

6. Place the larger bearing (2) [marked 197907] on

the end of the armature (D), with the machined

groove in the bearing (2) facing in toward the

armature. Align the legs of both bearings with each

other.

NOTE: When installed, the bearing legs must not block

the exhaust ports of the turbine alternator housing (B)

or the gun will not operate properly.

7. Carefully slide the turbine alternator housing (B)

over the turbine assembly (G), aligning the bearing

legs between the exhaust ports of the housing.

Push the turbine alternator housing onto the

turbine assembly until the assembly is seated

firmly in the turbine alternator housing.

8. Pro Xs Models only: Install the retaining ring (H)

in the turbine alternator housing (B).

9. Press the plastic plug (A) onto the back of the

turbine alternator housing (B).

10. Install the turbine alternator on the power cartridge

as instructed in your spray gun manual.

11. Install the power cartridge and assemble the gun.

E

A

TI15230a

308034 3

Page 4

Parts

Part No. 223688

Turbine Alternator Bearing Repair Kit

Ref

No. Part No. Description Qty

1 197906 BEARING 1

2 197907 BEARING 1

3 179397 FAN 1

4 180064 SPACER TOOL 1

PRO 3500 / 4500 / 5500,

PRO Xs, PRO Pulse,

and SuperCat, Xtreme Mix 185, ProMix Easy,

and ProMix I Proportioners

3

1

2

Part No. 223750

Turbine Alternator Coil Repair Kit

(PRO 3500 / 4500 / 5500)

Ref

No. Part No. Description Qty

101 218166 COIL 1

101

Part No. 244577

Turbine Alternator Coil

(PRO Xs)

Ref

No. Part No. Description Qty

101 244577 COIL 1

101

4

TI1884A

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the distributor closest to you:

Phone: 612–623–6921 or Toll Free: 1–800–328–0211 Fax: 612–378–3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

4ą308034

Original instructions. This manual contains English. MM 308034

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 1990, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 02/2010

Loading...

Loading...